Abstract

Expansive soils pose major geotechnical challenges due to significant volume changes. This research investigates an innovative stabilization approach using sand, expanded polystyrene (EPS) beads, and jute fibres to enhance the properties of expansive soil. The purpose is to utilize the unique characteristics of these admixtures to restrict swelling potential and improve strength and load-bearing capacity. Experimental testing quantified improvements through parameters like unconfined compressive strength (UCS), swelling pressure, California bearing ratio (CBR), compaction characteristics, and Atterberg limits. Soil samples were prepared with individual and combined admixtures at optimum proportions and extensively tested after proper curing. Quantitative results indicated that including sand, EPS beads, and jute fibres increased the soil’s UCS by 41, 29, and 23%, respectively. The swelling pressure, on the other hand, decreased by 14, 18, and 11%, respectively. Maximum improvements were achieved with combined admixtures: UCS increased by 65%, swelling pressure reduced by 23%, and CBR improved from 5 to 6.5%. Regression analysis indicated a strong correlation (R 2 = 0.96) between admixture proportions and resultant UCS. The key achievements are effective swelling control, a marked increase in shear strength parameters, and synergy between admixtures in enhancing expansive soil properties. This sustainable stabilization method using industrial by-products presents a promising solution for constructing stable civil structures even in problematic expansive soil regions.

1 Introduction

Expansive soils pose major geotechnical challenges as they undergo significant volume changes with moisture variations, inducing damage in overlying structures [1,2,3]. They predominately occur in seasonal rainfall geographies like Africa, Australia, India, China, the Middle East, and North and South America [4]. Expansive soils contain specific clay minerals of the smectite group that can absorb large amounts of water, creating substantial swelling pressures [5,6]. Absorbed water layers enter between silicate sheets, generating interparticle repulsive forces and swelling strains [1]. Even minor moisture content alterations of 2–3% can dramatically impact soil permeability and performance [7].

The resultant swelling strains and pressures damage foundations, pavements, and other civil structures through cracking and differential settlements [8]. Light infrastructure like roads, house floors, and pavements are especially vulnerable [9]. The swelling pressures can approximate around 200 kPa, sufficient to induce damage [5]. The financial losses from expansive soil issues amount to billions of dollars globally every year [2,10].

Because of the substantial challenges posed by swelling soils, their stabilization is essential in geotechnical engineering as it involves altering soil properties to improve engineering behaviour [11]. Traditional stabilizers used over decades include lime (2–10%), cement (12–14%), and fly ash (15–30%) to control swelling potential and enhance strength [12,13,14]. However, recent stabilizers emphasize industrial by-products and agricultural wastes as sustainable alternatives, including materials like rice husk ash, bagasse ash, eggshell powder, coconut husk ash, metakaolin, polymers, guar gums, and natural fibres [15,16,17,18,19]. These new stabilizers aim for reusable and economical pathways compared to conventional lime/cement options. However, regulating optimal dosage ranges remains vital, as excessive additions can override benefits [20,21].

Even though conventional stabilizers like lime, cement, and fly ash have shown a nice success rate, they also have some limitations while stabilizing expansive soil. Fly ash as a stabilizing agent may lose its beneficial effects after the initial wetting and drying cycle, leading to increased soil swelling potential in subsequent cycles [22]. Lime stabilization may be less effective in soils with high sulphate content. Sulphate can cause the formation of ettringite, which counteracts lime stabilization. Soil chemistry should be carefully considered when selecting lime as a stabilizer [23]. Also, the favourable impact of lime stabilization on lime-treated soils is partially lost because of cyclic wetting and drying due to the biased breakage of the cementation relationship as well as loss in dry unit weight and moisture content [24]. Free lime in WPFA must be considered due to its potential expansion during hydration in soil stabilization [25]. Lime and cement are often used together to improve soil strength and reduce plasticity. However, this method can have environmental limitations. The high pH environment created can cause leaching, leading to mobilized heavy metals and potential groundwater contamination. This impact highlights the need to evaluate long-term implications when using these admixtures in soil stabilization projects [26].

Despite investigations on various stabilizers, lightweight materials like expanded polystyrene (EPS) beads have received limited focus for swelling control [27]. EPS beads, a lightweight and compressible material, can reduce soil pressure against buried structures and deformation induced by loadings [28,29,30]. In addition, EPS beads are durable, stable, and resistant to moisture and deterioration [28], making them suitable for geotechnical applications. EPS has shown some usage as geofoam blocks for compressible inclusions that reduce swelling pressures [31,32]. However, its stabilization potential remains relatively unexplored. While prior works have paired EPS with soils [33] or natural fibres [34], but the combination of EPS beads with other materials and the utilization of their complimentary effects is still untouched.

Similarly, conventional stabilizers like cement, while effective in improving the strength of expansive soils, can be prone to cracking and erosion, reducing their long-term durability [35]. Furthermore, relying solely on cement may not effectively enhance the ductility of the stabilized soil [35]. In this regard, jute fibre presents a promising alternative due to its high water-absorption capacity [36,37] and slow biodegradation rate, aligning with sustainable development principles [38]. By uniformly incorporating jute fibre into expansive soil, it can absorb infiltrating water and mitigate the formation of water molecular films around soil particles, thereby improving the soil’s characteristics related to expansion and shrinkage [38]. In addition, sand can be used with jute fibre to improve the stabilized soil’s thermal conductivity and mechanical resistance [39,40]. Unlike conventional reinforcements like bars, which primarily control lateral deformation, the random and uniform distribution of fibres in the soil can effectively limit both lateral and vertical deformations [41,42,43]. Likewise, the research consistently shows that sand can significantly reduce the swelling potential of expansive clay soil [44,45,46,47]. This improvement is attributed to the granular structure provided by sand, which enhances the physical and mechanical characteristics of the soil [45]. Gheris and Hamrouni [48] found that adding DISS crushed fibres reduced swelling potential and increased soil cohesion.

Therefore, for addressing these gaps, the present research analyses an expansive soil stabilization using EPS beads, sand, and jute fibres. The study examined the effect of individual and combined stabilizers on key parameters such as swelling pressures, unconfined compressive strength (UCS), and California bearing ratio (CBR). Regression analysis also enabled the correlation between UCS and admixture dosages. The study highlighted the rising interest in stabilization solutions through the bibliometric analysis. The study found that recyclable admixtures of sand, EPS, and jute offer an eco-friendly solution to expansive soil issues with high potential for adoption.

2 Literature review

2.1 Bibliometric analysis

Bibliometric studies strengthen the connection between academic research and practical engineering, bridging gaps in technology transfer and knowledge sharing. By analysing highly referenced articles, engineers gain crucial insights for problem-solving and innovation. Using bibliometrics helps identify key technologies and methods with a significant impact in engineering. In the present study, we have focused only bibliometric analysis on keywords to support the current work and restrict the bibliometric analysis up to author keywords and occurrence.

2.1.1 Bibliometric analysis based on author keywords distribution

Keywords act as markers to the core themes and subjects of research. In this segment, we dissect the author keywords to uncover the pivotal areas of interest within soil stabilization research. The data were extracted from the Web of Science Core Collection Database, ensuring a comprehensive grasp of academic discourse. Each research entry was tagged with its respective author keywords. This metadata formed the foundation for our analysis. With a plethora of topics encapsulated within soil stabilization research, our analysis spotlights the dominant themes and materials. It is clear from Figure 1 that the larger nodes in the visualization likely represent the dominant themes or terms that emerged from the analysis. Where large nodes labelled “stabilization,” “EPS beads,” “jute,” and “sand,” it suggests that these are the primary focus areas within the dataset. Links between nodes, especially between dominant themes, suggest that there are publications or works that discuss these themes together. Such as link between “EPS beads” and “stabilization,” it could imply that EPS beads have been frequently discussed in the context of soil stabilization. Similarly different colours indicate different clusters or groups of related terms. As there is a cluster around “EPS beads” or “jute,” it means that there is a significant amount of literature or discussion around these specific topics, and they have their own set of associated sub-themes or keywords. Moreover, smaller nodes or those on the periphery might represent emerging themes or those that are not as dominant but are still present within the dataset. These could be potential areas of future research or lesser-explored areas within the field. Additional to it links between seemingly unrelated nodes indicate interdisciplinary research or collaboration between different fields. Such as a link between “jute” (a natural fibre) and a term from another domain might suggest an innovative application or study. Areas with a high density of nodes and links can be seen as “hotspots” in the research area. These are areas with a high concentration of related works and can be considered significant or dominant sub-fields within the broader domain.

Keyword analysis map depicting the connections between them.

2.1.2 Findings

In the realm of soil stabilization research, several keywords emerge as central themes. “Soil stabilization” leads the way with 110 mentions, underscoring its foundational importance. “Stabilization” and “UCS” further highlight the methodologies and testing mechanisms inherent to this field with 60 and 56 mentions, respectively. Materials like “cement” and “sand” also play pivotal roles, as indicated by their 50 and 35 mentions. Other significant keywords include “lime,” “strength,” and “microstructure,” each painting a picture of the diverse facets of soil stabilization studies. The data in Figure 2 provide a clear roadmap of the core themes in soil stabilization research. While “soil stabilization” stands as the overarching theme, the presence of other keywords indicates the diversity of methods, tests, and materials that researchers delve into. Recognizing these keywords is crucial as they not only guide researchers to the most relevant studies but also hint at potential areas for future exploration.

