Abstract

In this article, a numerical model based on site theory is developed to study the stability of a pipeline system consisting of a valve, pipe, and surge tank. In the study, four parameters were studied to see how they impact the water hammer phenomenon. They are the pressure in the pipelines, the velocity of the flow, diameter of the conduit carrying liquid, and the liquid’s density. The equations are programmed, analyzed, and graphed using MATLAB. The stability analysis shows that the force of the water hammer is significant at low frequencies and for large diameters. The high frequency of a particular pipe is affected by the type of material the pipe is made from, the method of installation, and the friction coefficient of the inner surface. High frequencies reduce the impact of water hammer forces. Among the main parameters listed, it is found that the oscillations of liquids of low density are higher in the case of water hammers.

1 Introduction

When the discharge suddenly changes, such as when one of the valves on the pipeline carrying liquids is closed or a power outage occurs, the condition of the water hammer (hydraulic transient) materializes. This occurs quickly and causes catastrophic damage to the closed duct system and hydraulic pumping equipment due to the high-pressure change. Considering the importance of maintaining stable hydraulic systems, researchers have studied this phenomenon for decades. By analyzing and studying these hydraulic systems, they were able to determine the amount of pressure changes due to changes in flow and thus set instructions regarding control and operating methods to protect the hydraulic system from collapse. Obtaining an analytical solution to nonlinear governing equations with the translational flow can be difficult. Thus, numerical models of water hammers are used to calculate this phenomenon in most studies. The model must be able to accurately predict the phenomenon of water hammer or transitional flow so that the designer or engineer can evaluate alternative solutions in controlling hydraulic systems with high pressures. Engineers should explore transition hydraulics to be able to simulate real-world conditions that prevent system failure [1,2].

Many researchers in those areas have examined the effect of different flow parameters on the water hammer phenomenon by using various techniques and have calculated various parameters. Weinerowska and Kodura [3] studied the results of water hammer when operating in closed channels. They investigated different pipe diameters, different conditions, leaks in the pipeline, and in another case, no leaks in the pipeline. They found that the maximum pressure generated would not necessarily be the first amplitude. Zukowski’s formula for increasing the diameter gives a theoretical value for the pressure that is often below the maximum value. However, the pressure value was found to be the value of the first amplitude to reduce the tube diameter, which can be compared with Zukowski’s theoretical formula.

Mansuri et al. [4] used the MATLAB program to simulate water hammers and the numerical method, as this numerical method depends on the characteristic method. They found that the range of fluctuation will be small with an increase in the diameter of the tube, meaning that the range of pressure fluctuation will obviously decrease with the increase in wave transmission when using a short tube. They found that when the velocity of the wave increased, the pressure band would decrease in a clear way, and they concluded that the ends of the tube have the minimum pressure and the maximum pressure, and therefore the critical point in the designs is at the ends of the fluid conveying lines. Chen et al. [5] developed a mathematical model that mitigates the phenomenon of the water hammer when a pump is cut off or when the valve is suddenly closed by including partial nonlinear differential equations that describe the flow along the tube. This method combines the method of estimating partial differential equations of the flow with the method of estimating and controlling the limits of the fluctuation range. The simulation results showed an excellent ability to reduce water hammer, and these results showed great ability to decrease flow fluctuation.

Behroozi and Vaghefi [6] simulates the water hammer phenomenon in a pipeline system consisting of a valve, pipe, and surge tank. The model is used to reduce computational costs and increase accuracy. By using Local Multiquadric Based Differential Quadrature and Crank-Nicholson schemes, the spatial and temporal derivatives of water hammers are implicitly discretized. The water hammer’s equations are discretized into matroids and solved by applying boundary and initial conditions. It has been found that the accuracy of the model is dependent on the Courant number. Even so, the model holds its stability better in Courant numbers than one. A model is proposed, and two cases are tested to verify it. According to the comparison between obtained results and experimental data reported, the proposed method is in good agreement with the experimental observations. El-Jumaily et al. [7] were among the first to examine the effect of water hammers on the water pipeline in Iraq. He studied water hammers in the Kufa water project in the Najaf governorate, where he used four parallel pipes. He then programed the equations and simulated them in the MATLAB program, taking each pipe as it is in studying this phenomenon, then studying the four pipes at a standard flow, shut off valves suddenly, determining the proper pressure for each case, and recommending operations for that station.

Gubashi and Kubba [8] studied the water hammer using an approximate method using equations of transitional flow and applied it to a pipeline that carries raw water from the drawing station to the payment station for an actual project to pump water to citizens. In summary, the method is intended to simulate the effect of a water hammer by closing the valves along the pipeline from the starting line to the end, where the computer software showed that the minimum and maximum amount of oscillation occurred in a specific controlled place, which is very close to an experimental environment.

In this research, a model for water hammer simulation is presented. With the help of root locus theory, pipelines used in water pumping stations to deliver water to citizens have been modeled. In the study, four parameters affecting the phenomenon of water hammer are studied, and they are pressure in pipes, flow velocity, the diameter of a conduit carrying liquid, and density of the liquid. This is the biggest challenge faced by many of the water production stations. A software program called MATLAB is used to program equations, solve them, and draw graphs.

2 Analytical investigation

Developing mathematical foundations for the water hammer is difficult and complex, mainly when dealing with the center of the water hammer. Therefore, the flow will stratify until a certain point occurs that can be mathematically analyzed. The flow is stable, when no friction exists between the liquid particles and between the liquid particles and the internal surface of the pipe, and pressure is equal at both ends. There are five input parameters: fluid pressure, fluid velocity, fluid mass, fluid density, and tube diameter and pipe length. Detailed results are presented as follows: state of stability of the system, settlement time, water hammer wave height and intensity, and hammer peak. The water hammer can be controlled with lock valves, control valves, and anti-return valves.

Pressure fluctuations at the water hammer using a pipe of length (L), the cause of the rapid change in pressure can be explained with the presence of a valve at the end of the pipe for sudden closure with analysis of an initial state V 0, is given as [2],

where g is the gravitational acceleration, and a is the speed of the pressure wave. The speed of the pressure wave can be found from the conduit material properties and the fluid, and is given as,

where ρ is the fluid density, E is the Young’s modulus of elasticity of the conduit wall material, K f is the bulk modulus of elasticity of the fluid, e is the wall thickness, and D is the inside diameter of the conduit (Figure 1).

![Figure 1

Schematic diagram of the system [2].](/document/doi/10.1515/eng-2022-0029/asset/graphic/j_eng-2022-0029_fig_001.jpg)

Schematic diagram of the system [2].

Therefore, the rate of change in fluid element momentum combined with Darcy–Weisbach equation is given as,

where Q

t

is the continuity equation, which is the flow through the valve Q

v plus the flow into the surge tank Q

s, which is given by

These equations have often been integrated into numerical methods. A first-order ordinary differential equation can be seen in this way,

where

where k is the spring stiffness of pipe, and m is the mass of pipe. The relation between damped natural frequency ω d, natural frequency ω n, and damping ratio ξ is given as,

where

Roots in the upper half of the s-plane.

Thus, radial lines passing through the origin correspond to different damping ratios as in the figure below. Therefore, when the radial lines = 0, have no damping (θ = 0), and the damped natural frequency will reduce to the undamped natural frequency; and same steps as above when ξ = 1.

It is good to mention here that two roots trace loci or paths in the form of circular arcs as the damping ratio is increased from zero to unity, as shown below. The root with the positive imaginary part moves in the counterclockwise direction, while the root with the negative imaginary part moves in the clockwise direction. When the damping ratio (ξ) is equal to one, the two loci meet, denoting that the two roots coincide, that is, the characteristic equation has repeated roots. Figure 3 shows some representative root locations in the s-plane and the responses they elicit. System response characteristics include oscillatory nature, frequency of oscillation, and response time. This is an inherent characteristic of the system [9,10,11,12].

Locations of characteristic roots (

3 Results and discussions

The root locus theory was used to determine the system’s stability after the occurrence of the water hammer phenomenon. Additionally, the theory shows the paths and roots of the characteristic equation governing the hydraulic system. This theory illustrates the oscillations of water hammer waves, the overshoot, and feedback defined by the amount and power of pipeline locks. It also shows the amount of damping that should be applied in order to avoid hydraulic breakdown. The four cases studied were common occurrences in water pumping stations, except the fourth case, which involved changing the liquid, as it is known that water pumping stations use only water. The developed equation was solved in MATLAB, which is a high-performance language. Several powerful routines are built into it, which it uses to perform many types of calculations. This makes MATLAB an outstanding tool for this type of research.

3.1 Impact of pressure on hydraulic systems

Figure 4 illustrates the stability, the zeros, the poles, the roots, the transient oscillations at each stage and the whole hydraulic system. A case of pressure change has been assessed under the following conditions: 1.5 m/s fluid flow velocity, 300 mm pipe diameter, and water with a density of 1,000 kg/m3. This graph shows the highest frequency at 12 bars of pressure and the lowest frequency at 4 bar of pressure. It is high in the stability regions when it comes to overshoot the upper and lower bounds of the oscillation of the function, as in Figure 4, which is the left side of the diagram, and it becomes zero at the right, which is the breakdown region. When it comes to the stability edge of the system, it is at 21.8 for almost all pressure pressures.

Stability of the system with different pressure effects.

In the stability region, the damping rate of the water hammer wave is high, resulting in speedy wave fading. Note the gain or energy required to dampen the impact of the water hammer wave in the left area of the diagram, and find that it reaches infinity at a pressure of 12 bar when the frequency reaches 170 Hz. According to the equation, the roots lie at pressures of 4 and 8 bar, which implies that the system remains stable and the water hammer does not affect the system but causes vibrations in the liquid conveying tube caused by vibrations transmitted from the liquid to the inner pipe wall. Even so, the roots are far from the edge or threshold of stability; at pressure of 4 bar, the frequency becomes 21.8 Hz, damping power is 0.221%, and the gain ratio equals zero, while with a pressure of 8 bar, the stability edge is at 14.3 and the wave is 74.9% of its total amplitude.

3.2 Impact of fluid velocity on hydraulic systems

As shown in Figure 5, water hammer occurs at a speed of 2.5 m/s higher than that of the rest of the velocity and at a lower frequency. There is an overshoot the upper and lower bounds of the oscillation of the function in the stability regions, at the left side of the diagram, which becomes zero at the right side, as in the pressure chart, the breakdown region or the instability region, while the stability edge is at the stability edge 5.68. In almost all velocities, the damping rate of water hammer waves is high in the area of stability, which leads to the wave fading speed. In the left area of the diagram, note that the energy required to dampen the water hammer wave reaches 0.458 when the frequency reaches 5.43 Hz. Therefore, all the roots of this equation are at the same velocity, 1, 2, and 2.5 m/s. As a result, the system remains stable, but the water hammer still causes vibrations in the tube, transferring from the liquid to the inner wall, and the roots remain far from the edge of stability.

Stability of the system with different flow rate effects.

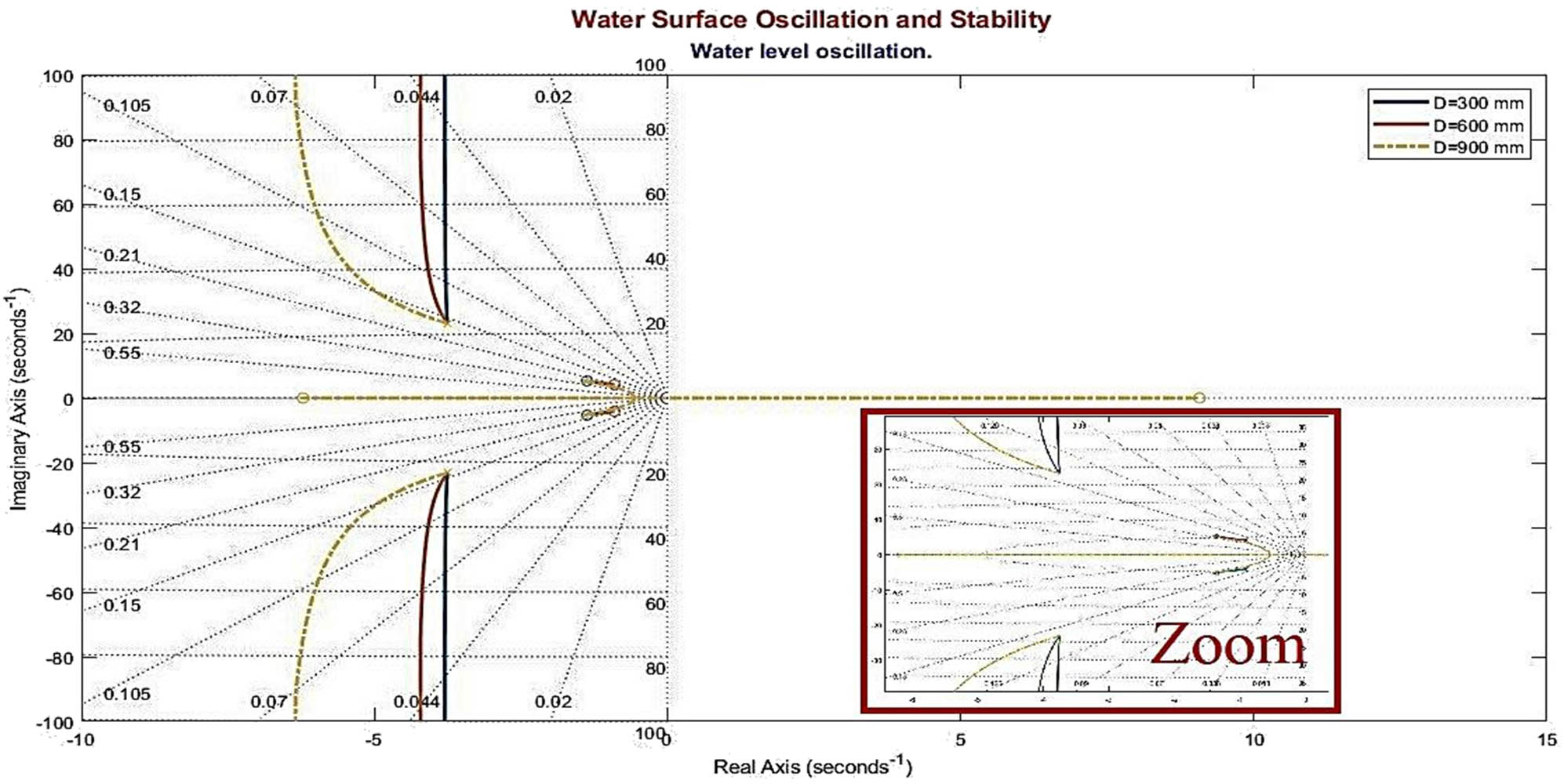

3.3 Impact of the diameter of the hydraulic system

For the third case, which represents the impact of the diameter of the hydraulic system as shown in Figure 6, the force of the water hammer is enormous at low frequencies and large diameters, for example, at 900 mm at 3 Hz with 1.5 m/s of velocity. At 600 mm in diameter, the overshoot is significant. There is no destructive effect of water hammer in all pipe diameters. The ideal case for the diameters as mentioned earlier is 300 mm at constant velocity and density.

Stability of the system with different diameter effects.

3.4 Impact of fluid type on the hydraulic system

Each type of fluid has its properties, such as viscosity or density. Figure 7 shows that low-density liquids such as alcohol and petrol exhibit more significant oscillation when subjected to a water hammer, yet less energy is required to dampen this phenomenon. The water reaches a critical state of stability when the roots of the governing equation approach the center of the diagram. In contrast, less dense liquids move away from the center of the scheme, meaning the system is more stable, and the phenomenon of the water hammer does not collapse it.

Stability of the system with different fluid type effects.

The best results obtained the best pressure to be generated for fluid transfer is 4 bar, which is accompanied by a suitable high frequency, low damping force, and zero system gain. As much as possible, the speed limit should be avoided at 2.5 m/s, as the frequency at this speed becomes as low as possible and therefore, the system is as close as possible to sudden collapse. The force of the water hammer is large at large diameters where at these diameters the frequencies are low, and the ideal case is to use the diameter of 300 mm at a constant speed and density. Low-density fluids have a weak water hammer effect compared to high-density fluids, meaning that the water hammer effect is less when transporting fuel (gasoline) or alcohol than when transporting water.

3.5 Verification case study

Validation of current and reference work shows great convergence between the current work and the reference as shown in Figure 8, as the location of the poles, the location of zeros, the paths of roots, stability, and the hydraulic behavior of the system are very close. The difference may be non-existent when the numerical method was used [13,14,15,16,17,18,19,20,21,22,23,24,25], the fourth-order Runge-Kutta method with the root locus method. A comparison was applied when changing the pipe pressure and changing the water flow velocity, as in the figures below, respectively. The verification study was required to give the agreement for technique used to calculate the required results [26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45].

![Figure 8

Validation of current work results and ref. [2] at (a) different pressure effects and (b) different flow rate effects.](/document/doi/10.1515/eng-2022-0029/asset/graphic/j_eng-2022-0029_fig_008.jpg)

Validation of current work results and ref. [2] at (a) different pressure effects and (b) different flow rate effects.

The results of the current research were compared with ref. [2] as follows, different pressure effects as shown in Figure 8(a) and different flow rate effects as shown in Figure 8(b), where a large and acceptable convergence of these results was found.

4 Conclusion

The main factors in order to verify the performance of the water hammer under several design parameters mainly: (1) pressure, (2) velocity, (3) diameter, and (4) density. The following conclusions are drawn from this work:

The ideal case is at a pressure of 4 bar compared to other pressures at the same hydraulic system parameters.

The velocity of the water in the closed pipes should not exceed 2.5 m/s as the wave of water hammer is large and destructive at speeds higher than the mentioned speed.

The force of the water hammer is significant at low frequencies and large diameters.

The high frequencies of a particular pipe depend on the type of material the pipe is made of, the installation method, and the friction coefficient of the pipe’s inner surface. The higher the frequencies, the less the impact of the water hammer force.

The oscillation of the low-density liquids was higher in the case of water hammers for the same main parameters listed.

-

Conflict of interest: Authors state no conflict of interest.

References

[1] Al-Waily M, Al-Baghdadi MARS, Al-Khayat RH. Flow velocity and crack angle effect on vibration and flow characterization for pipe induce vibration. Int J Mech Mechatron Eng. 2017;17(5):19–27.Suche in Google Scholar

[2] El-Turki A. Modeling of hydraulic transients in closed conduits. M.Sc. Thesis. Colorado State University; 2013.Suche in Google Scholar

[3] Kodura A, Weinerowska K. Some aspects of physical and numerical modeling of water hammer in pipelines. Int Symp Water Manag Hydraulic Eng. 2005;4(11):125–33.Suche in Google Scholar

[4] Mansuri B, Salmasi F, Oghati B. Sensitivity analysis for water hammer problem in pipelines. Iranica J Energy Environ. 2014;5(2):124–31.10.5829/idosi.ijee.2014.05.02.03Suche in Google Scholar

[5] Chen T, Ren Z, Xu C, Loxton R. Optimal boundary control for water hammer suppression in fluid transmission pipelines. Computers Math Appl. 2015;69(4):275–90.10.1016/j.camwa.2014.11.008Suche in Google Scholar

[6] Behroozi A, Vaghefi M. Numerical simulation of water hammer using implicit Crank-Nicolson local multiquadric based differential quadrature. Int J Press Vessel Pip. 2020;181:104078.10.1016/j.ijpvp.2020.104078Suche in Google Scholar

[7] El-Jumaily KK, Khsaf SI, Abd Al-Abbas Hassan F. Water hammer analysis for NAJAF-KUFA water supply project. J Eng Dev. 2005;9:1.Suche in Google Scholar

[8] Gubashi KR, Kubba FAA. Water hammer analysis in main pipeline of water treatment plant for the bakhma residents. Babylon J Appl Sci. 2010;18(2):263–75.Suche in Google Scholar

[9] Hussein DS, Al-Waily M. Frequency domain analysis by using the bode diagram method of pipes conveying fluid. Int J Energy Environ. 2019;10(6):345–58.Suche in Google Scholar

[10] Hussein DS, Al-Waily M. Active vibration control analysis of pipes conveying fluid rested on different supports using state-space method. Int J Energy Environ. 2019;10(6):329–44.Suche in Google Scholar

[11] Hussein DS, Al-Waily M. Root locus theory in active vibration control system of pipes conveying fluid rested on different supports. Int J Energy Environ. 2020;11(1):79–96.Suche in Google Scholar

[12] Hussein DS, Al-Waily M. Nyquist’s theorem in active vibration control system of conservative and non conservative pipes conveying fluid. Int J Energy Environ. 2020;11(1):61–78.Suche in Google Scholar

[13] Al-Shammari MA, Al-Waily M. Theoretical and numerical vibration investigation study of orthotropic hyper composite plate structure. Int J Mech Mechatron Eng. 2014;14:6.Suche in Google Scholar

[14] Al-Khayat RH, Al-Baghdadi MARS, Neama RA, Al-Waily M. Optimization CFD study of erosion in 3D elbow during transportation of crude oil contaminated with sand particles. Int J Eng Technol. 2018;7(3):1420–8.10.14419/ijet.v7i3.14180Suche in Google Scholar

[15] Abbas EN, Jweeg MJ, Al-Waily M. Analytical and numerical investigations for dynamic response of composite plates under various dynamic loading with the influence of carbon multi-wall tube nano materials. Int J Mech Mechatron Eng. 2018;18(6):1–10.Suche in Google Scholar

[16] Abbas HJ, Jweeg MJ, Al-Waily M, Diwan AA. Experimental testing and theoretical prediction of fiber optical cable for fault detection and identification. J Eng Appl Sci. 2019;14(2):430–8.10.36478/jeasci.2019.430.438Suche in Google Scholar

[17] Hussein SG, Al-Shammari MA, Takhakh AM, Al-Waily M. Effect of heat treatment on mechanical and vibration properties for 6061 and 2024 aluminum alloys. J Mech Eng Res Dev. 2020;43(1):48–66.Suche in Google Scholar

[18] Abbod EA, Al-Waily M, Al-Hadrayi ZMR, Resan KK, Abbas SM. Numerical and experimental analysis to predict life of removable partial denture. IOP Conference Series: Materials Science and Engineering, 1st International Conference on Engineering and Advanced Technology; 2020. p. 870.10.1088/1757-899X/870/1/012149Suche in Google Scholar

[19] Al-Waily M, Al-Shammari MA, Jweeg MJ. An analytical investigation of thermal buckling behavior of composite plates reinforced by carbon nano particles. Eng J. 2020;24:3.10.4186/ej.2020.24.3.11Suche in Google Scholar

[20] Njim EK, Bakhy SH, Al-Waily M. Optimization design of vibration characterizations for functionally graded porous metal sandwich plate structure. Mater Today Proc. 2021. 10.1016/j.matpr.2021.03.235.Suche in Google Scholar

[21] Njim EK, Bakhy SH, Al-Waily M. Analytical and numerical investigation of buckling load of functionally graded materials with porous metal of sandwich plate. Mater Today: Proc. 2021. 10.1016/j.matpr.2021.03.557.Suche in Google Scholar

[22] Kadhim AA, Abbod EA, Muhammad AK, Resan KK, Al-Waily M. Manufacturing and analyzing of a new prosthetic shank with adapters by 3D printer. J Mech Eng Res Dev. 2021;44(3):383–91.Suche in Google Scholar

[23] Aswad TSN, Bin Razali MA, Al-Waily M. Numerical study of the shape obstacle effect on improving the efficiency of photovoltaic cell. J Mech Eng Res Dev. 2021;44(2):209–24.Suche in Google Scholar

[24] Bakhy SH, Al-Waily M. Development and modeling of a soft finger in robotics based on force distribution. J Mech Eng Res Dev. 2021;44(1):382–95.Suche in Google Scholar

[25] Njim EK, Al-Waily M, Bakhy SH. A review of the recent research on the experimental tests of functionally graded sandwich panels. J Mech Eng Res Dev. 2021;44(3):420–41.Suche in Google Scholar

[26] Al-Waily M, Resan KK, Al-Wazir AH, Abud Ali ZAA. Influences of glass and carbon powder reinforcement on the vibration response and characterization of an isotropic hyper composite materials plate structure. Int J Mech Mechatron Eng. 2017;17:6.Suche in Google Scholar

[27] Kadhim AA, Al-Waily M, Abud Ali ZAA, Jweeg MJ, Resan KK. Improvement fatigue life and strength of isotropic hyper composite materials by reinforcement with different powder materials. Int J Mech Mechatron Eng. 2018;18:2.Suche in Google Scholar

[28] Resan KK, Alasadi AA, Al-Waily M, Jweeg MJ. Influence of temperature on fatigue life for friction stir welding of aluminum alloy materials. Int J Mech Mechatron Eng. 2018;18:2.Suche in Google Scholar

[29] Abbas SM, Resan KK, Muhammad AK, Al-Waily M. Mechanical and fatigue behaviors of prosthetic for partial foot amputation with various composite materials types effect. Int J Mech Eng Technol. 2018;9(9):383–94.Suche in Google Scholar

[30] Jweeg MJ, Al-Waily M, Muhammad AK, Resan KK. Effects of temperature on the characterisation of a new design for a non-articulated prosthetic foot. IOP Conference Series: Materials Science and Engineering, 2nd International Conference on Engineering Sciences; 2018. p. 433.10.1088/1757-899X/433/1/012064Suche in Google Scholar

[31] Jweeg MJ, Resan KK, Abbod EA, Al-Waily M. Dissimilar aluminium alloys welding by friction stir processing and reverse rotation friction stir processing. IOP Conference Series: Materials Science and Engineering, International Conference on Materials Engineering and Science; 2018. p. 454.10.1088/1757-899X/454/1/012059Suche in Google Scholar

[32] Abdulridha MM, Fahad ND, Al-Waily M, Resan KK. Rubber creep behavior investigation with multi wall tube carbon nano particle material effect. Int J Mech Eng Technol. 2018;9(12):729–46.Suche in Google Scholar

[33] Neama RA, Al-Baghdadi MARS, Al-Waily M. Effect of blank holder force and punch number on the forming behavior of conventional dies. Int J Mech Mechatron Eng. 2018;18:4.Suche in Google Scholar

[34] Abbas SM, Takhakh AM, Al-Shammari MA, Al-Waily M. Manufacturing and analysis of ankle disarticulation prosthetic socket (SYMES). Int J Mech Eng Technol. 2018;9(7):560–9.Suche in Google Scholar

[35] Al-Shammari MA, Al-Waily M. Analytical investigation of buckling behavior of honeycombs sandwich combined plate structure. Int J Mech Prod Eng Res Dev. 2018;8(4):771–86.10.24247/ijmperdaug201883Suche in Google Scholar

[36] Chiad JS, Al-Waily M, Al-Shammari MA. Buckling investigation of isotropic composite plate reinforced by different types of powders. Int J Mech Eng Technol. 2018;9(9):305–17.Suche in Google Scholar

[37] Al-Shammari MA, Bader QH, Al-Waily M, Hasson AM. Fatigue behavior of steel beam coated with nanoparticles under high temperature. J Mech Eng Res Dev. 2020;43(4):287–98.Suche in Google Scholar

[38] Al-Waily M, Al Saffar IQ, Hussein SG, Al-Shammari MA. Life enhancement of partial removable denture made by biomaterials reinforced by graphene nanoplates and hydroxyapatite with the aid of artificial neural network. J Mech Eng Res Dev. 2020;43(6):269–85.Suche in Google Scholar

[39] Abbas EN, Al-Waily M, Hammza TM, Jweeg MJ. An investigation to the effects of impact strength on laminated notched composites used in prosthetic sockets manufacturing. IOP Conference Series: Materials Science and Engineering, 2nd International Scientific Conference of Al-Ayen University; 2020. p. 928.10.1088/1757-899X/928/2/022081Suche in Google Scholar

[40] Al-Waily M, Jweeg MJ, Al-Shammari MJ, Resan KK, Takhakh AM. Improvement of buckling behavior of composite plates reinforced with hybrids nanomaterials additives. Mater Sci Forum. 2021;1039:23–41.10.4028/www.scientific.net/MSF.1039.23Suche in Google Scholar

[41] Jebur QH, Jweeg MJ, Al-Waily M, Ahmad HY, Resan KK. Hyperelastic models for the description and simulation of rubber subjected to large tensile loading. Arch Mater Sci Eng. 2021;108(2):75–85.10.5604/01.3001.0015.0256Suche in Google Scholar

[42] Jweeg MJ, Mohammed KI, Tolephih MH, Al-Waily M. Investigation into the distribution of erosion-corrosion in the furnace tubes of oil refineries. Mater Sci Forum. 2021;1039:165–81.10.4028/www.scientific.net/MSF.1039.165Suche in Google Scholar

[43] Fahad ND, Kadhim AA, Al-Khayat RH, Al-Waily M. Effect of SiO2 and Al2O3 hybrid nano materials on fatigue behavior for laminated composite materials used to manufacture artificial socket prostheses. Mater Sci Forum. 2021;1039:493–509.10.4028/www.scientific.net/MSF.1039.493Suche in Google Scholar

[44] Mechi SA, Al-Waily M, Al-Khatat A. The mechanical properties of the lower limb socket material using natural fibers: a review. Mater Sci Forum. 2021;1039:473–92.10.4028/www.scientific.net/MSF.1039.473Suche in Google Scholar

[45] Njim EK, Bakhy SH, Al-Waily M. Analytical and numerical investigation of free vibration behavior for sandwich plate with functionally graded porous metal core. Pertanika J Sci Technol. 2021;293:1655–82.10.47836/pjst.29.3.39Suche in Google Scholar

