Abstract

The paper presents the results of tests on the geometric structure of the surface, hardness and tribological tests of coatings produced by the method of physical vapor deposition (PVD) on the Ti13Nb13Zr alloy. Hardness was determined using MCT3 from Anton Paar, by instrumental indentation. A diamond indenter with Berkovich geometry was used for the measurement.Model tribological tests were carried out in reciprocating motion under conditions of technically dry friction, friction with lubrication of synovial fluid and Ringer’s solution. The counter-sample in the tested friction nodes was a ball of Al2O3 with a diameter of 6 mm. Nanometer hardness measurements showed that as a result of the diamond-like carbon coating (DLC), the hardness increased by an 7-fold. The lowest friction coefficients among all tested friction nodes were obtained for the material combination Ti13Nb13Zr a-C:H - Al2O3 regardless of the conditions of testing. In the case of technically dry friction, the coefficient of friction decreased by 80%, synovial fluid by 70%, and in the case of Ringer’s solution by 88% compared to the results obtained for Ti13Nb13Zr.

1 Introduction

In recent years there was a significant progress both in the testing and application subject regarding the amorphous carbon. The amorphous carbon might be the mixture of the atoms with the sp3, sp2 or even sp1 bonds, with the possibility of the hydrogen presence. Amorphous carbonic materials are characterized with high variety of structure, and their properties mainly due to the type and parameters of their production [1]. However, one of the important factors crucial regarding their properties is a sp3 bonds existing in diamond’s structure - responsible for a high hardness, and sp2 bonds - existing in graphite, resulting in excellent lubricating properties. Amorphous carbon with high contents of diamond sp3 bonds is known as DLC [2].

Due to their characteristics, diamond-like coatings are becoming increasingly important in today’s industry. Very good mechanical properties such as high elastic modulus, fracture resistance, chemical stability and low friction coefficient enable their use in various branches of industry. These coatings are used in automotive, aviation, chemical and medical industries [3, 4, 5, 6, 7].

The need to meet the requirements of the current market has resulted in a rapid development of manufacturing techniques both in terms of materials and construction. The deposited layers are characterized by increasing hardness and resistance to frictional wear. There is also a tendency of continuous reduction of their thickness and application of multilayer coatings. One of the fastest-wearing trends are modern techniques of surface engineering, including the formation of thin, hard diamond-like DLC coatings. A limitation in the widespread use of DLC coatings is the lack of comprehensive knowledge about their properties. The same layers applied with different methods and different parameters of the deposition process may have completely different properties. The selection of a anti-wear coating for a specific application requires detailed knowledge of its mechanical and tribological properties. Therefore, it is necessary to carry out tests of the coating-substrate systems [8, 9, 10]. The evaluation of tribological properties is carried out on the basis of the friction and wear characteristics, conducted under conditions of technically dry friction and friction with lubricating agents. In order to determine the hardness, elastic modulus and adhesion of the coating to the substrate, indentation and scratching tests are used. The results obtained during these tests will facilitate the selection of the coating and the development of an optimal technological process of deposition in the aspect of its application.

2 Materials and methods

A single-layer a-C:H diamond-like coating applied at the temperature of 250∘C using physical vapor deposition method (PVD) was investigated. The substrate was titanium alloy Ti13Nb13Zr.

The nano-hardness of the coating was determined using the Anton Paar UNHT ultra-nano hardness tester by means of instrumental indentation method. The test consisted in pressing into the tested material of an indenter of Berkovich geometry (Figure 1) with a radius of Ri = 100nm [11]. The measurement was made at a nominal load force of 10mN and a buildup speed of 20mN/min.

Geometry of Berkovich indenter

The applied research technique enabled precise recording of the load-indentation depth curve. Mechanical parameters, e.g. elastic modulus, were determined taking into account the inclination of the tangent to the initial part of the load curve, according to the Olivier-Pharr method based on the relation [12, 13, 14]:

where:

Ei , νi – indenter modulus and Poisson’s ratio

E, ν – sample modulus and Poisson’s ratio

S – stiffness

Ap – projected contact area

Nano-hardness is the ratio of the load force Pmax to the surface of the imprint after relieving A:

In addition, the load-relief curve provides information about the deformation of the material during the test and allows the determination of such parameters as: total work (total field under the recorded load-relief curve), elastic deformationwork (field under the relief curve) and plastic deformation work (field inside the load-displacement curve) [15].

During the test it is possible to measure the geometric parameters of a scratch, perform its microscopic analysis and record the acoustic emission during cracking of the coating [16]. The test was carried out on an MCT3 device manufactured by Anton Paar. It consisted in making a scratch on the surface of the sample with a diamond indenter Rockwell C (Figure 2) under a load of normal force FN. Destruction of the surface layer may have the character of cohesive cracks - perpendicular to the direction of the indenter motion or adhesive cracks - manifested as local delaminations of the coating [9]. The test was performed at an increasing load force of 0.03-15N, table travel speed of 1.2mm/min, table load speed of 10N/min and scratch length of 3mm.

A schematic illustrating w scratch test on a coated sample

The use of diamond-like coatings in various branches of industry also forces the need to carry out tests of resistance to wear through friction together with the determination of the friction coefficient. The tribological tests were conducted using a TRB3 ball-on disc system. In the TRB3 tribometer, a rotating ball made of Al2O3 (diameter = 6 mm) was pressed against a test sample (Ti13Nb13Zr with and without an a-C:H-type diamond-like carbon coating), applying a amplitude 1Hz and a load of 10N. The number of cycles was 10 000. The specimens were tested under dry friction conditions (TDF) and under lubricated friction conditions using Ringer solution (RS) and synovial fluid (SF). The tests were performed in laboratory conditions at a relative humidity of 50 ±5% and a temperature of 23 ±1∘C.

View of ball-on-disc

3 Discussion and results

The thickness of the diamond-like coating was measured at using a Phenom XL scaning microscope. Figure 4a shows a view of DLC coatings in cross-section together with its thickness measured. The green arrow indicates the direction of the linear analysis. The resultant DLC coating has a thickness of about 1.74 μm. During follow-up there were no defects and discontinuities structure. EDS analysis of a coating a-C:H (Figure 4b) showed that it consists of the subcoatings. The layer on the surface is mainly the carbon. An interlayer of thickness 0.98 μm lying between the substrate and the layer of a-C:H forms subcoat consisting essentially of wolfram with a small extent of chromium. Chromium and tungsten interlayer are responsible for increasing the adhesion of the DLC coating to the substrate.

The thickness of DLC coatings (a), distribution of elements from the surface down into the a-C:H coating atomic percentage (b)

Figure 5 presents the load-relief curves recorded when the indenter is pushed into the tested materials. Based on the measurement of indenter penetration depth and the knowledge of the geometry of the imprint, the mechanical parameters discussed above were determined. Table 1 shows their averaged values from 10 measurements.

Load – penetration depth curves from indentation tests

Mechanical parameters

| Parameters | Unit | Sample | |

|---|---|---|---|

| Ti13Nb13Zr | Ti13Nb13Zr a-C:H | ||

| Indentation hardness [HIT] | GPa | 3.5 | 25.5 |

| Vickers Hardness [HV] | HV | 331 | 2 328 |

| Young Modulus [E*] | GPa | 143 | 209 |

| Contact area [Ap] | μm2 | 2.822 | 4.292 |

| Plastic work [Wplast] | pJ | 1 035.2 | 153.2 |

| Elastic work [Welast] | pJ | 252.6 | 460.2 |

| Total work [Wtot] | pJ | 1 287.8 | 613.5 |

The curves shown in Figure 5 indicate high plasticity of the substrate and elasticity of the a-C: H coating. This is evidenced by the inclination of the indentation curve and the values of contact surfaces, total work, elastic and plastic deformation work.

As a result of application of the diamond-like coating, there was an 7-fold increase in hardness, almost 2-fold increase in elastic modulus, and a reduction in creep properties. This is proven by a decrease in the value of the increment in the penetration depth under the set load. In addition, the use of a diamond-like coating of a-C:H type caused a double decrease in the value of the total work of indentation Wtot and its components Wplast and Welast, which indicates a decrease in the susceptibility of the coating to deformation as a result of operating loads.

The measure of the adhesion of a layer to the substrate is the critical force that first causes the LC1 coating to crack and then destroys it (LC2). Figure 6 presents the results of the scratch test. The critical force was evaluated on the basis of microscopic observations and registered changes in acoustic emission. The values of the forces causing the first LC1 chip and the delamination of the LC2 layer are summarized in Table 2.

Scratch test results a) graph of variation of loading force and acoustic emission, b) scratch track: first critical load (LC1), second critital load (LC2)

The adhesion tests of diamond-like carbon coating

| Measurement number | ||||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | Mean | Standard deviation | ||

| LC1 | [N] | 2.87 | 3.02 | 2.98 | 2.95 | 0.06 |

| LC2 | [N] | 9.63 | 9.87 | 10.1 | 9.86 | 0.19 |

Tests of adhesion of the diamond-like layer showed that the mean value of the critical force LC1 was 2.95 N and LC2 - 9.86 N. The microscopic analysis showed that the destruction of the surface layer had the character of adhesive cracks. This type of cracks is visible in the form of local delaminations on the sides of the scratch or tearing off the coating in front of the indenter.

