Optimizing condition monitoring of ball bearings: An integrated approach using decision tree and extreme learning machine for effective decision-making

-

Riadh Euldji

Abstract

This article presents a study on condition monitoring and predictive maintenance, highlighting the importance of tracking ball bearing condition to estimate their Remaining Useful Life (RUL). The study proposes a methodology that combines three algorithms, namely Variational Mode Decomposition (VMD), Decision Tree (DT), and Extreme Learning Machine (ELM), to extract pertinent features and estimate RUL using vibration signals. To improve the accuracy of the method, the VMD algorithm is used to reduce noise from the original vibration signals. The DT algorithm is then employed to extract relevant features, which are fed into the ELM algorithm to estimate the RUL of the ball bearings. The effectiveness of the proposed approach is evaluated using ball bearing data sets from the PRONOSTIA platform. Overall, the results demonstrate that the suggested methodology successfully tracks the ball bearing condition and estimates RUL using vibration signals. This study provides valuable insights into the development of predictive maintenance systems that can assist decision-makers in planning maintenance activities. Further research could explore the potential of this methodology in other industrial applications and under different operating conditions.

1 Introduction

Rotating machines consist of vital components known as bearings, and their degradation can significantly impact dependability, availability, security, maintenance, ecology, and economy. Such effects directly influence the productivity and quality of the machine’s performance. Given the critical nature of bearings, reliable information about their state is essential. Vibration condition monitoring is a widely used method to evaluate the condition of bearings, and detecting flaws and predicting the Remaining Usable Life (RUL) of bearings are of particular interest to manufacturers and researchers. The process of vibration condition monitoring involves three primary stages, namely data acquisition, data processing, and maintenance decision-making, each of which is critical for ensuring the effectiveness of the approach. As such, efforts are continually being made to improve each stage of the process to enhance the overall reliability and accuracy of vibration condition monitoring for bearings [1,2,3].

Machine learning techniques can be used to extract useful information that aids decision-making from the vast amount of measured and stored data. Large volumes of data can be mined for knowledge using machine learning. In complicated systems where degradation processes are challenging to connect using a physics or statistical model, machine learning can handle prediction issues. In the literature, numerous strategies and methods for anomalies prediction have been put forth and assessed. SVM (Support Vector Machines) [4,5,6,7], Extreme Learning Machines (ELM) [8,9,10], and neural networks [11,12,13,14,15,16] are among them. A hybrid strategy uses different algorithms to enhance the performance of RUL prediction. For more details, Table 1 highlights the most significant studies that examined the state of machine learning applications in various algorithms at the time and showed potential future applications.

Review the current status and future opportunities for machine learning applications with various algorithms

| Authors | Highlights |

|---|---|

| Peng et al. [17] | To offer insights into the development of Decision Tree (DT) technology for rolling bearings, a comprehensive literature review was conducted, focusing on the fundamental aspects of DT construction, including detection, modeling, and Prognostics Health Management. The review provided a historical perspective of DT technology and identified the key challenges associated with establishing a robust DT technique for rolling bearings. Various proposals for future research directions were also evaluated to address the identified challenges and improve the performance of DT-based condition monitoring for rolling bearings. Overall, this study provides a valuable overview of the evolution and potential of DT technology in the context of rolling bearing condition monitoring, paving the way for further developments in the field |

| Xu and Saleh [18] | Several associated models and algorithms are noted along with an overview of various machine learning classes, subclasses, or tasks. Review machine learning’s use in applications for dependability and safety next. Each category and subcategory’s publications were examined in depth, and a brief overview of deep learning’s (DL) application is included to illustrate the technology’s rising popularity and unique benefits. Finally, a number of intriguing opportunities to apply machine learning to improved reliability and safety issues have been found |

| Bertolini et al. [19] | They examined the potential benefits and potential drawbacks of machine learning algorithms used in process management |

| Soni and Kumar [20] | This comprehensive review study provides a well-structured summary of the extensive research on the integration of machine learning methods within the rapidly evolving cloud computing paradigm. The study offers a comprehensive assessment of the literature, focusing on the latest cloud computing paradigms, including cloud, edge, fog, mist, Internet of Things, SDN (Software-Defined Networking), cybertwin, and industrial 4.0 (IIoT). In addition, the study explores how these paradigms can be effectively combined with machine learning techniques to enhance their performance and capabilities. By consolidating a large volume of research, this study offers valuable insights into the latest developments and potential applications of machine learning within the cloud computing paradigm, making it a valuable resource for researchers and practitioners in the field |

| Avci et al. [21] | Vibration-based Structural Damage Detection (SDD) techniques have traditionally relied on conventional approaches, with limited consideration of the potential benefits of machine learning and DL methods. This study aims to bridge this gap by providing an in-depth analysis of the latest machine learning and DL algorithms for vibration-based SDD, alongside a review of the key aspects of conventional approaches. Specifically, the study offers a comprehensive examination of the potential applications of machine learning and DL algorithms for structural damage diagnosis in civil constructions, highlighting their unique advantages and limitations. By exploring the latest developments and trends in this field, this study sheds new light on the potential of machine learning and DL for vibration-based SDD, paving the way for further research and innovation in this critical area |

| Li et al. [22] | In this paper, the authors present a systematic review of research advancements in monitoring tool breakage during machining processes, which is a critical aspect of preventing unexpected tool failure and potential production mishaps. The study offers a detailed overview of the methodology used for signal acquisition, feature extraction, and decision-making in tool breakage monitoring, which is compared to relevant methods for instrument wear monitoring. By exploring the latest developments in this field, this study provides a valuable resource for researchers and practitioners seeking to enhance tool breakage monitoring in machining processes. The authors’ methodical approach and critical analysis of the current state of the art in this area makes this study a valuable contribution to the field, providing new insights and identifying areas for further research and development |

| Ntemi et al. [23] | The authors of these studies have conducted a comprehensive evaluation of the latest advances in infrastructure monitoring and rapid quality diagnostics for computer numerical controlled (CNC) machining operations. With great attention to detail, they have analyzed the most current developments in these areas, offering a valuable resource for researchers and practitioners seeking to enhance CNC machining operations. By exploring the latest technologies and techniques, this research provides insights into how to improve the accuracy, reliability, and efficiency of CNC machining operations, and lays the groundwork for future innovations in this field. The authors’ careful and thorough analysis of the state of the art in infrastructure monitoring and quick quality diagnostics makes this study an essential reference for anyone working in CNC machining |

| van Dinter et al. [24] | 42 primary papers were examined as part of a systematic evaluation of the literature on predictive maintenance employing digital twins using active learning technology |

| Zhao et al. [25] | The use of modern DL models for machine health monitoring tasks has been carefully reviewed. |

| Gangsar and Tiwari [26] | In this study, the authors conducted a comprehensive investigation into several problems associated with induction motors. They employed traditional time and spectrum signal analysis techniques to examine the two most valuable types of signals for motor diagnosis, namely vibration and current. Additionally, the study provides an overview of the latest research and advancements in signal-based automation for condition monitoring, which can aid in detecting and diagnosing electrical and mechanical defects in induction motors. By exploring the most recent developments in this field, the authors offer valuable insights into how to enhance the accuracy and efficiency of condition monitoring and fault diagnosis for induction motors. This research represents a significant contribution to the field, offering a detailed analysis of signal analysis and condition monitoring of induction motors and providing a roadmap for future research and development. |

| Hakim et al. [27] | The aim of this review study was to offer a thorough and all-encompassing summary of the use of DL in bearing error diagnosis. To achieve this, the authors examined various DL techniques that are commonly used for bearing fault detection, including convolutional neural networks, recurrent neural networks, autoencoders, and generative adversarial networks. By exploring the most frequently employed DL methods, the authors provide valuable insights into how to effectively diagnose bearing faults and improve the overall reliability and performance of rotating machinery. This review study provides a solid foundation for future research in this area, offering a comprehensive analysis of DL-based bearing diagnosis that can guide the development of more effective techniques and tools for fault detection and diagnosis |

| Huang et al. [28] | The references analyzed were divided into two groups: enhanced SVM techniques and their use in RUL estimation |

| Liu et al. [29] | The authors aimed to summarize the methods for predicting the RUL of affordances, which can be broadly classified into three categories: physical model-based methods, statistical methods, and data-driven methods based on condition monitoring. By comparing the advantages and disadvantages of each of these methods, the authors also provide some guidance for selecting an appropriate prediction method for practical applications |

| Si et al. [30] | The authors reviewed current RUL estimation modeling advancements. The review’s main focus is on statistical data-driven methodologies that only use readily accessible historical observed data and statistical models. The methods are divided into two main categories of models: those that rely on knowledge about the asset’s state that has been directly seen and those that do not |

Numerous earlier studies focused on predicting RUL using just one feature. On the other hand, the DT is an effective tool for extracting important features. For this reason, it is suggested to use all the features extracted from the DT to estimate the RUL. The goal of this study is to develop a novel data-driven methodology for monitoring and predicting ball-bearing RUL. In order to cut down on noise, the vibration signals are first denoised using the Variational Mode Decomposition (VMD). Second, employ the DT algorithm to extract useful knowledge from two independent data sets made up of original signals and denoised signals. The RUL is modeled by regression using the ELM, which is the third step. Finally, performance criteria is used to assess the effectiveness of the given methodology. This article’s main contributions are as follows: (i) the suggested methodology offers a tool for monitoring the condition of ball bearings, (ii) the relevant features can be extracted using the DT technique, and (iii) combining the DT and ELM techniques enables estimation of the RUL based on various DT criteria. The rest of this essay is structured as follows: Three techniques (VMD, DT, and ELM) are briefly reviewed in the second section. The results, including comparisons, are covered in the third section. The most significant points made are highlighted in the final section.

2 Methodology

The suggested methodology’s flowchart to monitor the ball bearings’ health and predict the RUL is shown in Figure 1.

Flowchart of the proposed methodology.

During operation, bearings produce vibrations that can be monitored using indicators like RMS and peak value. By plotting these indicators over time, it is possible to observe the trend of the bearing’s degradation (Figure 2). Accurately estimating the current and future health of a bearing is crucial to extend its operation. By predicting the RUL of the bearing, which refers to the time until the machine ceases operating, appropriate maintenance decisions can be made.

Degradation indicator over time.

Before using the proposed methodology, some concepts must be clarified. Figure 2 depicts the evolution of a degradation indicator over RT (Run-Time). The alert point is denoted by

2.1 VMD algorithm

In ball bearings, for example, vibrations and noise, in the form of periodic impulses created when the balls pass over a flaw in the rings, are examples of complex and non-tationary vibration signals, and impulsive signatures are typically concealed by stochastic noise. Signal processing techniques are employed to improve follow-up on the degradation in order to lessen the impact of this noise. One of the newest methods for signal decomposition used to lower noise is VMD, which is similar to Empirical Modes Decomposition (EMD). As a brand-new technique for self-adapting signal decomposition, Dragomiretskiy and Zosso introduced VMD in 2014. The original signal can be divided using the VMD approach into a limited number of signals known as IMFs (Intrinsic Mode Functions) [31], which are defined as follows:

Here,

Here,

The solution is achieved by optimizing each IMF’s center frequency and bandwidth. The frequency

Here,

The VMD process is terminated as soon as the relative error

2.2 DT algorithm

To categorize data, DT are frequently utilized. The goal of classification is to categorize samples using a model created from a different data source. The latter consists of a collection of decision-making classes and predictive features. It is necessary to define the classes and characteristics that make up the data collection before building the DT. Leaf, node, and branch components make up a DT. An attribute, also known as a classified object property, is represented by each tree node. Each leaf of the tree represents a class, and each branch represents a potential node attribute value [32].

The foundation of this tree’s creation is the extraction of information from data using classification techniques. We cite the following algorithms for the construction tree: CART [33], ID3 [34], and C4.5 [35].

In this study, DTs are built using the C4.5 algorithm. WEKA uses this algorithm to create the J48 classifier. An overview of the C4.5 DT is provided in this section. The supervised learning algorithm C4.5 chooses attributes based on the following criteria [32]:

If

Entropy, which is defined as the amount of data required to determine the class of a

Entropy is minimum when the node is pure. All samples are in the same class, and maximum when the examples are evenly distributed. The quantity of data needed to determine a

Information gain is a metric used to measure the quality of a split. The most significant attribute can be chosen using this criterion. In comparison to the other traits, the chosen attribute has the most advantage. It is given as follows:

The gain ratio is a standard for correcting the gain of entropy’s slant while accounting for the quantity of attribute values and the proportion of these values in the data. The details are as follows:

with:

The selected predictive attribute maximizes the gain ratio.

2.3 ELM algorithm

ELMs are frequently utilized in machine learning due to their fast-learning capabilities and simplicity. ELM is a single hidden layer feedforward neural network that is trained differently than conventional network training methods [36,37,38]. In this section, ELM is briefly described.

Given

where

The jth input sample’s vector is represented by

Where

where

2.4 Data collection and features extraction

The PRONOSTIA platform [39] was utilized to gather the data for this investigation, as shown in Figure 3. This platform’s goal is to deliver accurate experimental data that can be utilized to track and describe how ball bearings degrade over the course of their full operational life. Several run-to-failure experiments were conducted by applying radial loads on ball bearings that exceeded the permitted loads to accelerate their degradation.

PRONOSTIA Platform.

In this study, we focus on the vibration signals that were measured during the operating conditions at 1,800 rpm rotation and 4,000 N

To collect monitoring data, high-frequency accelerometers, specifically DYTRAN3035B, were attached to the housing of the bearing being tested. One accelerometer is horizontally placed, while the other is vertically placed, allowing them to measure both horizontal and vertical accelerations. These accelerometers are connected to a data acquisition card, the NI DAQCard-9174, which provides monitoring data to the user. The acceleration measurement unit is g, where 1 g = 9.81 m/s². Vibration signals were acquired using two accelerometers and the following parameters: Sampling frequency is

During operation, rotating machines produce vibrations. The high level of these vibrations is due to the deterioration of the condition of its components. For this, statistical indicators, called features, are used to track the health status of these components.

From each vibration signal, 15 statistical features are taken out in order to monitor the condition of the ball bearings. These features can be divided into two subsets. The first subset has proven its effectiveness, such as RMS (Root Mean Square), Peak, Kurtosis, CF (Crest factor), and KF (K factor) [32], while the second subset can be used as a supplement to the first subsets: Rang, mean, STD (Standard Deviation), VAR (Variance), ADEV (Average Deviation), Skewness, Margin, RA (Root Amplitude), IF (Impulse factor), and shape. Table 2 gives the mathematical description of these features [40,41], and Figure 4 depicts their progression over time.

Features described mathematically

| Features | Description |

|---|---|

| Range |

|

| Mean |

|

| Peak |

|

| Root amplitude (RA) |

|

| Root mean square (RMS) |

|

| Average deviation (ADEV) |

|

| Variation (VAR) |

|

| Standard deviation (STD) |

|

| Skewness |

|

| Kurtosis |

|

| Crest factor (CF) |

|

| K Factor (KF) |

|

| Margin |

|

| Shape |

|

| Impulse factor (IF) |

|

Features over time.

3 Results and discussion

In the fault detection process, an anomaly can be detected if a feature exceeds a predetermined threshold. Standards (like ISO10816) or personal experience can be used to set thresholds. However, experience has shown that setting two thresholds for warning and alert is the best approach.