© 2022 Rasha Hayder Al-Khayat et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Performance of a horizontal well in a bounded anisotropic reservoir: Part I: Mathematical analysis

- Key competences for Transport 4.0 – Educators’ and Practitioners’ opinions

- COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Constraint evaluation and effects on selected fracture parameters for single-edge notched beam under four-point bending

- Minimizing form errors in additive manufacturing with part build orientation: An optimization method for continuous solution spaces

- The method of selecting adaptive devices for the needs of drivers with disabilities

- Control logic algorithm to create gaps for mixed traffic: A comprehensive evaluation

- Numerical prediction of cavitation phenomena on marine vessel: Effect of the water environment profile on the propulsion performance

- Boundary element analysis of rotating functionally graded anisotropic fiber-reinforced magneto-thermoelastic composites

- Effect of heat-treatment processes and high temperature variation of acid-chloride media on the corrosion resistance of B265 (Ti–6Al–4V) titanium alloy in acid-chloride solution

- Influence of selected physical parameters on vibroinsulation of base-exited vibratory conveyors

- System and eco-material design based on slow-release ferrate(vi) combined with ultrasound for ballast water treatment

- Experimental investigations on transmission of whole body vibration to the wheelchair user's body

- Determination of accident scenarios via freely available accident databases

- Elastic–plastic analysis of the plane strain under combined thermal and pressure loads with a new technique in the finite element method

- Design and development of the application monitoring the use of server resources for server maintenance

- The LBC-3 lightweight encryption algorithm

- Impact of the COVID-19 pandemic on road traffic accident forecasting in Poland and Slovakia

- Development and implementation of disaster recovery plan in stock exchange industry in Indonesia

- Pre-determination of prediction of yield-line pattern of slabs using Voronoi diagrams

- Urban air mobility and flying cars: Overview, examples, prospects, drawbacks, and solutions

- Stadiums based on curvilinear geometry: Approximation of the ellipsoid offset surface

- Driftwood blocking sensitivity on sluice gate flow

- Solar PV power forecasting at Yarmouk University using machine learning techniques

- 3D FE modeling of cable-stayed bridge according to ICE code

- Review Articles

- Partial discharge calibrator of a cavity inside high-voltage insulator

- Health issues using 5G frequencies from an engineering perspective: Current review

- Modern structures of military logistic bridges

- Retraction

- Retraction note: COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Special Issue: Trends in Logistics and Production for the 21st Century - Part II

- Solving transportation externalities, economic approaches, and their risks

- Demand forecast for parking spaces and parking areas in Olomouc

- Rescue of persons in traffic accidents on roads

- Special Issue: ICRTEEC - 2021 - Part II

- Switching transient analysis for low voltage distribution cable

- Frequency amelioration of an interconnected microgrid system

- Wireless power transfer topology analysis for inkjet-printed coil

- Analysis and control strategy of standalone PV system with various reference frames

- Special Issue: AESMT

- Study of emitted gases from incinerator of Al-Sadr hospital in Najaf city

- Experimentally investigating comparison between the behavior of fibrous concrete slabs with steel stiffeners and reinforced concrete slabs under dynamic–static loads

- ANN-based model to predict groundwater salinity: A case study of West Najaf–Kerbala region

- Future short-term estimation of flowrate of the Euphrates river catchment located in Al-Najaf Governorate, Iraq through using weather data and statistical downscaling model

- Utilization of ANN technique to estimate the discharge coefficient for trapezoidal weir-gate

- Experimental study to enhance the productivity of single-slope single-basin solar still

- An empirical formula development to predict suspended sediment load for Khour Al-Zubair port, South of Iraq

- A model for variation with time of flexiblepavement temperature

- Analytical and numerical investigation of free vibration for stepped beam with different materials

- Identifying the reasons for the prolongation of school construction projects in Najaf

- Spatial mixture modeling for analyzing a rainfall pattern: A case study in Ireland

- Flow parameters effect on water hammer stability in hydraulic system by using state-space method

- Experimental study of the behaviour and failure modes of tapered castellated steel beams

- Water hammer phenomenon in pumping stations: A stability investigation based on root locus

- Mechanical properties and freeze-thaw resistance of lightweight aggregate concrete using artificial clay aggregate

- Compatibility between delay functions and highway capacity manual on Iraqi highways

- The effect of expanded polystyrene beads (EPS) on the physical and mechanical properties of aerated concrete

- The effect of cutoff angle on the head pressure underneath dams constructed on soils having rectangular void

- An experimental study on vibration isolation by open and in-filled trenches

- Designing a 3D virtual test platform for evaluating prosthetic knee joint performance during the walking cycle

- Special Issue: AESMT-2 - Part I

- Optimization process of resistance spot welding for high-strength low-alloy steel using Taguchi method

- Cyclic performance of moment connections with reduced beam sections using different cut-flange profiles

- Time overruns in the construction projects in Iraq: Case study on investigating and analyzing the root causes

- Contribution of lift-to-drag ratio on power coefficient of HAWT blade for different cross-sections

- Geotechnical correlations of soil properties in Hilla City – Iraq

- Improve the performance of solar thermal collectors by varying the concentration and nanoparticles diameter of silicon dioxide

- Enhancement of evaporative cooling system in a green-house by geothermal energy

- Destructive and nondestructive tests formulation for concrete containing polyolefin fibers

- Quantify distribution of topsoil erodibility factor for watersheds that feed the Al-Shewicha trough – Iraq using GIS

- Seamless geospatial data methodology for topographic map: A case study on Baghdad

- Mechanical properties investigation of composite FGM fabricated from Al/Zn

- Causes of change orders in the cycle of construction project: A case study in Al-Najaf province

- Optimum hydraulic investigation of pipe aqueduct by MATLAB software and Newton–Raphson method

- Numerical analysis of high-strength reinforcing steel with conventional strength in reinforced concrete beams under monotonic loading

- Deriving rainfall intensity–duration–frequency (IDF) curves and testing the best distribution using EasyFit software 5.5 for Kut city, Iraq

- Designing of a dual-functional XOR block in QCA technology

- Producing low-cost self-consolidation concrete using sustainable material

- Performance of the anaerobic baffled reactor for primary treatment of rural domestic wastewater in Iraq

- Enhancement isolation antenna to multi-port for wireless communication

- A comparative study of different coagulants used in treatment of turbid water

- Field tests of grouted ground anchors in the sandy soil of Najaf, Iraq

- New methodology to reduce power by using smart street lighting system

- Optimization of the synergistic effect of micro silica and fly ash on the behavior of concrete using response surface method

- Ergodic capacity of correlated multiple-input–multiple-output channel with impact of transmitter impairments

- Numerical studies of the simultaneous development of forced convective laminar flow with heat transfer inside a microtube at a uniform temperature

- Enhancement of heat transfer from solar thermal collector using nanofluid

- Improvement of permeable asphalt pavement by adding crumb rubber waste

- Study the effect of adding zirconia particles to nickel–phosphorus electroless coatings as product innovation on stainless steel substrate

- Waste aggregate concrete properties using waste tiles as coarse aggregate and modified with PC superplasticizer

- CuO–Cu/water hybrid nonofluid potentials in impingement jet

- Satellite vibration effects on communication quality of OISN system

- Special Issue: Annual Engineering and Vocational Education Conference - Part III

- Mechanical and thermal properties of recycled high-density polyethylene/bamboo with different fiber loadings

- Special Issue: Advanced Energy Storage

- Cu-foil modification for anode-free lithium-ion battery from electronic cable waste

- Review of various sulfide electrolyte types for solid-state lithium-ion batteries

- Optimization type of filler on electrochemical and thermal properties of gel polymer electrolytes membranes for safety lithium-ion batteries

- Pr-doped BiFeO3 thin films growth on quartz using chemical solution deposition

- An environmentally friendly hydrometallurgy process for the recovery and reuse of metals from spent lithium-ion batteries, using organic acid

- Production of nickel-rich LiNi0.89Co0.08Al0.03O2 cathode material for high capacity NCA/graphite secondary battery fabrication

- Special Issue: Sustainable Materials Production and Processes

- Corrosion polarization and passivation behavior of selected stainless steel alloys and Ti6Al4V titanium in elevated temperature acid-chloride electrolytes

- Special Issue: Modern Scientific Problems in Civil Engineering - Part II

- The modelling of railway subgrade strengthening foundation on weak soils

- Special Issue: Automation in Finland 2021 - Part II

- Manufacturing operations as services by robots with skills

- Foundations and case studies on the scalable intelligence in AIoT domains

- Safety risk sources of autonomous mobile machines

- Special Issue: 49th KKBN - Part I

- Residual magnetic field as a source of information about steel wire rope technical condition

- Monitoring the boundary of an adhesive coating to a steel substrate with an ultrasonic Rayleigh wave

- Detection of early stage of ductile and fatigue damage presented in Inconel 718 alloy using instrumented indentation technique

- Identification and characterization of the grinding burns by eddy current method

- Special Issue: ICIMECE 2020 - Part II

- Selection of MR damper model suitable for SMC applied to semi-active suspension system by using similarity measures

Artikel in diesem Heft

- Regular Articles

- Performance of a horizontal well in a bounded anisotropic reservoir: Part I: Mathematical analysis

- Key competences for Transport 4.0 – Educators’ and Practitioners’ opinions

- COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Constraint evaluation and effects on selected fracture parameters for single-edge notched beam under four-point bending

- Minimizing form errors in additive manufacturing with part build orientation: An optimization method for continuous solution spaces

- The method of selecting adaptive devices for the needs of drivers with disabilities

- Control logic algorithm to create gaps for mixed traffic: A comprehensive evaluation

- Numerical prediction of cavitation phenomena on marine vessel: Effect of the water environment profile on the propulsion performance

- Boundary element analysis of rotating functionally graded anisotropic fiber-reinforced magneto-thermoelastic composites

- Effect of heat-treatment processes and high temperature variation of acid-chloride media on the corrosion resistance of B265 (Ti–6Al–4V) titanium alloy in acid-chloride solution

- Influence of selected physical parameters on vibroinsulation of base-exited vibratory conveyors

- System and eco-material design based on slow-release ferrate(vi) combined with ultrasound for ballast water treatment

- Experimental investigations on transmission of whole body vibration to the wheelchair user's body

- Determination of accident scenarios via freely available accident databases

- Elastic–plastic analysis of the plane strain under combined thermal and pressure loads with a new technique in the finite element method

- Design and development of the application monitoring the use of server resources for server maintenance

- The LBC-3 lightweight encryption algorithm

- Impact of the COVID-19 pandemic on road traffic accident forecasting in Poland and Slovakia

- Development and implementation of disaster recovery plan in stock exchange industry in Indonesia

- Pre-determination of prediction of yield-line pattern of slabs using Voronoi diagrams

- Urban air mobility and flying cars: Overview, examples, prospects, drawbacks, and solutions

- Stadiums based on curvilinear geometry: Approximation of the ellipsoid offset surface

- Driftwood blocking sensitivity on sluice gate flow

- Solar PV power forecasting at Yarmouk University using machine learning techniques

- 3D FE modeling of cable-stayed bridge according to ICE code

- Review Articles

- Partial discharge calibrator of a cavity inside high-voltage insulator

- Health issues using 5G frequencies from an engineering perspective: Current review

- Modern structures of military logistic bridges

- Retraction

- Retraction note: COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Special Issue: Trends in Logistics and Production for the 21st Century - Part II

- Solving transportation externalities, economic approaches, and their risks

- Demand forecast for parking spaces and parking areas in Olomouc

- Rescue of persons in traffic accidents on roads

- Special Issue: ICRTEEC - 2021 - Part II

- Switching transient analysis for low voltage distribution cable

- Frequency amelioration of an interconnected microgrid system

- Wireless power transfer topology analysis for inkjet-printed coil

- Analysis and control strategy of standalone PV system with various reference frames

- Special Issue: AESMT

- Study of emitted gases from incinerator of Al-Sadr hospital in Najaf city

- Experimentally investigating comparison between the behavior of fibrous concrete slabs with steel stiffeners and reinforced concrete slabs under dynamic–static loads

- ANN-based model to predict groundwater salinity: A case study of West Najaf–Kerbala region

- Future short-term estimation of flowrate of the Euphrates river catchment located in Al-Najaf Governorate, Iraq through using weather data and statistical downscaling model

- Utilization of ANN technique to estimate the discharge coefficient for trapezoidal weir-gate

- Experimental study to enhance the productivity of single-slope single-basin solar still

- An empirical formula development to predict suspended sediment load for Khour Al-Zubair port, South of Iraq

- A model for variation with time of flexiblepavement temperature

- Analytical and numerical investigation of free vibration for stepped beam with different materials

- Identifying the reasons for the prolongation of school construction projects in Najaf

- Spatial mixture modeling for analyzing a rainfall pattern: A case study in Ireland

- Flow parameters effect on water hammer stability in hydraulic system by using state-space method

- Experimental study of the behaviour and failure modes of tapered castellated steel beams

- Water hammer phenomenon in pumping stations: A stability investigation based on root locus

- Mechanical properties and freeze-thaw resistance of lightweight aggregate concrete using artificial clay aggregate

- Compatibility between delay functions and highway capacity manual on Iraqi highways

- The effect of expanded polystyrene beads (EPS) on the physical and mechanical properties of aerated concrete

- The effect of cutoff angle on the head pressure underneath dams constructed on soils having rectangular void

- An experimental study on vibration isolation by open and in-filled trenches

- Designing a 3D virtual test platform for evaluating prosthetic knee joint performance during the walking cycle

- Special Issue: AESMT-2 - Part I

- Optimization process of resistance spot welding for high-strength low-alloy steel using Taguchi method

- Cyclic performance of moment connections with reduced beam sections using different cut-flange profiles

- Time overruns in the construction projects in Iraq: Case study on investigating and analyzing the root causes

- Contribution of lift-to-drag ratio on power coefficient of HAWT blade for different cross-sections

- Geotechnical correlations of soil properties in Hilla City – Iraq

- Improve the performance of solar thermal collectors by varying the concentration and nanoparticles diameter of silicon dioxide

- Enhancement of evaporative cooling system in a green-house by geothermal energy

- Destructive and nondestructive tests formulation for concrete containing polyolefin fibers

- Quantify distribution of topsoil erodibility factor for watersheds that feed the Al-Shewicha trough – Iraq using GIS

- Seamless geospatial data methodology for topographic map: A case study on Baghdad

- Mechanical properties investigation of composite FGM fabricated from Al/Zn

- Causes of change orders in the cycle of construction project: A case study in Al-Najaf province

- Optimum hydraulic investigation of pipe aqueduct by MATLAB software and Newton–Raphson method

- Numerical analysis of high-strength reinforcing steel with conventional strength in reinforced concrete beams under monotonic loading

- Deriving rainfall intensity–duration–frequency (IDF) curves and testing the best distribution using EasyFit software 5.5 for Kut city, Iraq

- Designing of a dual-functional XOR block in QCA technology

- Producing low-cost self-consolidation concrete using sustainable material

- Performance of the anaerobic baffled reactor for primary treatment of rural domestic wastewater in Iraq

- Enhancement isolation antenna to multi-port for wireless communication

- A comparative study of different coagulants used in treatment of turbid water

- Field tests of grouted ground anchors in the sandy soil of Najaf, Iraq

- New methodology to reduce power by using smart street lighting system

- Optimization of the synergistic effect of micro silica and fly ash on the behavior of concrete using response surface method

- Ergodic capacity of correlated multiple-input–multiple-output channel with impact of transmitter impairments

- Numerical studies of the simultaneous development of forced convective laminar flow with heat transfer inside a microtube at a uniform temperature

- Enhancement of heat transfer from solar thermal collector using nanofluid

- Improvement of permeable asphalt pavement by adding crumb rubber waste

- Study the effect of adding zirconia particles to nickel–phosphorus electroless coatings as product innovation on stainless steel substrate

- Waste aggregate concrete properties using waste tiles as coarse aggregate and modified with PC superplasticizer

- CuO–Cu/water hybrid nonofluid potentials in impingement jet

- Satellite vibration effects on communication quality of OISN system

- Special Issue: Annual Engineering and Vocational Education Conference - Part III

- Mechanical and thermal properties of recycled high-density polyethylene/bamboo with different fiber loadings

- Special Issue: Advanced Energy Storage

- Cu-foil modification for anode-free lithium-ion battery from electronic cable waste

- Review of various sulfide electrolyte types for solid-state lithium-ion batteries

- Optimization type of filler on electrochemical and thermal properties of gel polymer electrolytes membranes for safety lithium-ion batteries

- Pr-doped BiFeO3 thin films growth on quartz using chemical solution deposition

- An environmentally friendly hydrometallurgy process for the recovery and reuse of metals from spent lithium-ion batteries, using organic acid

- Production of nickel-rich LiNi0.89Co0.08Al0.03O2 cathode material for high capacity NCA/graphite secondary battery fabrication

- Special Issue: Sustainable Materials Production and Processes

- Corrosion polarization and passivation behavior of selected stainless steel alloys and Ti6Al4V titanium in elevated temperature acid-chloride electrolytes

- Special Issue: Modern Scientific Problems in Civil Engineering - Part II

- The modelling of railway subgrade strengthening foundation on weak soils

- Special Issue: Automation in Finland 2021 - Part II

- Manufacturing operations as services by robots with skills

- Foundations and case studies on the scalable intelligence in AIoT domains

- Safety risk sources of autonomous mobile machines

- Special Issue: 49th KKBN - Part I

- Residual magnetic field as a source of information about steel wire rope technical condition

- Monitoring the boundary of an adhesive coating to a steel substrate with an ultrasonic Rayleigh wave

- Detection of early stage of ductile and fatigue damage presented in Inconel 718 alloy using instrumented indentation technique

- Identification and characterization of the grinding burns by eddy current method

- Special Issue: ICIMECE 2020 - Part II

- Selection of MR damper model suitable for SMC applied to semi-active suspension system by using similarity measures