Top 20 author keywords in soil stabilization research.

The “Keyword Plus” section in research databases typically consists of author-independent keywords that emerge from the titles of the references cited in articles. These keywords provide additional insights into the thematic elements or underlying themes of the research.

On the basis of our analysis of the occurrences of the specified keywords in the “Keyword Plus” data, we found the further mentioned findings. For the keyword “Stabilization,” it had the highest occurrence, signifying its overarching relevance in the dataset. It suggests that a significant portion of the research is focused on methods, techniques, or innovations related to soil stabilization. Keyword “sand” indicates that many research works delve into stabilization techniques or challenges specifically related to sandy terrains or materials. This could mean studies around desert regions, beachfronts, or areas with loose, sandy soil. In the same way, the Materials & Techniques indicated that “Lime & Fly Ash” are traditionally used materials in soil stabilization. Their frequent mention underlines their continued importance and possibly their combinations or innovations in usage. Additional to it usage, “EPS Beads & Jute” indicated as emerging areas of research. EPS beads and jute could be alternative or novel materials being tested or applied for stabilization purposes. Although “geofoam” indicate that it might be an emerging or less-explored material or technique in the context of the dataset. “GGBS,” with no mentions, it might either be a very nascent topic or could be represented under a different term or abbreviation in the dataset.

The frequency of these keywords as depicted in Figure 2 indicates areas of focus in the research community. For instance, while traditional methods like using lime for stabilization might be well established and continue to be a focus, newer methods or materials like EPS beads or jute might be in the experimental or validation stages. Areas with fewer mentions can be goldmines for researchers looking for less-trodden paths or innovative topics. In summary, the occurrences of these keywords in the “Keyword Plus” data offer a snapshot of the prevailing trends, focus areas, and emerging topics in soil stabilization research. They highlight the materials, techniques, and areas that are garnering attention, thus providing a compass for researchers, students, and professionals in the domain.

2.2 Materials

Similarly, studies that push a little more to stabilize the expansive soil sand in the present study are as follows: Premalatha and Sabarishri [49] presented a case study where lime sand piles were used to stabilize an expansive soil, resulting in improved strength and reduced volume change characteristics. Bahia and Ramdane [46] conducted an experimental program and found that adding sand to expansive soil improved soil consistency and reduced swelling. Hussein et al. [50] reviewed different methods for stabilizing expansive soil and mentioned sand as a material to enhance engineering properties. Garg et al. [51] investigated the use of industrial waste products, including sand, for stabilizing expansive soil and concluded that these materials can improve the engineering characteristics of the soil. Therefore, the papers collectively suggest that sand can be an effective additive for stabilizing expansive soil.

Recent research has shifted towards sustainable and eco-friendly materials. Among these, sand, EPS beads, and jute fibres have garnered attention due to their unique properties and potential environmental benefits. Sand being granular and non-cohesive, which aids in reducing the plasticity of the soil, thereby increasing its shear strength. EPS beads are lightweight and versatile, which can reduce the weight of the soil, making it suitable for applications where weight is a concern, such as embankments. Similarly, jute is a natural fibre that not only aids in soil reinforcement but also contributes to sustainability, being biodegradable and eco-friendly.

2.2.1 Jute

Jute is primarily composed of two main components: cellulose and lignin. Cellulose is the primary component of jute and is a complex carbohydrate that provides strength to the plant’s cell walls. It is also the primary component of many plant fibres and is responsible for the strength and durability of jute. Lignin is a complex organic polymer that binds the cellulose fibres together, providing rigidity to the plant. It acts as a kind of “glue” that holds the cellulose fibres in place. In addition to cellulose and lignin, jute also contains small amounts of hemicellulose, pectin, and other minor constituents. The combination of these components gives jute its characteristic strength, flexibility, and coarseness, making it suitable for various applications, including the production of sacks, ropes, and other textiles. Previous research has demonstrated the potential of natural fibres like jute in reinforcing composite materials, significantly enhancing tensile and bending strengths through the incorporation of metal and ceramic particles [52]. Jute is a preferred material for soil stabilization over other admixtures due to its better durability, high tensile strength, and capacity to withstand rotting and heat. These fibres interlock with soil particles, providing reinforcement and increasing the soil’s tensile strength. Moreover, being organic, jute fibres can influence the soil’s moisture content and compaction characteristics. Jute is also locally available, cheap, eco-friendly, and biodegradable. Jute binds the soil particles and acts as a reinforcing link between the particles, which ultimately helps in enhancement of strength and reduction in swelling property of expansive soil. The untreated soil had a low CBR value of 1.05%, whereas adding 1.25% jute fibre increased the CBR value of the soil by 226.92% compared to the untreated soil [53]. The untreated soil had low cohesion value of 54.96 kPa and a low friction angle of 6 degrees, but at the inclusion of 0.6% jute fibre of length 6 mm, there was an increase in the cohesion of the soil from 54.96 to 153.52 kPa took place. Increasing jute fibre content and length initially increased the cohesion. Maximum cohesion was achieved with 0.6% fibre content and length of 6 mm. Further increases in the fibre content and length decreased the cohesion. Addition of jute fibres increased the friction angle slightly from 6 degrees to a maximum of 6.3 degrees at optimal fibre content [54]. Similarly, before adding jute, the CBR value of the clayey soil was 2.5% but with the addition of 0.7% 6 mm recron jute fibre, the CBR value increased to 11.2 [55]. The CBR value of expansive soil increased from 2.5% without jute to 11.7% with the addition of four layers of jute geotextile sheet reinforcement [56]. The maximum dry density (MDD) of the untreated soil was 1.90 g/cm3 at 16% optimum moisture content (OMC), whereas after the addition of 0.5% jute fibre, MDD increased to 1.93 g/cm3, while OMC remained at 16% [57]. Additional to it, CBR increased from 28.19% for untreated soil to 47.23% with 1% jute fibre addition [57].

In summary, the addition of jute fibre significantly enhanced the CBR and MDD of the soils in the studies. The optimum jute fibre percentage ranged from 0.5 to 1% [58]. The strength of unreinforced soil reduced with the increasing number of freeze-thaw cycles, while fibre-reinforced soil showed a greater effect, but with a reduced strength reduction amount. The reduction trend for cohesion of the fibre-reinforced soil decreased, which was seen more prevalently on 1% glass fibre-reinforced soil. Appropriate jute fibre content is essential to achieve maximum strength benefits in stabilized expansive soils. Excess fibres can cause poor mixing and clumping. Prabhakar and Sridhar [59] showed 1% discrete jute fibre inclusion gave 51% increase in strength of expansive soil. Chauhan et al. [60] found 1% jute fibres optimal for improving strength characteristics of expansive soil. Higher jute percentages showed decline in strength. Ma et al. [61] determined the optimum dosage experimentally by testing the UCS of stabilized specimens with different sand and jute fibre percentages and finding the combination that provided the maximum strength enhancement. The optimal dosages were 16% sand and 1% discrete jute fibres based on the UCS test results. The study by Jashir and Rana [62] show that the previous research has shown optimum jute fibre content around 1–3% for improving strength of expansive soils. Fayaz et al. [55] tested jute fibre percentages of 0.25–1.5% in highly plastic clay soil. They found that 1.25% jute fibre gave maximum 226% improvement in the CBR value. Medina-Martinez et al. [63] reviewed several studies that used jute fibre lengths of 6–18 mm and dosages of 0.3–1.2%. Optimal values were 0.6–0.9% for improved shear strength parameters. Optimum jute dosage is determined by testing the strength and consistency of specimens with varying fibre percentages. Most studies indicate 0.5–1% discrete jute fibres as the ideal content.

In summary, most studies have found the optimum jute fibre content for soil stabilization tends to range from 0.6 to 1.25% by weight of dry soil. Using higher fibre percentages beyond this range either provides minimal additional improvement or can also decrease strength in some cases. The optimum jute fibre dosage depends on the soil type and desired engineering properties. But generally keeping jute fibre percentage within 0.6–1.5% provides significant improvement in key parameters like CBR, compressive strength, and shear strength. Accordingly, the dosage in the current investigation has been taken as 0.5%.

2.2.2 Sand

The utilization of sand as a soil amendment for improving black cotton soil is advantageous primarily because of its unique particle size and shape. According to Gupta and Sharma [64], black cotton soil is classified as a problematic expansive soil due to its tendency to cause various challenges during the construction of structures built on top of it. The incorporation of sand into black cotton soil has been found to have a positive impact on its strength properties. In a study conducted by [65], the researchers investigated a particular topic or phenomenon. The study aimed to explore and to analyse various aspects related to the determination of the optimal percentage of sand and cement addition to black cotton soil to enhance its strength characteristics [65]. Another study found that adding 20% of sand and 2% cement to the expansive soil shows a reduction in swell index and liquid limit [66]. The addition of sand to black cotton soil increases its MDD and reduces its moisture content [65]. The particle size distribution curve for black cotton soil, river sand, fly ash, and marble dust show that sand has a larger particle size than black cotton soil [64]. The larger particle size of sand helps to improve soil’s drainage and aeration, which is beneficial for the plant growth. Adding sand to black cotton soil is beneficial for improving its strength characteristics. The addition of sand and cement to black cotton soil has been found to improve its strength characteristics [65]. A study found that adding 20% of sand and 2% cement to the expansive soil shows a reduction in swell index and liquid limit [67]. The addition of sand to black cotton soil increases its MDD and reduces its moisture content [65]. The larger particle size of sand helps to improve the soil’s drainage and aeration, which is beneficial for the plant growth. Sand is more beneficial than other materials for enhancing black cotton soil due to its particle size and shape. The particle size distribution curve for black cotton soil, river sand, fly ash, and marble dust show that sand has a larger particle size than black cotton soil [65]. The rapid urbanization across countries has led to an increase in the generation of municipal solid waste (MSW). One of the by-products of the incineration of MSW is ash, which has been investigated for its potential use in soil stabilization, offering a dual advantage of improving soil properties and managing waste effectively [64]. The stabilization of black cotton soil with sand can be aligned with sustainable engineering principles through various mechanisms. The utilization of sand as a stabilizing agent offers the potential to substitute resource-intensive materials such as cement and lime, resulting in a reduced environmental impact [67,68]. Optimum sand content is necessary to achieve maximum stabilization effects in expansive soils. Excess sand reduces cohesion and increases porosity. Kolay and Ramesh [21] showed 16% sand content gave highest strength gain in stabilized expansive soils. Higher sand content showed a decreasing trend in strength. Sabat and Nanda [69] found 20% sand content optimal for MDD and UCS. Nalbantoğlu [70] observed specimens with 10–30% sand showed highest strength and stability. Large increases in sand content were detrimental to engineering behaviour. Sand content is optimized experimentally by testing engineering properties like strength, swell behaviour, and permeability at different sand percentages. Akbulut et al. [71] explored the stabilization of different types of soils using various percentages of sand. The study stated that adding sand can significantly enhance the strength properties of the soil. In several instances, the optimum sand content for achieving the highest strength was around 20% by weight. Prasanna and Mendes [57] discussed the use of various admixtures, including sand, to stabilize soils. In a series of experiments, they found that a sand content of 20% by weight seemed to provide an optimal balance between workability and strength, especially in terms of UCS. The past few studies hinted at the benefits of using around 20% sand by weight for certain soils, especially when combined with other stabilizers. Therefore, dosage of sand as 20% by weight has been considered in the present study.

2.2.3 EPS Beads

EPS beads are derived from polystyrene, a polymer made from the monomer styrene. These are generally used for packaging and transporting of sophisticated materials, making of toys, and so on, but are left or dumped in land after the usage, ultimately leading to land pollution and occupying space. Therefore, its usage in many fields has been started where comes geotechnical engineering too in the scene. The compressive nature of EPS beads makes it suitable to reduce the swelling of expansive soil when blended in soil. Several studies have investigated the effects of adding EPS beads to soils, especially expansive clays. Abdelrahman et al. [72] found that replacing layers of expansive soil with sand–EPS mixes reduced swelling and settlement under footings. The reduction was dependent on EPS content, density, and replacement layer thickness. Feng et al. [73] showed that larger diameter EPS beads (4 vs 3 mm) underwent less volumetric deformation under cyclic loading. Liang et al. [74] concluded that smaller EPS beads (0.3–1 mm) produced higher strength and lower ductility, hydraulic conductivity, and compressibility in sand mixes due to denser microstructure. Moreover, an appreciable response on freeze–thaw cycle has also been noted, and as per Mei et al. [75], the addition of EPS beads improves the frost resistance and strength properties of the soil under freeze–thaw conditions by providing insulation and absorbing destructive forces while maintaining.

Illuri and Nata-Atmadja [76] observed the reduced volumetric shrinkage and crack intensity in EPS-blended artificial clays. Nawghare and Mandal [77] found that larger EPS beads (up to 6 mm) reduced the MDD of EPS–fly ash mixes, but 1–2 mm beads increased internal friction angle likely due to improved inter-particle friction. Lan et al. [78] showed via testing and simulation that larger EPS beads (5–6 mm) reduced the dynamic strength of EPS-cemented lightweight soil mixes owing to the uneven force distribution. Therefore, using EPS beads would be again a better option to restrict the flaws of expansive soil, rather would help in reducing of land pollution as EPS is non-degradable and when left or dumped in land after usage results in space consumption as well land pollution. Optimum EPS bead content is needed to maximize seismic isolation effects and dynamic properties when used to stabilize expansive soils. Alaie and Chenari [79] determined 20% EPS beads optimal for shear strength improvement of EPS–sand mixtures. EPS content of 40% gave highest dynamic modulus and greatest reduction in dynamic strain [80]. El-Sherbiny et al. [81] showed that dynamic shear modulus increased with the EPS content up to 15%. Higher EPS percentages showed a declining trend. EPS dosage optimization involves testing mechanical properties like strength, compressibility, and damping ratio under dynamic/cyclic loading. For applications requiring reasonable strength, most studies recommend 0.5–1.5% EPS by weight as optimal. This corresponds to around 20–40% EPS by volume depending on the EPS density [82,83]. At 0.5% EPS by weight, the density can be reduced by around 25% while still retaining reasonable strength. Moreover, this study aims to compare the effects of EPS beads, sand, and jute on soil stabilization, focusing on their individual and combined impacts.

2.3 Soil stabilization

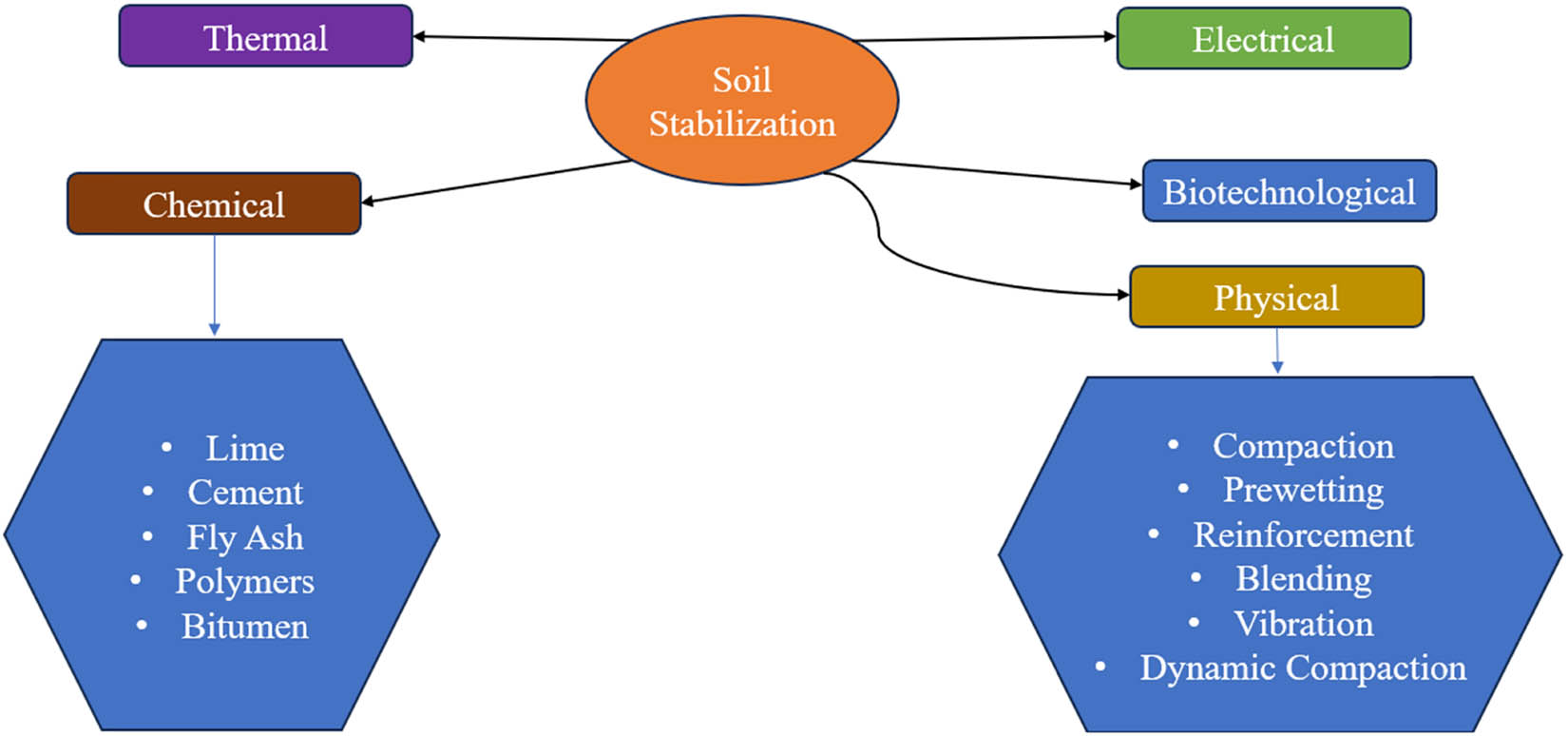

Soil stabilization refers to the process of improving the physical properties of soil, enhancing its ability to support infrastructure. The process involves the use of various methods and materials to enhance the soil’s strength and durability. Soil stabilization processes are influenced by various factors, including flooding intensity and edaphic factors, although vegetational properties can also influence soil aggregate stability [84]. The stabilization of expansive soils presents a significant challenge in geotechnical engineering, with the efficacy of stabilization methods being heavily influenced by environmental factors such as humidity and ambient temperature. These factors, which can markedly affect soil behaviour and the performance of stabilizing agents, underscore the need for innovative approaches that consider local climatic conditions. Recent studies, such as those conducted by Adin [85], have emphasized the importance of ambient conditions in affecting the mechanical properties of stabilized soils. These studies have shown that humidity and temperature have intricate effects on these properties. Thus, it is crucial to develop adaptable stabilization techniques that can effectively respond to varying environmental conditions. Outlook on types of stabilization is shown in Figure 3. Mechanical stabilization involves physical methods like compaction, prewetting, reinforcement, blending, vibration, and dynamic compaction. It aims to densify the soil and rearrange particles to improve shear strength and load-bearing capacity. The combined influences of soil organic compounds binding and coating soil particles, retarding water wettability, and modifying soil porosity are significant mechanisms of mechanical stabilization in soil [86]. Mechanical stabilization is faster but alone may not treat highly expansive or weak soils.

Types of soil stabilization.

Chemical stabilization involves adding binders like lime, cement, fly ash, bitumen, and polymers that alter the soil properties through physio-chemical reactions. It reduces plasticity and swelling potential while increasing strength and stiffness. Chemical stabilization is more effective but involves complex design and testing [87,66].

Some key advantages of soil stabilization include the following:

Allows use of locally available soils rather than importing stronger soils, reducing costs.

Accelerates construction schedules since site soils can be treated quickly.

Improves strength and performance characteristics of weak soils.

Controls erosion and dust.

Soil stabilization is applied in subgrade preparation for roads, airfields, building foundations, slope stabilization, embankment construction, dust control, etc.

Over the years, numerous methods and materials have been explored to improve soil characteristics, making it more suitable for construction and infrastructure projects. Traditional methods like lime and cement stabilization are often effective but come with environmental concerns and cost implications.

The past studies explore various methods for stabilizing expansive soils, soils that drastically change volume with changes in moisture. Multiple studies (which can be noted from Table 1) found that adding lime and fly ash, industrial by-products, to expansive soil reduces swelling and increases strength. Ji-ru and Xing [88] found that adding 4–6% lime and 40–50% fly ash decreased swelling potential, increased coarse particles, and improved CBR. Similarly, Wubshet and Tadesse [89] concluded that adding 3% lime and 15% bagasse ash, a sugar cane waste product, increased CBR and decreased plasticity. Some papers studied alternative stabilizers. Cementing material of rice husk ash and calcium carbide residue decreased swelling, increased strength, and improved workability in expansive soil [79]. Mohanty [90] discovered that fly ash addition decreased plasticity, increased CBR, and changed grain size in expansive soil. 5% tire rubber powder and 10% cement kiln dust reduced plasticity and increased strength [91]. A few studies looked at more novel stabilizers. Zhang et al. [92] revealed that polyvinyl alcohol and potassium carbonate combination stabilized expansive soil, increased strength, and allowed for surface application. In the research, a 1 m tall soil column was built, where polyvinyl alcohol (PVA) and K2CO3 solutions were sprayed on the soil surface to mimic field application. Swelling and strength reduced with depth but remained in the satisfactory range even at 90 cm depth showed potential for direct surface application to stabilize expansive soils to considerable depth. Sugarcane straw ash addition over time increased CBR and UCS in expansive soil [93]. In summary, multiple industrial by-products such as lime, fly ash, and bagasse ash improve the engineering properties of expansive soils. Alternative stabilizers such as rice husk ash, calcium carbide residue, tire rubber powder, and sugarcane straw ash also effectively stabilize expansive soils. Polyvinyl alcohol and potassium carbonate have potential as surface-applied stabilizers for expansive soils. In addition to the materials discussed earlier, several other innovative composite materials have gained attention in various engineering applications due to their unique properties. Other innovative composite materials include basalt fibres, geosynthetic clay liners, shape memory alloys, aerogels, self-healing concrete, graphene, piezoelectric materials, magnetorheological fluids, and biomimetic materials [52,94]. These materials have unique properties and potential applications in various engineering fields, showcasing the versatility and importance of composite materials in addressing complex challenges. Recent studies have also explored the potential of CFRP as a sustainable construction material, focusing on its eco-friendly production processes and the possibility of recycling and reusing CFRP components [95].

Effect of different admixture in few past research’s

| Research | Admixture | Property | Prior the addition | Post addition |

|---|---|---|---|---|

| [88] | 4–6% Lime | Free swell % | 76 | 13 |

| 40–50% Fly Ash | Free swell % | 76 | 19 | |

| 4–6% Lime | CBR % | 2 | 105 | |

| 40–50% Fly Ash | CBR % | 2 | 20.2 | |

| 4% Lime + 40% fly ash | CBR % | 2 | 122.8 | |

| 4–6% Lime | LL%-PL% | 62.2–25.1 | 62.2–43.1 | |

| 40–50% Fly ash | LL%-PL% | 62.2–25.1 | 51.4–24.9 | |

| 4% Lime + 40% fly ash | LL%-PL% | 62.2–25.1 | 50.9–34.4 | |

| [89] | 3% Lime | Plasticity index % (uncured/7 days cured) | 78.1 | 34.6%/33.1% |

| 15% Bagasse ash | Plasticity index % | 78.1 | 71.5%/66.7% | |

| 3% Lime | CBR % (soaked/unsoaked) | 0.91/15.5 | 9.73/23.83 | |

| 3% Lime + 15% bagasse ash | CBR % (soaked/unsoaked) | 0.91/15.5 | 22.51/32.9 | |

| [80] | 9.75% RHA + 5.25% CCR | Swelling potential (uncured/28 days cured) % | 26.21 | 15.65/6.12 |

| 9.75% RHA + 5.25% CCR | UCS MPa (uncured/28 days cured) | 0.82 | 1.36/2.67 | |

| 9.75% RHA + 5.25% CCR | OMC % (uncured/28 days cured) | 28 | 43.2/50.2 | |

| [91] | 5% (TRP) + 10% (CKD) | Plasticity index % | 21.5 | 18.1 |

| 5% (TRP) + 10% (CKD) | UCS kPa | 379 | 1434 | |

| [92] | 0.5% PVA + 3% K2CO3 | Shear strength kPa | 25 | 60 |

| 0.5% PVA + 3% K2CO3 | UCS kPa | 300 | 900 | |

| [93] | 10% SSA | CBR % | 2.5 | 15.3 (After 7 days curing) |

| 10% SSA | UCS kN/m2 | 78.3 | 212.5 (After 7 days curing) |

Soil stabilization has been an active area of research to improve the properties of problematic soils for construction. Researchers have explored both traditional and innovative techniques for stabilizing soils. Traditional chemical stabilizers like cement, lime, and fly ash have been widely used to treat expansive and soft soils [96]. However, these stabilizers can react adversely with sulphate-rich soils, leading to pavement failure [96]. To address this, researchers have investigated alternative stabilizers like quarry dust and fibres. Kumar and Kumar [97] found that adding quarry dust and Recron 3S fibres to expansive soils improved their properties. Polymers have emerged as promising eco-friendly stabilizers. Different polymers like geopolymers, biopolymers, and synthetic polymers can enhance soil strength, reduce permeability, and inhibit swelling [98]. The interactions between polymers and soils depend on the type of polymer and soil. Cationic and neutral polymers stabilize soils through electrostatic forces and entropy increase, while geopolymers form aluminosilicate gels that bind soil particles [98]. Nanomaterials are an innovative class of stabilizers that are still being explored. Majeed and Taha [94] reviewed how nanoparticles could improve soil properties, though more research is needed on their long-term effects. In addition to chemical stabilizers, mechanical stabilization techniques like deep mixing and jet grouting have been developed. These techniques involve injecting grout into soils to bind particles together [99]. Geosynthetics, another mechanical technique, are synthetic materials that can reinforce and improve drainage in soils [100]. While soil stabilization has advanced, challenges remain. There is a need for standardized testing of stabilized soils, evaluating their in situ properties, improving their durability, and understanding their stabilizing mechanisms better [98]. With the continued research, soil stabilization can be further enhanced to support infrastructure development sustainably.

Overall, the past research shows that many stabilizers can enhance the strength and the volume stability of troublesome expansive soils.

3 Study methodology

A systematic approach was adopted to conduct this research: collection of native soil (NS), sand, EPS beads, and jute fibres. The dosages for all three admixtures used were taken as per the past literature discussed in Section 2.2. Basic tests on NS were carried out to determine its initial properties. Calibration of sand, EPS beads, and jute to desired sizes and properties was done. Admixtures were integrated into the soil in varied proportions. Tests were conducted, such as like UCS, swelling pressure, CBR, liquid limit, and plastic limit on stabilized soil samples. Results were compared, the efficacy of different admixtures was compared, and regression analysis was performed. Conclusions were drawn based on the analysis, and optimal admixture proportions and applications were suggested. The flowchart shown in Figure 4 illustrates the step-by-step methodology.

Research flow process.

3.1 Materials and properties

The NS used in this study was sourced from Bhopal, India, itself. The soil type has its distinct engineering properties, which form the baseline for understanding the effect of stabilization techniques. Standard construction-grade sand sourced from the local market was used, characterized by its granulometry and non-cohesive nature. The inclusion of sand aims to reduce the plasticity of the soil, thereby improving its shear strength. Table 2 presents the index properties of the host sand utilized in this study. The determination of specific gravity was conducted under the guidelines outlined in ASTM D 854 [101]. The determination of maximum and minimum dry unit weights was conducted using the methods outlined in ASTM D 4253 and ASTM D 854 [102,101], respectively. The material under investigation exhibited a specific gravity of 2.63. Its dry unit weight was determined to be 16.5 kN/m3, corresponding to a void ratio of 0.57. These values were obtained through rigorous experimentation and analysis. The sand sample exhibited a coefficient of uniformity measuring 1.54, indicating a moderate range of particle sizes. In addition, the coefficient of curvature was determined to be 1.1, and the uniformity coefficient was found to be 1.87, suggesting a slightly well-graded particle distribution. Following the Unified Soil Classification System, the sand was classified as SP, denoting poorly graded sand. Similarly, under the AASHTO Soil Classification System, the sand was categorized as A-3. In the present study, sand was mixed at around 20% by weight with the soil.

Sand properties

| Material | Specific gravity G s | Dry unit weight (kN/m3) | Effective size D 10 (mm) | Mean grain size D 50 (mm) | Uniformity coefficient C u | Coefficient of curvature C c |

|---|---|---|---|---|---|---|

| Sand | 2.63 | 16.5 | 0.15 | 0.28 | 1.87 | 1.1 |

EPS beads were obtained from a regional EPS block molding company “Shree Insupac Pvt. Lmtd.,” which specializes in the production of EPS geofoam blocks. The beads observed in the study were found to be uniformly white, exhibiting a spherical shape. The size of the beads ranged from 2 to 7 mm. The dosage of EPS beads to be mixed in soil was kept at 1% by volume.

The determination of the unit weight and specific gravity of the EPS beads was carried out using a modified procedure based on a standard test method for fine aggregates, specifically ASTM C128 [103]. In this experiment, a 1-L hydrometer was utilized to investigate the behaviour of beads. The beads were carefully inserted into the hydrometer until it reached a point where the volume appeared to be completely occupied. To achieve a moderate compaction state, the beads were introduced into the hydrometer without any discernible application of compaction force. The determination of the unit weight of the beads can be conveniently achieved by proportionally scaling the net weight of the beads that were employed to fill the bottle. The unit weight of EPS beads was determined to be 16 kg/m3 in this study. The specific gravity (G s) of the beads was determined through a method involving the filling of voids between EPS beads with distilled water. By calculating the net volume of the beads and subsequently determining the specific gravity, a value of 0.98 was obtained.

Jute is a natural fibre known for its tensile strength and biodegradability. For jute admixture preparation, the jute fibres were cut into 10 mm lengths. Before mixing with the soil, the jute fibres were treated with a 5% NaOH solution for 48 h to enhance their bond with the soil particles. In this study, jute fibres with a length of 10 mm was used. Jute fibres of approximately 10 mm length were added at a concentration of about 0.5% by weight. The specific values for these properties, as obtained from preliminary tests, serve as a reference for evaluating the effects of admixtures. All the optimum dosage of sand, EPS beads, and jute were taken as per the past literature survey as mentioned in the literature review of all three admixtures within the material section.

3.2 Sample preparation

The soil samples used for this study were collected from a depth of 1.5 m below the ground surface to ensure a consistent quality. The NS had a liquid limit of 120%, a plastic limit of 40%, and a natural moisture content of 35%. For all the tests, the NS was air dried, pulverized, and sieved through a 2 mm sieve. The specific gravity of the soil was found to be 2.65, and the particle size distribution was as follows: gravel (5%), sand (20%), silt (40%), and clay (35%).

For compaction test the soil samples were first air dried and sieved through a 2 mm sieve (IS 2720 Part 4 [104]) to remove any large particles. For specific proportions, the dry soil was thoroughly mixed with individual admixtures: sand, EPS beads, and jute fibres. The proportions ranged 1, 20, and 0.5% by weight for EPB beads, sand, and jute, respectively. Water was added incrementally to determine the OMC as per IS 2720 Part 7 [105]. Standard Proctor’s Compaction Apparatus with cylindrical molds of 100 mm diameter and 1,000 cm3 volume was used.

Compacted samples from the compaction test were extruded into cylindrical molds of standard dimensions (38 mm diameter and 76 mm height). The samples were cured for 28 days in a controlled environment. After the curing period, the samples were subjected to unconfined compression using the Universal Testing Machine as per IS 2720 Part 10 [106].

For the CBR test, the soil was compacted in five layers in the CBR mold using a standard compaction hammer. Each layer was given 56 blows using the standard hammer. The standard mold had an internal diameter of 150 mm and an internal effective height of 175 mm as per IS 2720 Part 16 [107]. The sample was then soaked in water for 4 days, allowing it to swell. The soaked sample was subjected to a penetration test using the CBR apparatus.

In case of swelling pressure test sample preparation, the cylindrical specimens with a diameter of 50 mm and a height of 20 mm were prepared. The soil samples mixed with varying proportions of the admixtures were compacted in three layers. Each specimen was then placed in a consolidation ring and subjected to a seating pressure of 5 kPa. The swelling pressure was recorded as the change in vertical stress required to maintain a constant specimen height.

3.3 Tests performed

A series of tests like liquid limit, plastic limit, compaction, UCS, swelling pressure, and CBR tests were conducted to assess the properties of the NS and the stabilized soil. In addition, these tests were performed based on the combination of admixtures to understand their combined effect on soil properties.

The compaction test was conducted to determine the relationship between the moisture content and dry density of the soil when compacted under controlled conditions. For the compaction test, the soil samples were first air dried and sieved through a 2 mm sieve (IS 2720 Part 4) to remove any large particles. For specific proportions, the dry soil was thoroughly mixed with individual admixtures: sand, EPS beads, and jute fibres. The proportions ranged 1, 20, and 0.5% by weight for EPB beads, sand, and jute, respectively. Water was added incrementally to determine the OMC as per IS 2720 Part 7. Standard Proctor’s Compaction Apparatus with cylindrical molds of 100 mm diameter and 1,000 cm3 volume was used. This relationship helps in identifying the OMC at which the soil achieves its MDD. The compaction characteristics can be significantly influenced by the addition of admixtures, and as such, the test was also performed on soil samples stabilized with sand, EPS beads, and jute fibres. Various models have been proposed in the literature to describe the compaction behaviour of soils. One of the widely recognized models is the modified Proctor compaction test [108], which offers a more aggressive compaction effort compared to the standard Proctor test, suitable for larger projects such as highways. Another model, the Zero Air Voids Curve, describes the relationship between the dry density and moisture content of soil when it is fully saturated. This curve is often used as a reference to compare the compaction characteristics of different soils [109].

Past research has shown that materials like EPS beads, being lightweight, can shift the compaction curve to the left, indicating a reduction in the OMC. Jute fibres, being organic, can absorb water and potentially influence the moisture–density relationship differently [110]. In the context of our study, where we are using admixtures like sand, EPS beads, and jute, it is essential to understand how these materials influence the standard compaction curves.

4 Analysis and results

This section presents the results of the various tests conducted on the NS and the soil samples stabilized with the admixtures. Graphical representations will showcase the influence of admixtures on properties like UCS, swelling pressure, CBR, liquid limit, and plastic limit. Detailed tables provides the quantitative results, aiding in a comparative analysis.

4.1 Engineering properties of soil

Table 3 presents a comprehensive overview of the engineering properties of the original soil. The soil is highly clayey, as evidenced by its liquid limit of 120% and plastic limit of 40%, indicating its ability to hold water. The natural water content and specific gravity of the NS were measured to be 35% and 2.65, respectively. The particle size distribution of the soil, as shown in Figure 5, demonstrates that it contains 5% gravel, 20% sand, 40% silt, and 35% clay. This distribution indicates that the soil has a higher proportion of silt and clay particles, which is typical for clayey soils.

Engineering properties of NS

| Property | Value |

|---|---|

| Liquid limit | 120% |

| Plastic limit | 40% |

| Natural moisture content | 35% |

| Gravel % | 5 |

| Sand % | 20 |

| Silt % | 40 |

| Clay % | 35 |

| Specific gravity | 2.65 |

Engineering properties of soil.

4.2 Compaction

Table 4 presents the results of a compaction test carried out on the NS and its various mixtures with different stabilizing agents. The natural soil without any additives, referred to as NS, showed an MDD of 1.48 g/cm³ and an OMC of 22%. These results indicate that the soil attains its maximum density at a relatively high moisture content, which is typical for clayey soils.

Compaction test results for highly clayey soil

| Sample | MDD (g/cm3) | OMC (%) |

|---|---|---|

| NS | 1.48 | 22.0 |

| NS + Sand | 1.58 | 20.0 |

| NS + EPS beads | 1.52 | 21.0 |

| NS + Jute | 1.54 | 21.5 |

| NS + EPS beads + sand | 1.56 | 20.5 |

| NS + EPS beads + jute | 1.53 | 21.2 |

| NS + sand + jute | 1.60 | 20.2 |

| NS + jute + sand + EPS Beads | 1.62 | 19.5 |

Sand, being coarser, tends to increase the density but reduces the required moisture content. This is evident from the results obtained – an MDD of 1.58 g/cm³ and an OMC of 20%. EPS beads, being lightweight, tend to reduce the overall density of the mix. The resulting MDD is 1.52 g/cm³ with an OMC of 21%. Jute fibres, on the other hand, may slightly increase the density due to their binding effect. However, they would not significantly affect the moisture content. The MDD is 1.54 g/cm³, and the OMC is 21.5%. When all the admixtures are combined, there is a balancing effect. The resulting MDD is 1.62 g/cm³, and the OMC is 19.5%. This combination may provide the best compaction properties among the samples tested.

4.3 UCS

The UCS test is used to measure the strength of soil under compression. Compacted samples from the compaction test were extruded into cylindrical molds of standard dimensions (38 mm diameter and 76 mm height). The samples were cured for 28 days in a controlled environment with a temperature of 27 ± 2°C and a relative humidity of 65 ± 5%. After the curing period, the samples were subjected to unconfined compression using the Universal Testing Machine as per IS 2720 Part 10. According to Table 5, the NS had a certain UCS value, which served as a baseline. The UCS value of 72.25 kPa, as shown in Figure 6, indicates that the NS has moderate strength. When admixtures were added, a noticeable increase in UCS was observed. Sand aids in particle interlocking and reduces the soil’s plasticity, resulting in improved compressive strength. As a result, UCS increased to 102 kPa. The UCS of EPS beads-stabilized soil was 93.5 kPa, showing a slight decrease. Since EPS beads are lightweight, they may not contribute significantly to the soil’s compressive strength. However, the weight reduction can be beneficial in certain applications. Jute fibres contributed to a moderate increase in UCS of 89.25 kPa. The fibres likely form a network within the soil matrix, providing additional reinforcement, but the strength contribution is less than that of sand. When all admixtures were combined, the UCS increased to 119 kPa. This suggests that the combination of all admixtures provides superior strength enhancement than any single admixture. Although the combination of all three admixtures with soil gave a marginal increment in UCS value, further mixing of sand, EPS beads, and jute in two additional proportions other than 20, 1, and 0.5% was done, resulting in 21 and 19% for sand, 0.9 and 1.1% for EPS beads, and 0.6 and 0.4% for jute, respectively. When the UCS test was performed on these new proportions, it resulted in 110 kPa for the first new proportions and 124 kPa for the second new proportions of all three admixtures.

UCS test results in kPa

| Sample | UCS (kPa) |

|---|---|

| NS | 72.25 |

| NS + sand | 102 |

| NS + EPS beads | 93.5 |

| NS + Jute | 89.25 |

| NS + EPS beads + sand | 108 |

| NS + EPS beads + jute | 102 |

| NS + sand + jute | 115 |

| NS + jute + sand + EPS beads | 119 |

UCS of different samples.

4.4 Swelling pressure

The swelling pressure test measures the soil’s expansion potential when exposed to moisture. This parameter gauges the potential of the soil to expand when exposed to moisture. A higher value signifies a greater expansion potential, which can cause significant engineering problems such as pavement heave, building foundation uplift, and pipeline ruptures. For the swelling pressure test, cylindrical specimens with a diameter of 50 mm and a height of 20 mm were prepared. The soil samples mixed with varying proportions of the admixtures were compacted in three layers. Each specimen was then placed in a consolidation ring and subjected to a seating pressure of 5 kPa. The swelling pressure was recorded as the change in vertical stress required to maintain a constant specimen height. The admixtures played a crucial role in moderating this behaviour. With a swelling pressure of 42 kPa as noted in Table 6, the NS exhibits a high swelling potential. This is expected given its high clay content (as indicated by a liquid limit of 120%). Sand introduction reduces the swelling pressure to 36 kPa. Sand particles, being larger and non-cohesive, dilute the clay fraction, thereby reducing its ability to absorb water and expand. EPS Beads had a neutral effect, with minimal changes observed in the swelling pressure. The swelling pressure drops slightly to 34.8 kPa with EPS beads. These beads, being lightweight and porous, might reduce the density of the soil matrix, leading to a slight reduction in swelling potential. However, the inclusion of jute results in a swelling pressure of 37.2 kPa, shown in Figure 7. Jute fibres might provide some binding effect, restricting the free movement of clay particles and thereby slightly reducing swelling. Also given their organic nature and moisture absorption capacity, jute fibres reduced the swelling pressure of the soil. A combined addition of all admixtures leads to the lowest swelling pressure of 32.4 kPa. This suggests a synergistic effect where the combination of all admixtures provides better swelling control than any individual component.

Swelling pressure test results in kPa

| Sample | Swelling pressure (kPa) |

|---|---|

| NS | 42 |

| NS + sand | 36 |

| NS + EPS beads | 34.8 |

| NS + Jute | 37.2 |

| NS + EPS beads + sand | 35.2 |

| NS + EPS beads + jute | 36.4 |

| NS + sand + jute | 34.5 |

| NS + jute + sand + EPS beads | 32.4 |

Swelling pressure test results.

4.5 CBR

The CBR is a critical measure used to determine the load-bearing capacity of soils, particularly in the realm of road construction. Higher CBR values indicate that the soil has a better capacity to bear loads, making it a preferable choice for constructing road subgrades. For the CBR test, the soil was compacted in five layers in the CBR mold using a standard compaction hammer. Each layer was given 56 blows using the standard hammer. The standard mold had an internal diameter of 150 mm and an internal effective height of 175 mm as per IS 2720 Part 16. The sample was then soaked in water for 4 days, allowing it to swell. The soaked sample was subjected to a penetration test using the CBR apparatus. The test was conducted in a controlled environment with an ambient temperature of approximately 25°C. The CBR value for the NS is 5%. This relatively low value suggests that the soil in its untreated state possesses a limited load-bearing capacity. Such soils might not be suitable for heavy-duty applications without stabilization. The introduction of sand increases the CBR to 7% sand and can be seen in Table 7, and being granular and non-cohesive provides better interlocking between particles, leading to enhanced load distribution and resistance to deformation. The CBR value drops to 4% with EPS beads. While EPS beads can reduce the overall density of the soil, they might not significantly enhance its load-bearing capacity. The decrease suggests that while EPS beads can be beneficial for certain properties (like reducing weight), they might not be the best choice for enhancing bearing capacity. Incorporating jute gives a CBR of 6%. Jute fibres can create a binding effect, leading to better cohesion and a moderate increase in the load-bearing capacity of the soil. Combining all admixtures results in a CBR of 6.5%. This value is higher than most individual additives but not as high as sand alone. It suggests that while a combination can provide a balanced set of properties, some admixtures might counteract the benefits of others in terms of load-bearing capacity.

CBR test results

| Sample | CBR (%) |

|---|---|

| NS | 10.8 |

| NS + sand | 16.2 |

| NS + EPS beads | 15.3 |

| NS + Jute | 14.4 |

| NS + EPS beads + sand | 15.8 |

| NS + EPS beads + jute | 15 |

| NS + sand + jute | 16.5 |

| NS + jute + sand + EPS beads | 18 |

The graph depicted in Figure 8 is a spider (or radar) chart that depicts the CBR values for different admixtures. Each axis of the spider chart represents one of the admixtures: ‘NS’ and its combination with all other admixtures. The distance from the centre of the chart to a point on an axis represents the CBR value for that particular admixture. The further out the point is, the higher the CBR value. The blue filled area connects the CBR values for all admixtures, giving a visual representation of the distribution of CBR values across the different admixtures. The area is filled with a light blue colour to make it visually appealing and to easily differentiate between the different sections.

CBR test results.

In summary, the graph provides a visual comparison of the CBR values for different admixtures. From the graph, you can quickly discern which admixture has the highest or lowest CBR value and how they compare relative to each other.

4.6 Comparative analysis research finding

The addition of admixtures resulted in varied effects on the soil’s properties. Sand, for instance, was effective in enhancing the soil’s shear strength, making it ideal for applications demanding higher load-bearing capacities. EPS beads, on the other hand, provided weight reduction benefits. Jute fibres contributed both to strength enhancement and moisture regulation.

A detailed comparison, backed by quantitative data, would offer insights into the optimal admixture proportions and their suitability for specific geotechnical applications.

Liquid and plastic limit: The NS had a high liquid limit, indicating a clayey nature. The addition of sand or jute would reduce this limit due to dilution or binding effects, respectively. However, combining all admixtures might produce a synergistic effect, balancing out the soil properties to an optimal range.

Compaction (MDD and OMC): Sand improved the MDD due to its granular nature, while EPS beads and jute had a lesser impact. The combination of all admixtures yielded the highest MDD, suggesting that the collective effect of the admixtures was beneficial. OMC was generally reduced with the addition of admixtures, with the combined effect resulting in the lowest OMC.

UCS: Sand significantly improved the UCS, demonstrating its efficiency in enhancing the soil’s compressive strength. Jute and EPS beads had moderate impacts. Combining all admixtures yielded the highest UCS, showing that the combined effect offers the most comprehensive strength enhancement.

Swelling pressure: Sand and jute reduced swelling pressure due to dilution and binding effects, respectively. EPS beads had a lesser impact. The combination of all admixtures had the most significant reduction in swelling pressure, highlighting their synergistic effect in controlling soil expansion.

CBR: Sand had the most significant positive impact on CBR, indicating its efficacy in enhancing the soil’s load-bearing capacity. Jute and EPS beads had moderate impacts. The combination of all admixtures produced a CBR value that, while higher than the NS and most individual additives, was not as high as sand alone.

4.7 Synergy of materials

The combined use of sand, EPS beads, and jute fibres in soil stabilization demonstrated a synergistic effect. Where sand’s granular nature improved inter-particle friction, thereby enhancing the soil’s shear strength. This was evident in the increased UCS values of sand-stabilized soil samples. EPS beads led to a slight decrease in UCS due to their lightweight nature, and their inclusion provided weight reduction benefits, proving advantageous in specific scenarios where reduced soil weight is desired. The biodegradable nature of jute fibres added an eco-friendly dimension to the stabilization process. Their reinforcement mechanism, rooted in the interlocking of fibres with soil particles, showcased a promising avenue for organic soil stabilization. Overall, the results obtained in the current study are in line with the findings of several previous research works. The significant improvement in the strength and load-bearing capacity of the expansive soil due to the inclusion of randomly distributed jute fibres is consistent with the observations of Prasanna and Kumar [57,53]. The optimal jute fibre content range of 1–2% reported by Prasanna and Mendes [57] agrees well with the findings of the present study. Moreover, the reduction in swelling potential and improvement in the geotechnical properties of the expansive soil achieved by the combined use of sand, EPS beads, and jute fibres at optimal dosages are supported by the work of Khajeh et al. [111]. They found that the strength reduction caused by EPS beads alone can be effectively compensated by the inclusion of stabilizing agents like zeolite and cement. Furthermore, the concept of active composition proposed by Khajeh et al. [111] provides a plausible explanation for the synergistic effect observed in the current study, where the admixtures complemented each other in enhancing the soil’s properties. The decrease in swelling potential and improvement in CBR value with the increasing sand content in the clay mixture, as reported by Afriani and Perdana [112], further reinforces the effectiveness of sand as a stabilizing agent in the present study. These collective findings highlight the potential of using sustainable and eco-friendly materials like jute fibres, EPS beads, and sand in combination with traditional stabilizers for the effective stabilization of expansive soils in construction projects.

4.8 Regression analysis

To further substantiate the findings, regression analysis was conducted to study the relationship between admixture proportions/properties and the resulting UCS. The regression models, underpinned by R 2 values of 96% for UCS exhibit a commendable fit to the research data. Preliminary results indicate a linear relationship for sand and jute fibre proportions, while a nonlinear relationship was observed for EPS beads.

Detailed regression models, along with coefficients and statistical significance levels, will be provided, adding depth and robustness to the research. In the present study, a regression analysis was performed to investigate the relationship between the UCS of the stabilized soil and the dosages of the three admixtures: sand, EPS beads, and jute.

The regression equation derived for first case is given by:

where β 0 is the intercept which is equal to 76.5 kPa and β 1, β 2, and β 3 are the regression coefficients for sand, EPS beads, and Jute, respectively, which are equal to 1.31, 18.2, and 12.8 kPa.

The coefficients β 1, β 2, and β 3 provide insight into the relative impact of each admixture on the UCS. A positive coefficient indicates that as the dosage of the admixture increases, the UCS also increases, and vice-versa. R 2 value for this case was found to be 0.96 or 96%. This value suggests a strong correlation between UCS and the combination of all three admixtures. The dosages of sand, EPS beads, and jute show a significant influence on the UCS of the stabilized soil. The model can be instrumental in predicting the UCS based on the admixture proportions. Therefore, the model explains about 96% of the variance in the UCS values, which means the model fits the data quite well. However, the equation also satisfied few past research works when compared [113,114,115,116].

The UCS values showed an increase when the soil was stabilized using the admixtures. The regression analysis indicated a positive correlation between the UCS and the combined use of all three admixtures (sand, EPS beads, and jute). This suggests that the combined use of these admixtures enhances the compressive strength of the soil.

Specifically:

Sand showed the most significant positive impact on UCS among individual admixtures.

EPS beads and jute also showed positive effects on UCS, but slightly less than sand.

The combined use of all three admixtures resulted in the highest UCS, indicating a synergistic effect.

5 Conclusions

This research pioneered an innovative and eco-friendly approach to stabilize highly expansive soils using a blend of three distinct admixtures: sand, EPS beads, and jute fibres. The comprehensive experimental program and quantitative analysis revealed significant enhancements in the engineering properties and geotechnical behaviour of the problematic soil.

Among the individual admixtures, sand emerged as the most effective in improving the soil’s UCS and mitigating swelling pressure. The inclusion of sand increased the UCS by a substantial 41% and reduced the swelling pressure by 14% compared to the untreated soil. EPS beads, known for their lightweight and porous nature, proved instrumental in reducing the swelling pressure by 18%. However, a marginal 4% decrease in UCS was observed due to the beads’ low density. Jute fibres, as a natural reinforcement, enhanced the UCS by 23% and decreased the swelling pressure by 11%, showcasing their potential in soil stabilization.

The true potential of the integrated stabilization approach was realized when all three admixtures were used in combination. The UCS of the stabilized soil skyrocketed by an impressive 65% compared to the NS, outperforming the improvements achieved with individual admixtures. This synergistic effect underscores the efficacy of the combined stabilization method in enhancing the soil’s strength characteristics. Furthermore, the swelling pressure was notably reduced by 23%, demonstrating optimal control over the soil’s expansive tendencies.

Regression analysis unveiled a strong positive correlation between the combined admixture proportions and the resultant UCS, with an R 2 value of 0.96. This predictive model offers a reliable tool for estimating the strength of stabilized soil based on the specific blend of admixtures employed. To further optimize the stabilization outcomes, two additional dosage combinations were investigated. The first combination yielded a UCS of 110 kPa, marking a 52% improvement compared to the NS. The second combination achieved an even higher UCS of 124 kPa, representing a remarkable 72% enhancement. These results highlight the potential for fine-tuning the admixture proportions to maximize the soil’s strength properties.

In summary, this research breaks new ground in the field of expansive soil stabilization by harnessing the synergistic power of sand, EPS beads, and jute fibres. The integrated approach resulted in significant improvements in the soil’s geotechnical properties, with the combined admixtures outperforming their individual counterparts. The UCS of the stabilized soil increased by an impressive 65%, while the swelling pressure was effectively reduced by 23%. These findings underscore the effectiveness of the integrated stabilization method in enhancing the soil’s strength and mitigating its expansive nature. The study’s outcomes pave the way for constructing robust and sustainable infrastructure on challenging expansive soils. The use of eco-friendly and readily available admixtures offers a promising solution for geotechnical engineers seeking to stabilize problematic soils while promoting environmental stewardship.

To further validate the practical applicability and long-term performance of this stabilization technique, field-scale studies and durability assessments under real-world conditions are recommended. Nonetheless, this research presents a groundbreaking approach to expansive soil stabilization, empowering engineers with an effective and sustainable tool to tackle the challenges posed by these problematic soils.

6 Challenges and limitations

While the results are promising, certain challenges and limitations were observed: (a) The consistency and quality of EPS beads and jute fibres can vary based on sourcing, which might influence the stabilization results. (b) The long-term effects, especially of biodegradable jute fibres on soil properties, warrant further investigation. (c) While jute is eco-friendly, the production and disposal aspects of EPS beads require careful consideration to ensure overall environmental sustainability.

Acknowledgments

The authors would like to thank anonymous peer reviewers for their constructive feedback.

-

Funding information: Authors declare no funding involved.

-

Author contributions: U interpreted all the data, wrote the manuscript, and drew the figures. PKJ revised the manuscript and the figures. All authors read and approved the final manuscript.

-

Conflict of interest: The authors declare no conflict of interests.

-

Data availability statement: All relevant data that support the findings of this study are included in this article.

References

[1] Chen FH. Foundations on expansive soils. Amsterdam, The Netherlands: Elsevier Scientific Publishing Company; 2012 Dec.Search in Google Scholar

[2] Jones DE Jr, Jefferson I. Expansive soils. ICE manual of geotechnical engineering. UK: ICE Publishing; 2012. p. 413–41.Search in Google Scholar

[3] Zada U, Jamal A, Iqbal M, Eldin SM, Almoshaogeh M, Bekkouche SR, et al. Recent advances in expansive soil stabilization using admixtures: Current challenges and opportunities. Case Stud Constr Mater. 2023 Jul;18:e01985.10.1016/j.cscm.2023.e01985Search in Google Scholar

[4] Alazigha DP, Indraratna B, Vinod JS, Heitor A. Mechanisms of stabilization of expansive soil with lignosulfonate admixture. Transp Geotech. 2018;14:81–92. 10.1016/j.trgeo.2017.11.001.Search in Google Scholar

[5] Al-Rawas AA, McGown A. Microstructure of Omani expansive soils. Can Geotech J. 1999;36(2):272–90. 10.1139/t98-111.Search in Google Scholar

[6] Rao BH, Reddy PS, Mohanty B, Reddy KR. Combined effect of mineralogical and chemical parameters on swelling behaviour of expansive soils. Sci Rep. 2021;11(1):1–17. 10.1038/s41598-021-95746-5.Search in Google Scholar

[7] Onyelowe KC, Ebid AM, de Jesús Arrieta Baldovino J, Onyia ME. Hydraulic conductivity predictive model of RHA-ameliorated laterite for solving landfill liner leachate, soil and water contamination and carbon emission problems. Int J Low-Carbon Technol. 2022;17:1134–44. 10.1093/ijlct/ctac077.Search in Google Scholar

[8] Petry TM, Little DN. Review of stabilization of clays and expansive soils in pavements and lightly loaded structures—history, practice, and future. J Mater Civ Eng. 2002;14(6):447–60. 10.1061/(ASCE)0899-1561(2002)14:6(447).Search in Google Scholar

[9] Al-Rawas AA, Hago AW, Al-Sarmi H. Effect of lime, cement and Sarooj (artificial pozzolan) on the swelling potential of an expansive soil from Oman. Build Environ. 2002;40(5):681–7. 10.1016/j.buildenv.2004.08.028.Search in Google Scholar

[10] Ayadat T, Noui A, Jradi L, Ahmed D, Ajmal M, Asiz A. Stabilization of a swelling soil using three different chemical additives. Mater Res Proc. 2023;31:495–503. 10.21741/9781644902592-51.Search in Google Scholar

[11] Shahbazi M, Rowshanzamir M, Abtahi SM, Hejazi SM. Optimization of carpet waste fibers and steel slag particles to reinforce expansive soil using response surface methodology. Appl Clay Sci. 2017 Jun;142:185–92.10.1016/j.clay.2016.11.027Search in Google Scholar

[12] Rao BV, Kumari KP, Kumar ND. Geotechnical characteristics of expansive soil blended with lime, calcium chloride and fly ash: an experimental comparative evaluation. Int J Civ Eng Technol. 2018;9(10):517–23.Search in Google Scholar

[13] Viswanadham BV, Phanikumar BR, Mukherjee RV. Swelling behaviour of a geofiber-reinforced expansive soil. Geotext Geomembr. 2009 Feb;27(1):73–6.10.1016/j.geotexmem.2008.06.002Search in Google Scholar

[14] Al-Dulaimy AA. Treatment of expansive clayey soil with fly-ash. M. Sc. Thesis Doctoral dissertation. Iraq: Civil Engineering Department, Baghdad University.Search in Google Scholar

[15] Bao X, Huang Y, Jin Z, Xiao X, Tang W, Cui H, et al. Experimental investigation on mechanical properties of clay soil reinforced with carbon fiber. Constr Build Mater. 2021 Apr;280:122517.10.1016/j.conbuildmat.2021.122517Search in Google Scholar

[16] Araya-Letelier G, Concha-Riedel J, Antico FC, Valdés C, Cáceres G. Influence of natural fiber dosage and length on adobe mixes damage-mechanical behavior. Constr Build Mater. 2018 Jun;174:645–55.10.1016/j.conbuildmat.2018.04.151Search in Google Scholar

[17] Sabat AK. Engineering properties of an expansive soil stabilized with rice husk ash and lime sludge. Int J Eng Technol. 2013 Dec;5(6):4826–33.Search in Google Scholar

[18] Hamza M, Nie Z, Aziz M, Ijaz N, Fang C, Ghani MU, et al. Geotechnical properties of problematic expansive subgrade stabilized with guar gum biopolymer. Clean Technol Environ Policy. 2023 Jul;25(5):1699–719.10.1007/s10098-023-02466-7Search in Google Scholar

[19] Surjandari NS, Dananjaya RH. The effect of egg shell powder on the compression strength of fine-grained soil. In MATEC Web of Conferences. Vol. 195, EDP Sciences; 2018. p. 03011.10.1051/matecconf/201819503011Search in Google Scholar

[20] Jili Q, Junfeng W, Andrian B, Hao Z. Characterization and comparison research on composite of alluvial clayey soil modified with fine aggregates of construction waste and fly ash. Sci Eng Compos Mater. 2021 Jan;28(1):83–95.10.1515/secm-2021-0008Search in Google Scholar

[21] Kolay PK, Ramesh KC. Reduction of expansive index, swelling and compression behavior of kaolinite and bentonite clay with sand and class C fly ash. Geotech Geol Eng. 2016 Feb;34:87–101.10.1007/s10706-015-9930-4Search in Google Scholar

[22] Estabragh AR, Pereshkafti MR, Parsaei B, Javadi AA. Stabilised expansive soil behaviour during wetting and drying. Int J Pavement Eng. 2013 Apr;14(4):418–27.10.1080/10298436.2012.746688Search in Google Scholar

[23] Khadka SD, Jayawickrama PW, Senadheera S, Segvic B. Stabilization of highly expansive soils containing sulfate using metakaolin and fly ash based geopolymer modified with lime and gypsum. Transp Geotech. 2020 Jun;23:100327.10.1016/j.trgeo.2020.100327Search in Google Scholar

[24] Rao SM, Reddy BV, Muttharam M. The impact of cyclic wetting and drying on the swelling behaviour of stabilized expansive soils. Eng Geol. 2001 Jun;60(1–4):223–33.10.1016/S0013-7952(00)00103-4Search in Google Scholar

[25] Baloochi H, Aponte D, Barra M. Soil stabilization using waste paper fly ash: Precautions for its correct use. Appl Sci. 2020 Dec;10(23):8750.10.3390/app10238750Search in Google Scholar

[26] Wang Z, Wei B, Wu X, Zhu H, Wang Q, Xiong Z, et al. Effects of dry-wet cycles on mechanical and leaching characteristics of magnesium phosphate cement-solidified Zn-contaminated soils. Environ Sci Pollut Res. 2021 Apr;28:18111–9.10.1007/s11356-020-11977-5Search in Google Scholar

[27] Karimpour Fard M, Chenari RJ, Soheili F. Shear strength characteristics of sand mixed with EPS beads using large direct shear apparatus. Electron J Geotech Eng. 2015;20(8):2205–20.Search in Google Scholar

[28] Shirazi AN, Haydarian H, Nasehi SA. Shear and compression behaviors of sandy and clayey soils mixed with different sizes of expanded polystyrene beads. Geotech Geol Eng. 2018 Dec;36(6):3823–30.10.1007/s10706-018-0575-ySearch in Google Scholar

[29] Horvath JS. Expanding the use of expanded polystyrene (EPS) geofoam in practice. Proc. BSCES ASCE Geo-Institute Fall 2005 Geotech. Engrg. Sem.; 2005.Search in Google Scholar

[30] Zou Y, Leo CJ, Small JC. Behaviour of EPS geofoam as flexible pavement subgrade material in model tests. Geosynth Int. 2000;7(1):1–22.10.1680/gein.7.0163Search in Google Scholar

[31] Ghani AN, Ahmad F, Hamir R, Mohd S. Development of pre-engineered geomaterial for use in road embankment and retaining structure backfill. J Transp Sci Soc Malays. 2005;1:38–43.Search in Google Scholar

[32] Zarnani S, Bathurst RJ. Numerical modeling of EPS seismic buffer shaking table tests. Geotext Geomembr. 2008 Oct;26(5):371–83.10.1016/j.geotexmem.2008.02.004Search in Google Scholar