In this work, the warning and alert thresholds are determined as follows: the warning threshold is 2× rms0, and the alert threshold is 10× rms0 where rms0 is the average of the RMS values of the vibration signals measured at the start of the operation.

Under this approach, thresholds are placed in the RMS evolution curve (Figure 5) to categorize the remaining RMS values into the following states: normal, abnormal, and danger. This figure depicts three key points: A, B, and C. Point A signifies the normal operational condition when no defects are detected. Point B, on the other hand, denotes the alarm point, which is where the warning threshold line intersects with the degradation indicator curve. Lastly, Point C is the danger point, where the alert threshold line intersects with the degradation indicator curve.

RMS over time for original signal.

3.1 Denoised signals by the VMD approach

To identify features relevant that help in decision-making when the condition monitoring of ball bearings, two independent data sets are formed from original signals and denoised signals, and then, the features are extracted from these signals. The denoised signals are obtained by applying the VMD approach to the original signals as described earlier. VMD approach decomposes the original signal into a finite number of signals so-called IMFs. The sum of IMFs is the denoised signal. To validate the similarities between denoised signal and original signal, bias has been used. The bias is the difference average [42] and is defined as follows:

where

First, the maximum number of IMFs for a signal is set at

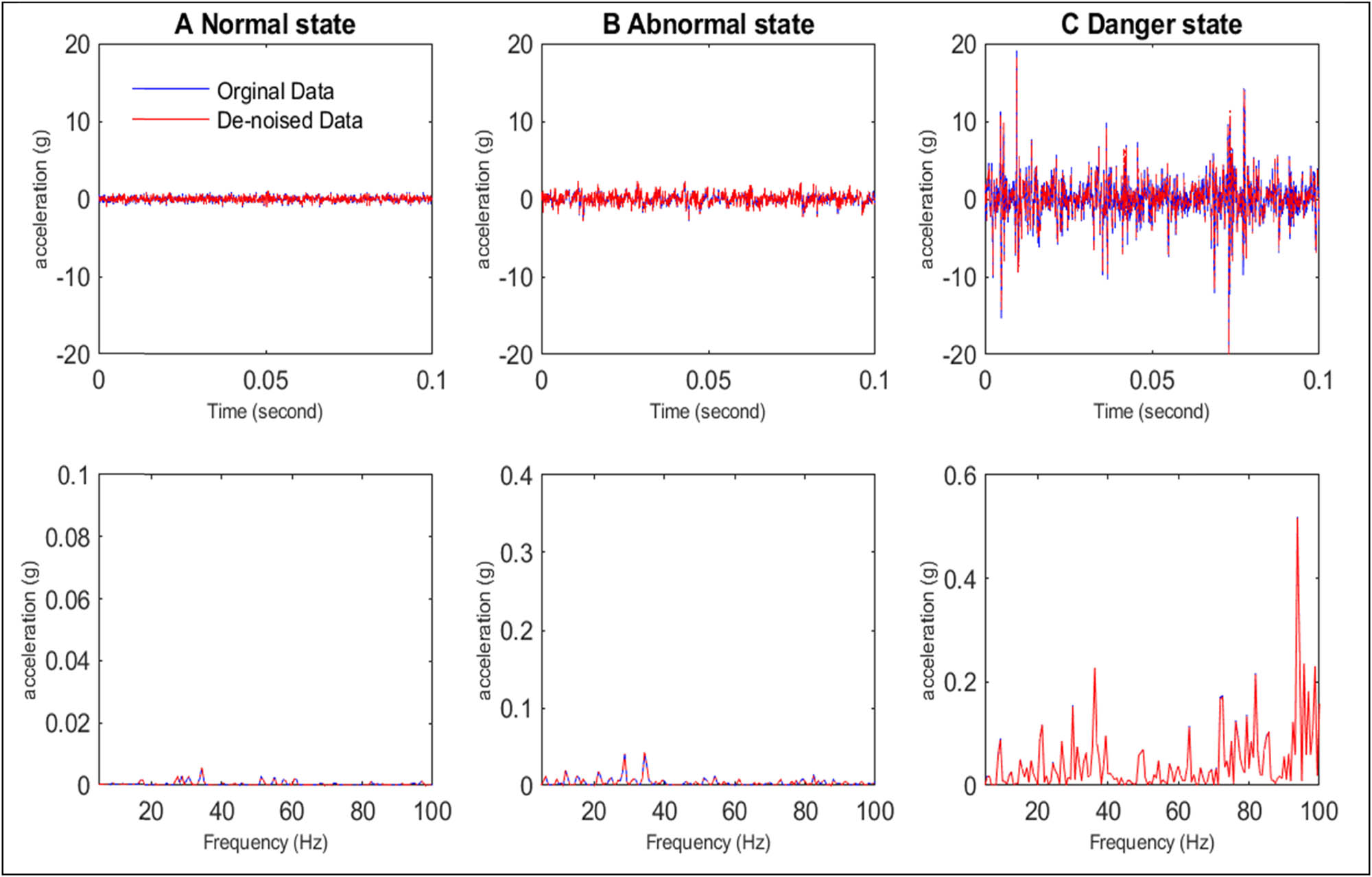

Figure 6 shows three frequency spectrums and the corresponding vibration signals (original and denoised) recorded by a radial accelerometer for three points (Figure 5):

Time signals and their spectrums for three states (normal, abnormal, and danger), 1 g = 9.81 m/s².

The features of the original and denoised signals for three different states (normal, abnormal, and danger) over time are depicted in Figure 7. The figure illustrates that the feature values of the two signals are quite similar to one another.

Features over time for three states (A, Normal; B, Abnormal; C, Danger).

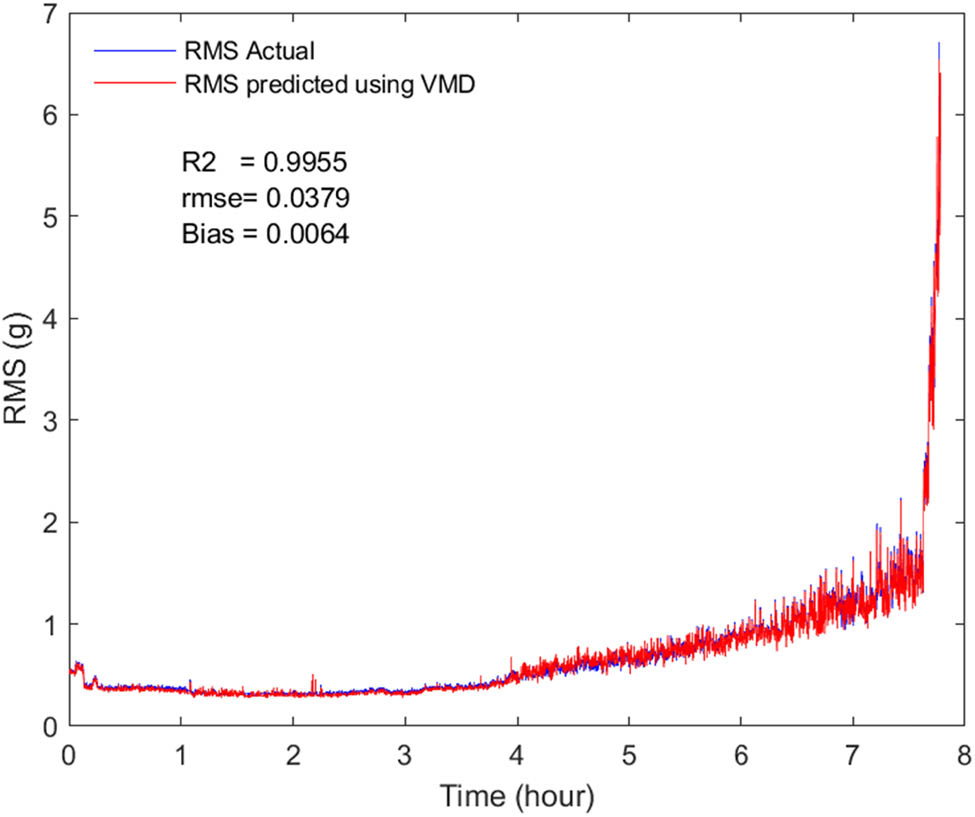

Figure 8 shows that the RMS feature values of both signals, namely the actual and the one processed with VMD to remove noise, are close to each other. Statistical criteria are used to evaluate the predictive values: the root mean square error (RMSE), the bias, and the determination coefficient (R²). These criteria are expressed as follows:

where

RMS over time for original signals and denoised signals.

