Abstract

Contemporary production companies operate in a dynamically changing environment and try to strengthen their competitive position. Therefore they take action acting at implementing new ones as well as improving and maintaining existing production processes, using for this purpose knowledge and available tools and methods. For dominant activities undertaken in the scope of improving and maintaining production the pro-quality activities can be included. Quality mainly depends on the efficiency of production processes, therefore manufacturing companies should focus their activities on maintaining and improving them. The methods of technical risk analysis and assessment are effective methods of maintaining production processes, whose application makes it possible to indicate any deviations from accepted standards. Analysis and assessment of the technical risk of the production process makes it possible not only to indicate non-conformities identified in the process, but mainly taking corrective actions. The aim of the article is to formulate of the method used to identify and assessment of the technical risk of the cutting process on the organizational side. The method has qualitative-quantitative type, and is the effective tools for technical risk assessment necessary to maintain the production process. It is assumed that the quality of the cutting process is ensured by the technical condition of the machine.

1 Introduction

Development of manufacturing organizations is connected with improvement and maintenance of manufacturing processes. The dominating approach of the manufacturing process improvement is its orientation on proquality activities, which enhance a competitive position of manufacturing companies acting in turbulent environment. Quality means a possibility of improvement of a manufacturing process and its products. European Quality Commission distinguished market quality connected with client assessment and utilitarian quality concerning the requirements arising from specific usable characteristics. In a scope of utilitarian quality, a quality of type and quality of workmanship were distinguished. Quality of type is referred to a collection of inherent properties (ISO 9000:2005), whereas quality of workmanship is created in a process of implementation (e.g. in a manufacturing process) pursuant to the adopted assumptions and taking into consideration a client’s needs. A desired approach in maintenance of quality of workmanship in manufacturing processes is the application of methodology of technical risk management.

The technical risk management in maintenance of a manufacturing process as a significant element which has impact on indication of potential irregularities in a manufacturing process, which lead to an incidence of defects or faults in a manufactured product. In the article the attention was drawn to a fact that identification and technical risk assessment in a manufacturing process enables for undertaking remedial actions, contributing to the achievement of planned results as well as maintenance and improvement of a manufacturing process.

In quantitative analysis of machinery process, especially used to quality and risk estimation the commonly used in engineering are the methods of designing of experiments which beginning goes to R.A. Fisher [1]. The methods have been developed till today. They are discussed and reviewed e.g. by D.C. Montgomery [2]. The main limitation of this methods is related to the use of statistical mathematics and theory of probability in analyses. The probabilistic attempt is not sufficient when the data are few or individual and knowledge of their values is inaccurate or incomplete [3]. One of the possible solution for the case when the number of data is low is application the non-parametric maximum likelihood estimation [4, 5]. In the end of XX century the method based on the fuzzy logic idea related to L.A. Zadeh [6] has been developed, having in mind the possibility of description of the so-called linguistic variable. The example of application of the idea to the ex-ante risk assessment in the project iss discussed by the author in [7], for interpretation of sequence of irregular data is discussed e.g. in [8] and for application of a fuzzy graph the algorithm based on fuzzy formal concept analysis is presented in [9]. Moreover in the analysis the methods of artificial intelligence and genetic algorithms are used [10]. The article [11] is dedicated to the problem od combine application of the genetic algorithms and fuzzy logic attempt. The other mathematically advanced methods which can be especially used to the estimation of class prevalence is based on novel algorithmic approach to content recommendation based on adaptive clustering of exploration-exploitation (the so-called bandit) strategies [12, 13, 14]. The example of applications of mathematical modeling in risk assessment can be find e.g. in [15, 16, 17].

The purpose of this article is formulation of the method used to identify and assessment of the technical risk of the cutting process on the organizational side. The method has a qualitative-quantitative type. The essence of the company’s operations is the timely execution of the order in accordance with the schedule and in accordance with the requirements specified in the order. It has been assumed that the quality of the cutting process, identified by keeping the geometric dimensions within the set tolerances, is ensured by the technical condition of the machine.

2 The issue of technical risk

Risk is a category of interdisciplinary character, which appears in all areas of human activity, therefore a natural need includes risk identification, measuring and management. Scientific approach to risk assessment arose from events which took place in history and their real impact on contemporary political, economic, social, cultural changes and technical progress. The development of scientific approach to an issue of risk was under the influence of a book published in 1921, written by F. Knight, entitled: Uncertainty and Profit, which drew the attention to differentiation of two notions, namely uncertainty and risk. F. Knight in his fundamental work separated the unmeasurable sensu stricto uncertainty from measurable uncertainty, i.e. risk [18, 19]. F. Knight began a scientific discourse regarding risk, which is continued in a scope of various scientific disciplines.

In a scope of management discipline, especially in its practical aspect, a risk is a key factor which has impact of effects of undertaken actions and a developmental potential of an organization [20]. Risk may be defined as combination of probability of occurrence of an event and its effects (ISO IEC Guide 73:2002) [21]. This general definition of risk is made more precise in two concepts distinguished in the professional literature, namely negative and neutral. Negative concept identifies a risk solely with hazard, loss, damage [22]. However, a neutral concept is based on an assumption that risk is neither negative nor positive [23]. It straightforwardly assumes that the occurrence of risk will make the achieved result of an action different than expected [24]. In management practice a sectoral approach may be noticed in a scope of identification and risk assessment, referring to selected areas [25, 26] and a holistic approach, identifying a collection of potential risks for the entire organization [27].

Generally the risk is perceived as measurable uncertainty which accompanies all actions undertaken in organizations. In the ISO 31000:2012 standard the risk is defined as impact of identified uncertainty on goals.

In the article the deliberations regarding the risk were restricted to technical risk in a scope of manufacturing processes implementation, whereas the technical risk was referred to hazards which may occur in a manufacturing process. These are the events which do not have a permanent and planned character. However, their occurrence causes interferences in a manufacturing process, what may contribute to a breakdown, irregularities or delays during the manufacturing of products. Exemplary reasons generating technical risk in manufacturing processes may be unverified or complex technologies, technological changes, new standards in an industry, inflated efficiency norms. Therefore, a goal of technical risk assessment in manufacturing processes is a reduction of probability of occurrence of undesired events by their elimination and monitoring of situations initiating their occurrence. Monitoring and restriction of occurrence of technical risk in a manufacturing process has impact on reduction of failure rates and defectiveness. Problem of assessment of current level of technical risk in a manufacturing process is reflected in a concept of a pyramid of events created by H. Heinrich, which involves the avoidance of „smaller caliber” events [28]. This approach is of essential significance in improvement and maintenance of manufacturing processes. In order to effectively manage the technical risk, one must employ a risk management methodology.

3 Methodology of technical risk in a manufacturing process

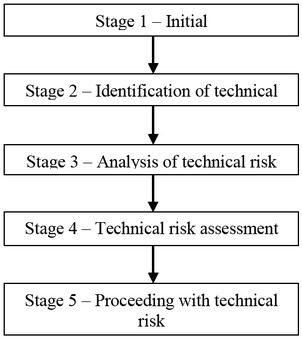

Risk assessment according to PN-ISO 31000:2012 is defined as an action which may be used in its range of significance both to an entirety of an organization, so therefore refers to its levels and areas of functioning, whereas towards its defined processes, functions, projects (PN-ISO 31000:2012). Pursuant to a definite research issue the risk analysis concerns the technical risk in a manufacturing process. In connection to more precise definition of a research scope a methodology of technical risk in manufacturing process was suggested, which include the following stages (Figure 1):

Methodology of technical risk assessment in a manufacturing process.

First stage – initial stage including the more precise definition of a scope of technical risk management, as well as a selection of methods and tools serving for its assessment.

Second stage – identification of technical risk, concerns the identification of its sources and potential effects, as well as development of a list of key hazards.

Third stage – analysis of technical risk is connected with definition of probability of occurrence of risks identified at a previous stage and assessment of its potential effects. Quality or quantity assessment of identified risks is made using methods defined at the first stage. At this stage the hierarchization of technical risk is performer, in order to define key risks.

Fourth stage – evaluation of technical risk is concentrated on undertaking optimal activities aiming at restriction and counteraction to key risks.

Fifth stage – proceeding with technical risk means undertaking actions defined at a previous stage. Moreover, control measures and monitoring is established, which are helpful in restriction of risk occurrence.

In improvement and maintenance of manufacturing processes the essential significance is attached to technical risk assessment of a manufacturing process, which in the suggested methodology is focused in a scope of actions undertaken in three stages: 2 – identification of risk, 3 – risk analysis and 4 – evaluation of technical risk.

4 Technical risk assessment on a basis of a manufacturing process – case study

Pursuant to the methodology of technical risk assessment in a manufacturing process at an initial stage, a subject of analysis was defined, which refers to a manufacturing process of longitudinal cutting line of rings. In a manufacturing process three stages were distinguished: collection, unpacking and introduction of rings and packing and storage. Technical risk assessment was conducted for a cutting procedure.

The research was conducted for the technological process of longitudinal cutting carried out on cutting machines:

cold-rolled, black, galvanized and coated steel strips: thickness 0.4–4 mm, width 30–1650 mm, yield strength up to 1000 MPa,

hot-rolled, pickled steel strips: thickness 4–16 mm, width 45–2100 mm, yield strength up to 1000 MPa,

cold-rolled, black, galvanized and hot-rolled, pickled sheets: thickness 0.4–3 mm, width 600–2020 mm, length 150–6000 mm, yield strength up to 500 MPa,

hot-rolled, black undigested and pickled sheets: thickness 1.5–20 mm, width 650–2150 mm, length 650–12000 mm, yield strength up to 900 MPa.

On a basis of analysis of a client’s requirements concerning specifications of cutting and documents and procedures introduced in a manufacturing company regarding quality management, i.e. reasons of occurring defects and failures, three most essential hazards were identified in a manufacturing process for a cutting stage:

Installing improper or blunt knives in a knife fixture

Failure of separation rolls

Improper setting of cutting parameters

Next, in order to perform analysis and assessment of identified risks for a cutting stage a severity assessment and probability of occurrence of damages according to the adopted scale (Table 1).

Assessment of a degree of losses in a Preliminary Hazard Analysis (PHA) method

| Degree of damages (S) | Assessment | Level of probability (P) |

|---|---|---|

| Insignificant damages | 1 | Insignificant, occurrence of incompliance highly improbable |

| Small damages | 2 | Low, relatively few incompliances |

| Medium damages | 3 | Moderate, low incompliance |

| Large damages | 4 | High, frequent incompliance |

| Very large damages | 5 | Very high, permanent incompliance |

Source: B. Chruszcz, J. Hansel [29]

Results of analysis of identified hazards for a cutting process were presented in Table 2, where additionally the technical risk was assessed (Rt) according to a formula:

Assessment of technical risk for indicated hazards at a stage of cutting

| Identified risks at a stage of cutting | Consequences | Degree of damages (S) | Probability level (P) | Technical risk assessment (R) |

|---|---|---|---|---|

| 1 | – damage to material | 4 | 3 | 12 |

| – incompliance of material with quality requirements | ||||

| 2 | – cutting the material without compliance with requirements defined in a client’s order | 5 | 3 | 15 |

| – client’s complaint | ||||

| 3 | – cutting the material in incompliance with an order | 4 | 1 | 4 |

| – destruction of material | ||||

| – loss of time connected with repeated performance of an operation |

Source: own source

where:

S – degree of damages (1-5)

P- level of probability of occurrence of damages (1-5).

Following the assessment of parameters the technical risk was valued on a basis of a risk matrix (Table 3) on a basis of three indicated levels:

first stage: 1-3 – acceptable risk,

second stage: 4-9 – risk is admissible after verification,

third level: 10-36 – unacceptable risk, preventive actions required.

Matrix of valuing technical risk for a stage of cutting

|

Source: own sources

On a basis of technical risk assessment of a manufacturing process concerning the cutting stage two unacceptable risks were identified, which refer to installation of improper or blunt knives in a fixture and occurrence of rolls breakdown. In face of identified hazards a preventive measure was undertaken, involving the implementation of a schedule of knife quality control, technical inspection of a device and training employees in this aspect.

