Abstract

In this study, solid waste titanium gypsum (TG) was used as raw material to design the basic mix ratio of aggregate, and TG artificial aggregate (TGA) was prepared based on alkali-activated cold bonding technology. The effects of different additives (slag, silica fume, and fly ash) on the properties of TGA were preliminarily investigated by using NaOH as activator in laboratory test, and the additives of TG aggregate were determined. Furthermore, the aggregate mix ratio was designed based on the additive, and the physical and mechanical properties, X-ray diffraction analysis, scanning electron microscopy analysis, and dry–wet cycle test of artificial aggregate were carried out. The results show that the artificial aggregate prepared by the same process and the aggregate prepared by silica fume as an additive has a high balling rate; it is technically feasible to use TG as the main raw material, silica fume as an additive, and NaOH as an activator to select a suitable mix ratio to prepare artificial aggregates. The microscopic test results reveal the internal products and structural degradation process of TG aggregate.

1 Introduction

At present, due to the rapid urbanization and industrialization of the world, the accumulation of industrial waste has led to a series of problems, such as environmental pollution, land occupation, deforestation, and global warming. It is urgent to determine an effective and environmentally friendly method to solve this problem [1,2,3,4]. In the past few years, the use of industrial waste to alleviate civil engineering problems has attracted great interest in sustainable development [5,6]. This approach can provide cost-effective, environmentally friendly, and sustainable solutions for construction and industrial waste management [7,8]. In the world, there are three main types of solid waste gypsum produced by the rapidly developing industrial production: titanium gypsum (TG), phosphor gypsum, and desulphurized gypsum. TG is a kind of weak alkaline waste residue, which is added with lime by sulfuric acid method to neutralize a large amount of acidic wastewater [9,10]. The main component of TG is CaSO4·2H2O. Due to the high free water content, high impurity content, and poor mechanical properties, it is difficult to recycle. At present, the annual emissions of TG in China alone have reached 300,000 tons. These wastes are usually treated in the form of stacking, which not only takes up a large area of land resources but also causes groundwater and air pollution during weathering.

Guo et al. [11] used fly ash as the main raw material and separately mixed metallurgical sludge and municipal solid waste incineration fly ash to prepare heavy metal-containing solid waste polymers with good acid and alkali erosion resistance. Xu et al. [12] studied the effect of silica fume on the macro and micro properties of cold-bonded unburned fly ash ceramsite and found that the increase of silica fume content improved the compressive strength and compactness of unburned ceramsite. Ceramsite is a kind of lightweight aggregate produced by using waste resource diameter technology. Gao et al. [13] studied the influence of solid-waste interaction on the strength of modified fly ash geopolymer by taking the content of carbide slag, desulfurization gypsum, and steel slag as the influencing factors and optimized the mix ratio design to improve the early strength of modified fly ash geopolymer. Shi [14] explored the process of wet extrusion granulation of dredged sediment to prepare cold-bonded unburned aggregate. The optimum process parameters were 35–40% water content of sediment, 3 mm extrusion diameter, and 30 min molding time. Hao et al. [15] prepared ceramsite by using steel slag and mineral powder as the main raw materials and adding water glass as an activator through the non-fired process, changing the proportion of steel slag and mineral powder, and designing multiple sets of experiments to study its effect on the performance of non-fired ceramsite. Xu et al. [16] proposed a simple physical modification to improve the performance of TG in the stability of expansive soil. The engineering properties and mechanism of stabilized soil are studied, and it is found that the stabilized soil with 25% TG admixture can meet the requirements of Chinese standard for subgrade below grade two. At present, in the field of building materials, it is mainly to modify TG or other solid wastes to prepare high-content TG cementing materials and explore the application [17,18,19,20].

Although the resource application of TG is varied, there is no research on the resource utilization of TG in the form of making aggregate [21], which may be due to the easy occurrence of alkali aggregate reaction in the process of making artificial aggregate by using solid waste, which is one of the important factors affecting the quality of aggregate [22,23,24]. TG artificial aggregate (TGA) was prepared by alkali-activated cold bond granulation using TG as precursor and NaOH as activator. TGA test schemes with different additives (fly ash, slag powder, and silica fume) and different TG contents were designed. The physical properties, density, water absorption, and reaction products were characterized and compared to explore its applicability in the construction field, alleviate environmental pollution problems, and the situation of resource shortage in the construction industry.

2 Experiment design

2.1 Raw material

The TG raw material used in the test is from a chemical plant in Henan Province, and the scanning electron microscope (SEM)/energy dispersive spectrometer (EDS) image is shown in Figure 1. S95 ore powder from Henan Yuanheng Environmental Protection Engineering Co., Ltd.; the grade I ash of Yulian Power Plant is selected; the high quality and high content silica fume from Henan Platinum New Material Co., Ltd. was used. The chemical composition of each raw material is shown in Table 1. Henan Tianrui P·O 42.5 ordinary Portland cement was used.

SEM/EDS graph of TG.

Chemical composition of raw materials

| Chemical constituents (%) | CaO | Fe2O3 | SO3 | Al2O3 | MgO | SiO2 | K2O | Na2O | TiO2 | Loss on ignition |

|---|---|---|---|---|---|---|---|---|---|---|

| TG | 31.43 | 15.41 | 37.63 | 2.47 | 1.45 | 5.08 | 0.06 | 0.99 | 3.69 | 12.9 |

| Mineral powder | 37.14 | 0.71 | — | 15.76 | 8.51 | 33.21 | — | — | 1.91 | — |

| Fly ash | 2.27 | 3.87 | — | 29.09 | 0.81 | 53.36 | — | — | — | 2.48 |

| Silica fume | 0.85 | — | — | 0.87 | 0.27 | 92.30 | 1.56 | — | — | 3.92 |

The activator uses industrial grade sodium hydroxide (NaOH), white flake, 99% content. The water reducer used is purchased from Shanxi Huangteng Chemical Co., Ltd., which is a HT-HPC polycarboxylate superplasticizer. When the dosage is 1%, the water reduction rate is 15%.

2.2 Aggregate mix ratio design and preparation method

To determine the basic composition of aggregate, reference is made to relevant literature [17,18]. The ratio of fixed TG, cement, and mineral additive excitation is 7:3, that is, (TG + cement)/(mineral admixtures) = 7:3, and the ratio of TG to cement is fixed at 5:2. A 40 mm × 40 mm × 40 mm paste test block was designed. The compressive test mix ratio is shown in Table 2. The compressive strength of the clean paste test block is measured according to GB/T 17671-1999 of the Cement Mortar Strength Testing Method (ISO Method). The TGA preparation process is shown in Figure 2.

Mixing ratio of artificial aggregate clean pulp test

| Group | TG (%) | Cement (%) | S95 mineral powder (%) | Silica fume (%) | Fly ash (%) | NaOH (%) | HT-HPC (%) |

|---|---|---|---|---|---|---|---|

| L1 | 50 | 20 | 30 | 1 | 1 | ||

| L2 | 50 | 20 | 30 | 1 | 1 | ||

| L3 | 50 | 20 | 30 | 1 | 1 |

TGA preparation process.

2.3 TGA preparation method

Raw material pretreatment: Figure 3 shows the reddish-brown solid original TG of uneven size. The large block TG is broken into small and uniform pieces, which are placed in the oven set at 50℃, dried at low temperature for 24 h, and then placed in the ball mill for grinding.

Raw TG.

Mixing: The treated TG and cement, additives (silica fume, fly ash, S95 mineral powder), and admixtures (activators, water reducing agents) are mixed according to the set mix ratio and then aged for use. The aging time is 1 h.

Granulation: the dry material is mixed with a certain proportion of water to obtain the mix in a plastic state, and then, the mix is pressed into sheets through the cake press station of the granulation equipment, and the strip is made through the strip making station. Finally, the prepared strip is placed horizontally on the pill making station to obtain granular or short rod-like wool.

Ball forming: the wool is placed in the pelletizer into a ball cylinder, and under the action of centrifugation, spherical particles are formed, that is, artificial aggregate.

Maintenance: Natural maintenance method is adopted. The formed aggregate is put into a plastic container and sprayed with water for maintenance every 24 h until the corresponding age is reached. During the period, the surface of the aggregate should be kept wet, and there is no water in the plastic container, and the curing temperature is room temperature 25℃.

2.4 Experimental method

According to GB/T 174312-2010 ‘Lightweight aggregate and test method-Part 2’, the industrial TGA cylinder compressive strength, grain shape coefficient, bulk density, water absorption, and other indicators were tested. X-ray diffraction analysis: the D8 ADVANCE X-ray diffractometer was used to determine the crystal structure of the aggregate. The target source was a Cu target with a continuous scanning range of 5–70°. The scanning voltage and current were 40 kV and 40 mA, respectively. Scanning electron microscope analysis: Gemini SEM 300 field emission scanning electron microscope was used to analyze the elements by Oxford X-MAX spectrometer. Instrument measurement parameters are as follows: working voltage 20 kV, working distance 10 mm, and scanning time 45 s. The dry–wet cycle test was carried out according to GB/T50082-2009 ‘Test method standard for long-term performance and durability of ordinary concrete’.

3 Experimental results and discussion

According to the previous section, the aggregate properties of the prepared TGA were characterized and the basic components of the TGA were determined. According to the results obtained, the physical and mechanical properties and micro phase analysis of TGA with different TG content are recorded in the following chapters.

3.1 Determination of basic components of TGA

Figure 4 is the compressive strength change curve of TG-based paste samples cured for 7 and 28 days. When silica fume (L3) is used as the admixture of TG-based composite cementitious material, the compressive strength of the sample at 7 and 28 days ages is the largest. As an admixture, fly ash (L2) has the lowest compressive strength at each age, because the hydration activity of fly ash is low, and the hydration products of cementitious materials are less, which affects the compactness of the specimen, resulting in low strength. When S95 ore powder (L1) is used as admixture, the strength is slightly lower than that of silica fume, but the strength growth rate from 7 to 28 days is higher than that of silica fume, which is about 43.6%.

Compress strength of different admixtures at different ages.

To finally determine the admixture of TGA, it is also necessary to observe the aggregate formation. The admixture is prepared according to the ratio of Table 3, and the aggregate morphology is shown in Figure 5. The aggregate prepared by S95 ore powder (L1) as admixture can be balled, but the particles are soft; the aggregate prepared by fly ash (L2) as an admixture is not easy to form a ball; the aggregate prepared by silica fume (L3) as admixture has high balling rate and regular shape. Therefore, silica fume was selected as an admixture to prepare TGA.

Mix ratio of artificial aggregate granulation test

| Group | TG (%) | Cement (%) | Silica fume (%) | NaOH (%) | HT-HPC (%) |

|---|---|---|---|---|---|

| L3 | 50 | 20 | 30 | 1 | 1 |

| L4 | 60 | 20 | 20 | 1 | 1 |

| L5 | 60 | 15 | 25 | 1 | 1 |

| L6 | 60 | 10 | 30 | 1 | 1 |

| L7 | 70 | 20 | 10 | 1 | 1 |

| L8 | 70 | 15 | 15 | 1 | 1 |

| L9 | 70 | 10 | 20 | 1 | 1 |

| L10 | 80 | 10 | 10 | 1 | 1 |

Form of aggregate.

According to relevant research, the amount of solid waste is generally more than 50%. To increase the utilization of TG resources, it is gradually increased on the basis of 50% TG content. At the same time, considering the high cost of cement, the amount of cement is reduced while increasing the TG and the total amount is kept unchanged, and silica fume is added. The design of artificial aggregate test with such as Table 3, the preparation of aggregate and aggregate related tests, to find the best performance of TGA.

3.2 Packing density and water absorption

Section 3.1 determines that the additive of TGA is silica fume. The statistical results of TGA particle shape coefficient and bulk density prepared according to Table 3 are shown in Table 4. It can be seen that the TGA average particle size coefficient is 1.0–1.2, which meets the requirements of GB/T 174312-2010 in Light Aggregates and their Test methods-Part 1. The aggregate after molding is approximately spherical, and the bulk density is between 700 and 800 kg/m3, which belongs to the 800-grade aggregate.

Particle form factor and bulk density of aggregate

| Group | Granular factor | Specification value | Bulk density (kg/m3) | Density range | ||

|---|---|---|---|---|---|---|

| Max | Min | Mean value | ||||

| L3 | 1.22 | 1.03 | 1.13 | ≤2.0 | 767.42 | >700, ≤800 |

| L4 | 1.23 | 1.06 | 1.14 | 775.25 | ||

| L5 | 1.37 | 1.03 | 1.20 | 751.08 | ||

| L6 | 1.17 | 1.03 | 1.10 | 745.08 | ||

| L7 | 1.20 | 1.04 | 1.12 | 772.25 | ||

| L8 | 1.23 | 1.02 | 1.13 | 761.75 | ||

| L9 | 1.29 | 1.04 | 1.17 | 762.25 | ||

| L10 | 1.22 | 1.02 | 1.12 | 766.70 | ||

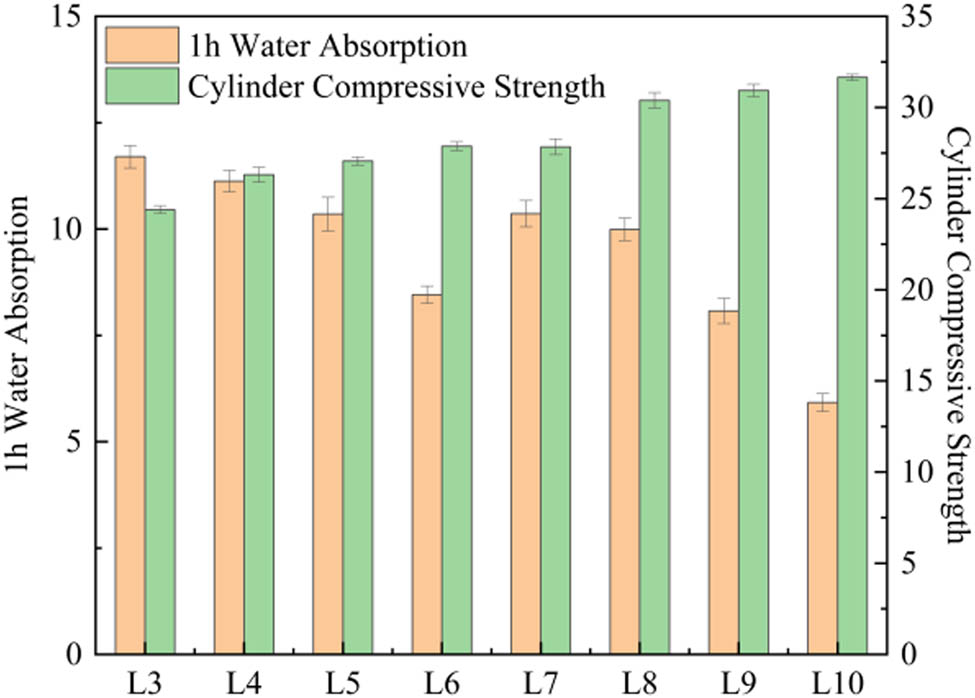

Figure 6 is the relationship between the water absorption of TGA 1 h and the cementitious material. In each group, three equal amounts of aggregate were placed in the container, and the average value was taken as the final water absorption rate of the aggregate. With the decrease of the total amount of cementitious materials, the water absorption of aggregate showed an upward trend. When L3 group (cement:silica fume = 20%:30%), the water absorption of aggregate was the lowest at 1 h, which was 24.40%. The maximum water absorption rate of aggregate in L10 group is 31.65%. The high water absorption rate of aggregate may be due to the high water absorption rate of TG itself, which needs to be further studied and solved.

1 h water absorption and cylinder compressive strength of aggregate.

3.3 Mechanical property

Figure 6 is the change rule of the compressive strength of TGA cylinder under different mix proportions. With the decrease of the total amount of cementitious materials, the compressive strength of the aggregate is generally decreasing. When the total amount of cementitious materials is 50%, that is, L3 group (cement:silica fume = 20%:30%), the aggregate cylinder compressive strength is the highest, which is 11.7 MPa. According to the tests of L4, L5, L6 and L7, L8, L9 groups, when the total amount of cementitious materials is constant, the compressive strength of aggregate cylinder decreases with the decrease of cement content, indicating that the decisive factor affecting the compressive strength of aggregate cylinder is cement. In addition, when the total amount of cementitious material is more than 20%, the compressive strength of the aggregate tube is more than 6 MPa, which belongs to high-strength aggregate according to the provisions of GB/T 174312-2010 ‘Lightweight aggregate and its test methods-Part 1’.

3.4 Phase analysis

Samples from group L3 to L10 at the age of 14 days were selected to analyze the composition of hydration products by X-ray diffractometer (XRD). From the analysis of the characteristic diffraction peaks in Figure 7, it can be seen that the characteristic peaks of ettringite (AFt), CaSO4·2H2O and calcium silicate hydrate (C–S–H) in the XRD patterns of hydration products of different test groups at 14 days age are strong. The specific reaction of cement and TG is as follows:

XRD pattern of aggregates.

The content of TG increased with the decrease of cementitious materials. From L3 sample to L10 sample, the diffraction peak of CaSO4·2H2O increased, and the content of CaSO4·2H2O which did not participate in the reaction increased. When the total amount of cementitious materials is constant, the amount of cement is reduced, the amount of silica fume is increased, the diffraction characteristic peak of the hydration product AFt is weakened, the diffraction peak of C–S–H is weakened, and the diffraction characteristic peak of the alkali-silica gel is enhanced. Ca(OH)2 can stimulate the activity of TG, and a small amount of active SiO2 and Al2O3 in TG react with Ca(OH)2 to form C–(A)–S–H, which is similar to the C–(A)–S–H produced by cement hydration. These hydration products increase the strength of aggregates as part of cementitious materials. In addition, the amorphous SiO2 pozzolanic activity in silica fume is higher, which can react with the cement hydration product Ca(OH)2 to form C–S–H gel [19,20]. When the TG content is large, the dissolved CaSO4·2H2O will continue to react with C–S–H to form AFt. With the decrease of cement content, the hydration products decrease, and too much active silicon reacts with NaOH under alkaline conditions to form alkali-silica gel, so the characteristic peaks are gradually enhanced in the XRD pattern.

Figure 8 is the SEM image of L3–L10 groups of samples at 14 days age, and the causes of TGA performance change are analyzed by analyzing the generation of hydration products and the microstructure of aggregates. With the increase of TG content, no matter how to change the content of cement and silica fume, the main component of TG, CaSO4·2H2O, has not been fully utilized. Combined with the relevant alkali-silica gel literature [22], the L3 group can be observed that the alkali-silica gel and ettringite intersect and closely connect with each other. The gelling system is excited by NaOH and CaSO4·2H2O dissolves to provide Ca2+, Na+, etc., which react with active silicon under alkaline conditions to produce alkali-silica gel. The structure of L4–L6 is loose and gel is produced. It can be observed that there is still unhydrated CaSO4·2H2O in the aggregate. At the same time, with the decrease of cement content, less and less ettringite is observed. Ettringite plays a supporting role inside the aggregate and ettringite decreases, so the cylinder compressive strength of the aggregate will gradually decrease, cracks and pores are observed in L6. It shows that the hydration products of L6 group are not much, which is one of the reasons for its low strength. Alkali-silica gel, Aft, and some dihydrate gypsum can be observed in L7 group. The structure is better than that of L8–L10 group and the products are also rich. This is because the cement is fully hydrated and the small amount of silica fume is fully utilized to produce more ettringite and alkali silica gel. Through the SEM images of L8–L10 groups of samples, it was also observed that there were a large number of columnar, plate-like and clastic unhydrated dihydrate gypsum in the internal structure of the aggregate, and only a small amount of gel was bonded to the unhydrated gypsum on the surface, with loose structure and a large number of pores.

Microscopic morphology of L3–L7 specimens at the age of 14 days (3,000×).

As a whole, the needle-like ettringite crystal and fibrous calcium silicate hydrate are the main hydration products of the cement material and are accompanied by the formation of alkali-silicon gel. The ettringite crystal and the remaining unreacted gypsum dihydrate crystal are interspersed and dispersed in the structure and are cross-bonded with the calcium silicate hydrate and alkali-silicon gel. Spicular ettringite crystal plays the role of skeleton support in the microstructure, fibrous hydrated calcium silicate and alkali silicon gel can play the role of intertwining bond, and their mutual matching can improve the compactness and strength of the aggregate structure. After phase analysis and comparison, it is concluded that the aggregate structure and performance of L7 group are better, and the product is more abundant. This ratio can be used as the optimal ratio in this study.

3.5 Durability

To investigate the durability and stability of aggregates, dry and wet cycles are carried out on the dried aggregates. The damage situation of aggregates is shown in Figure 9, the quantitative calculation results are shown in Table 5, and the statistical chart of cracking rate is shown in Figure 10.

Cracking diagram of aggregate after dry and wet cycling.

Statistical table of silica fume content, cracking rate, and SiO2/Na2O molar ratio of each group

| Group | L3 | L4 | L5 | L6 | L7 | L8 | L9 | L10 |

|---|---|---|---|---|---|---|---|---|

| Addition in silica fume (%) | 30 | 20 | 25 | 30 | 10 | 15 | 20 | 10 |

| Cracking rate (%) | 19.60 | 11.28 | 18.63 | 35.97 | 2.13 | 8.26 | 26.43 | 13.58 |

| SiO2/Na2O | 15.958 | 11.026 | 13.521 | 16.485 | 6.826 | 8.790 | 11.091 | 6.560 |

Statistical diagram of silica fume and cracking rate of each group.

As can be seen from Figure 9, some aggregates crack a few minutes after the aggregate is injected into the water. The reason for this phenomenon [23,24] is that the alkali-silicon reaction (ASR) generates an expansive alkali-silicon gel (Na2O·nSiO2). TG is used to prepare artificial aggregate. After mixing the cement material with water, highly active minerals such as dicalcium silicate, tricalcium silicate and tricalcium aluminate in the clinker will quickly dissolve in water and undergo chemical reactions. Hydrated calcium silicate, hydrated calcium aluminate, Ca(OH)2, and other hydrated products are generated. Ca(OH)2 and NaOH dissolve and precipitate strongly alkaline OH−, which will react strongly with active minerals such as silica ash. Products such as calcium silicate hydrate gel, calcium aluminate hydrate and alkali silicon gel with gelling ability are generated. Calcium aluminate hydrate reacts with gypsum dihydrate dissolved in TG to produce ettringite crystals and other gelling substance. Ettringite and hydrated calcium silicate are the main basis of aggregate strength, which is also verified by XRD analysis of the aggregate. Alkali-silicon gel has expansibility and strong water absorption. After its expansion of water absorption, expansion stress is generated in the aggregate, resulting in the collapse of the aggregate structure.

As can be seen from Figure 10, the greater the dosage of silica fume, the greater the cracking rate of aggregate. The cracking rate of L6 group is the largest 35.97%, and the cracking rate of L7 group is the smallest 2.13%. Therefore, controlling the molar ratio of SiO2/Na2O has a good effect on inhibiting the cracking of aggregate. According to the calculated values of SiO2/Na2O molar ratio of each group in Table 5, the maximum SiO2/Na2O molar ratio of group L6 is 16.485, and the minimum SiO2/Na2O molar ratio of group L7 is 6.826, which is also consistent with the changing trend of silica fume content and cracking rate. This indicates that the content of silica fume changes the molar ratio of SiO2/Na2O. The greater the molar ratio of SiO2/Na2O, the more active silicon in the aggregate system, the more alkali-silicon gel is produced, and the greater the cracking rate of the aggregate. There are different cracking rates for the same dosage of silica fume, which is related to the amount of TG and cement in the aggregate system. Based on the above research results, the compressive strength, water absorption, and cracking rate of the aggregate cylinder are compared and analyzed. It is concluded that the aggregate of L7 group has the best overall performance and is the optimal mix ratio in this paper.

4 Conclusion

According to the research and analysis of the test results, the following conclusions are obtained:

The artificial aggregate was prepared by cold-bonded granulation technology using mineral powder, fly ash, and silica fume as additive mixed with TG and NaOH as activator. The results showed that the TGA prepared by silica fume as additive had the best performance.

The results show that the shaped TGA is approximately spherical, the average grain shape coefficient of TGA is 1.0–1.2, and the bulk density is 700–800 kg/m3. The higher the TG content, the higher the water absorption of TGA. In addition, the cylinder compressive strength of TGA is in the range of 6–12 MPa.

By XRD and SEM analyses, the main products of TGA system are C–S–H, alkalosilica-gel, and a small amount of AFt, and the internal structure of aggregate gradually deteriorates as the specific gravity of cementing material decreases. The experimental results show that group L7 (TG:cement:silica ash = 7:2:1, 1% NaOH and 1% water-reducing agent) TGA has the best comprehensive performance in this study.

The cracking after TGA dry and wet cycle is due to the ASR of the gelling system. The selection of 10% silica fume as an additive can improve the dry and wet resistance of the aggregate and reduce the effect of ASR on the performance of TG artificial aggregate.

-

Funding information: This study was funded by the National Natural Science Foundation of China, (52109154); the Natural Science Foundation of Henan Province (202300410270); and guiding river to assist Huai River (Henan section) engineering scientific research service project.

-

Author contributions: LG Data analysis and Writing. HW Formal analysis and Investigation. LZ Validation and Visualization. JZ Methodology and Writing - Review & Editing. LL Validation and Methodology.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: All data, models, and code generated or used during the study appear in the published article.

References

[1] Thirumalai R, Babu SS, Naveennayak V, Nirmal R, Lokesh G. A review on stabilization of expansive soil using industrial solid wastes. Engineering. 2017;9(12):1008–17. 10.4236/eng.2017.912060.Search in Google Scholar

[2] Vijayan DS, Parthiban D. Effect of solid waste based stabilizing material for strengthening of expansive soil-A review. Environ Technol Innov. 2020;20:101108. 10.1016/j.eti.2020.101108.Search in Google Scholar

[3] Ozel HU, Ozel HB, Cetin M, Sevik H, Gemici BT, Varol T. Base alteration of some heavy metal concentrations on local and seasonal in Bartin River. Environ Monit Assess. 2019;191:1–15. 10.1007/s10661-019-7753-0.Search in Google Scholar PubMed

[4] Ozel HU, Gemici BT, Gemici E, Ozel HB, Cetin M, Sevik H. Application of artificial neural networks to predict the heavy metal contamination in the Bartin River. Environ Sci Pollut Res. 2020;27:42495–42512. 10.1007/s11356-020-10156-w.Search in Google Scholar PubMed

[5] Feng DY, Wei ZT, Yu Z, Wen LQ, Qiong W. Mechanical behaviour and microstructure of steel slag-based composite and its application for soft clay stabilisation. Eur J Environ Civ Eng. 2017;1–16. 10.1080/19648189.2017.1357787.Search in Google Scholar

[6] Du YJ, Jiang NJ, Liu SY, Horpibulsuk S, Arulrajah A. Field evaluation of soft highway subgrade soil stabilized with calcium carbide residue. Soils Found. 2016;56(2):301–14. 10.1016/j.sandf.2016.02.012.Search in Google Scholar

[7] Ijaz N, Dai F, Rehman ZU. Paper and wood industry waste as a sustainable solution for environmental vulnerabilities of expansive soil: A novel approach. J Environ Manag. 2020;262:110285. 10.1016/j.jenvman.2020.110285.Search in Google Scholar PubMed

[8] Ghaffar SH, Burman M, Braimah N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J Clean Prod. 2020;244:118710. 10.1016/j.jclepro.2019.118710.Search in Google Scholar

[9] Fauziah I, Zauyah S, Jamal T. Characterization and land application of red gypsum: a waste product from the titanium dioxide industry. Sci Total Environ. 1996;188(2–3):243–51. 10.1016/0048-9697(96)05179-0.Search in Google Scholar

[10] Li JW, Wang WL, Xu D, Wang XJ, Mao YP. Preparation of sulfoaluminate cementitious material using harmful titanium gypsum: Material properties and heavy metal immobilization characteristics. Waste Dispos Sustain Energy. 2020;2:127–37. 10.1007/s42768-020-00038-9.Search in Google Scholar

[11] Guo XL, Wu L, Zhang LY, Shi HS. Chemical modification and mechanism of solid waste earth polymer containing heavy metals. J Build Mater. 2016;19(6):976–82.Search in Google Scholar

[12] Xu SC, Su ZF, Liu Z, Wang DM, Zhang T. Effect of silica fume content on properties of no-burning pulverized coal ash ceramics. Bull Silicate. 2021;41(2):506–12. 10.16552/j.cnki.issn1001-1625.20211224.002.Search in Google Scholar

[13] Gao YL, Zhu ZH, Meng H, Hu XL, Li ZK. Synergistic strengthening mechanism of fly ash polymers modified by calcium carbide slag, desulfurization gypsum and steel slag. J Build Mater. 2023;26(8):870–8.Search in Google Scholar

[14] Shi HL. Study on preparation and properties of burnt-free aggregate by wet extruded granulation of dredged sediment. China: Tianjin University of Science and Technology; 2019.Search in Google Scholar

[15] Hao JY, Mu BL, Tian YM. Study on preparation and properties of non-fired ceramic particles based on steel slag. J Taiyuan Univ Sci Technol. 2021;42(5):399–402.Search in Google Scholar

[16] Zha FS, Qiao BR, Kang B, Xu L, Chu CF, Yang CB. Engineering properties of expansive soil stabilized by physically amended titanium gypsum. Constr Build Mater. 2021;303:124456. 10.1016/j.conbuildmat.2021.124456.Search in Google Scholar

[17] Huang XQ, Liu LM, Bie SQ, Yang CF, Liu YJ, Gan T, et al. Preparation and hydration mechanism of titanium-gypsum modified cementing material. J China Three Gorges Univ (Nat Sci Ed). 2016;38(1):45–50. 10.13393/j.cnki.issn.1672-948X.2016.01.010.Search in Google Scholar

[18] Shi X. Research on properties and Application of titanium-gypsum based mortar. China: Guangzhou University; 2021.Search in Google Scholar

[19] Luo T, Hua C, Sun Q, Tang LY, Yi Y, Pan XF. Early-age hydration reaction and strength formation mechanism of solid waste silica fume modified concrete. Molecules. 2021;26(18):5663. 10.3390/molecules26185663.Search in Google Scholar PubMed PubMed Central

[20] Liu ZD, Lei W, Liu JX. Hydration mechanism of yellow gypsum and cement composite cementing material. Nonferrous Met. 2007;5:26–8 + 39.Search in Google Scholar

[21] Li XY, Yang JY. Production, characterisation, and application of titanium gypsum: A review. Process Saf Environ Prot. 2024;181:64–74. 10.1016/j.psep.2023.11.008.Search in Google Scholar

[22] Li Z, Xiao L, Chen L. Study on micromorphology of alkali-silicon reaction products. J Yangtze River Sci Res Inst. 2012;29(3):62–6.Search in Google Scholar

[23] Murmu M, Singh SP. Hydration products, morphology and microstructure of activated slag cement. Int J Concr Struct Mater. 2014;8(1):61–8. 10.1007/s40069-013-0056-x.Search in Google Scholar

[24] Wen ZY, Yin SH, Yin Q, Dai XX, Guo WY, Wu GL, et al. Basic laws and principles of alkali-silicic acid reaction and alkali-excited gelling materials. Chinese Silicate Society: Abstracts of the 10th National Conference on Cement and Concrete Chemistry and Application Technology; 2007. p. 1.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Research on damage evolution mechanisms under compressive and tensile tests of plain weave SiCf/SiC composites using in situ X-ray CT

- Structural optimization of trays in bolt support systems

- Continuum percolation of the realistic nonuniform ITZs in 3D polyphase concrete systems involving the aggregate shape and size differentiation

- Multiscale water diffusivity prediction of plain woven composites considering void defects

- The application of epoxy resin polymers by laser induction technologies

- Analysis of water absorption on the efficiency of bonded composite repair of aluminum alloy panels

- Experimental research on bonding mechanical performance of the interface between cementitious layers

- A study on the effect of microspheres on the freeze–thaw resistance of EPS concrete

- Influence of Ti2SnC content on arc erosion resistance in Ag–Ti2SnC composites

- Cement-based composites with ZIF-8@TiO2-coated activated carbon fiber for efficient removal of formaldehyde

- Microstructure and chloride transport of aeolian sand concrete under long-term natural immersion

- Simulation study on basic road performance and modification mechanism of red mud modified asphalt mixture

- Extraction and characterization of nano-silica particles to enhance mechanical properties of general-purpose unsaturated polyester resin

- Roles of corn starch and gellan gum in changing of unconfined compressive strength of Shanghai alluvial clay

- A review on innovative approaches to expansive soil stabilization: Focussing on EPS beads, sand, and jute

- Experimental investigation of the performances of thick CFRP, GFRP, and KFRP composite plates under ballistic impact

- Preparation and characterization of titanium gypsum artificial aggregate

- Characteristics of bulletproof plate made from silkworm cocoon waste: Hybrid silkworm cocoon waste-reinforced epoxy/UHMWPE composite

- Experimental research on influence of curing environment on mechanical properties of coal gangue cementation

- Multi-objective optimization of machining variables for wire-EDM of LM6/fly ash composite materials using grey relational analysis

- Synthesis and characterization of Ag@Ni co-axial nanocables and their fluorescent and catalytic properties

- Beneficial effect of 4% Ta addition on the corrosion mitigation of Ti–12% Zr alloy after different immersion times in 3.5% NaCl solutions

- Study on electrical conductive mechanism of mayenite derivative C12A7:C

- Fast prediction of concrete equivalent modulus based on the random aggregate model and image quadtree SBFEM

- Research on uniaxial compression performance and constitutive relationship of RBP-UHPC after high temperature

- Experimental analysis of frost resistance and failure models in engineered cementitious composites with the integration of Yellow River sand

- Influence of tin additions on the corrosion passivation of TiZrTa alloy in sodium chloride solutions

- Microstructure and finite element analysis of Mo2C-diamond/Cu composites by spark plasma sintering

- Low-velocity impact response optimization of the foam-cored sandwich panels with CFRP skins for electric aircraft fuselage skin application

- Research on the carbonation resistance and improvement technology of fully recycled aggregate concrete

- Study on the basic properties of iron tailings powder-desulfurization ash mine filling cementitious material

- Preparation and mechanical properties of the 2.5D carbon glass hybrid woven composite materials

- Improvement on interfacial properties of CuW and CuCr bimetallic materials with high-entropy alloy interlayers via infiltration method

- Investigation properties of ultra-high performance concrete incorporating pond ash

- Effects of binder paste-to-aggregate ratio and polypropylene fiber content on the performance of high-flowability steel fiber-reinforced concrete for slab/deck overlays

- Interfacial bonding characteristics of multi-walled carbon nanotube/ultralight foamed concrete

- Classification of damping properties of fabric-reinforced flat beam-like specimens by a degree of ondulation implying a mesomechanic kinematic

- Influence of mica paper surface modification on the water resistance of mica paper/organic silicone resin composites

- Impact of cooling methods on the corrosion behavior of AA6063 aluminum alloy in a chloride solution

- Wear mechanism analysis of internal chip removal drill for CFRP drilling

- Investigation on acoustic properties of metal hollow sphere A356 aluminum matrix composites

- Uniaxial compression stress–strain relationship of fully aeolian sand concrete at low temperatures

- Experimental study on the influence of aggregate morphology on concrete interfacial properties

- Intelligent sportswear design: Innovative applications based on conjugated nanomaterials

- Research on the equivalent stretching mechanical properties of Nomex honeycomb core considering the effect of resin coating

- Numerical analysis and experimental research on the vibration performance of concrete vibration table in PC components

- Assessment of mechanical and biological properties of Ti–31Nb–7.7Zr alloy for spinal surgery implant

- Theoretical research on load distribution of composite pre-tightened teeth connections embedded with soft layers

- Coupling design features of material surface treatment for ceramic products based on ResNet

- Optimizing superelastic shape-memory alloy fibers for enhancing the pullout performance in engineered cementitious composites

- Multi-scale finite element simulation of needle-punched quartz fiber reinforced composites

- Thermo-mechanical coupling behavior of needle-punched carbon/carbon composites

- Influence of composite material laying parameters on the load-carrying capacity of type IV hydrogen storage vessel

- Review Articles

- Effect of carbon nanotubes on mechanical properties of aluminum matrix composites: A review

- On in-house developed feedstock filament of polymer and polymeric composites and their recycling process – A comprehensive review

- Research progress on freeze–thaw constitutive model of concrete based on damage mechanics

- A bibliometric and content analysis of research trends in paver blocks: Mapping the scientific landscape

- Bibliometric analysis of stone column research trends: A Web of Science perspective

Articles in the same Issue

- Regular Articles

- Research on damage evolution mechanisms under compressive and tensile tests of plain weave SiCf/SiC composites using in situ X-ray CT

- Structural optimization of trays in bolt support systems

- Continuum percolation of the realistic nonuniform ITZs in 3D polyphase concrete systems involving the aggregate shape and size differentiation

- Multiscale water diffusivity prediction of plain woven composites considering void defects

- The application of epoxy resin polymers by laser induction technologies

- Analysis of water absorption on the efficiency of bonded composite repair of aluminum alloy panels

- Experimental research on bonding mechanical performance of the interface between cementitious layers

- A study on the effect of microspheres on the freeze–thaw resistance of EPS concrete

- Influence of Ti2SnC content on arc erosion resistance in Ag–Ti2SnC composites

- Cement-based composites with ZIF-8@TiO2-coated activated carbon fiber for efficient removal of formaldehyde

- Microstructure and chloride transport of aeolian sand concrete under long-term natural immersion

- Simulation study on basic road performance and modification mechanism of red mud modified asphalt mixture

- Extraction and characterization of nano-silica particles to enhance mechanical properties of general-purpose unsaturated polyester resin

- Roles of corn starch and gellan gum in changing of unconfined compressive strength of Shanghai alluvial clay

- A review on innovative approaches to expansive soil stabilization: Focussing on EPS beads, sand, and jute

- Experimental investigation of the performances of thick CFRP, GFRP, and KFRP composite plates under ballistic impact

- Preparation and characterization of titanium gypsum artificial aggregate

- Characteristics of bulletproof plate made from silkworm cocoon waste: Hybrid silkworm cocoon waste-reinforced epoxy/UHMWPE composite

- Experimental research on influence of curing environment on mechanical properties of coal gangue cementation

- Multi-objective optimization of machining variables for wire-EDM of LM6/fly ash composite materials using grey relational analysis

- Synthesis and characterization of Ag@Ni co-axial nanocables and their fluorescent and catalytic properties

- Beneficial effect of 4% Ta addition on the corrosion mitigation of Ti–12% Zr alloy after different immersion times in 3.5% NaCl solutions

- Study on electrical conductive mechanism of mayenite derivative C12A7:C

- Fast prediction of concrete equivalent modulus based on the random aggregate model and image quadtree SBFEM

- Research on uniaxial compression performance and constitutive relationship of RBP-UHPC after high temperature

- Experimental analysis of frost resistance and failure models in engineered cementitious composites with the integration of Yellow River sand

- Influence of tin additions on the corrosion passivation of TiZrTa alloy in sodium chloride solutions

- Microstructure and finite element analysis of Mo2C-diamond/Cu composites by spark plasma sintering

- Low-velocity impact response optimization of the foam-cored sandwich panels with CFRP skins for electric aircraft fuselage skin application

- Research on the carbonation resistance and improvement technology of fully recycled aggregate concrete

- Study on the basic properties of iron tailings powder-desulfurization ash mine filling cementitious material

- Preparation and mechanical properties of the 2.5D carbon glass hybrid woven composite materials

- Improvement on interfacial properties of CuW and CuCr bimetallic materials with high-entropy alloy interlayers via infiltration method

- Investigation properties of ultra-high performance concrete incorporating pond ash

- Effects of binder paste-to-aggregate ratio and polypropylene fiber content on the performance of high-flowability steel fiber-reinforced concrete for slab/deck overlays

- Interfacial bonding characteristics of multi-walled carbon nanotube/ultralight foamed concrete

- Classification of damping properties of fabric-reinforced flat beam-like specimens by a degree of ondulation implying a mesomechanic kinematic

- Influence of mica paper surface modification on the water resistance of mica paper/organic silicone resin composites

- Impact of cooling methods on the corrosion behavior of AA6063 aluminum alloy in a chloride solution

- Wear mechanism analysis of internal chip removal drill for CFRP drilling

- Investigation on acoustic properties of metal hollow sphere A356 aluminum matrix composites

- Uniaxial compression stress–strain relationship of fully aeolian sand concrete at low temperatures

- Experimental study on the influence of aggregate morphology on concrete interfacial properties

- Intelligent sportswear design: Innovative applications based on conjugated nanomaterials

- Research on the equivalent stretching mechanical properties of Nomex honeycomb core considering the effect of resin coating

- Numerical analysis and experimental research on the vibration performance of concrete vibration table in PC components

- Assessment of mechanical and biological properties of Ti–31Nb–7.7Zr alloy for spinal surgery implant

- Theoretical research on load distribution of composite pre-tightened teeth connections embedded with soft layers

- Coupling design features of material surface treatment for ceramic products based on ResNet

- Optimizing superelastic shape-memory alloy fibers for enhancing the pullout performance in engineered cementitious composites

- Multi-scale finite element simulation of needle-punched quartz fiber reinforced composites

- Thermo-mechanical coupling behavior of needle-punched carbon/carbon composites

- Influence of composite material laying parameters on the load-carrying capacity of type IV hydrogen storage vessel

- Review Articles

- Effect of carbon nanotubes on mechanical properties of aluminum matrix composites: A review

- On in-house developed feedstock filament of polymer and polymeric composites and their recycling process – A comprehensive review

- Research progress on freeze–thaw constitutive model of concrete based on damage mechanics

- A bibliometric and content analysis of research trends in paver blocks: Mapping the scientific landscape

- Bibliometric analysis of stone column research trends: A Web of Science perspective