The Use of Statistical Functions for the Selection of Laser Texturing Parameters

-

Piotr Sęk

Abstract

Laser surface texturing is currently the most developed technique for producing fully reproducible microcavities on the surfaces of machine elements. From the point of view of texture technology, an important aspect is the proper selection of process parameters to obtain texture elements with desirable and repetitive geometries and physicochemical properties. Surface texturing improves mottling and fretting resistance and is also used wherever the adhesion properties of surface layers (printing techniques, bonding materials, biological and chemical activity, coatings, etc.) are important. The article shows the possibility of applying statistical functions to the selection of appropriate machining parameters to obtain microgeometry useful in the application of textured surfaces [1].

1 Introduction

The development of technology places very high demands on the reliability and durability of machine elements, while constantly increasing the threshold values for their operating parameters. One of the ways to meet these demands is to direct the efforts of designers and technologists to activities towards involving the formation of micro-geometry of selected surfaces of machine elements. This is facilitated by advances in technology, which in recent years has made good progress, especially in the area of laser technology, enabling local intensified impact on the workpiece.

In order to achieve maximum material utilization and the best possible material performance, it is extremely important to modify the material surface properties. For example, it is possible to influence the surface morphology and its absorption properties by changing the structure of the material [2] or chemical impurities contained in the surface. The susceptibility of a material to abrasion and surface damage may be reduced by changing the chemical composition, morphology and crystal structure of its surface [3]. Moreover, it can beassumed that the forces of friction, adhesion and wetting occurring in the transitional (interphase) layer of the material are largely determined by the size and shape of the elements in the micro and nanoscale [4]. Currently, surface engineering focuses on the modification of surface microgeometry in order to improve its performance properties, while trying not to affect the structure and mechanical properties of the workpiece.

A laser beam is a carrier that allows to obtain a very high concentration of energy in terms of area and time of impact on the workpiece. In laser micromachining, the area of the actual impact on the material is determined by the size of the focused laser dot or the mask that transmits only the desired portion of the beam. The impact of the beam pulse time is particularly important as different mechanisms of impact on the material can be used depending on the radiation intensity and exposure time. This is due to the finite response times of electrons and atomic network of the material to photons. One of the main advantages of laser as a tool for material processingis the ability to precisely control where and at what rate energy is deposited. This control is carried out by appropriate selection of laser processing parameters in order to achieve the desired material modification [1, 5, 6, 7, 8].

Laser ablation is the removal of material from the substrate by direct absorption of laser energy. Laser ablation is usually discussed in connection with pulse lasers, but it is also possible in the case of intense radiation of permanent waves. Above the ablation threshold, the thickness or volume of the material ablated per pulse usually exhibits a logarithmic increase together with fluence for short pulses or a linear increase for long pulses according to Beer-Lambert’s law. Microsecond and nanosecond pulses are long pulses whereas picosecond and femtosecond pulses are short or ultrashort pulses [1].

During laser ablation, different material removal mechanisms can activate depending on the specific material layout and laser processing parameters such as wave-length, fluence and pulse length [9, 10]. At low fluences, photothermal ablation mechanisms include evaporation and sublimation of a material. In the case of multicomponent systems, more volatile components can be depleted more quickly, changing the chemical composition of the remaining material. At higher fluences, the heterogeneous nucleation of steam bubbles leads to normal boiling.

The laser pulse length can have a significant impact on the dynamics of the ablation process. In general, since the pulse duration is shortened, energy is stored more quickly in the material, which leads to its faster removal. The amount of material excited directly by the laser has less time to transfer energy to the surrounding material before ablation [9].

Surface texturing has been used for many years as a method of improving tribological properties of surfaces. The formation of a controlled texture on one of two sliding surfaces in relative motion can have many positive effects, such as reduction of friction and wear and increase in the capacity of a sliding pair [1, 5].

In industrial processes such as protective coating application, catalysis, lubrication, flotation, gluing and printing, wettability of solids with various liquids is extremely important in practice. Studies of the properties of the surface layer of various solids, including surface free energy and wettability, which constitute important elements of the assessment of adhesive properties of solids necessary for the analysis of the effects of modification of their surface layer, have been underway for many years.Wettability and the SEP have long had its place in the research in the field of physics, chemistry, biology, materials engineering, and most recently in surface engineering [11].

Laser surface texturing surpasses mechanical (e.g. shot blasting, honing or blasting), chemical and electrical (electrical discharge texturing) methods because it allows local changes with a high degree of control over the shape and size of the resulting components and allows for greater size variation. It is generally cheaper than electron beam texturing and is therefore less restricted because it does not require a vacuum. Various textures can be produced in a well-defined way by controlling process parameters such as beam intensity, spatial and time profile,wave-lengths and selection of the environment (gaseous or liquid). The basic dimensions of surface attributes (e.g. the width of a melted or ablation area) are usually determined by the shape and size of the beam. In the case of LST, however, secondary attributes may form around the radiation area at microscale or even nanoscale due to the variety of mechanisms involved, including melting after ablation, re-solidification, or surface liquid splashes resulting from the jet pressure. These secondary attributes may be as important as the primary dimensions when determining the function of the material in the selected application [5, 12, 13, 14, 15].

Currently, surface engineering focuses on the modification of surface microgeometry in order to improve its performance properties, while trying not to affect the structure and mechanical properties of the workpiece.

