Abstract

Sport plays a crucial role in human society, fostering physical health, collaboration, and the spirit of rivalry. The importance of sports in promoting a sense of well-being, self-control, and cognitive sharpness should be considered. The efficacy of sports and athletic performance often relies on the caliber of clothing used. Traditional sportswear encounters many issues, including but not limited to restricted breathability, inefficient moisture management, and insufficient ultraviolet (UV) protection. To examine these concerns, the present study investigates the Intelligent Sportswear Design (ISWD), an innovative advancement rooted in conjugated nanomaterials. The field of ISWD covers the development of sports apparel and footwear specifically intended to boost performance and provide optimal comfort. Coatings of graphene, silver nanoparticles, and environmentally friendly green nanomaterials are employed in these multipurpose PES fabrics. This research looks at how we might better protect athletes from the sun by developing fabrics with UV-blocking qualities. Results show increased moisture-wicking efficiency, better UV-radiation protection, and enhanced electrical conductivity. The study found that fabric moisture management could be improved by 25%, UV-blocking performance could be increased by 30%, fabric conductivity could be increased by 15%, and heat retention could be decreased by 20%. The experimental results show that the proposed ISWD exhibits notable performance in several necessary measures, including moisture-wicking effectiveness (23.22%), UV-blocking performance (34.22%), fabric conductivity (20.88%), heat retention reduction (26.94%), and UV radiation shielding (35.68%).

1 Introduction

In recent years, optimizing materials and design in sportswear has emerged as a crucial area of interest [1], with a particular emphasis on incorporating advanced nanomaterials, leading to a transformative impact on the industry [2,3].

Sportswear bridges the gap between athletes and their respective disciplines, effectively enhancing performance, ensuring safety, and providing optimal comfort [4]. The design and composition of athletic apparel have significant ramifications for an athlete’s performance, healing, and injury prevention. Traditional athletes have developed heightened expectations beyond comfort and elegance as clothing has evolved to optimize physical performance. Materials designed to maximize moisture management, regulate temperature, and minimize air resistance are paramount for athletes who want exceptional performance [5].

Integrating nanoparticles into athletic apparel has opened up a novel range of potentialities [6]. Nanotechnology has facilitated the development of textiles with exceptional characteristics, including heightened resilience, ultraviolet (UV) shielding capabilities, and excellent air permeability. Nanoparticles have distinct advantages, facilitating the enhancement of sportswear in terms of performance and protection [7].

Conjugated nanomaterials are particularly notable within the field of nanomaterials [8]. These materials have remarkable electrical characteristics, making them very suitable for use in sports electronics and wearable devices. An example of using conjugated nanomaterials is the integration of sensors into sportswear, enabling the monitoring of vital signs, tracking performance measures, and providing real-time feedback to athletes. This development paves the way for a new age of intelligent sportswear, whereby data-driven insights are easily incorporated into the textile material [9].

Despite the continuous progress in sportswear technology, there are enduring obstacles. Conventional sportswear must often improve its durability, breathability, and capacity to protect against various environmental conditions. Athletes often express the need for enhanced performance from their equipment since they frequently encounter challenges such as excessive heat, discomfort, or insufficient moisture control when engaging in demanding physical exercises. The need to confront these difficulties has prompted fabric technology and design advancements.

The grafted cotton was coated with graphene oxide (GO) nanosheets to increase the fabric’s thermal resistance and shield it from damaging UV rays. Ceramic coatings are more effective in protecting against high temperatures, while graphene coatings are better at preventing damage from UV light and acid rain. Discovered and isolated from graphite flakes, the two-dimensional substance known as graphene has a remarkable sp2 carbon atom structure and has contributed significantly to advances in the study of materials. Because of its unique characteristics, graphene has excellent promise in various industrial applications due to its exceptional mechanical, electrical, thermal, chemical, and physical properties. The most recent article reveals an extensive understanding of various graphene fabrication methods. A study found that GRP sheets made from sugar beet leaf biomass may effectively filter out UV light while remaining transparent to ordinary light.

An intriguing topic for developing multipurpose textiles to fulfil worldwide needs is surface alteration of textile products. Because of their inherent inertness, natural goods do not possess the specific qualities needed to impart functionality to textiles. Modifying fabrics’ physical or chemical properties through sophisticated surface treatments without compromising their characteristics is now possible. Chemical, physical, and microencapsulation methods are used to functionalize and modify textiles. As a result of the harmful effects of the substances used in chemically modified treatments on the environment, several companies are switching to using disposable and natural coatings for their wet chemical surface modification processes. Recent decades have seen a dramatic increase in the creation of aqueous dispersions due to a decline in VOCs and other harmful environmental contaminants.

Pursuing enhanced athletic apparel has generated an increasing demand for intelligent sportswear that surpasses conventional norms. Developing intelligent sportswear that can effectively cater to an athlete’s requirements is crucial. This entails providing features such as temperature control, moisture management, and data collecting capabilities to optimize performance. The garment should possess a multifunctional role, functioning as an integrated tool for athletes, coaches, and trainers [10]. When athletic prowess is heavily reliant on data and technology, the advent of intelligent sportswear can transform our approach to sports and fundamentally enhance athletic performance. The convergence of nanomaterials and sportswear technology can usher in a new epoch of sportswear that possesses cognitive capabilities and adaptability to athletes’ requirements, augmenting their performance and overall engagement.

The novelty of the article:

This article presents a novel method for ISWD in sportswear that uses the special characteristics of conjugated nanomaterials. Smart sportswear that can detect physiological changes in real-time and respond adaptively to improve performance and safety is now within reach, thanks to this groundbreaking integration. Sportswear can adapt to different situations and demands by incorporating sensors and responsive materials into the fabric, allowing immediate input and support. Moreover, these cutting-edge materials will revolutionize high-performance, environmentally conscious sportswear by increasing sustainability and reducing damage.

The primary contributions of the article are

This study investigates using conjugated nanomaterials to develop intelligent sportswear to enhance sportswear performance.

Incorporating graphene, silver nanoparticles (AgNPs), and green nanomaterials onto polyester (PES) fabric in the Intelligent Sportswear Design (ISWD) system enhances crucial features.

The results indicate significant improvements in moisture regulation, UV protection, electrical conductivity, and thermal insulation.

The organizations of the remaining sections are listed as follows: In Section 2, the significance of nanomaterials and intelligent sportswear is highlighted as the research and advancements in sportswear technology are examined. The novel idea of ISWD, which combines cutting-edge technology with conjugated nanomaterials for improved sportswear performance, is introduced in Section 3. A thorough description of the tests carried out to verify the suggested ISWD is given in Section 4, together with quantitative information on its advantages and efficacy. The results are outlined in Section 5, along with their implications and possible directions for future research and development in intelligent sportswear.

2 Literature survey and analysis

This section conducts a comprehensive review of the existing literature, focusing on the contemporary landscape of sportswear technology. This section explicitly emphasizes nanomaterials’ significance in augmenting athletic performance and comfort. This study examines the current obstacles encountered in the field of sportswear design, as well as the developing patterns seen in the development of intelligent sportswear.

Nanoparticles designed for use in textiles were fabricated by Jadoun et al. [11] using a green synthesis (GS) strategy. The GS technique is a green nanomaterial synthesis strategy that relies on plant extracts and non-toxic reducing agents. The results of the experiments showed that the materials’ tensile strength significantly increased, with a measured value of 38 MPa. The fabric’s UV protection factor (UPF) rating of 45 exemplifies its superiority in blocking the sun’s rays. The antibacterial and colorfast properties of the fabrics were enhanced as a consequence of the experiments. This approach offers a practical and efficient way to manufacture eco-friendly nanoparticles for textiles.

Andra et al. [12] researched the potential of nanoparticles in creating antimicrobial textiles. The technique includes a chemical reduction process to deposit AgNPs into fabric surfaces. The findings showed a tremendous antibacterial effectiveness, with 98% less bacterial multiplication than before. The UPF 40 rating indicates that the textiles are very effective in repelling UV rays and preventing the buildup of unpleasant odors. Therefore, these textiles are optimal for usage in hospital and outdoor situations.

The easy process for synthesizing zinc oxide (ZnO) nanorods on conductive textiles, known as ZnO-CT, was presented by Lim et al. to develop multifunctional sensors [13]. The ZnO-CT sensors had a high level of sensitivity, as seen by their reaction time of 6 s. These sensors could detect NH3 gas at a concentration as low as 0.2 ppm, indicating a low detection limit. The linear range of these sensors spanned from 10 to 100 ppm. The approach exhibits characteristics such as room temperature synthesis and enhanced gas sensing capabilities, rendering it very attractive for applications in environmental monitoring and wearable technology.

Yan et al. used an approach to fabricate photothermal silk-based textiles (PTST) [14]. The PTST methodology encompassed the incorporation of reduced graphene oxide (rGO) and AgNP into silk fibers. The experimental findings demonstrated effective photothermal conversion, resulting in a temperature elevation of 36°C when subjected to near-infrared (NIR) irradiation. The PTST material showed adequate UV protection with a UPF 50. It displayed remarkable flexibility and enhanced thermal management capabilities. This technique presents innovative opportunities for developing functional fabrics that possess photothermal abilities.

Yao et al. introduced a novel use of smart nanotextiles (SNTs) in fashion and aesthetics. SNT uses carbon nanotubes (CNTs) and conductive polymers to develop textiles with interactive and lighting properties [15]. The empirical findings showed the capacity to customize lighting patterns, the conductivity level, and the wash’s longevity. Integrating technology and aesthetics in SNT presents novel opportunities for developing interactive and visually captivating fashion and wearable apps.

Farooq and Zhang examined personal thermal control using advanced fabrics [16]. The suggested methodology included incorporating phase change materials into textile materials to control and maintain optimal body temperature. The experimental findings provided evidence of successful thermal regulation, as shown by a phase change temperature of 28°C. This resulted in a notable decrease in energy use for heating and cooling, up to 30%. The study revealed enhanced wearer comfort, signifying a noteworthy progression in personal thermal management via textiles.

Wang et al. introduced a novel adsorption-catalytic oxidation system, which consists of arrays of nickel/zinc imidazolate framework-8/zinc oxide (Ni/ZIF-8/ZnO) generated from metal-organic frameworks (MOFs) deposited onto carbon fiber cloth (CFC) [17]. This system aims to enhance the efficiency of adsorption and catalytic oxidation processes. The procedure included producing a composite nickel material, ZIF-8, and ZnO on a carbon fiber cloth substrate. This composite material exhibited a high level of effectiveness in removing organic contaminants. The experimental findings demonstrated a notable adsorption capacity of 98.3 mg/g, a fast catalytic oxidation process resulting in a removal efficiency of 98%, and a commendable ability to be reused several times.

Akbar et al. fabricated a hierarchical core–shell heterostructure of NiCo@NiOOH@CoMoO4 on carbon cloth [18]. This novel design was explicitly aimed at enhancing the performance of asymmetric supercapacitors. The methodology included the electrochemical deposition of core–shell materials onto a carbon cloth substrate. The experiment’s results revealed a notable specific capacitance value of 2,925 F/g, commendable cycling stability with 89% capacitance retention after undergoing 2,000 cycles, and a broad operational voltage range. The establishment of a hierarchical core–shell architecture facilitates the development of supercapacitors that are both efficient and long-lasting.

The study conducted by Martínez-Barbosa and Moreno-Corral investigated the characteristics and applications of medical textiles that are washable, reusable, and disposable [19]. The suggested methodology included using antimicrobial substances, namely AgNPs and chitosan, to produce medicinal fabrics. The study’s findings demonstrated the textiles’ notable antibacterial efficacy, exhibiting a substantial decrease of 99.9% in bacterial proliferation. These textiles show great potential for use in medical contexts. The advancement of these textile materials caters to the need for infection control inside healthcare environments.

Tsai and Jhong presented a novel production decision model incorporating a carbon tax inside the framework of activity-based pricing [20]. The specific context of their research was the knitted footwear sector. The suggested model includes the evaluation of the environmental consequences associated with manufacturing processes and the analysis of the financial ramifications of implementing a carbon price. The results demonstrated a decrease in carbon emissions by 20%, enhanced operational efficiency, and cost-effectiveness by carbon tax policies, providing significant knowledge for promoting sustainable manufacturing practices within the footwear sector.

Cosma et al. [21] provide pre-treating cotton and leather substrates with cold atmospheric pressure plasma (CAPP), then coating them with dispersion-form TiO2–SiO2–reduced graphene oxide (GR) composites. To determine how three essential factors – CAPP pre-treatment, organic dispersion coating, and TiO2–SiO2–GR composites – may influence the morphostructural characteristics and photocatalytic performance of modified cotton and leather surfaces, this study employed a Taguchi scheme. Coating formulations containing TiO2–SiO2–rGO composites in an organic dispersion medium showed promise as photocatalytic materials for producing novel photocatalytic cotton and leather goods that can clean themselves.

Liang et al. [22] focused on improving the dispersion of GO in waterborne polyurethane coatings (WPU) using molecular grafting. The goal was to introduce GO, which has nanoscale size, wide surface area, and plentiful functional groups, into WPU. As a consequence, WPU coatings exhibited outstanding durability and resisting solvents. At a GO concentration of 0.7 wt%, the GO-modified WPU coating layer showed a 64.89% increase in tensile strength, a 28.19% increase in abrasion resistance, and a 15.87% improvement in pendulum hardness. This study’s chemical grafting technique offers a practical means of increasing GO dispersion in WPU and gives a valuable point of reference for modifying waterborne wood coatings.

Karypidis et al. [23] evaluate the pros and cons of synthetic antibacterial drugs, including triclosan, quaternary ammonia compounds, polyhexamethylene biguanide, and nitrogen-halamines. Synthetic antimicrobial chemicals are effective against bacteria but endanger people, wildlife, and the environment. Antimicrobial coating treatments for textiles made of copper nanoparticles (CNPs) and AgNPs derived from chitosan, herbal extracts, and green synthesis emerged in response to these worries. These solutions reduced environmental impact without sacrificing top-notch antibacterial performance or lifespan.

Miao [24] delves into the potential application of graphene and CNTs in sports gear as part of natural rubber composites, and it also suggests using these materials. The experimental results demonstrated that the CNT capacitance values of M-120//GO, M-160//GO, and M-180//GO attained 43.3, 87.3, and 46.5% of the initial particular capacitance, respectively, after 1,200 cycles. This suggests that the M-160//GO capacitor has superior electrolytic storage efficiency and high equilibrium. Incorporating it into sporting goods increases their usability and battery life.

The use of nanotechnology and flexible conjugated materials in sports events (nano-FCM-SE) investigates the potential of conjugated materials to improve equipment, track sports progress, and increase athletes’ training effectiveness [25]. There is a significant performance gap between the suggested damage severity model and its rivals (0.2). This study’s sports injury prevention system outperforms the state-of-the-art by 5.17% points regarding detection efficiency.

The article summarizes the properties of conjugated materials and how they are used in sports training [26]. It then investigates the possible applications of conjugated materials to improve athletes’ training effects, track their sports status, and make better equipment. The average scores for the 20 athletes’ apparel were 9.0475, 9.0075, 9.01, 9.025, 9.0325, and 9.04, while for their sports shoes, the average ratings were 9.035, 9.055, 9.02, 9.085, 9.0175, and 8.9975.

Composite conjugated materials play an important role in soft tissue injuries by acting as matrices or supporting structures that promote the healing of injured tissue [27]. Composite conjugated materials modulate immune responses, decreasing inflammatory reactions and eliciting a faster healing reaction. Study participants’ skin healed at 42.55% in the treatment group and 58.17% in the experimental group 1 week after the experiment and at a rate of 51.28% and 73.24% 5 weeks after the study’s start.

The summary of the literature survey is listed in Table 1.

Summary of literature survey

| S. no. | Method | Advantages | Drawbacks |

|---|---|---|---|

| 1 | Green synthesis (Jadoun et al. [11]) | Sustainable, environmentally friendly manufacturing | Restricted ability to scale up and inconsistent effectiveness |

| 2 | Silver nanoparticle deposition (Andra et al. [12]) | Potent antimicrobial properties | Possible toxicity, expense, and decreased adaptability |

| 3 | ZnO nanorod synthesis (Lim et al. [13]) | Sensitivity high, ambient temperature | Restricted gas range and sensor reaction time |

| 4 | Photothermal integration (Yan et al. [14]) | Effective photothermal characteristics | Possible discomfort and constrained design choices |

| 5 | Carbon nanotube inclusion (Yao et al. [15]) | Personalized lighting and conductivity | Intricate production, short wash life |

| 6 | Phase change material integration (Farooq and Zhang [16]) | Efficiency in energy use and efficient thermal regulation | Temperature restriction during phase transition, possible discomfort |

| 7 | MOF-derived catalytic oxidation (Wang et al. [17]) | Quick oxidation and a high adsorption capacity | Intricate synthesis and possible toxicity |

| 8 | Core–shell super capacitor (Akbar et al. [18]) | Stability and a high specific capacitance | Intricate synthesis, possible expense |

| 9 | Antimicrobial agent integration (Martínez-Barbosa and Moreno-Corral [19]) | Strong antibacterial qualities | Restricted durability and possible opposition |

| 10 | Carbon tax-based decision model (Tsai and Jhong [20]) | Decreased carbon impact and affordability | Implementation complexity and possible cost burden |

| 11 | CAPP (Cosma et al. [21]) | TiO2–SiO2–rGO composites | Complex, costly synthesis |

| 12 | Dispersion of GO in WPU (Liang et al. [22]) | Increase GO dispersion in WPU | Expanded nanoscale size, surface area, and functional groupings |

| 13 | CNPs and AgNPs (Karypidis et al. [23]) | Reduced environmental impact without compromising antibacterial effectiveness | Risks of triclosan and QACs |

| 14 | Potential application of graphene and CNTs Miao [24] | Superior electrolytic storage efficiency and high equilibrium | Graphene composites lower capacitor capacitance |

| 15 | nano-FCM-SE (Liu and Ren [25]) | Provides evidence that flexible conjugated materials may help athletes avoid injuries | These materials could be expensive to design and apply |

| 16 | Application of conjugated materials [26] | Improves the efficiency of training tools by incorporating cutting-edge components | Being unfamiliar with the new materials can cause initial acceptance to be sluggish |

| 17 | Tissue healing during exercise rehabilitation training (Li and Zhang [27]) | During rehabilitation, it shows potential to hasten the mending of tissues and facilitate healing | Thorough clinical studies are necessary to determine the effectiveness and safety |

This section demonstrates the increasing importance of nanomaterials in improving textiles’ performance, particularly in thermal management and environmental purification. Nevertheless, significant issues still need to be addressed in sustainable synthesis processes and the incorporation of these methods into intelligent textiles. These challenges require the development of novel solutions within the sector.

Researchers first performed a comprehensive literature study to find conjugated nanomaterials with desired qualities including responsiveness, flexibility, and durability. This accomplished both the theoretical groundwork and the reduction of candidates. Afterwards, several practical tests were run on these materials to see how well they performed and if they were suitable to be used in athletic apparel. This research ensured that the selected nanoparticles were good for novel sportswear uses by verifying their effectiveness using literature reviews and experimental results. Research and development in innovative sportswear focusing on comfort and performance is known as ISWD. These versatile PES textiles use biodegradable green nanomaterials, AgNPs, and graphene coatings. This study investigates the possibility of creating UV-blocking materials to provide sportsmen with enhanced sun protection.

3 System methodology

This section presents the ISWD concept as an innovative methodology within sports textiles. Integrating innovative conjugated nanomaterials by ISWD increases sports clothes and footwear’s performance, comfort, and sustainability. This section explores the characteristics of ISWD, including a multifunctional PES fabric coated with graphene/AgNPs and a pattern that blocks UV radiation. The study provides empirical evidence, including quantitative data, to emphasize the efficacy of ISWD in optimizing sports gear.

3.1 Synthesis of GO and graphene

A 1 g of natural graphite powder was placed into an Erlenmeyer flask and agitated inside an ice bath. A mixture of 1 g of sodium nitrate (NaNO3) and 30 mL of concentrated sulfuric acid (H2SO4) was introduced into the system and subjected to stirring at 100 rpm for 30 min. Three grams of potassium permanganate (KMnO4) was gradually introduced for 40 min, ensuring the temperature remained below 12°C. The solution was subjected to thermal treatment in a water bath maintained at 40°C, with continuous agitation for 2 h. Distilled water (50 mL) was incrementally introduced into the suspension while vigorously agitating at 98°C for 40 min, forming a break with a dark brown appearance. Totally 16 mL of hydrogen peroxide (50%) was introduced into the suspension to eliminate the surplus of potassium permanganate. This mixture was then diluted by adding 260 mL of distilled water. To achieve purification, the combination underwent a washing process using a 5% aqueous hydrochloric acid (HCl) solution, followed by further washing with distilled water until it reached a pH of 7. The method of obtaining graphite oxide included using centrifugation to separate the substance, followed by additional washing and drying procedures conducted under vacuum conditions at a temperature of 60°C. The synthesis of graphene included the exfoliation of GO, followed by a chemical reduction process with hydrazine as the reducing agent. A colloidal suspension of GO was prepared by dispersing 50 mg of GO in 50 mL of deionized water at a 1 mg/mL concentration. The mixture was then subjected to ultrasonication for 1 h. Following that, a volume of 5 mL of N2H4 was introduced into the colloidal suspension, which was then subjected to reflux at a temperature of 100°C for 1 h. The synthesized item, which exhibited a graphitic tint, underwent a cooling process followed by filtration. It was washed with deionized water and dried beneath vacuum conditions at a temperature of 60°C.

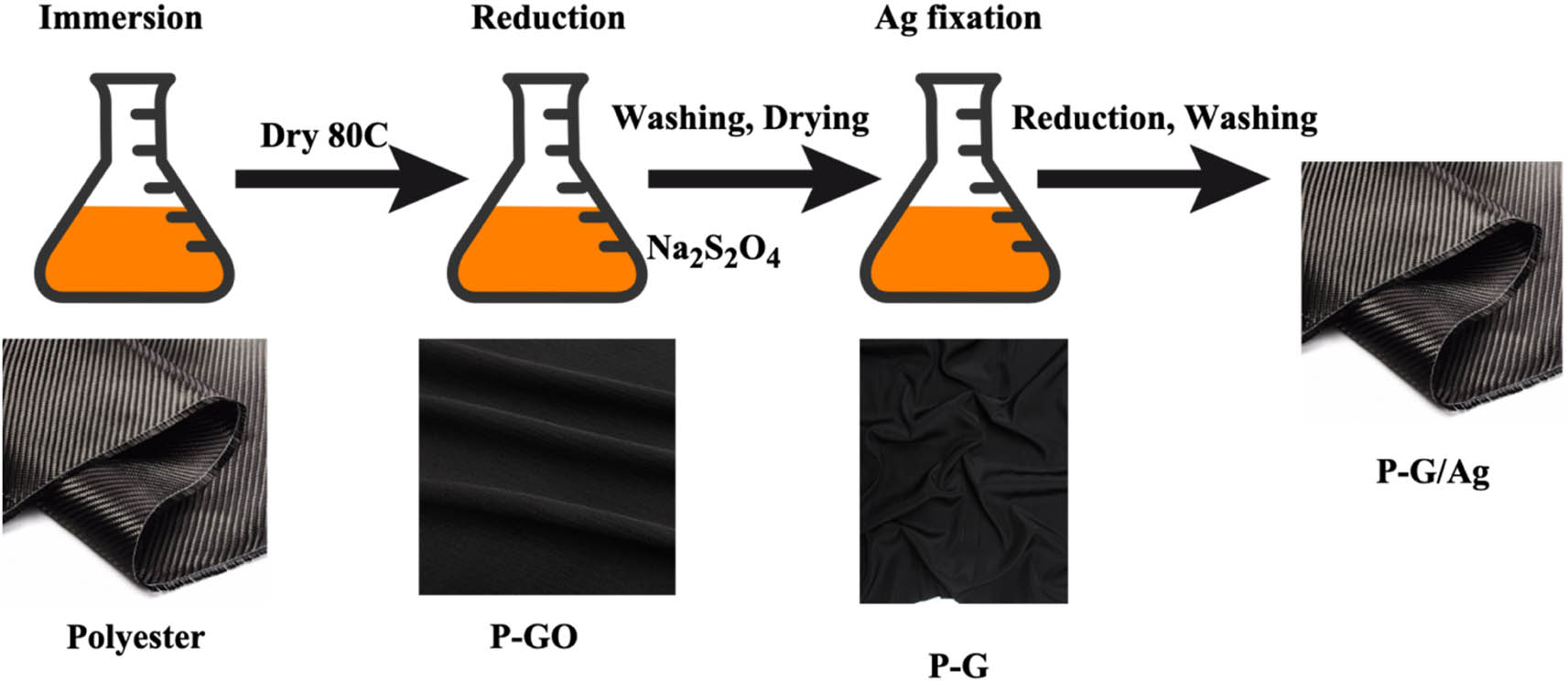

3.1.1 Coating of knitted PES with conjugated materials

The PES–GO conjugated material has been synthesized using a straightforward method known as the “immersion and drying” technique [21]. Samples of knit PES yarn were cut to the measurements specified below: The object is 10 cm in length and 4 cm in breadth. The models received a preparation before the application of the coating. The specimens were immersed in a water-based solution comprising 3 g/L of ammonia and 2 g/L of nonionic detergent for 60 min at 100°C. The textiles were washed using deionized water, followed by a drying procedure in an oven set at 80°C for 4 h. Later, pre-treated PES specimens were subsequently immersed in a fluid solution containing exfoliated GO for 60 min under ambient conditions. The samples were then dried in an oven set at 90°C for 1 h. The methodology was repeated multiple times to augment the quantity of GO in the specimens. A discernible alteration in color, transitioning from white to brown, becomes apparent with a rise in the number of covering cycles.

3.1.2 In situ synthesis of Na2S2O4

The conjugated material specimens acquired in their current state were subjected to chemical reduction using Na2S2O4 as the reducing agent to produce conjugated material. The conjugated material specimens were submerged in a 100 mL aqueous solution containing Na2S2O4 (50.10–3 M) and subjected to stirring for 1 h at a temperature of 95°C. The textiles underwent several wash cycles using deionized water, followed by a drying process at a temperature of 90°C for 1 h. To validate the decrease of GO to graphite, the graphene mixture underwent a washing and filtration process to facilitate the X-ray diffraction (XRD) observations.

3.1.3 In situ synthesis of conjugated material

This section outlines a methodology for the deposition of AgNPs onto PES textiles that have been coated with graphene. The fabrics coated with graphene were submerged in an aqueous solution with a concentration of 0.05 mol/L of AgNO3 and subjected to ultrasonication for 30 min. The silver ions (Ag+) that were consumed onto the fabric’s surface underwent reduction to form elemental silver by using a 1.0 mol/L N2H4·H2O solution for 15 min while maintaining ambient temperature. The nanocomposites of PES textiles impregnated with G/Ag nanomaterials were washed and dried at 90°C for 3 h.

3.2 Fabricated UV-protected PES fabric

The semiconductor industry has shown significant interest in graphite and its variants due to its exceptional mechanical, electrical, heat, and optical characteristics. The study used the pad-dry-cure method to modify cotton fabric covered with a small amount (0.05–0.4 wt%) of low graphite nanoplate (GNP). The altered cotton exhibited remarkable UV safeguards, resulting in a tenfold increase in the UPF from 30 to 350, although accounting for a mere 0.4% of the GNP by weight. A novel approach was suggested to enhance cotton textiles’ UPF using a non-toxic hydrothermal method to deposit rGO. The UPF values of naked cotton and rGO-deposited cotton textiles were determined to be 7, 440, and 432 before and after washing. The fabricated material was developed with exceptional UV protection capabilities and prolonged durability. The study used a novel electrostatic self-assembly (ESA) technique to enhance the UPF of cotton fabrics.

Figure 1 shows the proposed intelligent sportswear designed PES material. The principal test specimen used in this investigation is a PES fabric. Conjugated nanoparticles are smoothly incorporated into the PES matrix to optimize its efficiency. The nanomaterials have been carefully chosen based on their distinct characteristics. After the integration process, a thorough microscopic study assesses the resultant modifications and enhancements in the fabric’s qualities.

Fabricated UV-protected PES fabric.

GO is a nanotechnology with a negative charge in a water solution. The ESA process can assemble it on a substrate using a negatively charged polyelectrolyte, forming a multilayer network. The ESA technology was used to fabricate cotton fabric with enhanced UV protection. GO was utilized as a polyanion, while chitosan (CS) was a polycation. The UPF values exhibited an upward trend with increased GO/CS layers placed on the textile. When comparing the UPF values of different fabrics, the fabric with a single coating of GO/CS had a UPF of 8.27, while the material with a double layer of GO/CS exhibited a much higher UPF value of 87.73.

The fabric with ten double layers of GO/CS showed an even greater UPF value of 432. After subjecting the (GO/CS)1 and (GO/CS)10 samples to ten water cleaning cycles, their UPF values declined. The UPF level of the (GO/CS)1 piece fell from 82.43 to 81.42, while the UPF level of the (GO/CS)10 sample dropped from 432 to 421.29. The transmittance of both types of UV radiation, namely UV-A and UV-B, exhibited a marginal increase of less than 1%. This finding indicates that textiles treated with GO/CS deposition had exceptional capabilities in terms of UV protection and resistance to the effects of washing.

3.3 Intelligent sportswear material synthesis

To conduct a more comprehensive analysis of the impact of coatings on the optical characteristics of textiles, the research performed UV transmission spectrometry on fabrics composed of PES, polyester with GO (P-GO), polyester with graphite (P-G), and polyester with silver and graphite (P-G/Ag). Traditional PET fabrics have several drawbacks, the most common of which are low anti-bacterial activity and poor surface wettability. Consequently, there is a significant interest in various practical applications in creating easy procedures for imparting multifunctional characteristics. Figure 2 shows a straightforward, scalable, and inexpensive way to coat multifunctional PES fabric with graphene/AgNPs using a simple dip coating process in three different types of PES: P-G, P-GO, and P-G/Ag. This method proposes graphene nanosheets attached to the PES fabric as a superior substrate for Ag° deposition. Graphene nanosheets can simultaneously serve as a linker and stabilizer to improve AgNPs’ dispersion and stability thanks to their large specific surface area. Researchers used optical microscopy, color supervises, scanning electron microscopy, and Raman spectroscopy to study the structure and surface morphology of the laminated PES fabric Na2S2O4. The amount of nitrogen deposited at a temperature of −194.8°C was used to determine the surface areas. With water contact angles of 122, 126, and 124°, coated PES fabrics demonstrated enhanced hydrophobic behavior compared to pure PES fabric. Among the remarkable multifunctional characteristics exhibited by the treated fabrics were protection from UV radiation, high electrical conductivity, and superior mechanical properties. The measurements were taken throughout the 320–410 nm wavelength spectrum, as seen in Figure 2.

Synthesis process of intelligent sportswear material.

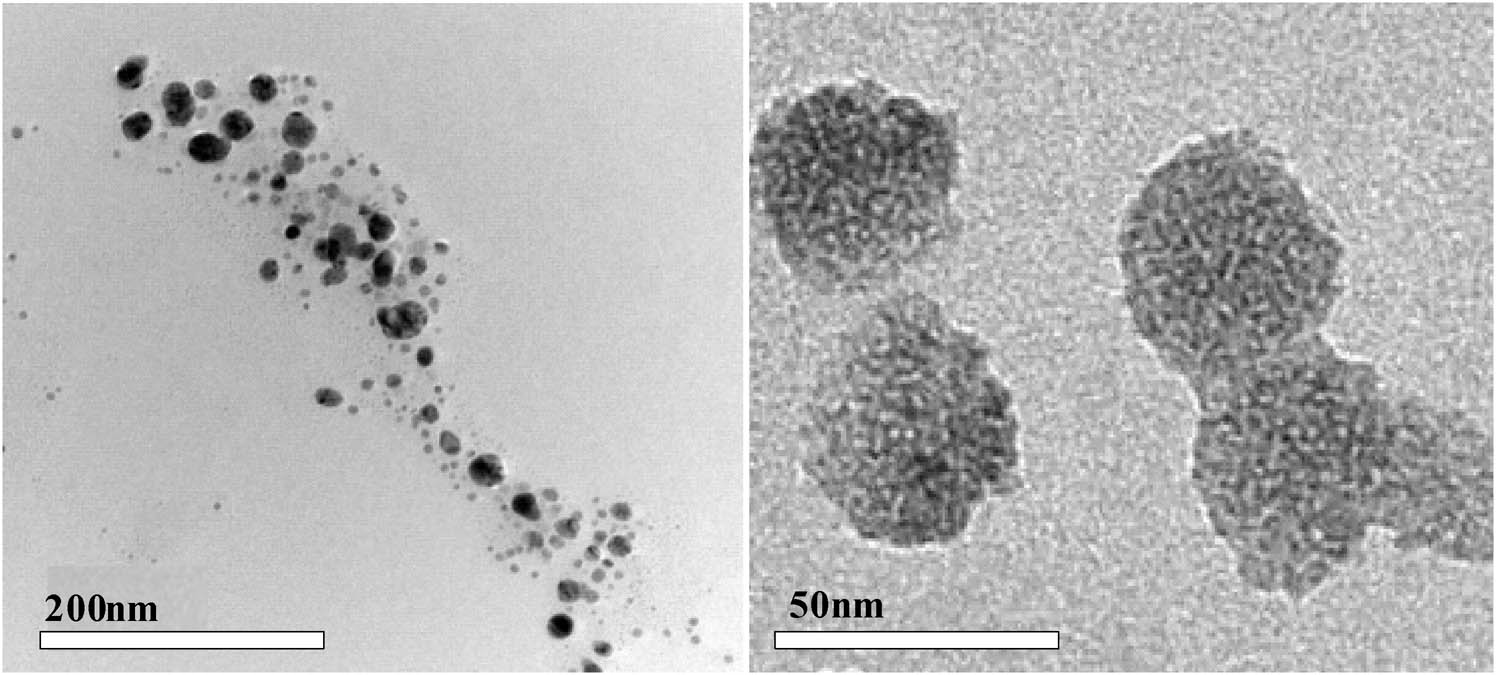

The transmittance spectra exhibited a clear difference across all the specimens. It was observed that the uncoated PES fabric showed a higher percentage of UV transmission than the coated textiles. This finding suggests that the PES fabric did not substantially impact its UV defense capabilities. After applying GO overlaying onto PES fabric, the resulting spectrum of P-GO was reduced by around 33% compared to the untreated PES fabric. The analysis of the transmittance ratio of P-G fabric revealed that the decrease in the chemical makeup of GO leads to a drop in the transmittance percentage terms, resulting in a value of 43%. Prior research has shown that incorporating CS/G and CS/GO conjugates into cotton fabric boosts its UV protection capabilities, mainly attributed to the planar shape of graphene nanosheets. Hence, the study’s findings demonstrate that P-GO and P-G can absorb UV radiation, aligning with current research outcomes. Our study also assessed the UV protective capabilities of textiles coated with graphene/silver nanostructures. This article analyzes the nanostructure morphology characteristics of material samples at different wavelengths using scanning electron microscopy, as shown in Figure 3.

Scanning electron microscopy image.

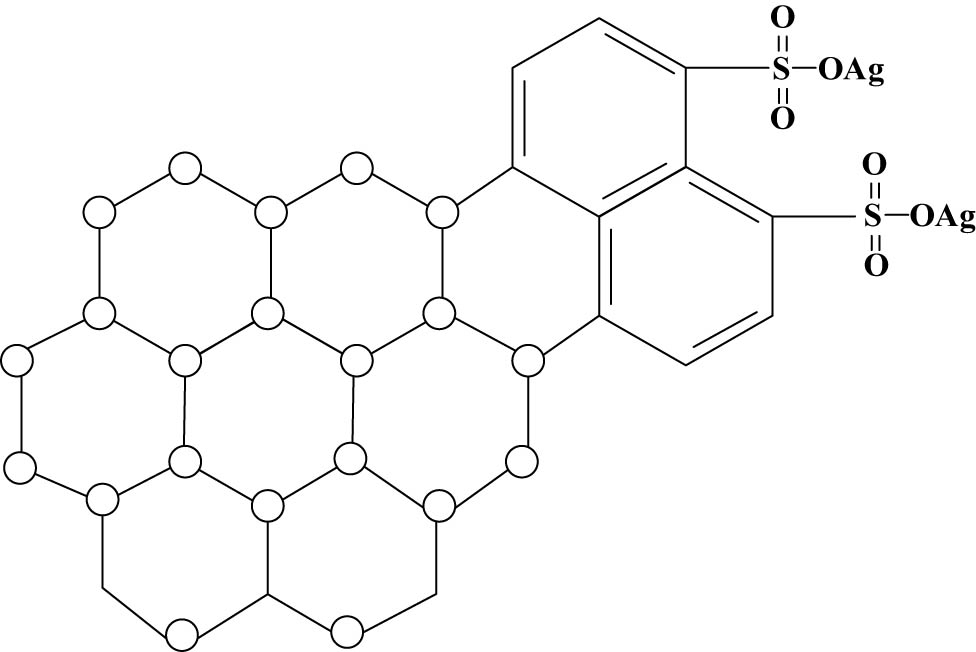

From Figure 3, it can be seen that integrating small silver particles onto fabric-coated graphite can significantly reduce UV transmittance. This finding suggests that AgNPs have a solid ability to shield against UV radiation. Consistent with the results on reflectance, GO and G serve as effective UV-blocking drivers for PES fabric. Incorporating a minor quantity of nickel nanoparticles into the graphene-coated material significantly boosts its UV-blocking capabilities compared to the unprotected fabric. The UPF for UV-B is expressed in Equation (1).

The UPF for UV-B denoted as

The UPF for UV-A, denoted as

The

Material molecular structure formula.

The composite function finishing technique imparts several functionalities to knitted fabric and preserves its inherent wearability. The clothing industry has incorporated three essential functions into knitted materials: antibacterial properties, mite prevention, and UV protection. These functions have gained significant attention from consumers due to their potential benefits. Combining these three functions in a single fabric has proven effective without compromising the overall performance and value of the garment.

While the PES fabric was prepared with a 100 g/m2 mass for coating, many essential components and chemicals were used. The materials were carefully chosen and obtained with great attention to detail to guarantee the utmost quality and appropriateness for the intended use. The fabric coating procedure’s fundamental basis is using a knit PES fabric characterized by a weight of 100 g/m2. The selection of this particular weight was made to achieve a harmonious equilibrium between durability and comfort, making it highly suitable for applications in the realm of sportswear.

To augment the fabric’s characteristics, namely its electrical conductivity, a selection of chemicals and agents were obtained from trustworthy vendors. The coating process was facilitated by using several chemical agents obtained from Sigma-Aldrich in addition to graphite powder. Each of these compounds fulfilled distinct functions throughout the coating process, such as improving conductivity, facilitating the decrease of nanoparticles, or enhancing the overall performance of the fabric.

3.3.1 Sample preparation and coupled material selection

The specimens consist of combing cotton double-rib knitting fabric. Before completion, the finishing fabric must undergo a thorough washing process to eliminate any residual contaminants present on the material, as these substances potentially interfere with the efficacy of the cleansing finishing chemical. The textile surface must possess a neutral or mild acid value. Textiles with a neutral or slightly acidic pH benefit the human body. Imbalances in textiles’ pH level might lead to skin injury susceptibility. Thoroughly cleaning the finishing apparatus, including the rolling grooves and roller, is imperative. Holders utilized over an extended period should be employed for something other than chemical and consuming supplies. This precautionary measure is taken to prevent the surfactant residue on the machinery from following the fabric, thereby impeding the desired finishing outcome.

Functional knitted textiles typically involve weaving available fibers or applying beneficial auxiliary chemicals by spraying and dipping. There has been a notable surge in the need for composite applicable completing items. Composite finishing is a complex technique that involves several technical scores rather than a simple collection of finishing processes.

The compound finishing function involves using two different bath procedures since failure to do so may negatively impact the overall finishing outcome. The chemical finishing process uses water as a medium to maintain the chemical in solution or dispersion. At the same time, heat is utilized to activate the chemicals and remove the water through drying. Although some studies have been conducted on the waterless finishing of textile materials, it is essential to note that water remains the primary medium in the chemical finishing business. Specific chemical finishing techniques integrate mechanical and chemical processes to enhance the outcome. The primary factors contributing to this phenomenon are the presence of bleach in the fabric covering, other ionic ingredients, and the resulting condensation of an essential water-repellent agent. Empirical evidence from manufacturing procedures has shown that composite finish is typically more effective when conducted using the one-bath approach instead of the two-bath technique, which yields worse finishing results. This experimental study showed that the anti-bacterial and anti-mite finishing dipping temperatures significantly differed from the anti-UV finishing. The method used for the finishing process also exhibited variations. The direct combination of the two chemicals was not feasible. The two-bath method was used to mitigate any potential impact on the outcome.

3.3.2 Single factor analysis

Given the need for outside evaluation and the lengthy duration of the antimicrobial examination, this study focuses solely on analyzing the textile’s anti-UV work. By comparing appropriate norms, the aim is to identify a finishing technique that exhibits favorable functionality and minimal comfort loss based on experimental values. The study aims to determine optimal finishing process variables.

The experimental study used a nano metallic organic molecule as an antibacterial and anti-mite finishing product. The reagent refers to the initial solution possessing a high concentration, necessitating dilution in a specific ratio at completion. The stages involved in the diluting procedure are as follows:

Step 1: Take a certain amount of the stock solution for the nanoscale inorganic–organic conjugate antibacterial and anti-mite finishing agent. To get a final completing agent solution content of 5% (on the weight of the cloth), dilute this solution 1:10 with water.

Step 2: Place the knitted fabric with functionality into the nano-inorganic–organic conjugate antimicrobial and anti-mite finishing chemical solution that has been created. Set the water bath’s temperature to 60°C, then let the cloth soak for 45 min.

Step 3: Put the practical knit fabric from the water bath process in a centrifuge. The cloth should be centrifuged until all moisture has been removed.

Step 4: After the dehydrated practical knit fabric has been laid out and smoothed, place it in an oven that is kept at a constant 80°C. Let the cloth air dry completely in the oven to ensure the finishing procedure is finished.

3.3.3 Nanoanti-UV method

After applying anti-bacterial and anti-mite completing, the samples received an anti-UV completing treatment. This procedure included a discussion of the effects of three variables on the UV protection efficacy of the subjected models: soaking temperatures, finishing chemical quantity, and impregnation period. The three variables, soaking temperatures, finishing chemical quantity, and impregnation period, are the procedures of the nanoanti-UV method, one of the methods of UV blocking. For protection against UV and near-infrared (NIR) light, nanocoatings made of metal oxide nanoparticles like ZnO and titanium dioxide (TiO2) are standard practices. Glass, plastics, and textiles can all benefit from these coatings’ superior UV protection. The knitted material was finished with an antimicrobial treatment. The last step involves heat immersion, rotational dehydration, and drying at an ongoing temperature of 80°C.

3.3.4 Qualitative functional evaluation

Before identifying the best procedure parameters, the sample underwent treatment to demonstrate that the final process could provide the specimen with antibacterial, anti-mite/anti-UV conjugate activity. The most suitable completing procedure settings were chosen. This work treated materials with anti-UV therapy after being treated with antibacterial and anti-mite technologies. The procedure for finishing consists of the following steps:

30 min of impregnation – Most heterogeneous catalysts are prepared by incipient moisture impregnation.

30 g/L of finishing agent – An exclusive finishing solution for all varieties of stamped and colored cotton and blends that enhance their wet or dry rub rapidity.

50°C centrifuge dehydration – Concentric force isolates floc-state particles from water as it gathers in a cylindrical shape around the screw shaft while it revolves fast.

80°C constant temperature dryness – Humidity was 80% and air temperature 26–28°C. Samples dried at 40–80°C. Uniform drying was achieved by placing samples in 5 g trays in the center of the drying chamber.

The fundamental characteristics of the processed samples, such as depth, surface, longitudinal, and crosswise weight, were ascertained. Both the transmittance and wavelength of the material were determined before and following anti-UV completion. The material’s anti-UV impact was evaluated to track changes in the specimen’s essential variables before and after composite completion.

3.4 Application of conjugated materials in sportswear

3.4.1 Research on elements of colour design

Conjugated polymers are used to create sportswear colors using continuous knitting. The design guidelines are the same as those used for other polymers. With black, red, blue, and other primary colors dominating most of them, various color designs come next, and a small quantity of color designs is finished by publishing. Vibrant and high pure hues were often used in sports training apparel, with the general mood intended to convey a sense of beauty and vibrancy. But thanks to the increasing appeal of sportswear and the ongoing advancements in conjugated substances, developers are now able to create a wide range of creative designs that reflect a variety of tastes, design traits, and stylistic ideas by incorporating conjugated polymers into a variety of sportswear hues. Figure 5 displays the color scheme for exercise apparel based on conjugated polymers.

Conjugated material-based intelligent sportswear.

3.4.2 Waterproof and moisture permeability needs

When individuals pause to recuperate after intense physical activity, a low external temperature inhibits the timely dispersion of sweat. Water droplets accumulate on the inner fabric layer of clothing, resulting in discomfort for individuals. This phenomenon is often referred to as “dew.” The functionality of sports apparel necessitates that garments can effectively repel moisture from rain and snow while simultaneously facilitating the timely evaporation of sweat from the body. The sweat produced by human beings is categorized into two distinct types: visible and invisible. During the process of moisturizing clothes, both gas and fluid humidity are transformed. The term “invisible sweat” pertains to the process of water vapor evaporation from the human skin, resulting in the presence of gaseous water. Visible perspiration, commonly called sweat, is the bodily secretion that becomes apparent when an individual perspires excessively or when exposed to elevated temperatures. The fluid transfer performance of motion has significant importance due to its specialized wear function. Conjugated polymers provide inherent benefits in terms of their waterproof and breathability properties. The apparel has a notable capacity for moisture permeation, enabling the efficient dispersion of perspiration and facilitating the maintenance of the human body’s thermal and humidity equilibrium under the following circumstances: (1) Sweat can undergo rapid core absorption or migrate toward the outside surface of garments, so exhibiting a commendable perspiration effect. (2) The presence of residual sweat for a brief duration impedes the process of perspiration. After ingesting moisture from the fabric, it can rapidly undergo wetting and drying. Considering the composition of clothing polymers, garment weight is typically appropriate, resulting in a low burden. This facilitates unobstructed airflow inside the garment, enabling the attainment of thermal equilibrium in the torso. The schematic representation of the composite material-based waterproof sportswear construction is shown in Figure 6.

Conjugated material-based waterproof sportswear.

3.4.3 Reduce the thickness of the sole

The use of conjugated polymers has the potential to provide a thin sole width, reducing the sole’s overall thickness. This approach accomplishes the objective of creating a thin and light sole. The total width of the sole is determined by the combined width of the specimen and the bottom dish, with the latter often being the primary factor influencing the reduction in thickness. The smaller size of the bottom surface does not necessitate using advanced technological equipment. When the width of the sole is diminished to a specific extent, extra precautions must be implemented. Incorporating conjugated materials can enhance the durability and substantial elasticity of the foot, thereby augmenting its general durability.

3.4.4 Change the structure of the sole

Historically, early iterations of footwear often resembled socks with boat-like structures and side walls. These shoes generally had a mesh design on the inside surface of the sole, resulting in a visually substantial and voluminous appearance. The use of conjugated polymers in sports footwear manufacturing has grown more prevalent due to the ongoing advancements in making shoe technology, supplies, and procedures. The aesthetic appeal of running shoe bodies has started to improve. Conjugated polymers have the potential to serve as substitutes for a portion or the whole of the sidewall of the foot. Removing or reducing the wire mesh structure inside the sole would result in a decline in sole excellence and alterations to the bottom’s look and construction. Figure 7 illustrates the configuration of football footwear bottoms by connection data.

Intelligent sports shoe and sole design with conjugated material.

The overall workflow of the proposed intelligent sportswear is listed in Algorithm 1.

| #Algorithm 1 |

|---|

| Step 1: Initialization |

| Define the size and properties of conjugated materials |

| Step 2: Graphene synthesis |

| For each chemical reaction |

| Mix and reaction chemicals (Na2S2O4, AgNO3) |

| Step 3: Coat polyester |

| For every coating method |

| Apply coating material |

| Step 4: Characterization |

| For every material (P-G, P-GO, P-G/Ag CS/G, CS/GO) |

| Measure properties |

| Step 5: UV protection |

| For every fabric sample |

| Compute UV protection function |

| Measure UV transmittance |

| Step 6: Sportswear and footwear design |

| Apply design considerations |

| Step 7: Data analysis of conjugated materials |

| Analyze experimental outcomes for nano metallic organic molecule, knitted fabrics |

Initialization: Establish the starting points for the conjugated materials in the athletic apparel, including their dimensions, form factor, and desired characteristics (such as conductivity and flexibility).

Generating graphene:

Graphene may be synthesized by reacting chemicals such as Na2S2O4 and AgNO3. Making graphene derivatives for coating techniques requires this step.

Protective Garment: Polyester

Use various coating techniques to incorporate graphene or its derivatives into PES fabric. The result is smarter athletic apparel with improved fabric conductivity and other useful features.

Characterization:

Evaluate and assess the characteristics of coated materials, such as P-G, P-GO, P-G/Ag CS/G, and CS/GO. Ensuring quality and performance may include evaluating properties such as mechanical strength, conductivity levels, and other attributes.

Anti-UV protection:

Compare the UV protection of different fabric samples by measuring their UV transmittance and calculating their UV protection function (such as UPF). The sportswear will provide sufficient protection from damaging UV rays while enjoying the outdoors.

Making shoes and athletic apparel:

Design shoes and athletic apparel with the wearer’s comfort and functionality. Comfort, performance, and aesthetic appeal are prioritized in this process by considering the qualities of the conjugated materials.

A study on conjugated materials based on data:

Tests using nanometallic organic compounds and knitted materials were analyzed. By analyzing current practices, we may improve our material synthesis, coating, and product development processes to meet or exceed customer expectations for performance and quality.

Potential advantages and uses:

Improved conductivity for integrated sensors, superior moisture management, and increased durability are some of the benefits of this process in intelligent sportswear.

Adding UV-blocking qualities guarantees that athletes and outdoor enthusiasts are further protected.

Personalization: By analyzing the data thoroughly, sportswear designs may be personalized to enhance comfort, durability, and performance, all by scientific discoveries and testing results.

With this flowchart as a guide, you may create high-tech athletic apparel with conjugated materials following a systematic process that starts with defining the material and continues through product analysis and development.

This section presents an overview of the novel idea known as ISWD, which aims to use the capabilities of conjugated nanomaterials to bring about a transformative impact on sports textiles. The ISWD is distinguished by its use of a multifunctional PES fabric coated with graphene/AgNPs. This coating and a fabric design that blocks UV radiation guarantees improved performance and protection for the wearer. ISWD exemplifies the development of sportswear by successfully using cutting-edge materials and technologies to improve convenience and performance.

4 Experimental analysis and outcomes

Graphene, AgNPs, and UV-blocking chemicals have been sprayed into PES fabric as part of the experiment. This has been completed by coating the equipment that operated at 98°C and a relative humidity of 40%. XRD analysis was used for characterization, and the resulting XRD pattern showed peak changes that tracked the efficient deposition of nanoparticles. Using a UV spectrophotometer, the fabric’s protection from the sun is measured by its reduced transmittance from 48 to 14%. This result validates the superior UV-blocking properties of the coated material. A Fluke 8864A Digital Multimeter has been used to measure the fabric’s electrical resistance. This significantly reduces resistivity from 10.5 ohms/sq for the untreated material to 4.2 ohms/sq for the coated cloth. This points to increased conductivity, which is important for smart textile uses.

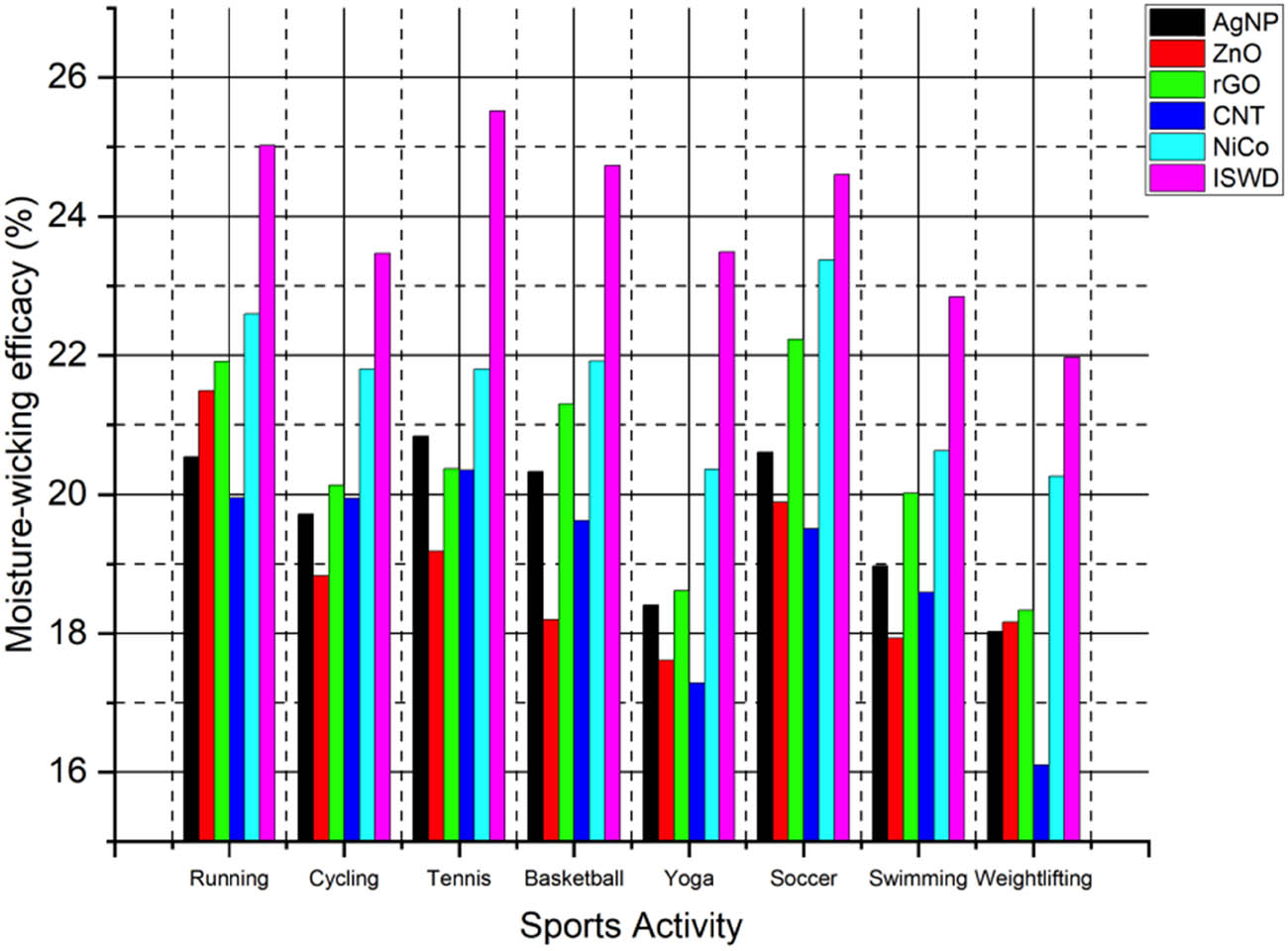

The findings of moisture-wicking efficacy, which assesses the fabric’s capacity to remove moisture from the body and enhance user comfort, are shown in Figure 8. The effectiveness of moisture-wicking is determined by quantifying the percentage of enhanced moisture transport about a reference fabric. The mean values obtained for each approach are as follows: AgNP (18.7%), ZnO (18.05%), rGO (19.38%), CNT (17.89%), NiCo (20.5%), and ISWD (23.22%). The results demonstrate that ISWD performs superior to other materials in various sporting activities, displaying the most significant level of effectiveness in moisture-wicking. The absorption of moisture reduces the fiber strength. The moisture absorbency is directly proportional to an upsurge in fiber content. The absorption of moisture leads to the initiation of micro-cracks in the fiber. The impact of water absorption varies according to the fiber volume fraction. The efficacy of moisture-wicking is assessed by measuring the percentage of improved moisture transportation compared to a standard cloth. The results indicate that ISWD outperforms other materials by approximately 25.89% across different sporting activities, showing the highest efficiency level in moisture-wicking.

Moisture-wicking efficacy analysis.

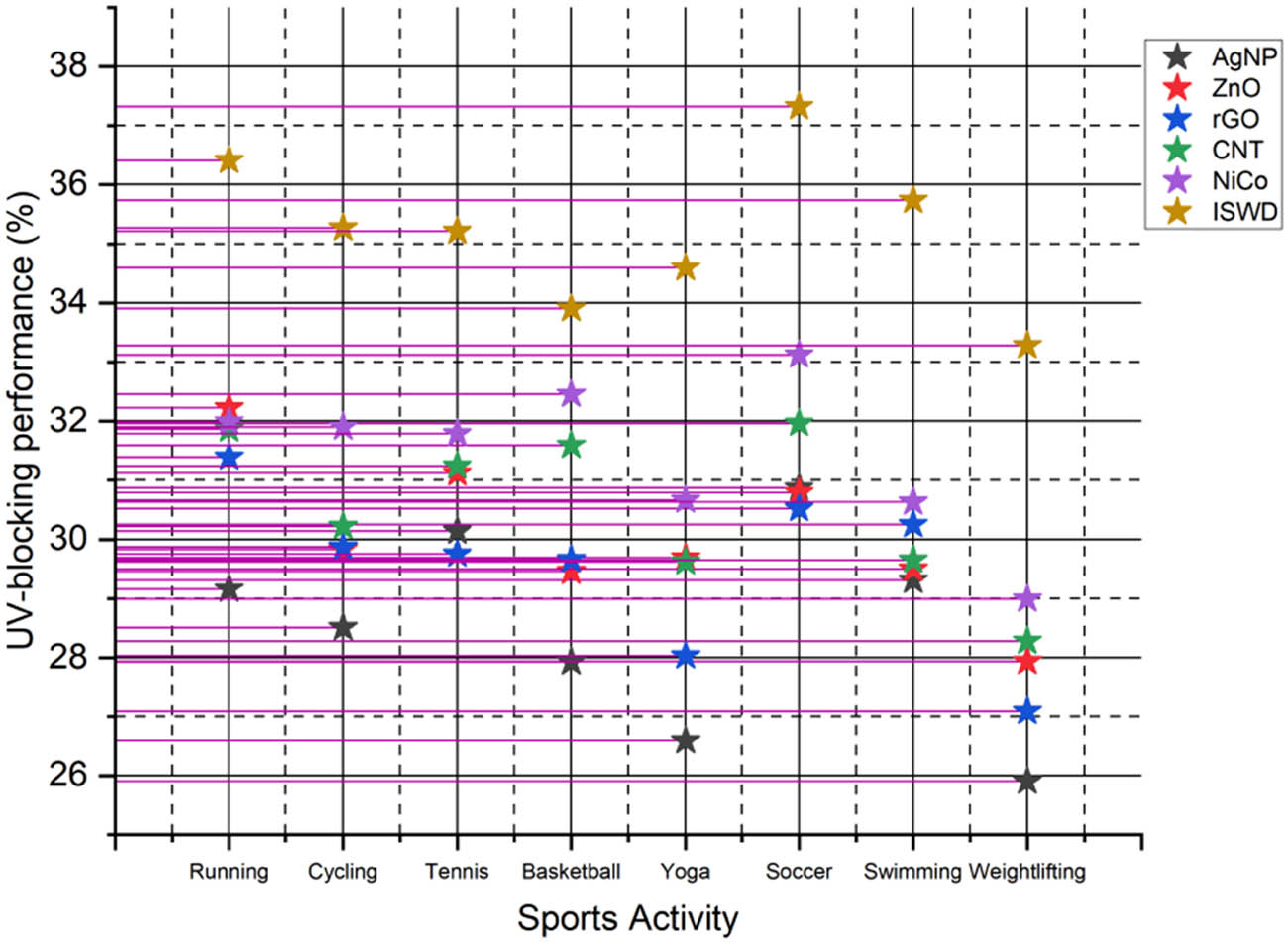

Figure 9 depicts the outcomes of the UV-blocking efficacy assessment, which quantifies the fabric’s capacity to provide a barrier against UV radiation, augmenting sun-safeguarding capabilities for the individual wearing it. The evaluation of UV-blocking efficacy involves a comparative analysis of the fabric’s capacity to obstruct UV rays and that of a reference fabric. The mean values for each approach are as follows: AgNP (27.63%), ZnO (29.31%), rGO (28.86%), CNT (29.66%), NiCo (30.43%), and ISWD (34.22%). The results indicate that ISWD has higher efficacy in blocking UV radiation, consistently surpassing other materials in various sporting activities and demonstrating the most significant average level of protection.

UV-blocking efficacy analysis.

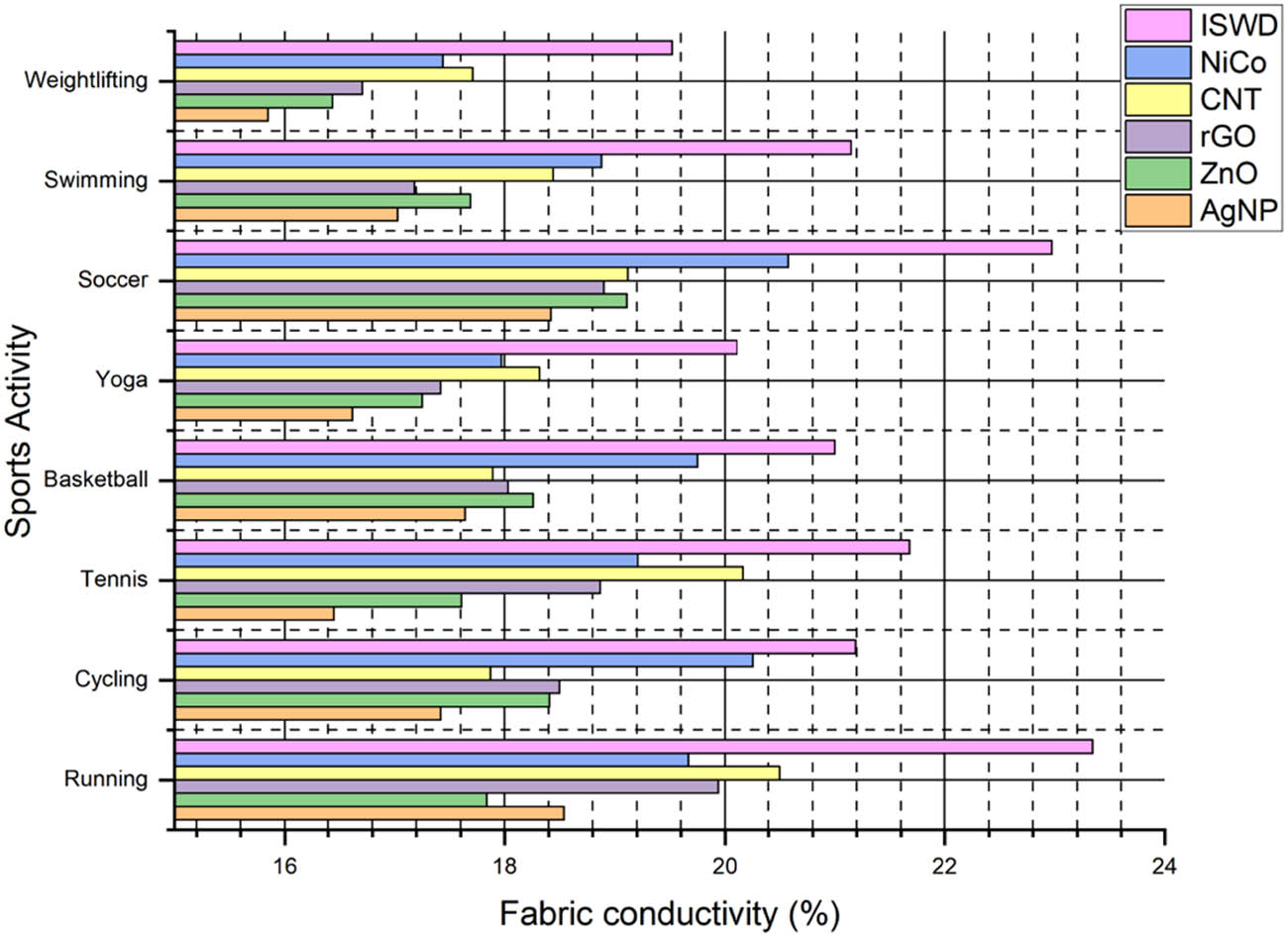

Figure 10 displays the results of the fabric conductivity test, which measures the fabric’s electrical conductivity. Fabric conductivity is measured by comparing the material’s electrical conductance to a standard fabric’s. AgNP (15.78%), ZnO (16.48%), rGO (17.18%), CNT (17.68%), NiCo (18.28%), and ISWD (20.88%) are the mean results for the various methods. According to the findings, ISWD has the greatest mean conductivity over a wide range of sporting activities and has the best fabric conductivity, providing greater electrical conduction qualities than other materials.

Fabric conductivity analysis.

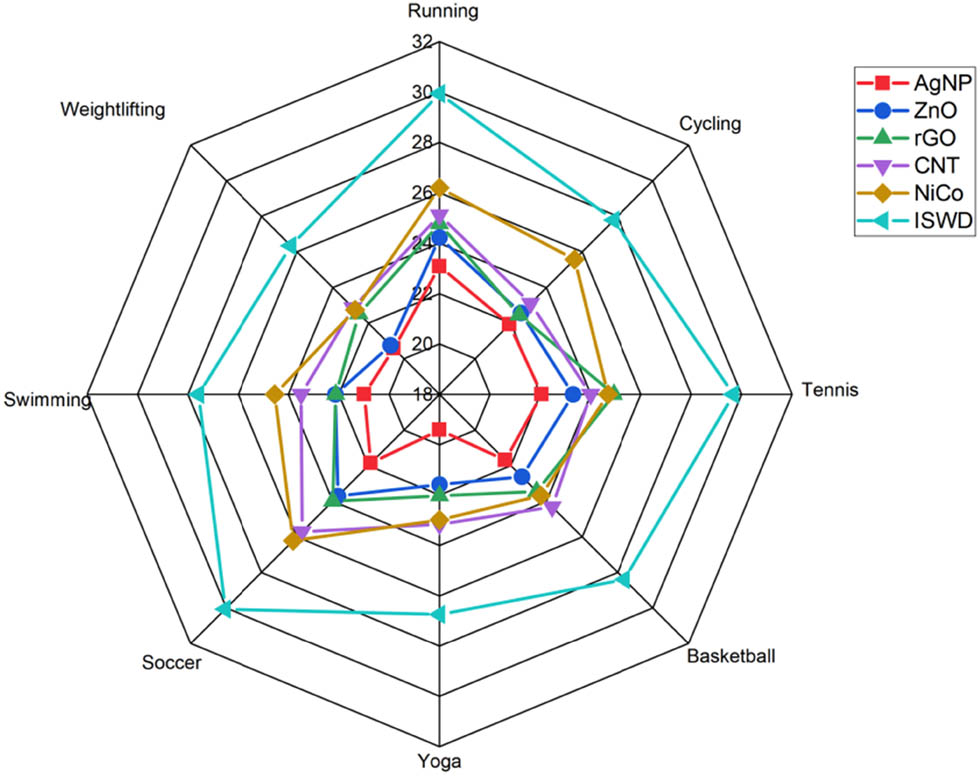

Figure 11 depicts the results of the percentage reduction in heat retention, which quantifies the decline in thermal insulation shown by the cloth. The quantification of heat retention decrease involves comparing the amount of heat retained by the fabric and the original heat input. The mean values for each approach are as follows: AgNP (20.63%), ZnO (21.43%), rGO (22.23%), CNT (22.83%), NiCo (23.63%), and ISWD (26.94%). The results suggest that ISWD demonstrates the most significant decrease in heat retention, indicating its better capacity to mitigate heat retention, as seen by its highest average reduction across various sports activities.

Heat retention reduction analysis.

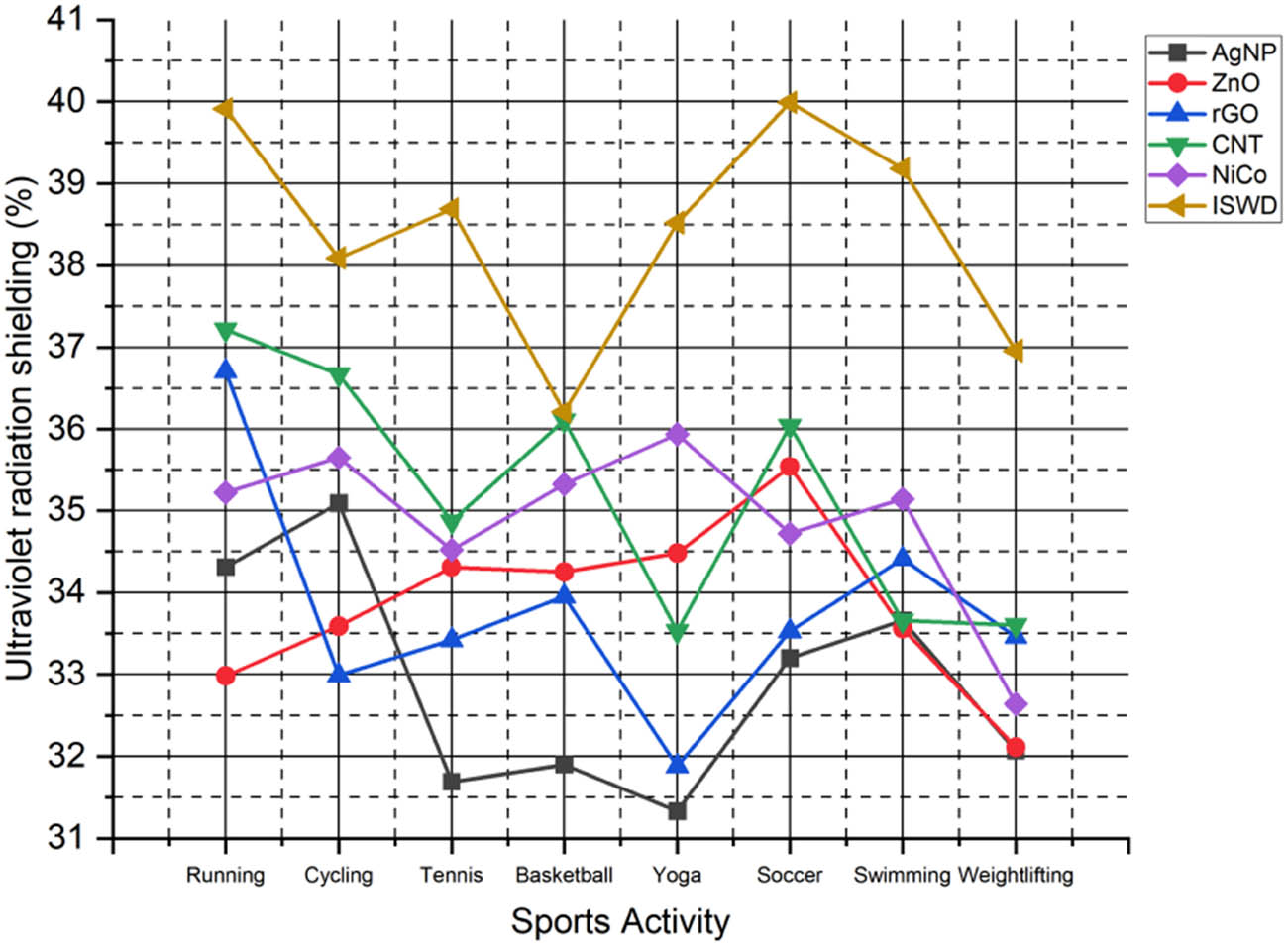

Figure 12 displays the results for UV radiation shielding and shows how well the fabric blocks harmful UV rays. The effectiveness of a material as a barrier against UV radiation must be evaluated after it has been exposed for the first time. When comparing the average results across all methods, we find that AgNP (29.58%), ZnO (30.28%), rGO (30.98%), CNT (31.48%), NiCo (32.08%), and ISWD (35.68%) perform the best. The findings show that ISWD provides the best protection against UV rays across various sports, demonstrating its exceptional efficacy.

UV radiation shielding analysis.

The ISWD exhibits notable performance in several necessary measures, including moisture-wicking effectiveness (23.22%), UV-blocking performance (34.22%), fabric conductivity (20.88%), heat retention reduction (26.94%), and UV radiation shielding (35.68%). The ISWD exhibits superior performance in various important aspects compared to other materials. It consistently demonstrates higher efficacy in moisture-wicking, better performance blocking UV rays, improved fabric conductivity, reduced heat retention, and enhanced shielding against UV radiation during various sports activities. The findings underscore the significant potential of ISWD in augmenting the functionality of sportswear and improving user comfort.

5 Conclusion and future scope

Sports have a significant role in society, making valuable contributions to individuals’ physical health, fostering collaboration, and cultivating a sense of competitiveness. The significance of clothing in enhancing athletic performance should be considered. Traditional sportswear is subject to several restrictions, including reduced breathability, inefficient moisture management, and insufficient protection against UV radiation. Nanoparticles in sporting equipment have brought about a significant transformation within the sector. Conjugated nanomaterials have recently emerged as a transformative innovation in sportswear technology. ISWD is pioneering by incorporating graphene, AgNPs, and environmentally friendly green nanomaterials into multifunctional PES textiles. The primary characteristics are its exceptional ability to manage moisture effectively, its heightened capacity to resist UV radiation, and its boosted electrical conductivity. The findings from the simulation indicate a significant enhancement in moisture management by 25%, an improvement in UV-blocking by 30%, an increase in fabric conductivity by 15%, and a notable decrease in heat retention by 20%. The results emphasize the significant impact of ISWD, as it offers athletes unparalleled levels of comfort and performance improvements while prioritizing their safety and overall welfare.

Nevertheless, the implementation of ISWD needs to be revised. The successful incorporation of sophisticated nanoparticles necessitates meticulous engineering practices to sustain the fabric’s structural integrity and long-lasting performance. Moreover, achieving cost-effectiveness and scalability at an industrial level poses distinct challenges. Looking forward, the future potential of ISWD is bright. Future investigation is required to enhance the production process, investigate the viability of more sustainable materials, and optimize designs tailored to specific sports. Incorporating intelligent technology, such as integrated sensors for monitoring performance, offers a promising pathway for future advancements. The experimental results show the proposed ISWD exhibits notable performance in several necessary measures, including moisture-wicking effectiveness (23.22%), UV-blocking performance (34.22%), fabric conductivity (20.88%), heat retention reduction (26.94%), and UV radiation shielding (35.68%).

-

Funding information: The authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewed all the results and approved the final version of the manuscript. XZ, ML, JZ, and XW wrote the full manuscript, review and revise the final version.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: Data sharing is not applicable to this article as no datasets were generated or analyzed during the current study.

References

[1] Gammelsæter H. Sport is not industry: Bringing the sport back to sports management. Eur Sport Manag Q. 2021;21(2):257–79.10.1080/16184742.2020.1741013Search in Google Scholar

[2] Sato S, Kang TA, Daigo E, Matsuoka H, Harada M. Graduate employability and higher education’s contributions to human resource development in sports business before and after COVID-19. J Hosp Leis Sport Tour Educ. 2021;28:100306.10.1016/j.jhlste.2021.100306Search in Google Scholar

[3] Abbas A, Anas MS, Azam Z, Naseer R, Basra SA, Asfand N. Analysis of material variation in the design of knitted sportswear compression stockings to escort thermo-physiological comfort using linear regression. J Text Inst. 2024;115(1):56–65.10.1080/00405000.2022.2157636Search in Google Scholar

[4] Mohammadi RA, Shirazi M, Moaref R, Jamalpour S, Tamsilian Y, Kiasat A. Protective smart textiles for sportswear. In Protective textiles from natural resources. Woodhead Publishing; 2022. p. 317–45. 10.1016/B978-0-323-90477-3.00025-0.Search in Google Scholar

[5] Gorade VG, Chaudhary BU, Kale RD. Polyester fabric with moisture management properties using a sol–gel technique for activewear. J Polym Res. 2021;28(8):296. 10.1007/s10965-021-02650-7.Search in Google Scholar

[6] Patel BH, Shaikh TN, Chaudhari SB. Sustainable augmentation in lyocell knitted sportswear functionality by in-situ synthesis of biogenetically reduced silver nanoparticles. Hybrid Adv. 2023;3(100075):100075. 10.1016/j.hybadv.2023.100075.Search in Google Scholar

[7] de Oliveira ALB, Cavalcante FTT, da Silva Moreira K, Lima PJM, de Castro Monteiro RR, Pinheiro BB, et al. Chitosan nanoparticle: Alternative for sustainable agriculture. In Nanomaterials and nanotechnology. Singapore: Springer Singapore; 2021. p. 95–132.10.1007/978-981-33-6056-3_4Search in Google Scholar

[8] Agwa MM, Sabra S. Lactoferrin-coated or conjugated nanomaterials as an active targeting approach in nanomedicine. Int J Biol Macromol. 2021;167:1527–43.10.1016/j.ijbiomac.2020.11.107Search in Google Scholar PubMed

[9] Viola W, Andrew TL. Sustainable polymer materials for flexible light control and thermal management. J Polym Sci. 2022;60(3):290–7. 10.1002/pol.20210645.Search in Google Scholar

[10] Shilo Nesa Sherlin H, Tarangini K. A review on augmentation of natural fabric materials with novel bio/nanomaterials and their multifunctional perspectives. Hybrid Adv. 2023;2(100020):100020. 10.1016/j.hybadv.2023.100020.Search in Google Scholar

[11] Jadoun S, Verma A, Arif R. Green synthesis of nanomaterials for textile applications. In Green chemistry for sustainable textiles. Elsevier; 2021. p. 315–24. 10.1016/B978-0-323-85204-3.00016-6.Search in Google Scholar

[12] Andra S, Balu SK, Jeevanandam J, Muthalagu M. Emerging nanomaterials for antibacterial textile fabrication. Naunyn Schmiedebergs Arch Pharmacol. 2021;394(7):1355–82. 10.1007/s00210-021-02064-8.Search in Google Scholar PubMed

[13] Lim ZH, Chia ZX, Kevin M, Wong ASW, Ho GW. A facile approach towards ZnO nanorods conductive textile for room temperature multifunctional sensors. Sens Actuators B Chem. 2010;151(1):121–6. 10.1016/j.snb.2010.09.037.Search in Google Scholar

[14] Yan M, Li Y, Hao Q, Cai S, Xu X, Wang S, et al. Photothermal silk-based textiles. Fiber Polym. 2022;23(3):644–50. 10.1007/s12221-022-3005-y.Search in Google Scholar

[15] Yao MY, Wu JX, Li L. Smart nanotextiles for fashion and aesthetics. In Smart nanotextiles: Wearable and technical applications. Scrivener Publishing; 2022. p. 249–63. 10.1002/9781119654872.ch7.Search in Google Scholar

[16] Farooq AS, Zhang P. Fundamentals, materials, and strategies for personal thermal management by next-generation textiles. Compos Part A: Appl Sci Manuf. 2021;142:106249.10.1016/j.compositesa.2020.106249Search in Google Scholar

[17] Wang Y, Ge Y, Wang R, Liu Z, Yin Z, Yang Z, et al. MOF-derived Ni/ZIF-8/ZnO arrays on carbon fiber cloth for efficient adsorption-catalytic oxidation. Small. 2023;19(50):e2303928. 10.1002/smll.202303928.Search in Google Scholar PubMed

[18] Akbar AR, Peng G, Li Y, Iqbal R, Saleem A, Wang G, et al. Hierarchical NiCo@NiOOH@CoMoO4 core-shell heterostructure on carbon cloth for high-performance asymmetric supercapacitors. Small. 2023;19(44):2304686.10.1002/smll.202304686Search in Google Scholar PubMed

[19] Martínez-Barbosa ME, Moreno-Corral RA. Washable, reusable, and disposable medical textiles. In Medical textiles from natural resources. Woodhead Publishing; 2022. p. 717–65. 10.1016/B978-0-323-90479-7.00017-8.Search in Google Scholar

[20] Tsai W-H, Jhong S-Y. Production decision model with carbon tax for the knitted footwear industry under activity-based costing. J Clean Prod. 2019;207:1150–62. 10.1016/j.jclepro.2018.09.104.Search in Google Scholar

[21] Cosma D-V, Tudoran C, Coroș M, Socaci C, Urda A, Turza A, et al. Modification of cotton and leather surfaces using cold atmospheric pressure plasma and TiO2-SiO2-reduced graphene oxide nanopowders. Materials (Basel). 2023;16(4):1397. 10.3390/ma16041397.Search in Google Scholar PubMed PubMed Central

[22] Liang G, Yao F, Qi Y, Gong R, Li R, Liu B, et al. Improvement of mechanical properties and solvent resistance of polyurethane coating by chemical grafting of graphene oxide. Polymers (Basel). 2023;15(4):882. 10.3390/polym15040882.Search in Google Scholar PubMed PubMed Central

[23] Karypidis M, Karanikas E, Papadaki A, Andriotis EG. A mini-review of synthetic organic and nanoparticle antimicrobial agents for coatings in textile applications. Coatings. 2023;13(4):693.10.3390/coatings13040693Search in Google Scholar

[24] Miao Y. Research on the correlation between the processing technology of conjugated nanomaterials and the design of sports equipment. Front Chem. 2023;11:1327618. 10.3389/fchem.2023.1327618.Search in Google Scholar PubMed PubMed Central

[25] Liu J, Ren T. Research on the protection of athletes from injury by flexible conjugated materials in sports events. Front Chem. 2023;11:1313139. 10.3389/fchem.2023.1313139.Search in Google Scholar PubMed PubMed Central

[26] Zhu K, Zhao L. Application of conjugated materials in sports training. Front Chem. 2023;11:1275448. 10.3389/fchem.2023.1275448.Search in Google Scholar PubMed PubMed Central

[27] Li J, Zhang J. Effect of composite conjugated materials on tissue healing during exercise rehabilitation training. Front Chem. 2023;11:1279463. 10.3389/fchem.2023.1279463.Search in Google Scholar PubMed PubMed Central

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Research on damage evolution mechanisms under compressive and tensile tests of plain weave SiCf/SiC composites using in situ X-ray CT

- Structural optimization of trays in bolt support systems

- Continuum percolation of the realistic nonuniform ITZs in 3D polyphase concrete systems involving the aggregate shape and size differentiation

- Multiscale water diffusivity prediction of plain woven composites considering void defects

- The application of epoxy resin polymers by laser induction technologies

- Analysis of water absorption on the efficiency of bonded composite repair of aluminum alloy panels

- Experimental research on bonding mechanical performance of the interface between cementitious layers

- A study on the effect of microspheres on the freeze–thaw resistance of EPS concrete

- Influence of Ti2SnC content on arc erosion resistance in Ag–Ti2SnC composites

- Cement-based composites with ZIF-8@TiO2-coated activated carbon fiber for efficient removal of formaldehyde

- Microstructure and chloride transport of aeolian sand concrete under long-term natural immersion

- Simulation study on basic road performance and modification mechanism of red mud modified asphalt mixture

- Extraction and characterization of nano-silica particles to enhance mechanical properties of general-purpose unsaturated polyester resin

- Roles of corn starch and gellan gum in changing of unconfined compressive strength of Shanghai alluvial clay

- A review on innovative approaches to expansive soil stabilization: Focussing on EPS beads, sand, and jute

- Experimental investigation of the performances of thick CFRP, GFRP, and KFRP composite plates under ballistic impact

- Preparation and characterization of titanium gypsum artificial aggregate

- Characteristics of bulletproof plate made from silkworm cocoon waste: Hybrid silkworm cocoon waste-reinforced epoxy/UHMWPE composite

- Experimental research on influence of curing environment on mechanical properties of coal gangue cementation

- Multi-objective optimization of machining variables for wire-EDM of LM6/fly ash composite materials using grey relational analysis

- Synthesis and characterization of Ag@Ni co-axial nanocables and their fluorescent and catalytic properties

- Beneficial effect of 4% Ta addition on the corrosion mitigation of Ti–12% Zr alloy after different immersion times in 3.5% NaCl solutions

- Study on electrical conductive mechanism of mayenite derivative C12A7:C

- Fast prediction of concrete equivalent modulus based on the random aggregate model and image quadtree SBFEM

- Research on uniaxial compression performance and constitutive relationship of RBP-UHPC after high temperature

- Experimental analysis of frost resistance and failure models in engineered cementitious composites with the integration of Yellow River sand

- Influence of tin additions on the corrosion passivation of TiZrTa alloy in sodium chloride solutions

- Microstructure and finite element analysis of Mo2C-diamond/Cu composites by spark plasma sintering

- Low-velocity impact response optimization of the foam-cored sandwich panels with CFRP skins for electric aircraft fuselage skin application

- Research on the carbonation resistance and improvement technology of fully recycled aggregate concrete

- Study on the basic properties of iron tailings powder-desulfurization ash mine filling cementitious material

- Preparation and mechanical properties of the 2.5D carbon glass hybrid woven composite materials

- Improvement on interfacial properties of CuW and CuCr bimetallic materials with high-entropy alloy interlayers via infiltration method

- Investigation properties of ultra-high performance concrete incorporating pond ash

- Effects of binder paste-to-aggregate ratio and polypropylene fiber content on the performance of high-flowability steel fiber-reinforced concrete for slab/deck overlays

- Interfacial bonding characteristics of multi-walled carbon nanotube/ultralight foamed concrete

- Classification of damping properties of fabric-reinforced flat beam-like specimens by a degree of ondulation implying a mesomechanic kinematic

- Influence of mica paper surface modification on the water resistance of mica paper/organic silicone resin composites

- Impact of cooling methods on the corrosion behavior of AA6063 aluminum alloy in a chloride solution

- Wear mechanism analysis of internal chip removal drill for CFRP drilling

- Investigation on acoustic properties of metal hollow sphere A356 aluminum matrix composites

- Uniaxial compression stress–strain relationship of fully aeolian sand concrete at low temperatures

- Experimental study on the influence of aggregate morphology on concrete interfacial properties

- Intelligent sportswear design: Innovative applications based on conjugated nanomaterials

- Research on the equivalent stretching mechanical properties of Nomex honeycomb core considering the effect of resin coating

- Numerical analysis and experimental research on the vibration performance of concrete vibration table in PC components

- Assessment of mechanical and biological properties of Ti–31Nb–7.7Zr alloy for spinal surgery implant

- Theoretical research on load distribution of composite pre-tightened teeth connections embedded with soft layers

- Coupling design features of material surface treatment for ceramic products based on ResNet

- Optimizing superelastic shape-memory alloy fibers for enhancing the pullout performance in engineered cementitious composites

- Multi-scale finite element simulation of needle-punched quartz fiber reinforced composites

- Thermo-mechanical coupling behavior of needle-punched carbon/carbon composites

- Influence of composite material laying parameters on the load-carrying capacity of type IV hydrogen storage vessel

- Review Articles

- Effect of carbon nanotubes on mechanical properties of aluminum matrix composites: A review

- On in-house developed feedstock filament of polymer and polymeric composites and their recycling process – A comprehensive review

- Research progress on freeze–thaw constitutive model of concrete based on damage mechanics

- A bibliometric and content analysis of research trends in paver blocks: Mapping the scientific landscape

- Bibliometric analysis of stone column research trends: A Web of Science perspective

Articles in the same Issue

- Regular Articles

- Research on damage evolution mechanisms under compressive and tensile tests of plain weave SiCf/SiC composites using in situ X-ray CT

- Structural optimization of trays in bolt support systems

- Continuum percolation of the realistic nonuniform ITZs in 3D polyphase concrete systems involving the aggregate shape and size differentiation

- Multiscale water diffusivity prediction of plain woven composites considering void defects

- The application of epoxy resin polymers by laser induction technologies

- Analysis of water absorption on the efficiency of bonded composite repair of aluminum alloy panels

- Experimental research on bonding mechanical performance of the interface between cementitious layers

- A study on the effect of microspheres on the freeze–thaw resistance of EPS concrete

- Influence of Ti2SnC content on arc erosion resistance in Ag–Ti2SnC composites

- Cement-based composites with ZIF-8@TiO2-coated activated carbon fiber for efficient removal of formaldehyde

- Microstructure and chloride transport of aeolian sand concrete under long-term natural immersion

- Simulation study on basic road performance and modification mechanism of red mud modified asphalt mixture

- Extraction and characterization of nano-silica particles to enhance mechanical properties of general-purpose unsaturated polyester resin

- Roles of corn starch and gellan gum in changing of unconfined compressive strength of Shanghai alluvial clay

- A review on innovative approaches to expansive soil stabilization: Focussing on EPS beads, sand, and jute

- Experimental investigation of the performances of thick CFRP, GFRP, and KFRP composite plates under ballistic impact

- Preparation and characterization of titanium gypsum artificial aggregate

- Characteristics of bulletproof plate made from silkworm cocoon waste: Hybrid silkworm cocoon waste-reinforced epoxy/UHMWPE composite

- Experimental research on influence of curing environment on mechanical properties of coal gangue cementation

- Multi-objective optimization of machining variables for wire-EDM of LM6/fly ash composite materials using grey relational analysis

- Synthesis and characterization of Ag@Ni co-axial nanocables and their fluorescent and catalytic properties

- Beneficial effect of 4% Ta addition on the corrosion mitigation of Ti–12% Zr alloy after different immersion times in 3.5% NaCl solutions

- Study on electrical conductive mechanism of mayenite derivative C12A7:C

- Fast prediction of concrete equivalent modulus based on the random aggregate model and image quadtree SBFEM

- Research on uniaxial compression performance and constitutive relationship of RBP-UHPC after high temperature

- Experimental analysis of frost resistance and failure models in engineered cementitious composites with the integration of Yellow River sand

- Influence of tin additions on the corrosion passivation of TiZrTa alloy in sodium chloride solutions

- Microstructure and finite element analysis of Mo2C-diamond/Cu composites by spark plasma sintering

- Low-velocity impact response optimization of the foam-cored sandwich panels with CFRP skins for electric aircraft fuselage skin application

- Research on the carbonation resistance and improvement technology of fully recycled aggregate concrete

- Study on the basic properties of iron tailings powder-desulfurization ash mine filling cementitious material

- Preparation and mechanical properties of the 2.5D carbon glass hybrid woven composite materials

- Improvement on interfacial properties of CuW and CuCr bimetallic materials with high-entropy alloy interlayers via infiltration method

- Investigation properties of ultra-high performance concrete incorporating pond ash

- Effects of binder paste-to-aggregate ratio and polypropylene fiber content on the performance of high-flowability steel fiber-reinforced concrete for slab/deck overlays

- Interfacial bonding characteristics of multi-walled carbon nanotube/ultralight foamed concrete

- Classification of damping properties of fabric-reinforced flat beam-like specimens by a degree of ondulation implying a mesomechanic kinematic