Abstract

The interfacial transition zone (ITZ) percolation is an effective parameter reflecting the connectivity of ITZs in cementitious materials, and its emergence may accelerate the penetration of inimical ions. In the existing literature on ITZ percolation, aggregates are generally simplified as the identical-shaped particles and the thickness of the ITZ phase around them is set to be uniform, which differs greatly from the realities and may cause the large deviation. To determine the ITZ percolation with the response of different phases in a more realistic way, a more satisfying three-dimensional (3D) polyphase model of concrete is developed, in which the convex ovoids and polyhedrons are separately adopted to represent the sands and gravels. The realistic nonuniform ITZ is also assigned for these aggregates based on their specific sizes and the W/C for the cement matrix. By coupling these models with the continuum percolation theory in statistical physics, the influence of individual phases on the global percolation threshold ϕ agg,c of ITZs is further studied by the simulation. The results reveal that the models here provide a smaller percolation threshold ϕ agg,c than the previous prediction models containing the simplistic uniform ITZs. There is reason to believe that these results in the work would be closer to the actual threshold in the realistic circumstance.

1 Introduction

Percolation is a commonly used physical definition reflecting the global connectivity of individual phases in the composite system [1,2], and it can be roughly divided into two groups: lattice percolation [3,4,5] and continuum percolation [6,7,8,9] according to the characteristics of study objects. Especially, the continuum percolation has always been applied by domestic and foreign researchers to explore the connectivity of various components in materials such as the pore phase (i.e., the soft particles) [10,11,12,13] and the interface phase (i.e., the rigid particles) [14,15,16] in a wide range of fields. For example, for the polyphase concrete materials in civil engineering, the interfacial transition zone (ITZ) surrounding the aggregate particles is commonly deemed to be a weak phase in concrete because of its higher porosity and greater permeability compared with the aggregates and cement paste [17,18,19]. According to the continuum percolation theory in the study by Stauffer and Aharony [1], when the effective fraction of the ITZs in concrete reaches the critical percolation condition (i.e., the connected path of ITZ through the whole systems can be formed), the great change of macroscopic properties of materials may occur. That is to say, the percolation of ITZs may have a significant influence on the mechanical and transport properties of concrete structures. Hence, the relevant issues about the ITZ percolation have always drawn the attention in recent years.

Because of the variability and complexity of the ITZ phase around the aggregates, a series of its characteristics including its percolation are always very difficult to be identified and quantified accurately by experiments. To compensate for the aforementioned shortcoming, the numerical simulation methods have been developed recently and become an effective research toolkit for the ITZ percolation. As of now, a large number of numerical investigations have been carried out to clarify the dependence of the ITZ percolation properties on the characteristics of aggregate particles as well as their effect on the macroscopic performance. For instance, by assuming all the aggregates in concrete as the group of polydisperse convex particles with the smooth surface (e.g., spheres [20,21], ellipsoids [22,23], and ovoids [24]), the influence of both uniform ITZ thickness and particle morphologies on the critical percolation thresholds ϕ agg,c of uniform ITZs is evaluated recently. The findings reveal that (a) whatever the aggregate shape is, the ITZ thickness always presents the dominant impact on the critical threshold ϕ agg,c; (b) as the specific surface area (SSA) of aggregates increases, the threshold ϕ agg,c generally possesses an increasing trend; and (c) as the aspect ratio of aggregates deviates from 1.0, the value of ϕ agg,c would reduce dramatically. Besides, in view of the realistic morphology of gravels (one of the commonly used coarse aggregates) in concrete, the concrete is assumed as three-phase systems consisting of polyhedral aggregates, uniform ITZs, and homogeneous cement paste, and the sensitivity of the critical percolation of the ITZ phase to the polyhedral particles is further studied in the studies by Lin et al. [25,26]. On the one hand, several interesting conclusions that are similar to those in the literature [20,21,22,23,24] are obtained. On the other hand, the value of ϕ agg,c also shows an obviously declining tendency with the decrease of the face of these regular particles. This is mainly because the ITZs around the polyhedral particles with their shape far from the spherical are easier to form the global percolation paths than the ITZs around the spherical particles. According to the aforementioned studies, it can be concluded that the geometric features of aggregates have the crucial effect on ITZ percolation. However, it should also be pointed out that, in most previous studies, both coarse aggregates and fine aggregates are usually simplified as the convex-shaped particles with the identical morphologies and the geometric differences between them are generally not considered. Strictly speaking, the morphologies of gravels in concrete are more similar to the two-dimensional (2D)/three-dimensional (3D) convex fillers with the limited number of faces. But the shapes of sands are much closer to the fillers with the smooth morphology, as described in the studies by Lin et al. [27,28]. To explore the ITZ percolation with the response of the diversities of aggregate shapes, the four-component polyphase models of concrete are developed by assuming the aggregate particles as a mixture of ovals/ovoids and polygons/polyhedrons in different dimensions. Based on the obtained results, the corresponding empirical expressions of ϕ agg,c are also derived in these studies [27,28].

Up till now, the specific relationship between the regular aggregate morphologies and the ITZ percolation has been clarified. However, there are still some serious oversimplifications in previous studies, which may lead to the great deviation between the predictions and the realities. It is well known that the effective thickness of the ITZs in cementitious materials may generally fluctuate within a certain range (e.g., [0.1 mm, 0.2 mm] in Ref. [29], [0.015 mm, 0.05 mm] in Ref. [30], and [0.05 mm, 0.2 mm] in Ref. [31]), which would be affected by a variety of factors such as the compositions, spatial distribution, and hydration degree of cement. Moreover, according to the study by Elsharief et al. [32] and Lyu et al. [33], the aggregate size is also a critical parameter that determines the ITZ thickness. Thus, it may not be very appropriate for the prediction of ITZ percolation to adopt the simplistic uniform ITZs, rather than the realistic differential ITZs in the modeling of concrete. Recently, the ITZ percolation involving the differential thickness has been studied by us in 2D space [34], and the results show that the critical threshold ϕ agg,c can be greatly overestimated once the uniform ITZs are applied. However, whether this finding can also be applicable in 3D cases is still unknown, which is an issue of concern for many researchers and reviewers.

To clarify the ITZ percolation with the response of different phases, especially the effect of the nonuniform ITZs in a more realistic way, a variety of 3D polyphase composite models of concrete materials containing gravels as regular polyhedrons and sands as ovoids are presented by referring to description in the study by Lin et al. [28]. Moreover, the more realistic nonuniform ITZs are further assigned for all the aggregates according to their equivalent diameters and the water–cement (W/C) ratio. Afterward, by combining these polyphase models with the theory of continuum percolation, the percolation behavior of nonuniform ITZs surrounding the mixture of ovoidal and polyhedral particles is simulated explicitly, and the effect of individual phases (e.g., aggregate shape- and size-differentiation, sand ratio, W/C) on the critical threshold ϕ agg,c in concrete is explored numerically. Simultaneously, the critical threshold ϕ agg,c for the realistic nonuniform ITZs is also in comparison with the corresponding ϕ agg,c for the simplistic uniform ITZs through the whole process of analysis. Based on the numerical results and comparisons, several significant findings are clarified finally.

2 3D polyphase models of concrete materials

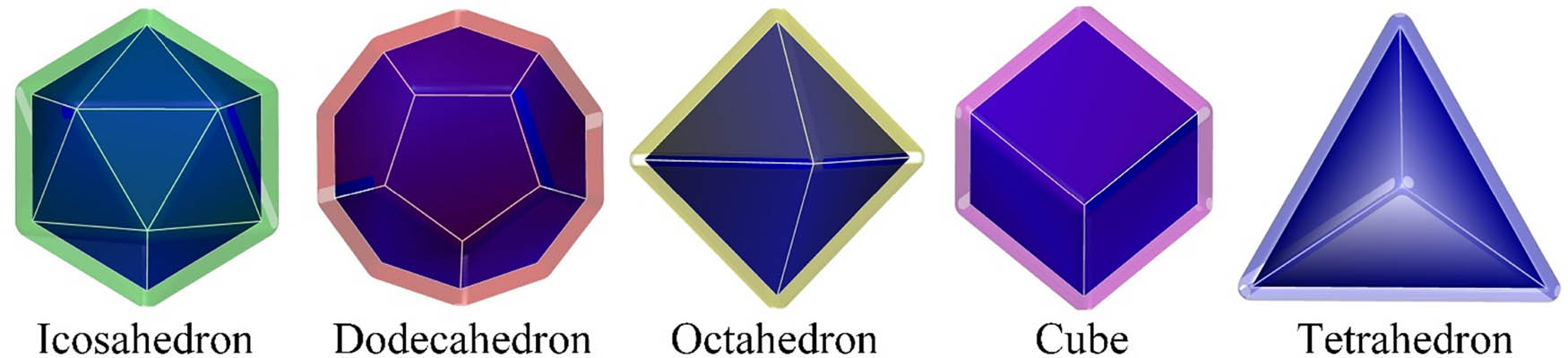

As described in the study by Lin et al. [26], the regular polyhedron, also known as “Platonic particle” is a general term for a variety of 3D regular particles with the limited number of faces, such as regular icosahedrons, dodecahedrons, octahedrons, cubes, and tetrahedrons, as shown in Figure 1, and they have been widely adopted by researchers to represent the particulate components in the modeling of granular composites in the literature [26,35,36]. Mathematically, the surfaces of all these particles can be expressed by the collections of their vertices, edges, and faces, and the specific expressions have been elaborated in the study by Lin and Chen [37]. In view of their similar morphologies to the gravels in concrete, they are also be applied here to represent the coarse aggregates.

The surface of five kinds of 3D regular polyhedrons along with the interfaces.

By comparison, the ovoid, which is generally used to stand for the fine aggregates, can be considered as the catch-all name for a variety of particles with the smooth surface such as spheres, egg-like particles, ellipsoids, etc., and the surfaces of these particles could be simply expressed by the extension of the formula (i.e., equation (1)) for the ellipsoids, as given in the study by Lin et al. [28]:

where a, b, and c are the measures of particle sizes in the x-, y- and z-axis direction, respectively, and the ratio of c to a (i.e. c/a) is defined as the aspect ratio of these particles. The parameter ζ is termed as the tapering coefficient that can also determine the geometric morphology of ovoid. In this work, the values of c/a in [0.2, 2.0] and ζ in [0.0, 0.6] are applied by reference to our previous paper [28]. Moreover, to reduce the complexity of particle shapes, the ratio b/a is always set to be 1.0. Figure 2 illustrates an example of the ovoid with c/a = 1.5 and ζ = 0.3.

The surface of 3D ovoidal particle (c/a = 1.5, ζ = 0.3) along with the interfaces.

In most of numerical simulation of concrete materials, their ITZ phase is commonly assumed to be an identical-thickness layer around the aggregates, and the ITZs for different aggregates can be overlapped freely. However, as stated in Section 1, the ITZ thickness in realistic concrete is not a fixed quantity. Naija and Miled [38] stated that the ITZ thickness t ITZ in concrete can be simplistically formulized as a function of both the W/C and aggregate sizes, and its applicability has also been verified by comparison with the experimental data. To explore the influence of nonuniform ITZs on its percolation, the formula of ITZ thickness t ITZ is adopted from the study by Naija and Miled [38], as expressed by equation (2).

where D eq is the equivalent diameter of aggregate particles.

In addition, to explore the sensitivity of ITZ percolation to the aggregate size gradations, two mathematical gradation functions (i.e., equations (3) and (4)), which are commonly adopted in the area of cement-based composites are also utilized to express the size gradations (PSG) of both gravels and sands in the work.

where D eq,min and D eq,max represent the minimum and maximum equivalent diameters of these 3D nonspherical aggregates, respectively. F V (D eq) is the volume-based cumulative probability function.

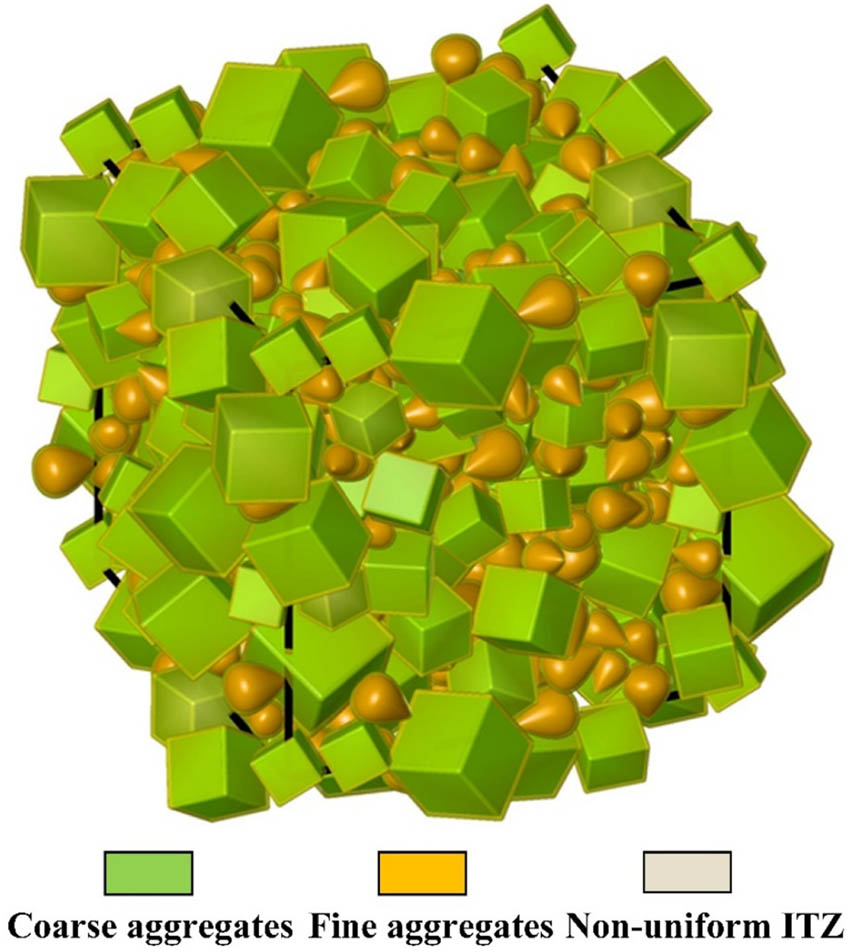

Finally, by incorporating the aforementioned formulas (i.e., equations (2)–(4)) into the RSA algorithm in the literature [28], the simplified 3D polyphase models of concrete specimen containing the smaller-sized ovoidal sands (i.e., fine aggregates), larger-sized polyhedral gravels (i.e., coarse aggregates), and nonuniform ITZs can be quickly constructed by using computer simulation technology, as shown in Figure 3.

An example of the 3D polyphase model of concrete containing the polyhedral coarse aggregates, ovoidal fine aggregates and nonuniform ITZs (W/C = 0.42, for cubes, D eq = Fuller 5–10 mm, for ovoids, D eq = Fuller 2.0–4.5 mm, and the sand ratio β s = 0.42).

3 Percolation simulation of nonuniform ITZs

As depicted in Figure 4, the ITZ percolation mainly reflects the global connectivity of the ITZs through the whole system and the critical threshold is generally represented by the total relative content ϕ agg,c of aggregate particles when the ITZ percolation is exactly emerged. For a 3D polyphase model with the finite size length L, the existence or not of the effective ITZ percolation paths is random, which can be expressed by the binominal distribution function, as given in the previous studies [27,39,40]. With the increase of the number N total of the specimen models, a new parameter P ITZ(ϕ agg), which is termed the percolation probability, is proposed to represent the probability of the emergence of the percolation paths for the given model of L and aggregate fraction ϕ agg, and its value can be approximated by the number ratio N pcl/N total of the percolated samples to the total samples, as expressed in equation (5). For instance, it is assumed that there is a total of 200 models of concrete specimen (i.e., N total = 200). If the ITZ percolation paths can be formed in 50 models (i.e., N pcl = 50), the value of P ITZ can be considered to be approximately equal to the number ratio N pcl/N total (i.e., P ITZ ≈ 50/200 = 0.25). Moreover, to guarantee the stability of P ITZ, both the size length L and the sample number N total should be large enough. According to the description in the study by Lin et al. [28] as well as the criterion for the REV in [41], the values of N total and L are, respectively, set to 1,000 and to be at least four times as wide as the value of D eq,max,p for the polyhedral coarse aggregates.

where ϕ agg is the volume fraction of aggregate particles in the model of concrete, N total is the total number of generated sample models, and N pcl is the number of samples in which the ITZ percolation paths can be found.

The schematic diagram of the percolation path of nonuniform ITZs in the polyphase model in Figure 3.

Afterward, as the statistical results of PITZ for a wide range of aggregate fraction ϕ agg (i.e., the curves of P ITZ vs ϕ agg) are obtained, the critical percolation threshold ϕ agg,c could be obtained easily through the curve-fitting analysis of these P ITZ vs ϕ agg curves by equation (6).

where Δ is the percolation transition and ϕ agg,c is the critical percolation threshold, which corresponds to the total aggregate fraction when the ITZ phase is exactly at the critical percolation state.

4 Results and discussion

In this section, the systematic simulations of the ITZ percolation under the different cases are carried out one after another, and the corresponding numerical predictions of ϕ agg,c are analyzed and compared with the analytical solutions predicted by the analytical formulas in the study by Lin et al. [28]. In what follows, a brief recall of the formula is presented first.

In our previous study [28], the gravels and sands in concrete are separately simplified as the larger-sized polyhedrons and smaller-sized ovoids, and the critical percolation of the uniform ITZs around them is simulated. Based on the simulated results, the quantitative relationship between the percolation threshold ϕ agg,c and the geometrical characteristics of these aggregate particles is derived, and the detailed expression of ϕ agg,c is written as equation (7).

where t ITZ is the ITZ thickness; s 3D,P and s 3D,O are the sphericities of polyhedrons and ovoids, respectively; S V,P and S V,O denote the SSA of polyhedrons and ovoids, respectively; and β s is the sand ratio of aggregates.

In view of that the effective thickness of the ITZs in equation (7) is assigned as a constant for all the aggregates, to compare our obtained results of ϕ

agg,c here with the analytical predictions, the effective average thickness

where D eq,p and D eq,o are the equivalent diameter of polyhedrons and ovoids, respectively; f N is the number-based probability function; D eq,max,p and D eq,min,p are the maximum and minimum equivalent diameters of polyhedral aggregates, respectively; and D eq,max,o and D eq,min,o are the maximum and minimum equivalent diameters of ovoidal aggregates, respectively.

By using the aforementioned technique, a range of the parametric studies are conducted hereafter to investigate the influence of the microstructural characteristics of individual phases on the percolation thresholds of these nonuniform ITZs in concrete.

4.1 Aggregate shape effect on ITZ percolation

Figure 5 shows the sensitivity of the critical threshold ϕ agg,c of both nonuniform and uniform ITZs to the geometrical shapes of polyhedral gravels and ovoidal sands. It is found that all the variations of ϕ agg,c with the morphology shift of aggregate particles for the nonuniform ITZs are consistent with the variations of ϕ agg,c for the uniform ITZs. In Figure 5(a), when the shape of ovoidal particles is given, ϕ agg,c shows an apparently declining trend along with the shift of polyhedral aggregate from sphere to tetrahedron for both nonuniform and uniform ITZs. It means that the fewer the number of the face of polyhedral aggregates is, the effective percolation paths of the ITZ phase would be easier to be formed. As shown in Figure 5(b), when the shape of polyhedron is given, the threshold ϕ agg,c can be deemed as an obvious ζ- and c/a-dependent parameter. On the one hand, ϕ agg,c decays slightly with the increasing ζ from 0.0 to 0.6. On the other hand, the evolution curve of ϕ agg,c with c/a in [2.0, 0.2] is generally divided into two stages (i.e., the slowly declining stage and the rapidly growing stages) by the inflection point c/a = 1.0. The maximum threshold ϕ agg,c is roughly reached when ζ = 0.0 and c/a = 1.0. That is to say, when the spheres are used to stand for the sands in concrete, the ITZ percolation threshold ϕ agg,c may generally be larger than realities. Essentially, the influence of particle morphology on the value of ϕ agg,c can be attributed to the aggregate sphericity s 3D. No matter for polyhedral coarse aggregates or ovoidal fine aggregates, the threshold ϕ agg,c in both Figure 5(a) and (b) presents the roughly declining variation with the decrease of particle sphericities (i.e., s 3D,P and s 3D,O). This is due to that the smaller the aggregate sphericities (s 3D,P or s 3D,O) are, the greater the circumradius of aggregates and the effective content of the ITZ phase for a single particle would be, which would result in the increase of the collision probabilities of adjacent ITZs around the different aggregates.

The sensitivity of ϕ agg,c of nonuniform and uniform ITZs to the geometric shapes of (a) regular polyhedral gravels and (b) ovoidal sands.

According to the results presented in Figure 5, it is observed that whatever the geometric shape of polyhedrons or ovoids is, when the same average ITZ thickness is given for all the aggregate particles, the corresponding ϕ agg,c predicted by the models in the literature [28] would be commonly greatly overestimated than that for the realistic nonuniform ITZs, and the overestimation degree of ϕ agg,c is not sensitive to the specific shapes of particles. The above trends of ϕ agg,c further emphasizes the necessity and importance of the realistic nonuniform ITZ thickness for the prediction of its percolation.

Figure 6 illustrates the evolution of ϕ agg,c of the nonuniform ITZs with the increasing W/C in [0.3, 0.66]. It is shown that no matter what the aggregate shape is, ϕ agg,c always decrease with the increasing W/C ratio in a linear manner, and its attenuation amplitude is also not sensitive to the specific shapes of both polyhedral and ovoidal aggregates. This is mainly because in the proposed model of t ITZ, the ITZ thickness is formulized as a linear function of W/C, and consequently, the linear increase of ITZ thickness in concrete can naturally result in a regularly linear decline for the percolation of these nonuniform ITZs.

Impact of W/C ratio on the percolation threshold ϕ agg,c of nonuniform ITZs.

4.2 Sand ratio effect on ITZ percolation

In the cases of W/C = 0.30, 0.42, and 0.54, Figure 7 further presents the evolution of ϕ

agg,c of both the realistic nonuniform ITZs and the simplistic uniform ITZs along with the increase of β

s from 0.30 to 0.70. It can be seen that, on the one hand, the influence of the W/C ratio on ϕ

agg,c here is also consistent with the proposed trend shown in Figure 6 (i.e., the greater the value of W/C is, the smaller the value of ϕ

agg,c is), which is untouched by the sand ratio β

s. This is a logical and expected trend, which is mainly due to that the larger W/C ratio would correspond to the greater value of

![Figure 7

The variation of the percolation threshold ϕ

agg,c of both nonuniform and uniform ITZs with the increasing β

s in [0.3, 0.7] under the cases of different W/C.](/document/doi/10.1515/secm-2022-0237/asset/graphic/j_secm-2022-0237_fig_007.jpg)

The variation of the percolation threshold ϕ agg,c of both nonuniform and uniform ITZs with the increasing β s in [0.3, 0.7] under the cases of different W/C.

In addition, the obviously different curves of ϕ agg,c-β s are presented in Figure 7 when the nonuniform and uniform ITZs are considered, respectively. For the simplistic uniform ITZs, ϕ agg,c shows the perfectly linear declining tendency with the increase of β s in [0.3, 0.7]. By referring to the description by Naija and Miled [38], the aforementioned phenomenon can be explained by the fact that as the sand ratio β s increases, the total number of aggregate particles would be greatly increased for the same aggregate fraction ϕ agg, which in turn leads to the greater contact surface between the aggregates and the cement matrix. However, for the realistic nonuniform ITZs in Figure 7, all the curves of ϕ agg,c-β s present a slightly increasing trend first and then decreasing trend with the increase of β s. On the one hand, the growth of the total contact surface of aggregate particles along with the increasing β s in concrete is conducive to the formation of the ITZ percolation paths (i.e., the lower threshold ϕ agg,c). On the other hand, under a constant W/C, the smaller-sized aggregate corresponds to the thinner ITZ thickness according to the expression in equation (2), which would be unfavorable to the formation of ITZ percolation path and may in turn lead to the larger percolation threshold ϕ agg,c. Actually, the percolation of the nonuniform ITZs here would be subjected to the synergetic influence of the aforementioned two factors. Hence, the assumption (i.e., the nonuniform ITZs) gives the different results from that for the uniform ITZs.

4.3 Aggregate size gradation effect on ITZ percolation

In Figure 8, the effect of aggregate size gradation on the percolation threshold ϕ

agg,c of both nonuniform ITZs and uniform ITZs under W/C = 0.30, 0.42 and 0.54 is explored. One can see that whatever the aggregate size gradation is, the threshold ϕ

agg,c always shows the rapid declining tendency with the increase of W/C. The value of ϕ

agg,c for the realistic nonuniform ITZs is still much lower than the predicted solutions obtained by substituting the same average thickness

Effect of PSG on the percolation threshold ϕ agg,c of both nonuniform and uniform ITZs under the cases of different W/C values.

4.4 Maximum aggregate diameter effect on ITZ percolation

Under the case of D eq,o = Fuller 1.0–4.5 mm, Figure 9 further displays the evolution of ϕ agg,c with the increase of maximum equivalent diameter D eq,max,p of polyhedral aggregates. It is shown that whatever the W/C or ITZ thickness is, the ITZ percolation threshold ϕ agg,c shows the slightly upward trend as the aggregate size D eq,max,p increases. This is also an expected and logical result. It can be explained by the fact that as the value of D eq,max,p increases, the contact surface between the cement matrix and aggregate particles would decrease, which can be not conducive to the formation of the ITZ percolation (i.e., the more fraction of aggregate particles is needed to form the global percolation paths of the ITZ phase). Besides, the aforementioned phenomenon can also be explained by the variation of the SSA of these aggregates (i.e., the aggregate fineness). According to our previous study [26], the larger maximum diameter of aggregates can result in the greater value of SSA, which corresponds to the higher ITZ percolation threshold ϕ agg,c. In addition, it should be noticeable that the sensitivity of ϕ agg,c to D eq,max,p for the realistic nonuniform ITZs in this figure is also obviously lighter than that for the simplistic uniform ITZs. All in all, for the realistic ITZs with the differential thickness, the influence of the microstructural factors on the ITZ percolation is much more complicated than that reported in the previously published studies [20,22,26,27,28].

Effect of maximum aggregate diameter D eq,max,p on the percolation threshold ϕ agg,c of both nonuniform and uniform ITZs under the cases of different W/C values.

By using the computer simulation technology, a variety of 3D polyphase composite models of concrete materials that are closer to the realistic structure of concrete are generated in this work and the critical percolation behavior (i.e., the global connectivity) of the ITZ phase around different aggregates is further simulated based on the combination of percolation theory and Hard core-soft shell network. Afterward, the percolation property of the ITZ phase in different polyphase systems is explored numerically, and the sensitivity of the critical percolation threshold ϕ agg,c of ITZ to the geometric features of both aggregate particles and nonuniform ITZs is clarified. All of the aforementioned processes are implemented through our own programming and the numerical results are obtained by the computer technique. According to the continuum percolation theory, the ITZ percolation is mainly applied to represent the global connectivity of the ITZ phase through the whole concrete. The relevant researches here can be generally regarded as a pre-phase preparation for exploring the influence of ITZ percolation on the macroscopic properties of concrete and thus may provide some meaning guide for the optimization of a variety of material properties.

5 Conclusions

In the work, a variety of more realistic 3D polyphase composite model of concrete are developed, in which the gravels and sands are separately simplified as the regular polyhedrons and ovoids according to their actual morphologies. In this way, the geometric difference between them becomes a major consideration here. Moreover, on the basis of the specific aggregate size and the W/C for the cement paste, the differential ITZ thickness for the nonuniform ITZs is also assigned for each aggregate in these models. By coupling these polyphase models with the continuum percolation theory, the sensitivities of the percolation threshold ϕ agg,c of nonuniform ITZs to the microstructural features of individual phases are studied by the simulation. Furthermore, a range of the numerical comparisons of the threshold ϕ agg,c for both the realistic nonuniform ITZs and simplistic uniform ITZs are also presented through the whole process of analysis. According to the obtained results and comparisons, several noticeable conclusions are obtained here.

For the nonuniform ITZs, the value of W/C has a dominant influence on the ITZ percolation. The ITZ percolation threshold ϕ agg,c would significantly decrease along with the increase of W/C.

When the realistic ITZs with the nonuniform thickness are replaced by their average value, their percolation threshold ϕ agg,c would be greatly overestimated in varying degrees than the reality (i.e., the nonuniform ITZs).

The sensitivity of ϕ agg,c to the aggregate size distribution for the realistic nonuniform ITZs is much lighter than that for the simplistic uniform ITZs.

For the nonuniform ITZs, ϕ agg,c shows a slightly increasing first and then decreasing trend with the increase of sand ratio β s, which is distinctly different from the curves of ϕ agg,c-β s for the uniform ITZs.

-

Funding information: J. Lin acknowledges the financial support from Natural Science Foundation of Hebei Province (Grant No. E2021203141), National Natural Science Foundation of China (Grant No. 52108251), and the open research fund of Jiangsu Key Laboratory of Construction Materials, Southeast University (Grant No. 202203). M. Li acknowledges the financial support from National Natural Science Foundation of China (No. 52308245), China Postdoctoral Science Foundation (No. 2023M730907), Science and Technology Project of Hebei Education Department (No. BJK2023053), and Tianjin Education Commission Scientific Research Project (No. 2022KJ100). H. Cao acknowledges the financial support from Central Guiding Local Science and Technology Development Fund Project (No. 236Z5401G). C. Jing acknowledges the financial support from the Natural Science Foundation of Hebei Province (Grant No. E2019203559).

-

Conflict of interest: We declare that there are no known competing financial interests or personal relationships that could have appeared to influence the work reported in this article.

-

Data availability statement: The raw data required to reproduce these findings is not shared here. All the data included in this work can be available upon request by contact with the corresponding authors.

References

[1] Stauffer D, Aharony A. Introduction to percolation theory. London: Taylor & Francis; 2003.10.1016/B0-12-227410-5/00550-0Search in Google Scholar

[2] Zhang SF, Ukrainczyk N, Zaoui A, Koenders E. Electrical conductivity of geopolymer-graphite composites: Percolation, mesostructure and analytical modeling. Constr Build Mater. 2024;411:134536.10.1016/j.conbuildmat.2023.134536Search in Google Scholar

[3] Newman MEJ, Ziff RM. Fast Monte Carlo algorithm for site or bond percolation. Phys Rev E. 2001;64:016706.10.1103/PhysRevE.64.016706Search in Google Scholar PubMed

[4] Malarz K. Random site percolation thresholds on square lattice for complex neighborhoods containing sites up to the sixth coordination zone. Phys A: Stat Mech Appl. 2023;632:129347.10.1016/j.physa.2023.129347Search in Google Scholar

[5] Shahid MI, Xiong NN, Ren JL. A novel method for the 3D inhomogeneous percolation on the lattice with its application. Results Phys. 2023;46:106275.10.1016/j.rinp.2023.106275Search in Google Scholar

[6] Hunt AG, Sahimi M. Flow, transport and reaction in porous media: percolation scaling, critical-path analysis, and effective-medium approximation. Rev Geophys. 2017;55:993–1078.10.1002/2017RG000558Search in Google Scholar

[7] Katori M, Katori M. Continuum percolation and stochastic epidemic models on Poisson and Ginibre point processes. Phys A: Stat Mech Appl. 2021;581:126191.10.1016/j.physa.2021.126191Search in Google Scholar

[8] Lambrou E, Gergidis LN. A particle digitization-based computational method for continuum percolation. Phys A: Stat Mech Appl. 2022;590:126738.10.1016/j.physa.2021.126738Search in Google Scholar

[9] Fathidoost M, Yang YYW, Oechsner M, Xu BX. Data-driven thermal and percolation analyses of 3D composite structures with interface resistance. Mater Des. 2023;227:111746.10.1016/j.matdes.2023.111746Search in Google Scholar

[10] Yazdi A, Hamzehpour H, Sahimi M. Permeability, porosity, and percolation properties of two-dimensional disordered fracture networks. Phys Rev E. 2011;84:046317.10.1103/PhysRevE.84.046317Search in Google Scholar PubMed

[11] Pervago E, Mousatov A, Kazatchenko E, Markov M. Computation of continuum percolation threshold for pore systems composed of vugs and fractures. Comput Geosci. 2018;116:53–63.10.1016/j.cageo.2018.04.008Search in Google Scholar

[12] Li MQ, Qing LB, Chen HS, Xu WX, Lin JJ. Diffusivity of porous media considering the coupling influence of pore shape- and size-polydispersities on the percolation: Theoretical and numerical studies. Comput Methods Appl Mech Eng. 2023;404:115830.10.1016/j.cma.2022.115830Search in Google Scholar

[13] Xu WX, Zhang YF, Jiang JY, Liu ZY, Jiao Y. Thermal conductivity and elastic modulus of 3D porous/fractured media considering percolation. Int J Eng Sci. 2021;161:103456.10.1016/j.ijengsci.2021.103456Search in Google Scholar

[14] Ambrosetti G, Johner N, Grimaldi C, Danani A, Pyser P. Percolative properties of hard oblate ellipsoids of revolution with a soft shell. Phys Rev E. 2008;78:061126.10.1103/PhysRevE.78.061126Search in Google Scholar PubMed

[15] Xu WX, Lan P, Jiang YQ, Lei D, Yang HX. Insights into excluded volume and percolation of soft interphase and conductivity of carbon fibrous composites with core-shell networks. Carbon. 2020;161:392–402.10.1016/j.carbon.2020.01.083Search in Google Scholar

[16] Pan ZC, Ma RJ, Chen AR. A study on ITZ percolation threshold of air-entrained mortar: Numerical simulation and analytical model. Constr Build Mater. 2022;322:126358.10.1016/j.conbuildmat.2022.126358Search in Google Scholar

[17] Ollivier JP, Maso JC, Bourdette B. Interfacial transition zone in concrete. Adv Cem Based Mater. 1995;2:30–8.10.1016/1065-7355(95)90037-3Search in Google Scholar

[18] Gao Y, Schutter GD, Ye G, Huang HL, Tan ZJ, Wu K. Characterization of ITZ in ternary blended cementitious composites: Experiment and simulation. Constr Build Mater. 2013;41:742–50.10.1016/j.conbuildmat.2012.12.051Search in Google Scholar

[19] Kishore K, Tomar R. Understanding the role of interfacial transition zone in cement paste and concrete. Mater Today Proc. 2023;80:877–81.10.1016/j.matpr.2022.11.322Search in Google Scholar

[20] Zheng JJ, Zhou XZ. Percolation of ITZs in concrete and effects of attributing factors. J Mater Civ Eng. 2007;517:784–90.10.1061/(ASCE)0899-1561(2007)19:9(784)Search in Google Scholar

[21] Bentz DP. Influence of internal curing using lightweight aggregates on interfacial transition zone percolation and chloride ingress in mortars. Cem Concr Compos. 2009;31:285–9.10.1016/j.cemconcomp.2009.03.001Search in Google Scholar

[22] Pan ZC, Wang DL, Ma RJ, Chen AR. A study on ITZ percolation threshold in mortar with ellipsoidal aggregate particles. Comput Concr. 2018;22:551–61.Search in Google Scholar

[23] Bentz DP, Hwang JTG, Hagwood C, Garboczi EJ, Snyder KA. Interfacial zone percolation in concrete: Effects of interfacial zone thickness and aggregate shape. MRS Proc. 1994;370:437–42.10.1557/PROC-370-437Search in Google Scholar

[24] Li MQ, Chen HS, Qing LB, Lin JJ. Generalized implicit solution of ITZ percolation threshold and its effect on the diffusivity of concrete: Influence of aggregate shape- and size-polydispersities. Int J Heat Mass Transf. 2023;200:123514.10.1016/j.ijheatmasstransfer.2022.123514Search in Google Scholar

[25] Lin JJ, Chen HS, Zhao QX, Li MQ. Statistical analysis of the critical percolation of ITZ around polygonal aggregates in three-phase concrete materials. Phys A: Stat Mech Appl. 2021;572:125878.10.1016/j.physa.2021.125878Search in Google Scholar

[26] Lin JJ, Zhao QX, Chen HS, Zhu ZG, Li MQ, Zhao DH. Insight into the diffusivity of particulate composites considering percolation of soft interphases around hard fillers: From spherical to polyhedral particles. Powder Technol. 2021;392:459–72.10.1016/j.powtec.2021.06.047Search in Google Scholar

[27] Lin JJ, Zhao QX, Chen HS, Li MQ, Yuan LL. A numerical study of ITZ percolation in polyphase concrete systems considering the synergetic effect of aggregate shape- and size-diversity. Materials. 2023;16:2515.10.3390/ma16062515Search in Google Scholar PubMed PubMed Central

[28] Lin JJ, Zhao QX, Chen HS, Xue CH, Li MQ. The fraction and percolation of soft interfaces in granular composites containing polyhedral and ovoidal fillers: A theoretical and numerical study. Adv Powder Technol. 2023;34:104057.10.1016/j.apt.2023.104057Search in Google Scholar

[29] Chen ZY, Ivan O. The interfacial zone between marble and tricalcium silicate. Cem Concr Res. 1987;17:784–92.10.1016/0008-8846(87)90041-XSearch in Google Scholar

[30] Mindess S. Bonding in cementitious composites: How important is it. MRS Proc. 1987;114:3–10.10.1557/PROC-114-3Search in Google Scholar

[31] Van Breugel K. Simulation of hydration and formation of structure in hardening cement-based materials. Delft University of Technology, TU Delft; 1991.Search in Google Scholar

[32] Elsharief A, Cohen MD, Olek J. Influence of aggregate size, water cement ratio and age on the microstructure of the interfacial transition zone. Cem Concr Res. 2003;33:1837–49.10.1016/S0008-8846(03)00205-9Search in Google Scholar

[33] Lyu K, She W, Chang H, Gu Y. Effect of fine aggregate size on the overlapping of interfacial transition zone (ITZ) in mortars. Constr Build Mater. 2020;248:118559.10.1016/j.conbuildmat.2020.118559Search in Google Scholar

[34] Lin JJ, Zhao QX, Chen HS, Li MQ, Yuan LL. A numerical framework for the ITZ percolation, effective fraction and diffusivity of concrete systems considering the nonuniform ITZ. J Build Eng. 2023;77:107429.10.1016/j.jobe.2023.107429Search in Google Scholar

[35] Liu L, Shen DJ, Chen HS, Xu WX. Aggregate shape effect on the diffusivity of mortar: A 3D numerical investigation by random packing models of ellipsoidal particles and of convex polyhedral particles. Comput Struct. 2014;144:40–51.10.1016/j.compstruc.2014.07.022Search in Google Scholar

[36] Zhu ZG, Chen HS, Liu L, Li XY. Multi-scale modelling for diffusivity based on practical estimation of interfacial properties in cementitious materials. Powder Technol. 2017;307:109–18.10.1016/j.powtec.2016.11.036Search in Google Scholar

[37] Lin JJ, Chen HS. Lattice Boltzmann simulation of fluid flow through random packing beds of Platonic particles: Effect of particle characteristics. Particuology. 2019;47:41–53.10.1016/j.partic.2018.08.014Search in Google Scholar

[38] Naija A, Miled K. Numerical study of the influence of W/C ratio and aggregate shape and size on the ITZ volume fraction in concrete. Constr Build Mater. 2022;351:128950.10.1016/j.conbuildmat.2022.128950Search in Google Scholar

[39] Walpole RE, Myers RH, Myers SL, Ye KY. Probability & statistics for engineers & scientists. Boston: Pearson; 2012.Search in Google Scholar

[40] Lin JJ, Zhang WL, Chen HS, Zhang RL, Liu L. Effect of pore characteristic on the percolation threshold and diffusivity of porous media comprising overlapping concave-shaped pores. Int J Heat Mass Transf. 2019;138:1333–45.10.1016/j.ijheatmasstransfer.2019.04.110Search in Google Scholar

[41] Chen HS, Stroeven P, Sluys LJ, Sun W. An approach to determine the size of representative volume element for microstructural parameters of cementitious composites. In Proceedings of International Congress on the Chemistry of Cement, Madrid; July, 2011. p. 1–7.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Research on damage evolution mechanisms under compressive and tensile tests of plain weave SiCf/SiC composites using in situ X-ray CT

- Structural optimization of trays in bolt support systems

- Continuum percolation of the realistic nonuniform ITZs in 3D polyphase concrete systems involving the aggregate shape and size differentiation

- Multiscale water diffusivity prediction of plain woven composites considering void defects

- The application of epoxy resin polymers by laser induction technologies

- Analysis of water absorption on the efficiency of bonded composite repair of aluminum alloy panels

- Experimental research on bonding mechanical performance of the interface between cementitious layers

- A study on the effect of microspheres on the freeze–thaw resistance of EPS concrete

- Influence of Ti2SnC content on arc erosion resistance in Ag–Ti2SnC composites

- Cement-based composites with ZIF-8@TiO2-coated activated carbon fiber for efficient removal of formaldehyde

- Microstructure and chloride transport of aeolian sand concrete under long-term natural immersion

- Simulation study on basic road performance and modification mechanism of red mud modified asphalt mixture

- Extraction and characterization of nano-silica particles to enhance mechanical properties of general-purpose unsaturated polyester resin

- Roles of corn starch and gellan gum in changing of unconfined compressive strength of Shanghai alluvial clay

- A review on innovative approaches to expansive soil stabilization: Focussing on EPS beads, sand, and jute

- Experimental investigation of the performances of thick CFRP, GFRP, and KFRP composite plates under ballistic impact

- Preparation and characterization of titanium gypsum artificial aggregate

- Characteristics of bulletproof plate made from silkworm cocoon waste: Hybrid silkworm cocoon waste-reinforced epoxy/UHMWPE composite

- Experimental research on influence of curing environment on mechanical properties of coal gangue cementation

- Multi-objective optimization of machining variables for wire-EDM of LM6/fly ash composite materials using grey relational analysis

- Synthesis and characterization of Ag@Ni co-axial nanocables and their fluorescent and catalytic properties

- Beneficial effect of 4% Ta addition on the corrosion mitigation of Ti–12% Zr alloy after different immersion times in 3.5% NaCl solutions

- Study on electrical conductive mechanism of mayenite derivative C12A7:C

- Fast prediction of concrete equivalent modulus based on the random aggregate model and image quadtree SBFEM

- Research on uniaxial compression performance and constitutive relationship of RBP-UHPC after high temperature

- Experimental analysis of frost resistance and failure models in engineered cementitious composites with the integration of Yellow River sand

- Influence of tin additions on the corrosion passivation of TiZrTa alloy in sodium chloride solutions

- Microstructure and finite element analysis of Mo2C-diamond/Cu composites by spark plasma sintering

- Low-velocity impact response optimization of the foam-cored sandwich panels with CFRP skins for electric aircraft fuselage skin application

- Research on the carbonation resistance and improvement technology of fully recycled aggregate concrete

- Study on the basic properties of iron tailings powder-desulfurization ash mine filling cementitious material

- Preparation and mechanical properties of the 2.5D carbon glass hybrid woven composite materials

- Improvement on interfacial properties of CuW and CuCr bimetallic materials with high-entropy alloy interlayers via infiltration method

- Investigation properties of ultra-high performance concrete incorporating pond ash

- Effects of binder paste-to-aggregate ratio and polypropylene fiber content on the performance of high-flowability steel fiber-reinforced concrete for slab/deck overlays

- Interfacial bonding characteristics of multi-walled carbon nanotube/ultralight foamed concrete

- Classification of damping properties of fabric-reinforced flat beam-like specimens by a degree of ondulation implying a mesomechanic kinematic

- Influence of mica paper surface modification on the water resistance of mica paper/organic silicone resin composites

- Impact of cooling methods on the corrosion behavior of AA6063 aluminum alloy in a chloride solution

- Wear mechanism analysis of internal chip removal drill for CFRP drilling

- Investigation on acoustic properties of metal hollow sphere A356 aluminum matrix composites

- Uniaxial compression stress–strain relationship of fully aeolian sand concrete at low temperatures

- Experimental study on the influence of aggregate morphology on concrete interfacial properties

- Intelligent sportswear design: Innovative applications based on conjugated nanomaterials

- Research on the equivalent stretching mechanical properties of Nomex honeycomb core considering the effect of resin coating

- Numerical analysis and experimental research on the vibration performance of concrete vibration table in PC components

- Assessment of mechanical and biological properties of Ti–31Nb–7.7Zr alloy for spinal surgery implant

- Theoretical research on load distribution of composite pre-tightened teeth connections embedded with soft layers

- Coupling design features of material surface treatment for ceramic products based on ResNet

- Optimizing superelastic shape-memory alloy fibers for enhancing the pullout performance in engineered cementitious composites

- Multi-scale finite element simulation of needle-punched quartz fiber reinforced composites

- Thermo-mechanical coupling behavior of needle-punched carbon/carbon composites

- Influence of composite material laying parameters on the load-carrying capacity of type IV hydrogen storage vessel

- Review Articles

- Effect of carbon nanotubes on mechanical properties of aluminum matrix composites: A review

- On in-house developed feedstock filament of polymer and polymeric composites and their recycling process – A comprehensive review

- Research progress on freeze–thaw constitutive model of concrete based on damage mechanics

- A bibliometric and content analysis of research trends in paver blocks: Mapping the scientific landscape

- Bibliometric analysis of stone column research trends: A Web of Science perspective

Articles in the same Issue

- Regular Articles

- Research on damage evolution mechanisms under compressive and tensile tests of plain weave SiCf/SiC composites using in situ X-ray CT

- Structural optimization of trays in bolt support systems

- Continuum percolation of the realistic nonuniform ITZs in 3D polyphase concrete systems involving the aggregate shape and size differentiation

- Multiscale water diffusivity prediction of plain woven composites considering void defects

- The application of epoxy resin polymers by laser induction technologies

- Analysis of water absorption on the efficiency of bonded composite repair of aluminum alloy panels

- Experimental research on bonding mechanical performance of the interface between cementitious layers

- A study on the effect of microspheres on the freeze–thaw resistance of EPS concrete

- Influence of Ti2SnC content on arc erosion resistance in Ag–Ti2SnC composites

- Cement-based composites with ZIF-8@TiO2-coated activated carbon fiber for efficient removal of formaldehyde

- Microstructure and chloride transport of aeolian sand concrete under long-term natural immersion

- Simulation study on basic road performance and modification mechanism of red mud modified asphalt mixture

- Extraction and characterization of nano-silica particles to enhance mechanical properties of general-purpose unsaturated polyester resin

- Roles of corn starch and gellan gum in changing of unconfined compressive strength of Shanghai alluvial clay

- A review on innovative approaches to expansive soil stabilization: Focussing on EPS beads, sand, and jute

- Experimental investigation of the performances of thick CFRP, GFRP, and KFRP composite plates under ballistic impact

- Preparation and characterization of titanium gypsum artificial aggregate

- Characteristics of bulletproof plate made from silkworm cocoon waste: Hybrid silkworm cocoon waste-reinforced epoxy/UHMWPE composite

- Experimental research on influence of curing environment on mechanical properties of coal gangue cementation

- Multi-objective optimization of machining variables for wire-EDM of LM6/fly ash composite materials using grey relational analysis

- Synthesis and characterization of Ag@Ni co-axial nanocables and their fluorescent and catalytic properties

- Beneficial effect of 4% Ta addition on the corrosion mitigation of Ti–12% Zr alloy after different immersion times in 3.5% NaCl solutions

- Study on electrical conductive mechanism of mayenite derivative C12A7:C

- Fast prediction of concrete equivalent modulus based on the random aggregate model and image quadtree SBFEM

- Research on uniaxial compression performance and constitutive relationship of RBP-UHPC after high temperature

- Experimental analysis of frost resistance and failure models in engineered cementitious composites with the integration of Yellow River sand

- Influence of tin additions on the corrosion passivation of TiZrTa alloy in sodium chloride solutions

- Microstructure and finite element analysis of Mo2C-diamond/Cu composites by spark plasma sintering

- Low-velocity impact response optimization of the foam-cored sandwich panels with CFRP skins for electric aircraft fuselage skin application

- Research on the carbonation resistance and improvement technology of fully recycled aggregate concrete

- Study on the basic properties of iron tailings powder-desulfurization ash mine filling cementitious material

- Preparation and mechanical properties of the 2.5D carbon glass hybrid woven composite materials

- Improvement on interfacial properties of CuW and CuCr bimetallic materials with high-entropy alloy interlayers via infiltration method

- Investigation properties of ultra-high performance concrete incorporating pond ash

- Effects of binder paste-to-aggregate ratio and polypropylene fiber content on the performance of high-flowability steel fiber-reinforced concrete for slab/deck overlays

- Interfacial bonding characteristics of multi-walled carbon nanotube/ultralight foamed concrete

- Classification of damping properties of fabric-reinforced flat beam-like specimens by a degree of ondulation implying a mesomechanic kinematic

- Influence of mica paper surface modification on the water resistance of mica paper/organic silicone resin composites

- Impact of cooling methods on the corrosion behavior of AA6063 aluminum alloy in a chloride solution

- Wear mechanism analysis of internal chip removal drill for CFRP drilling

- Investigation on acoustic properties of metal hollow sphere A356 aluminum matrix composites

- Uniaxial compression stress–strain relationship of fully aeolian sand concrete at low temperatures

- Experimental study on the influence of aggregate morphology on concrete interfacial properties

- Intelligent sportswear design: Innovative applications based on conjugated nanomaterials

- Research on the equivalent stretching mechanical properties of Nomex honeycomb core considering the effect of resin coating

- Numerical analysis and experimental research on the vibration performance of concrete vibration table in PC components

- Assessment of mechanical and biological properties of Ti–31Nb–7.7Zr alloy for spinal surgery implant

- Theoretical research on load distribution of composite pre-tightened teeth connections embedded with soft layers

- Coupling design features of material surface treatment for ceramic products based on ResNet

- Optimizing superelastic shape-memory alloy fibers for enhancing the pullout performance in engineered cementitious composites

- Multi-scale finite element simulation of needle-punched quartz fiber reinforced composites

- Thermo-mechanical coupling behavior of needle-punched carbon/carbon composites

- Influence of composite material laying parameters on the load-carrying capacity of type IV hydrogen storage vessel

- Review Articles

- Effect of carbon nanotubes on mechanical properties of aluminum matrix composites: A review

- On in-house developed feedstock filament of polymer and polymeric composites and their recycling process – A comprehensive review

- Research progress on freeze–thaw constitutive model of concrete based on damage mechanics

- A bibliometric and content analysis of research trends in paver blocks: Mapping the scientific landscape

- Bibliometric analysis of stone column research trends: A Web of Science perspective