Abstract

Hip joint is an important human joints system. The damaged hip joints need to be replaced with artificial hip joints. The Study of the hip joint is very costly therefore another calculation method is demanded to produce good result in acceptable time and cost. Considering this problem, a series of study to assess hip joint performance is conducted using numerical approach. Important parameter for example applied materials are used in the modelling by idealizing Ti-6Al-4V compared to SS 316 L, and stemlengthwas chosen to be 128 mm. ANSYS software was used to analyze models, and designed element size variations were set to be in range 1 to 2.5 mm. The magnitude of force was placed on the femoral head with an angle of 16∘C from the vertical axis. Results showed that SS 316 L material has smaller deformation than Ti material. Whereas Central Processing (CP) time decreases in increasing element size for both materials. In addition, more variations in mesh size are needed to get more accurate convergent results.

1 Introduction

Hip joint is an important human system which connects the femur and pelvis. Hip joint consists of three main parts, namely: femur, femoral head, and rounded socked. The hip is one of most common joints that are most likely to be replaced during our lifetime due to wear and tear of cartilage, bone degeneration and other factors where weight bearing is a factor [1]. The most common reason to have an artificial hip joint operation is to relieve severe arthritis pain that is limiting daily activities [2]. Hip joint damages require replacement with an artificial hip joint. Total hip replacement (THR) is the most successful application of biomaterials in the short term in order to alleviate joint pain, joint architecture and to increase functional mobility in deceased traumatized joint [3].

Total hip replacement has become a very common operation with over 300 000 operations carried out world-wide every year [4]. Appropriate bone and implant geometry is an important factor for successful total hip arthro-plasty. Besides other factors that must be considered are age, weight, bone quality, gender, implant costs. In preparing a THR, an orthopedic surgeon carefully selects an implant from the various type [5].

A typical total hip replacement prosthesis consists of a stem and femoral neck inserted into the top of the femur, a femoral head attached to the femoral neck, an acetabular shell fitted to the hip bone, and an acetabular cup liner fixed to the inside of the acetabular cup and against the femoral head [6]. The design of a hip implant involves many parameters,which include stem length, cross-section, neck length, neck angle, and ball diameter [7].

Numerous studies have been conducted on the use of FEM to determine the strength of hip stem. Bannet used FEM to analyse six hip designs. The results obtained are the stress and displacement of the hip stem. One of the most important factors is cross-section [7]. Mbulelo and Goswami conducted research with FEM to determine the effect on steminterfacial motion. Implants of distinct cross section and stem profile were analyzed [8]. The study also analyzed material which contributed to the stem interfacial motion. The study showed that implant stem cross sectional area may have an effect on the stability and interfacial motion. In addition, Ti 6Al-4V showed the greatest difference in implant interfacial motion as compared to SS316L and CoCr [8]. Kluess conducted a study of the effect of femoral head size on impingement, dislocation, and stress distribution [9]. Galanis N, Manolakos D conducted design of a complete hip joint implant, textural from stem, femoral head and cup, and then used CAE software to analyse and examine of these parts and finally produced inspection of these part for its surface roughnes accuracy [10].

The aim of this project was to investigate meshing strategy on mechanical behaviour of hip stem implant design using finite element analysis. In this study, researcher also compared SS 316 L to Ti materials.

2 Materials and Methods

2.1 Design

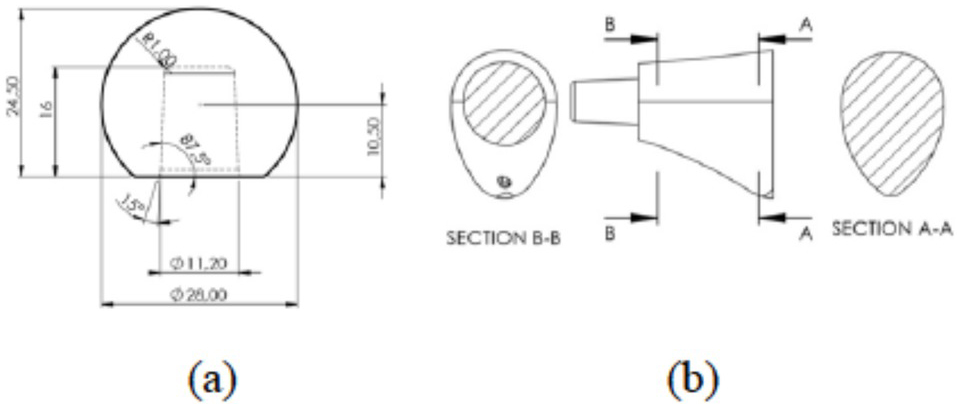

Many types of hip stem are marketed commercially in Indonesia. Commonly it is imported product. The hip stem design used in this research consists of two components: femoral head dan stem. Femoral head design refers to the study conducted by Tuan P N et al. according ISO 7206-1 as Figure 1 (a) [11]. Commercial hip stem is used as a reference for shape. The shape of the neck and the cross section which were made is ilustrated in Figure 1 (b). Smaller neck in the design is unavoidable because there would be contact to the cup of the acetabulum. If possible, even a slight increase in the neck area will certainly have positive implications [12]. In this study rectangular cross sections are used on all types of hip stem.

(a) Size dan shape of femoral head; and (b) Cross section femoral neck

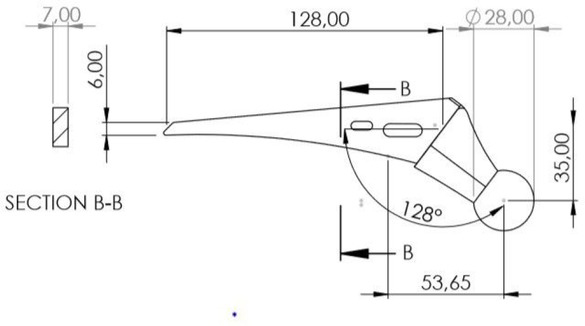

The length of the intramedullary stem of the femoral prosthesis varies in a large scale from 12 to 18 cm for standard prosthesis [13]. The chosen stem length was 128 mm. In the stem, there are two slot holes. Hip stem design and slot hole is shown in Figure 2

Main size of hip stem with stem length 128 (mm)

2.2 Materials

The selected material needs a requirement as implant material. In this study the material chosen was Titanium (Ti-6Al-4V) compared to SS 316 L. Metal biomaterials are extensively used in medical applications due to their high strength and corrosion resistance. In addition, stainless steel, Ti, magnesium and Co-based alloys have superior biomedical properties among other metal biomaterials [14]. Following are the unique properties that made titanium the ultimate choice as a biomaterial in total joint replacements:

Inert to human body fluids

Osseointegration capability

Strong, yet light weight

Non-magnetic [15]

The material properties of Titanium (Ti-6Al-4V) and SS 316 L are shown in Table 1. The data of mechanical properties of materials was from literature.

2.3 Finite Element Analysis

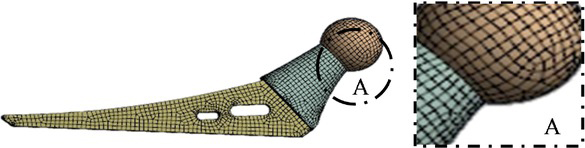

Two different materials hip stem models were analyzed. Stress distribution (von misses) and displacement models were analyzed using ANSYS 16.0. The material properties for all models were assumed to be isotropic, linear elastic and follow the Hooke’s law. Rawal used the number of elements 41000 to analyze the stem for equivalent stress. This study used 9 variations of elements size: 2.5; 2.25; 2; 1.85; 1.75; 1.65; 1.5; 1.35; 1.Method of meshing which was chosen was hex-dom-quad-tri, which is considered based on theory that it is essential to mesh biologic structures with hexahedral elements [2]. In addition, the researcher applied fine mesh to the implant models [15]. The example of the used mesh type is shown in Figure 3.

The shape of the FE model mesh used.

All models were set to the same boundary conditions. Model was set up with adequate boundary conditions, including fixing of the implant bottom surface along all degrees of freedom, and the load was applied in the appropriate direction relative to the top of the femoral head of the prosthesis [18]. The type of connections contact chosen between the femoral head and neck was bonded. The analysis setting consists of fixed force and force. Fixed boundary condition is set-up along the stem in all orientations as shown in Figure 4. While the magnitude of force was 2,700 N in the femoral head with an angle of 16∘C from the vertical axis and 78∘C from the horizontal axis. The magnitude of the load component was determined based on literature studies from Pachioga et al. Figure 5 shows the magnitude of the load.

Fixed force

The magnitude of the load

3 Results and Discussion

Two type materials have been analyzed with FEM to determine the meshing strategy that produces optimum mechanical properties. The results taken from the simulation are stress (von misses), deformation, strain, and Central Processing (CP) time. All the results will be presented in the form of graphs and in the form of two dimensional images. In the selected element size variations, the stress (von misses) for each materials is shown in Figure 6. The graph shows that the stress (von misses) max for Titanium is 198.93 MPa at 1,85 element size. While the stress (von misses) max for SS 316 L is 188.37 MPa at 1,25 element size.

Graph of relationship between element size and stress (von misses) Ti-6Al-4V and SS 316 L.

Deformation generated by the elements size variations is shown in Figure 7. For SS 316 L material, the resulting curve tends to be linear in all element size variations. While the resulting deformation for Ti-6Al-4V material continues to decrease at element size <1,5 and increase at element size >1,65 and linear up to element size 2,5. The resulting smallest deformation is 0,032287 mm at element size 1,5 for Ti and 0,020640 mm at element size 2,5 and 2,25 for SS 316 L.

Graph of relationship between element size and deformation (mm) Ti-6Al-4V and SS 316 L

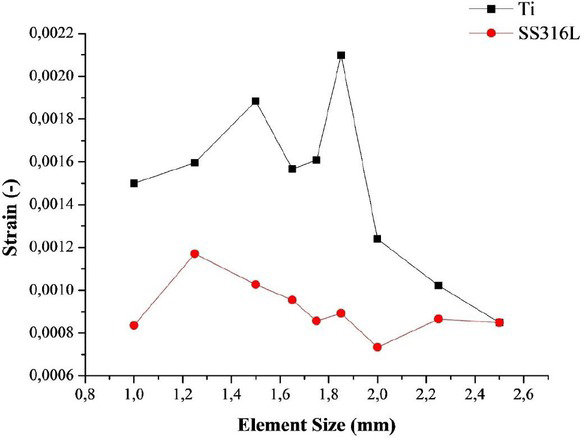

Figure 8 shows the strain (von misses) produced by the element size variations. SS 316 L strain deacreases at element size 1,25 to 1,75. The maximum resulting strain is 0,00117 at element size 1,25. While Ti strain deacreases at element size 2,00 to 2,50. The maximum resulting strain is 0,0020966 at element size 1,85.

Graph of relationship between element size and strain (von misses) Ti-6Al-4V and SS 316 L

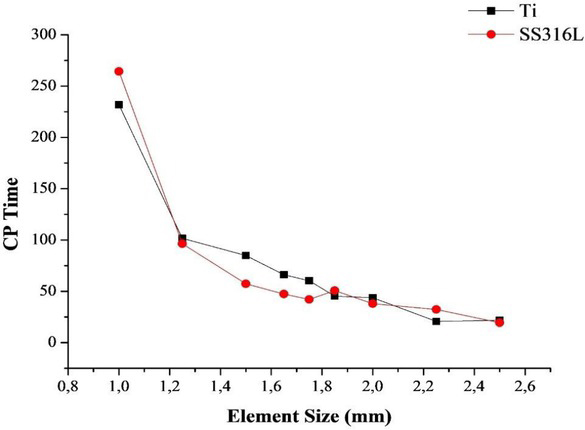

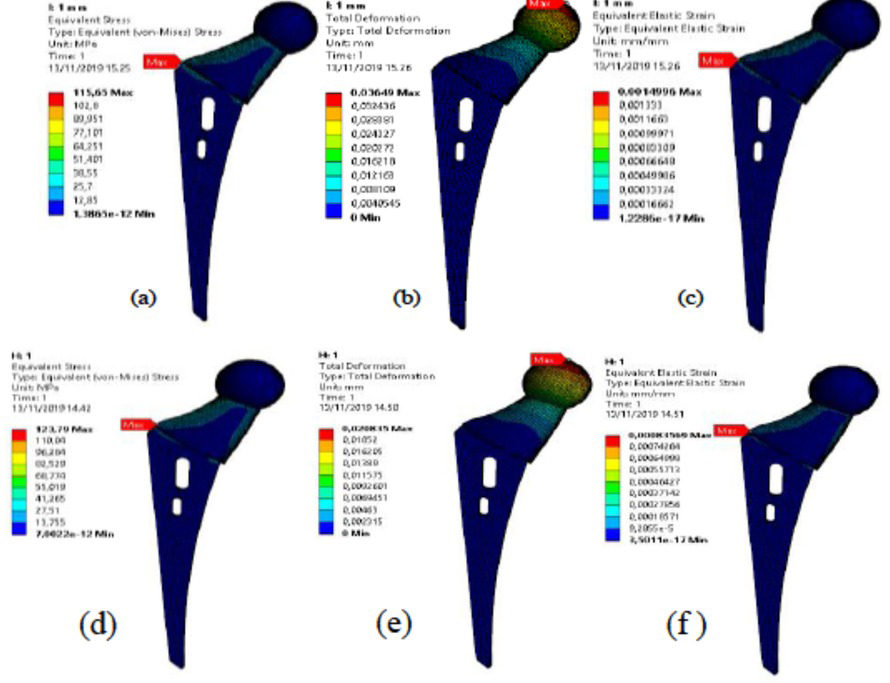

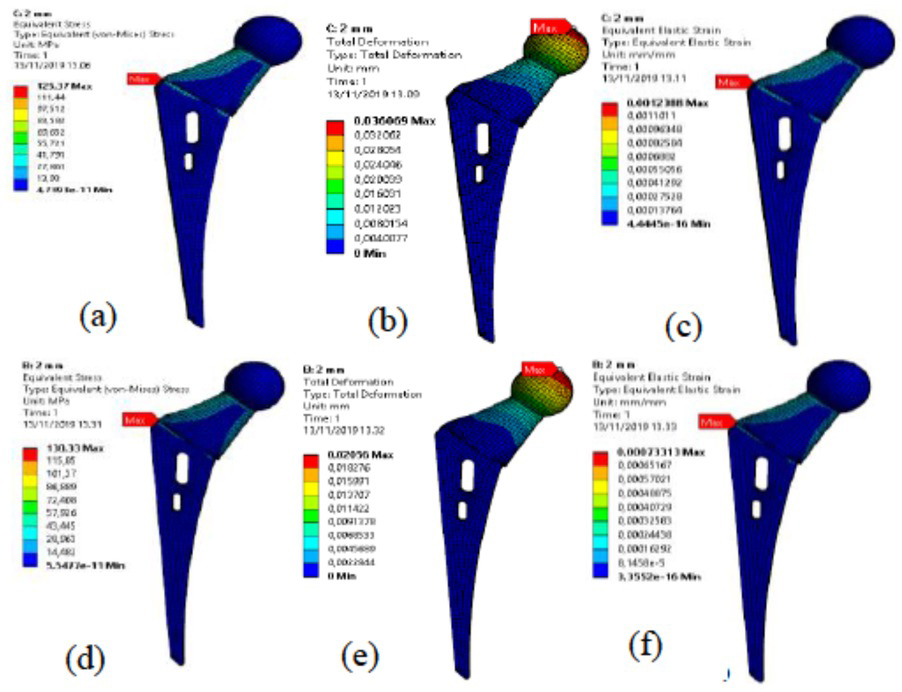

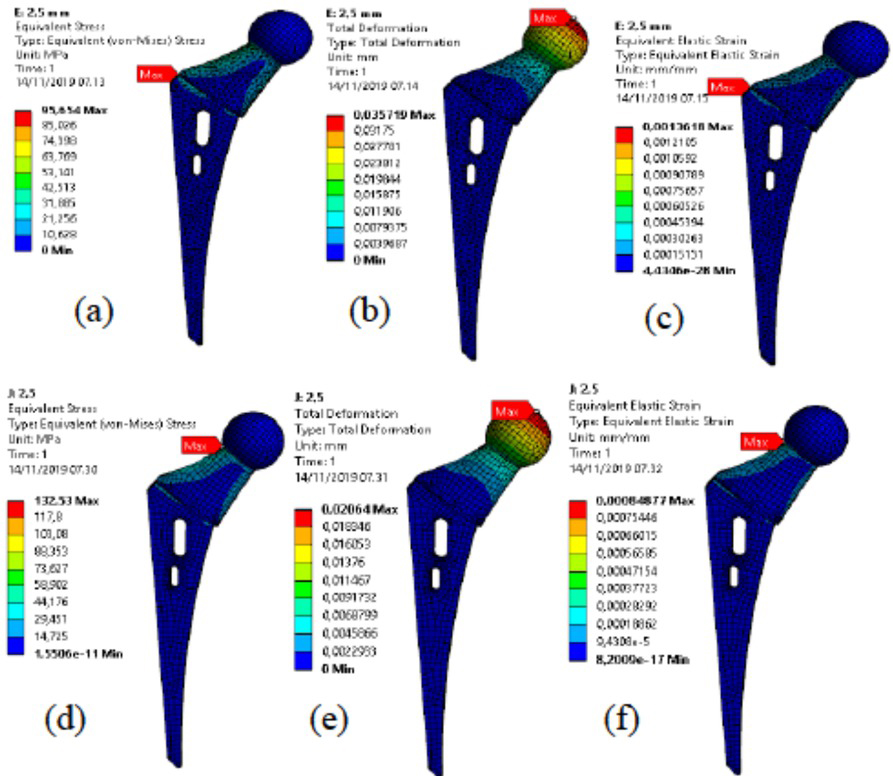

The relationship between element size and CP time of Ti-6Al-4V and SS316L are shown in Figure 9. The graph shows CP time is decreasing at element size 1,00 to 2,5 for both Ti and SS 316 L. Maximum CP time is generated by element size 1,00 for Ti and SS 316 L. Maximum CP time for Ti is 231,719 seconds and 264,328 for SS 316 L. From the simulation that has been done, the results of stress (von misses), deformation, strain (von misses) and CP time are obtained. The Figure 10 to 12 show the results of the simulation that has been carried out on meshing size 1mm, 2mm, 2,5mm. In other meshing sizes, the results of contour are almost similar except for the resulting value.

Graph of relationship between element size and CP-time Ti-6Al-4V and SS316L

For element size 1 mm on Ti-6Al-4V (a) Stress (von misses), (b) deformation, (c) strain (von misses) and on SS 316 L 4V (d) Stress (von misses), (e) deformation, (f) strain (von misses)

For element size 2 mm on Ti-6Al-4V (a) Stress (von misses), (b) deformation, (c) strain (von misses) and on SS 316 L 4V (d) Stress (von misses), (e) deformation, (f) strain (von misses)

For element size 2,5 mm on Ti-6Al-4V (a) Stress (von misses), (b) deformation, (c) strain (von misses) and on SS 316 L 4V (d) Stress (von misses), (e) deformation, (f) strain (von misses)

4 Conclusion

A finite element analysis has been carried out with variations of the meshing strategy for the two types of implant material. Mesh size variations have an influence on mechanical properties. It is necessary to determine the right mesh size to get the right analysis and optimum CP time. Two types of material have been compared with FEA. From the simulation, SS 316 L material has smaller deformation than Ti material. Whereas CP time decreases in increasing element size for both materials. From this study the recommended mesh size is 2 mm. More variations in mesh size are needed to get more accurate convergent results.

References

[1] Amirouche F, Solitro GF. Challenges in modeling total knee arthro-plasty and total hip replacement. Volume 2. 2011. pp. 18–25.10.1016/j.piutam.2011.04.003Suche in Google Scholar

[2] Shin J, Lee DS, Kim D. Jeong, Lee HG, and Kim J. 136-701, r, vol. 15, no. 1, pp. 57–65, 2011.Suche in Google Scholar

[3] Affatato S. Development of a Novel in Silico Model to Investigate the Influence of Radial Clearance on the Acetabular Cup Contact Pressure in Hip Implants. 2018. pp. 1–11.10.3390/ma11081282Suche in Google Scholar PubMed PubMed Central

[4] Darwish SM. Optimization of Artificial Hip Joint Parameters, no. 3, 2009.10.1002/mawe.200900430Suche in Google Scholar

[5] Jun Y, Choi K. Advances in Engineering Software Design of patient-specific hip implants based on the 3D geometry of the human femur. Adv Eng Softw. 2010;41(4):537–47.10.1016/j.advengsoft.2009.10.016Suche in Google Scholar

[6] Hocking L, Pramanik A, Basak AK, Chattopadhyaya S. Designing and analysis of the femoral neck for an artificial hip joint prosthesis. Elsevier Ltd.; 2019. https://doi.org/10.1016/B978-0-08-102174-3.00002-410.1016/B978-0-08-102174-3.00002-4Suche in Google Scholar

[7] Bennett D.Materials&Design Finite element analysis of hip stem designs. Volume 29. 2008. pp. 45–60.10.1016/j.matdes.2006.12.014Suche in Google Scholar

[8] Makola MT, and Goswami T. Hip implant stem interfacial motion, a finite element analysis Hip implant stem interfacial motion, a finite element analysis Mbulelo T. Makola* Tarun Goswami, no. February 2015, 2011.10.1504/IJECB.2011.039946Suche in Google Scholar

[9] Kluess D, Martin H, Mittelmeier W, Schmitz K, Bader R. Influence of femoral head size on impingement, dislocation and stress distribution in total hip replacement. Volume 29. 2007. pp. 465–71.10.1016/j.medengphy.2006.07.001Suche in Google Scholar PubMed

[10] Galanis N, and Manolakos D. Design, Numerical Analysis and Manufacturing of Artificial Hip Design, Numerical Analysis and Manufacturing, no. June, 2009.Suche in Google Scholar

[11] Chi H, City M, Trang N. Design of Femoral Head in Total Hip for Vietnamese Patients. 2016;(June):3–7.Suche in Google Scholar

[12] Khouzani MK, Bahrami A, Eslami A. Metallurgical aspects of failure in a broken femoral HIP prosthesis, Eng. Fail. Anal., vol. 90, no. November 2017, pp. 168–178, 2018.10.1016/j.engfailanal.2018.03.018Suche in Google Scholar

[13] El-shiekh HEF, and Hashmi MSJ. Replacement under Static and Dynamic, no. March, 2002.Suche in Google Scholar

[14] Khorasani AM. Goldberg, Doeven MEH, and Littlefair G. Titanium in Biomedical Applications—Properties and Fabrication. RE:view. 2015;5(8):593–619.10.1166/jbt.2015.1361Suche in Google Scholar

[15] Rawal BR, Ribeiro R, Malhotra R, Bhatnagar N. Design and manufacturing of femoral stems for the Indian population. J Manuf Process. 2012;14(3):216–23.10.1016/j.jmapro.2011.12.004Suche in Google Scholar

[16] Sabatini AL, Goswami T. Materials & Design Hip implants VII: Finite element analysis and optimization of cross-sections, vol. 29, pp. 1438–1446, 2008.10.1016/j.matdes.2007.09.002Suche in Google Scholar

[17] Kocich R, Lowe TC, Kunc L. Progress in Materials Science Advances in metals and alloys for joint replacement. Volume 88. 2017. pp. 232–80.10.1016/j.pmatsci.2017.04.002Suche in Google Scholar

[18] Colic K, Sedmak A, Grbovic A, Tatic U, Sedmak S, Djordjevic B. Finite Element Modeling of Hip Implant Static Loading. Procedia Eng. 2016;149(June):257–62.10.1016/j.proeng.2016.06.664Suche in Google Scholar

[19] Pacioga A, Palade DD, and Scomşa. Volume 73. Computational Simulation of Bone- Personalized Hip Prosthesis Assembly; 2011.Suche in Google Scholar

© 2020 Ikhsan et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor

Artikel in diesem Heft

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor