Abstract

Floating geosynthetic encased columns (GEC) are an increasingly popular method of strengthening weak subsoil. Design of floating columns is a difficult and not fully recognized issue. This paper treats the floating GEC column as a special kind of “pile” and its bearing capacity is calculated using five selected methods for calculating the bearing capacity of piles based on CPTU penetration tests. The calculations were done on the basis of insitu tests carried out on one of the sections of the Bargłów Kościelny bypass. The paper contains a comparison of the bearing capacities of floating GEC columns calculated with different methods based on CPTU penetration tests.

1 Introduction

A floating column is a column with a base in weak subsoil. Floating columns are an increasingly popular method of strengthening weak subsoil, mainly for economic and technological reasons [1]. Guidelines for the design of reinforcement for geosynthetic encased columns (GEC) [2] apply only to end-bearing columns, and there are no guidelines for designing reinforcement for floating columns.

The floating GEC column can be treated as a special kind of “pile” and its bearing capacity can be calculated with methods based on CPTU penetration tests [3].

2 Methods of calculating the bearing capacity of piles based on CPTU tests

In this paper, the bearing capacity of the column was determined by five selected methods: LCPC [4], Beringen and De Ruiter [5], DIN 4014 [6], Schmertmann [7] and Philipponnat [8].

Pile bearing capacity is the sum of the base capacity Qbk and shaft capacity Qsk [9]:

where Ak and As are the area of the pile base and pile shaft respectively, qb is the unit end-bearing pressure and fp is the average shaft resistance.

2.1 LCPC method

In the Laboratoire Central des Ponts et Chausees (LCPC) method, the unit end-bearing pressure and average shaft resistance can be calculated directly from the tip cone resistance qc [4].

where kc, α′ are coefficients that depend on the pile and soil type, qc,avg is the equivalent average cone resistance between 1.5Dk below and 1.5Dk above the pile tip, Dk is the diameter of the pile and qc,z is the cone resistance at depth zk.

The value qc,avg should be calculated in three steps:

Calculate qac as a mean value of qc at a depth between 1.5Dk below and 1.5Dk above the pile tip.

Eliminate qc values higher than 1.3qac and lower than 0.7 qac.

Calculate qc,avg within the range defined in the previous step.

2.2 Beringen and De Ruiter method

In the Beringen and De Ruiter method, also known as the European method, the values of qb and fp in Equations 2 and 3 should be determined from the following equations [5]:

where β = 1 for normally consolidated soils, β = 0.5 for over consolidated soils and cu is the undrained shear strength determined from Equation 8 [10].

where qt is the corrected cone resistance, σv0 is the total initial stress at the considered depth, Nkt is a coefficient depending on the plasticity index Ip and the degree of soil consolidation. Nkt values are usually in the range of 10 to 20 [11].

2.3 DIN 4014 method

In the DIN 4014 method, the shaft resistance fp and the unit end-bearing pressure qb in cohesive soils are determined from the undrained shear strength cu.

The value of cu can be determined from Equation 8, using an average qc value over a zone of three times the pile diameter under the tip.

2.4 Schmertmann method

In the Schmertmann method, the value of qb is determined from Equation 9 [7].

where qc1 is the minimum average value of the cone resistance at a depth of 0.7Dk or 4Dk below the pile tip and qc2 is the minimum average value of the cone resistance in the zone equal to 8Dk above the pile tip.

For piles with a base in cohesive soils, the fp value can be determined from Equation 10 [7].

where fs is the sleeve friction and αc is a coefficient selected in the range 0.2 to 1.25, depending on the sleeve friction and the type of pile. For values of fs equal to 30 kPa and less, the value of the coefficient αc is the same for all types of piles.

2.5 Philipponnat method

In the Philipponnat method, the values of qb and fp can be determined from Equations 11 and 12 [8].

where kb is a coefficient that depends on the type of soil in which the pile tip is located (for clays, kb = 0.5), qca(A) is the average cone resistance in the zone equal to 3B above the pile tip, qcb(B) is the average cone resistance at a depth of 3B below the pile tip, Fs is a coefficient depending on the type of soil in which the pile tip is located (for clays, Fs = 50), αs is a coefficient equal to 1.25 and qcs is the average cone resistance along the pile shaft. For circular foundations B = B′ and a B′ value can be calculated from Equation 13.

3 Calculation arrangements

The GEC column is treated as a special kind of “pile” and its bearing capacity is calculated using five selected methods for determining the pile bearing capacity based on CPTU tests.

This paper considers the characteristic value of the bearing capacity Qk (Figure 1) of a single column for reinforcingweak subsoil for plans with large dimensions (road embankments, spatial structures). Negative friction was omitted in the calculations because the reinforced soil mattress on the subsoil causes settlement of the column and the weak subsoil surrounding the column to be equal. The calculations were carried out for columns with diameter Dk equal to 0.8 m.

Geometry of the problem.