The results of friction tests were summarized on a graph of the friction coefficient - μ (Figure 7) of test elements depending on the types of materials, friction pairs and lubricants used.

Mean coefficient of friction during: technical dry friction (TDF), Ringer solution (RS) and synovial fluid (SF)

Figure 7 indicates that the best tribological characteristics were obtained for the material combination of Ti13Nb13Zr with a DLC - Al2O3 coating using Ringer’s solution as a lubricant. In the case of technically dry friction and friction with lubrication using synovial fluid solution, the recorded values of the friction coefficient were comparable. They were respectively 0.11 and 0.12. In comparison with the Ti13Nb13Zr substrate they were80%lower for TDF, 88% lower for RS and 70% lower for SF.

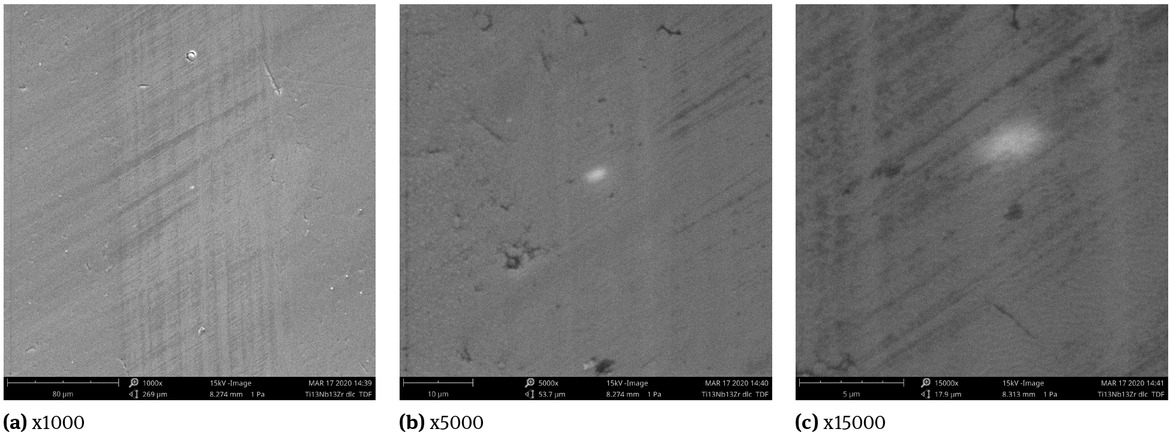

After tribological tests, surface morphology observation (Figure 8-13) and analysis of the geometric structure of the surface were conducted (Figure 14-15). The maximum depth and the area of the friction surface determined on the basis of the generated profile of the worn out surface (after tribological tests) were taken as the measure of the sample’s wear (Figure 16).

Surface morphology of the wear traces after techncal dry friction (TDF) for Ti13Nb13Zr

Surface morphology of the wear traces after friction with Ringer’s solution (RS) for Ti13Nb13Zr

Surface morphology of the wear traces after friction with synovial fluid (SF) for Ti13Nb13Zr

Surface morphology of the wear traces after techncal dry friction (TDF) for Ti13Nb13Zr a-C:H

Surface morphology of the wear traces after friction with Ringer’s solution (RS) for Ti13Nb13Zr a-C:H

Surface morphology of the wear traces after friction with synovial fluid (SF) for Ti13Nb13Zr a-C:H

The isometric image of the trace of wear and the wear profile in a cross-section for Ti13Nb13Zr a) TDF, b) RS, c) SF

The isometric image of the trace of wear and the wear profile in a cross-section for Ti13Nb13Zr a-C:H a) TDF, b) RS, c) SF

The area of wear in a cross-section

Analysis of the surface of the wear trace (Figures 14-15) indicates that for Ti13Nb13Zr during technically dry friction, friction using Ringer’s solution and synovial fluid, the dominant wear mechanism is abrasive wear. This is due to the different properties of the materials from which the friction components have been made. The ball hardness with Al2O3 is several times higher than the Ti13Nb13Zr titanium alloy. The scratches and furrows visible in the SEM images were created due to the movement of loose wear products in the friction area. In the case a single-layer a-C:H diamond-like coating, the trace of wear was invisible.

Test results of the geometric structure of the surface after tribological tests shows that the diamond-like coating has a high resistance to abrasion. This is evidenced by the very small area of the wear field (Figure 16). In the case of the Ti13Nb13Zr substrate, the lowest wear was observed in tests in which the Ringer’s solution was used. It was lower by 5% and 15% respectively in comparison with TDF and SF.

4 Conclusion

The results of nano-hardness measurements showed that as a result of diamond-like coating deposition there was an 80% increase in hardness. Moreover, it was observed that the Ti13Nb13Zr substrate is characterized by high plasticity and the a-C: H-type coating by elasticity. Tests of adhesion of the diamond-like layer showed that the mean critical force at which the first cracking of the coating occurs (LC1) is 2.95 N, while the total delamination of the layer occurs at a force of 9.86 N. It was also observed that the destruction of the coating had the character of adhesive cracks. Among all investigated material pairs, the best tribological characteristics were obtained for Ti13Nb13Zr and a-C:H – Al2O3 using Ringer’s solution as lubrication. The obtained results showed that the application of DLC coatings significantly increased the hardness and reduced the friction pair movement resistance. The analysis of the morphology of wear trace and geometric structure of the surface after tribological tests revealed high wear resistance of the a-C:H type coating.

References

[1] Forsich C, Heim D, Mueller T. Influence of the deposition temperature on mechanical and tribological properties of a-C:H:Si coatings on nitrided and postoxidized steel deposited by DC-PACVD. Surf Coat Tech 2008;203:521–5.10.1016/j.surfcoat.2008.05.044Suche in Google Scholar

[2] Madej M, Ozimina D, Kurzydłowski K, Płociński T, Wieciński P, Styp-Rekowski M. Some operational features of coating obtained with PACVD method. J. Mech. Eng. 2012;12:53-66.Suche in Google Scholar

[3] Pawelec K, Baranowicz P, Wysokińska-Miszczuk J, Madej M. The influence of diamond-like coatings on the properties of titanium. MRF. 2018;5:84-9.Suche in Google Scholar

[4] Zimowski S, Kot M, Moskalewicz T. The effect of mec nanoparticles on the micromechanical and tribological properties of carbon composite coatings. Tribologia. 2018;4:157-63.10.5604/01.3001.0012.7557Suche in Google Scholar

[5] Gałuszka G, Madej M, Ozimina D, Kasińska J, Gałuszka R. The characterisation of pure titanium for biomedical applications. MJoM. 2017;56:191-4.Suche in Google Scholar

[6] Catania G, Strozzi M. Damping Oriented Design of Thin-Walled Mechanical Components by Means of Multi-Layer Coating Technology. Coatings. 2018;8;73.10.3390/coatings8020073Suche in Google Scholar

[7] Balandin A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011;10:569–81.10.1038/nmat3064Suche in Google Scholar

[8] Posti E, Nieminen I. Influence of coating thickness on the life of TiN – coated high speed steel cutting tools. Wear. 1989;129:273-83.10.1016/0043-1648(89)90264-0Suche in Google Scholar

[9] Chronowska-Przywara K, Kot M, Zimowski S. Research techniques in the analysis of mechanical and tribological properties of thin layers and coatings. Scientific notebooks of the SUT. 2014;83:39-49.Suche in Google Scholar

[10] Kot M. Deformations and fracture analysis of coating-substrate systems using indentation method with different indenter. Tribologia. 2011;2:47-60.Suche in Google Scholar

[11] PN-EN ISO 14577-1:2015-09. Metallic materials — Instrumented indentation test for hardness and materials parameters — Part 1: Test methodSuche in Google Scholar

[12] Schuh AC. Nanoindentation Studies of Materials. Mater. Today. 2006;9:32-4010.1016/S1369-7021(06)71495-XSuche in Google Scholar

[13] Sakharova NA, Fernandes JV, Antunes JM, Oliveira MC. Comparison between Berkovich, Vickers and conical indentation tests: A three-dimensional numerical simulation study. Int J Solids Struct. 2009;46:1095-104.10.1016/j.ijsolstr.2008.10.032Suche in Google Scholar

[14] Tarnowski J, Gawędzki W, Kot M. Study of the modulus of elasticity and the microhardness changes of nikasil coatings in cylinder sleeves of combustion engines due to wear. Tribologia. 2015;3:183-92.Suche in Google Scholar

[15] Maszybrocka J, Cybo J, Barylski A. The applications of microindentation for an assessment of radiation modification of UHMPE from the acpect of reducing the effects of plastic deformation od polimer elements of endoprotheses. Technical transactions Mechanics. 2009;3:215-19.Suche in Google Scholar

[16] Li XX, He JH. Nanoscale adhesion and attachment oscillation under the geometric potential. Part 1: The formation mechanism of nanofiber membrane in the electrospinning. Results in Physics. 2019;12:1405-10.10.1016/j.rinp.2019.01.043Suche in Google Scholar

© 2020 K. Piotrowska et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor

Artikel in diesem Heft

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor