Abstract

This study was conducted to observe the characteristics of sodium carboxymethyl cellulose (Na-CMC) made from bacterial cellulose from pineapple peel waste obtained from the results of community business activities. Na-CMC was made from pineapple peel waste cellulose with various sodium hydroxide concentration treatments. The alkalization process with NaOH is critical to start the carboxymethylation process to produce CMC. Na-CMC was manufactured with various NaOH concentrations in the range of 5, 7.5, 10, 12.5, and 15%. The resulting Na-CMC was then analyzed for quality using several parameters such as water content, NaCl content, Na-CMC purity, and degree of substitution (DS). The application of Na-CMC was tested in the view of viscosity and pH. As a result, it can be reported that the concentration of NaOH dramatically affects the character of the resulting Na-CMC. The NaOH concentration of 10% produced the best Na-CMC in this study, with the highest purity and DS value. As information for the application of the Na-CMC produced, the Na-CMC produced was measured for the pH value and viscosity. As a result, it can be reported that the pH of the Na-CMC solution was categorized as neutral, and the viscosity value was directly proportional to the purity of Na-CMC. The findings of this study have provided information on the potential of pineapple peel waste to produce Na-CMC, even though the material was not standardized because it comes from annual public activity.

1 Introduction

Pineapple (Ananas comosus L.) is a fruit plant widely cultivated in tropical and subtropical regions. This plant has many benefits, especially its fruit. The pineapple processing industry in Indonesia is a priority plant to be developed because it has export potential [1]. Along with the large capacity of the pineapple industry in Indonesia, a condition that needs attention is pineapple peel waste. The pineapple industry processes pineapples to convert the fruit’s flesh into canned products or other derivative products. However, the fruit’s peel will be thrown away, which leads to problems. Therefore, it is necessary to think about the technical processing of pineapple peel waste that goes hand in hand with the industrialization of pineapple in the country.

It is well known that pineapple peel waste still contains various chemical compounds such as carbohydrates (75.67%), proteins (5.78%), fat (5.57), and ash (378%) [2,3]. The high carbohydrate content which also represents the sugar content means that pineapple skin waste can be processed into bacterial cellulose [3,4]. Cellulose produced from pineapple peel can be used directly or to make derivative products with high economic value [5]. One of the potential products that can be produced from pineapple peel waste cellulose is sodium carboxymethyl cellulose (Na-CMC). The pineapple peel waste has been widely used as a raw material for cellulose. The cellulose produced is used as a raw material for paper membranes as a filtration material to remove contaminants in water. However, using cellulose from pineapple peel waste to prepare compounds with other broader benefits, such as Na-CMC, has yet to be widely carried out. Na-CMC is a compound that has various uses in the pharmaceutical, textile, construction, and food sectors. Due to the wide application of Na-CMC, processing pineapple peel waste into Na-CMC will significantly increase the economic value of the pineapple peel [6]. This economic potential can be a strong incentive for the development of industries using pineapple peel waste as a raw material.

The process of making Na-CMC from either natural cellulose or bacterial cellulose includes two steps, namely, alkalization and carboxymethylation [7,8,9,10,11]. Alkalization is carried out by reacting cellulose with NaOH to reactivate the –OH group. The cellulose structure expands and allows the carboxymethyl reagent to enter and bind to the cellulose. The characteristic of the Na-CMC produced will, of course, depend on the quality of the cellulose available [12]. In this study, Na-CMC production has been carried out from cellulose produced from pineapple peel waste obtained from community activities in Padang, West Sumatra Province, Indonesia. Industrially, the characteristic of the cellulose produced to be used as the raw material for Na-CMC will be uniform because pineapple peel waste comes from the same source. However, if pineapple peel waste is from community activities, the characteristics will be different, such as different varieties, different ages, and so on. Therefore, it is interesting to know the quality of Na-CMC produced when using cellulose from a collection of pineapple peel waste which are from different sources. As previously informed, the process of making Na-CMC will be influenced by two factors, namely, the composition of NaOH for the alkalization process and the composition of sodium monochloroacetate (SMCA) for the carboxymethylation process. So, in this study, the process of forming Na-CMC will be focused on the influence of the NaOH concentration used in the treatment because this is considered to be the initial step towards the perfection of the reaction of the formation of Na-CMC. However, it is important to note that the industrial production of Na-CMC from pineapple peel waste may face challenges such as maintaining consistent quality and dealing with variations in the source material.

This study describes the production of Na-CMC from pineapple peel trash that was collected from the local waste. Furthermore, as this was a crucial step in the production of Na-CMC from cellulose, improvement of the Na-CMC creation process using NaOH treatment was focused instead. Since the properties of pineapple peel waste will influence the type of Na-CMC product that is produced, the results of this study will give more information about the Na-CMC products that can be made from this waste, offering an alternative viewpoint for the growth of industries that use it as a raw material.

2 Material and methods

This research was conducted in a laboratory employed under the management of the Department of Food Technology and Agricultural Products, Andalas University, and the production workshop of the Culinary Arts Study Program, Padang State University, West Sumatra, Indonesia. The research was conducted during the period of April–September 2024.

The primary material used in this study was pineapple peel waste obtained from traditional markets in two sub-districts in Padang, West Sumatra Province. The pineapple peels were obtained from one sampling point, approximately 20 kg per day. Other materials used were Acetobacter xylinum bacterial culture, sugar, urea, acetic acid, distilled water, 95% ethanol, NaOH, isopropyl alcohol, SMCA, glacial acetic acid, sulfuric acid, sodium chlorite, and ethanol. All materials used were of technical grade quality.

The tools used to produce nata de pina were simple equipment consisting of laboratory glassware, blenders, and trays. Also, instruments such as pH meters (pH Meter Mettler Toledo S-220-KIT), Viscometers (B-One model BMV 102 M), and measuring glassware were used for analytical purposes.

In this study, different concentrations of NaOH are used to create alkalization condition for Na-CMC formation. The NaOH concentrations used were 5, 7.5, 10, 12.5, and 15%, with similar amounts (20 mL) in the reaction system (approx. 220 mL mixture solution).

2.1 Production of nata de pina from pineapple peel waste

Pineapple peel waste extract was taken using a juicer. Then, water was added in a ratio of 1:4 (1 kg of pineapple puree was added to 4 kg of water). Then, 0% sugar, 0.5% ammonium sulfate, and 0.5% acetic acid (v/v) were added to the mixture. The pH was then adjusted to 4.5 and sterilized by cooking until boiling. Subsequently, the mixture was cooled, and Acetobacter xylinum bacteria was added as much as 10% of the total liquid and fermented for 14 days [13,14].

2.2 Purification of produced nata de pina

Nata in the form of sheets was harvested and then washed until neutral. The nata de pina sheets were reduced into small pieces and then boiled five times. The boiled nata was dried using a food dehydrator at 40°C for 12 h. The dried cellulose was reduced in size using a blender.

2.3 Production of CMC from nata de pina cellulose raw material

The formulation used for making CMC from nata de pina is shown in Table 1.

Formulation for Na-CMC from cellulose of pineapple peel waste with various NaOH concentrations

| Materials | Treatments | ||||

|---|---|---|---|---|---|

| A (NaOH 5%) | B (NaOH 7.5%) | C (NaOH 10%) | D (NaOH 12.5%) | E (NaOH 15%) | |

| Cellulose (g) | 5 | 5 | 5 | 5 | 5 |

| SMCA | 5 | 5 | 5 | 5 | 5 |

| (g) | |||||

| Isopropanol (mL) | 100 | 100 | 100 | 100 | 100 |

| NaOH (mL) | 20 | 20 | 20 | 20 | 20 |

| Acetic acid glacial 98% (mL) | Up to pH 7 | Up to pH 7 | Up to pH 7 | Up to pH 7 | Up to pH 7 |

| Methanol (mL) | 100 | 100 | 100 | 100 | 100 |

The production of CMC was referred to in the study by Syukri et al., 2024 [15]. The production of CMC was carried out through two processes, namely, alkalization and carboxymethylation. In the alkalization process, 5 g dry weight of nata de pina cellulose was put into a 250 mL Erlenmeyer flask. Then, 100 mL of isopropanol was added while stirring using a 100 rpm hotplate stirrer at 30°C (room temperature), until mixed. Then, 20 mL of NaOH solution with several concentrations (5, 7.5, 10, 12.5, 15%) was added drop by drop for 1 h while stirring. After the alkalization process, the carboxymethylation process was continued by adding 6 g of SMCA. The carboxymethylation process was carried out with a hotplate stirrer at 60°C for 3 h. Then, the mixture of the carboxymethylation process is cooled and neutralized with 98% glacial acetic acid to pH 7 at room temperature. After that, it was filtered and soaked in 100 mL of methanol for 24 h. Then, the filtering was done again, and the residue was dried in an oven until its weight was constant at 60°C. The dried Na-CMC was then ground and stored in a closed container before being characterized and tested for application.

2.4 Quality analysis of produced Na-CMC

The quality of Na-CMC produced was then tested using several parameters based on the applicable quality standards in Indonesia. The test parameters carried out include water content (gravimetric), NaCl content (volumetric), Na-CMC purity (gravimetric), degree of substitution (DS; volumetric), and application of produced Na-CMC for the general utilization was indicated by viscosity and pH value [16,17,18]. All treatments and analyses were performed in at least three replicates.

3 Results and discussion

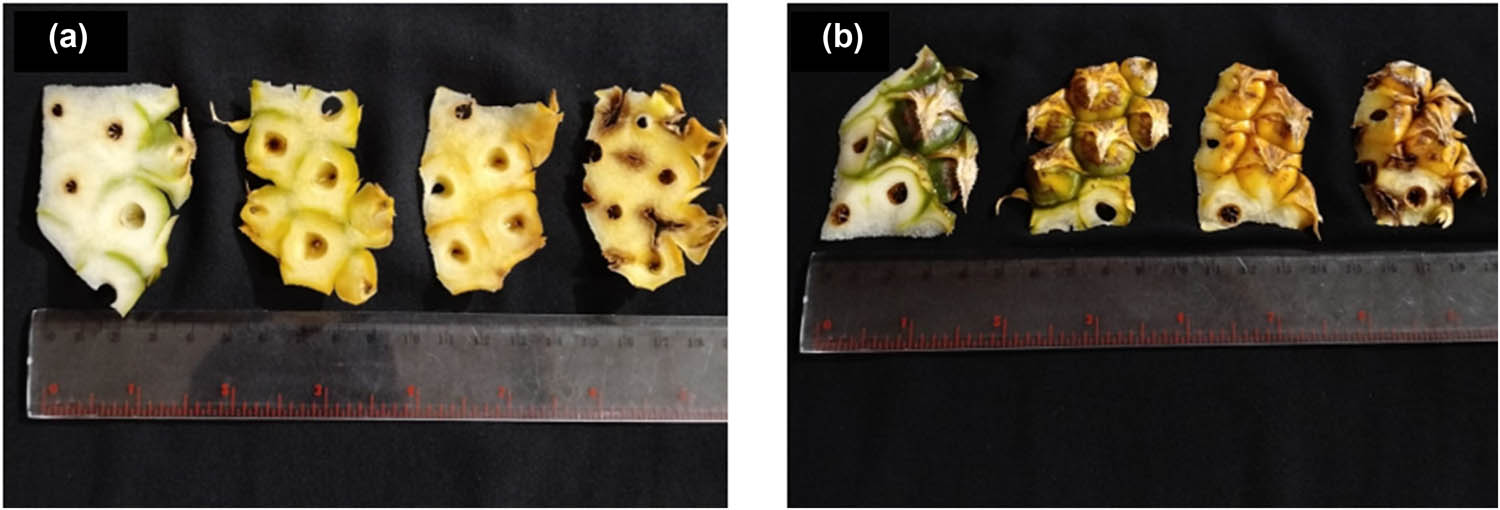

Figure 1 shows a picture of pineapple peel waste as raw material for bacterial cellulose. Figure 1a shows the physical appearance of the inner part of pineapple peel waste used in this study, whereas Figure 1b describes the outer part of the peel. It can be seen that the pineapple peel waste used was different. There were still some fresh pineapple peel wastes, while some were entirely wilted. Pineapple peel has been known to contain many components of both sugar and secondary metabolite compounds, such as vitamin C, carotenoids, flavonoids, organic acids, and other phenolic compounds [19,20,21]. The complexity of these components will affect the physical condition of pineapple peel if stored for a long time. The most dominant browning process occurs along with the wilting that occurs. Pineapple is a plant that has a short shelf life due to its high respiration rate [22]. The high respiration rate induces the wilting process faster [23], which will impact the formation of cellulose in the further process.

The appearance of pineapple waste as the source of nata de pina.

The un-uniformity of pineapple peel condition could affect the bacterial cellulose formed. Indirectly, this condition will also affect the quality of the Na-CMC produced. Although there have been many studies discussing the process of producing bacterial cellulose from pineapple peel waste, till date, there has been no study discussing the effect of wilted pineapple peel waste on the quality of bacterial cellulose produced. This study is expected to provide a little knowledge related to this basic thinking.

Figure 2 illustrates Na-CMC produced from pineapple peel waste with five NaOH treatments. From the visible appearance, it can be seen that the Na-CMC powder produced from pineapple peel waste under different NaOH concentrations is almost similar. The results of this study are similar to the previous studies that have stated that the effect of NaOH concentration does not significantly affect the physical characteristics of Na-CMC made from bacterial cellulose made from coconut water [9]. The Na-CMC creation process is proceeding well, as evidenced by the white hue of the product. Pure cellulose, which was also white, was the raw material required to produce Na-CMC; hence, a white product will likewise be produced when cellulose and SMCA are mixed in an alkaline environment to produce Na-CMC. Based on these results, chemical observations need to be carried out to see the effect of NaOH concentration on the characteristics of the Na-CMC formed. The characteristics of Na-CMC produced, which this study focused on, are the appearance, purity, and DS. This is because, these are the minimum quality requirements that must be met based on the provisions in Indonesia.

The appearance of produced Na-CMC from nata de pina under various NaOH concentrations.

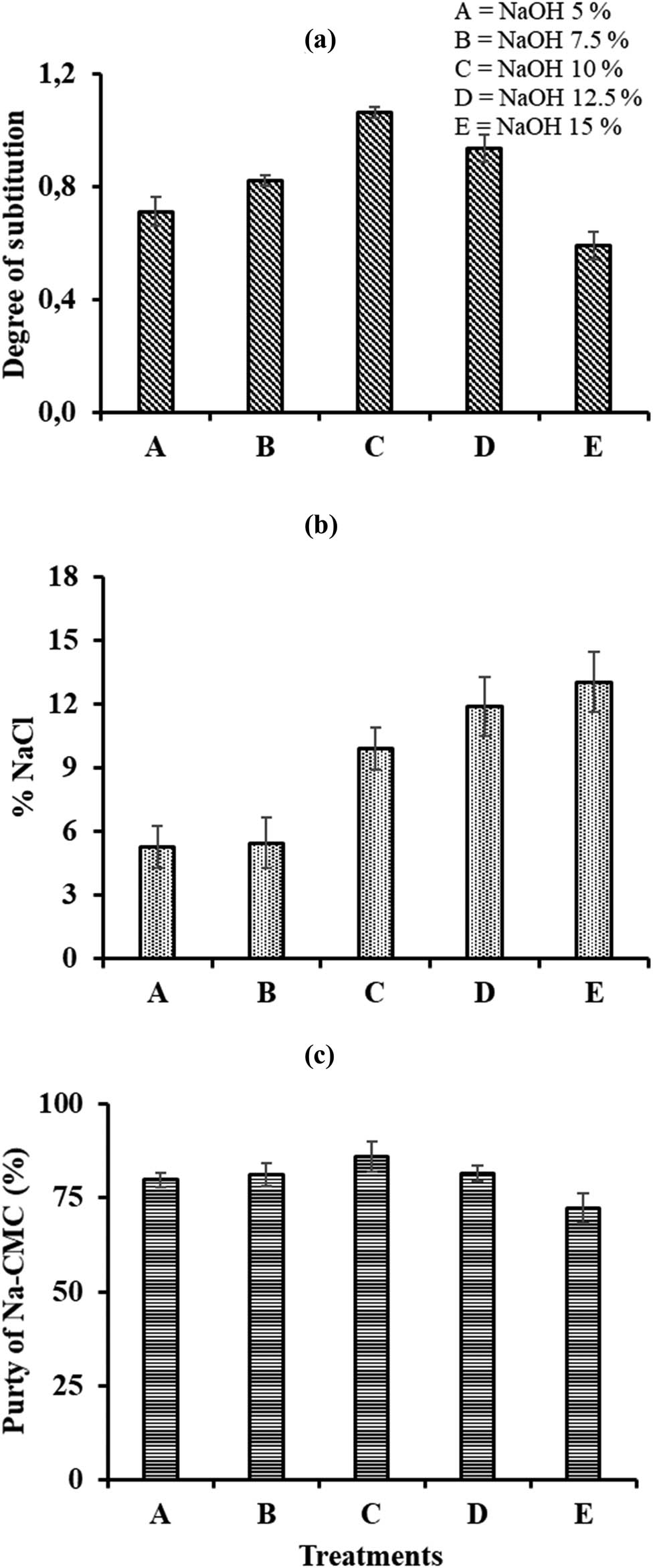

Figure 3 shows the chemical characteristics of Na-CMC from pineapple peel waste with various NaOH concentrations. Figure 3a shows the DS value of each Na-CMC produced. The DS is the average substitution value per anhydroglucose unit of the cellulose molecule. Generally, good-quality cellulose has a DS value close to 1 [24], which means that one anhydroglucose group has been substituted by ten carboxyl groups of SMCA. Na-CMC, with a DS of 0.7, or an average of seven carboxymethyl groups per ten anhydroglucose units, is the most frequently used type. Because it is easier for adjacent chains to form hydrogen bonds, higher DS values offer improved compatibility with other dissolved components, including salts and non-solvents. The more quicker the CMC dissolves, the more substitution of anhydroglucose group has occured [25]. The DS value shows an optimum point at a NaOH concentration of 10% (C). The DS decreases at a NaOH concentration greater than 10% due to excess alkali conditions that can disrupt the reaction conditions. Several studies have linked the formation of NaCl by-products when the DS value decreases [26,27]. Figure 3b shows the NaCl content formed in the Na-CMC production process with various NaOH concentrations. Figure 3b shows that the NaCl concentration was relatively similar in treatments C, D, and E. Adding more than 10% NaOH can reduce the DS because it can develop cellulose maximally and make the remaining NaOH react with SMCA to form sodium glycolate and NaCl chloride, decreasing the DS. So, the data in Figure 3a and b shows the synchronicity of the reactions that occur to obtain optimum Na-CMC according to high purity.

Basic chemical characteristic of Na-CMC produced from the waste of pineapple peel with various NaOH concentrations. (a) Degree of substitution, (b) NaCl content and (c) purity of Na-CMC).

Figure 3c shows the purity of the Na-CMC produced in this study. Na-CMC’s purity was analyzed using gravimetric analysis techniques where Na-CMC was dissolved in methanol, and the insoluble fraction was calculated as Na-CMC. The purity of Na-CMC is directly proportional to the value of the DS, where treatment C gives the highest purity value of 87%. Surprisingly, the results obtained in this study, where the highest purity of the Na-CMC formed was only 87%. Na-CMC with a content of <90% can only be grouped in the technical grade group [28]. Of course, this makes the resulting Na-CMC unusable for food applications. Hypothetically, this condition will likely occur because of the raw materials used. It has been previously informed that the raw material of pineapple peel waste used in this study was different because it was obtained from community businesses. The condition of pineapple peel waste is not uniform, which means its content was also not uniform, so the cellulose produced is likely not of good quality. This condition may be the reason why the Na-CMC produced cannot achieve high purity.

Moreover, the purification process of cellulose also affects the characteristics of the Na-CMC produced. Several studies have reported that Na-CMC manufacture has been carried out using microcrystalline cellulose [29,30]. Therefore, in the future, pineapple peel cellulose could be converted to microcrystalline form before reacting with SMCA, as the cellulose’s surface area may influence the interaction that forms CMC.

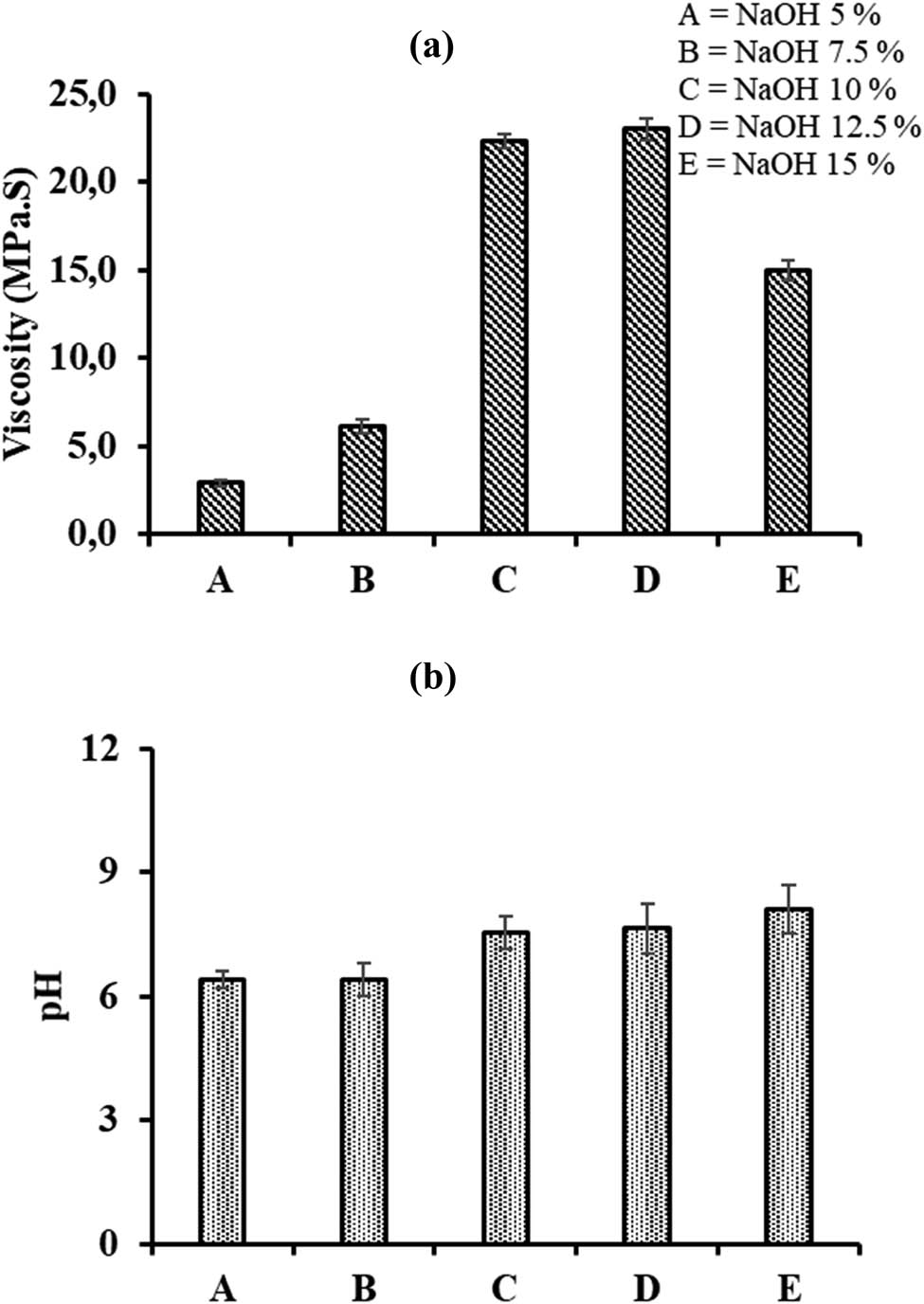

In general, CMC will be used as a thickening agent. Therefore, the application of this study is to dissolve Na-CMC in water and observe the thickening effect and its effect on pH value. In this study, observations were made on a CMC solution with a concentration of 1%. Figure 4 shows the results of experiments related to applying Na-CMC when used later. According to the purity value of Na-CMC that has been produced, Na-CMC with high purity can increase the viscosity value of the solution significantly (Figure 4a). The higher the CMC content, the greater the formation of cross-links and the higher the immobilization of solvent molecules, causing a tendency for viscosity to increase [31]. The opposite was observed for the pH parameter. It can be seen in Figure 4b that when Na-CMC is dissolved in water, the pH of the solution is not significantly affected. Due to the neutral basic pH of CMC, the presence of Na-CMC in a system will only affect the viscosity process but not the pH value. Furthermore, it can be seen from Figure 4b that there is no difference in pH values. This result also indicated that the Na-CMC produced is free from by-products such as NaCl or NaOH contaminants.

Application of Na-CMC produced from the waste of pineapple peel with various NaOH concentrations on (a) viscosity and (b) pH value of treated solution (1% of Na-CMC in water).

In this study, the utilization of pineapple peel waste as a raw material for cellulose that can be processed into Na-CMC has been successfully carried out. The quality of the Na-CMC produced could not reach high purity, so it could not be used for food industry purposes. In general, Na-CMC is widely used as a food thickener. With a purity that is not too high, the use of Na-CMC from pineapple peel waste from this study can still be used for other purposes, such as a thickener in non-food products such as paint and other semi-solid products. Therefore, the potential of the products produced from this study can be further refined in further research.

4 Conclusion

Na-CMC production from pineapple peel waste has been carried out using various NaOH concentration treatments. The NaOH concentration of 10% is the best treatment in this study. Na-CMC produced from this study had quite good characteristics with a purity of around 87% and a DS value approaching 1. Although the purity level of Na-CMC produced in this study is still in the category of technical materials, the use of Na-CMC as a thickener can be done well from the simulation results that have been carried out. Therefore, this study can be a basis for further research to improve the quality of Na-CMC produced from pineapple peel waste cellulose in the future.

Acknowledgements

Thank you to the Institute for Research and Community Service of Universitas Negeri Padang for supporting the research.

-

Funding information: This research is part of the Indonesian collaborative research program (RKI [MITRA-A]) with funding support from LPPM Universitas Negeri Padang with contract number: 1160/UN35.15/LT/2024.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewed all the results and approved the final version of the manuscript. AF: funding responsibility and wrote the manuscript; AA: administration; HS: conceptualization; IS: conducted the experiment; OPU: conducted the experiment; Kasmita: formal analysis; MM: data validation; DS: conceptualization and wrote the manuscript.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: On request, the authors will provide the data that underpin the study’s findings.

