Abstract

This elementary work aims to address agglomeration and non-uniform dispersion of reinforcement particles in stir casting using Al6061 alloy (AA 6061) as a matrix and Aluminium oxide (Al2O3) as reinforcement particles. A novel combined feeding method of Encapsulate feeding technique & Two Step Stir Casting was developed & attempted to produce good quality composites by varying weight fractions of Aluminium Oxide (0 to 5 wt.%). The wetting agent Mg (2 wt.%) added in all castings to ensure better binding between ceramics and matrix. The SEM photomicrograph ensures homogenous dispersion of reinforcement particles by combined feeding method. The thermal properties of produced good quality composites are enhanced with increase in Aluminium Oxide (Al2O3) from 0 to 5 wt.%.

1 Introduction

Aluminium matrix composite materials (AMCs) embarks high attention among research community as its replacing conventional engineering materials over decades due to its superior customized properties like high strength to light weight, stiffness, corrosion resistance etc. majorly as structural components in automotive and aerospace industry [1]. Research community also did too many structural examinations than thermal behavior observation of produced composites [2, 3]. Al6061 alloys composites are vastly concentrated on structural applications only [4, 5]. The objective of the present work predominantly to control contemporary challenges like agglomeration and non-uniform dispersion of reinforcement particles in stir casting. Some researchers attempted with the above perspective and ended up in vain, although some may claim uniform dispersion but enough clarity in results is not discussed [6]. In the present work, combined feeding method of novel encapsulate feeding and two step stir casting was developed to produce good quality aluminium composites with uniform particle distribution. Apart from structural applications, Al6061 T-6 grade (AA 6061) is used as Material of construction in Heat Sink fins due to its cast ability and good workability nature as well as its alloy composition supports thermal & corrosion balance in a greater extent. Amidst numerous ceramic particles, Aluminium Oxide (Al2O3) is chemically suitable with aluminium due to its excellent bonding nature between base metal and ceramics without any inter-metallic phases [6].

2 Materials & methods

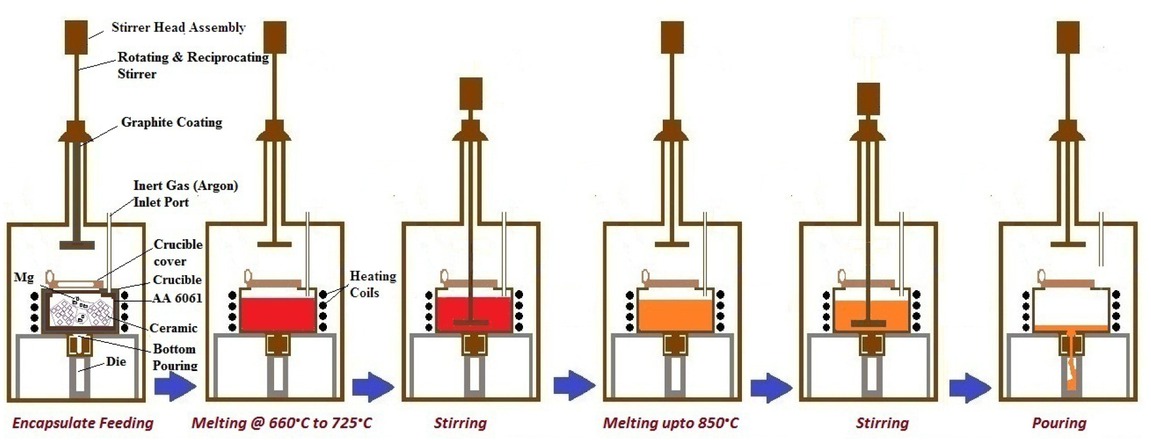

To overcome agglomeration and uneven dispersion of particles combined feeding method of novel innovative Encapsulate feeding technique and two step mixing is used to produce good quality AMC’s. Sequential process is as follows. In this feeding method, To suit with the crucible the preliminarily purchased Al6061 solid shaft with 85mm Outer diameter (OD) machined as a hollow cylindrical cup shape with the dimensions of 85mmOuter diameter, 65mm internal diameter, 150mm length and 30mm of bottom thickness. Next, the reinforcement particles (5% of Aluminium Oxide) kept inside aluminum foil sheet (as shown in Figure 1). 2% of Mg is used as wetting and binding agent to enhance bonding between reinforcement particles and base metal [4].

Schematic Representation of Sequential process in combined Feeding

The wrapped ceramic powder (Aluminium Oxide) & wetting agent (Magnesium) are placed inside hollow cylindrical cup and closed using cup cap. The furnace heats up to 725∘C (even though melting point of base metal around 660∘C to 680∘C) and the molten slurry base metal arresting reinforcement particles in all the directions due to gaseous layer formed by the base metal. Next, the single blade graphite coated mechanical stirrer agitates to break gaseous region and reinforcement particles mix up with base metal. The speed of the stirrer gradually increases up to 500 rpm for 4 minutes with argon gas environment to avoid oxidation. Then stirrer speed gradually reduced to null (zero) value and the composite slurry again heated upto 850∘C then the stirrer is further rotated with gradual increase in rpm upto 500 rpm for the same 4 mins and then slurry transferred into preheated mould (500∘C) through an arrangement namely bottom tapping with the help of funnel. Then it is quickly air quenched to reduce the time for settling of fragments/molecules (particles) in the fluid/liquefied matrix [6]. The above cycle is repeated with varied fractions as 1, 2, 3, and 4 Vol.% of Al2O3 molecules (particles) reinforcement to fabricate different composition of Al/ Al2O3 composites [6]. Casted ingots were machined to suit SEM, EDS & Pin-fin Apparatus as per their own standards and norms.

3 Results & discussion

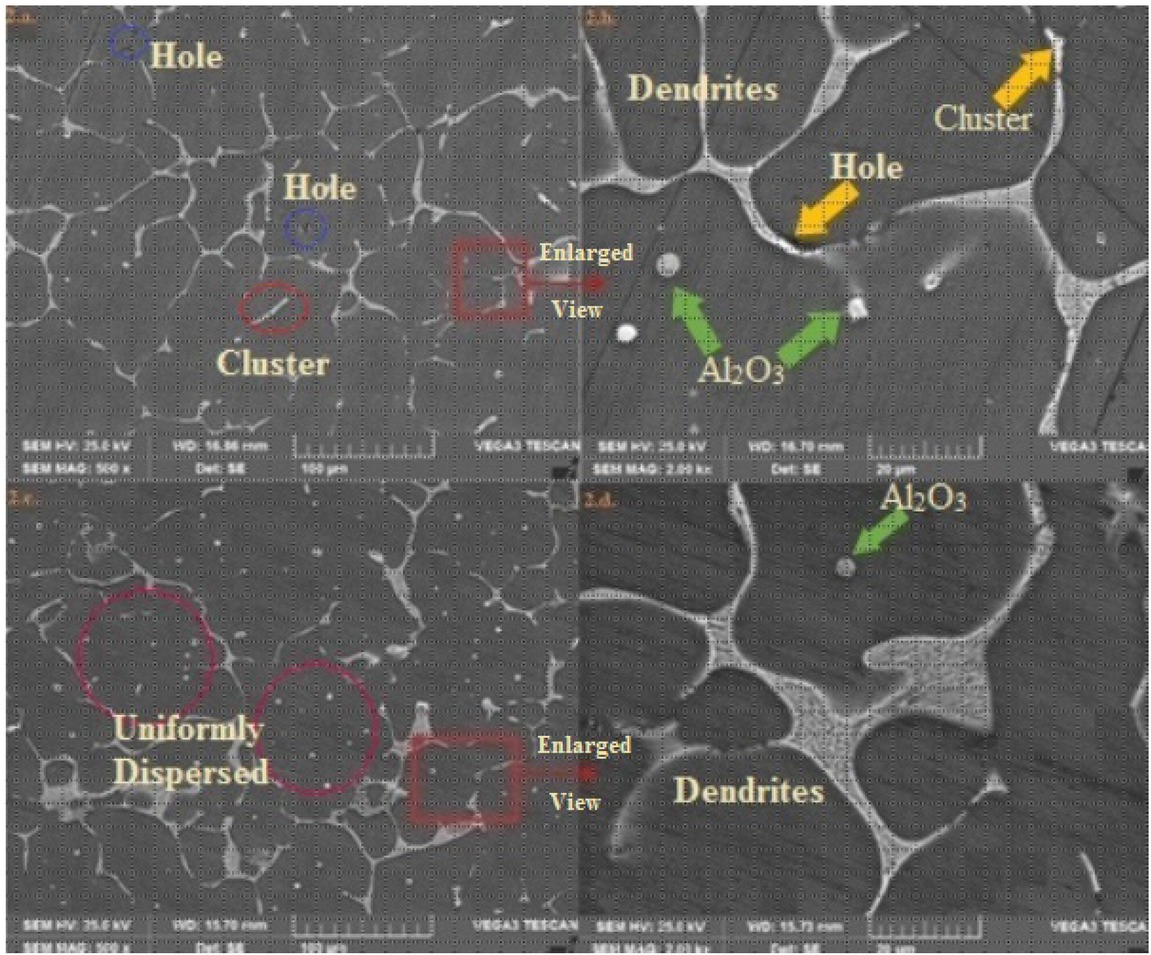

In regular feeding the composites produced are of least quality with blow holes and breaks many a times due to reinforcement clusters during secondary operations such as drilling, machining while sample preparation whereas the innovative combined feeding method of Encapsulate feeding technique & Two Step Stir Casting casted composites supports as user friendly during secondary operations. In below SEM images (Figure 2) indicates clusters, blow holes, defect zone, uniformly distributed region. In this combined feeding novel approach, the base metal, reinforcement & wetting agent undergo thermal decomposition so that it forms gaseous layer in-between the top & bottom of the wrapped ceramic particles. Hence the reinforcement particles are arrested within the molten metal. This mechanism put forth an essential part in uniform dispersion pattern of reinforcement particles rather than regular feeding technique. After the mechanical stirring process with the argon gas environment, stirring breaks their gaseous layer around and the arrested reinforcement particle splitted into the liquefied/fluidized matrix material. Then it is further heated upto 850∘C and again stirred to accomplish uniform dispersion evenly. Thus, reinforcement particles dispersion is uniformly achieved as shown in Figure 2.c. & 2.d in AA 6061+5% Al2O3 through this combined feeding novel approach.

SEM comparison of AMCs

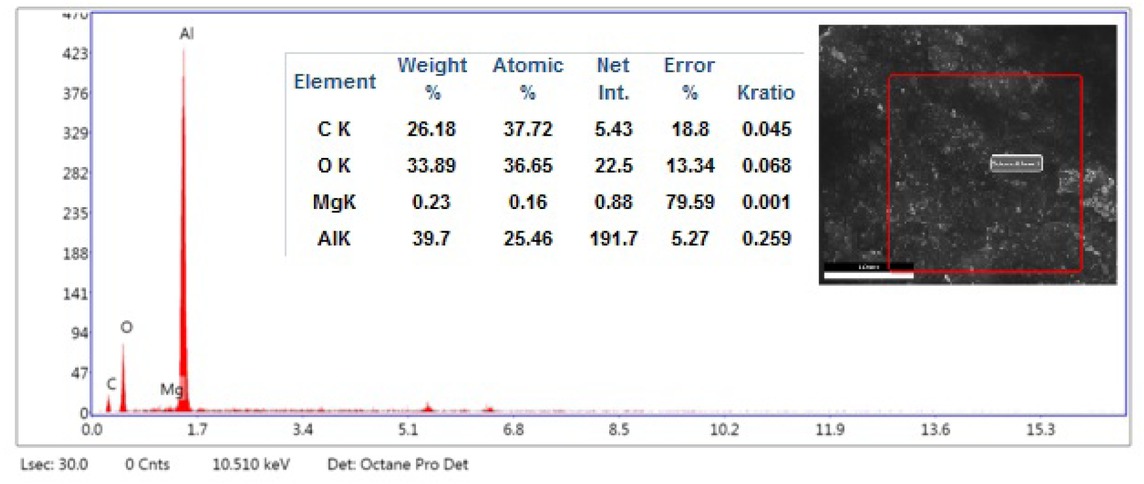

This EDS (elemental distribution analysis) result corresponds to the prepared Al/Al2O3 composite of 5% composition. The below Figure 3 proves the traces of Carbon, Oxygen, Magnesium, Aluminium presence in the composite specimen.

EDS image of 5% Al/Al2O3 composite

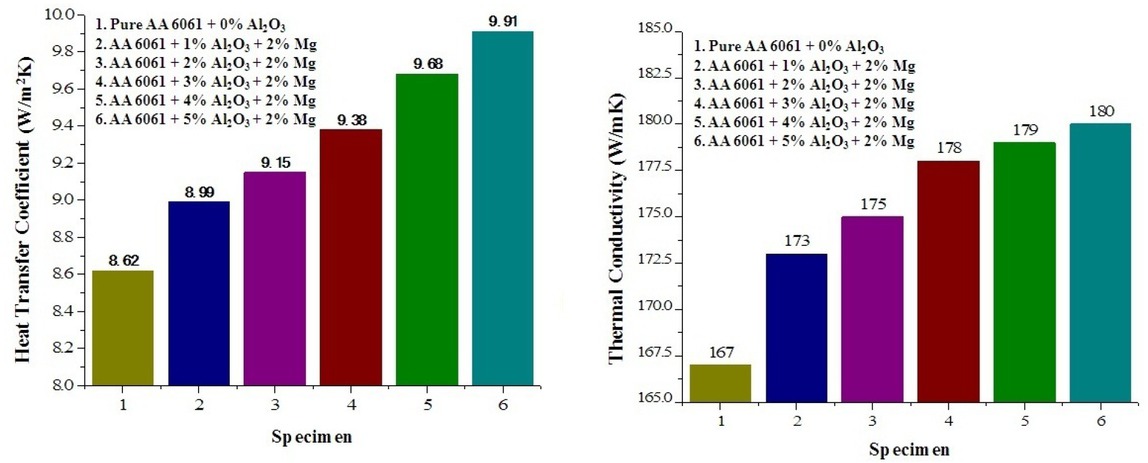

The below graph plot Figure 4 shows the enhancement of thermal conductivity in Al6061 by adding various percentages of ceramic fillers. This interface filler reduces the contact resistance offered by thermal ambience in the molten matrix. The thermal conductivity property purely depends on heat conduction propogated by diffusion which solely the material behaviour where as the coefficient of heat transfer is a convection property due to the macroscopic movement of the air above the solid surface. from the graph, it evidently shows that by increasing the Al2O3 contents in Al matrix, there is a decrement in thermal contact resistance i.e. it reduces coefficient of thermal expansion. So that thermal conductivity increases gradually by percentage whereas in 3% drastic raise denotes peak point even though enhancement continues further.

Thermal Properties of Al/Al2O3 composites with pure AL6061 through Pin-Fin

4 Conclusion

The combined feeding approach is the best & efficient way to produce good quality Al/Al2O3 homogenously dispersed composites in stir casting method. The fabricated Al/Al2O3 composites of varied composition exhibits high thermal conductivity (180W/mK at 5% composition) properties compared with same sort of presently used heat transfer aluminum alloys especially in electronics, heat sinks and also for various applications. This constitutes the exceptional expectation for enhancement of heat transfer. The probable advantages of the Al/Al2O3 composites such as further characterization and analyzing of mechanical properties will be estimated in future as extension work of this research.

Acknowledgement

The authors wish to thank SERB, DST (YSS/2015/000823) and also Selvam College of Technology management for their consistent motivation & support to bring out this work progressively at Selvam Composites Materials Research Lab.

References

[1] D.K. Das, P.C. Mishra, S. Singh and S.Pattanaik, Int. J of Mech. & Mater. Engg., 9 (2014) 6.10.1186/s40712-014-0006-7Search in Google Scholar

[2] M.Sambathkumar, P. Navaneethakrishnan, K. Ponappa and K.S.K. Sasikumar, Latin American J of Solids & Structures, 14 (2017) 243-255.10.1590/1679-78253132Search in Google Scholar

[3] A. Gnanavelbabu, K. Rajkumar, and P. Saravanan,Mater.&Manuf. Processes, 33 (2018) 1313-1323.10.1080/10426914.2018.1453146Search in Google Scholar

[4] S. Gopalakrishnan and N. Murugan, Composites Part B: Engineering, 43 (2012) 302-308.10.1016/j.compositesb.2011.08.049Search in Google Scholar

[5] Y. Pazhouhanfar and B. Eghbali, Materials Science and Engineering: A, 710 (2018) 172-180.10.1016/j.msea.2017.10.087Search in Google Scholar

[6] S. M. Quader, B. S. Murthy, P. R. Reddy. J of Minerals & Mater. Characterization & Engg. 4 (2016) 135-142.10.4236/jmmce.2016.42013Search in Google Scholar

© 2019 M. Asokan et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 Public License.

Articles in the same Issue

- Frontmatter

- Review Article

- Research on the Influence of Furnace Structure on Copper Cooling Stave Life

- Influence of High Temperature Oxidation on Hydrogen Absorption and Degradation of Zircaloy-2 and Zr 700 Alloys

- Correlation between Travel Speed, Microstructure, Mechanical Properties and Wear Characteristics of Ni-Based Hardfaced Deposits over 316LN Austenitic Stainless Steel

- Factors Influencing Gas Generation Behaviours of Lump Coal Used in COREX Gasifier

- Experiment Research on Pulverized Coal Combustion in the Tuyere of Oxygen Blast Furnace

- Phosphate Capacities of CaO–FeO–SiO2–Al2O3/Na2O/TiO2 Slags

- Microstructure and Interface Bonding Strength of WC-10Ni/NiCrBSi Composite Coating by Vacuum Brazing

- Refill Friction Stir Spot Welding of Dissimilar 6061/7075 Aluminum Alloy

- Solvothermal Synthesis and Magnetic Properties of Monodisperse Ni0.5Zn0.5Fe2O4 Hollow Nanospheres

- On the Capability of Logarithmic-Power Model for Prediction of Hot Deformation Behavior of Alloy 800H at High Strain Rates

- 3D Heat Conductivity Model of Mold Based on Node Temperature Inheritance

- 3D Microstructure and Micromechanical Properties of Minerals in Vanadium-Titanium Sinter

- Effect of Martensite Structure and Carbide Precipitates on Mechanical Properties of Cr-Mo Alloy Steel with Different Cooling Rate

- The Interaction between Erosion Particle and Gas Stream in High Temperature Gas Burner Rig for Thermal Barrier Coatings

- Permittivity Study of a CuCl Residue at 13–450 °C and Elucidation of the Microwave Intensification Mechanism for Its Dechlorination

- Study on Carbothermal Reduction of Titania in Molten Iron

- The Sequence of the Phase Growth during Diffusion in Ti-Based Systems

- Growth Kinetics of CoB–Co2B Layers Using the Powder-Pack Boriding Process Assisted by a Direct Current Field

- High-Temperature Flow Behaviour and Constitutive Equations for a TC17 Titanium Alloy

- Research on Three-Roll Screw Rolling Process for Ti6Al4V Titanium Alloy Bar

- Continuous Cooling Transformation of Undeformed and Deformed High Strength Crack-Arrest Steel Plates for Large Container Ships

- Formation Mechanism and Influence Factors of the Sticker between Solidified Shell and Mold in Continuous Casting of Steel

- Casting Defects in Transition Layer of Cu/Al Composite Castings Prepared Using Pouring Aluminum Method and Their Formation Mechanism

- Effect of Current on Segregation and Inclusions Characteristics of Dual Alloy Ingot Processed by Electroslag Remelting

- Investigation of Growth Kinetics of Fe2B Layers on AISI 1518 Steel by the Integral Method

- Microstructural Evolution and Phase Transformation on the X-Y Surface of Inconel 718 Ni-Based Alloys Fabricated by Selective Laser Melting under Different Heat Treatment

- Characterization of Mn-Doped Co3O4 Thin Films Prepared by Sol Gel-Based Dip-Coating Process

- Deposition Characteristics of Multitrack Overlayby Plasma Transferred Arc Welding on SS316Lwith Co-Cr Based Alloy – Influence ofProcess Parameters

- Elastic Moduli and Elastic Constants of Alloy AuCuSi With FCC Structure Under Pressure

- Effect of Cl on Softening and Melting Behaviors of BF Burden

- Effect of MgO Injection on Smelting in a Blast Furnace

- Structural Characteristics and Hydration Kinetics of Oxidized Steel Slag in a CaO-FeO-SiO2-MgO System

- Optimization of Microwave-Assisted Oxidation Roasting of Oxide–Sulphide Zinc Ore with Addition of Manganese Dioxide Using Response Surface Methodology

- Hydraulic Study of Bubble Migration in Liquid Titanium Alloy Melt during Vertical Centrifugal Casting Process

- Investigation on Double Wire Metal Inert Gas Welding of A7N01-T4 Aluminum Alloy in High-Speed Welding

- Oxidation Behaviour of Welded ASTM-SA210 GrA1 Boiler Tube Steels under Cyclic Conditions at 900°C in Air

- Study on the Evolution of Damage Degradation at Different Temperatures and Strain Rates for Ti-6Al-4V Alloy

- Pack-Boriding of Pure Iron with Powder Mixtures Containing ZrB2

- Evolution of Interfacial Features of MnO-SiO2 Type Inclusions/Steel Matrix during Isothermal Heating at Low Temperatures

- Effect of MgO/Al2O3 Ratio on Viscosity of Blast Furnace Primary Slag

- The Microstructure and Property of the Heat Affected zone in C-Mn Steel Treated by Rare Earth

- Microwave-Assisted Molten-Salt Facile Synthesis of Chromium Carbide (Cr3C2) Coatings on the Diamond Particles

- Effects of B on the Hot Ductility of Fe-36Ni Invar Alloy

- Impurity Distribution after Solidification of Hypereutectic Al-Si Melts and Eutectic Al-Si Melt

- Induced Electro-Deposition of High Melting-Point Phases on MgO–C Refractory in CaO–Al2O3–SiO2 – (MgO) Slag at 1773 K

- Microstructure and Mechanical Properties of 14Cr-ODS Steels with Zr Addition

- A Review of Boron-Rich Silicon Borides Basedon Thermodynamic Stability and Transport Properties of High-Temperature Thermoelectric Materials

- Siliceous Manganese Ore from Eastern India:A Potential Resource for Ferrosilicon-Manganese Production

- A Strain-Compensated Constitutive Model for Describing the Hot Compressive Deformation Behaviors of an Aged Inconel 718 Superalloy

- Surface Alloys of 0.45 C Carbon Steel Produced by High Current Pulsed Electron Beam

- Deformation Behavior and Processing Map during Isothermal Hot Compression of 49MnVS3 Non-Quenched and Tempered Steel

- A Constitutive Equation for Predicting Elevated Temperature Flow Behavior of BFe10-1-2 Cupronickel Alloy through Double Multiple Nonlinear Regression

- Oxidation Behavior of Ferritic Steel T22 Exposed to Supercritical Water

- A Multi Scale Strategy for Simulation of Microstructural Evolutions in Friction Stir Welding of Duplex Titanium Alloy

- Partition Behavior of Alloying Elements in Nickel-Based Alloys and Their Activity Interaction Parameters and Infinite Dilution Activity Coefficients

- Influence of Heating on Tensile Physical-Mechanical Properties of Granite

- Comparison of Al-Zn-Mg Alloy P-MIG Welded Joints Filled with Different Wires

- Microstructure and Mechanical Properties of Thick Plate Friction Stir Welds for 6082-T6 Aluminum Alloy

- Research Article

- Kinetics of oxide scale growth on a (Ti, Mo)5Si3 based oxidation resistant Mo-Ti-Si alloy at 900-1300∘C

- Calorimetric study on Bi-Cu-Sn alloys

- Mineralogical Phase of Slag and Its Effect on Dephosphorization during Converter Steelmaking Using Slag-Remaining Technology

- Controllability of joint integrity and mechanical properties of friction stir welded 6061-T6 aluminum and AZ31B magnesium alloys based on stationary shoulder

- Cellular Automaton Modeling of Phase Transformation of U-Nb Alloys during Solidification and Consequent Cooling Process

- The effect of MgTiO3Adding on Inclusion Characteristics

- Cutting performance of a functionally graded cemented carbide tool prepared by microwave heating and nitriding sintering

- Creep behaviour and life assessment of a cast nickel – base superalloy MAR – M247

- Failure mechanism and acoustic emission signal characteristics of coatings under the condition of impact indentation

- Reducing Surface Cracks and Improving Cleanliness of H-Beam Blanks in Continuous Casting — Improving continuous casting of H-beam blanks

- Rhodium influence on the microstructure and oxidation behaviour of aluminide coatings deposited on pure nickel and nickel based superalloy

- The effect of Nb content on precipitates, microstructure and texture of grain oriented silicon steel

- Effect of Arc Power on the Wear and High-temperature Oxidation Resistances of Plasma-Sprayed Fe-based Amorphous Coatings

- Short Communication

- Novel Combined Feeding Approach to Produce Quality Al6061 Composites for Heat Sinks

- Research Article

- Micromorphology change and microstructure of Cu-P based amorphous filler during heating process

- Controlling residual stress and distortion of friction stir welding joint by external stationary shoulder

- Research on the ingot shrinkage in the electroslag remelting withdrawal process for 9Cr3Mo roller

- Production of Mo2NiB2 Based Hard Alloys by Self-Propagating High-Temperature Synthesis

- The Morphology Analysis of Plasma-Sprayed Cast Iron Splats at Different Substrate Temperatures via Fractal Dimension and Circularity Methods

- A Comparative Study on Johnson–Cook, Modified Johnson–Cook, Modified Zerilli–Armstrong and Arrhenius-Type Constitutive Models to Predict Hot Deformation Behavior of TA2

- Dynamic absorption efficiency of paracetamol powder in microwave drying

- Preparation and Properties of Blast Furnace Slag Glass Ceramics Containing Cr2O3

- Influence of unburned pulverized coal on gasification reaction of coke in blast furnace

- Effect of PWHT Conditions on Toughness and Creep Rupture Strength in Modified 9Cr-1Mo Steel Welds

- Role of B2O3 on structure and shear-thinning property in CaO–SiO2–Na2O-based mold fluxes

- Effect of Acid Slag Treatment on the Inclusions in GCr15 Bearing Steel

- Recovery of Iron and Zinc from Blast Furnace Dust Using Iron-Bath Reduction

- Phase Analysis and Microstructural Investigations of Ce2Zr2O7 for High-Temperature Coatings on Ni-Base Superalloy Substrates

- Combustion Characteristics and Kinetics Study of Pulverized Coal and Semi-Coke

- Mechanical and Electrochemical Characterization of Supersolidus Sintered Austenitic Stainless Steel (316 L)

- Synthesis and characterization of Cu doped chromium oxide (Cr2O3) thin films

- Ladle Nozzle Clogging during casting of Silicon-Steel

- Thermodynamics and Industrial Trial on Increasing the Carbon Content at the BOF Endpoint to Produce Ultra-Low Carbon IF Steel by BOF-RH-CSP Process

- Research Article

- Effect of Boundary Conditions on Residual Stresses and Distortion in 316 Stainless Steel Butt Welded Plate

- Numerical Analysis on Effect of Additional Gas Injection on Characteristics around Raceway in Melter Gasifier

- Variation on thermal damage rate of granite specimen with thermal cycle treatment

- Effects of Fluoride and Sulphate Mineralizers on the Properties of Reconstructed Steel Slag

- Effect of Basicity on Precipitation of Spinel Crystals in a CaO-SiO2-MgO-Cr2O3-FeO System

- Review Article

- Exploitation of Mold Flux for the Ti-bearing Welding Wire Steel ER80-G

- Research Article

- Furnace heat prediction and control model and its application to large blast furnace

- Effects of Different Solid Solution Temperatures on Microstructure and Mechanical Properties of the AA7075 Alloy After T6 Heat Treatment

- Study of the Viscosity of a La2O3-SiO2-FeO Slag System

- Tensile Deformation and Work Hardening Behaviour of AISI 431 Martensitic Stainless Steel at Elevated Temperatures

- The Effectiveness of Reinforcement and Processing on Mechanical Properties, Wear Behavior and Damping Response of Aluminum Matrix Composites

Articles in the same Issue

- Frontmatter

- Review Article

- Research on the Influence of Furnace Structure on Copper Cooling Stave Life

- Influence of High Temperature Oxidation on Hydrogen Absorption and Degradation of Zircaloy-2 and Zr 700 Alloys

- Correlation between Travel Speed, Microstructure, Mechanical Properties and Wear Characteristics of Ni-Based Hardfaced Deposits over 316LN Austenitic Stainless Steel

- Factors Influencing Gas Generation Behaviours of Lump Coal Used in COREX Gasifier

- Experiment Research on Pulverized Coal Combustion in the Tuyere of Oxygen Blast Furnace

- Phosphate Capacities of CaO–FeO–SiO2–Al2O3/Na2O/TiO2 Slags

- Microstructure and Interface Bonding Strength of WC-10Ni/NiCrBSi Composite Coating by Vacuum Brazing

- Refill Friction Stir Spot Welding of Dissimilar 6061/7075 Aluminum Alloy

- Solvothermal Synthesis and Magnetic Properties of Monodisperse Ni0.5Zn0.5Fe2O4 Hollow Nanospheres

- On the Capability of Logarithmic-Power Model for Prediction of Hot Deformation Behavior of Alloy 800H at High Strain Rates

- 3D Heat Conductivity Model of Mold Based on Node Temperature Inheritance

- 3D Microstructure and Micromechanical Properties of Minerals in Vanadium-Titanium Sinter

- Effect of Martensite Structure and Carbide Precipitates on Mechanical Properties of Cr-Mo Alloy Steel with Different Cooling Rate

- The Interaction between Erosion Particle and Gas Stream in High Temperature Gas Burner Rig for Thermal Barrier Coatings

- Permittivity Study of a CuCl Residue at 13–450 °C and Elucidation of the Microwave Intensification Mechanism for Its Dechlorination

- Study on Carbothermal Reduction of Titania in Molten Iron

- The Sequence of the Phase Growth during Diffusion in Ti-Based Systems

- Growth Kinetics of CoB–Co2B Layers Using the Powder-Pack Boriding Process Assisted by a Direct Current Field

- High-Temperature Flow Behaviour and Constitutive Equations for a TC17 Titanium Alloy

- Research on Three-Roll Screw Rolling Process for Ti6Al4V Titanium Alloy Bar

- Continuous Cooling Transformation of Undeformed and Deformed High Strength Crack-Arrest Steel Plates for Large Container Ships

- Formation Mechanism and Influence Factors of the Sticker between Solidified Shell and Mold in Continuous Casting of Steel

- Casting Defects in Transition Layer of Cu/Al Composite Castings Prepared Using Pouring Aluminum Method and Their Formation Mechanism

- Effect of Current on Segregation and Inclusions Characteristics of Dual Alloy Ingot Processed by Electroslag Remelting

- Investigation of Growth Kinetics of Fe2B Layers on AISI 1518 Steel by the Integral Method

- Microstructural Evolution and Phase Transformation on the X-Y Surface of Inconel 718 Ni-Based Alloys Fabricated by Selective Laser Melting under Different Heat Treatment

- Characterization of Mn-Doped Co3O4 Thin Films Prepared by Sol Gel-Based Dip-Coating Process

- Deposition Characteristics of Multitrack Overlayby Plasma Transferred Arc Welding on SS316Lwith Co-Cr Based Alloy – Influence ofProcess Parameters

- Elastic Moduli and Elastic Constants of Alloy AuCuSi With FCC Structure Under Pressure

- Effect of Cl on Softening and Melting Behaviors of BF Burden

- Effect of MgO Injection on Smelting in a Blast Furnace

- Structural Characteristics and Hydration Kinetics of Oxidized Steel Slag in a CaO-FeO-SiO2-MgO System

- Optimization of Microwave-Assisted Oxidation Roasting of Oxide–Sulphide Zinc Ore with Addition of Manganese Dioxide Using Response Surface Methodology

- Hydraulic Study of Bubble Migration in Liquid Titanium Alloy Melt during Vertical Centrifugal Casting Process

- Investigation on Double Wire Metal Inert Gas Welding of A7N01-T4 Aluminum Alloy in High-Speed Welding

- Oxidation Behaviour of Welded ASTM-SA210 GrA1 Boiler Tube Steels under Cyclic Conditions at 900°C in Air

- Study on the Evolution of Damage Degradation at Different Temperatures and Strain Rates for Ti-6Al-4V Alloy

- Pack-Boriding of Pure Iron with Powder Mixtures Containing ZrB2

- Evolution of Interfacial Features of MnO-SiO2 Type Inclusions/Steel Matrix during Isothermal Heating at Low Temperatures

- Effect of MgO/Al2O3 Ratio on Viscosity of Blast Furnace Primary Slag

- The Microstructure and Property of the Heat Affected zone in C-Mn Steel Treated by Rare Earth

- Microwave-Assisted Molten-Salt Facile Synthesis of Chromium Carbide (Cr3C2) Coatings on the Diamond Particles

- Effects of B on the Hot Ductility of Fe-36Ni Invar Alloy

- Impurity Distribution after Solidification of Hypereutectic Al-Si Melts and Eutectic Al-Si Melt

- Induced Electro-Deposition of High Melting-Point Phases on MgO–C Refractory in CaO–Al2O3–SiO2 – (MgO) Slag at 1773 K

- Microstructure and Mechanical Properties of 14Cr-ODS Steels with Zr Addition

- A Review of Boron-Rich Silicon Borides Basedon Thermodynamic Stability and Transport Properties of High-Temperature Thermoelectric Materials

- Siliceous Manganese Ore from Eastern India:A Potential Resource for Ferrosilicon-Manganese Production

- A Strain-Compensated Constitutive Model for Describing the Hot Compressive Deformation Behaviors of an Aged Inconel 718 Superalloy

- Surface Alloys of 0.45 C Carbon Steel Produced by High Current Pulsed Electron Beam

- Deformation Behavior and Processing Map during Isothermal Hot Compression of 49MnVS3 Non-Quenched and Tempered Steel

- A Constitutive Equation for Predicting Elevated Temperature Flow Behavior of BFe10-1-2 Cupronickel Alloy through Double Multiple Nonlinear Regression

- Oxidation Behavior of Ferritic Steel T22 Exposed to Supercritical Water

- A Multi Scale Strategy for Simulation of Microstructural Evolutions in Friction Stir Welding of Duplex Titanium Alloy

- Partition Behavior of Alloying Elements in Nickel-Based Alloys and Their Activity Interaction Parameters and Infinite Dilution Activity Coefficients

- Influence of Heating on Tensile Physical-Mechanical Properties of Granite

- Comparison of Al-Zn-Mg Alloy P-MIG Welded Joints Filled with Different Wires

- Microstructure and Mechanical Properties of Thick Plate Friction Stir Welds for 6082-T6 Aluminum Alloy

- Research Article

- Kinetics of oxide scale growth on a (Ti, Mo)5Si3 based oxidation resistant Mo-Ti-Si alloy at 900-1300∘C

- Calorimetric study on Bi-Cu-Sn alloys

- Mineralogical Phase of Slag and Its Effect on Dephosphorization during Converter Steelmaking Using Slag-Remaining Technology

- Controllability of joint integrity and mechanical properties of friction stir welded 6061-T6 aluminum and AZ31B magnesium alloys based on stationary shoulder

- Cellular Automaton Modeling of Phase Transformation of U-Nb Alloys during Solidification and Consequent Cooling Process

- The effect of MgTiO3Adding on Inclusion Characteristics

- Cutting performance of a functionally graded cemented carbide tool prepared by microwave heating and nitriding sintering

- Creep behaviour and life assessment of a cast nickel – base superalloy MAR – M247

- Failure mechanism and acoustic emission signal characteristics of coatings under the condition of impact indentation

- Reducing Surface Cracks and Improving Cleanliness of H-Beam Blanks in Continuous Casting — Improving continuous casting of H-beam blanks

- Rhodium influence on the microstructure and oxidation behaviour of aluminide coatings deposited on pure nickel and nickel based superalloy

- The effect of Nb content on precipitates, microstructure and texture of grain oriented silicon steel

- Effect of Arc Power on the Wear and High-temperature Oxidation Resistances of Plasma-Sprayed Fe-based Amorphous Coatings

- Short Communication

- Novel Combined Feeding Approach to Produce Quality Al6061 Composites for Heat Sinks

- Research Article

- Micromorphology change and microstructure of Cu-P based amorphous filler during heating process

- Controlling residual stress and distortion of friction stir welding joint by external stationary shoulder

- Research on the ingot shrinkage in the electroslag remelting withdrawal process for 9Cr3Mo roller

- Production of Mo2NiB2 Based Hard Alloys by Self-Propagating High-Temperature Synthesis

- The Morphology Analysis of Plasma-Sprayed Cast Iron Splats at Different Substrate Temperatures via Fractal Dimension and Circularity Methods

- A Comparative Study on Johnson–Cook, Modified Johnson–Cook, Modified Zerilli–Armstrong and Arrhenius-Type Constitutive Models to Predict Hot Deformation Behavior of TA2

- Dynamic absorption efficiency of paracetamol powder in microwave drying

- Preparation and Properties of Blast Furnace Slag Glass Ceramics Containing Cr2O3

- Influence of unburned pulverized coal on gasification reaction of coke in blast furnace

- Effect of PWHT Conditions on Toughness and Creep Rupture Strength in Modified 9Cr-1Mo Steel Welds

- Role of B2O3 on structure and shear-thinning property in CaO–SiO2–Na2O-based mold fluxes

- Effect of Acid Slag Treatment on the Inclusions in GCr15 Bearing Steel

- Recovery of Iron and Zinc from Blast Furnace Dust Using Iron-Bath Reduction

- Phase Analysis and Microstructural Investigations of Ce2Zr2O7 for High-Temperature Coatings on Ni-Base Superalloy Substrates

- Combustion Characteristics and Kinetics Study of Pulverized Coal and Semi-Coke

- Mechanical and Electrochemical Characterization of Supersolidus Sintered Austenitic Stainless Steel (316 L)

- Synthesis and characterization of Cu doped chromium oxide (Cr2O3) thin films

- Ladle Nozzle Clogging during casting of Silicon-Steel

- Thermodynamics and Industrial Trial on Increasing the Carbon Content at the BOF Endpoint to Produce Ultra-Low Carbon IF Steel by BOF-RH-CSP Process

- Research Article

- Effect of Boundary Conditions on Residual Stresses and Distortion in 316 Stainless Steel Butt Welded Plate

- Numerical Analysis on Effect of Additional Gas Injection on Characteristics around Raceway in Melter Gasifier

- Variation on thermal damage rate of granite specimen with thermal cycle treatment

- Effects of Fluoride and Sulphate Mineralizers on the Properties of Reconstructed Steel Slag

- Effect of Basicity on Precipitation of Spinel Crystals in a CaO-SiO2-MgO-Cr2O3-FeO System

- Review Article

- Exploitation of Mold Flux for the Ti-bearing Welding Wire Steel ER80-G

- Research Article

- Furnace heat prediction and control model and its application to large blast furnace

- Effects of Different Solid Solution Temperatures on Microstructure and Mechanical Properties of the AA7075 Alloy After T6 Heat Treatment

- Study of the Viscosity of a La2O3-SiO2-FeO Slag System

- Tensile Deformation and Work Hardening Behaviour of AISI 431 Martensitic Stainless Steel at Elevated Temperatures

- The Effectiveness of Reinforcement and Processing on Mechanical Properties, Wear Behavior and Damping Response of Aluminum Matrix Composites