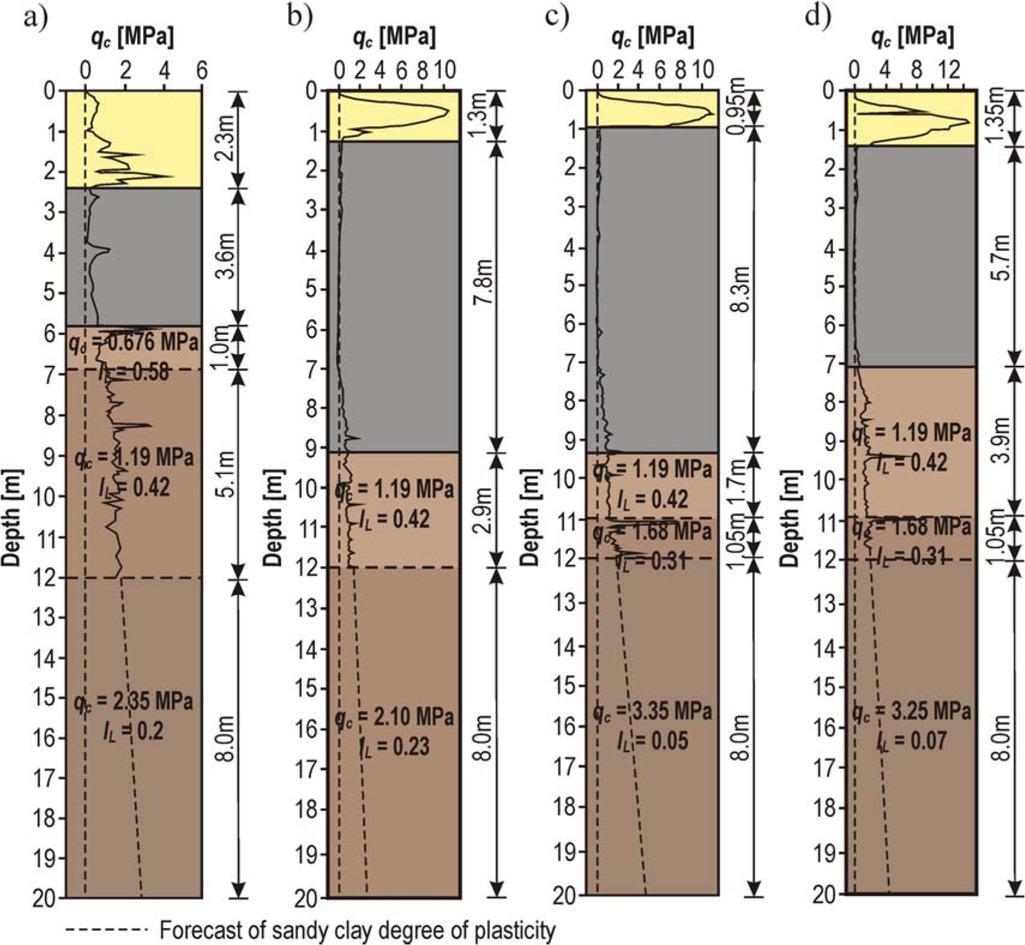

The bearing capacity of floating GEC columns was determined on the basis of CPTU tests carried out on one of the sections of the Bargłów Kościelny bypass, where a weak subsoil was reinforced with floating GEC columns.

On the analyzed section of the Bargłów Kościelny bypass, there are organic soils, mainly peat with a thickness of from about 3 m to about 9 m. Below the organic soils there are glacial deposits in the form of sandy clays. On top of the layer of glacial deposits, the clays are soft. With depth, the moisture of the cohesive soils decreases, and thus the liquidity index decreases, dropping to a value corresponding to stiff clay. The ground water level is located at a depth of 0.2–0.3 m below the ground surface.

The relationships between the liquidity index IL of sandy clay and the cone resistance qc, undrained shear strength cu and sleeve friction fs were determined on the basis of the CPTU penetration tests (Figure 2).

Relationships between: a) qc – IL, b) cu – IL, c) fs – IL.

Bearing capacity of the columns was calculated for soil conditions determined in four selected locations located on the section of Bargłów Kościelny bypass under consideration. The analyzed locations were spaced about 30mapart. The calculations weremade for different depths of columns in the weak subsoil zk (Figure 1) equal to 0, 0.75, 1.5 and 3.0 m for location 1 and 4; 0, 0.75, 1.5 and 2.5 for location 2; and 0, 0.75, 1.5 and 2.0 for location 3.

Different values of the maximum depth for locations 2 and 3 are due to the fact that a depth of 3 m would mean that the tip of the column would be located in stiff soil and the column would not be a floating column.

Figure 3 presents the results of the CPTU tests in the four selected locations located on the section of the Bargłów Kościelny bypass under consideration and the thickness of the layers of peat and sandy clay with a variable liquidity index IL.

CPTU tests were carried out to a depth of about 12 m, which wouldbe insufficient to make calculations based on the cone resistance graphs; therefore a forecast of the liquidity index was made to a depth of 20 m (Figure 3).

Results of CPTU tests: a) location 1, b) location 2, c) location 3, d) location 4.

Table 1 shows the values of the cone resistance, sleeve friction and undrained shear strength from Figure 2 for different liquidity indexes of the sandy clay located at the tip of the floating GEC column.

Parameters of the sandy clay determined on the basis of the CPTU penetration tests.

| Degree of plasticity IL | Cone resistance qc | Sleeve friction fs | Undrained shear strength cu |

|---|---|---|---|

| [-] | [kPa] | [kPa] | [kPa] |

| 0.58 | 676.1 | 11.05 | 30.10 |

| 0.42 | 1193.4 | 23.67 | 56.98 |

| 0.31 | 1679.9 | 34.67 | 81.90 |

4 Bearing capacity of the floating GEC columns

Figure 4 shows the bearing capacity of the floating columns at different depths of the column tip in the soft sandy clay for the five selected calculation methods.

Bearing capacity of the floating GEC columns: a) location 1, b) location 2, c) location 3, d) location 4.

5 Conclusions

From the calculations, comparable values of the column bearing capacity were obtained for the five calculation methods analyzed in this paper. Differences in the values for the different calculation methods are due to the different assumptions on which the methods were based.

In all the analyzed locations, the lowest bearing capacity of the column was determined using the LCPC method. The highest bearing capacity was calculated using the European and Schmertmann methods, and for location 3, using the DIN 4014 method.

The bearing capacity of the columns increased with increasing depth of the column tip in sandy clay. A more than three times higher bearing capacity that varied with the depth was observed in location 1.

The highest bearing capacity was determined for the columns in location 3, while the smallest was for the columns in location 1. This can be related to the soil conditions in each individual location.

The methods of determining the bearing capacity of floating GEC columns described in this paper do not allow the distribution of the load in the columns and weak subsoil to be included in the calculations; thus, it does not take into account cooperation between the column and the surrounding soil. However, the author believes that these methods can be successfully used to pre-estimate the bearing capacity of floating GEC columns based on the results of CPTU penetration tests.

Main Nomenclature

- Ak

column base area

- As

column shaft area

- cu

undrained shear strength

- Dk

column diameter

- fp

shaft resistance

- fs

sleeve friction

- IL

liquidity index

- Qbk

column base capacity

- qb

unit end-bearing pressure

- qc

cone resistance

- Qk

column bearing capacity

- Qsk

column shaft capacity

- qt

corrected cone resistance

- zk

depth of the column base

- CPTU

cone penetration test

- GEC

geosynthetic encased column

Acknowledgement

This paper, carried out at Bialystok University of Technology, was supported by Polish financial resources on science under project WZ/WBiIŚ/7/2019.

References

[1] Ng KS, Tan SA. Design and analyses of floating stone columns. Soils and Foundations. 2014;54(3):478-87.10.1016/j.sandf.2014.04.013Suche in Google Scholar

[2] EBGEO. Recommendations for Design and Analysis of Earth Structures using Geosynthetic Reinforcements. Berlin, Germany: Ernst & Sohn. A Wiley Company; 2011.Suche in Google Scholar

[3] Chmielewska I. Wpływ technologii wykonania zawieszonej kolumny GEC na jej nośność i osiadanie [dissertation]. Bialystok University of Technology; 2019. Polish.Suche in Google Scholar

[4] Bustamante M, Gianeselli L. Pile bearing capacity prediction by means of static penetrometer CPT. Proceedings of the Second European Symposium on Penetration Testing; 1982 May 24-27; Amsterdam, The Netherlands. USA: MBS; 1982. p. 493-500.Suche in Google Scholar

[5] De Ruiter J, Beringen FL. Pile foundation for large North Sea structures. Marine Geotechnology. 1979;3(3):267-314.10.1080/10641197909379805Suche in Google Scholar

[6] DIN 4014: 1990-03. Bored cast in place piles – Formation, design and bearing capacity; 1990.Suche in Google Scholar

[7] Schmertmann JH. Guidelines for cone penetration test, performance and design. Final Report. United States Department of Transportation (Washington); 1978 Dec. Report No. FHWA-TS-78-209.Suche in Google Scholar

[8] Philipponnat G. Methode pratique de calcul d’un pieu isole a l’aide du penetrometre statique. Revue Francaise de Geotechnicue. 1980;10:55-64. French.10.1051/geotech/1980010055Suche in Google Scholar

[9] Schnaid F. In situ testing in geomechanics. The main tests. London and New York: Taylor & Francis; 2009.10.1201/9781482266054Suche in Google Scholar

[10] PN-EN 1997-2. Eurokod 7: Projektowanie geotechniczne – Część 2: Rozpoznanie i badanie podłoża gruntowego; 2009. Polish.Suche in Google Scholar

[11] Kowalska M, Orzeł A. Identyfikacja rodzaju gruntu oraz parametrów wytrzymałościowych podłoża na podstawie wyników badań sondą statyczną CPTU. Przegląd Komunikacyjny. 2014;8:31-6. Polish.Suche in Google Scholar

© 2020 I. Chmielewska, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor

Artikel in diesem Heft

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor