Abstract

The study deals with the topic of the implementation of modern production methods with emphasis on the solution of a new production with the utilization of lean principles and respecting the limiting conditions of the production company. In the summary, an economic assessment of the designed concept using the Lean Method is presented. The outcomes of the researched problem are a performed analysis, its acceptance of the user and the acceptance of the designed concept of the new production line.

1 Introduction

Lean is an innovative yet time-tested way to lead organizations to efficiency, productivity and continuous process improvement. The implementation of lean methods ensures organizations high quality, efficiency of all processes, work productivity and at the same time, reduction of costs or at least their control [1].

By analysing the work, we obtain information about work processes, which are then analysed in order to discover waste. It can be stated that it focuses on finding the best way to do the activities without all the unproductive actions – simplifying the work performed. The result is higher productivity by eliminating waste. The output is a new, optimal workflow, which should be defined by an appropriate standard [2].

The study of working methods is a systematic record and critical examination of the ways in which things are done so that improvements can be made [4].

Due to the rising total cost of production of individual products, there is increasing pressure to increase productivity to minimize the risk that, from an economic point of view, there will be a turning point when the company will increase the loss with each piece produced instead of profit. Therefore, while today the concept of lean production is no longer just a foreign word, the analysis and measurement of work are one of the basic knowledge of industrial engineers and lean specialists [3]. It is a relatively simple and at the same time very effective tool in the fight against waste and inefficiency in processes and at the same time the first step on the path to standardization. Under the name of analysis and measurement of work, we can imagine activities leading to the definition of the optimal work procedure and determination of time consumption for individual activities [4].

How to be productive and innovative, how to go slow and fast, how to create your own future from the present, how to create a “blue ocean” and put the competition out of the game? These are the issues whose solutions determine the existence and non-existence of companies in global markets at the beginning of the twenty-first century [5].

There are a number of tools that help with the introduction of lean manufacturing in the company – the 5S method, kanban system, spaghetti diagram and preparation, and their strength flourishes in combination with their use, then the maximum effect is achieved [5].

When making a strategic decision with respect to the risk and uncertainty, it is possible to use various methods and tools, whereas every one of these methodology elements has some advantages and disadvantages and their implementation in practice must correspond to the environment in which the company operates [6].

Tomáš Baťa was an example of the use of work measurement and new knowledge in production processes. It was especially typical for the company Baťa that it paid considerable attention to the introduction of new technology into production, product innovation and new thinking at work in general [7]. The main motto, written in large letters on the factory wall, “People of thought, hard work,” was not a phrase, but a project that was carried out literally every hour in every workplace [8].

Automated logistic systems are becoming more widely used within enterprise logistics processes. Their main advantage is that they allow increasing the efficiency and reliability of logistics processes [9]. Kodym et al. [10] investigated the use of the logistics chain model (train transport system) as a source for data processing. Fedorko et al. [11] resolved the design of production lines and logistic flows in production by optimizing method for layout of workstations, triangular method and computer simulation by program EXTEND. One of the possible ways of effective waste management is environmental consciousness, but the science brings different ways of solution, for example in connection of waste management and simulation of wastes flow [12]. Mikušová et al. [13] dealt with the optimization of the production of a selected component in the automotive industry.

Industry 4.0 philosophy and the associated method of digital factory require a wide range of tasks and skills to be managed for their successful application and efficient operating. One of the key competencies for their reliable operation is mastering computer simulation of various logistics processes that take place within the enterprise [14].

2 The theory of work analysis and measurement

The growth of total production costs of individual products causes higher pressure on productivity growth with the aim to minimize the risk that with every piece produced, the loss will increase too. Lean production requires a detailed analysis of work measurement.

These are simple and very efficient tools to prevent wastage and ineffectiveness in processes and they are the first step towards standardization at the same time. The analysis and measurement of work include activities leading to the definition of optimal work process and the determination of necessary time for individual activities (see Figure 1).

Scheme of analysis and measurement of work.

The activities linked to the analysis and measurement of work can be divided into two groups as follows:

The study of work methods or the work analysis provides information about work processes which are further analysed to discover any wastage. It can be stated that it focuses on finding the best processes of how to perform the analysed activities without unproductive operations, i.e. to simplify the performed work. Its result is higher productivity and elimination of wastage. The output is a new, optimal work process that will be defined by a work standard.

The objective of the analysis is a detailed observation of work activities. We repeatedly ask questions whether the operation observed is performed in the best possible way, if any operations could be eliminated, merged or simplified? To perform the work analysis, supportive analytical tools are used, e.g. process diagrams, assembly diagrams or spaghetti diagrams (see Figure 2).

Workers often perform some operations in a needlessly complicated way because they were taught that way and they do not realize it is wasting. Unbiased point of view and the right questions can set new and easier work methods.

Measurement of work – the time determination for given activities. It is a numeric representation of time consumption for individual operations or performed activities. The standards in the observed company were set incorrectly and therefore they failed to meet the workers’ productivity performance and deadlines for goods production considering the capacity planning based on incorrect data.

The knowledge of precise time periods for individual operations and setting the optimal work procedure guarantees the best productivity in the given conditions.

Example of spaghetti diagram.

3 Analysis of current status

The initial snapshotting of production operations was carried out according to the workers structure (mechanic, electro-fitter, preassembly, floors, testing and packaging) and the stairlifts models. The objective of these snapshots was to discover the potential of unemployed workers from the reasons of wastage or their insufficient equipment with work tools. The output of the snapshots was the data of work times, i.e. time X for the original duration of the operation, time Y lowered by discovered wastage that will be eliminated within lean production implementation and time Z, so-called optimized time providing the production line with the lean production technology will be implemented.

Within the analysis, it was essential to focus on preassembly as well because even these activities created a substantial part of the total time consumption. For each activity, a detailed snapshot that summarizes time consumption for the work operation was made.

An example of the output of initial snapshotting during the platform stairlift production is in Figure 3. Technological times refer to mechanic worker 1.

Snapshot example of mechanic worker.

Improvement potentials of technologic times for mechanic worker 1 are stated in the scheme (see Figure 4).

Time consumption example for mechanic worker 1.

The optimized time consumption of mechanic worker 1 counted 1:38:14 h in total. The total time consumption without pre-assemblies to produce the platform stairlift is stated in Table 1 and it reached the value of 8:51:20 h.

Total optimized time consumption to produce platform stairlift

| No | Whole | Total time (h) |

|---|---|---|

| 1 | Mechanical part 1 | 1:38:14 |

| 2 | Mechanical part 2 | 1:31:43 |

| 3 | Electrical connected | 4:19:40 |

| 4 | Testing | 1:07:13 |

| 5 | Packaging | 0:14:30 |

| Line 2 time consumption | 8:51:20 |

After the elimination of wastage and production adjustment in the perspective of lean production, the time saving goes up to around 18% of the original time. The analysis output is the comparison of the company’s standard (Altech) and the standard measured during snapshotting. The result of these measurements for the platform stairlift is stated in Table 2. The required standard is higher by 47.02% than the measured one.

Comparison of company’s standard and measured standard

| Meeting standards | ||

|---|---|---|

| Date | Product | Product number |

| Time consumption standard | 605.00 | |

| Measured time consumption standard | 320.55 | |

| Difference (%) | 47.02 | |

4 Realization of production lines concept

Relating to the results of the snapshots, a new production concept was realized. It was necessary to carry out a detailed analysis of assemblies in which recommended corrective measures will be used. In terms of production type segmenting, the future assembly concept can be ranked among series production. Serial (repetitive) production refers to the production of one or more similar products. An advanced level of applied standardization enables to reach a significant level of effectiveness. Typically for the series production, a certain number of specialized devices, including partial flexible automation, are employed.

As a follow-up to the next stage, it was essential to set the number of individual products manufactured daily and the number of workers. The analysis with the utilization of snapshots was carried out within four months using the form of video shooting. The attained snapshots of product manufacturing showed the observed workers’ activities and technological work procedures.

On the basis of the attained data, joining the assembly with the pre-assembly was recommended and it was proposed to relocate the electro-assembly working place into a parallel area. The vertical storage system for small-sized parts was relocated into the area of the final assembly and so lower level of elaboration was achieved.

The latter part of snapshotting was focused on the detailed analysis of technological times which would be subsequently used to design the production line with the utilization of so-called balance index.

The client´s requirement was set at a product tact of up to 30 min on two lines of 6 tacts and supportive pre-assemblies. The most suitable in terms of universality seemed the concept of so-called super line and because of the fact that the production tact will be set up to 16 min with 12 tacts of the line and supportive pre-assembly. Any limits of this concept were given by the working area and human resources as the line must be operated by fully trained staff at each tact when in full shift performance. The planned short production tact would be easier for the training of new workers.

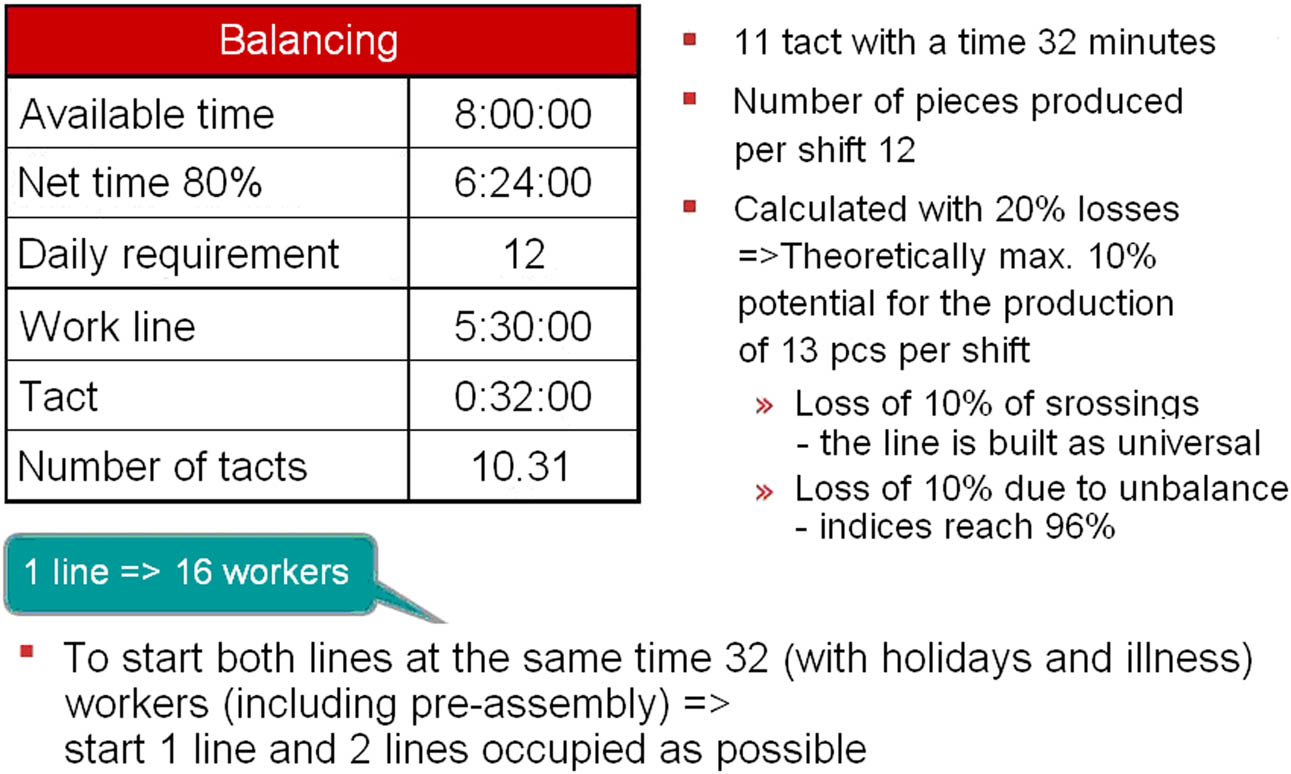

Once the lines were made universal, work procedures and labour intensity were unified. The unified labour intensity got to 5:30:00 h. Balance indices were 90–96%. Two lines were set with the production tact of 32 min with 11 tacts (including packaging), where 22 workers are required. Within the optimization, a new position of handler was created due to the need of supplying individual workplaces during the course of the shift. In Figure 5, the capacity calculation of time needed for one line is stated.

Summary of planned output of Line 1, necessary number of tacts and number of qualified workers.

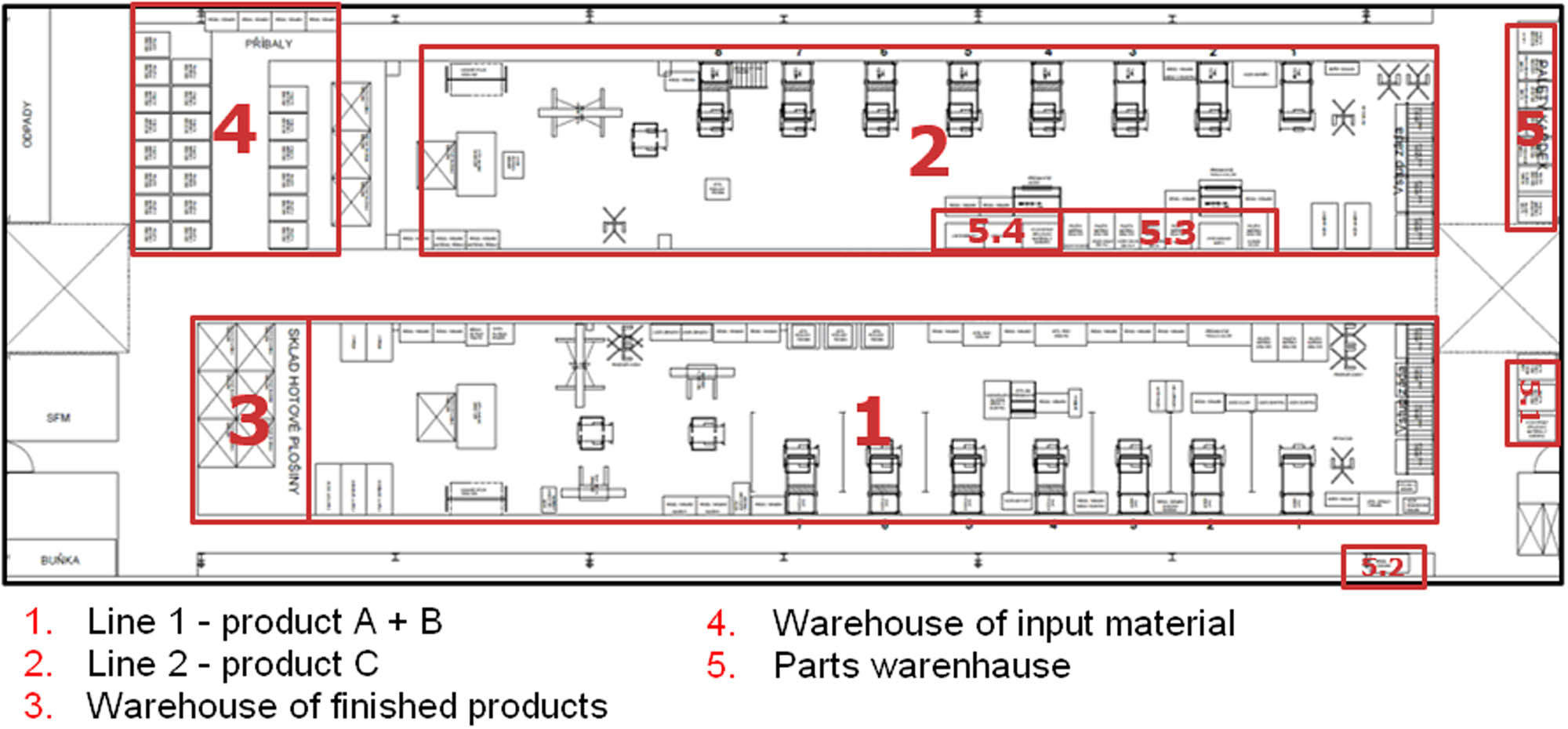

Once the number of tacts was approved by the client, the setting of action plan followed – further implementation of the design and production lines realization to manufacture the final product. Within the concept of the production line, the tacts were divided in a mechanical and electric part with the respect of working position during the work performance (sitting down or standing) – this limitation was also taken into account. Within the project, a design of production working place was elaborated, see Figure 6.

Design of working place layout.

The new layout of the production line involved a new working activity of a “logistician”, who will be responsible for supplying individual workplaces with the material. Storage boxes create the basic supplying handling unit using the Kanban system. The size of the boxes was determined according to the consumption of particular materials in related workplaces.

The electronic transmission of requests to Kanban is also used for the supply of assembly lines. The electronic data transfer process was recommended to increase the efficiency of individual workstations by adding RFID chip readers, touch tablets and readers. The introduction will increase the accuracy of time consumption tracking at individual workplaces, and the workers will be able to consult the order documentation and, with the use of QR codes on individual fastener packages, create requirements for a new delivery. Thus, the traceability of planned and actual consumption of small materials will be improved.

Based on the steps implementation of the 5S method and the creation of the floor visualization, it was necessary to set standards of the individual workplaces so that it would be possible to check the compliance with these rules.

5 Conclusion

The objective of the study was to present subsequent steps leading to the production optimization in the given company with the setting of production layout and improvement of internal logistics. The research was focused on mapping of the current production status and the basis of obtained data to design and implement a new concept of production lines and afterwards to realize it. In the theoretical part, the authors present different approaches to the analysis and work standardization and they describe methods that are used in industrial engineering.

The analytical part of the study presents the calculated potential which can be achieved by implementing the new production concept. This potential is based on the snapshots of individual workers and on subsequent division in working activities and downtime as well as Value-added and Non-value-added activities.

The proposed changes in the production process are designed due to the year on year increase in product manufacturing and the present production process did not meet these requirements. The year on year 2018/2019 production growth was as high as 19.6%. The comparison of the initial status and the new capacity possibilities of the production lines shows a production increase by 61%.

Within the analysis of the work performance, the set standards in the company were compared with the actually measured times, including the relevant allowance. Following the obtained data, a new production concept for the assembly of final products was designed. Not only the design but also the subsequent implementation of this new production concept was considered. In the course of the realization, it was necessary to decide which of the proposed solutions would be implemented. In terms of lean philosophy, one super line with several production tacts would be the best solution. Based on local space conditions, two production lines had to be designed. It was the right decision because the requirements for the final products are constantly changing and two lines are more flexible in responding to these changes. The new production concept was designed so that the planned production quantities could be produced in a single-shift operation without the need for overtime or extra weekend shifts.

As part of the production setup, the internal logistics in the supply of the individual lines and pre-assembly workplaces were changed and a stock rack with a standby stock of fasteners and small materials was designed. The supplied material will bring savings as it will be supplied according to actual consumption and the accounting records will record the actual quantity consumed. Deliveries will be made in so-called external kanban circuit. This setup will result in savings of the warehouse staff.

Acknowledgements

This work is a part of the projects VEGA 1/0403/18, VEGA 1/0600/20, KEGA 012TUKE-4/2019, KEGA 013TUKE-4/2019 and APVV SK-SRB-18-0053.

-

Conflict of interest: Authors state no conflict of interest.

References

[1] Gros I. Big book of logistics. Prague: University of Chemistry and Technology Prague; 2016. ISBN: 978-80-7080-952-5.Search in Google Scholar

[2] Gros I, Dyntar J. Mathematical models for managerial decision making. Prague: University of Chemistry and Technology Prague; 2015. ISBN: 978-80-7080-910-5.Search in Google Scholar

[3] Kavan M. Production and operations management. Prague: Grada; 2002. ISBN: 80-247-0199-5.Search in Google Scholar

[4] Tomek G, Vávrová V. Production and purchasing management. Prague: Grada; 2007. ISBN: 978-80-247-1479-0.Search in Google Scholar

[5] Košturiak J, Frolík Z. Lean and innovative business. Prague: Alfa Publishing; 2006. ISBN: 80-86851-38-9.Search in Google Scholar

[6] Dockalikova I, Flokova L. Selection of localization – determining importance of the factors using MADM methods and GIS. 12th International days of statistics and economics. Prague: Prague University of Economics and Business; 2018. p. 364–72.Search in Google Scholar

[7] Lešingrová R. Baťa’s control system. Olomouc: Booksprint s.r.o.; 2008. ISBN: 978-80-903808-9-9.Search in Google Scholar

[8] Kudzbel M. Action management: the first Czech-Slovak manual of Baťa business. Bratislava: Marada Capital Services a.s.; 2012. ISBN: 978-80-970079-5-9.Search in Google Scholar

[9] Fedorko G, Neradilová H. The use of computer simulation methods to reach data for economic analysis of automated logistic systems. Open Eng. 2016;6(1):700–10.10.1515/eng-2016-0085Search in Google Scholar

[10] Kodym O, Kavka L, Sedlacek M. Logistics chain data processing. 15th International Multidisciplinary Scientific GeoConference SGEM 2015. Albena: Bulgaria; 2015. p. 183–90.10.5593/SGEM2015/B21/S7.024Search in Google Scholar

[11] Fedorko G, Husakova N, Dudas G. Design of allocation of new technological equipment within the frame of production process in company Getrag Ford Transmissions Slovakia, s.r.o. Acta Mont Slovaca. 2010;15(SI):14–22.Search in Google Scholar

[12] Mikusova N, Tomkova E, Dovica M, Debelic B, Peric-Hadzic A, Zajac J. Use of simulation for waste management and reverse material flow. Adv Sci Technol Res J. 2018;12(4):136–43.10.12913/22998624/94965Search in Google Scholar

[13] Mikusova N, Badiarova S, Jerabek K. Optimization of welding pliers production for the automotive industry – case study. Adv Sci Technol Res J. 2020;14(4):240–49.10.12913/22998624/128105Search in Google Scholar

[14] Neradilova H, Fedorko G. Simulation of the supply of workplaces by the AGV in the digital factory. Procedia Eng. 2017;192:638–43.10.1016/j.proeng.2017.06.110Search in Google Scholar

© 2021 Vieroslav Molnár et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Electrochemical studies of the synergistic combination effect of thymus mastichina and illicium verum essential oil extracts on the corrosion inhibition of low carbon steel in dilute acid solution

- Adoption of Business Intelligence to Support Cost Accounting Based Financial Systems — Case Study of XYZ Company

- Techno-Economic Feasibility Analysis of a Hybrid Renewable Energy Supply Options for University Buildings in Saudi Arabia

- Optimized design of a semimetal gasket operating in flange-bolted joints

- Behavior of non-reinforced and reinforced green mortar with fibers

- Field measurement of contact forces on rollers for a large diameter pipe conveyor

- Development of Smartphone-Controlled Hand and Arm Exoskeleton for Persons with Disability

- Investigation of saturation flow rate using video camera at signalized intersections in Jordan

- The features of Ni2MnIn polycrystalline Heusler alloy thin films formation by pulsed laser deposition

- Selection of a workpiece clamping system for computer-aided subtractive manufacturing of geometrically complex medical models

- Development of Solar-Powered Water Pump with 3D Printed Impeller

- Identifying Innovative Reliable Criteria Governing the Selection of Infrastructures Construction Project Delivery Systems

- Kinetics of Carbothermal Reduction Process of Different Size Phosphate Rocks

- Plastic forming processes of transverse non-homogeneous composite metallic sheets

- Accelerated aging of WPCs Based on Polypropylene and Birch plywood Sanding Dust

- Effect of water flow and depth on fatigue crack growth rate of underwater wet welded low carbon steel SS400

- Non-invasive attempts to extinguish flames with the use of high-power acoustic extinguisher

- Filament wound composite fatigue mechanisms investigated with full field DIC strain monitoring

- Structural Timber In Compartment Fires – The Timber Charring and Heat Storage Model

- Technical and economic aspects of starting a selected power unit at low ambient temperatures

- Car braking effectiveness after adaptation for drivers with motor dysfunctions

- Adaptation to driver-assistance systems depending on experience

- A SIMULINK implementation of a vector shift relay with distributed synchronous generator for engineering classes

- Evaluation of measurement uncertainty in a static tensile test

- Errors in documenting the subsoil and their impact on the investment implementation: Case study

- Comparison between two calculation methods for designing a stand-alone PV system according to Mosul city basemap

- Reduction of transport-related air pollution. A case study based on the impact of the COVID-19 pandemic on the level of NOx emissions in the city of Krakow

- Driver intervention performance assessment as a key aspect of L3–L4 automated vehicles deployment

- A new method for solving quadratic fractional programming problem in neutrosophic environment

- Effect of fish scales on fabrication of polyester composite material reinforcements

- Impact of the operation of LNG trucks on the environment

- The effectiveness of the AEB system in the context of the safety of vulnerable road users

- Errors in controlling cars cause tragic accidents involving motorcyclists

- Deformation of designed steel plates: An optimisation of the side hull structure using the finite element approach

- Thermal-strength analysis of a cross-flow heat exchanger and its design improvement

- Effect of thermal collector configuration on the photovoltaic heat transfer performance with 3D CFD modeling

- Experimental identification of the subjective reception of external stimuli during wheelchair driving

- Failure analysis of motorcycle shock breakers

- Experimental analysis of nonlinear characteristics of absorbers with wire rope isolators

- Experimental tests of the antiresonance vibratory mill of a sectional movement trajectory

- Experimental and theoretical investigation of CVT rubber belt vibrations

- Is the cubic parabola really the best railway transition curve?

- Transport properties of the new vibratory conveyor at operations in the resonance zone

- Assessment of resistance to permanent deformations of asphalt mixes of low air void content

- COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Review Articles

- FMEA method in operational reliability of forest harvesters

- Examination of preferences in the field of mobility of the city of Pila in terms of services provided by the Municipal Transport Company in Pila

- Enhancement stability and color fastness of natural dye: A review

- Special Issue: ICE-SEAM 2019 - Part II

- Lane Departure Warning Estimation Using Yaw Acceleration

- Analysis of EMG Signals during Stance and Swing Phases for Controlling Magnetorheological Brake applications

- Sensor Number Optimization Using Neural Network for Ankle Foot Orthosis Equipped with Magnetorheological Brake

- Special Issue: Recent Advances in Civil Engineering - Part II

- Comparison of STM’s reliability system on the example of selected element

- Technical analysis of the renovation works of the wooden palace floors

- Special Issue: TRANSPORT 2020

- Simulation assessment of the half-power bandwidth method in testing shock absorbers

- Predictive analysis of the impact of the time of day on road accidents in Poland

- User’s determination of a proper method for quantifying fuel consumption of a passenger car with compression ignition engine in specific operation conditions

- Analysis and assessment of defectiveness of regulations for the yellow signal at the intersection

- Streamlining possibility of transport-supply logistics when using chosen Operations Research techniques

- Permissible distance – safety system of vehicles in use

- Study of the population in terms of knowledge about the distance between vehicles in motion

- UAVs in rail damage image diagnostics supported by deep-learning networks

- Exhaust emissions of buses LNG and Diesel in RDE tests

- Measurements of urban traffic parameters before and after road reconstruction

- The use of deep recurrent neural networks to predict performance of photovoltaic system for charging electric vehicles

- Analysis of dangers in the operation of city buses at the intersections

- Psychological factors of the transfer of control in an automated vehicle

- Testing and evaluation of cold-start emissions from a gasoline engine in RDE test at two different ambient temperatures

- Age and experience in driving a vehicle and psychomotor skills in the context of automation

- Consumption of gasoline in vehicles equipped with an LPG retrofit system in real driving conditions

- Laboratory studies of the influence of the working position of the passenger vehicle air suspension on the vibration comfort of children transported in the child restraint system

- Route optimization for city cleaning vehicle

- Efficiency of electric vehicle interior heating systems at low ambient temperatures

- Model-based imputation of sound level data at thoroughfare using computational intelligence

- Research on the combustion process in the Fiat 1.3 Multijet engine fueled with rapeseed methyl esters

- Overview of the method and state of hydrogenization of road transport in the world and the resulting development prospects in Poland

- Tribological characteristics of polymer materials used for slide bearings

- Car reliability analysis based on periodic technical tests

- Special Issue: Terotechnology 2019 - Part II

- DOE Application for Analysis of Tribological Properties of the Al2O3/IF-WS2 Surface Layers

- The effect of the impurities spaces on the quality of structural steel working at variable loads

- Prediction of the parameters and the hot open die elongation forging process on an 80 MN hydraulic press

- Special Issue: AEVEC 2020

- Vocational Student's Attitude and Response Towards Experiential Learning in Mechanical Engineering

- Virtual Laboratory to Support a Practical Learning of Micro Power Generation in Indonesian Vocational High Schools

- The impacts of mediating the work environment on the mode choice in work trips

- Utilization of K-nearest neighbor algorithm for classification of white blood cells in AML M4, M5, and M7

- Car braking effectiveness after adaptation for drivers with motor dysfunctions

- Case study: Vocational student’s knowledge and awareness level toward renewable energy in Indonesia

- Contribution of collaborative skill toward construction drawing skill for developing vocational course

- Special Issue: Annual Engineering and Vocational Education Conference - Part II

- Vocational teachers’ perspective toward Technological Pedagogical Vocational Knowledge

- Special Issue: ICIMECE 2020 - Part I

- Profile of system and product certification as quality infrastructure in Indonesia

- Prediction Model of Magnetorheological (MR) Fluid Damper Hysteresis Loop using Extreme Learning Machine Algorithm

- A review on the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters

- Facile rheological route method for LiFePO4/C cathode material production

- Mosque design strategy for energy and water saving

- Epoxy resins thermosetting for mechanical engineering

- Estimating the potential of wind energy resources using Weibull parameters: A case study of the coastline region of Dar es Salaam, Tanzania

- Special Issue: CIRMARE 2020

- New trends in visual inspection of buildings and structures: Study for the use of drones

- Special Issue: ISERT 2021

- Alleviate the contending issues in network operating system courses: Psychomotor and troubleshooting skill development with Raspberry Pi

- Special Issue: Actual Trends in Logistics and Industrial Engineering - Part II

- The Physical Internet: A means towards achieving global logistics sustainability

- Special Issue: Modern Scientific Problems in Civil Engineering - Part I

- Construction work cost and duration analysis with the use of agent-based modelling and simulation

- Corrosion rate measurement for steel sheets of a fuel tank shell being in service

- The influence of external environment on workers on scaffolding illustrated by UTCI

- Allocation of risk factors for geodetic tasks in construction schedules

- Pedestrian fatality risk as a function of tram impact speed

- Technological and organizational problems in the construction of the radiation shielding concrete and suggestions to solve: A case study

- Finite element analysis of train speed effect on dynamic response of steel bridge

- New approach to analysis of railway track dynamics – Rail head vibrations

- Special Issue: Trends in Logistics and Production for the 21st Century - Part I

- Design of production lines and logistic flows in production

- The planning process of transport tasks for autonomous vans

- Modeling of the two shuttle box system within the internal logistics system using simulation software

- Implementation of the logistics train in the intralogistics system: A case study

- Assessment of investment in electric buses: A case study of a public transport company

- Assessment of a robot base production using CAM programming for the FANUC control system

- Proposal for the flow of material and adjustments to the storage system of an external service provider

- The use of numerical analysis of the injection process to select the material for the injection molding

- Economic aspect of combined transport

- Solution of a production process with the application of simulation: A case study

- Speedometer reliability in regard to road traffic sustainability

- Design and construction of a scanning stand for the PU mini-acoustic sensor

- Utilization of intelligent vehicle units for train set dispatching

- Special Issue: ICRTEEC - 2021 - Part I

- LVRT enhancement of DFIG-driven wind system using feed-forward neuro-sliding mode control

- Special Issue: Automation in Finland 2021 - Part I

- Prediction of future paths of mobile objects using path library

- Model predictive control for a multiple injection combustion model

- Model-based on-board post-injection control development for marine diesel engine

- Intelligent temporal analysis of coronavirus statistical data

Articles in the same Issue

- Regular Articles

- Electrochemical studies of the synergistic combination effect of thymus mastichina and illicium verum essential oil extracts on the corrosion inhibition of low carbon steel in dilute acid solution

- Adoption of Business Intelligence to Support Cost Accounting Based Financial Systems — Case Study of XYZ Company

- Techno-Economic Feasibility Analysis of a Hybrid Renewable Energy Supply Options for University Buildings in Saudi Arabia

- Optimized design of a semimetal gasket operating in flange-bolted joints

- Behavior of non-reinforced and reinforced green mortar with fibers

- Field measurement of contact forces on rollers for a large diameter pipe conveyor

- Development of Smartphone-Controlled Hand and Arm Exoskeleton for Persons with Disability

- Investigation of saturation flow rate using video camera at signalized intersections in Jordan

- The features of Ni2MnIn polycrystalline Heusler alloy thin films formation by pulsed laser deposition

- Selection of a workpiece clamping system for computer-aided subtractive manufacturing of geometrically complex medical models

- Development of Solar-Powered Water Pump with 3D Printed Impeller

- Identifying Innovative Reliable Criteria Governing the Selection of Infrastructures Construction Project Delivery Systems

- Kinetics of Carbothermal Reduction Process of Different Size Phosphate Rocks

- Plastic forming processes of transverse non-homogeneous composite metallic sheets

- Accelerated aging of WPCs Based on Polypropylene and Birch plywood Sanding Dust

- Effect of water flow and depth on fatigue crack growth rate of underwater wet welded low carbon steel SS400

- Non-invasive attempts to extinguish flames with the use of high-power acoustic extinguisher

- Filament wound composite fatigue mechanisms investigated with full field DIC strain monitoring

- Structural Timber In Compartment Fires – The Timber Charring and Heat Storage Model

- Technical and economic aspects of starting a selected power unit at low ambient temperatures

- Car braking effectiveness after adaptation for drivers with motor dysfunctions

- Adaptation to driver-assistance systems depending on experience

- A SIMULINK implementation of a vector shift relay with distributed synchronous generator for engineering classes

- Evaluation of measurement uncertainty in a static tensile test

- Errors in documenting the subsoil and their impact on the investment implementation: Case study

- Comparison between two calculation methods for designing a stand-alone PV system according to Mosul city basemap

- Reduction of transport-related air pollution. A case study based on the impact of the COVID-19 pandemic on the level of NOx emissions in the city of Krakow

- Driver intervention performance assessment as a key aspect of L3–L4 automated vehicles deployment

- A new method for solving quadratic fractional programming problem in neutrosophic environment

- Effect of fish scales on fabrication of polyester composite material reinforcements

- Impact of the operation of LNG trucks on the environment

- The effectiveness of the AEB system in the context of the safety of vulnerable road users

- Errors in controlling cars cause tragic accidents involving motorcyclists

- Deformation of designed steel plates: An optimisation of the side hull structure using the finite element approach

- Thermal-strength analysis of a cross-flow heat exchanger and its design improvement

- Effect of thermal collector configuration on the photovoltaic heat transfer performance with 3D CFD modeling

- Experimental identification of the subjective reception of external stimuli during wheelchair driving

- Failure analysis of motorcycle shock breakers

- Experimental analysis of nonlinear characteristics of absorbers with wire rope isolators

- Experimental tests of the antiresonance vibratory mill of a sectional movement trajectory

- Experimental and theoretical investigation of CVT rubber belt vibrations

- Is the cubic parabola really the best railway transition curve?

- Transport properties of the new vibratory conveyor at operations in the resonance zone

- Assessment of resistance to permanent deformations of asphalt mixes of low air void content

- COVID-19 lockdown impact on CERN seismic station ambient noise levels

- Review Articles

- FMEA method in operational reliability of forest harvesters

- Examination of preferences in the field of mobility of the city of Pila in terms of services provided by the Municipal Transport Company in Pila

- Enhancement stability and color fastness of natural dye: A review

- Special Issue: ICE-SEAM 2019 - Part II

- Lane Departure Warning Estimation Using Yaw Acceleration

- Analysis of EMG Signals during Stance and Swing Phases for Controlling Magnetorheological Brake applications

- Sensor Number Optimization Using Neural Network for Ankle Foot Orthosis Equipped with Magnetorheological Brake

- Special Issue: Recent Advances in Civil Engineering - Part II

- Comparison of STM’s reliability system on the example of selected element

- Technical analysis of the renovation works of the wooden palace floors

- Special Issue: TRANSPORT 2020

- Simulation assessment of the half-power bandwidth method in testing shock absorbers

- Predictive analysis of the impact of the time of day on road accidents in Poland

- User’s determination of a proper method for quantifying fuel consumption of a passenger car with compression ignition engine in specific operation conditions

- Analysis and assessment of defectiveness of regulations for the yellow signal at the intersection

- Streamlining possibility of transport-supply logistics when using chosen Operations Research techniques

- Permissible distance – safety system of vehicles in use

- Study of the population in terms of knowledge about the distance between vehicles in motion

- UAVs in rail damage image diagnostics supported by deep-learning networks

- Exhaust emissions of buses LNG and Diesel in RDE tests

- Measurements of urban traffic parameters before and after road reconstruction

- The use of deep recurrent neural networks to predict performance of photovoltaic system for charging electric vehicles

- Analysis of dangers in the operation of city buses at the intersections

- Psychological factors of the transfer of control in an automated vehicle

- Testing and evaluation of cold-start emissions from a gasoline engine in RDE test at two different ambient temperatures

- Age and experience in driving a vehicle and psychomotor skills in the context of automation

- Consumption of gasoline in vehicles equipped with an LPG retrofit system in real driving conditions

- Laboratory studies of the influence of the working position of the passenger vehicle air suspension on the vibration comfort of children transported in the child restraint system

- Route optimization for city cleaning vehicle

- Efficiency of electric vehicle interior heating systems at low ambient temperatures

- Model-based imputation of sound level data at thoroughfare using computational intelligence

- Research on the combustion process in the Fiat 1.3 Multijet engine fueled with rapeseed methyl esters

- Overview of the method and state of hydrogenization of road transport in the world and the resulting development prospects in Poland

- Tribological characteristics of polymer materials used for slide bearings

- Car reliability analysis based on periodic technical tests

- Special Issue: Terotechnology 2019 - Part II

- DOE Application for Analysis of Tribological Properties of the Al2O3/IF-WS2 Surface Layers

- The effect of the impurities spaces on the quality of structural steel working at variable loads

- Prediction of the parameters and the hot open die elongation forging process on an 80 MN hydraulic press

- Special Issue: AEVEC 2020

- Vocational Student's Attitude and Response Towards Experiential Learning in Mechanical Engineering

- Virtual Laboratory to Support a Practical Learning of Micro Power Generation in Indonesian Vocational High Schools

- The impacts of mediating the work environment on the mode choice in work trips

- Utilization of K-nearest neighbor algorithm for classification of white blood cells in AML M4, M5, and M7

- Car braking effectiveness after adaptation for drivers with motor dysfunctions

- Case study: Vocational student’s knowledge and awareness level toward renewable energy in Indonesia

- Contribution of collaborative skill toward construction drawing skill for developing vocational course

- Special Issue: Annual Engineering and Vocational Education Conference - Part II

- Vocational teachers’ perspective toward Technological Pedagogical Vocational Knowledge

- Special Issue: ICIMECE 2020 - Part I

- Profile of system and product certification as quality infrastructure in Indonesia

- Prediction Model of Magnetorheological (MR) Fluid Damper Hysteresis Loop using Extreme Learning Machine Algorithm

- A review on the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters

- Facile rheological route method for LiFePO4/C cathode material production

- Mosque design strategy for energy and water saving

- Epoxy resins thermosetting for mechanical engineering

- Estimating the potential of wind energy resources using Weibull parameters: A case study of the coastline region of Dar es Salaam, Tanzania

- Special Issue: CIRMARE 2020

- New trends in visual inspection of buildings and structures: Study for the use of drones

- Special Issue: ISERT 2021

- Alleviate the contending issues in network operating system courses: Psychomotor and troubleshooting skill development with Raspberry Pi

- Special Issue: Actual Trends in Logistics and Industrial Engineering - Part II

- The Physical Internet: A means towards achieving global logistics sustainability

- Special Issue: Modern Scientific Problems in Civil Engineering - Part I

- Construction work cost and duration analysis with the use of agent-based modelling and simulation

- Corrosion rate measurement for steel sheets of a fuel tank shell being in service

- The influence of external environment on workers on scaffolding illustrated by UTCI

- Allocation of risk factors for geodetic tasks in construction schedules

- Pedestrian fatality risk as a function of tram impact speed

- Technological and organizational problems in the construction of the radiation shielding concrete and suggestions to solve: A case study

- Finite element analysis of train speed effect on dynamic response of steel bridge

- New approach to analysis of railway track dynamics – Rail head vibrations

- Special Issue: Trends in Logistics and Production for the 21st Century - Part I

- Design of production lines and logistic flows in production

- The planning process of transport tasks for autonomous vans

- Modeling of the two shuttle box system within the internal logistics system using simulation software

- Implementation of the logistics train in the intralogistics system: A case study

- Assessment of investment in electric buses: A case study of a public transport company

- Assessment of a robot base production using CAM programming for the FANUC control system

- Proposal for the flow of material and adjustments to the storage system of an external service provider

- The use of numerical analysis of the injection process to select the material for the injection molding

- Economic aspect of combined transport

- Solution of a production process with the application of simulation: A case study

- Speedometer reliability in regard to road traffic sustainability

- Design and construction of a scanning stand for the PU mini-acoustic sensor

- Utilization of intelligent vehicle units for train set dispatching

- Special Issue: ICRTEEC - 2021 - Part I

- LVRT enhancement of DFIG-driven wind system using feed-forward neuro-sliding mode control

- Special Issue: Automation in Finland 2021 - Part I

- Prediction of future paths of mobile objects using path library

- Model predictive control for a multiple injection combustion model

- Model-based on-board post-injection control development for marine diesel engine

- Intelligent temporal analysis of coronavirus statistical data