Abstract

The sandwich plate can be used to replace the conventional steel stiffened plates on the ship’s hull structure. By using the sandwich plate, not only the stiffness of the plate can be increased but also the overall ship weight can be reduced, as well as the ship payload can be increased. The sandwich plate should be accompanied by the damage identification system to prevent ship structural failure. In this paper, the global damage identification method, which is based on the vibration analysis, is investigated. For that purpose, the vibration-based damage identification using the Finite Element Method (FEM) is explored. The variables being investigated are the damage sizes, damage locations, and the boundary conditions which affect the natural frequencies of the structures. The sandwich plate considered in this study consisted of steel faceplates with the polyurethane elastomer core, which has been checked to meet Lloyd’s register, an international maritime standard. From the analysis, it is found that the fully clamped boundary conditions accompanied by high vibration modes are more sensitive to the presence of artificial damage. The changes in the natural frequencies can be used as a reference to identify the size and location of damage in the sandwich plate.

1 Introduction

The needs of ships to operate more efficiently have been investigated by engineers. One of the most interest is to use lightweight material for the ship hull structures. By using this lightweight material, the overall ship weight can be reduced and eventually increases the ship payload. In this paper, the lightweight material being investigated is the sandwich plate. The investigated sandwich plate consisted of two parts, namely the faceplate and the core. The face-plate layer is made from materials that have high strength and high stiffness, while the core layer is made from materials that have low strength, low stiffness, and low density [1]. The combination of these layers will provide better strength to weight ratio, which is the main requirement for structures used in the shipping industry [2].

The purpose of having a high stiffness to weight ratio [3, 4, 5] is to reduce stiffener usage in ship construction [6] and eventually reduces the overall weight of the structures. From [7], the use of sandwich plates can reduce the ship’s overall weight up to 15% compared to the structure with the stiffened plate. Another researcher, which also investigate the replacement of conventional structure with sandwich plates, was able to get weight reduction between 5% to 12% [8].

However, the use of a sandwich plate should be accompanied by the damage identification system to ensure structural integrity, reliability, and safety to be used safely. At present, to identify the damage, there are two approaches that can be used. The first approach is to use the local damage identification techniques such as ultrasonic testing, eddy current, radiography, thermography, and shearography [9, 10]. This local damage identification can be efficiently applied for small- to medium-sized structures [11]. For large and complex structures that are difficult to assess, the use of local damage identification techniques can be costly and inefficient. Therefore, the use of a global damage identification technique is more preferred and was found to be more effective.

One of the most widely used global damage identification techniques is the vibration-based method. This vibration-based damage identification can classify as the nondestructive technique and can be cheap for large structures [12, 13]. This underlying principle of this method is to evaluate the modal parameters of the damaged structures such as the natural frequencies [14, 15, 16], mode shapes [17, 18], and damping ratios [19, 20].

The use of mode shapes measurement in the field may take lots of time and can be complicated. Other modal parameters, such as the damping ratios can also be challenging to measure due to its sensitiveness with environmental factors such as humidity and temperature [20]. Fortunately, the use of natural frequencies can be easily measured using a single sensor at several points at the same time and can be monitored in real-time with high accuracy [21, 22]. Although the use of natural frequencies does seem to be promising, this method does not give any information about the size of the damage and its location [23]. Therefore, further research is needed to process the recorded natural frequencies to quantify the size and location of damage in the sandwich plate.

Vibration-based damage identification with natural frequency damage indicators has been conducted on truss structures [15, 17], composite materials [14, 21, 23], and cantilever beams [16, 22]. The influence of local damage on changes in natural frequencies was used to detect damage to composite pyramidal truss core sandwich plates experimentally and numerically. Natural frequencies obtained experimentally and numerically had an average relative error of 12.26% [24]. In other research, the effect of random damage on the vibration properties of sandwich panels with truss cores (SPTCs) was analyzed using the Finite Element Method,which is associated with stochastic analysis. The results showed that the effect of damage area on the SPTC vibration properties must be analyzed by combining shape mode, damage size, and boundary conditions [25]. Seguel [26] showed a technique for measuring vibrations at thousands of surface points using 3-D digital image correlation (DIC) techniques. The technique was used to conduct debonding detection from an aluminum honeycomb sandwich panel using shape curvatures, Uniform Load Surface (ULS), Modal Strain Energy (MSE), and Gapped Smoothing method (GS) modes. MSE showed the best results in detecting, finding the location of damage, and roughly quantifying damage [26]. Damage identification using dimensionless time domain and Teager energy operator (TEO) method was developed for metallic sandwich panels with truss core. The results showed that the method could identify single damage and multiple damages with different sizes. In addition, the effectiveness of the method was improved when the boundary conditions change from CFFF to CCFF or CCCC [27]. However, vibration-based damage identification has never been investigated on a ship’s sandwich plate with a polyurethane elastomer core.