Currently, many studies are available on the impact of LST application on the operational properties of machine components. Most of them focus on the impact of texture application on friction reduction in sliding friction pairs and adjusting adhesive properties of modified surfaces. Yet mostly it is associated with the mere application of this solution. In my previous research [1, 5, 12] I showed that the most important factor influencing the operational behavior of a textured surface is the microgeometry of individual texture elements. The most important factor affecting the reduction of friction is the ratio of depth to diameter of the texture element and in the case of impact on contact angles and free surface energy, the most important micro-geometry parameter is the mutual distance of the texture elements. It is essential to study the influence of machining parameters on texture geometry and to use of appropriate parameters for obtaining a texture with geometry that will have a significant impact on the planned application.

2 Experiment

When producing the test samples, the average power range of laser radiation from 5W to 1.5W and laser pulse frequencies of 400kHz, 200kHz, 133.33kHz, 100kHz, 80kHz and 66.66kHz were examined. For average power less than 1.5W and frequencies less than 66.66kHz, the fluence was less than 1.33 J/cm2; no significant influence of machining on the material or ablative mass loss was observed. It can therefore be concluded that 1.33 J/cm2 is the threshold fluence n for 100Cr6 steel. All samples were produced at a constant scanning speed of 100 mm/s. The set diameter of the microcavity was 100μm. The surfaces of the samples were prepared before laser processing on a specimen polisher (Ra = 0.392÷0.694, Rz = 1.336÷1.919).

Taylor Hobson’s Talysurf CCI optical profiler, using a consistent correlation interferometry method with a range of 2.2mm and a resolution of 0.01nm in an x50 zoom lens to measure 330 μm× 330 μm× 27.7∘ slope and 330 μmarea, was used to determine the geometry of the microcavities. For each sample, 3 measurements were taken concentrating on the depth of the microcavity, its volume, the height of the flash and the deviation from the set diameter. Coherent Correlation Interferometry (CCI) based on the collection of interference stripe images and their location during vertical scanning combines vertical scanning with optical interferometry. The limitation of this method when measuring microcavities is the numerical aperture of the lens used, which limits the possibility of measuring on slopes with high inclination. Using a lens with too small aperture for measuring steep slopes will result in areas with non-measured points marked as white spots in the surface topography image [1, 5, 12]. Table 2 presents the average values of 3 measurements of the geometry of the tested samples.

Comparison of parameters of laser micromachining of tested samples

| N | P [W] | f [kHz] | F [J/cm2] | N | P [W] | f [kHz] | F [J/cm2] |

|---|---|---|---|---|---|---|---|

| 1 | 5 | 400 | 4.76 | 46 | 3.25 | 100 | 2.96 |

| 2 | 5 | 200 | 4.69 | 47 | 3.25 | 80 | 2.92 |

| 3 | 5 | 133.3 | 4.62 | 48 | 3.25 | 66.66 | 2.88 |

| 4 | 5 | 100 | 4.56 | 49 | 3 | 400 | 2.85 |

| 5 | 5 | 80 | 4.49 | 50 | 3 | 200 | 2.81 |

| 6 | 5 | 66.66 | 4.43 | 51 | 3 | 133.3 | 2.77 |

| 7 | 4.75 | 400 | 4.52 | 52 | 3 | 100 | 2.73 |

| 8 | 4.75 | 200 | 4.46 | 53 | 3 | 80 | 2.69 |

| 9 | 4.75 | 133.3 | 4.39 | 54 | 3 | 66.66 | 2.66 |

| 10 | 4.75 | 100 | 4.33 | 55 | 2.75 | 400 | 2.62 |

| 11 | 4.75 | 80 | 4.27 | 56 | 2.75 | 200 | 2.58 |

| 12 | 4.75 | 66.66 | 4.20 | 57 | 2.75 | 133.3 | 2.54 |

| 13 | 4.5 | 400 | 4.28 | 58 | 2.75 | 100 | 2.51 |

| 14 | 4.5 | 200 | 4.22 | 59 | 2.75 | 80 | 2.47 |

| 15 | 4.5 | 133.3 | 4.16 | 60 | 2.75 | 66.66 | 2.43 |

| 16 | 4.5 | 100 | 4.10 | 61 | 2.5 | 400 | 2.38 |

| 17 | 4.5 | 80 | 4.04 | 62 | 2.5 | 200 | 2.35 |

| 18 | 4.5 | 66.66 | 3.98 | 63 | 2.5 | 133.3 | 2.31 |

| 19 | 4.25 | 400 | 4.04 | 64 | 2.5 | 100 | 2.28 |

| 20 | 4.25 | 200 | 3.99 | 65 | 2.5 | 80 | 2.25 |

| 21 | 4.25 | 133.3 | 3.93 | 66 | 2.5 | 66.66 | 2.21 |

| 22 | 4.25 | 100 | 3.87 | 67 | 2.25 | 400 | 2.14 |

| 23 | 4.25 | 80 | 3.82 | 68 | 2.25 | 200 | 2.11 |

| 24 | 4.25 | 66.66 | 3.76 | 69 | 2.25 | 133.3 | 2.08 |

| 25 | 4 | 400 | 3.81 | 70 | 2.25 | 100 | 2.05 |

| 26 | 4 | 200 | 3.75 | 71 | 2.25 | 80 | 2.02 |

| 27 | 4 | 133.3 | 3.70 | 72 | 2.25 | 66.66 | 1.99 |

| 28 | 4 | 100 | 3.65 | 73 | 2 | 400 | 1.90 |

| 29 | 4 | 80 | 3.59 | 74 | 2 | 200 | 1.88 |

| 30 | 4 | 66.66 | 3.54 | 75 | 2 | 133.3 | 1.85 |

| 31 | 3.75 | 400 | 3.57 | 76 | 2 | 100 | 1.82 |

| 32 | 3.75 | 200 | 3.52 | 77 | 2 | 80 | 1.80 |

| 33 | 3.75 | 133.3 | 3.47 | 78 | 2 | 66.66 | 1.77 |

| 34 | 3.75 | 100 | 3.42 | 79 | 1.75 | 400 | 1.66 |

| 35 | 3.75 | 80 | 3.37 | 80 | 1.75 | 200 | 1.64 |

| 36 | 3.75 | 66.66 | 3.32 | 81 | 1.75 | 133.3 | 1.62 |

| 37 | 3.5 | 400 | 3.33 | 82 | 1.75 | 100 | 1.60 |

| 38 | 3.5 | 200 | 3.28 | 83 | 1.75 | 80 | 1.57 |

| 39 | 3.5 | 133.3 | 3.24 | 84 | 1.75 | 66.66 | 1.55 |

| 40 | 3.5 | 100 | 3.19 | 85 | 1.5 | 400 | 1.43 |

| 41 | 3.5 | 80 | 3.14 | 86 | 1.5 | 200 | 1.41 |

| 42 | 3.5 | 66.66 | 3.10 | 87 | 1.5 | 133.3 | 1.39 |

| 43 | 3.25 | 400 | 3.09 | 88 | 1.5 | 100 | 1.37 |

| 44 | 3.25 | 200 | 3.05 | 89 | 1.5 | 80 | 1.35 |

| 45 | 3.25 | 133.3 | 3.01 | 90 | 1.5 | 66.66 | 1.33 |

where:

N– sample number

P– adjustable laser power [W]

f– laser pulse frequency [kHz]

F– laser radiation fluence [J/cm2]

Results of measurements of geometry of tested samples

| N | hp [μm] | V [μm] | hw [μm] | ᐃø [μm] | N | hp [μm] | V [μm] | hw [μm] | ᐃø [μm] |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 3.37 | 7039.11 | 1.03 | 1.08 | 46 | 0.83 | 2339.58 | 0.12 | 0.10 |

| 2 | 1.31 | 4691.53 | 0.74 | 0.99 | 47 | 1.03 | 3085.22 | 0.27 | 0.10 |

| 3 | 1.27 | 4659.95 | 0.73 | 0.93 | 48 | 0.82 | 2042.91 | 0.19 | 0.09 |

| 4 | 1.11 | 3842.18 | 0.68 | 0.81 | 49 | 3.61 | 5577.23 | 0.58 | 0.12 |

| 5 | 0.86 | 3338.72 | 0.56 | 0.78 | 50 | 1.82 | 5276.71 | 0.53 | 0.11 |

| 6 | 0.84 | 2052.12 | 0.62 | 0.74 | 51 | 1.61 | 4681.09 | 0.42 | 0.10 |

| 7 | 2.86 | 8878.55 | 2.64 | 1.04 | 52 | 0.85 | 1839.51 | 0.16 | 0.09 |

| 8 | 1.91 | 5191.08 | 1.04 | 0.95 | 53 | 1.01 | 2735.81 | 0.26 | 0.08 |

| 9 | 1.84 | 4874.18 | 0.56 | 0.89 | 54 | 0.97 | 2370.89 | 0.24 | 0.08 |

| 10 | 1.38 | 4638.32 | 0.61 | 0.78 | 55 | 2.70 | 7548.41 | 0.78 | 0.25 |

| 11 | 1.13 | 3984.54 | 0.57 | 0.75 | 56 | 1.87 | 5981.52 | 0.48 | 0.23 |

| 12 | 1.15 | 3641.88 | 0.54 | 0.71 | 57 | 1.12 | 2830.57 | 0.22 | 0.22 |

| 13 | 2.35 | 4840.24 | 1.22 | 0.97 | 58 | 1.07 | 2945.46 | 0.25 | 0.19 |

| 14 | 1.64 | 3594.67 | 0.76 | 0.89 | 59 | 0.67 | 1602.12 | 0.14 | 0.18 |

| 15 | 1.98 | 3771.97 | 0.55 | 0.84 | 60 | 0.82 | 1274.65 | 0.21 | 0.17 |

| 16 | 1.44 | 3794.18 | 0.57 | 0.73 | 61 | 2.19 | 4994.17 | 0.39 | 0.22 |

| 17 | 1.53 | 4292.34 | 0.71 | 0.70 | 62 | 1.64 | 4857.72 | 0.36 | 0.20 |

| 18 | 1.39 | 4076.31 | 0.64 | 0.67 | 63 | 1.03 | 3358.46 | 0.33 | 0.19 |

| 19 | 2.54 | 6003.54 | 0.59 | 0.88 | 64 | 0.92 | 2644.21 | 0.23 | 0.17 |

| 20 | 1.56 | 5085.85 | 0.63 | 0.80 | 65 | 0.85 | 2190.64 | 0.19 | 0.16 |

| 21 | 1.41 | 3424.89 | 0.24 | 0.76 | 66 | 0.71 | 2081.01 | 0.18 | 0.15 |

| 22 | 1.49 | 4525.22 | 0.43 | 0.66 | 67 | 2.56 | 6285.55 | 0.55 | 0.48 |

| 23 | 1.45 | 4181.93 | 0.36 | 0.63 | 68 | 1.06 | 3168.32 | 0.29 | 0.44 |

| 24 | 1.13 | 3576.34 | 0.31 | 0.60 | 69 | 0.91 | 2409.12 | 0.25 | 0.42 |

| 25 | 3.21 | 9787.13 | 0.16 | 0.69 | 70 | 0.81 | 2008.04 | 0.17 | 0.36 |

| 26 | 2.81 | 9734.08 | 0.87 | 0.64 | 71 | 0.88 | 1475.01 | 0.13 | 0.35 |

| 27 | 1.62 | 5949.17 | 0.38 | 0.60 | 72 | 0.51 | 1390.06 | 0.11 | 0.33 |

| 28 | 1.51 | 4912.17 | 0.41 | 0.52 | 73 | 1.28 | 2938.98 | 0.22 | 0.42 |

| 29 | 1.53 | 3369.35 | 0.32 | 0.50 | 74 | 1.26 | 2912.14 | 0.27 | 0.39 |

| 30 | 1.28 | 3742.19 | 0.29 | 0.47 | 75 | 0.94 | 2002.81 | 0.19 | 0.36 |

| 31 | 2.59 | 9614.92 | 0.11 | 0.15 | 76 | 0.89 | 1559.17 | 0.15 | 0.32 |

| 32 | 2.57 | 9524.14 | 0.09 | 0.14 | 77 | 0.88 | 1275.93 | 0.13 | 0.31 |

| 33 | 1.53 | 5751.72 | 0.09 | 0.13 | 78 | 0.57 | 1117.49 | 0.14 | 0.29 |

| 34 | 1.42 | 3579.29 | 0.09 | 0.11 | 79 | 1.69 | 4675.54 | 0.39 | 0.92 |

| 35 | 1.18 | 2912.58 | 0.21 | 0.11 | 80 | 1.23 | 2800.33 | 0.25 | 0.84 |

| 36 | 1.17 | 2405.72 | 0.21 | 0.10 | 81 | 0.87 | 2351.41 | 0.23 | 0.79 |

| 37 | 3.81 | 9024.71 | 1.07 | 0.11 | 82 | 0.67 | 1814.66 | 0.15 | 0.69 |

| 38 | 2.38 | 7792.98 | 0.45 | 0.10 | 83 | 0.74 | 1452.02 | 0.13 | 0.66 |

| 39 | 1.12 | 3611.18 | 0.21 | 0.09 | 84 | 0.41 | 738.32 | 0.06 | 0.63 |

| 40 | 0.85 | 1347.98 | 0.16 | 0.08 | 85 | 1.02 | 1933.32 | 0.17 | 0.81 |

| 41 | 0.85 | 1347.21 | 0.15 | 0.08 | 86 | 0.72 | 1204.47 | 0.11 | 0.74 |

| 42 | 0.79 | 2275.08 | 0.21 | 0.07 | 87 | 0.51 | 1119.04 | 0.01 | 0.69 |

| 43 | 2.73 | 6128.57 | 0.56 | 0.13 | 88 | 0.65 | 933.18 | 0.12 | 0.60 |

| 44 | 0.85 | 3021.65 | 0.19 | 0.12 | 89 | 1.01 | 801.57 | 0.07 | 0.58 |

| 45 | 1.22 | 3102.98 | 0.29 | 0.12 | 90 | 0.42 | 553.71 | 0.05 | 0.55 |

where:

N– sample number

hp – microcavity depth obtained [μm]

hw – flash height obtained [μm]

ᐃø – difference between the set and the measured diameter of the microcavity [μm]

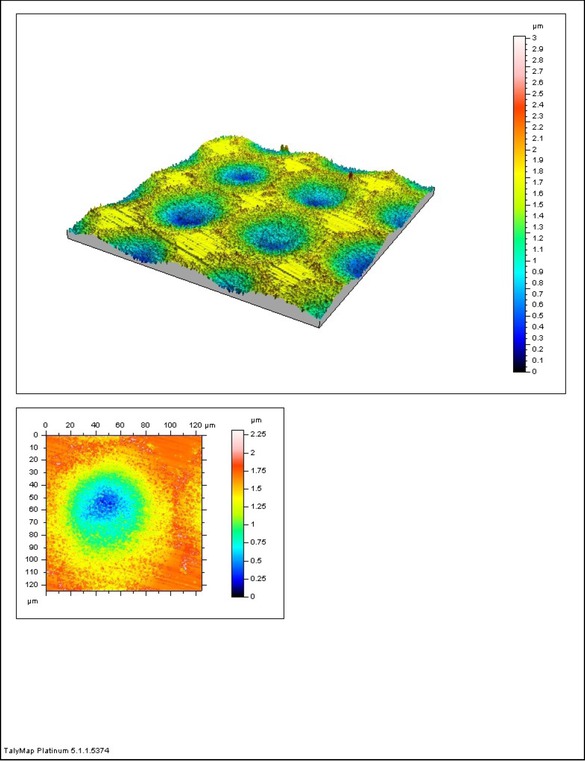

Isometric view of sample obtained with parameters: power 4W, frequency 133,33kHz, fluency 3,7 J/cm2

For F-values below 2.62 J/cm2, there is an insufficient quality of a single texture element due to insufficient energy supplied to the machined surface. Microcavities made at these F-values were inaccurate and their diameter was much smaller than the set diameter. In the case of machining with fluence higher than 3.57 J/cm2 we observe micro-cavities of irregular shape resulting from the melting of the material. The diameter of microcavities made at F-values greater than J/cm2 was greater than the set value.

3 Analysis of Results

In order to make a comprehensive assessment of the tested samples, taking into account all the accepted assessment criteria, the multi-criteria optimization method was applied, using the overall desirability function [16, 17, 18, 19]. The analysis was performed in the SAS system, version 9.4. In this method, all criteria considered are expressed in a common dimensionless scale. To construct such a scale, it is necessary to specify for each criterion y(i) the range of satisfactory values, indicating inferior value

In addition to ranges of satisfactory values, non-negative weighting factors reflecting the validity of each criterion are assigned to each criterion.Obviously, the sum of the weights must be equal to 1. The ranges of satisfactory values and weights for individual criteria should take into account the conditions of the intended use. Partial desirabilities assigned to each criterion y(i) are defined by the following formula:

Desirabilities Ui are numbers within the range (0;1), where numbers close to 0 correspond to particularly unfavorable values of y(i) attributeand those close to 1 – to the most favorable ones. When substituting the ”inferior” end of the range of satisfactory values, i.e.

The overall desirability U is defined as the weighted exponential mean of the partial desirabilities Ui.

where wi are the weights assigned to each criterion y(i),

The overall desirability U takes values from the range (0, 1), with higher values of U corresponding to more favorable properties of the tested sample.

By determining the overall desirability value it is possible to assess the tested sample on the basis of the whole set of criteria adopted, taking into account their validity. Optimization utilizing the desirability starts with numerous criteria, while in the last phase the task is reduced to single-criteria optimization. This is due to the fact that the overall desirability is a complex criterion, integrating all the requirements in the form of a single indicator. By determining the overall desirability value for individual samples, it is possible to classify them according to their suitability for the intended use.

The change of weights and ranges of satisfactory values does not require the repetition of tests, but only the repetition of calculations. This way it is made possible to, using the results of a single test cycle, consider multiple potential applications and determine the optimal solution each time.

This multi-criteria optimization method was used to determine solutions for two assumed laser texturing applications:

1st variant. Improvement of tribological properties of friction pairs (increase of hydrodynamic load capacity, reduction of friction resistance).

2nd variant. Surface enhancement for changes in surface energy (gluing, printing, photovoltaic applications).

Table 3 summarizes the ranges of satisfactory values and weights assigned to the criteria in two examples of laser texturing applications. The values in Table 3 are based on literature studies and the author’s own experimental research [1, 5, 12, 20, 21, 22].

Summary of ranges of satisfactory values and weights assigned to particular criteria in two assumed laser texturing applications

| Criteria | Ranges of satisfactory values | Weights 1st | Weights 2nd | |

|---|---|---|---|---|

| inferior value | superior value | variant | variant | |

| hp | 1.8 | 2.3 | 0.4 | 0.1 |

| V | 3700 | 4400 | 0.4 | 0.1 |

| hw | 0.6 | 0.2 | 0.1 | 0.3 |

| ᐃø | 0.8 | 0.5 | 0.1 | 0.5 |

Table 4 presents the calculated partial and overall desirability values in the two assumed applications of laser texturing.

Summary of partial and overall desirabilities for tested samples

| No. | Uhp | UV | Uhw | Uᐃø | U1 | U2 |

|---|---|---|---|---|---|---|

| 1 | 0.95764 | 0.99156 | 0.0534 | 0.07863 | 0.94966 | 0.35814 |

| 2 | 0.06964 | 0.78461 | 0.24194 | 0.152 | 0.39591 | 0.25183 |

| 3 | 0.05578 | 0.77588 | 0.25057 | 0.21387 | 0.38579 | 0.27289 |

| 4 | 0.01878 | 0.44212 | 0.29482 | 0.35562 | 0.19417 | 0.28488 |

| 5 | 0.00143 | 0.18721 | 0.40461 | 0.39239 | 0.07695 | 0.30579 |

| 6 | 0.00109 | 0.00003 | 0.34949 | 0.44099 | 0.00432 | 0.22751 |

| 7 | 0.88689 | 0.99939 | 0 | 0.10801 | 0.96072 | 0.00186 |

| 8 | 0.4482 | 0.88796 | 0.04958 | 0.1923 | 0.6323 | 0.20352 |

| 9 | 0.39728 | 0.82956 | 0.40461 | 0.25928 | 0.60343 | 0.41767 |

| 10 | 0.09863 | 0.76972 | 0.35868 | 0.39239 | 0.44256 | 0.38904 |

| 11 | 0.02195 | 0.51377 | 0.39545 | 0.42892 | 0.2422 | 0.36573 |

| 12 | 0.02549 | 0.33737 | 0.42286 | 0.47672 | 0.1897 | 0.3777 |

| 13 | 0.71686 | 0.8219 | 0.00899 | 0.17164 | 0.66046 | 0.14109 |

| 14 | 0.2523 | 0.31274 | 0.22496 | 0.25928 | 0.27401 | 0.2464 |

| 15 | 0.49774 | 0.40564 | 0.41375 | 0.31898 | 0.43531 | 0.39316 |

| 16 | 0.12817 | 0.41723 | 0.39545 | 0.45299 | 0.29361 | 0.38588 |

| 17 | 0.17978 | 0.65113 | 0.26806 | 0.48844 | 0.41496 | 0.36535 |

| 18 | 0.10326 | 0.55758 | 0.33115 | 0.52291 | 0.33862 | 0.38691 |

| 19 | 0.79641 | 0.96346 | 0.37708 | 0.27101 | 0.85902 | 0.51482 |

| 20 | 0.19868 | 0.87101 | 0.34031 | 0.36788 | 0.57523 | 0.40917 |

| 21 | 0.11288 | 0.22731 | 0.66593 | 0.41679 | 0.23651 | 0.50214 |

| 22 | 0.15584 | 0.73519 | 0.52008 | 0.53414 | 0.48121 | 0.51442 |

| 23 | 0.13349 | 0.60511 | 0.57764 | 0.56699 | 0.40902 | 0.53487 |

| 24 | 0.02195 | 0.30324 | 0.61611 | 0.59845 | 0.20271 | 0.51525 |

| 25 | 0.94214 | 0.99983 | 0.71686 | 0.50005 | 0.99141 | 0.84926 |

| 26 | 0.87577 | 0.99982 | 0.14029 | 0.55619 | 0.98572 | 0.66226 |

| 27 | 0.23851 | 0.96057 | 0.56161 | 0.59845 | 0.75365 | 0.62655 |

| 28 | 0.16762 | 0.83779 | 0.53693 | 0.67487 | 0.57811 | 0.58791 |

| 29 | 0.17978 | 0.20114 | 0.60861 | 0.6922 | 0.28229 | 0.56121 |

| 30 | 0.05906 | 0.39004 | 0.63084 | 0.71686 | 0.29324 | 0.5838 |

| 31 | 0.81385 | 0.99979 | 0.74546 | 0.89176 | 0.98719 | 0.90142 |

| 32 | 0.80704 | 0.99976 | 0.75621 | 0.89511 | 0.98641 | 0.9031 |

| 33 | 0.17978 | 0.94806 | 0.75621 | 0.89837 | 0.76295 | 0.80818 |

| 34 | 0.11786 | 0.30477 | 0.75621 | 0.9046 | 0.36219 | 0.74748 |

| 35 | 0.03157 | 0.04597 | 0.68578 | 0.9046 | 0.15629 | 0.6769 |

| 36 | 0.02944 | 0.00174 | 0.68578 | 0.90758 | 0.08281 | 0.65955 |

| 37 | 0.98221 | 0.9995 | 0.03924 | 0.9046 | 0.9915 | 0.75413 |

| 38 | 0.73089 | 0.99712 | 0.50294 | 0.90758 | 0.9548 | 0.81523 |

| 39 | 0.02032 | 0.32133 | 0.68578 | 0.91047 | 0.27316 | 0.70444 |

| 40 | 0.00125 | 0 | 0.71686 | 0.91328 | 0.0031 | 0.62175 |

| 41 | 0.00125 | 0 | 0.72278 | 0.91328 | 0.00313 | 0.6254 |

| 42 | 0.00053 | 0.00047 | 0.68578 | 0.916 | 0.02728 | 0.64147 |

| 43 | 0.85584 | 0.96934 | 0.40461 | 0.89837 | 0.91034 | 0.75151 |

| 44 | 0.00125 | 0.07168 | 0.69852 | 0.90153 | 0.10362 | 0.66744 |

| 45 | 0.04117 | 0.09571 | 0.63084 | 0.90153 | 0.19198 | 0.65669 |

| 46 | 0.00095 | 0.00093 | 0.73993 | 0.90758 | 0.03614 | 0.66908 |

| 47 | 0.00942 | 0.09011 | 0.64517 | 0.90758 | 0.14685 | 0.65792 |

| 48 | 0.00083 | 0.00002 | 0.69852 | 0.91047 | 0.01792 | 0.63512 |

| 49 | 0.97357 | 0.93385 | 0.38627 | 0.90153 | 0.93821 | 0.76866 |

| 50 | 0.38259 | 0.9002 | 0.43194 | 0.9046 | 0.73192 | 0.69391 |

| 51 | 0.23171 | 0.78176 | 0.52854 | 0.90758 | 0.60465 | 0.69906 |

| 52 | 0.00125 | 0 | 0.71686 | 0.91047 | 0.01256 | 0.63926 |

| 53 | 0.00779 | 0.01897 | 0.65219 | 0.91328 | 0.09458 | 0.65199 |

| 54 | 0.0052 | 0.00126 | 0.66593 | 0.91328 | 0.05056 | 0.64209 |

| 55 | 0.84764 | 0.99591 | 0.2084 | 0.85225 | 0.95408 | 0.70591 |

| 56 | 0.41922 | 0.96231 | 0.47672 | 0.86108 | 0.81381 | 0.70717 |

| 57 | 0.02032 | 0.03135 | 0.67927 | 0.86531 | 0.11976 | 0.63656 |

| 58 | 0.01349 | 0.05294 | 0.65911 | 0.87731 | 0.12703 | 0.63625 |

| 59 | 0.00007 | 0 | 0.7286 | 0.88108 | 0.00264 | 0.59926 |

| 60 | 0.00083 | 0 | 0.68578 | 0.88474 | 0.0016 | 0.56967 |

| 61 | 0.63229 | 0.85434 | 0.55347 | 0.86531 | 0.7609 | 0.71814 |

| 62 | 0.2523 | 0.82588 | 0.57764 | 0.87342 | 0.6362 | 0.70061 |

| 63 | 0.00942 | 0.19614 | 0.601 | 0.87731 | 0.17968 | 0.62196 |

| 64 | 0.00299 | 0.0109 | 0.67265 | 0.88474 | 0.06513 | 0.62812 |

| 65 | 0.00125 | 0.00018 | 0.69852 | 0.8883 | 0.02488 | 0.6226 |

| 66 | 0.00014 | 0.00004 | 0.70473 | 0.89176 | 0.01261 | 0.61633 |

| 67 | 0.80355 | 0.97543 | 0.41375 | 0.70882 | 0.89557 | 0.66698 |

| 68 | 0.01236 | 0.11797 | 0.63084 | 0.73993 | 0.13394 | 0.55299 |

| 69 | 0.00266 | 0.0018 | 0.65911 | 0.75445 | 0.03206 | 0.53026 |

| 70 | 0.00072 | 0.00001 | 0.71085 | 0.79398 | 0.01108 | 0.55764 |

| 71 | 0.00184 | 0 | 0.73431 | 0.80001 | 0.00336 | 0.55694 |

| 72 | 0 | 0 | 0.74546 | 0.81161 | 0.00035 | 0.54342 |

| 73 | 0.05906 | 0.05152 | 0.67927 | 0.75445 | 0.15318 | 0.59091 |

| 74 | 0.05262 | 0.04588 | 0.64517 | 0.77495 | 0.14361 | 0.57825 |

| 75 | 0.00376 | 0.00001 | 0.69852 | 0.79398 | 0.01673 | 0.55773 |

| 76 | 0.00209 | 0 | 0.72278 | 0.81718 | 0.0047 | 0.56312 |

| 77 | 0.00184 | 0 | 0.73431 | 0.82261 | 0.00184 | 0.5607 |

| 78 | 0.00001 | 0 | 0.7286 | 0.83303 | 0.00015 | 0.53528 |

| 79 | 0.28763 | 0.78022 | 0.55347 | 0.22496 | 0.53925 | 0.46248 |

| 80 | 0.04386 | 0.0269 | 0.65911 | 0.31898 | 0.08633 | 0.42467 |

| 81 | 0.00162 | 0.00104 | 0.67265 | 0.38014 | 0.01605 | 0.40235 |

| 82 | 0.00007 | 0 | 0.72278 | 0.50005 | 0.00194 | 0.43273 |

| 83 | 0.00024 | 0 | 0.73431 | 0.53414 | 0.00078 | 0.43895 |

| 84 | 0 | 0 | 0.77164 | 0.56699 | 0 | 0.42064 |

| 85 | 0.00858 | 0 | 0.71085 | 0.35562 | 0.0099 | 0.4116 |

| 86 | 0.00017 | 0 | 0.74546 | 0.44099 | 0.00019 | 0.40461 |

| 87 | 0 | 0 | 0.7955 | 0.50005 | 0.00004 | 0.44848 |

| 88 | 0.00005 | 0 | 0.73993 | 0.59845 | 0.00004 | 0.43185 |

| 89 | 0.00779 | 0 | 0.76659 | 0.61859 | 0.00033 | 0.48041 |

| 90 | 0 | 0 | 0.77659 | 0.64752 | 0 | 0.44533 |

where:

Uhp – partial desirability of hp attribute

Uhw – partial desirability of hwattribute

UV – partial desirability of V attribute

Uᐃø – partial desirability of ᐃø attribute U1

U1 – overall desirability for the 1st variant

U2 – overall desirability for the 2nd variant

4 Conclusions

Research shows that the most important factor influencing the operational behavior of a textured surface is the micro-geometry of individual texture elements. Basing on literature studies and the author’s own experimental research ranges of satisfactory values and weights assigned to particular criteria in two assumed laser texturing applications were chosen.

Table 4 shows that samples number: 37 (U=0.9915), 25 (U=0.9914), 31 (U=0.9872), 32 (U=0.9864) have the most favorable properties for the first variant of laser texturing application considered. In the case of the second variant of application considered, the samples numbered 32 (U=0.9031) and 31 (U=0.,9014) have the highest overall desirability. Table 5 shows the processing parameters for samples of the highest desirability.

Processing parameters of samples of the highest desirability

| Sample no. | v [mm/sec] | P [W] | f [kHz] | F [J/cm2] |

|---|---|---|---|---|

| 25 | 100 | 4 | 400 | 3.81 |

| 31 | 100 | 3.75 | 400 | 3.57 |

| 32 | 100 | 3.75 | 200 | 3.52 |

| 37 | 100 | 3.5 | 400 | 3.33 |

Since the fluence during the production of sample no. 25 amounted to 3.81, this set of processing parameters should be rejected because they do not fall within the range in which cold laser ablation and a satisfactory regularity of the microcavity according to Table 2 is achieved. Identical desirabilities and geometry parameters of samples can be obtained with any laser micromachine while maintaining laser radiation fluence at the appropriate level.

Application of statistical functions during the selection of machining parameters will allow to develop the application of laser texturing on an industrial scale and better use of the benefits that it brings in the considered applications.

References

[1] Sęk P. Wytwarzanie i własności powierzchni z teksturą, Wydawnictwo Politechniki Świętokrzyskiej, Kielce 2014Search in Google Scholar

[2] Vemak V, Dahotre N. Lasers in Surface Engineering. Surface Engineering Series. ASM International. Materials Park. OH USA. 1998Search in Google Scholar

[3] Gregson V. Laser Material Processing. Holland Publishing Company. 1984Search in Google Scholar

[4] Ion JC. Laser Processing of Engineering Materials: Principles, Procedure and Industrial Applications. Elsevier Butterworth-Heinemann. ISBN: 9780750660792Search in Google Scholar

[5] Antoszewski B, Sęk P. Laser surface texturing - chosen problems. Proc. SPIE 8703, Laser Technology 2012: Applications of Lasers, 87030H, https://doi.org/10.1117/12.201524010.1117/12.2015240Search in Google Scholar

[6] Otmianowski T, Antoszewski B, Żórawski W. Local laser treatment of tribological plasma sprayed coatings. Proc. of 15th International Thermal Spray Conference, 25-29 May, Nice, France, 1998, 1333-1336.10.31399/asm.cp.itsc1998p1333Search in Google Scholar

[7] Góral A, Lityńska-Dobrzyńska L, Żórawski W, Berent K,Wojewoda-Budka J. Microstructure of Al2O3-13TiO2 coatings deposited from nanoparticles by plasma spraying. Arch. Metall. Mater. 58(2013)2. 335-339, DOI: 10.2478/v10172-012-0194-110.2478/v10172-012-0194-1Search in Google Scholar

[8] Żórawski W, Makrenek M, Góral A. Mechanical properties and corrosion resistance of HVOF sprayed coatings using nanostructured carbide powders. Arch. Metall. Mater.,Vol.61. (2016), No 4, 1839-1846. DOI: 10.1515/amm-2016-029710.1515/amm-2016-0297Search in Google Scholar

[9] Chichkov BN, Momma C, Nolte S, von Alvensleben F, Tünnermann A. Femtosecond, picosecond and nanosecond laser ablation of solid. Appl Phys A-Mater 63, 109-115, https://doi.org/10.1007/BF0156763710.1007/BF01567637Search in Google Scholar

[10] Chrisey DB, Hubler GK. Pulsed Laser Deposition of Thin Films. Wiley-Interscience. New York. 1994Search in Google Scholar

[11] Żenkiewicz M. Adhezja i modyfikowanie warstwy wierzchniej tworzyw wielocząsteczkowych. WNT Warszawa 2000. ISBN 83-204-2547-6Search in Google Scholar

[12] Radek N, Bartkowiak K. Laser treatment of electro-spark coatings deposited in the carbon steel substrate with using nanostructured WC-Cu electrodes. Phys. Procedia. 2012, 39, 295-301, https://doi.org/10.1016/j.phpro.2012.10.04110.1016/j.phpro.2012.10.041Search in Google Scholar

[13] Scendo M, Trela J, Radek N. Influence of laser power on the corrosive resistance of WC-Cu coating. Surf. Coat. Technol. 2014, 259, 401-407, https://doi.org/10.1016/j.surfcoat.2014.10.06210.1016/j.surfcoat.2014.10.062Search in Google Scholar

[14] Radek N, Bartkowiak K. Laser treatment of Cu-Mo electro-spark deposited coatings. Phys. Procedia. 2011, 12, 499-505, https://doi.org/10.1016/j.phpro.2011.03.06110.1016/j.phpro.2011.03.061Search in Google Scholar

[15] Pietraszek J, Radek N, Bartkowiak K. Advanced statistical refinement of surface layer’s discretization in the case of electro-spark deposited carbide-ceramic coatings modified by a laser beam. Solid State Phenom. 197 (2013), 198-202. https://doi.org/10.4028/www.scientific.net/SSP.197.19810.4028/www.scientific.net/SSP.197.198Search in Google Scholar

[16] Grabiec A, Piasta Z. Analysis of superplasticizer influence on cement paste with multicriteria statistical optimization. Archives of Civil Engineering XLII, 1996Search in Google Scholar

[17] Harrington EC. The desirability function. Industrial Quality Control. 21. 494-498, 1965Search in Google Scholar

[18] Pettersson U, Jacobson S. Influence of surface texture on boundary lubricated sliding contacts. Tribol. Int. 36. 857-864, https://doi.org/10.1016/S0301-679X(03)00104-X10.1016/S0301-679X(03)00104-XSearch in Google Scholar

[19] Piasta Z, Lenarcik A. Applications of statistical multi-criteria optimisation in design of concretes, in Optimization Methods for Material Design of Cement-based Composites. E & FN Spon. London, 1998Search in Google Scholar

[20] Nosal S. Tribologia. Wprowadzenie do zagadnień tarcia, zużywania i smarowania. Oficyna Wydawnicza Politechniki Opolskiej. 2011, ISBN 978-83-7775-146-6Search in Google Scholar

[21] Radek N, Bartkowiak K. Laser treatment of electro-spark coatings deposited in the carbon steel substrate with using nanostructured WC-Cu electrodes. Phys. Procedia. 2012, 39, 295-301, https://doi.org/10.1016/j.phpro.2012.10.04110.1016/j.phpro.2012.10.041Search in Google Scholar

[22] Owens DK, Wendt RC. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. vol. 13. 1741-1747, https://doi.org/10.1002/app.1969.07013081510.1002/app.1969.070130815Search in Google Scholar

© 2020 P. Sęk, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor

Articles in the same Issue

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor

![Figure 2 Illustration of the selection of the range of values satisfactory for criterion Y [16, 17, 18]](/document/doi/10.1515/eng-2020-0044/asset/graphic/j_eng-2020-0044_fig_002.jpg)