Results of FMEA analysis for a procedure of cutting

| Potential defects | Effects of potential defects | LPZ | Reasons for potential defects | LPW | Methods of supervision of a process | LPO | LPR | Recommended actions | |

|---|---|---|---|---|---|---|---|---|---|

| Prevention | Detection | ||||||||

| Too wide, too narrow cut, incompliant with a specificity of a manufacturing order | Damage of material Damage of press Damage of S-block rollers | 7 | Error in preparation of an order for production | 6 | none | None | 8 | 336 | Implementation of a procedure of accepting orders and preparation of technical specifications Employee training in a scope of technical procedures |

| Scratches, dents | Damage of material Client’s compliant | 8 | Damage of S-block rollers | 7 | Replacement of rollers | Technical review of a machine | 3 | 168 | Specification of a schedule of machine servicing |

Source: own material

Bearing in mind the improvement of a cutting process one must take advantage of the Failure Mode and Effects Analysis (FMEA) to calculate the value of priority technical risk (LPR), which is a quotient of three parameters, the following formula was applied:

where:

LPW (value of priority occurrence) – assessment of defect occurrence frequency

LPZ (value of priority significance) – assessment of defect significance

LPO (value of priority detectability) – assessment of defect detectability

Criteria for coefficients LPW, LPZ, LPO, was defined in a scale from 1 to 10.

FMEA analysis results indicated potential defects and

incompliances in a process of cutting. Next, pursuant to the FMEA and PHA analysis, a FTA error-tree was developed, where the focus was concentrated only on basic events (incompliances) regarding operator’s errors and improper use of a device in a process of cutting, as to which the conducted assessment of technical risk indicated a need for intervention. As a result of conducted analysis the hazards were grouped in an area of a device breakdown, problems with preservation of requirements of an order and a client’s complaint, what was supposed to facilitate monitoring and proceeding with technical risk at a stage of cutting. In Table 5 the impact of incompliance on effective implementation of a cutting process was assessed.

Impact of incompliance on effective implementation of a cutting process

| No. | Description of incompliance | Description of impact | Assesment (1-10) |

|---|---|---|---|

| Machine failure | |||

| 1. | Operator’s error at setting the rolls | Reduction of effectiveness of operations, hazard of causing machine failure and product damage | 10 |

| 2. | Damage of material during cutting (blunt knives) | Reduction of operations effectiveness, product damage | 10 |

| Impossibility of performance of manufacturing order | |||

| 3. | Error of setting a measuring device | Receipt of improper parameters of measurement | 10 |

| Complaint | |||

| 4. | Ignorance of procedures by an employee | Risk of causing machine failure and product damage as well as client’s compliant | 10 |

Source: own source

Assessment of an impact of identified events on maintenance of a process of cutting constitutes the highest degree of hazard. Therefore, it is necessary to undertake interventions and remedial measures in order to restrict the occurrence of technical risk. Additionally, one may develop a checklist, based on which an internal audit should be conducted. In an event of occurrence of new hazards, the technical risk analysis and assessment of a process of cutting should be updated.

5 Results and discussion

The effect of technical risk identification and assessment are the pyramids of events, developed for groups of hazards in a process of cutting specified in Figure 2, Figure 3 and Figure 4.

![Figure 2 Pyramid of potential events in a machine failureSource: B. Eckhardt [28]](/document/doi/10.1515/eng-2020-0047/asset/graphic/j_eng-2020-0047_fig_002.jpg)

Pyramid of potential events in a machine failure

Source: B. Eckhardt [28]

![Figure 3 Pyramid of events of impossibility of implementation of an orderSource: B. Eskhardt [28]](/document/doi/10.1515/eng-2020-0047/asset/graphic/j_eng-2020-0047_fig_003.jpg)

Pyramid of events of impossibility of implementation of an order

Source: B. Eskhardt [28]

![Figure 4 Pyramid of events of complaintsSource: B. Eckhardt [28]](/document/doi/10.1515/eng-2020-0047/asset/graphic/j_eng-2020-0047_fig_004.jpg)

Pyramid of events of complaints

Source: B. Eckhardt [28]

The proposal of a methodology for technical risk assessment in the production process refers to organizational problems related to individual requirements of the clients. The assessment of technical risk at the stage of preparation and execution of the order according to the technical requirements of the ordering party is of particular importance from the point of view of efficient execution of orders. The proposed approach to technical risk assessment in terms of developing an efficient order execution procedure in the company, effectively reduces organizational errors and allows optimization of time and costs of order execution. The proposed methodology of technical risk assessment is to draw attention to the importance, besides the technological dimension of production processes, of the organizational dimension, which is a part of the contemporary trend of process improvement.

A novelity in the approach to technical risk assessment in the extension of performance quality assessment in production processes to the organizational dimension.

6 Conclusions

Assessment of technical risk in a manufacturing process is a key problem for its maintenance and improvement. In identification and assessment of technical risk in a manufacturing process one should use active and reactive approach. Active approach involves identification of all potential hazards already at an early stage of preparation of a manufacturing process in order to undertake actions preventing or minimizing their impact on end effects of a process. This means that at an initial stage it is appropriate to perform the ex ante assessment of technical risk. However, in a scope of occurrence during the implementation of a manufacturing process of risks unidentified at an initial manufacturing stage the reactive approach should be applied, what means the ongoing undertaking of remedial measures aimed at elimination or restriction of risks which may have impact on a course of a process and obtaining full-valued products. In a course of a manufacturing process it is necessary to perform technical risk on-line assessment. Technical risk assessment requires from manufacturing companies of a holistic approach including the use and adjustment of methods of its assessment at every stage of a manufacturing process. Technical risk assessment in a manufacturing process is an ongoing process connected with a chance of obtaining planned quality of a product.

Technical risk assessment in manufacturing processes is a difficult issue on account of shortening manufacturing cycles, implementation of individual requirements of clients, technical progress is also a challenge for managers and employees in a scope of development of methodologies and procedures of effective implementation of a manufacturing process with maintenance of planned quality.

The proposed technical risk assessment, focused on the organizational dimension is simply and fast. The method does not require a lot of cost and time, and may be carried out ex-ante. An important advantage of the method is the assessment of technical risk given in quantitative terms and the final preparation of the so called pyramids of events. which are helpful for process managers in eliminating possible causes of bad process implementation. It may be added that methods that can be carried out on-line and, in principle ex-post, which are advanced, also in terms of mathematical background, may include: fuzzy logic attempt, artificial intelligence, genetic algorithms, adaptive clustering of exploration-exploitation strategies. The analysis of the application of these methods goes beyond the aim and scope of the paper.

References

[1] Fisher RA. The Design of Experiments. Edinburgh: Oliver and Boyd Press; 1935.Search in Google Scholar

[2] Montgomery DC. Design and analysis of experiment. New York: John Wiley and Sons; 2004.Search in Google Scholar

[3] Pietraszek J. Metody planowania badań doświadczalnych eksploatowanych maszyn i urządzeń. Monografia nr 378. Kraków: Wydawnictwo Politechniki Krakowskiej; 2010 [in Polish].Search in Google Scholar

[4] Owen AB. Empirical Likelihood. Boca Raton: CRC Press; 2001. https://doi.org/10.1201/978142003615210.1201/9781420036152Search in Google Scholar

[5] Pietraszek J, Dwornicka R, Krawczyk M, Kolomycki M. The non-parametric approach to the quantification of the uncertainity in the design of experiments modelling. In: Papadrakakis M, Papadopoulos V, Stefanou G, editors. UNCECOMP 2017: Proceedings of the 2nd International Conference on Uncertainty Quantification in Computational Sciences and Engineering; 2017 Jun 15-17; Rhodes Island, Greece. Athens: Institute of Structural Analysis and Antiseismic Research. School of Civil Engineering. National Technical University of Athens; 2017. p. 598-604.10.7712/120217.5395.17225Search in Google Scholar

[6] Zadeh LA. Probability measures of fuzzy events. J Math Anal Appl. 1968;23(2):421–7.10.1016/0022-247X(68)90078-4Search in Google Scholar

[7] Kozien E, Kozien MS. Using the fuzzy logic description for the ex-ante risk assessment in the project. In: Ribeiro H, Naletina D, Lorga da Silva A., editors. Economic and Social Development. Book of Proceedings: 35th International Scientific Conference on Economic and Social Development; 2018 Nov 15-16; Lisbon, Portugal. Varazdin: Varazdin Development and Entrepreneurship Agency; 2018. p. 224-31.Search in Google Scholar

[8] Pietraszek J, Sobczyk A, Skrzypczak-Pietraszek E, Kolomycki M. The fuzzy interpretation of the statistical test for irregular data. Technical Transactions. 2016;113(14):119–26.Search in Google Scholar

[9] Hao F, Park DS, Li S, Lee HM. Mining λ-Maximal Cliques from a Fuzzy Graph. Sustainability. 2016;8(6):553.10.3390/su8060553Search in Google Scholar

[10] De Jong KA. Evolutionary Computation. A Unified Approach. Cambridge: MIT Press; 2006.10.1145/1274000.1274109Search in Google Scholar

[11] Guo H, Feng Y, Hao F, Zhong S, Li S. Dynamic Fuzzy Logic Control of Genetic Algorithm Probabilities. J Comput (Taipei). 2014 Jan;9(1):22–7.10.4304/jcp.9.1.22-27Search in Google Scholar

[12] Li S. The Art of Clustering Bandits [dissertation]. Varese: University of Insubria, Department of Theoretical and Applied Sciences; 2016.Search in Google Scholar

[13] Li S, Karatzoglou A, Gentile C. Collaborative Filtering Bandits. In: SIGIR’16: Proceedings of the 39th International ACM SIGIR Conference on Research and development in Information Retrieval; 2016 Jul 17-21; Pisa, Italy. ACM; 2016: p. 539-48.10.1145/2911451.2911548Search in Google Scholar

[14] Korda N, Szorenyi B, Li S. Distributed Clustering of Linear Bandits in Peer to Peer Networks. Proceedings of the 33rd International Conference on Machine Learning ICML 2016; 2016 Jun 19-24; New York, NY, USA. 2016: JMLR: W&CP volume 48: p. 1301-9.Search in Google Scholar

[15] Shang K, Hossen Z. Applying fuzzy logic to risk assessment and decision-making. Casuality Actuarial Society, Canadian Institute of Actuaries, Society of Actuaries; 2013.Search in Google Scholar

[16] Shapiro AF, Koissi MC. Risk assessment applications of fuzzy logic. Casuality Actuarial Society, Canadian Institute of Actuaries, Society of Actuaries; 2015.Search in Google Scholar

[17] Kozien E, Kozien MS. Ex-Ante Risk Estimation in the Production Project. Sciendo, System safety: Human – Technical Facility – Environment. 2019;1(1):708-15. https://doi.org/10.2478/czoto-2019-009010.2478/czoto-2019-0090Search in Google Scholar

[18] Knight F. Risk, Uncertainty and Profit. New York: Dover Publication Inc.; 2006.Search in Google Scholar

[19] De Meyer A, Loch C, Pich M. Managing project uncertainty. From variation to chaos. MIT Sloan Manag Rev. 2002;43(2):60–7.Search in Google Scholar

[20] Kozien E. Identification of stage phase growth in the checklist method using different statistical parameters. In: Yongqiang L., Hunjet A., Roncevic, A., editors. Economic and Social Development. Book of Proceedings: 20th International Scientific Conference on Economic and Social Development; 2017 Apr 27-28; Prague, Czech Republic. Varazdin: Varazdin Development and Entrepreneurship Agency; 2017. p. 538-45.Search in Google Scholar

[21] Federation of European Risk Management Associations. Risk Management Standard. Brussels: The Assotiations; 2003.Search in Google Scholar

[22] Wilson D. Risk.Wiley Encyclopedia of Management, 12: Strategic Management. Oxford: Blackwell Publishing; 2005.Search in Google Scholar

[23] Jajuga K. Zarządzanie ryzykiem. Warszawa: PWN; 2007 [in Polish].Search in Google Scholar

[24] Kaczmarek T. Zarządzanie ryzykiem handlowym, finansowym, produkcyjnym dla praktyków. Gdansk: ODiTK; 2002.Search in Google Scholar

[25] Bannister JE, Bawcutt PA. Practical risk management. Livingstone: Witherby; 1981.Search in Google Scholar

[26] Kloman HF. Rethinking risk management. Geneva Pap Risk Insur Issues Pract. 1992;17(3):299–313.10.1057/gpp.1992.19Search in Google Scholar

[27] Bromiley P, McShane M, Nair A, Rustambekov E. Enterprise risk management: Reviev, Critique, and Research Directions. Long Range Plann. 2015;48(4):265–76.10.1016/j.lrp.2014.07.005Search in Google Scholar

[28] Eckhardt B. Reevaluating the incident pyramid. Concrete Products. 2003 May;106(5):38–40.Search in Google Scholar

[29] Chrószcz B, Hansel J. Analiza i ocena ryzyka zawodowego. Kraków: Wydawnictwa AGH; 2011 [in Polish].Search in Google Scholar

© 2020 E. Kozień, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor

Articles in the same Issue

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor