Waste aggregate concrete properties using waste tiles as coarse aggregate and modified with PC superplasticizer

-

Salama Nasim Yousif Al-Labban

, Firas Abdulhadi Abdullah

Abstract

Concrete is the most popular construction material and has a relatively high compressive strength and it does not crack under its own weight, but its tensile strength is much lower compared to its compressive strength. The compressive strength can be changed according to the water to cement ratio during concrete formation or mixing, while the tensile strength rises when additives are used, concrete needs reinforcing steel, and added to plain concrete, resulting in reinforced concrete. In other terms, concrete consists of sand or fine aggregate, gravel (which is a coarse aggregate), water, and cement (which is considered a bonding material), and it is a brittle material that needs reinforcement and also some admixtures to improve its low tensile resist. This research aims to increase and improve some mechanical properties of concrete by using waste tiles as coarse aggregate. The study includes replacing normal aggregates with waste tile and using them as crushed aggregate with 25, 50, 75, and 100% replacement. Studies show increment in compressive and tensile strength and flexural strength by using waste tile aggregate compared with ordinary concrete; compressive strength increased from 34.1 MPa for reference mixes without waste tiles to 39.8 MPa using waste tiles. The study included improving all mixes with polycarboxylate superplasticizer and gaining high strength concrete, especially mixes with 50, 75, and 100% waste tile aggregate; the compressive strength with totally waste tile replacement gave the highest value of compressive strength, which was 57.5 MPa, tensile and flexural strength also increased by using waste tile aggregate, and 100% replacement shows optimum values of mechanical properties in this study.

1 Introduction

Concrete is the most excellent material used in the construction projects all over the world, because of its low cost compared with the steel used in steel structures. Concrete is highly used in bridges, foundations, multi-story buildings, tower construction, houses, tunnels, water tanks, water pipes, sewerage structures, or even in repairs like cement pastes; this highly and large use makes concrete the best composite material in the world.

Using waste materials in concrete gives several benefits, such as reducing the total cost of concrete structures, less environmental pollution, and higher mechanical properties in concrete [1,2]. Tamanna and Sharma [3] studied the effect of replacing average aggregate in concrete with waste tiles as coarse aggregate and found that replacing leads to increasing compressive strength of concrete; Adehola and Kuye [4] studied the effect of using waste tiles as aggregate in concrete by replacing average aggregate with 10, 20, and 25% and gain improvement in compressive strength for all replacements. Ceramic tiles are used in other research studies as aggregate in concrete, and Amos [5] studied the use of ceramic as waste aggregate in mixes with grade 25 and found slight decrement in compressive strength. Magesh [6] used coarse and fine ceramic tiles as the replacement from average aggregate in concrete; the compressive strength increased from 28 MPa for control mix to 31 MPa for 50% replacement in his study, and the optimum dosage was 50%. Also, he gained increment in tensile and flexural strength by using waste ceramic tiles. Naveen [7] studied the use of waste tiles as aggregate in concrete for 10, 20, 30, and 40% replacements from average aggregate and got increment in compressive, tensile, and flexural strength by using waste tiles aggregate. Daniyal [8] studied the application of waste ceramic tiles as coarse aggregate in concrete, and found that coarse waste ceramic tiles improve the compressive strength of concrete up to 20% replacement. Shruthi [9] studied the compressive and tensile strength of concrete by using waste ceramic tiles and found out that the optimum ratio of replacement that gives maximum compressive strength was 30% from normal aggregates. Concrete is the most significant material worldwide and its properties differ from steel structures upon comparing the durability considerations and its fire resistance; all steel structures totally collapsed under fire, but concrete was not totally collapsed under fire, it is more durable, so, developing the concrete industry is our goal. This study aimed to use different percentages of replacements until 100% replacement of waste tiles as coarse aggregate in concrete. It modified all mixes with polycarboxylate (PC) superplasticizer to gain high-strength concrete.

2 Experimental program

2.1 Materials and mixes

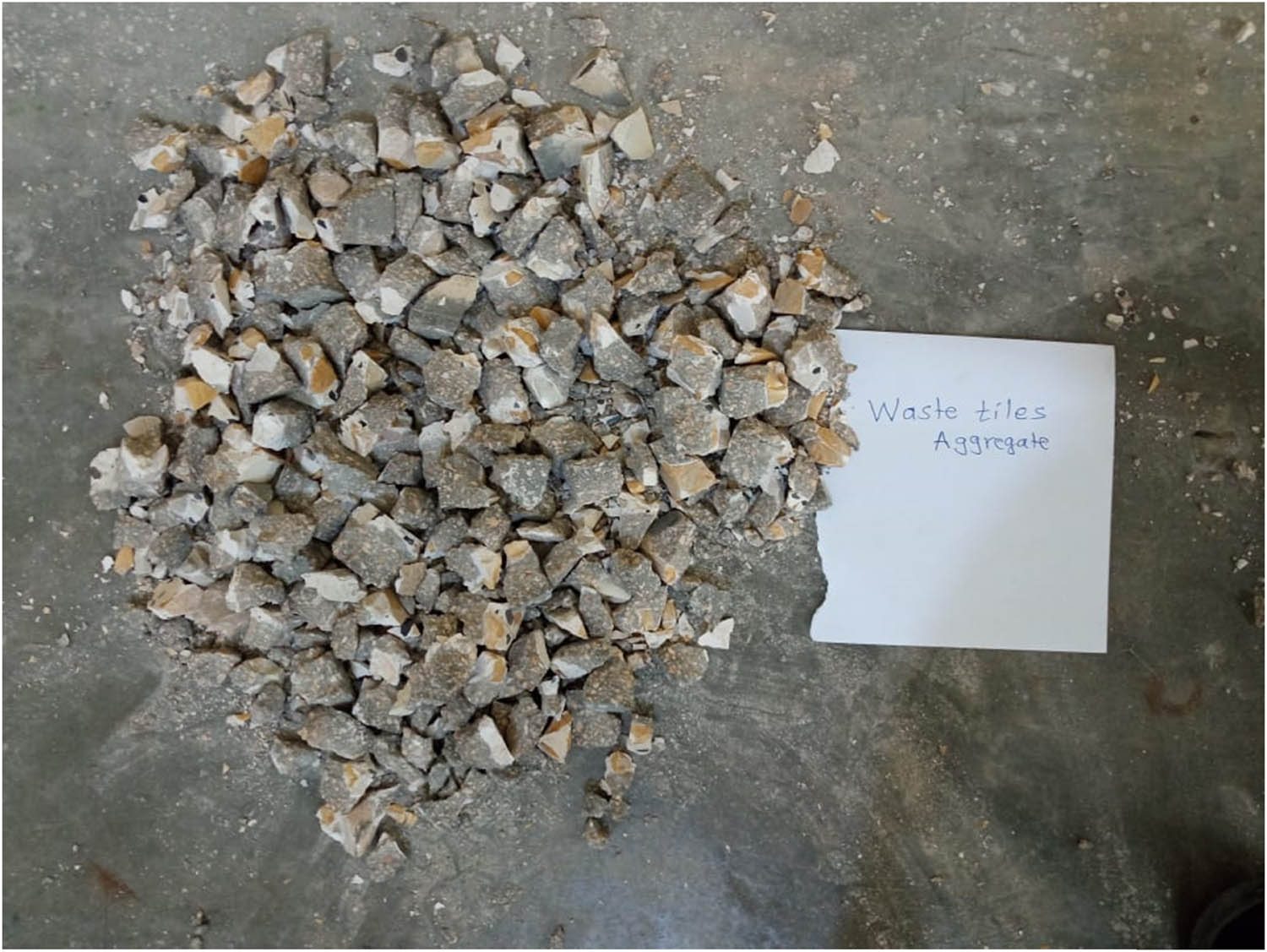

Ordinary Portland cement is used in all mixes with a cement is used content of 600 kg for each cubic meter with mix proportion as shown in Table 1. Table 2 shows mix details improved with superplasticizer Type PC-200. Ordinary red sand used as fine aggregate in concrete with zone 3 sieve grading confirms Indian standards I.S-383 [10]. The sieve analysis of sand is shown in Table 3. Coarse aggregate was used with a maximum size of 20 mm in this study, and the sieve analysis of coarse aggregate is shown in Table 4. Waste tiles are used as replacement of coarse aggregate only with ratios of 0.0, 25, 50, 75, and 100%, and some properties of waste tiles are shown in Table 5. Figure 1 shows the waste ceramic after crushing it to use it as waste aggregate.

Reference mix details (without PC superplasticizer)

| Cement | Fine aggregate | Coarse aggregate | Water | Mix prop |

|---|---|---|---|---|

| 600 kg | 600 kg | 1,000 kg | 240 kg | 1:1:1.67 |

Modified mix details (with PC superplasticizer)

| Cement | Fine aggregate | Coarse aggregate | Water | PC-200 superplasticizer | Mix prop |

|---|---|---|---|---|---|

| 600 kg | 600 kg | 1,000 kg | 150 kg | 9.6 L | 1:1:1.67 |

Fine aggregate sieve analysis (zone 3 grading)

| Sieve dimension | Passing by weight (%) | Indian limits for zone 3 (I.S-383 specification) |

|---|---|---|

| 10 mm | 100 | 100 |

| 4.75 mm | 94.3 | 90–100 |

| 2.36 mm | 90.6 | 85–100 |

| 1.18 mm | 83.7 | 75–100 |

| 600

|

71.2 | 60–79 |

| 300

|

25.8 | 12–40 |

| 150

|

1.3 | 0–10 |

Coarse aggregate sieve analysis for normal and waste tile aggregates

| Sieve dimension (mm) | Passing by weight (%) | Indian standards (I.S-383) (%) |

|---|---|---|

| 40 | 100 | 100 |

| 20 | 95.4 | 90–100 |

| 10 | 27.8 | 25–55 |

| 5 | 2.7 | 0–10 |

Fine aggregate sieve analysis (zone 3 grading)

| Waste tiles | Original tiles | Flexural strength | Absorption | Compressive strength |

|---|---|---|---|---|

| Description and values | Najaf, Iraq, waste from laboratories after test | 8.51 MPa | 2.60% | More than 80 MPa for

|

Waste ceramic after crushing, used as a coarse aggregate in concrete.

2.2 Testing procedure

Three types of tests for all specimens are used in this research. Compressive strength test was carried out by using

where

Compressive strength for 100% waste tile concrete – modified mix.

Tensile strength test was carried out using

where

Flexural strength is determined by using third point loading according to British Standard 1881 [11]; the flexural strength can be found in equation (3). The flexural strength was determined using

where

Figure 3 shows concrete specimen under compression test, and also shows after failure load, the flexural strength test for a waste aggregate concrete beam.

Flexural strength test for 100% waste tile concrete – modified mix.

3 Results and discussion

Table 6 shows the mechanical properties of ordinary concrete mixes and mixes with 25, 50, 75, and 100% replacement of waste tile aggregates. The compressive strength increased from 34.1 MPa for reference mix to 39.78 MPa for mixes with 100% replacement; tensile strength also increased from 1.8 to 2.93 MPa. Flexural strength increased from 3.1 MPa to about 4.6 MPa by using 100% replacement, which can be attributed to the excellent properties of waste tiles that have excellent flexural and compressive strength and also low absorption; and also, the second reason is the sharp edges of aggregate that achieve an excellent bond with cement paste.

Mechanical properties of reference and waste tile aggregate concrete

| Mix description | Compressive strength (MPa) | Tensile strength (MPa) | Flexural strength (MPa) |

|---|---|---|---|

| Reference 1:1:1.8 | 34.15 | 1.81 | 3.12 |

| 25% waste aggregate replacement | 35.55 | 2.23 | 3.85 |

| 50% waste aggregate replacement | 37.06 | 2.54 | 4.27 |

| 75% waste aggregate replacement | 38.33 | 2.68 | 4.59 |

| 100% waste aggregate replacement | 39.78 | 2.93 | 4.90 |

Table 7 shows all mixes in Table 6 (same mix proportions) but improved with PC superplasticizer. Compressive strength is highly increased by using superplasticizer; it increased from 45.47 MPa for reference mixes to 57.5 MPa for 100% waste tile aggregates. From Table 6 it can also be seen that high strength concrete (exceeds 50 MPa) is achieved in waste tile aggregate concrete in this study, especially in 50, 75, and 100% replacement and that is a good achievement which makes concrete in less cost and higher mechanical property achievement and less environmental pollution due to using waste materials.

Mechanical properties of reference and waste tiles aggregate concrete modified with PC superplasticizer

| Mix description | Compressive strength (MPa) | Tensile strength (MPa) | Flexural strength (MPa) |

|---|---|---|---|

| Reference 1:1:1.8 | 45.47 | 2.87 | 4.27 |

| 25% waste aggregate replacement | 47.35 | 3.35 | 5.07 |

| 50% waste aggregate replacement | 50.91 | 3.87 | 6.38 |

| 75% waste aggregate replacement | 53.73 | 4.11 | 7.51 |

| 100% waste aggregate replacement | 57.52 | 4.65 | 8.20 |

Figures 4, 5, and 6 show the relationship between compressive tensile and flexural strength and % replacement of average aggregate with waste aggregates.

Relation between % replacement and compressive strength of concrete without using superplasticizer.

Relation between % replacement and tensile strength of concrete without using superplasticizer.

Relation between % replacement and flexural strength without using superplasticizer.

In contrast, Figures 7, 8, and 9 show the relationship between compressive, tensile, and flexural strength and % replacement of aggregate for concrete mixes modified with PC superplasticizer. Figures 10, 11, and 12 compare the mechanical properties of mixes with and without using a superplasticizer. Figures 13 and 14 show comparison between previous study data in ref. [5] and this study The data in this study. show higher values for compressive and tensile strength compared with of data ref. [5].

Relation between % replacement and compressive strength of concrete modified with PC superplasticizer.

Relation between % replacement and tensile strength of concrete modified with PC superplasticizer.

Relation between % replacement and flexural strength of concrete modified with PC superplasticizer.

Compares on the relationship between compressive strength and replacement with and without modification by super-plasticizer.

Compares on the relationship between tensile strength and replacement with and without modification by super-plasticizer.

Compares on the relationship between flexural strength and replacement with and without modification by superplasticizer.

![Figure 13

Compressive strength development due to waste tiles replacement (comparison with previous study given in ref. [5]).](/document/doi/10.1515/eng-2022-0356/asset/graphic/j_eng-2022-0356_fig_013.jpg)

Compressive strength development due to waste tiles replacement (comparison with previous study given in ref. [5]).

![Figure 14

Tensile strength development due to waste tiles replacement (comparison with previous study given in ref. [5]).](/document/doi/10.1515/eng-2022-0356/asset/graphic/j_eng-2022-0356_fig_014.jpg)

Tensile strength development due to waste tiles replacement (comparison with previous study given in ref. [5]).

4 Conclusion

Using waste tiles as coarse aggregate improves the mechanical properties of normal concrete, giving several benefits such as less environmental pollution and less cost of concrete.

Compressive strength increased by using waste tiles as coarse aggregate; the compressive strength increased from 34.1 to 39.7 MPa for mixes with 100% waste tile aggregate.

Flexural and tensile strength also increased by using waste tile aggregate.

Modified mixes with superplasticizers improve the mechanical properties for reference mixes and waste aggregate mixes and lead to high-strength concrete.

Using waste materials in concrete can give more clean environment and less cost to concrete in addition to the improvements in the strength of concrete and that can make concrete more durable to environmental conditions such as change in weather heat or climate changes and durability against the freeze and thaw conditions and even durability to salty ground water or sulfate attack to concrete.

-

Conflict of interest: The authors declare that they have no conflict of interest.

-

Data availability statement: Most datasets generated and analyzed in this study are comprised in the submitted manuscript. The other datasets are available on reasonable request from the corresponding author with the attached information.

References

[1] Maryam A, Wadhah M. Using crushed tiles as coarse agg in conc. mix. In: Third International Conference on Civil, Environment and Waste Management, September: 12–14, 2016, Dubai, UAE, p. 106–11. Search in Google Scholar

[2] Vaariseenivasan K. Properties of conc. with crushed waste ceramic tiles as coarse aggregate. Int J Civil Eng Technol. 2018;9(4):614–9. Search in Google Scholar

[3] Punnet S, Tamanna. An experimental work on crushed ceramic waste tiles by coarse aggregate in the concrete mix. Int Res J Eng. Tech. 2018;5(2):1133–5. Search in Google Scholar

[4] Adehola A, Kuye R. Utilization of construction waste tiles as a replacement for fine aggregate in concrete. Eng Tech Appl Sci Res. 2017;7(5):1930–3. 10.48084/etasr.1071Search in Google Scholar

[5] Amos K. Full replacement of fine aggregate in concrete with crushed ceramic waste. Global J Environ Sci Tech. 2017;5(6):488–520. Search in Google Scholar

[6] Magesh B. Replacement of coarse and fine aggregate by waste ceramic tiles and ceramic powder in concrete. Int J Eng Technol Eng Res. 2018;6(2):25–32. Search in Google Scholar

[7] Naveen N. Partial replacement of coarse aggregate by crushed tiles and fine aggregate by granite powder to improve the concrete properties. J Mechanical. Civil Eng. 2018;13(6):168–76. Search in Google Scholar

[8] Daniyal M. Application of waste ceramic tile aggregates in concrete. Int J Innovative Res Sci Eng Technol. 2015;4(12): 12808–15. Search in Google Scholar

[9] Shruthi H. Reuse of ceramic waste as aggregate in concrete. Int Res J Eng Technol. 2016;3(7):115–9. Search in Google Scholar

[10] Indian Standards I.S-383. Specification for coarse and fine aggregates from natural sources for concrete. Bureau of Indian Standards, New Delhi, 2002. Search in Google Scholar

[11] British Standard 1881,118. Testing concrete part 118-method for determination of flexural strength. B.S.I, 1983. Search in Google Scholar

© 2022 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Performance of a horizontal well in a bounded anisotropic reservoir: Part I: Mathematical analysis

- Key competences for Transport 4.0 – Educators’ and Practitioners’ opinions

- COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Constraint evaluation and effects on selected fracture parameters for single-edge notched beam under four-point bending

- Minimizing form errors in additive manufacturing with part build orientation: An optimization method for continuous solution spaces

- The method of selecting adaptive devices for the needs of drivers with disabilities

- Control logic algorithm to create gaps for mixed traffic: A comprehensive evaluation

- Numerical prediction of cavitation phenomena on marine vessel: Effect of the water environment profile on the propulsion performance

- Boundary element analysis of rotating functionally graded anisotropic fiber-reinforced magneto-thermoelastic composites

- Effect of heat-treatment processes and high temperature variation of acid-chloride media on the corrosion resistance of B265 (Ti–6Al–4V) titanium alloy in acid-chloride solution

- Influence of selected physical parameters on vibroinsulation of base-exited vibratory conveyors

- System and eco-material design based on slow-release ferrate(vi) combined with ultrasound for ballast water treatment

- Experimental investigations on transmission of whole body vibration to the wheelchair user's body

- Determination of accident scenarios via freely available accident databases

- Elastic–plastic analysis of the plane strain under combined thermal and pressure loads with a new technique in the finite element method

- Design and development of the application monitoring the use of server resources for server maintenance

- The LBC-3 lightweight encryption algorithm

- Impact of the COVID-19 pandemic on road traffic accident forecasting in Poland and Slovakia

- Development and implementation of disaster recovery plan in stock exchange industry in Indonesia

- Pre-determination of prediction of yield-line pattern of slabs using Voronoi diagrams

- Urban air mobility and flying cars: Overview, examples, prospects, drawbacks, and solutions

- Stadiums based on curvilinear geometry: Approximation of the ellipsoid offset surface

- Driftwood blocking sensitivity on sluice gate flow

- Solar PV power forecasting at Yarmouk University using machine learning techniques

- 3D FE modeling of cable-stayed bridge according to ICE code

- Review Articles

- Partial discharge calibrator of a cavity inside high-voltage insulator

- Health issues using 5G frequencies from an engineering perspective: Current review

- Modern structures of military logistic bridges

- Retraction

- Retraction note: COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Special Issue: Trends in Logistics and Production for the 21st Century - Part II

- Solving transportation externalities, economic approaches, and their risks

- Demand forecast for parking spaces and parking areas in Olomouc

- Rescue of persons in traffic accidents on roads

- Special Issue: ICRTEEC - 2021 - Part II

- Switching transient analysis for low voltage distribution cable

- Frequency amelioration of an interconnected microgrid system

- Wireless power transfer topology analysis for inkjet-printed coil

- Analysis and control strategy of standalone PV system with various reference frames

- Special Issue: AESMT

- Study of emitted gases from incinerator of Al-Sadr hospital in Najaf city

- Experimentally investigating comparison between the behavior of fibrous concrete slabs with steel stiffeners and reinforced concrete slabs under dynamic–static loads

- ANN-based model to predict groundwater salinity: A case study of West Najaf–Kerbala region

- Future short-term estimation of flowrate of the Euphrates river catchment located in Al-Najaf Governorate, Iraq through using weather data and statistical downscaling model

- Utilization of ANN technique to estimate the discharge coefficient for trapezoidal weir-gate

- Experimental study to enhance the productivity of single-slope single-basin solar still

- An empirical formula development to predict suspended sediment load for Khour Al-Zubair port, South of Iraq

- A model for variation with time of flexiblepavement temperature

- Analytical and numerical investigation of free vibration for stepped beam with different materials

- Identifying the reasons for the prolongation of school construction projects in Najaf

- Spatial mixture modeling for analyzing a rainfall pattern: A case study in Ireland

- Flow parameters effect on water hammer stability in hydraulic system by using state-space method

- Experimental study of the behaviour and failure modes of tapered castellated steel beams

- Water hammer phenomenon in pumping stations: A stability investigation based on root locus

- Mechanical properties and freeze-thaw resistance of lightweight aggregate concrete using artificial clay aggregate

- Compatibility between delay functions and highway capacity manual on Iraqi highways

- The effect of expanded polystyrene beads (EPS) on the physical and mechanical properties of aerated concrete

- The effect of cutoff angle on the head pressure underneath dams constructed on soils having rectangular void

- An experimental study on vibration isolation by open and in-filled trenches

- Designing a 3D virtual test platform for evaluating prosthetic knee joint performance during the walking cycle

- Special Issue: AESMT-2 - Part I

- Optimization process of resistance spot welding for high-strength low-alloy steel using Taguchi method

- Cyclic performance of moment connections with reduced beam sections using different cut-flange profiles

- Time overruns in the construction projects in Iraq: Case study on investigating and analyzing the root causes

- Contribution of lift-to-drag ratio on power coefficient of HAWT blade for different cross-sections

- Geotechnical correlations of soil properties in Hilla City – Iraq

- Improve the performance of solar thermal collectors by varying the concentration and nanoparticles diameter of silicon dioxide

- Enhancement of evaporative cooling system in a green-house by geothermal energy

- Destructive and nondestructive tests formulation for concrete containing polyolefin fibers

- Quantify distribution of topsoil erodibility factor for watersheds that feed the Al-Shewicha trough – Iraq using GIS

- Seamless geospatial data methodology for topographic map: A case study on Baghdad

- Mechanical properties investigation of composite FGM fabricated from Al/Zn

- Causes of change orders in the cycle of construction project: A case study in Al-Najaf province

- Optimum hydraulic investigation of pipe aqueduct by MATLAB software and Newton–Raphson method

- Numerical analysis of high-strength reinforcing steel with conventional strength in reinforced concrete beams under monotonic loading

- Deriving rainfall intensity–duration–frequency (IDF) curves and testing the best distribution using EasyFit software 5.5 for Kut city, Iraq

- Designing of a dual-functional XOR block in QCA technology

- Producing low-cost self-consolidation concrete using sustainable material

- Performance of the anaerobic baffled reactor for primary treatment of rural domestic wastewater in Iraq

- Enhancement isolation antenna to multi-port for wireless communication

- A comparative study of different coagulants used in treatment of turbid water

- Field tests of grouted ground anchors in the sandy soil of Najaf, Iraq

- New methodology to reduce power by using smart street lighting system

- Optimization of the synergistic effect of micro silica and fly ash on the behavior of concrete using response surface method

- Ergodic capacity of correlated multiple-input–multiple-output channel with impact of transmitter impairments

- Numerical studies of the simultaneous development of forced convective laminar flow with heat transfer inside a microtube at a uniform temperature

- Enhancement of heat transfer from solar thermal collector using nanofluid

- Improvement of permeable asphalt pavement by adding crumb rubber waste

- Study the effect of adding zirconia particles to nickel–phosphorus electroless coatings as product innovation on stainless steel substrate

- Waste aggregate concrete properties using waste tiles as coarse aggregate and modified with PC superplasticizer

- CuO–Cu/water hybrid nonofluid potentials in impingement jet

- Satellite vibration effects on communication quality of OISN system

- Special Issue: Annual Engineering and Vocational Education Conference - Part III

- Mechanical and thermal properties of recycled high-density polyethylene/bamboo with different fiber loadings

- Special Issue: Advanced Energy Storage

- Cu-foil modification for anode-free lithium-ion battery from electronic cable waste

- Review of various sulfide electrolyte types for solid-state lithium-ion batteries

- Optimization type of filler on electrochemical and thermal properties of gel polymer electrolytes membranes for safety lithium-ion batteries

- Pr-doped BiFeO3 thin films growth on quartz using chemical solution deposition

- An environmentally friendly hydrometallurgy process for the recovery and reuse of metals from spent lithium-ion batteries, using organic acid

- Production of nickel-rich LiNi0.89Co0.08Al0.03O2 cathode material for high capacity NCA/graphite secondary battery fabrication

- Special Issue: Sustainable Materials Production and Processes

- Corrosion polarization and passivation behavior of selected stainless steel alloys and Ti6Al4V titanium in elevated temperature acid-chloride electrolytes

- Special Issue: Modern Scientific Problems in Civil Engineering - Part II

- The modelling of railway subgrade strengthening foundation on weak soils

- Special Issue: Automation in Finland 2021 - Part II

- Manufacturing operations as services by robots with skills

- Foundations and case studies on the scalable intelligence in AIoT domains

- Safety risk sources of autonomous mobile machines

- Special Issue: 49th KKBN - Part I

- Residual magnetic field as a source of information about steel wire rope technical condition

- Monitoring the boundary of an adhesive coating to a steel substrate with an ultrasonic Rayleigh wave

- Detection of early stage of ductile and fatigue damage presented in Inconel 718 alloy using instrumented indentation technique

- Identification and characterization of the grinding burns by eddy current method

- Special Issue: ICIMECE 2020 - Part II

- Selection of MR damper model suitable for SMC applied to semi-active suspension system by using similarity measures

Articles in the same Issue

- Regular Articles

- Performance of a horizontal well in a bounded anisotropic reservoir: Part I: Mathematical analysis

- Key competences for Transport 4.0 – Educators’ and Practitioners’ opinions

- COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Constraint evaluation and effects on selected fracture parameters for single-edge notched beam under four-point bending

- Minimizing form errors in additive manufacturing with part build orientation: An optimization method for continuous solution spaces

- The method of selecting adaptive devices for the needs of drivers with disabilities

- Control logic algorithm to create gaps for mixed traffic: A comprehensive evaluation

- Numerical prediction of cavitation phenomena on marine vessel: Effect of the water environment profile on the propulsion performance

- Boundary element analysis of rotating functionally graded anisotropic fiber-reinforced magneto-thermoelastic composites

- Effect of heat-treatment processes and high temperature variation of acid-chloride media on the corrosion resistance of B265 (Ti–6Al–4V) titanium alloy in acid-chloride solution

- Influence of selected physical parameters on vibroinsulation of base-exited vibratory conveyors

- System and eco-material design based on slow-release ferrate(vi) combined with ultrasound for ballast water treatment

- Experimental investigations on transmission of whole body vibration to the wheelchair user's body

- Determination of accident scenarios via freely available accident databases

- Elastic–plastic analysis of the plane strain under combined thermal and pressure loads with a new technique in the finite element method

- Design and development of the application monitoring the use of server resources for server maintenance

- The LBC-3 lightweight encryption algorithm

- Impact of the COVID-19 pandemic on road traffic accident forecasting in Poland and Slovakia

- Development and implementation of disaster recovery plan in stock exchange industry in Indonesia

- Pre-determination of prediction of yield-line pattern of slabs using Voronoi diagrams

- Urban air mobility and flying cars: Overview, examples, prospects, drawbacks, and solutions

- Stadiums based on curvilinear geometry: Approximation of the ellipsoid offset surface

- Driftwood blocking sensitivity on sluice gate flow

- Solar PV power forecasting at Yarmouk University using machine learning techniques

- 3D FE modeling of cable-stayed bridge according to ICE code

- Review Articles

- Partial discharge calibrator of a cavity inside high-voltage insulator

- Health issues using 5G frequencies from an engineering perspective: Current review

- Modern structures of military logistic bridges

- Retraction

- Retraction note: COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Special Issue: Trends in Logistics and Production for the 21st Century - Part II

- Solving transportation externalities, economic approaches, and their risks

- Demand forecast for parking spaces and parking areas in Olomouc

- Rescue of persons in traffic accidents on roads

- Special Issue: ICRTEEC - 2021 - Part II

- Switching transient analysis for low voltage distribution cable

- Frequency amelioration of an interconnected microgrid system

- Wireless power transfer topology analysis for inkjet-printed coil

- Analysis and control strategy of standalone PV system with various reference frames

- Special Issue: AESMT

- Study of emitted gases from incinerator of Al-Sadr hospital in Najaf city

- Experimentally investigating comparison between the behavior of fibrous concrete slabs with steel stiffeners and reinforced concrete slabs under dynamic–static loads

- ANN-based model to predict groundwater salinity: A case study of West Najaf–Kerbala region

- Future short-term estimation of flowrate of the Euphrates river catchment located in Al-Najaf Governorate, Iraq through using weather data and statistical downscaling model

- Utilization of ANN technique to estimate the discharge coefficient for trapezoidal weir-gate

- Experimental study to enhance the productivity of single-slope single-basin solar still

- An empirical formula development to predict suspended sediment load for Khour Al-Zubair port, South of Iraq

- A model for variation with time of flexiblepavement temperature

- Analytical and numerical investigation of free vibration for stepped beam with different materials

- Identifying the reasons for the prolongation of school construction projects in Najaf

- Spatial mixture modeling for analyzing a rainfall pattern: A case study in Ireland

- Flow parameters effect on water hammer stability in hydraulic system by using state-space method

- Experimental study of the behaviour and failure modes of tapered castellated steel beams

- Water hammer phenomenon in pumping stations: A stability investigation based on root locus

- Mechanical properties and freeze-thaw resistance of lightweight aggregate concrete using artificial clay aggregate

- Compatibility between delay functions and highway capacity manual on Iraqi highways

- The effect of expanded polystyrene beads (EPS) on the physical and mechanical properties of aerated concrete

- The effect of cutoff angle on the head pressure underneath dams constructed on soils having rectangular void

- An experimental study on vibration isolation by open and in-filled trenches

- Designing a 3D virtual test platform for evaluating prosthetic knee joint performance during the walking cycle

- Special Issue: AESMT-2 - Part I

- Optimization process of resistance spot welding for high-strength low-alloy steel using Taguchi method

- Cyclic performance of moment connections with reduced beam sections using different cut-flange profiles

- Time overruns in the construction projects in Iraq: Case study on investigating and analyzing the root causes

- Contribution of lift-to-drag ratio on power coefficient of HAWT blade for different cross-sections

- Geotechnical correlations of soil properties in Hilla City – Iraq

- Improve the performance of solar thermal collectors by varying the concentration and nanoparticles diameter of silicon dioxide

- Enhancement of evaporative cooling system in a green-house by geothermal energy

- Destructive and nondestructive tests formulation for concrete containing polyolefin fibers

- Quantify distribution of topsoil erodibility factor for watersheds that feed the Al-Shewicha trough – Iraq using GIS

- Seamless geospatial data methodology for topographic map: A case study on Baghdad

- Mechanical properties investigation of composite FGM fabricated from Al/Zn

- Causes of change orders in the cycle of construction project: A case study in Al-Najaf province

- Optimum hydraulic investigation of pipe aqueduct by MATLAB software and Newton–Raphson method

- Numerical analysis of high-strength reinforcing steel with conventional strength in reinforced concrete beams under monotonic loading

- Deriving rainfall intensity–duration–frequency (IDF) curves and testing the best distribution using EasyFit software 5.5 for Kut city, Iraq

- Designing of a dual-functional XOR block in QCA technology

- Producing low-cost self-consolidation concrete using sustainable material

- Performance of the anaerobic baffled reactor for primary treatment of rural domestic wastewater in Iraq

- Enhancement isolation antenna to multi-port for wireless communication

- A comparative study of different coagulants used in treatment of turbid water

- Field tests of grouted ground anchors in the sandy soil of Najaf, Iraq

- New methodology to reduce power by using smart street lighting system

- Optimization of the synergistic effect of micro silica and fly ash on the behavior of concrete using response surface method

- Ergodic capacity of correlated multiple-input–multiple-output channel with impact of transmitter impairments

- Numerical studies of the simultaneous development of forced convective laminar flow with heat transfer inside a microtube at a uniform temperature

- Enhancement of heat transfer from solar thermal collector using nanofluid

- Improvement of permeable asphalt pavement by adding crumb rubber waste

- Study the effect of adding zirconia particles to nickel–phosphorus electroless coatings as product innovation on stainless steel substrate

- Waste aggregate concrete properties using waste tiles as coarse aggregate and modified with PC superplasticizer

- CuO–Cu/water hybrid nonofluid potentials in impingement jet

- Satellite vibration effects on communication quality of OISN system

- Special Issue: Annual Engineering and Vocational Education Conference - Part III

- Mechanical and thermal properties of recycled high-density polyethylene/bamboo with different fiber loadings

- Special Issue: Advanced Energy Storage

- Cu-foil modification for anode-free lithium-ion battery from electronic cable waste

- Review of various sulfide electrolyte types for solid-state lithium-ion batteries

- Optimization type of filler on electrochemical and thermal properties of gel polymer electrolytes membranes for safety lithium-ion batteries

- Pr-doped BiFeO3 thin films growth on quartz using chemical solution deposition

- An environmentally friendly hydrometallurgy process for the recovery and reuse of metals from spent lithium-ion batteries, using organic acid

- Production of nickel-rich LiNi0.89Co0.08Al0.03O2 cathode material for high capacity NCA/graphite secondary battery fabrication

- Special Issue: Sustainable Materials Production and Processes

- Corrosion polarization and passivation behavior of selected stainless steel alloys and Ti6Al4V titanium in elevated temperature acid-chloride electrolytes

- Special Issue: Modern Scientific Problems in Civil Engineering - Part II

- The modelling of railway subgrade strengthening foundation on weak soils

- Special Issue: Automation in Finland 2021 - Part II

- Manufacturing operations as services by robots with skills

- Foundations and case studies on the scalable intelligence in AIoT domains

- Safety risk sources of autonomous mobile machines

- Special Issue: 49th KKBN - Part I

- Residual magnetic field as a source of information about steel wire rope technical condition

- Monitoring the boundary of an adhesive coating to a steel substrate with an ultrasonic Rayleigh wave

- Detection of early stage of ductile and fatigue damage presented in Inconel 718 alloy using instrumented indentation technique

- Identification and characterization of the grinding burns by eddy current method

- Special Issue: ICIMECE 2020 - Part II

- Selection of MR damper model suitable for SMC applied to semi-active suspension system by using similarity measures