3.2 Construction of DT

To build a DT, the following steps are taken as shown in Figure 9:

collection and processing of vibration signals,

define a list of features and decisions, then build the data set using the Weka software, and

the data set is subjected to the J48 classification algorithm in order to create a DT and get knowledge from it.

Features and decisions.

In this study, two data set were constructed. The first data set is based on original vibration signals, and the second is based on denoised vibration signals. Using the J48 classifier algorithm on the data set allowed us to build the DTs shown in Figures 10 and 11, which correspond to noised and denoised signals, respectively. Figure 10, which corresponds to the original vibration signals, demonstrates that the most significant features to evaluate throughout the monitoring process are RMS and RA.

DT from original vibration signals.

DT from denoised vibration signals.

On the other hand, Figure 11, which corresponds to the denoised vibration signals, shows that the most important features to consider during the monitoring process are RMS and RANGE (Table 2). Furthermore, the RMS feature appears to be more reliable than the other features for monitoring the fault.

The number of correctly classified samples can be found in the diagonal elements of the confusion matrix for the original and denoised signals, as shown in Tables 3 and 4. The elements on the outer diagonal, on the other hand, represent the number of samples that were classified incorrectly using the DT method.

Confusion matrix correspondent to original signals

| Classified as → | Normal | Abnormal | Danger |

|---|---|---|---|

| Normal | 1,616 | 35 | 0 |

| Abnormal | 49 | 1,060 | 0 |

| Danger | 0 | 4 | 39 |

Confusion matrix correspondent to denoised signals

| Classified as → | Normal | Abnormal | Danger |

|---|---|---|---|

| Normal | 1,612 | 37 | 0 |

| Abnormal | 68 | 1,043 | 0 |

| Danger | 0 | 4 | 39 |

Classification rates ranged from

The DT’s performance

| Original signals | Denoised signals | |

|---|---|---|

| Classification rate | 96.86 | 96.11 |

| Kappa statistic | 0.93 | 0.92 |

| Mean absolute error | 0.04 | 0.05 |

| Root mean square error | 0.14 | 0.16 |

| Number of samples | 2,803 | 2,803 |

| Number of leaves | 4 | 3 |

| Size of the tree | 8 | 5 |

Although the results of the two trees are similar, we notice a difference in the characteristics of each tree on which they rely for decision-making. This difference is due to how the signals are processed.

3.3 RUL estimation by ELM

Several improved versions of the basic ELM have recently been developed to solve regression and classification problems. Interested readers are referred to references [37,43], which survey ELM and its variants.

The ELM technique is used in this part to build a nonlinear relationship between features collected from vibration signals and the RUL of ball bearings. Table 6 summarizes the details of the parameters and performance of ELM. The RUL obtained by applying the ELM algorithm on the two independent data sets formed from original and denoised signals is shown in Figures 12 and 13. The effect of the number of hidden neurons and the features of the DTs in RUL modeling is clearly shown.

Performances of ELM

| Original signals | Denoised signals | |

|---|---|---|

| R Squared | 1.0 | 1.0 |

| Number of hidden neurons (NHN) | 3,500 | 5,700 |

| Neural transfer function | Triangular basis | Triangular basis |

| Input | RMS, RA | RMS, RANGE |

RUL Prediction based on original vibration signals.

RUL Prediction based on denoised vibration signals.

4 Conclusions

In this research article, a novel approach to condition monitoring was presented, utilizing VMD, DT, and ELM algorithms. The VMD algorithm was first used to reduce noise in the original vibration signals, followed by the application of the J48 algorithm to both signals, namely the actual and the one processed with VMD. Finally, the ELM algorithm was used to estimate the RUL of the monitored system. The results of this study demonstrate that this methodology provides highly accurate RUL prediction, allowing for the health monitoring of ball bearings and RUL estimation based on multiple features rather than relying solely on the RMS feature as done in many previous studies. The proposed methodology therefore has the potential to be highly beneficial in the decision-making process for condition monitoring applications. Overall, this research presents a promising new methodology for accurate and efficient condition monitoring.

-

Funding information: The authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Jardine AK, Lin D, Banjevic D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech Syst Signal Process. 2006;20(7):1483–510. 10.1016/j.ymssp.2005.09.012.Search in Google Scholar

[2] Lee J, Abujamra R, Jardine AK, Lin D, Banjevic D. An integrated platform for diagnostics, prognostics and maintenance optimization. Proceedings of the Intelligent Maintenance Systems; 2004 Jul 15. p. 15–27.Search in Google Scholar

[3] Boumahdi M, Rechak S, Hanini S. Analysis and prediction of defect size and remaining useful life of thrust ball bearings: modelling and experiment procedures. Arab J Sci Eng. 2017;42(11):4535–46. 10.1007/s13369-017-2550-y.Search in Google Scholar

[4] Soualhi A, Medjaher K, Zerhouni N. Bearing health monitoring based on Hilbert–Huang transform, support vector machine, and regression. IEEE Trans Instrum Meas. 2014;64(1):52–62. 10.1109/TIM.2014.2330494.Search in Google Scholar

[5] Benkedjouh T, Medjaher K, Zerhouni N, Rechak S. Remaining useful life estimation based on nonlinear feature reduction and support vector regression. Eng Appl Artif Intell. 2013;26(7):1751–60. 10.1016/j.engappai.2013.02.006.Search in Google Scholar

[6] Yan M, Wang X, Wang B, Chang M, Muhammad I. Bearing remaining useful life prediction using support vector machine and hybrid degradation tracking model. ISA Trans. 2020;98:471–82. 10.1016/j.isatra.2019.08.058.Search in Google Scholar PubMed

[7] Ambrosino F, Thinová L, Briestenský M, Šebela S, Sabbarese C. Detecting time series anomalies using hybrid methods applied to Radon signals recorded in caves for possible correlation with earthquakes. Acta Geodaetica et Geophysica. 2020;55:405–20. 10.1007/s40328-020-00298-1.Search in Google Scholar

[8] Mao W, He J, Li Y, Yan Y. Bearing fault diagnosis with auto-encoder extreme learning machine: A comparative study. Proc Inst Mech Engineers, Part C: J Mech Eng Sci. 2017;231(8):1560–78. 10.1177/0954406216675896.Search in Google Scholar

[9] Lee J, Sun Z, Tan TB, Mendez J, Flores-Cerrillo J, Wang J, et al. Remaining useful life estimation for ball bearings using feature engineering and extreme learning machine. IFAC-PapersOnLine. 2022;55(7):198–203. 10.1016/j.ifacol.2022.07.444.Search in Google Scholar

[10] Mao W, He L, Yan Y, Wang J. Online sequential prediction of bearings imbalanced fault diagnosis by extreme learning machine. Mech Syst Signal Process. 2017;83:450–73. 10.1016/j.ymssp.2016.06.024.Search in Google Scholar

[11] Wu Y, Yuan M, Dong S, Lin L, Liu Y. Remaining useful life estimation of engineered systems using vanilla LSTM neural networks. Neurocomputing. 2018;275:167–79. 10.1016/j.neucom.2017.05.063.Search in Google Scholar

[12] Ren L, Sun Y, Wang H, Zhang L. Prediction of bearing remaining useful life with deep convolution neural network. IEEE Access. 2018;6:13041–49. 10.1109/ACCESS.2018.2804930.Search in Google Scholar

[13] Chen Y, Peng G, Zhu Z, Li S. A novel deep learning method based on attention mechanism for bearing remaining useful life prediction. Appl Soft Comput. 2020;86:105919. 10.1016/j.asoc.2019.105919.Search in Google Scholar

[14] Gupta M, Wadhvani R, Rasool A. A real-time adaptive model for bearing fault classification and remaining useful life estimation using deep neural network. Knowl Syst. 2023;259:110070. 10.1016/j.knosys.2022.110070.Search in Google Scholar

[15] Ambrosino F, Sabbarese C, Roca V, Giudicepietro F, Chiodini G. Analysis of 7-years Radon time series at Campi Flegrei area (Naples, Italy) using artificial neural network method. Appl Radiat Isotopes. 2020;163:109239. 10.1016/j.apradiso.2020.109239.Search in Google Scholar PubMed

[16] Santosh T, Soni RK, Eswaraiah C, Kumar S. Application of artificial neural network method to predict the breakage properties of PGE bearing chromite ore. Adv Powder Technol. 2022;33(3):103450. 10.1016/j.apt.2022.103450.Search in Google Scholar

[17] Peng F, Zheng L, Peng Y, Fang C, Meng X. Digital Twin for rolling bearings: a review of current simulation and PHM techniques. Measurement. 2022;201:111728. 10.1016/j.measurement.2022.111728.Search in Google Scholar

[18] Xu Z, Saleh JH. Machine learning for reliability engineering and safety applications: Review of current status and future opportunities. Reliab Eng & Syst Saf. 2021;211:107530. 10.1016/j.ress.2021.107530.Search in Google Scholar

[19] Bertolini M, Mezzogori D, Neroni M, Zammori F. Machine learning for industrial applications: A comprehensive literature review. Expert Syst Appl. 2021;175:114820. 10.1016/j.eswa.2021.114820.Search in Google Scholar

[20] Soni D, Kumar N. Machine learning techniques in emerging cloud computing integrated paradigms: A survey and taxonomy. J Netw Comput Appl. 2022;205:103419. 10.1016/j.jnca.2022.103419.Search in Google Scholar

[21] Avci O, Abdeljaber O, Kiranyaz S, Hussein M, Gabbouj M, Inman DJ. A review of vibration-based damage detection in civil structures: From traditional methods to machine learning and deep learning applications. Mech Syst Signal Process. 2021;147:107077. 10.1016/j.ymssp.2020.107077.Search in Google Scholar

[22] Li X, Liu X, Yue C, Liang SY, Wang L. Systematic review on tool breakage monitoring techniques in machining operations. Int J Mach Tools Manufacture. 2022;103882. 10.1016/j.ijmachtools.2022.103882.Search in Google Scholar

[23] Ntemi M, Paraschos S, Karakostas A, Gialampoukidis I, Vrochidis S, Kompatsiaris I. Infrastructure monitoring and quality diagnosis in CNC machining: A review. CIRP J Manuf Sci Technol. 2022;38:631–49. 10.1016/j.cirpj.2022.06.001.Search in Google Scholar

[24] van Dinter R, Tekinerdogan B, Catal C. Predictive maintenance using digital twins: A systematic literature review. Inf Softw Technol. 2022;151:107008. 10.1016/j.infsof.2022.107008.Search in Google Scholar

[25] Zhao R, Yan R, Chen Z, Mao K, Wang P, Gao RX. Deep learning and its applications to machine health monitoring. Mech Syst Signal Process. 2019;115:213–37. 10.1016/j.ymssp.2018.05.050.Search in Google Scholar

[26] Gangsar P, Tiwari R. Signal based condition monitoring techniques for fault detection and diagnosis of induction motors: A state-of-the-art review. Mech Syst signal Process. 2020;144:106908. 10.1016/j.ymssp.2020.106908.Search in Google Scholar

[27] Hakim M, Omran AAB, Ahmed AN, Al-Waily M, Abdellatif A. A systematic review of rolling bearing fault diagnoses based on deep learning and transfer learning: Taxonomy, overview, application, open challenges, weaknesses and recommendations. Ain Shams Eng J. 2022;14:101945. 10.1016/j.asej.2022.101945.Search in Google Scholar

[28] Huang HZ, Wang HK, Li YF, Zhang L, Liu Z. Support vector machine-based estimation of remaining useful life: current research status and future trends. J Mech Sci Technol. 2015;29(1):151–63. 10.1007/s12206-014-1222-z.Search in Google Scholar

[29] Liu H, Mo Z, Zhang H, Zeng X, Wang J, Miao Q. Investigation on rolling bearing remaining useful life prediction: A review. In 2018 Prognostics and System Health Management Conference (PHM-Chongqing) (pp. 979-984). IEEE; 2018, October. 10.1109/PHM-Chongqing.2018.00175.Search in Google Scholar

[30] Si XS, Wang W, Hu CH, Zhou DH. Remaining useful life estimation–a review on the statistical data driven approaches. Eur J Oper Res. 2011;213(1):1–14. 10.1016/j.ejor.2010.11.018.Search in Google Scholar

[31] Huang Y, Lin J, Liu Z, Wu W. A modified scale-space guiding variational mode decomposition for high-speed railway bearing fault diagnosis. J Sound Vibratio. 2019;444:216–34. 10.1016/j.jsv.2018.12.033.Search in Google Scholar

[32] Boumahdi M, Dron JP, Rechak S, Cousinard O. On the extraction of rules in the identification of bearing defects in rotating machinery using decision tree. Expert Syst Appl. 2010;37(8):5887–94. 10.1016/j.eswa.2010.02.017.Search in Google Scholar

[33] Breiman L, Friedman JH, Olshen RA, Stone CJ. Classification and regression trees. technical report. Belmont, CA: Wadsworth International Group; 1984.Search in Google Scholar

[34] Quinlan JR. Induction of decision trees. Mach Learn. 1986;1(1):81–106.10.1007/BF00116251Search in Google Scholar

[35] Quinlan JR. C4.5: Programs for machine learning. Mach Learn. Vol. 16. Morgan Kaufmann Publishers; 1993. p. 235–40.10.1007/BF00993309Search in Google Scholar

[36] Huang GB, Zhu QY, Siew CK. Extreme learning machine: theory and applications. Neurocomputing. 2006;70(1–3):489–501. 10.1016/J.NEUCOM.2005.12.126.Search in Google Scholar

[37] Ding S, Xu X, Nie R. Extreme learning machine and its applications. Neural Comput Appl. 2014;25(3):549–56. 10.1007/s00521-013-1522-8.Search in Google Scholar

[38] Sureka N, Gunaseelan K. Investigations on detection and prevention of primary user emulation attack in cognitive radio networks using extreme machine learning algorithm. J Ambient Intell Humanized Comput. 2021;1–10. 10.1007/s12652-021-03080-5.Search in Google Scholar

[39] Nectoux P, Gouriveau R, Medjaher K, Ramasso E, Chebel-Morello B, Zerhouni N, et al. PRONOSTIA: An experimental platform for bearings accelerated degradation tests. IEEE International Conference on Prognostics and Health Management, PHM’12., Jun 2012. Denver, Colorado, United States; 2012, June; p. 1–8. HAL Id: hal-00719503. https://hal.archives-ouvertes.fr/hal-00719503.Search in Google Scholar

[40] Wang L, Zhang L, Wang XZ. Reliability estimation and remaining useful lifetime prediction for bearing based on proportional hazard model. J Cent South Univ. 2015;22(12):4625–33. 10.1007/s11771-015-3013-9.Search in Google Scholar

[41] Euldji R, Boumahdi M, Bachene M. Decision-making based on decision tree for ball bearing monitoring. 2020 2nd Int Workshop Human-Centric Smart EnvirHealth Well-being (IHSH). IEEE; 2021, Febr. p. 171–5. 10.1109/IHSH51661.2021.9378734.Search in Google Scholar

[42] Isham MF, Leong MS, Lim MH, Ahmad ZA. Variational mode decomposition: mode determination method for rotating machinery diagnosis. J Vibroengineering. 2018;20(7):2604–21. 10.21595/jve.2018.19479.Search in Google Scholar

[43] Huang GB, Wang DH, Lan Y. Extreme learning machines: a survey. Int J Mach Learn Cybern. 2011;2(2):107–22. 10.1007/s13042-011-0019-y.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Dynamic properties of the attachment oscillator arising in the nanophysics

- Parametric simulation of stagnation point flow of motile microorganism hybrid nanofluid across a circular cylinder with sinusoidal radius

- Fractal-fractional advection–diffusion–reaction equations by Ritz approximation approach

- Behaviour and onset of low-dimensional chaos with a periodically varying loss in single-mode homogeneously broadened laser

- Ammonia gas-sensing behavior of uniform nanostructured PPy film prepared by simple-straightforward in situ chemical vapor oxidation

- Analysis of the working mechanism and detection sensitivity of a flash detector

- Flat and bent branes with inner structure in two-field mimetic gravity

- Heat transfer analysis of the MHD stagnation-point flow of third-grade fluid over a porous sheet with thermal radiation effect: An algorithmic approach

- Weighted survival functional entropy and its properties

- Bioconvection effect in the Carreau nanofluid with Cattaneo–Christov heat flux using stagnation point flow in the entropy generation: Micromachines level study

- Study on the impulse mechanism of optical films formed by laser plasma shock waves

- Analysis of sweeping jet and film composite cooling using the decoupled model

- Research on the influence of trapezoidal magnetization of bonded magnetic ring on cogging torque

- Tripartite entanglement and entanglement transfer in a hybrid cavity magnomechanical system

- Compounded Bell-G class of statistical models with applications to COVID-19 and actuarial data

- Degradation of Vibrio cholerae from drinking water by the underwater capillary discharge

- Multiple Lie symmetry solutions for effects of viscous on magnetohydrodynamic flow and heat transfer in non-Newtonian thin film

- Thermal characterization of heat source (sink) on hybridized (Cu–Ag/EG) nanofluid flow via solid stretchable sheet

- Optimizing condition monitoring of ball bearings: An integrated approach using decision tree and extreme learning machine for effective decision-making

- Study on the inter-porosity transfer rate and producing degree of matrix in fractured-porous gas reservoirs

- Interstellar radiation as a Maxwell field: Improved numerical scheme and application to the spectral energy density

- Numerical study of hybridized Williamson nanofluid flow with TC4 and Nichrome over an extending surface

- Controlling the physical field using the shape function technique

- Significance of heat and mass transport in peristaltic flow of Jeffrey material subject to chemical reaction and radiation phenomenon through a tapered channel

- Complex dynamics of a sub-quadratic Lorenz-like system

- Stability control in a helicoidal spin–orbit-coupled open Bose–Bose mixture

- Research on WPD and DBSCAN-L-ISOMAP for circuit fault feature extraction

- Simulation for formation process of atomic orbitals by the finite difference time domain method based on the eight-element Dirac equation

- A modified power-law model: Properties, estimation, and applications

- Bayesian and non-Bayesian estimation of dynamic cumulative residual Tsallis entropy for moment exponential distribution under progressive censored type II

- Computational analysis and biomechanical study of Oldroyd-B fluid with homogeneous and heterogeneous reactions through a vertical non-uniform channel

- Predictability of machine learning framework in cross-section data

- Chaotic characteristics and mixing performance of pseudoplastic fluids in a stirred tank

- Isomorphic shut form valuation for quantum field theory and biological population models

- Vibration sensitivity minimization of an ultra-stable optical reference cavity based on orthogonal experimental design

- Effect of dysprosium on the radiation-shielding features of SiO2–PbO–B2O3 glasses

- Asymptotic formulations of anti-plane problems in pre-stressed compressible elastic laminates

- A study on soliton, lump solutions to a generalized (3+1)-dimensional Hirota--Satsuma--Ito equation

- Tangential electrostatic field at metal surfaces

- Bioconvective gyrotactic microorganisms in third-grade nanofluid flow over a Riga surface with stratification: An approach to entropy minimization

- Infrared spectroscopy for ageing assessment of insulating oils via dielectric loss factor and interfacial tension

- Influence of cationic surfactants on the growth of gypsum crystals

- Study on instability mechanism of KCl/PHPA drilling waste fluid

- Analytical solutions of the extended Kadomtsev–Petviashvili equation in nonlinear media

- A novel compact highly sensitive non-invasive microwave antenna sensor for blood glucose monitoring

- Inspection of Couette and pressure-driven Poiseuille entropy-optimized dissipated flow in a suction/injection horizontal channel: Analytical solutions

- Conserved vectors and solutions of the two-dimensional potential KP equation

- The reciprocal linear effect, a new optical effect of the Sagnac type

- Optimal interatomic potentials using modified method of least squares: Optimal form of interatomic potentials

- The soliton solutions for stochastic Calogero–Bogoyavlenskii Schiff equation in plasma physics/fluid mechanics

- Research on absolute ranging technology of resampling phase comparison method based on FMCW

- Analysis of Cu and Zn contents in aluminum alloys by femtosecond laser-ablation spark-induced breakdown spectroscopy

- Nonsequential double ionization channels control of CO2 molecules with counter-rotating two-color circularly polarized laser field by laser wavelength

- Fractional-order modeling: Analysis of foam drainage and Fisher's equations

- Thermo-solutal Marangoni convective Darcy-Forchheimer bio-hybrid nanofluid flow over a permeable disk with activation energy: Analysis of interfacial nanolayer thickness

- Investigation on topology-optimized compressor piston by metal additive manufacturing technique: Analytical and numeric computational modeling using finite element analysis in ANSYS

- Breast cancer segmentation using a hybrid AttendSeg architecture combined with a gravitational clustering optimization algorithm using mathematical modelling

- On the localized and periodic solutions to the time-fractional Klein-Gordan equations: Optimal additive function method and new iterative method

- 3D thin-film nanofluid flow with heat transfer on an inclined disc by using HWCM

- Numerical study of static pressure on the sonochemistry characteristics of the gas bubble under acoustic excitation

- Optimal auxiliary function method for analyzing nonlinear system of coupled Schrödinger–KdV equation with Caputo operator

- Analysis of magnetized micropolar fluid subjected to generalized heat-mass transfer theories

- Does the Mott problem extend to Geiger counters?

- Stability analysis, phase plane analysis, and isolated soliton solution to the LGH equation in mathematical physics

- Effects of Joule heating and reaction mechanisms on couple stress fluid flow with peristalsis in the presence of a porous material through an inclined channel

- Bayesian and E-Bayesian estimation based on constant-stress partially accelerated life testing for inverted Topp–Leone distribution

- Dynamical and physical characteristics of soliton solutions to the (2+1)-dimensional Konopelchenko–Dubrovsky system

- Study of fractional variable order COVID-19 environmental transformation model

- Sisko nanofluid flow through exponential stretching sheet with swimming of motile gyrotactic microorganisms: An application to nanoengineering

- Influence of the regularization scheme in the QCD phase diagram in the PNJL model

- Fixed-point theory and numerical analysis of an epidemic model with fractional calculus: Exploring dynamical behavior

- Computational analysis of reconstructing current and sag of three-phase overhead line based on the TMR sensor array

- Investigation of tripled sine-Gordon equation: Localized modes in multi-stacked long Josephson junctions

- High-sensitivity on-chip temperature sensor based on cascaded microring resonators

- Pathological study on uncertain numbers and proposed solutions for discrete fuzzy fractional order calculus

- Bifurcation, chaotic behavior, and traveling wave solution of stochastic coupled Konno–Oono equation with multiplicative noise in the Stratonovich sense

- Thermal radiation and heat generation on three-dimensional Casson fluid motion via porous stretching surface with variable thermal conductivity

- Numerical simulation and analysis of Airy's-type equation

- A homotopy perturbation method with Elzaki transformation for solving the fractional Biswas–Milovic model

- Heat transfer performance of magnetohydrodynamic multiphase nanofluid flow of Cu–Al2O3/H2O over a stretching cylinder

- ΛCDM and the principle of equivalence

- Axisymmetric stagnation-point flow of non-Newtonian nanomaterial and heat transport over a lubricated surface: Hybrid homotopy analysis method simulations

- HAM simulation for bioconvective magnetohydrodynamic flow of Walters-B fluid containing nanoparticles and microorganisms past a stretching sheet with velocity slip and convective conditions

- Coupled heat and mass transfer mathematical study for lubricated non-Newtonian nanomaterial conveying oblique stagnation point flow: A comparison of viscous and viscoelastic nanofluid model

- Power Topp–Leone exponential negative family of distributions with numerical illustrations to engineering and biological data

- Extracting solitary solutions of the nonlinear Kaup–Kupershmidt (KK) equation by analytical method

- A case study on the environmental and economic impact of photovoltaic systems in wastewater treatment plants

- Application of IoT network for marine wildlife surveillance

- Non-similar modeling and numerical simulations of microploar hybrid nanofluid adjacent to isothermal sphere

- Joint optimization of two-dimensional warranty period and maintenance strategy considering availability and cost constraints

- Numerical investigation of the flow characteristics involving dissipation and slip effects in a convectively nanofluid within a porous medium

- Spectral uncertainty analysis of grassland and its camouflage materials based on land-based hyperspectral images

- Application of low-altitude wind shear recognition algorithm and laser wind radar in aviation meteorological services

- Investigation of different structures of screw extruders on the flow in direct ink writing SiC slurry based on LBM

- Harmonic current suppression method of virtual DC motor based on fuzzy sliding mode

- Micropolar flow and heat transfer within a permeable channel using the successive linearization method

- Different lump k-soliton solutions to (2+1)-dimensional KdV system using Hirota binary Bell polynomials

- Investigation of nanomaterials in flow of non-Newtonian liquid toward a stretchable surface

- Weak beat frequency extraction method for photon Doppler signal with low signal-to-noise ratio

- Electrokinetic energy conversion of nanofluids in porous microtubes with Green’s function

- Examining the role of activation energy and convective boundary conditions in nanofluid behavior of Couette-Poiseuille flow

- Review Article

- Effects of stretching on phase transformation of PVDF and its copolymers: A review

- Special Issue on Transport phenomena and thermal analysis in micro/nano-scale structure surfaces - Part IV

- Prediction and monitoring model for farmland environmental system using soil sensor and neural network algorithm

- Special Issue on Advanced Topics on the Modelling and Assessment of Complicated Physical Phenomena - Part III

- Some standard and nonstandard finite difference schemes for a reaction–diffusion–chemotaxis model

- Special Issue on Advanced Energy Materials - Part II

- Rapid productivity prediction method for frac hits affected wells based on gas reservoir numerical simulation and probability method

- Special Issue on Novel Numerical and Analytical Techniques for Fractional Nonlinear Schrodinger Type - Part III

- Adomian decomposition method for solution of fourteenth order boundary value problems

- New soliton solutions of modified (3+1)-D Wazwaz–Benjamin–Bona–Mahony and (2+1)-D cubic Klein–Gordon equations using first integral method

- On traveling wave solutions to Manakov model with variable coefficients

- Rational approximation for solving Fredholm integro-differential equations by new algorithm

- Special Issue on Predicting pattern alterations in nature - Part I

- Modeling the monkeypox infection using the Mittag–Leffler kernel

- Spectral analysis of variable-order multi-terms fractional differential equations

- Special Issue on Nanomaterial utilization and structural optimization - Part I

- Heat treatment and tensile test of 3D-printed parts manufactured at different build orientations

Articles in the same Issue

- Regular Articles

- Dynamic properties of the attachment oscillator arising in the nanophysics

- Parametric simulation of stagnation point flow of motile microorganism hybrid nanofluid across a circular cylinder with sinusoidal radius

- Fractal-fractional advection–diffusion–reaction equations by Ritz approximation approach

- Behaviour and onset of low-dimensional chaos with a periodically varying loss in single-mode homogeneously broadened laser

- Ammonia gas-sensing behavior of uniform nanostructured PPy film prepared by simple-straightforward in situ chemical vapor oxidation

- Analysis of the working mechanism and detection sensitivity of a flash detector

- Flat and bent branes with inner structure in two-field mimetic gravity

- Heat transfer analysis of the MHD stagnation-point flow of third-grade fluid over a porous sheet with thermal radiation effect: An algorithmic approach

- Weighted survival functional entropy and its properties

- Bioconvection effect in the Carreau nanofluid with Cattaneo–Christov heat flux using stagnation point flow in the entropy generation: Micromachines level study

- Study on the impulse mechanism of optical films formed by laser plasma shock waves

- Analysis of sweeping jet and film composite cooling using the decoupled model

- Research on the influence of trapezoidal magnetization of bonded magnetic ring on cogging torque

- Tripartite entanglement and entanglement transfer in a hybrid cavity magnomechanical system

- Compounded Bell-G class of statistical models with applications to COVID-19 and actuarial data

- Degradation of Vibrio cholerae from drinking water by the underwater capillary discharge

- Multiple Lie symmetry solutions for effects of viscous on magnetohydrodynamic flow and heat transfer in non-Newtonian thin film

- Thermal characterization of heat source (sink) on hybridized (Cu–Ag/EG) nanofluid flow via solid stretchable sheet

- Optimizing condition monitoring of ball bearings: An integrated approach using decision tree and extreme learning machine for effective decision-making

- Study on the inter-porosity transfer rate and producing degree of matrix in fractured-porous gas reservoirs

- Interstellar radiation as a Maxwell field: Improved numerical scheme and application to the spectral energy density

- Numerical study of hybridized Williamson nanofluid flow with TC4 and Nichrome over an extending surface

- Controlling the physical field using the shape function technique

- Significance of heat and mass transport in peristaltic flow of Jeffrey material subject to chemical reaction and radiation phenomenon through a tapered channel

- Complex dynamics of a sub-quadratic Lorenz-like system

- Stability control in a helicoidal spin–orbit-coupled open Bose–Bose mixture

- Research on WPD and DBSCAN-L-ISOMAP for circuit fault feature extraction

- Simulation for formation process of atomic orbitals by the finite difference time domain method based on the eight-element Dirac equation

- A modified power-law model: Properties, estimation, and applications

- Bayesian and non-Bayesian estimation of dynamic cumulative residual Tsallis entropy for moment exponential distribution under progressive censored type II

- Computational analysis and biomechanical study of Oldroyd-B fluid with homogeneous and heterogeneous reactions through a vertical non-uniform channel

- Predictability of machine learning framework in cross-section data

- Chaotic characteristics and mixing performance of pseudoplastic fluids in a stirred tank

- Isomorphic shut form valuation for quantum field theory and biological population models

- Vibration sensitivity minimization of an ultra-stable optical reference cavity based on orthogonal experimental design

- Effect of dysprosium on the radiation-shielding features of SiO2–PbO–B2O3 glasses

- Asymptotic formulations of anti-plane problems in pre-stressed compressible elastic laminates

- A study on soliton, lump solutions to a generalized (3+1)-dimensional Hirota--Satsuma--Ito equation

- Tangential electrostatic field at metal surfaces

- Bioconvective gyrotactic microorganisms in third-grade nanofluid flow over a Riga surface with stratification: An approach to entropy minimization

- Infrared spectroscopy for ageing assessment of insulating oils via dielectric loss factor and interfacial tension

- Influence of cationic surfactants on the growth of gypsum crystals

- Study on instability mechanism of KCl/PHPA drilling waste fluid

- Analytical solutions of the extended Kadomtsev–Petviashvili equation in nonlinear media

- A novel compact highly sensitive non-invasive microwave antenna sensor for blood glucose monitoring

- Inspection of Couette and pressure-driven Poiseuille entropy-optimized dissipated flow in a suction/injection horizontal channel: Analytical solutions

- Conserved vectors and solutions of the two-dimensional potential KP equation

- The reciprocal linear effect, a new optical effect of the Sagnac type

- Optimal interatomic potentials using modified method of least squares: Optimal form of interatomic potentials

- The soliton solutions for stochastic Calogero–Bogoyavlenskii Schiff equation in plasma physics/fluid mechanics

- Research on absolute ranging technology of resampling phase comparison method based on FMCW

- Analysis of Cu and Zn contents in aluminum alloys by femtosecond laser-ablation spark-induced breakdown spectroscopy

- Nonsequential double ionization channels control of CO2 molecules with counter-rotating two-color circularly polarized laser field by laser wavelength

- Fractional-order modeling: Analysis of foam drainage and Fisher's equations

- Thermo-solutal Marangoni convective Darcy-Forchheimer bio-hybrid nanofluid flow over a permeable disk with activation energy: Analysis of interfacial nanolayer thickness

- Investigation on topology-optimized compressor piston by metal additive manufacturing technique: Analytical and numeric computational modeling using finite element analysis in ANSYS

- Breast cancer segmentation using a hybrid AttendSeg architecture combined with a gravitational clustering optimization algorithm using mathematical modelling

- On the localized and periodic solutions to the time-fractional Klein-Gordan equations: Optimal additive function method and new iterative method

- 3D thin-film nanofluid flow with heat transfer on an inclined disc by using HWCM

- Numerical study of static pressure on the sonochemistry characteristics of the gas bubble under acoustic excitation

- Optimal auxiliary function method for analyzing nonlinear system of coupled Schrödinger–KdV equation with Caputo operator

- Analysis of magnetized micropolar fluid subjected to generalized heat-mass transfer theories

- Does the Mott problem extend to Geiger counters?

- Stability analysis, phase plane analysis, and isolated soliton solution to the LGH equation in mathematical physics

- Effects of Joule heating and reaction mechanisms on couple stress fluid flow with peristalsis in the presence of a porous material through an inclined channel

- Bayesian and E-Bayesian estimation based on constant-stress partially accelerated life testing for inverted Topp–Leone distribution

- Dynamical and physical characteristics of soliton solutions to the (2+1)-dimensional Konopelchenko–Dubrovsky system

- Study of fractional variable order COVID-19 environmental transformation model

- Sisko nanofluid flow through exponential stretching sheet with swimming of motile gyrotactic microorganisms: An application to nanoengineering

- Influence of the regularization scheme in the QCD phase diagram in the PNJL model

- Fixed-point theory and numerical analysis of an epidemic model with fractional calculus: Exploring dynamical behavior

- Computational analysis of reconstructing current and sag of three-phase overhead line based on the TMR sensor array

- Investigation of tripled sine-Gordon equation: Localized modes in multi-stacked long Josephson junctions

- High-sensitivity on-chip temperature sensor based on cascaded microring resonators

- Pathological study on uncertain numbers and proposed solutions for discrete fuzzy fractional order calculus

- Bifurcation, chaotic behavior, and traveling wave solution of stochastic coupled Konno–Oono equation with multiplicative noise in the Stratonovich sense

- Thermal radiation and heat generation on three-dimensional Casson fluid motion via porous stretching surface with variable thermal conductivity

- Numerical simulation and analysis of Airy's-type equation

- A homotopy perturbation method with Elzaki transformation for solving the fractional Biswas–Milovic model

- Heat transfer performance of magnetohydrodynamic multiphase nanofluid flow of Cu–Al2O3/H2O over a stretching cylinder

- ΛCDM and the principle of equivalence

- Axisymmetric stagnation-point flow of non-Newtonian nanomaterial and heat transport over a lubricated surface: Hybrid homotopy analysis method simulations

- HAM simulation for bioconvective magnetohydrodynamic flow of Walters-B fluid containing nanoparticles and microorganisms past a stretching sheet with velocity slip and convective conditions

- Coupled heat and mass transfer mathematical study for lubricated non-Newtonian nanomaterial conveying oblique stagnation point flow: A comparison of viscous and viscoelastic nanofluid model

- Power Topp–Leone exponential negative family of distributions with numerical illustrations to engineering and biological data

- Extracting solitary solutions of the nonlinear Kaup–Kupershmidt (KK) equation by analytical method

- A case study on the environmental and economic impact of photovoltaic systems in wastewater treatment plants

- Application of IoT network for marine wildlife surveillance

- Non-similar modeling and numerical simulations of microploar hybrid nanofluid adjacent to isothermal sphere

- Joint optimization of two-dimensional warranty period and maintenance strategy considering availability and cost constraints

- Numerical investigation of the flow characteristics involving dissipation and slip effects in a convectively nanofluid within a porous medium

- Spectral uncertainty analysis of grassland and its camouflage materials based on land-based hyperspectral images

- Application of low-altitude wind shear recognition algorithm and laser wind radar in aviation meteorological services

- Investigation of different structures of screw extruders on the flow in direct ink writing SiC slurry based on LBM

- Harmonic current suppression method of virtual DC motor based on fuzzy sliding mode

- Micropolar flow and heat transfer within a permeable channel using the successive linearization method

- Different lump k-soliton solutions to (2+1)-dimensional KdV system using Hirota binary Bell polynomials

- Investigation of nanomaterials in flow of non-Newtonian liquid toward a stretchable surface

- Weak beat frequency extraction method for photon Doppler signal with low signal-to-noise ratio

- Electrokinetic energy conversion of nanofluids in porous microtubes with Green’s function

- Examining the role of activation energy and convective boundary conditions in nanofluid behavior of Couette-Poiseuille flow

- Review Article

- Effects of stretching on phase transformation of PVDF and its copolymers: A review

- Special Issue on Transport phenomena and thermal analysis in micro/nano-scale structure surfaces - Part IV

- Prediction and monitoring model for farmland environmental system using soil sensor and neural network algorithm

- Special Issue on Advanced Topics on the Modelling and Assessment of Complicated Physical Phenomena - Part III

- Some standard and nonstandard finite difference schemes for a reaction–diffusion–chemotaxis model

- Special Issue on Advanced Energy Materials - Part II

- Rapid productivity prediction method for frac hits affected wells based on gas reservoir numerical simulation and probability method

- Special Issue on Novel Numerical and Analytical Techniques for Fractional Nonlinear Schrodinger Type - Part III

- Adomian decomposition method for solution of fourteenth order boundary value problems

- New soliton solutions of modified (3+1)-D Wazwaz–Benjamin–Bona–Mahony and (2+1)-D cubic Klein–Gordon equations using first integral method

- On traveling wave solutions to Manakov model with variable coefficients

- Rational approximation for solving Fredholm integro-differential equations by new algorithm

- Special Issue on Predicting pattern alterations in nature - Part I

- Modeling the monkeypox infection using the Mittag–Leffler kernel

- Spectral analysis of variable-order multi-terms fractional differential equations

- Special Issue on Nanomaterial utilization and structural optimization - Part I

- Heat treatment and tensile test of 3D-printed parts manufactured at different build orientations