In this paper, the vibration-based damage identification is carried out on a sandwich plate, which is designed for the side-shell (hull) of a 100 TEUS container ship using the Finite Element Method (FEM). This sandwich plates consisted of the steel faceplates and the polyurethane elastomer cores [8, 28, 29]. The investigated sandwich plate types have met Lloyd’s Register (LR) regulations [30] and have been commercially used in the shipping industry. The vibration-based damage identification is applied by observing changes in the natural frequency of the sandwich plates for ship structures using the Finite Element Method (FEM). The purpose was to evaluate the damage sizes, boundary conditions, and the damage locations by processing the natural frequencies at the first sixth modes.

2 Method

2.1 Material Properties of The Ship Sandwich Plate

The faceplate material is steel with material properties as in [31]. The steel density is 7850 kg/m3. The elastic modulus is 206 GPa, and the Poisson’s ratio is 0.3. The core material used is a polyurethane elastomer (PU) with the density obtained by testing the material in the laboratory. The ultimate tensile stress, elongation at break, and modulus of elasticity are obtained using the uniaxial tensile test. While the hardness tests are performed to determine the hardness of the polyurethane elastomer using a shore-D durometer. All of these material properties must comply with the LR regulations [30]. The Poisson’s ratio of the PU is assumed to be 0.3. Based on the strength index analysis [30], the thickness of the upper faceplate, the thickness of the lower faceplate, and the thickness of the core are obtained to be 3 mm, 3 mm, and 15 mm, respectively.

2.2 FEM Model of The Ship Sandwich Plate

Figure 1 shows the 3D geometry model of the sandwich plate. The model is generated using the ABAQUS finite element package. The dimension of the sandwich plate is 382 mm × 382 mm × 21 mm, which is similar to the model used in [24]. For faceplates and core, the eight-node linear brick element (C3D8), solid, and homogeneous assumptions are used with elastic and isotropic material properties. A regular size mesh is used. The interaction between the face-plate and the core is established using the tie constraints with hard contact and frictionless interaction. Both the perfect intact model and model with the defect are modeled and investigated.Mesh-convergence analysis has been carried out to obtain accurate results while having reasonably computation time.

FEM models of ship sandwich plate: (a) the intact sandwich plate, (b) the damaged sandwich plate where damage occurs inside the core

The type of damage investigated is debonding damage that occurs between the faceplate and the core. The damaged element is introduced to the 2 mm upper part of the core, with a damaged ratio of 5%, 7.5%, and 10%, see in Figure 2, to determine the effect of the damage size on the natural frequency deviation (the changes of natural frequency). Only the first six modes with the same boundary conditions, which are clamping of all edges, are investigated. In [26, 32], the natural frequency deviation was investigated in the first six modes, followed by damage identification analysis. From [26, 32], it had been analyzed that the first six initial natural frequencies could be considered sufficient to be used as a parameter of the damage identification.

FEM models of ship sandwich plate with damage ratios variations: (a) Intact sandwich plate, (b) 5% damaged sandwich plate, (c) 7.5% damaged sandwich plate, and (d) 10% damaged sandwich plate.

The damage ratio is defined as:

where, D is the damage ratio (%), Ad is the damaged area (m2), and Atotal is the total area of the sandwich plate model (m2).

The natural frequency deviation is defined as:

in the above, Δω (%) is the change in the natural frequency that becomes the damage parameter in this study,ωD is the natural frequency of damaged sandwich plate (Hz), and ωI is the natural frequency of the intact sandwich plate (Hz).

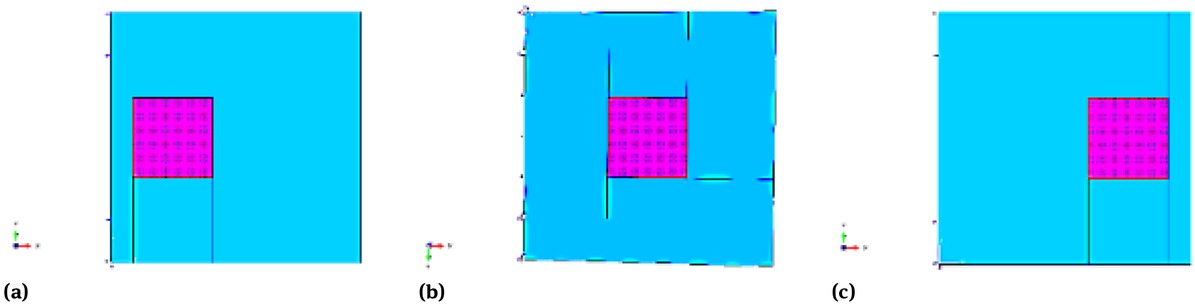

In the analysis, the attention is focused not only on the effect of the damaged ratio to the natural frequencies but also to the damage identification itself. This damage identification involves an in-depth study on the effect of boundary conditions and on the damage locations. The boundary conditions being investigated are CCCC, CFCF, CSCS, CFFF, and SSSS, C means clamp, F means free, and S means simply supported as the definition of a boundary condition in [33]. The location of damage is investigated by variations of 10% damaged located at 0.25 of the model length (near the clamp edge, location A), 0.5 of the model length (middle of the sandwich plate model, location B), and 0.75 of the model length (far from clamp edge, location C). Figure 3 illustrates the ship sandwich plates with 10% damage in 3 locations with CFFF boundary conditions.

FEM models of ship sandwich plate with damage locations variation: (a) Location A: 10% damaged sandwich plate at 0.25 of the model length, (b) Location B: 10% damaged sandwich plate at 0.5 of the model length, and (c) Location C: 10% damaged sandwich plate at 0.75 of the model length.

3 Result and Discussion

3.1 Mechanical Properties of The Core Material

The mechanical properties of the elastomeric polyurethane cores have been obtained from experimental investigations. The polyurethane elastomer tensile test was performed based on ASTM D412. By using the tensile stress-strain curve, the ultimate tensile stress, elongation at break, and elastic modulus of polyurethane elastomer is obtained at 25 MPa, 191%, and 181 MPa, respectively. Whereas, based on density test using ISO 845 and hardness test using DIN 53505, polyurethane elastomer has a density of 1124 kg/m3 and a hardness of 65 shore-D. So, the experimental test shows that the polyurethane elastomer has met the requirements of the core material in the LR standard [30], as summarized in Table 1. The mechanical properties of steel faceplates and elastomeric polyurethane cores are used as FEM inputs.

Mechanical properties of the polyurethane elastomer and the requirements of the core material in Lloyd’s Register standard [30]

| Test | Standard | Result | LR Criteria [30] |

|---|---|---|---|

| Density | ISO 845 | 1124 kg/m3 | ≥ 1000 kg/m3 at room temperature |

| Hardness | DIN 53505 | 65 shore-D | Shore D≥ 65 at room temperature |

| Tensile stress | ASTM D412 | 25 MPa | ≥ 20MPa at room temperature |

| Elongation | ASTM D412 | 191% | Min. 20% at room temperature |

3.2 Numerical Simulation

A finite element model has been developed to determine the vibration characteristics of the intact sandwich plate and damaged sandwich plate, where the observed vibration characteristic is the natural frequency. The sandwich plate model has been developed according to the material properties, as illustrated in Table 1.

A mesh convergence study is carried out to ensure the accuracy of the numerical analysis results. Convergence analysis of the full intact sandwich plates and 5% damaged sandwich plates in the first six modes are illustrated in Figure 4 and Figure 5. Based on Figure 4, the natural frequency value is stable in a meshing size of 4 mm, especially in 4th, 5th, and 6th mode. But, based on Figure 5, the first six natural frequency tends to be stable at a meshing size of 3 mm, or in other words, 5% damaged ship sandwich plates require smaller meshing size to get a more stable natural frequency value. Therefore, to accommodate both the convergence analysis for the intact sandwich plate and the damaged sandwich plate, it was decided that the meshing size used in this study should not be greater than 3 mm. A meshing size of 3 mm was also used in research on the damage identification to the pyramidal truss core sandwich structure [24]. The meshing size is applied to the intact sandwich plate and damaged sandwich plate to investigate the effect of damage ratios, boundary conditions, and damage locations on natural frequency deviation.

Convergence analysis for intact ship sandwich plate: (a) the first mode, (b) the second and the third mode, (c) the fourth, the fifth, and the sixth mode

Convergence analysis for 5% damaged ship sandwich plate: (a) the first, second, and third mode, (b) the fourth, the fifth, and the sixth mode.

3.3 Effect of The Damage Ratio

The effect of damage ratio on natural frequency deviation in various modes of a clamped sandwich plate is analyzed in this section. The natural frequency of the intact sandwich plates and damaged sandwich plates with several damage ratios in various modes are illustrated in Table 2. The effect of the damage ratios on the natural frequency deviation is summarized in Table 3.

Natural frequency (Hz) of the ship sandwich plate in the first sixth mode.

| Natural frequency (Hz) | ||||

|---|---|---|---|---|

| 0% damage | 5% damage | 7.5% damage | 10% damage | |

| Mode 1 | 267 | 269 | 210 | 163 |

| Mode 2 | 423 | 335 | 301 | 296 |

| Mode 3 | 423 | 410 | 380 | 320 |

| Mode 4 | 538 | 410 | 380 | 320 |

| Mode 5 | 602 | 564 | 457 | 408 |

| Mode 6 | 603 | 610 | 457 | 408 |

Natural frequency deviation (%) of the ship sandwich plate in the first sixth mode.

| Natural frequency deviation (%) | ||||

|---|---|---|---|---|

| 5% damage | 7.5% damage | 10% damage | Average | |

| Mode 1 | 0.6 | 21.3 | 38.9 | 20.3 |

| Mode 2 | 20.7 | 28.9 | 30.1 | 26.6 |

| Mode 3 | 3.2 | 10.2 | 24.3 | 12.6 |

| Mode 4 | 23.9 | 29.4 | 40.5 | 31.3 |

| Mode 5 | 6.4 | 24.1 | 32.3 | 20.9 |

| Mode 6 | 1.2 | 24.2 | 32.3 | 19.2 |

The damage indicator proposed in this study is natural frequency deviation. The definition of the natural frequency deviation is similar to that used by Seguel [26]. Damage indicator, which is also similar to natural frequency deviation, namely the relative natural frequency change (RNFC), has been used by other researchers [32].

It can be seen in Table 2 that, damage causes a decrease in natural frequency. As observed in Table 3, the larger the size of the damage, the higher the natural frequency deviation. The highest natural frequency deviation occurs in the 4th mode by taking into account the average deviation in each mode. The most significant natural frequency deviation at 5%, 7.5%, and 10% damage also occurred in the 4th mode, at 23.9%, 29.4%, and 40.5%, respectively. Changes in natural frequency occur due to local deformation around the damaged areas, especially in higher modes. Damage detection in the sandwich plate is more sensitive in higher modes [24, 25]. Thus, the damage identification to determine the size of the damage in the sandwich plate should be performed in higher modes.

3.4 Effect of The Boundary Condition

Boundary conditions have a significant effect on the vibration response and modal parameters of a structure; this includes the natural frequency. The effect of various boundary conditions on the average of the natural frequency deviation in the first six modes is summarized in Table 4.

Effect of the boundary condition on the natural frequency deviation.

| Natural frequency deviation (%) | ||||

|---|---|---|---|---|

| 5% damaged | 7.5% damaged | 10% damaged | Average | |

| CCCC | 9.33 | 23.02 | 33.07 | 21.81 |

| CSCS | 9.32 | 23.00 | 33.07 | 21.79 |

| CFCF | 8.91 | 12.26 | 23.08 | 14.75 |

| CFFF | 5.68 | 10.28 | 16.71 | 10.89 |

| SSSS | 9.37 | 18.99 | 27.77 | 18.71 |

The natural frequency deviation of 5%, 7.5%, and 10% damaged in CCCC is 9.33%, 23.02%, and 33.07%, respectively. The natural frequency deviation of 5%, 7.5%, and 10% damaged in CFCF is 8.91%, 12.26%, and 23.08%, respectively. The natural frequency deviation increases with the increase of the damage ratios for all types of boundary conditions. The highest average of the natural frequency deviation is obtained on the fully clamped sandwich plates (CCCC), where these results are confirmed by other studies [24, 27]. Fully clamped boundary conditions made the sandwich plates have a higher stiffness compared to other boundary conditions with the same geometry parameters [34]. It was observed that the CCCC boundary conditions had the highest natural frequency deviation. The results of this study are also found to be consistent with other studies that use the fixed-fixed boundary conditions and can detect damage more sensitive than the fixed-free boundary conditions [35]. Thus, it can be expected that the damage will be more easily detected through the natural frequency deviation parameter by using the CCCC boundary condition.

3.5 Effect of The Damage Locations

The investigated sandwich plates with different damage locations can cause changes in natural frequency, even for the same damage ratios. The effect of damage locations on the natural frequency deviation of the 10% damaged sandwich plate with CFFF boundary condition is shown in Table 5. Based on Table 5, the damage in location A (close to the clamped edge) causes the highest natural frequency deviation of 15.8%. Whereas the damage in location C (far away from the clamped edge) causes the lowest natural frequency deviation of 13.8%.

Effect of the damage locations on the natural frequency deviation.

| Intact sandwich | Damaged at Location A | Damaged at Location B | Damaged at Location C | |

|---|---|---|---|---|

| Natural frequency (Hz) | 368 | 309 | 314 | 317 |

| Natural frequency deviation (%) | - | 15.8 | 14.6 | 13.8 |

It can be concluded that the farther the location of the damage from the clamped edge, the lower the natural frequency deviation. The results are confirmed by other studies [24], which states that the farther away from the clamped edge, the effect of damage on the natural frequency becomes smaller. Thus, the natural frequency deviation parameter can be used as a reference to detect the location of damage in the ship sandwich plate.

4 Conclusion

This paper investigated the experimentally developed polyurethane core material for ship sandwich plates and has evaluated the vibration-based damage identification for ship sandwich plates using the Finite Element Method. The core material developed has met the Lloyd’s Register standard, an international maritime standard. Vibration-based damage identification was developed with the assistance of the natural frequency deviation parameter.

Analysis of the damage ratio effect on the natural frequency deviation shows that the greater the size of the damage, the higher the natural frequency deviation. If there is a specific natural frequency deviation on the ship sandwich plate, the size of the damage can be predicted. Moreover, damage identification in the sandwich plate is better observed in higher modes, such as in the 4th modes.

Furthermore, boundary conditions have a great effect on the damage identification. The higher sensitivity of the damage identification is obtained with a fully clamped boundary condition. Investigation of the damage locations effect on the natural frequency deviation shows that the farther the damage locations from the clamped edge, the lower the natural frequency deviation. Therefore, the location of the damage can be interpreted as a function of the distance to the clamped edge of the sandwich plate.

Acknowledgement

This research is funded by Directorate of Research and Community Services, Ministry of Research, Technology and Higher Education, The Republic of Indonesia under The Master’s Degree Program Leading to Doctoral Degree for Excellent Bachelor Graduates (PMDSU) research scheme.

References

[1] Borsellino C, Calabrese L, Valenza A. Experimental and Numerical Evaluation of Sandwich Composite Structures. Compos Sci Technol. 2004;64:1709-1715.10.1016/j.compscitech.2004.01.003Search in Google Scholar

[2] Ismail A, Zubaydi A, Budipriyanto A, Yudiono. Damage identification of the rice husk sandwich structure for ship deck structure. Proceedings of the 3rd International Conference on Marine Technology; 2018 Dec 5-6; Surabaya, Indonesia.Search in Google Scholar

[3] Yang JS, Ma L, Schmidt R, Qi G, Schröder KU, Xiong J, et al. Hybrid lightweight composite pyramidal truss sandwich panels with high damping and stiffness efficiency. Compos Struct. 2016;148:85–96.10.1016/j.compstruct.2016.03.056Search in Google Scholar

[4] Zhang X, Zhou H, Shi W, Zeng F, Zeng H, Chen G. Vibration tests of 3D printed satellite structure made of lattice sandwich panels. AIAA J. 2018;1–5.10.2514/1.J057241Search in Google Scholar

[5] Li C, Shen HS, Wang H. Nonlinear bending of sandwich beams with functionally graded negative poisson’s ratio honeycomb core. Compos Struct. 2019;212:317-325.10.1016/j.compstruct.2019.01.020Search in Google Scholar

[6] Sujiatanti SH, Zubaydi A, Budipriyanto A. Finite element analysis of ship deck sandwich panel. Appl Mech Mater. 2018;874:134-139.10.4028/www.scientific.net/AMM.874.134Search in Google Scholar

[7] Momčilović N, Motok M. Estimation of ship lightweight reduction by means of application of sandwich plate system. FME Transactions. 2009;37:123-128.Search in Google Scholar

[8] Brooking M, Kennedy S. The performance, safety and production benefits of SPS structures for double hull tankers. Proceedings of RINA Conference on Double Hull Tankers; 2004 Feb 25-26; London, UK.10.3940/rina.dht.2004.7Search in Google Scholar

[9] Bond LJ. Needs and opportunities: nondestructive evaluation for energy systems. In: Meyendorf NG, editors. Proceedings of Society of Photo-Optical Instrumentation Engineers (SPIE) 9439; 2015 Mar 27; San Diego,USA.10.1117/12.2086279Search in Google Scholar

[10] Gholizadeh S. A review of non-destructive testing methods of composite materials. Procedia Structural Integrity 1; 2016 Feb 10-12; Paço de Arcos, Portugal. Amsterdam: Elsevier; 2016. p. 50–57.10.1016/j.prostr.2016.02.008Search in Google Scholar

[11] Yan YJ, Cheng L, Wu ZY, Yam LH. Development in vibration-based structural damage detection technique. Mech Syst Signal Pr. 2007;21:2198–2211.10.1016/j.ymssp.2006.10.002Search in Google Scholar

[12] Vamvoudakis-Stefanou KJ, Sakellariou JS, Fassois SD. Vibration-based damage detection for a population of nominally identical structures: Unsupervised Multiple Model (MM) statistical time series type methods. Mech Syst Signal Pr. 2018;111:149–171.10.1016/j.ymssp.2018.03.054Search in Google Scholar

[13] Cruz PJS, Salgado R. Performance of vibration-based damage detection methods in bridges. Comput-Aided Civ Inf. 2009;24:62–79.10.1111/j.1467-8667.2008.00546.xSearch in Google Scholar

[14] Al-Waily M. Experimental and numerical vibration study of woven reinforcement composite laminated plate with delamination effect. Int J Mech Eng. 2013;2:1-18.Search in Google Scholar

[15] Yang C, Hou XB,Wang L, Zhang XH. Applications of different criteria in structural damage identification based on natural frequency and static displacement. Sci. China Technol. Sci. 2016;59:1746–1758.10.1007/s11431-016-6053-ySearch in Google Scholar

[16] Zhao B, Xu Z, Kan X, Zhong J, Guo T. Structural damage detection by using single natural frequency and the corresponding mode shape. Shock Vib. 2016;2016:8194549.10.1155/2016/8194549Search in Google Scholar

[17] Kaveh A, Zolghadr A. An improved CSS for damage detection of truss structures using changes in natural frequencies and mode shapes. Adv Eng Softw. 2015;80:93–100.10.1016/j.advengsoft.2014.09.010Search in Google Scholar

[18] Xu W, Cao M, Ostachowicz W, Radzieński M, Xia N. Two-dimensional curvature mode shape method based on wavelets and teager energy for damage detection in plates. J Sound Vib. 2015;347:266–278.10.1016/j.jsv.2015.02.038Search in Google Scholar

[19] Frizzarin M, Feng MQ, Franchetti P, Soyoz S, Modena C. Damage detection based on damping analysis of ambient vibration data. Struct Control Hlth. 2010;17:368-385.10.1002/stc.296Search in Google Scholar

[20] Cao MS, Sha GG, Gao YF, Ostachowiczm W. Structural damage identification using damping: a compendium of uses and features. Smart Mater Struct. 2017;26:043001.10.1088/1361-665X/aa550aSearch in Google Scholar

[21] Zhang Z, Shankar K, Ray T, Morozov EV, Tahtali M. Vibration-based inverse algorithms for detection of delamination in composites, Compos Struct. 2013;102:226–236.10.1016/j.compstruct.2013.03.012Search in Google Scholar

[22] Radzienski M, Krawczuk M, Palacz M. Improvement of damage detection methods based on experimental modal parameters. Mech Syst Signal Pr. 2011;25:2169–2190.10.1016/j.ymssp.2011.01.007Search in Google Scholar

[23] Zhang Z, Shankar K, Morozov EV, Tahtali M. Vibration-based delamination detection in composite beams through frequency changes. J Vib Control. 2014;22:496–512.10.1177/1077546314533584Search in Google Scholar

[24] Lou J, Wu L, Ma L, Xiong J, Wang B. Effects of local damage on vibration characteristics of composite pyramidal truss core sandwich structure. Compos Part B-Eng. 2014;62:73–87.10.1016/j.compositesb.2014.02.012Search in Google Scholar

[25] Lu L, Song H, Huang C. Effects of random damages on dynamic behavior of metallic sandwich panel with truss core. Compos Part B-Eng. 2017;116:278–290.10.1016/j.compositesb.2016.10.051Search in Google Scholar

[26] Seguel F, Meruane V. Damage assessment in a sandwich panel based on full-field vibration measurements. J Sound Vib. 2018;417:1–18.10.1016/j.jsv.2017.11.048Search in Google Scholar

[27] Lu L, Le J, Song H, Wang Y, Huang C. Damage detection of sandwich panels with truss core based on time domain dynamic responses. Compos Struct. 2019;211:443-454.10.1016/j.compstruct.2018.12.052Search in Google Scholar

[28] Kennedy SJ, Bond J, Braun D, Noble PG, Forsyth JD. An innovative “no hot work” approach to hull repair on in-service FPSOs using sandwich plate system over-lay. Proceedings of Offshore Technology Conference 15315; 2003 May; Houston, USA.10.4043/15315-MSSearch in Google Scholar

[29] Ramakrishnan KV, Kumar PGS. Applications of sandwich plate system for ship structures. IOSR J Mech Civ Eng. 2016; 83-90.Search in Google Scholar

[30] Lloyd’s Register Group Limited. Provisional Rules for the Application of Sandwich Panel Construction to Ship Structure. London: Lloyd’s Register; 2015.Search in Google Scholar

[31] Lee CS, Cho JR., Kim WS, Noh BJ, Kim MH, Lee JM. Evaluation of sloshing resistance performance for LNG carrier insulation system based on fluid-structure interaction analysis. Int J Nav Arch Ocean. 2013;5:1–20.10.2478/IJNAOE-2013-0114Search in Google Scholar

[32] Sha G, Radzieński M, Cao M, Ostachowicz W. A novel method for single and multiple damage detection in beams using relative natural frequency changes. Mech Syst Signal Pr. 2019;132:335-352.10.1016/j.ymssp.2019.06.027Search in Google Scholar

[33] Vinyas M, Kattimani SC. Static analysis of stepped functionally graded magneto-electro-elastic plates in thermal environment: a finite element study. Compos Struct. 2017;178:63–86.10.1016/j.compstruct.2017.06.068Search in Google Scholar

[34] Arunkumar MP, Jagadeesh M, Pitchaimani J, Gangadharan KV, Babu MCL. Sound radiation and transmission loss characteristics of a honeycomb sandwich panel with composite facings: effect of inherent material damping. J Sound Vib. 2016;383:221–232.10.1016/j.jsv.2016.07.028Search in Google Scholar

[35] Waldron K, Ghoshal A, Schulz MJ, Sundaresan MJ, Ferguson F, Pai PF, et al. Damage detection using finite element and laser operational deflection shapes. Finite Elem Anal Des. 2002;38:193–226.10.1016/S0168-874X(01)00061-0Search in Google Scholar

© 2020 A. Ismail et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor

Articles in the same Issue

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor