Abstract

This paper investigates the influence of T6 post-weld heat treatment (PWHT), and welding orientation on the strength and microstructure of tungsten inert gas (TIG) welded AL6061 aluminum alloy. The TIG process was used to weld the AL6061 at the transversal and longitudinal orientations with reference to the rolling direction. The T6-PWHT is a two-phase heat treatment process, and was applied to AL6061 in order to increase its strength. This T6 was carried out under three different artificial aging; 8, 18, and 24 hours. The influence of PWHT and welding orientation on the strength of AL6061-T6 were investigated through a series of tensile and microhardness tests. In addition, the microstructure observations were performed using the optical and scanning electron microscopes. It was established that the strength and microstructural characteristics of AL6061 are significantly dependent on the T6 artificial aging. Accordingly, the improvements in the strength and ductility were mainly contributed by the grain growth and subsequent precipitate strengthening. Moreover, the welding orientation only affects their fracture surfaces and locations after tensile testing.

1 Introduction

By having excellent mechanical properties, high corrosion and fatigue resistance, lightweight ratios, low cost, and good weldability, the aluminum-magnesium-silicon (Al-Mg-Si) denotes as 6xxx series alloy is widely used for fabrication of critical structural components in the aircraft and aerospace industries. The application requires high strength and ductility of the material to restrain such mechanical loadings in operation. The AL6061 is a precipitation hardening Al alloy with a high content of Mg and Si elements. The Mg contents will significantly improve its strength, and the silicon will enhance the castability and high-temperature crack resistance of AL6061.

For fabrication of large structures, a solid state joining can be used for welding of AL6061 [1, 2]. In the welding process, the microstructure heterogeneity will occur between the weld metal (WM) and base metal (BM) afterwards, which will cause the differences in mechanical properties. Therefore, a suitable welding method must be employed for producing and designing a good welded product. The tungsten inert gas (TIG) welding is the most extensive gas shielded arc-welding process that can be applied in joining Al alloys due to their flexibility and relatively low-cost production. TIG welding can produce a high-quality and stable process, which has less spatter characteristics and better weld bead appearance. Currently, the TIG welding has attracted the scientific interest because of the difficulties for ensuring the integrity and reliability at the joints of Al alloys. Previous works use TIG welding for thin Aluminum sheet, and thus, has more advantageous other than conventional welding methods [3, 4]. However, further investigation is remained to improve the mechanical strength and determine the welding parameters of the TIG-welded AL6061.

Numerous reports have been published in the past years in the investigation of post-weld heat treatments (PWHT) on the AL 6061. Eltai et al. investigated the influence of PWHT on the corrosion behaviour of the TIG-welded AL6061-T6 [2]. According to his findings, the TIG-welded led to a reduction of microhardness in the area of the WM, and the most significant decline was found in the heat-affected zone (HAZ). Literature studies show that the PWHT had been successfully used to improve the properties of WM that give it particular characteristics [1, 2]. The PWHT is well-known to enhance the performance of the WM since the increase in temperature will form generous precipitations to various degrees. Based on many investigations, they approved that the T6 artificial aging process is well-applied to AL6061. It is also noticed that the T6 process on Al alloys can dissolve the β phase (Mg2Si), homogenize the solid solution, and spheroidize the eutectic Si. Although, there are several works of literature reported the influence of the PWHT on the microstructure of AL6061, yet, there are still excessively data set needed regarding the implication of PWHT on the mechanical performance of the AL6061.

In the complex geometry, the welding process is not always inline within the rolling direction on the metal plate due to the impediment in application. Since the WM will undoubtedly affect the deformed zone and strain localization during service loadings, one of the other set parameters to be understood is the appropriate characteristic of welding orientation. Therefore, in this paper, the investigation is focused on the combination of PWHT under three different artificial aging at 8, 18, and 24 hours and the welding orientation, which was welded at the transversal and longitudinal axis concerning the rolling direction, thus, to improve the strength and microstructure of the TIG-welded AL6061.

2 Research Methods

2.1 Specimen Preparations

The AL6061 aluminum alloy BM plates with the dimensions of 400 × 300 × 2.5 mm were joined by TIG welding process. Prior to the welding process, the Al alloy plates were polished and cleaned to eliminate the impurities. This TIG process used the heat generated by an electric arc between the metals to be joined and a non-consumable tungsten electrode, located in the welding torch. The arc area was shrouded in an inert gas shield to protect the weld pool and the tungsten electrode. The filler metal as a rod was applied manually into the weld pool. The ER4043 filler wire was chosen for the process due to its good fluidity and most importantly, resistance to crack (excellence choice for PWHT specimens). The filler material ER4043 was utilised to fill the weld groove and bonding the two surfaces. The non-consumable tungsten electrode used in this investigation has a dimension of 1.6 mm in diameter to produce the WM. Figure 1 shows the energy-dispersive x-ray spectroscopy (EDS) analysis of AL6061 for BM and WM for chemical characterisation. Based on the results, Silicon composition is evident in the WM part due to the utilisation of ER4043 Al-Si filler wire. The complete chemical compositions of AL6061 Aluminum alloy BM and ER4043 filler wire material are listed in Table 1.

The energy-dispersive x-ray spectroscopy (EDS) results of AL6061 (a) BM; and (b) WM.

The chemical Composition of AL6061 and Wire Filler ER4043 (wt%).

| References | Al | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Etc. |

|---|---|---|---|---|---|---|---|---|---|---|

| AL 6061 (BM) | 96.07 | 0.64 | 0.9 | 0.38 | 0.35 | 1.03 | 0.33 | 0.30 | - | - |

| AL 6061 (WM) | 89.86 | 7.22 | 1.03 | 0.38 | 0.29 | 0.82 | 0.10 | 0.30 | - | - |

| ER 4043 | Bal | 4.8 | 0.2 | 0.02 | <0.01 | 0.01 | - | 0.02 | 0.01 | <0.15 |

| ASM Spec. | 0.4-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 |

The miller welding machine was used with manual process by the welder. The details of welding parameters used in this investigation are listed in Table 2. The AL6061 BM plates were TIG welded and hot-rolled by following several testing conditions, such as welding longitudinal rolling longitudinal (WLRL), welding longitudinal rolling transversal (WLRT), welding transversal rolling longitudinal (WTRL), and welding transversal rolling transversal (WTRT). After welding, the as-welded plate was subjected to the PWHT (T6) process. The PWHT (T6) is a two-phase process, which was applied to AL6061 in order to increase the strength. The detail steps and procedures of the T6 artificial aging is shown in Figure 2. The T6 two-phase process was initiated by the rapid increase of temperature from room temperature (RT) until 520∘C and was held for 1 h. After 1 h, the as-welded plate was quenched in water until 175∘C and subsequently applying the T6 artificial aging for 8, 18, and 24 hours, respectively. This process is expected to cause extensive grain growth across the WM, and consequently improving the strength.

The PWHT (T6) process diagram.

The welding parameters used in this investigation.

| Parameters | Value |

|---|---|

| Welding equipment | Miller |

| Tungsten electrode diameter | 1.6 mm |

| Filler wire diameter | 2.4 mm |

| Heat input | 2.5kJ/mm |

| Peak current | 70 Amps |

| Base current | 60 Amps |

| Peak voltage | 14.3 Volts |

| Base voltage | 13.8 Volts |

| Welding speed | 4.19 mm/sec |

| Welding grade | 99.9995% |

| Pulse frequency | 6 Hz |

| Pulse on time | 50% |

| Shielding gas | Argon |

| Gas flow rate | 15 L/min |

2.2 Test Methods

The Vickers microhardness tests were conducted across the plate with 0.3 kgf of indentation load and 12 secs of dwell time, as recommended in ASTM E384-16 [5]. The indentations were set at the centre position from the WM area to the BM area every 1 mm, as schematically shown in Figure 3. The tensile test specimen used in this investigation was rectangular in shape, and the dimension can be seen in Figure 4. The WM specimens were specifically machined to the required dimensions from the weld pad, as shown in Figure 4(b). Series of tensile tests were conducted in RT laboratory environment with a tension rate at 1 mm/min. These test specifications were adjusted with the standard of ASTM B557 [6].

Welding profiles (BM, HAZ, and WM) across the plate and schematic illustration of microhardness test path.

(a) The tensile test specimen geometry; and (b) Configuration for longitudinal and transversal direction of the welding and rolling orientation (all units are in millimetres).

The samples for microstructure examinations were perpendicularly extracted from the fractured specimens after tensile testing. The samples were polished and etched with Keller’s reagent containing 2.5 ml of HNO3, 1.5 ml of HCl, 1 ml of HF, and 95 ml of H2O for 10-20 secs to reveal their microstructure. Microstructural characterization was performed via optical microscope (OM) and scanning electron microscope (SEM) coupled with energy-dispersive x-ray spectroscopy (EDS) equipment. The grain measurement was carried out using the linear intercept method from the microstructure image, as recommended in the ASTM E112 [7].

3 Results

3.1 Microstructure

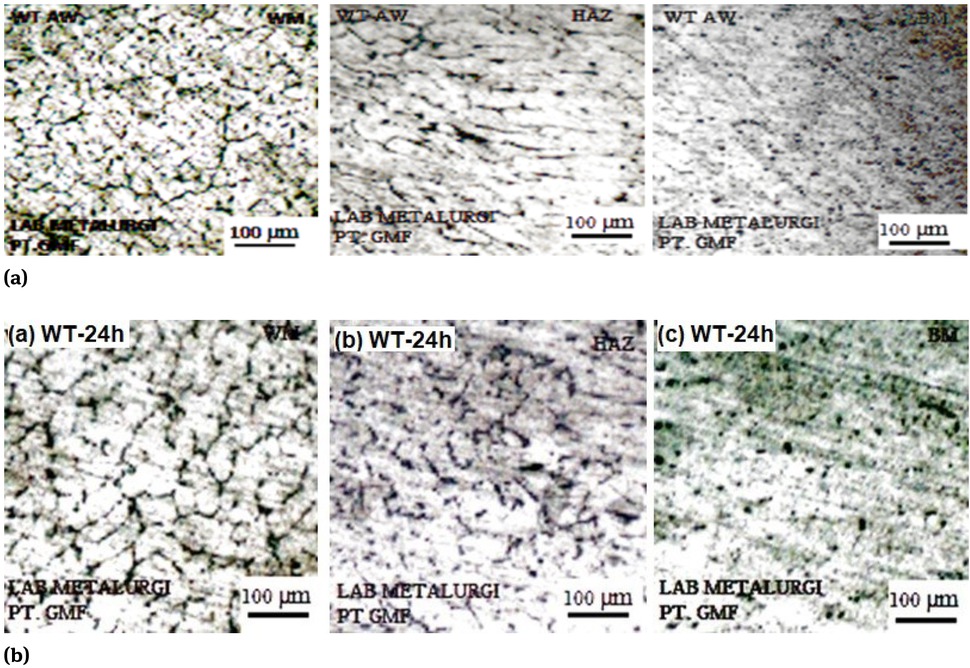

Figures 5 and 6 show typical OM images of the AL6061-T6 after 24 hours of aging compared with the as-welded AL6061. From the figures, the dual phases can be observed as the bright colour for the solid Al solution (Al-matrix), and a darker colour for low melting phase (Mg-Si) of AL6061-T6 specimens. Similar finding revealed that these Mg and Si are bound each other into Mg2Si precipitate at particular temperature environment but a quite low solubility at RT, generating a precipitate strengthening property [8]. It is clearly seen that larger size and amount of precipitates are desirable due to the PWHT in comparison with the as-welded AL6061.

OM images as a comparison of; (a) As-welded AL6061, and (b) AL6061-T6 aged for 24 hours on longitudinal welding orientation for WM, HAZ, and BM (left to right).

OM images as a comparison of; (a) As-welded AL6061, and (b) AL6061-T6 aged for 24 hours on transversal welding orientation for WM, HAZ, and BM (left to right).

After TIG welding, the heterogeneity between microstructure occurred within the WM and B Mregion due to the heat. The WM is surrounded by the HAZ, the area that had its microstructure and properties altered by the welding. These each microstructure have different properties depend on the BM and filler metal used when subjected to heat. The uniform equiaxed dendritic grain type can be seen in the WM. The microstructure of AL6061-T6 consists of α-Al dendrites and eutectic Si particles along the dendritic grain boundaries (GBs) and the grain configuration is more uniformly dispersed and reduced in size after heat-treatment. This finding is coincided as in Ref. [9]. While the precipitate strengthening mechanism can be illustrated as the interaction of the recurrent dislocation, which is hindered by precipitate particles (Mg2Si) [10]. If the particle is massive and hard, the driving force results mainly in a significant enhancement of the strength. Furthermore, if the driving force is attained, thus the precipitate will be sheared, or the moving dislocation will pass through (looping) for the hard enough particle.

The grain growth measurement was conducted using the linear intercept method, as schematically illustrated in Figure 7. Figure 8 shows the average grain size results under different set-up parameter conditions for WM and HAZ. Based on the results, the average grain size tends to decrease with an increase in the T6 artificial aging. Variation in T6 aging process is affecting the grain growth after recrystallization, resulting in smaller grain size in the WM and HAZ microstructure.

![Figure 7 Conception of the linear intercept method to measure the grain size for the as-welded specimen [5].](/document/doi/10.1515/eng-2020-0084/asset/graphic/j_eng-2020-0084_fig_007.jpg)

Conception of the linear intercept method to measure the grain size for the as-welded specimen [5].

Average grain size measurement for as-welded AL6061 and AL6061-T6 especially for WM and HAZ.

3.2 Microhardness Analysis

The exact extension of the HAZ and WM region are not easily measurable. Thus, each indentation of the microhardness is drawn based on the average points. Previous report said that the microhardness can be affected by dissolving precipitates in grains, and GBs called precipitation hardening due to the PWHT [11]. The variation of microhardness on the WM, HAZ, and BM (taking origin at the centre of the WM) for longitudinal and transversal welding orientation specimens are shown in Figure 9. For as-welded specimen, the profile exhibits that the WM has the highest microhardness compared to the HAZ and BM. The highest microhardness of the WM is two times more than the BM. However, after PWHT, the microhardness significantly increased compared to the as-welded specimen and nearly uniform in the WM, HAZ, and BM. It is also obtained that the highest microhardness is observed at 24 hours aging for both transversal and longitudinal welding, which are 114.4 HV and 124 HV, respectively.

Vickers micro-hardness profiles distribution across the WM specimen; (a) Longitudinal, and (b) Transversal welding.

3.3 Mechanical Properties of the TIG-welded AL6061

Figure 10 shows the tensile test results of the AL6061-T6. It is shown that the yield strength (YS) and ultimate tensile strength (UTS) are increased along with an increase in T6 artificial aging. The T6 at 24 hours is found to have the most superior YS and UTS. However, after T6 (>8 hours) the strength of transversal welding is lower compared to the longitudinal welding. The tensile test results are in a good agreement with the results from the microhardness test and grain size measurement. It has been reported that the grain growth and strengthening mechanism after T6 process enhanced the strength of the TIG-welded AL6061 since the T6 took over the process [10, 11, 12]. The dissolution and growth of precipitates were developed in a range of T6 artificial aging, meaning more precipitates were developed along with a long period of T6 aging, as it is seen in the Figures 5-6. With an increase in precipitates number, and the strength is expected to increase. It has been also reported that the skinny needles and high density of β′′- type precipitates were observed in the interior of AL6061-T6 microstructure [12, 13, 14, 15, 16]. Those precipitates served as obstacles to block the movement of dislocations during deformation. Dislocations are recognized to be the site for heterogeneous nucleation and paths for increasing the atomic movement during growth. These changes are again associated with the variation in the temperature experienced in the different T6 artificial aging, which in turn affects the dissolution or coarsening of precipitates. In another case, the elongation is decreased along with an increase in T6 artificial aging. However, the longitudinal WM specimens have higher ductility than the transversal WM specimens.

The tensile test results of the AL6061-T6 at RT; (a) Yield strength, (b) Ultimate tensile strength, and (c) Elongation.

It is noted that, if the welding and rolling direction is in the same line, the mechanical properties is the most superior compared to that with other set-up parameters.

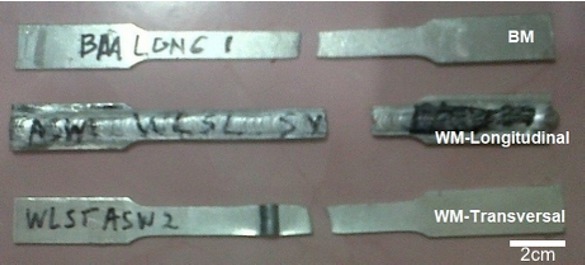

3.4 Fracture Behaviour

Figure 11 shows the representative fractured samples of BM and TIG AL6061. For BM, the fracture location is located in the middle of the specimen with a cup-and-cone fracture shape, indicating a ductile fracture. For the WM longitudinal specimens, fracture location has encompassed the WM, HAZ, and BM regions with flat-type fracture, and somewhat sheared due to the high strength of WM. In the case of the transversal WM samples, fracture location is also located in the BM with a cup-and-cone fracture shape. In this case, the strength was required to restrain the deformation during tension. Meanwhile, the WM has higher strength rather than the BM, and in other words, the strain was localized in the lower strength zone, namely BM until fracture. Figure 12 shows typical SEM images of as-welded AL6061 and AL6061-T6 for 24 hours of WLRL specimens. Based on this observation, the morphologies of fractures include a great number of fine dimples which are distributed uniformly on the fracture surface. A ductile fracture is seen in as-welded sample accompanied with a good plastic deformation. However, due to the less elongation and finer grain size in PWHT, a relatively smaller dimple features is expected for this type of samples in Figure 12(b). This type of fracture may prove that the crack was developed from the void in the interior of the structure and expanded under continued deformation until separation or fracture. Although, not all fractograph are shown. It is also worth to note that the welding orientation is an essential factor for influencing the type of fractography, for example, in WLRL fractured sample, a deep dimple fracture and multiple internal cracks can be observed.

Typical fractured specimens from tensile tests, showing the fracture location of the AL6061 BM and WM.

Typical SEM fractographs of; (a) As-welded AL6061, and (b) AL6061-T6 aged for 24 hours on WLRL specimen, indicating WM, HAZ, and BM (left to right).

4 Conclusions

This paper has presented the complete results of the influence of PWHT and welding orientation on the AL6061-T6 strength and microstructure characteristics. It is observed that both longitudinal and transversal welding orientation have only a slight difference on their mechanical performance, except after being heat-treated above 8 hours. The results have shown that on the specimens that undergo PWHT process, the increase in artificial aging period can significantly affect the grain growth after recrystallization, resulting in smaller grain size, especially for the WM specimens. Their microhardness is significantly increased and nearly uniform in the WM, HAZ, and BM compared to the as-welded specimen. It can be concluded that specimen from the T6-24 hours has the highest microhardness along with the smallest measured grain size. Subsequently, the tensile testing supports this result, showing the most superior of YS and UTS values is from the T6-24 hours for WLRL and WTRT specimens. The improvements in the strength and ductility were mainly contributed by the microstructural evolution as grain growth, dissolution, and precipitation hardening by Mg2Si due to the artificial aging.

Acknowledgement

The authors would like to acknowledge the department of mechanical engineering of the Diponegoro University for providing any cost of this project.

References

[1] Ahmad R, Bakar MA. Effect of a post-weld heat treatment on the mechanical and microstructure properties of AL6061 joints welded by the gas metal arc welding cold metal transfer method. Mater Des. 2011;32:5120-6.10.1016/j.matdes.2011.06.007Search in Google Scholar

[2] Eltai E, Mahdi E, Alfantazi A. The effects of gas tungsten arc welding on the corrosion and mechanical properties of AL6061 T6. Int J Electrochem Sci. 2013;8:7004-15.10.4028/www.scientific.net/AMM.575.210Search in Google Scholar

[3] Haryadi GD, Dewa RT, Ekaputra IMW. Fatigue crack growth and probability assessment for transverse TIG welded Aluminum alloy 6013-t4. J Theor App Mech-Pol. 2018;56(1):179-90.10.15632/jtam-pl.56.1.179Search in Google Scholar

[4] Ekaputra IMW, Haryadi GD, Mardikus S, Dewa RT. Probabilistic evaluation of fatigue crack growth rate for longitudinal tungsten inert gas welded Al 6013-T4 under various post weld heat treatment conditions. E3S Web Conf. 2019;130:01016.10.1051/e3sconf/201913001016Search in Google Scholar

[5] ASTM International. ASTM E384-16: 2016. Standard test method for microindentation hardness ofmaterials. West Conshohocken, PA, USA: ASTM; 2016.Search in Google Scholar

[6] ASTM International. ASTM B557-15: 2015. Standard test methods for tension testing wrought and cast aluminum- and magnesium-alloy products. West Conshohocken, USA: ASTM; 2015.Search in Google Scholar

[7] ASTM International. ASTM E112-13: 2013. Standard test methods for determining average grain size. West Conshohocken, USA: ASTM; 2013.Search in Google Scholar

[8] Nie F, Dong H, Chen S, Li P, Wang L, Zhao Z, et al. Microstructure and mechanical properties of pulse MIG welded 6061/A356 aluminum alloy dissimilar butt joints. J Mater Sci Technol. 2018;34:551-60.10.1016/j.jmst.2016.11.004Search in Google Scholar

[9] Liang Y, Hu S, Shena J, Zhang H, Wang P. Geometrical and microstructural characteristics of the TIG-CMT hybrid welding in 6061 aluminum alloy cladding. J Mater Process Technol. 2017;239:18-30.10.1016/j.jmatprotec.2016.08.005Search in Google Scholar

[10] Maisonnette D, Suery M, Nelias D, Chaudet P, Epicier T. Effects of heat treatments on the microstructure and mechanical properties of A 6061 aluminium alloy. Mater Sci Eng A. 2011;528:2718-24.10.1016/j.msea.2010.12.011Search in Google Scholar

[11] Boonchouytan W, Chatthong J, Rawangwong S, Burapa R. Effect of heat treatment T6 on the friction stir welded SSM6061 aluminum alloys. Energy Procedia. 2014;56:172-80.10.1016/j.egypro.2014.07.146Search in Google Scholar

[12] Gussev MN, Sridharan N, Norfolk M, Terrani KA, Babu SS. Effect of post weld heat treatment on the 6061 aluminum alloy produced by ultrasonic additive manufacturing. Mater Sci Eng A. 2017;684:606-16.10.1016/j.msea.2016.12.083Search in Google Scholar

[13] Lee WS, Tang ZC. Relationship between mechanical properties and microstructural response of 6061-T6 aluminum alloy impacted at elevated temperatures. Mater Des. 2014;58:116-24.10.1016/j.matdes.2014.01.053Search in Google Scholar

[14] Singh R, Chauhan S, Gope PC. Influence of notch radius and strain rate on the mechanical properties and fracture behavior of TIG-welded 6061 aluminum alloy. Arch Civ Mech Eng. 2016;16:513-2310.1016/j.acme.2016.01.002Search in Google Scholar

[15] Feng AH, Chen DL, Ma ZY. Microstructure and low-cycle fatigue of a friction-stir-welded 6061 aluminum alloy. Metall Mater Trans A. 2010;41A:2626-41.10.1007/s11661-010-0279-2Search in Google Scholar

[16] Fadaeifard F, Matori KA, Aziz SA, Zolkarnain L, Zairie BA, Rahim MA. Effect of the welding speed on the macrostructure, microstructure and mechanical properties of Al6061-T6 friction stir butt welds. Metals-Basel. 2017;7:48.10.3390/met7020048Search in Google Scholar

© 2020 G. Dwi Haryadi et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor

Articles in the same Issue

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor