Abstract

Ceramic products is one of the important carriers of various civilizations, reflecting the lifestyle, aesthetic concepts, and technological level of society at that time. In order to study the surface treatment design features of ceramic craft products, this article analyzed the ceramic features through computer vision technology and used residual neural networks to detect the surface treatment features of ceramic craft products. The extracted texture features were classified to study and analyze the coupling features of different glazes, colors, and shapes on the formation of different textures. This study used ResNeXt50-SSD, which combined ResNeXt50 and SSD (Single Shot MultiBox Detector) algorithms, to compare feature detection with LeNet-5, VGG-16, and MobileNetV2 network models. From the experimental findings, it can be concluded that ResNeXt50-SSD was the most effective for feature recognition of ceramic craft products, with precision, recall, and mAP of 94.3, 92.1, and 89.5%, respectively. Therefore, the combination of ResNeXt50 and SSD algorithms is an effective method for detecting surface treatment features of ceramic craft products.

1 Introduction

Craft cultural and creative products are based on traditional craftsmanship, integrating creative design and modern life elements to create products with artistic, practical, and cultural connotations. There are a variety of cultural and creative products [1], covering various fields, including ceramic artworks, embroidered handicrafts, handmade wooden crafts, traditional paper crafts, ethnic handicrafts, and craft gift sets. Among them, ceramics [2], as an important component of human development, have a wide and profound impact on the world. Ceramic artworks not only represent a form of art, but also carry the inheritance and expression of culture, history, and human spirit. With the advancement of technology, new processing techniques are constantly being applied in the production of ceramic crafts. Atmospheric pressure plasma [3,4] technology, with its unique physical and chemical properties, can finely treat the surface of ceramics at room temperature and pressure, achieving various effects such as surface modification, cleaning, and etching, providing more possibilities for the surface design of ceramic crafts. This technology not only improves the production efficiency of ceramic crafts, but also enriches their surface texture and texture, making ceramic crafts more diverse and personalized. Before the eighteenth century, ceramic craft products were created to be simple and practical. From the eighteenth century to the mid-twentieth century of the modern era, the production design of ceramic craft products began to develop in the direction of aristocratic and luxury. Nowadays, the surface design of ceramic craft products pays more attention to art and personalization, as well as the pursuit of uniqueness and innovation. As people pay attention to environmental protection and sustainable development, the surface design of modern ceramic craft products also pays more and more attention to the selection of environmentally friendly materials and sustainable design. Therefore, the recognition and analysis of surface features of ceramic craft products [5] has become the direction of today’s research on ceramics. The traditional method for extracting surface features of ceramic craft products is mainly through manual observation and identification of the surface features of ceramic craft products, including color, texture, gloss, and shape. Different art craft features and styles are identified from them and then compared and categorized with known samples. Based on the similarity [6] or difference [7] of their surface features, the art craft type [8] and production style are determined. By relying on the professional knowledge and experience of ceramic craft product experts or craftsmen, the production process and age features of ceramics can be determined through observation and analysis of their surface features. Finally, relevant literature and research results are referenced to understand the features of ceramic craft products in different periods and regions, in order to identify the surface features of ceramic craft products. This method relies on manual observation and judgment, has strong subjectivity, and requires high time and cost and a significant amount of knowledge and experience from the operator.

This study used ResNeXt50 as the basic network combined with SSD (Single Shot MultiBox Detector) algorithm to extract multi-scale features of ceramic craft products that have undergone different treatments on the surface. This can provide richer feature representations, help improve the performance and accuracy of object detection, and better capture the feature information of ceramic craft products. The surface treatment of ceramic craft products usually involves multiple process parameters and treatment methods, each of which has an impact on the surface features of the final product. Through feature fusion, this article comprehensively analyzed the color, shape, and texture features of ceramic craft products, in order to comprehensively consider the overall impact of multiple features on the surface features of the product.

2 Related work

With the development of technology, Li et al. [9] proposed an image texture feature extraction method based on wavelet transform [10,11], which effectively extracted the spatial distribution information of colors. Chen [12] proposed the Contourlet-SIFT invariant feature extraction algorithm, which combined local features with global features and spatial and temporal features to improve matching efficiency and reduce feature errors in texture similar regions. However, these methods may encounter a large amount of duplicate information in image retrieval [13,14].

To alleviate this issue, Zhu [15] proposed a clustering-based ceramic image diversity retrieval method, which met the requirement of diversity retrieval while ensuring the relevance of retrieval results and improved retrieval efficiency. The adopted Gist [16,17] feature extraction method mainly concerns with the global structure and scene of the image, while ignoring the local details and texture information of the image, and it may not be able to fully capture the unique surface features of ceramic craft products, which are rich in texture and details. Gist features are mainly described based on the grayscale information of the image [18,19], which is less sensitive to color information. However, ceramic craft products often have rich colors and color variations, and ignoring color information may result in incomplete feature extraction. Besides, texture features and structural features at different scales need to be taken into account [20]. ResNeXt50 [21,22] is a deep neural network model on the basis of the Residual Network (ResNet) architecture [23], which is featured by the application of a concept called “cardinality” to increase the expressive power of the model, and has achieved good results in computer vision [24] tasks such as image classification, object detection, and semantic segmentation. The SSD [25,26] algorithm is an algorithm for object detection that combines different layers of feature maps by applying a multi-scale [27] convolutional sliding window on the image. The SSD algorithm utilizes information from feature maps at different scales, enabling the model to have better detection capabilities for targets at different scales. To our knowledge, it has not been adopted the combination of ResNeXt50 and SSD algorithms for feature detection.

3 Experimental preprocessing

3.1 Obtaining ceramic images of different types

In order to study the coupling design features of ceramic surface treatment, 200 images of 5 types of ceramics are collected from public datasets according to their shapes, totaling 1,000 images. The shapes of five types of ceramics are shown in Figure 1.

Ceramics of different shapes.

In Figure 1, five types of ceramics are shown: ceramic barrel, ceramic bottle, ceramic pot, ceramic bowl, and ceramic plate. This article studies their design features by obtaining these multi-scale features. After balancing the processing of various types of ceramic samples, it is necessary to normalize the samples. Data augmentation techniques such as random horizontal flipping, random cropping, and color jitter are used to make the size and contrast of each image the same. The unified pixel size of the image is 255 × 255 pixels.

3.2 Image classification

3.2.1 Classification of ceramic surface glazes

Different glaze materials can be processed differently to obtain ceramic craft products with different textures. Ceramic surface glaze can be divided into five categories, as shown in Figure 2.

Glaze classification diagram. (a) Clear glaze, (b) Colored glaze, (c) Crystal glaze, (d) Cracked glaze and (e) Cloud patterned glaze.

In Figure 2, from left to right, there are clear glaze, colored glaze, crystal glaze, cracked glaze, and cloud patterned glaze. Glazes play multiple roles in the production of ceramic craft products, endowing works with rich decorative effects, protecting surfaces, improving hand feel, waterproofing and antifouling, changing colors, and decorating defects, thus providing an important support for the beautification and protection of ceramic craft products. The selection of glaze also has an important impact on the formation of surface texture of ceramic craft products.

3.2.2 Classification of ceramic surface texture

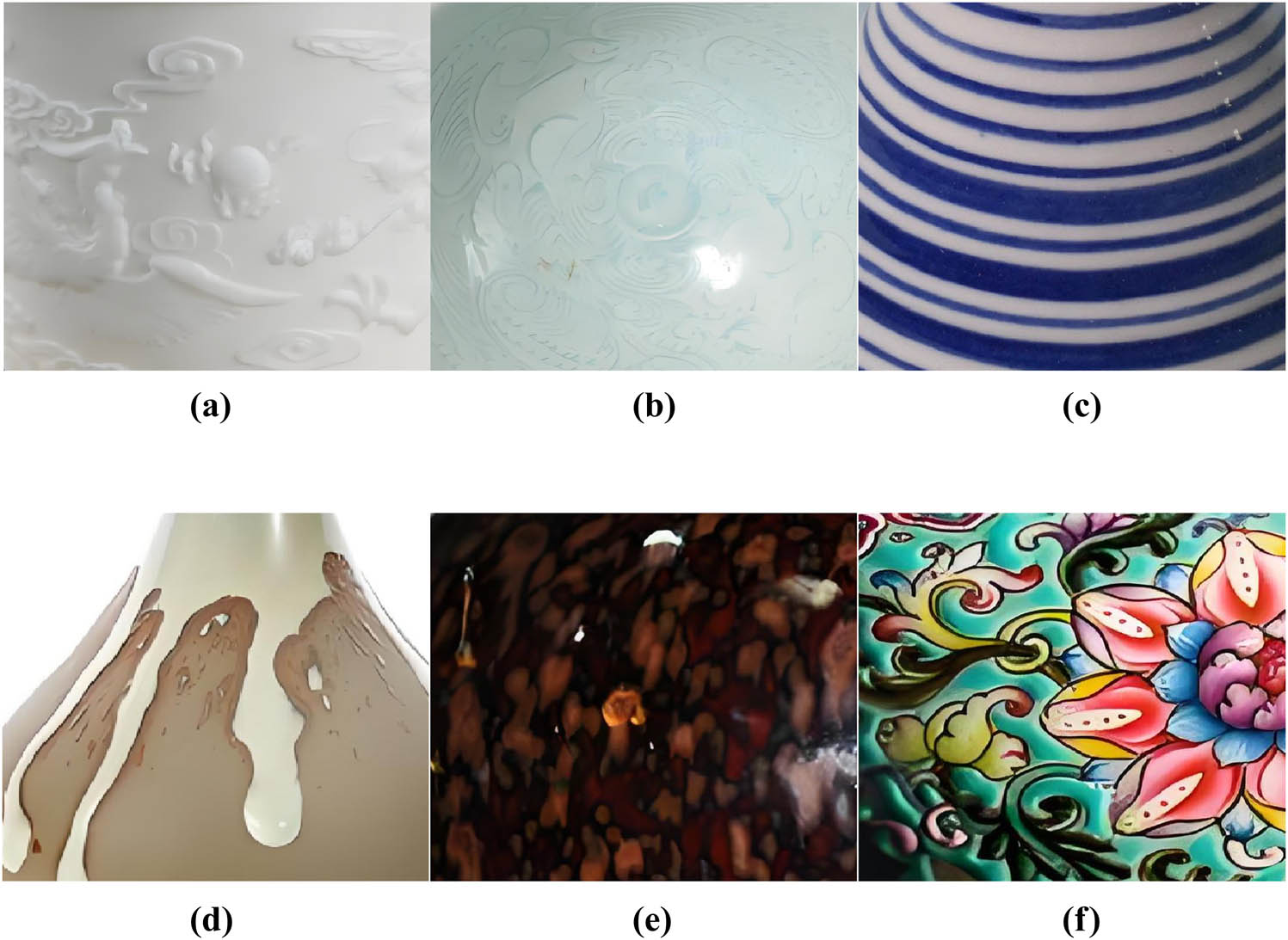

The surface texture of ceramic craft products is diverse, and based on the features of ceramic texture [28] itself, it is divided into six categories, as illustrated in Figure 3.

Classification of ceramic texture. (a) Relief texture, (b) Scratch texture, (c) Line texture, (d) Flowing texture, (e) Mottled texture and (f) Concave convex texture.

Figure 3 shows the classification of surface textures of ceramic process products, from A to F, which are relief texture: a raised pattern or pattern formed on the surface of ceramics, usually with a sense of three dimensionality and touch; scratch texture: a line, text, or pattern formed by carving or engraving on a ceramic surface, commonly used in carving techniques; line texture: a linear pattern presented by a texture, including slender lines, ripples, and interlaced lines; flowing texture: a pattern that presents a flowing or liquid feeling, commonly found in glaze flow or glaze surface texture; mottled texture: an irregular spot or pattern formed on the surface, often caused by uneven distribution of glaze or changes during firing; concave convex texture: irregular undulations or patterns formed due to surface depressions and protrusions.

3.3 ResNeXt50 and SSD algorithms

3.3.1 ResNeXt50

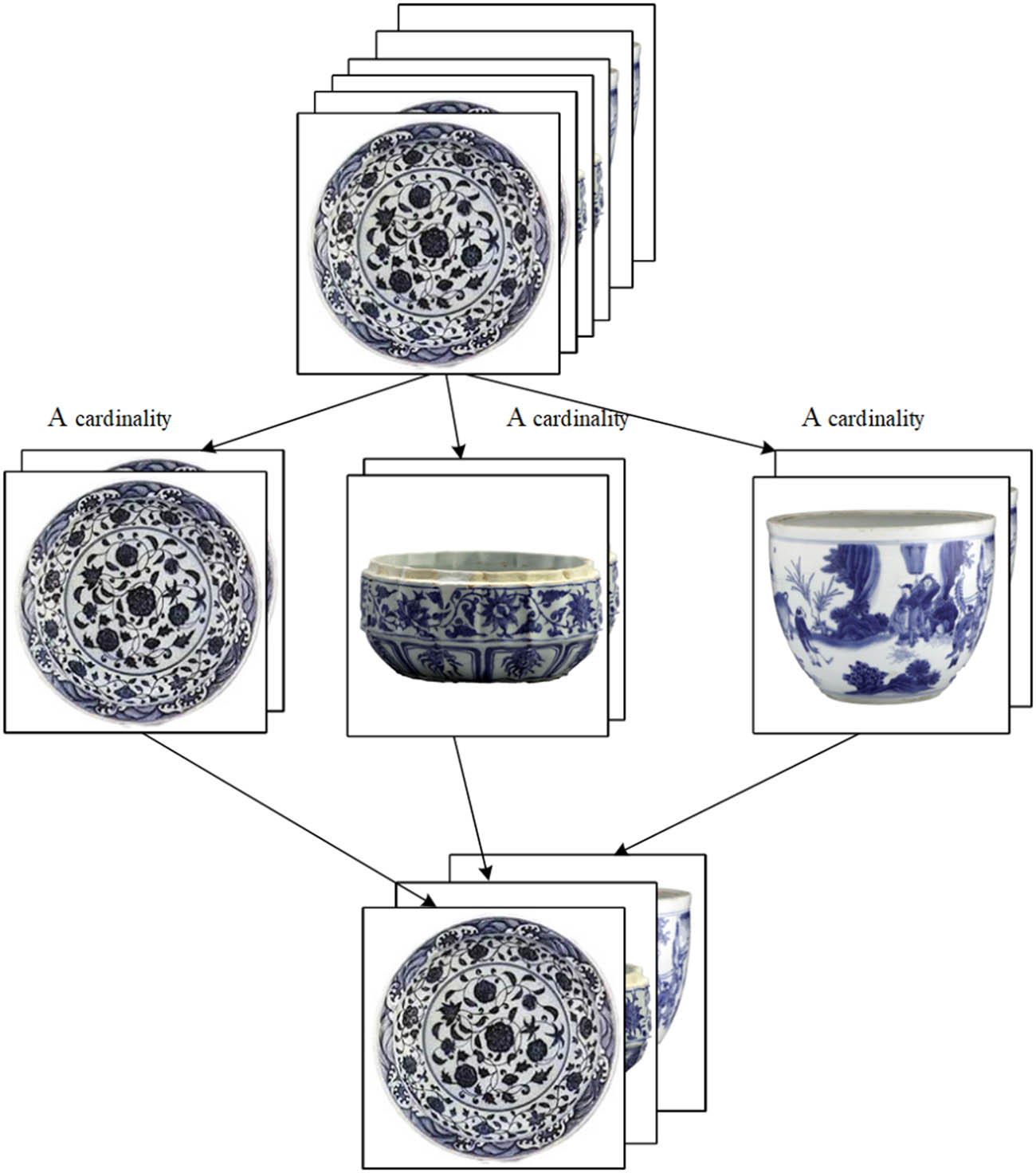

ResNeXt50 is a deep neural network model based on ResNet structure, which is used to enhance the model’s expressive power. ResNeXt50 contains 50 convolutional layers, with a structure similar to ResNet50. Figure 4 depicts a schematic diagram of the structure.

Structural schematic diagram of ResNeXt50.

In Figure 4, the convolutional layers in each residual block of ResNeXt50 are organized into multiple branches, each of which is called a “cardinality.” These branches are executed in parallel and finally fused in a special way. By increasing cardinality, ResNeXt can better capture the complex features of the data and improve the network’s representation ability. ResNeXt50, as a powerful deep learning model, has achieved good results in computer vision tasks such as image classification [29], object detection, and semantic segmentation, especially in tasks with large-scale datasets and complex features.

3.3.2 SSD algorithm

The SSD algorithm is a deep learning algorithm commonly used for object detection, which is characterized by the simultaneous completion of object detection and classification in a single neural network. Features are extracted from input images through neural networks and transferred to detection and classification modules [30]. During the feature extraction process, SSD obtains feature maps of different scales by adding multiple convolutional layers to the feature extraction network and uses a predefined set of anchor boxes on each feature map to detect targets. For each anchor box, the SSD predicts the category and location of the target. Category prediction uses the softmax function to determine the probability distribution of the target category contained in each anchor box; position prediction is used to adjust the position and size of the anchor box to match the target more accurately.

The SSD model uses a multi-task loss function to train the model, including position loss and category loss. The position loss usually uses Smooth L1 loss to measure the difference between the predicted bounding box and the true bounding box. The calculation formula for the Smooth L1 loss function is shown in formula (1):

where

where

After the model outputs the prediction results, the SSD algorithm uses non-maximum suppression to filter overlapping bounding boxes and selects the bounding box with the highest confidence as the final detection result.

The SSD algorithm has end-to-end advantages, allowing for object detection directly from the original image, and performs excellently in accuracy and speed. This makes SSD one of the preferred algorithms in many real-time object detection applications.

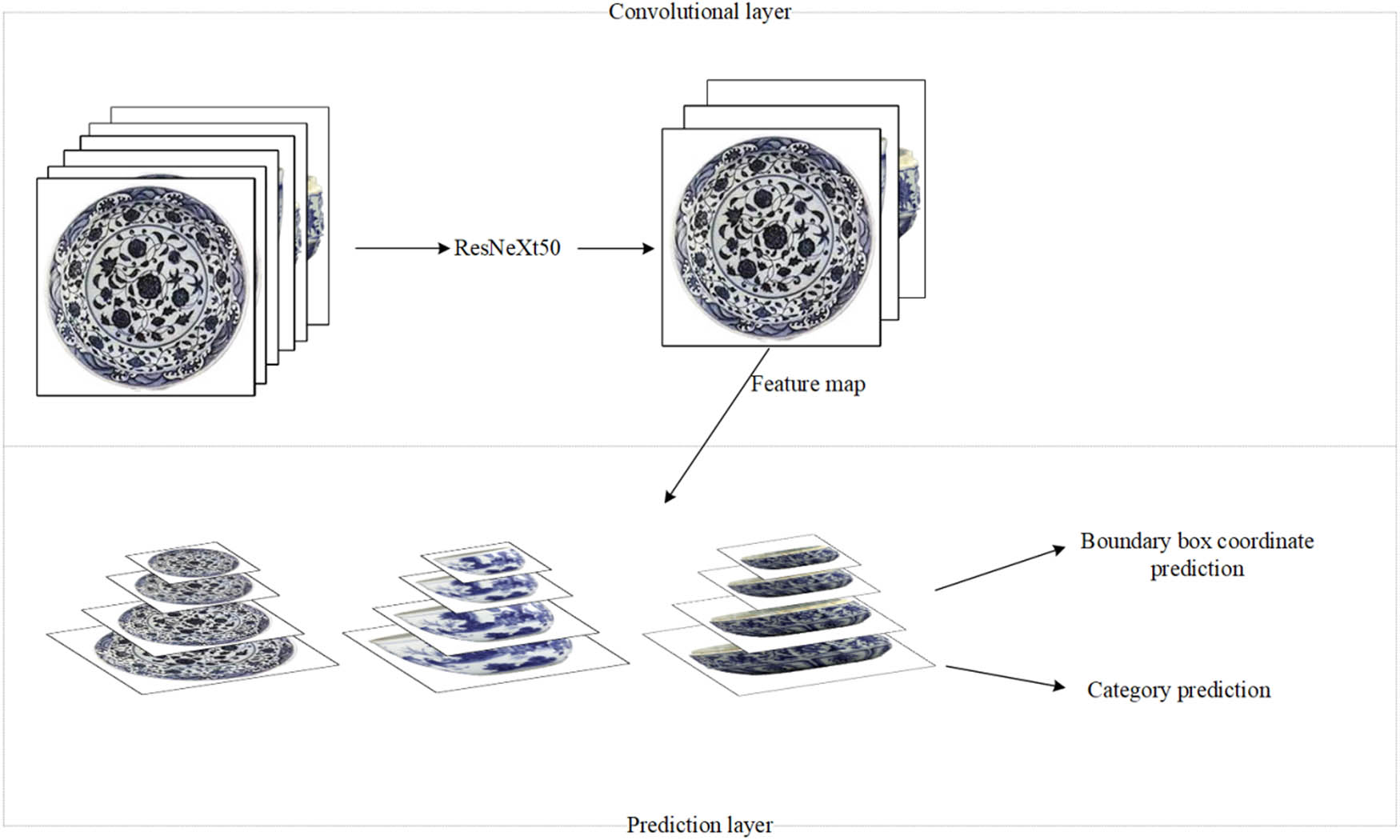

3.3.3 Building ResNeXt50-SSD network model

SSD network models typically include multiple feature layers for predicting targets of different scales. In this study, the ResNeXt50-SSD network model is constructed based on the output of ResNeXt50, which consists of a convolutional layer and a prediction layer that are responsible for detecting targets at different scales. Figure 5 is a schematic diagram of the ResNeXt50-SSD model constructed in this study.

Schematic diagram of ResNeXt50-SSD model.

In Figure 5, the ResNeXt50-SSD model is divided into convolutional layers and prediction layers. In the convolutional layer, ResNeXt50 is used as a feature extraction network to extract features from the input image. In the prediction layer, SSD serves as the prediction network to generate boundary boxes and category predictions for the target box. The dataset images are processed by the ResNeXt50-SSD model to obtain a series of features. This study mainly detects and analyzes texture features, which can improve the production efficiency of ceramic craft products.

3.4 Obtaining feature representation of ceramic images

This study extracts the color, texture, and shape features of ceramic craft products. Using ResNeXt50 as the feature extractor, the process of extracting feature representations with rich semantic information from ceramic images includes the following steps:

Ceramic images are input into the ResNeXt50 model, and feature extraction of five ceramic craft product images from the dataset is achieved through a series of convolutional and pooling layers. Among them, the ResNeXt50 model has multiple branches, allowing the model to capture rich semantic information of images from different perspectives and scales.

Using deep residual connections, the output of the previous layer is added to the input of the subsequent layer, in order to better transfer gradients and avoid gradient vanishing during the training process. Meanwhile, attention mechanisms are utilized to enable the model to better learn and express details and structural information in ceramic images.

The final result is a highly abstract and semantically rich feature representation, and the extracted image feature information is shown in Table 1, which can be used for subsequent object detection or classification tasks.

Table 1 shows the extracted feature information of ceramic barrels, bottles, basins, bowls, and plates. Among them, the color features of the ceramic barrel are monochromatic dimness, rough and sparse texture, and a three-dimensional cylindrical shape. The color features of ceramic bottles are bright monochromatic, smooth, and delicate texture, and the bottle body is circular. The color features of the ceramic basin are monochromatic dimness, rough, and sparse texture, and the overall shape is a three-dimensional column. Ceramic bowls have diverse and bright colors, delicate, and dense textures, and a round mouth with symmetrical shapes. Ceramic plates have two main colors, the color of the material itself and the color of the engraved pattern. The texture is smooth and uniform, and the flat image is circular.

Features of five types of ceramic craft products

| Image name | Color features | Texture features | Shape features |

|---|---|---|---|

| Ceramic barrel | Monochrome, subdued | Rough, sparse | Columnar, three-dimensional |

| Ceramic bottle | Monochrome, bright | Smooth, delicate | Circular, three-dimensional |

| Ceramic basin | Monochrome, subdued | Rough, sparse | Columnar, three-dimensional |

| Ceramic bowl | Multi-color, vivid | Delicate, dense | Circular, symmetrical |

| Ceramic plate | Bicolor, bright | Smooth, uniform | Circular, planar |

To fully utilize the information of ceramic images at different scales, the next step is to improve the performance of the model in tasks such as object detection and classification by obtaining multi-scale feature maps.

3.5 Feature fusion to obtain multi-scale feature representations

In the SSD model, Feature Pyramid Networks (FPNs) [31] are applied to fuse features from different levels. FPN establishes connections between feature maps of different resolutions to obtain richer semantic information.

First, the basic network ResNeXt50 for extracting image features is selected, which is responsible for extracting feature images from the input image. These feature maps have different levels and resolutions, forming a feature pyramid. For each feature map in the feature pyramid, pooling kernels of different sizes are applied to perform pooling operations. Usually, larger pooling kernels are used to capture coarser features, while smaller pooling kernels are used to capture finer features, allowing for the capture of multi-scale semantic information at different scales.

The pooled feature maps of different scales are fused through cascading or weighted averaging to obtain richer multi-scale feature representations, and then, texture classification is performed on the fused feature images.

This study presents a new feature representation by fusing the color, surface texture, and shape of ceramic craft products. The fusion strategy is to combine color, texture, and shape features to obtain a new feature representation, which is represented by formula (3):

where NF represents the new features after feature fusion; C represents the color features; T represents the texture features; and S represents the shape features.

4 Experiment on extracting surface texture features of ceramic craft products

4.1 Experimental environment

The experimental environment configuration table for this study is described in Table 2.

Experimental environment configuration table

| Serial number | Experimental environment | Content |

|---|---|---|

| 1 | Operating system | Windows 11 |

| 2 | Programming language | Python |

| 3 | GPU | NVIDIA GetForce RTX 4060 |

| 4 | CPU | Intel Corei9-14900 |

| 5 | Software | Pycharm |

In Table 2, the operating system used is Windows 11. Due to the significant computational resources required for training deep learning models, the experimental platform uses NVIDIA GetForce RTX 4060 as the GPU, Intel Corei9-14900 as the CPU, PyTorch as the deep learning framework, Python as the programming language, and Pycharm as the compiler.

4.2 Evaluation indicators

To ensure that the model can effectively extract multi-scale features from ceramic surface images and accurately perform object detection, the performance of the model under different scales, lighting conditions, angles, etc., is determined by evaluating the performance of the model. This study uses precision (P) and recall (R) to evaluate the detection precision of the model on targets. The calculation of precision P is shown in formula (4):

where

The formula for calculating the recall R is shown in formula (5):

where

AP (average precision) calculates the area under the precision/recall (PR) curve to represent the average precision at different recall rates. The calculation is shown in formula (6):

where P(k) represents the precision in the first k detection results, and

The mean average precision (mAP) is used as a comprehensive evaluation index for model performance, and its calculation formula is shown in formula (7):

where

5 Experimental detection results

5.1 Surface feature detection results of ceramic craft products

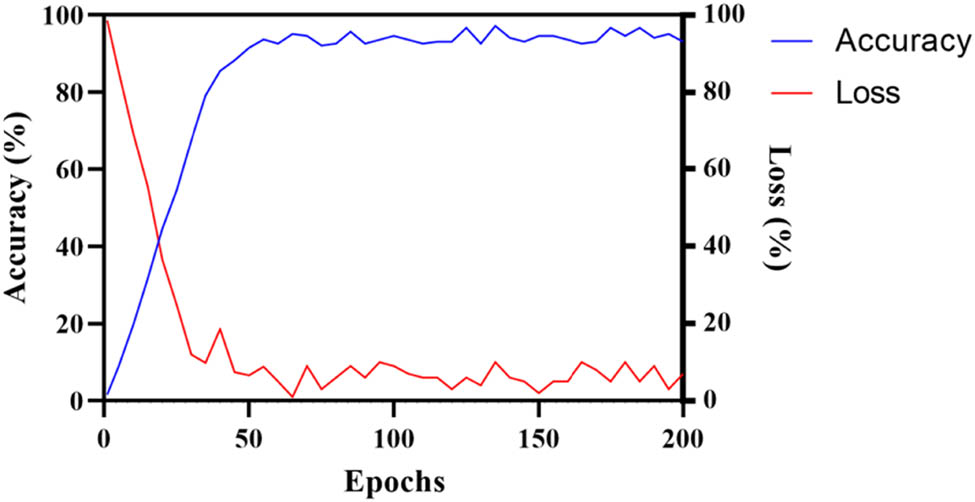

This study combined ResNeXt50 neural network with SSD algorithm to collect image features of ceramic craft products and analyze the detection model’s accuracy and loss values for feature detection of various processing methods. The accuracy detection results and loss situation are shown in Figure 6.

Accuracy and loss curve of model feature detection.

The accuracy and loss of feature recognition for ceramic craft product images using the ResNeXt50-SSD model are displayed in Figure 6. From it, it can be learned that as the number of training sessions increased, the loss curve of the model gradually decreased and stabilized at around 5% as the number of tests increased. The accuracy of detection increased with the number of tests and ultimately stabilized at around 95%. The results indicate that the ResNeXt50-SSD model can accurately detect target categories and perform precise localization.

5.2 Comparison of different network models

The ResNeXt50 network model was compared with the LeNet-5, VGG-16, and MobileNetV2 network models. The comparison results are described in Table 3.

Comparison of various network models

| Model | Number of parameters | Depth | Computational complexity | Application scenario |

|---|---|---|---|---|

| ResNeXt50 | Large | Deep | High | Complex tasks |

| LeNet-5 | Small | Shallow | Low | Simple tasks |

| VGG-16 | Large | Deep | High | Complex tasks |

| MobileNetV2 | Small | Shallow | Low | Resource-constrained |

In Table 3, the more parameters there are, the stronger the representational ability of the model. Depth represents the number of layers in a model, and models with larger depths are usually better able to capture image features. Computational complexity represents the computational resource requirements of a model, and models with higher computational complexity may require more computational resources. Application scenario represents the type of task that the model is suitable for. Some models may be more suitable for handling complex tasks, while others may be more suitable for running in resource-constrained environments.

The dataset in this study was subjected to feature detection experiments on the four models mentioned earlier. The recognition precision P, recall R, and mAP are described in Table 4.

Comparison results of detection indicators among different models (%)

| Model | P | R | mAP |

|---|---|---|---|

| ResNeXt50 | 94.3 | 92.1 | 89.5 |

| LeNet-5 | 71.9 | 76.2 | 69.5 |

| VGG-16 | 85.1 | 88.2 | 82.8 |

| MobileNetV2 | 81.6 | 83.2 | 78.1 |

Bold value indicates the maximum P-value.

In the results obtained in Table 4, ResNeXt50 had the highest recognition precision P, recall R, and mAP, reaching 94.3, 92.1, and 89.5%, indicating that ResNeXt50 had high effectiveness and accuracy in capturing and identifying complex features of ceramic craft products. In contrast, as one of the pioneers of deep learning, the LeNet-5 model performed poorly in the task of ceramic craft product image feature recognition, with the lowest values in all aspects, and its mAP value only reached 69.5%. Although the VGG-16 model was larger in depth and parameter quantity than LeNet-5, its performance was still slightly inferior to ResNeXt50, with an accuracy rate of only 85.1%. As a lightweight network model, MobileNetV2 performed moderately in identifying image features of ceramic craft products. Although it had lower computational complexity and smaller model size, its performance was still lacking compared to ResNeXt50. Therefore, for the task of image feature recognition of ceramic craft products, the ResNeXt50 model is a more preferred choice with higher accuracy and performance.

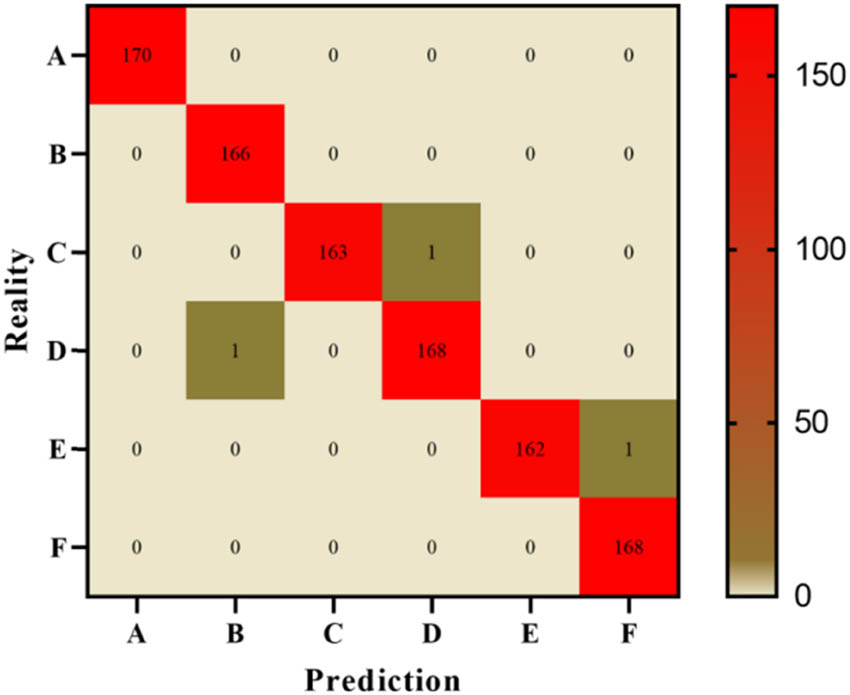

5.3 Classification of surface texture of ceramic craft products

The surface texture classification of ceramic craft products covers a variety of features, from smooth to rough, from concave and convex to flat, from decorative to naturally formed textures, each with its own features. The classification of surface textures can better understand and appreciate the beauty and craftsmanship of ceramic craft products. Processing on different types of glazes can yield different ceramic craft products. This article collected texture images of five types of ceramics that have undergone different treatments. After detection and classification by the model, the classification results are illustrated in Figure 7.

Classification results of surface texture of ceramic craft products.

Figure 7 shows the classification results of the model on the surface texture of ceramic craft products. A to F are relief texture, scratch texture, line texture, flowing texture, mottled texture, and concave convex texture in order. The horizontal axis indicates the classification prediction, and the vertical axis indicates the actual classification results. Among them, there were 164 line texture images, of which 163 were correctly predicted and 1 was predicted as a flowing texture. There were 169 flowing texture images, of which 168 were correctly predicted and 1 was predicted as a scratch texture. There were 163 mottled texture images, of which 162 were correctly predicted and 1 was predicted to have a concave convex texture. The image recognition of relief texture, scratch texture, and concave convex texture was all correctly predicted. In this experiment, the vast majority of images can be accurately recognized.

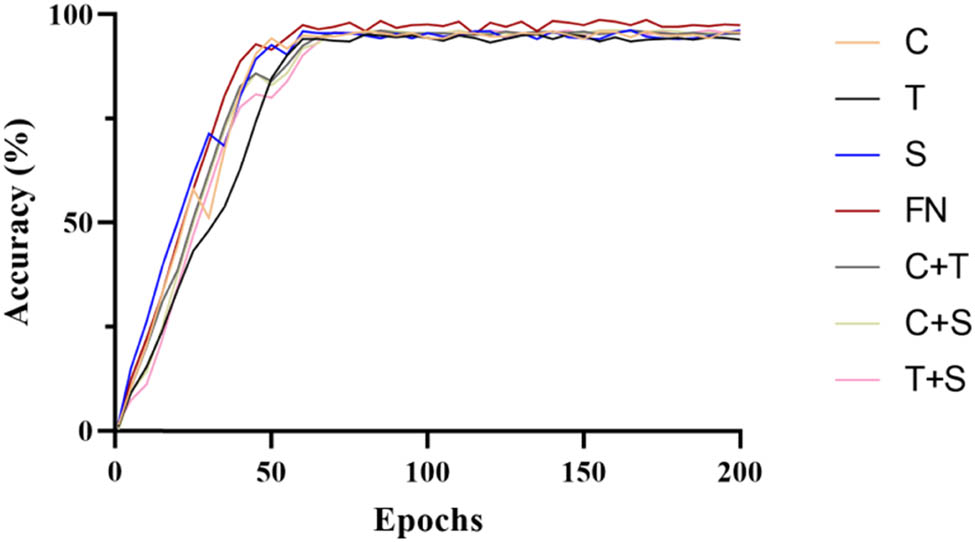

5.4 Feature coupling

New features were recognized by ResNeXt50-SSD after fusion of color, texture, and shape with the features, and the recognition accuracy was compared. The findings are illustrated in Figure 8.

Recognition accuracy of the model for different features.

In Figure 8, the recognition accuracy of the ResNeXt50-SSD model for color C, texture T, shape S, as well as pairwise feature fusion and the new feature FN after three types of feature fusion, is shown. The model had the highest recognition accuracy for FN, and as the number of tests increased, it ultimately stabilized at around 97%. The recognition accuracy for color, texture, and shape remained stable at around 95, 94, and 95%, respectively. The accuracy of feature recognition for pairwise feature fusion remained stable at around 96%.

The color, texture, and shape features of ceramic craft products are coupled with each other, presenting a harmonious and unified artistic effect. The interweaving of light blue tones and slight green tones in color features gives the product a fresh and elegant atmosphere; the delicate texture features of water ripples and decorative patterns add a visual sense of hierarchy and dimensionality; the streamlined or soft-curved shape of the shape features makes the overall shape appear smooth and relaxed, with harmonious proportions of each part. These three features interact with each other to create a ceramic craft product.

6 Conclusions

In order to study the coupling features of surface treatment of ceramic craft products, this study adopted computer vision technology, which realizes automated and efficient feature extraction and analysis, is not affected by subjective factors, and provides consistent and reliable results. It can accurately locate and measure the surface features of ceramic craft products, detect subtle changes and defects, and is a non-destructive analysis method, protecting the integrity of the original components. This study used residual networks to extract and classify features from surface treatment images of ceramic craft products. First, ResNeXt50 was used to extract features from the input image of ceramic craft products, mainly extracting the color, texture, and shape features of ceramic craft products. Then, these features were transmitted to the SSD model, which detects and locates various features in the image, including cracks and color spots. Finally, the surface texture of ceramic craft products was classified based on the SSD detection results. The color features, texture features, and shape features of ceramic craft products were coupled with each other, together forming the overall aesthetic and artistic value of the product. The soft combination of colors, delicate texture, and smooth proportion of shapes complements each other, making the product have high quality and attractiveness in both visual and tactile aspects. The feature extraction method used in this study can effectively extract the surface treatment features of ceramic craft products, which plays an important role in the production of ceramic craft products. Experiments have shown that the accuracy P, recall R, and mAP of the model reach 94.3, 92.1, and 89.5%, respectively. Although residual neural networks perform well in image recognition tasks, they still need to consider the drawbacks of overfitting risk, limited feature extraction, poor interpretability, and high computational resource requirements when applied to surface feature analysis of ceramic craft products. Therefore, optimizing data, improving models, and optimizing computational resource requirements are future research directions.

7 Future works

Based on the current research findings, future studies can further optimize the architecture of the ResNeXt50 SSD model, particularly in terms of computational efficiency and handling complex textures. Exploring new texture classification methods, especially automatic classification algorithms for highly complex or mixed textures, will help the model maintain high performance in a wider range of application scenarios. Studying how to apply this model in practical production environments and address performance fluctuations caused by factors such as lighting and image resolution is also an important direction for future research. Through these studies, the ResNeXt50 SSD model is expected to be widely applied in more fields, providing more efficient solutions for the automated detection of complex surface features.

-

Funding information: Key Project of Humanities and Social Sciences Research in Higher Education Institutions in Anhui Province: Research on the Construction of Brand Image System of Colleges and Universities under the Perspective of “Visual Hammer” (Project No. 2024AH052875), Key Project of Humanities and Social Sciences Research in Higher Education Institutions in Anhui Province: Research on Campus Cultural and Creative Design and Development Mode under the Perspective of the Construction of Colleges and Universities’ Cultural and Creative Branding (Project No. 2024AH052869).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewed all the results, and approved the final version of the manuscript. TX and PY: editing, data curation, supervision. ZC: writing – original draft preparation.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: All data generated or analysed during this study are included in this published article.

References

[1] Yang XS, Xu H, Ni S. The creative renewal of a craft cluster: the role of materiality and mobility in cluster evolution. 2021;55(3):546–55.10.1080/00343404.2020.1802417Search in Google Scholar

[2] Zhang F. A review of 3D printed porous ceramics. J Eur Ceram Soc. 2022;42(8):3351–73.10.1016/j.jeurceramsoc.2022.02.039Search in Google Scholar

[3] Yildirim C, Hasan U, Bertan B, Abdulrahman AN, Serra T, Mehmet Y, et al. Effect of atmospheric plasma treatment on Mode-I and Mode-II fracture toughness properties of adhesively bonded carbon fiber/PEKK composite joints. Eng Fract Mech. 2023;289:109463.10.1016/j.engfracmech.2023.109463Search in Google Scholar

[4] Yildirim C, Hasan U, Bertan B, Abdulrahman AN, Serra T, Mehmet Y, et al. Tailoring adherend surfaces for enhanced bonding in CF/PEKK composites: Comparative analysis of atmospheric plasma activation and conventional treatments. Compos Part A: Appl Sci Manuf. 2024;180:108101.10.1016/j.compositesa.2024.108101Search in Google Scholar

[5] Bansal M, Munish K, Manish K. 2D object recognition: A comparative analysis of SIFT, SURF and ORB feature descriptors. Multimed Tools Appl. 2021;80(12):18839–57.10.1007/s11042-021-10646-0Search in Google Scholar

[6] Chandrasekaran D, Vijay M. Evolution of semantic similarity—a survey. ACM Comput Surv (CSUR). 2021;54(2):1–37.10.1145/3440755Search in Google Scholar

[7] Cislaghi B, Lori H. Gender norms and social norms: Differences, similarities and why they matter in prevention science. Sociol Health Illn. 2020;42(2):407–22.10.1111/1467-9566.13008Search in Google Scholar PubMed PubMed Central

[8] Jueming HUA. The definition and classification of traditional handicrafts. Stud History Nat Sci. 2022;40(1):120–9.Search in Google Scholar

[9] Li Y, Wang B, Li W. Image texture feature extraction method based on wavelet transform and its application. J Sens Technol. 2009;22(9):1308–11.Search in Google Scholar

[10] Arts LP, van den Broek EL. The fast continuous wavelet transformation (fCWT) for real-time, high-quality, noise-resistant time–frequency analysis. Nat Comput Sci. 2022;2(1):47–58.10.1038/s43588-021-00183-zSearch in Google Scholar PubMed PubMed Central

[11] Begum M, Jannatul F, Mohammad SU. A Hybrid robust watermarking system based on discrete cosine transform, discrete wavelet transform, and singular value decomposition. J King Saud Univ-Computer Inf Sci. 2022;34(8):5856–67.10.1016/j.jksuci.2021.07.012Search in Google Scholar

[12] Chen S. Color deviation detection based on feature extraction and color segmentation. MA thesis. Nanjing, Jiangsu, China: Nanjing University; 2014.Search in Google Scholar

[13] Yan C, Gong B, Wei Y, Gao Y. Deep multi-view enhancement hashing for image retrieval. IEEE Trans Pattern Anal Mach Intell. 2021;43(4):1445–51.10.1109/TPAMI.2020.2975798Search in Google Scholar PubMed

[14] Ma J, Jiang X, Fan A, Jiang J, Yan J. Image matching from handcrafted to deep features: A survey. Int J Computer Vis. 2021;129(1):23–79.10.1007/s11263-020-01359-2Search in Google Scholar

[15] Zhu SP. Research on the diversity retrieval method of ceramic images based on clustering. China Ceram Ind. 2021;28(4):21–5.Search in Google Scholar

[16] Mahami A, Rahmoune C, Zair M, Bettahar T, Benazzouz D. Automated Transformer fault diagnosis using infrared thermography imaging, GIST and machine learning technique. Proc Inst Mech Eng Part E: J Process Mech Eng. 2022;236(4):1747–57.10.1177/09544089221083455Search in Google Scholar

[17] Allapakam V, Yepuganti K. A hybrid feature pyramid network and Efficient Net-B0-based GIST detection and segmentation from fused CT-PET image. Soft Comput. 2023;27(16):11877–93.10.1007/s00500-023-08614-xSearch in Google Scholar

[18] Wan S, Xia Y, Qi L, Yang YH. Automated colorization of a grayscale image with seed points propagation. IEEE Trans Multimed. 2020;22(7):1756–68.10.1109/TMM.2020.2976573Search in Google Scholar

[19] An JC, Koffi GK, Qingnan S. Grayscale images colorization with convolutional neural networks. Soft Comput. 2020;24(7):4751–8.10.1007/s00500-020-04711-3Search in Google Scholar

[20] Liao X, Yin J, Chen M, Qin Z. Adaptive payload distribution in multiple images steganography based on image texture features. IEEE Trans Dependable Secure Comput. 2020;19(2):897–911.Search in Google Scholar

[21] Tanwar SS, Jaspreet S. ResNext50 based convolution neural network-long short term memory model for plant disease classification. Multimed Tools Appl. 2023;82(19):29527–45.10.1007/s11042-023-14851-xSearch in Google Scholar

[22] Cai C, Li R, Gao MH. Bearing fault diagnosis method based on the Gramian angular field and an SE-ResNeXt50 transfer learning model. Insight-Non-Destr Test Cond Monit. 2023;65(12):695–704.10.1784/insi.2023.65.12.695Search in Google Scholar

[23] Huang C-J, Shen Y, Chen YH, Chen HC. A novel hybrid deep neural network model for short-term electricity price forecasting. Int J Energy Res. 2021;45(2):2511–32.10.1002/er.5945Search in Google Scholar

[24] Guo MH, Xu TX, Liu JJ, Liu ZN, Jiang PT, Mu TJ, et al. Attention mechanisms in computer vision: A survey. Comput Vis Media. 2022;8(3):331–68.10.1007/s41095-022-0271-ySearch in Google Scholar

[25] Yadgar SS. SSD-based workload characteristics and their performance implications. ACM Trans Storage (TOS). 2021;17(1):1–26.10.1145/3423137Search in Google Scholar

[26] Hepisuthar M. Comparative analysis study on SSD, HDD, and SSHD. Turkish J Computer Math Educ (TURCOMAT). 2021;12(3):3635–41.10.17762/turcomat.v12i3.1644Search in Google Scholar

[27] Tang Y, Zhang L, Min F, He J. Multiscale deep feature learning for human activity recognition using wearable sensors. IEEE Trans Ind Electron. 2022;70(2):2106–16.10.1109/TIE.2022.3161812Search in Google Scholar

[28] Lu AG, Yan J, Tan L, Zeng XC, Shang QR, Zhen T. Effects of surface roughness and texture on the bacterial adhesion on the bearing surface of bio-ceramic joint implants: An in vitro study. Ceram Int. 2020;46(5):6550–9.10.1016/j.ceramint.2019.11.139Search in Google Scholar

[29] Chandra MA, Bedi SS. Survey on SVM and their application in image classification. Int J Inf Technol. 2021;13(5):1–11.10.1007/s41870-017-0080-1Search in Google Scholar

[30] Zhao ZC, Li J, Luo Z, Li J, Chen C. Remote sensing image scene classification based on an enhanced attention module. IEEE Geosci Remote Sens Lett. 2020;18(11):1926–30.10.1109/LGRS.2020.3011405Search in Google Scholar

[31] Zhou XX, Long Z. SA-FPN: An effective feature pyramid network for crowded human detection. Appl Intell. 2022;52(11):12556–68.10.1007/s10489-021-03121-8Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Research on damage evolution mechanisms under compressive and tensile tests of plain weave SiCf/SiC composites using in situ X-ray CT

- Structural optimization of trays in bolt support systems

- Continuum percolation of the realistic nonuniform ITZs in 3D polyphase concrete systems involving the aggregate shape and size differentiation

- Multiscale water diffusivity prediction of plain woven composites considering void defects

- The application of epoxy resin polymers by laser induction technologies

- Analysis of water absorption on the efficiency of bonded composite repair of aluminum alloy panels

- Experimental research on bonding mechanical performance of the interface between cementitious layers

- A study on the effect of microspheres on the freeze–thaw resistance of EPS concrete

- Influence of Ti2SnC content on arc erosion resistance in Ag–Ti2SnC composites

- Cement-based composites with ZIF-8@TiO2-coated activated carbon fiber for efficient removal of formaldehyde

- Microstructure and chloride transport of aeolian sand concrete under long-term natural immersion

- Simulation study on basic road performance and modification mechanism of red mud modified asphalt mixture

- Extraction and characterization of nano-silica particles to enhance mechanical properties of general-purpose unsaturated polyester resin

- Roles of corn starch and gellan gum in changing of unconfined compressive strength of Shanghai alluvial clay

- A review on innovative approaches to expansive soil stabilization: Focussing on EPS beads, sand, and jute

- Experimental investigation of the performances of thick CFRP, GFRP, and KFRP composite plates under ballistic impact

- Preparation and characterization of titanium gypsum artificial aggregate

- Characteristics of bulletproof plate made from silkworm cocoon waste: Hybrid silkworm cocoon waste-reinforced epoxy/UHMWPE composite

- Experimental research on influence of curing environment on mechanical properties of coal gangue cementation

- Multi-objective optimization of machining variables for wire-EDM of LM6/fly ash composite materials using grey relational analysis

- Synthesis and characterization of Ag@Ni co-axial nanocables and their fluorescent and catalytic properties

- Beneficial effect of 4% Ta addition on the corrosion mitigation of Ti–12% Zr alloy after different immersion times in 3.5% NaCl solutions

- Study on electrical conductive mechanism of mayenite derivative C12A7:C

- Fast prediction of concrete equivalent modulus based on the random aggregate model and image quadtree SBFEM

- Research on uniaxial compression performance and constitutive relationship of RBP-UHPC after high temperature

- Experimental analysis of frost resistance and failure models in engineered cementitious composites with the integration of Yellow River sand

- Influence of tin additions on the corrosion passivation of TiZrTa alloy in sodium chloride solutions

- Microstructure and finite element analysis of Mo2C-diamond/Cu composites by spark plasma sintering

- Low-velocity impact response optimization of the foam-cored sandwich panels with CFRP skins for electric aircraft fuselage skin application

- Research on the carbonation resistance and improvement technology of fully recycled aggregate concrete

- Study on the basic properties of iron tailings powder-desulfurization ash mine filling cementitious material

- Preparation and mechanical properties of the 2.5D carbon glass hybrid woven composite materials

- Improvement on interfacial properties of CuW and CuCr bimetallic materials with high-entropy alloy interlayers via infiltration method

- Investigation properties of ultra-high performance concrete incorporating pond ash

- Effects of binder paste-to-aggregate ratio and polypropylene fiber content on the performance of high-flowability steel fiber-reinforced concrete for slab/deck overlays

- Interfacial bonding characteristics of multi-walled carbon nanotube/ultralight foamed concrete

- Classification of damping properties of fabric-reinforced flat beam-like specimens by a degree of ondulation implying a mesomechanic kinematic

- Influence of mica paper surface modification on the water resistance of mica paper/organic silicone resin composites

- Impact of cooling methods on the corrosion behavior of AA6063 aluminum alloy in a chloride solution

- Wear mechanism analysis of internal chip removal drill for CFRP drilling

- Investigation on acoustic properties of metal hollow sphere A356 aluminum matrix composites

- Uniaxial compression stress–strain relationship of fully aeolian sand concrete at low temperatures

- Experimental study on the influence of aggregate morphology on concrete interfacial properties

- Intelligent sportswear design: Innovative applications based on conjugated nanomaterials

- Research on the equivalent stretching mechanical properties of Nomex honeycomb core considering the effect of resin coating

- Numerical analysis and experimental research on the vibration performance of concrete vibration table in PC components

- Assessment of mechanical and biological properties of Ti–31Nb–7.7Zr alloy for spinal surgery implant

- Theoretical research on load distribution of composite pre-tightened teeth connections embedded with soft layers

- Coupling design features of material surface treatment for ceramic products based on ResNet

- Optimizing superelastic shape-memory alloy fibers for enhancing the pullout performance in engineered cementitious composites

- Multi-scale finite element simulation of needle-punched quartz fiber reinforced composites

- Thermo-mechanical coupling behavior of needle-punched carbon/carbon composites

- Influence of composite material laying parameters on the load-carrying capacity of type IV hydrogen storage vessel

- Review Articles

- Effect of carbon nanotubes on mechanical properties of aluminum matrix composites: A review

- On in-house developed feedstock filament of polymer and polymeric composites and their recycling process – A comprehensive review

- Research progress on freeze–thaw constitutive model of concrete based on damage mechanics

- A bibliometric and content analysis of research trends in paver blocks: Mapping the scientific landscape

- Bibliometric analysis of stone column research trends: A Web of Science perspective

Articles in the same Issue

- Regular Articles

- Research on damage evolution mechanisms under compressive and tensile tests of plain weave SiCf/SiC composites using in situ X-ray CT

- Structural optimization of trays in bolt support systems

- Continuum percolation of the realistic nonuniform ITZs in 3D polyphase concrete systems involving the aggregate shape and size differentiation

- Multiscale water diffusivity prediction of plain woven composites considering void defects

- The application of epoxy resin polymers by laser induction technologies

- Analysis of water absorption on the efficiency of bonded composite repair of aluminum alloy panels

- Experimental research on bonding mechanical performance of the interface between cementitious layers

- A study on the effect of microspheres on the freeze–thaw resistance of EPS concrete

- Influence of Ti2SnC content on arc erosion resistance in Ag–Ti2SnC composites

- Cement-based composites with ZIF-8@TiO2-coated activated carbon fiber for efficient removal of formaldehyde

- Microstructure and chloride transport of aeolian sand concrete under long-term natural immersion

- Simulation study on basic road performance and modification mechanism of red mud modified asphalt mixture

- Extraction and characterization of nano-silica particles to enhance mechanical properties of general-purpose unsaturated polyester resin

- Roles of corn starch and gellan gum in changing of unconfined compressive strength of Shanghai alluvial clay

- A review on innovative approaches to expansive soil stabilization: Focussing on EPS beads, sand, and jute

- Experimental investigation of the performances of thick CFRP, GFRP, and KFRP composite plates under ballistic impact

- Preparation and characterization of titanium gypsum artificial aggregate

- Characteristics of bulletproof plate made from silkworm cocoon waste: Hybrid silkworm cocoon waste-reinforced epoxy/UHMWPE composite

- Experimental research on influence of curing environment on mechanical properties of coal gangue cementation

- Multi-objective optimization of machining variables for wire-EDM of LM6/fly ash composite materials using grey relational analysis

- Synthesis and characterization of Ag@Ni co-axial nanocables and their fluorescent and catalytic properties

- Beneficial effect of 4% Ta addition on the corrosion mitigation of Ti–12% Zr alloy after different immersion times in 3.5% NaCl solutions

- Study on electrical conductive mechanism of mayenite derivative C12A7:C

- Fast prediction of concrete equivalent modulus based on the random aggregate model and image quadtree SBFEM

- Research on uniaxial compression performance and constitutive relationship of RBP-UHPC after high temperature

- Experimental analysis of frost resistance and failure models in engineered cementitious composites with the integration of Yellow River sand

- Influence of tin additions on the corrosion passivation of TiZrTa alloy in sodium chloride solutions

- Microstructure and finite element analysis of Mo2C-diamond/Cu composites by spark plasma sintering

- Low-velocity impact response optimization of the foam-cored sandwich panels with CFRP skins for electric aircraft fuselage skin application

- Research on the carbonation resistance and improvement technology of fully recycled aggregate concrete

- Study on the basic properties of iron tailings powder-desulfurization ash mine filling cementitious material

- Preparation and mechanical properties of the 2.5D carbon glass hybrid woven composite materials

- Improvement on interfacial properties of CuW and CuCr bimetallic materials with high-entropy alloy interlayers via infiltration method

- Investigation properties of ultra-high performance concrete incorporating pond ash

- Effects of binder paste-to-aggregate ratio and polypropylene fiber content on the performance of high-flowability steel fiber-reinforced concrete for slab/deck overlays

- Interfacial bonding characteristics of multi-walled carbon nanotube/ultralight foamed concrete

- Classification of damping properties of fabric-reinforced flat beam-like specimens by a degree of ondulation implying a mesomechanic kinematic

- Influence of mica paper surface modification on the water resistance of mica paper/organic silicone resin composites

- Impact of cooling methods on the corrosion behavior of AA6063 aluminum alloy in a chloride solution

- Wear mechanism analysis of internal chip removal drill for CFRP drilling

- Investigation on acoustic properties of metal hollow sphere A356 aluminum matrix composites

- Uniaxial compression stress–strain relationship of fully aeolian sand concrete at low temperatures

- Experimental study on the influence of aggregate morphology on concrete interfacial properties

- Intelligent sportswear design: Innovative applications based on conjugated nanomaterials

- Research on the equivalent stretching mechanical properties of Nomex honeycomb core considering the effect of resin coating

- Numerical analysis and experimental research on the vibration performance of concrete vibration table in PC components

- Assessment of mechanical and biological properties of Ti–31Nb–7.7Zr alloy for spinal surgery implant

- Theoretical research on load distribution of composite pre-tightened teeth connections embedded with soft layers

- Coupling design features of material surface treatment for ceramic products based on ResNet

- Optimizing superelastic shape-memory alloy fibers for enhancing the pullout performance in engineered cementitious composites

- Multi-scale finite element simulation of needle-punched quartz fiber reinforced composites

- Thermo-mechanical coupling behavior of needle-punched carbon/carbon composites

- Influence of composite material laying parameters on the load-carrying capacity of type IV hydrogen storage vessel

- Review Articles

- Effect of carbon nanotubes on mechanical properties of aluminum matrix composites: A review

- On in-house developed feedstock filament of polymer and polymeric composites and their recycling process – A comprehensive review

- Research progress on freeze–thaw constitutive model of concrete based on damage mechanics

- A bibliometric and content analysis of research trends in paver blocks: Mapping the scientific landscape

- Bibliometric analysis of stone column research trends: A Web of Science perspective