References

[1] Nath P, Ojha A, Debnath S, Neetu K, Bardhan S, Mitra P, et al. Recent advances in valorization of pineapple (Ananas comosus) processing waste and by-products: A step towards circular bioeconomy. Trends Food Sci Technol. 2023;136:100–11. 10.1016/j.tifs.2023.04.008.Suche in Google Scholar

[2] Sarangi P, Srivastava R, Sahoo U, Singh A, Parikh J, Bansod S, et al. Biotechnological innovations in nanocellulose production from waste biomass with a focus on pineapple waste. Chemosphere. 2024;349:140833. 10.1016/j.chemosphere.2023.140833. Full article link: https://authors.elsevier.com/c/1iFXJ_12RqCyd-.Suche in Google Scholar PubMed

[3] Panchan N, Wattanapan P, Sungsinchai S, Roddecha S, Dittanet P, Seubsai A, et al. Optimization of synthesis conditions for carboxymethyl cellulose from pineapple leaf waste using microwave-assisted heating and its application as a food thickener. BioResources. 2021;16:7684–701. 10.15376/16.4.7684-7701.Suche in Google Scholar

[4] Owoeye T, Kehinde A, Ajayi OO, Afolalu A, Popoola J, Ajani O. Phytochemical constituents and proximate analysis of dry pineapple peels. IOP Conf Ser: Earth Environ Sci. 2022;993:012027. 10.1088/1755-1315/993/1/012027.Suche in Google Scholar

[5] Aili Hamzah AF, Hamzah MH, Che Man H, Jamali NS, Siajam SI, Ismail MH. Recent updates on the conversion of pineapple waste (Ananas comosus) to value-added products, future perspectives and challenges. Agronomy. 2021;11(11):2221. 10.3390/agronomy11112221.Suche in Google Scholar

[6] Suryanto H, Kurniawan F, Syukri D, Binoj JS, Hari PD, Yanuhar U. Properties of bacterial cellulose acetate nanocomposite with TiO2 nanoparticle and graphene reinforcement. Int J Biol Macromol. 2023;235:123705. 10.1016/j.ijbiomac.2023.123705. Epub 2023 Feb 16. PMID: 36801305.Suche in Google Scholar PubMed

[7] Syukri D, Suryanto H, Kurniawan F, Hari PD, Fiana RM, Rini. Bacterial reduction in river water using nanocellulose membrane from pineapple biomass with ferrous-ferric oxide reinforcement. Glob J Environ Sci Manag. 2024;10(2):643–56. 10.22034/gjesm.2024.02.14.Suche in Google Scholar

[8] Wahyuni HS, Yuliasmi S, Aisyah HS, Riati D. Characterization of synthesized sodium carboxymethyl cellulose with variation of solvent mixture and alkali concentration. Open Access Maced J Med Sci. 2019 Nov;7(22):3878–81. 10.3889/oamjms.2019.524. PMID: 32127996; PMCID: PMC7048337.Suche in Google Scholar PubMed PubMed Central

[9] Rachtanapun P, Jantrawut P, Klunklin W, Jantanasakulwong K, Phimolsiripol Y, Leksawasdi N, et al. Carboxymethyl bacterial cellulose from nata de Coco: Effects of NaOH. Polymers (Basel). 2021;13(3):348. 10.3390/polym13030348. PMID: 33499064; PMCID: PMC7865890.Suche in Google Scholar PubMed PubMed Central

[10] Yuliasmi S, Ginting N, Wahyuni HS, Sigalingging RT, Sibarani T. The effect of alkalization on carboxymethyl cellulose synthesis from stem and peel cellulose of banana. Open Access Maced J Med Sci. 2019;7(22):3874–7. 10.3889/oamjms.2019.523. PMID: 32127995; PMCID: PMC7048354.Suche in Google Scholar PubMed PubMed Central

[11] Sayanjali S, Lu Y, Howell K. Extraction and characterization of cellulose from broccoli stems as a new biopolymer source for producing carboxymethyl cellulose films. Int J Food Sci. 2024;2024:7661288. 10.1155/2024/7661288. PMID: 38680866; PMCID: PMC11052598.Suche in Google Scholar PubMed PubMed Central

[12] Mazween MM, Lau K, Hassan F, Mohammad J, Zoheb K, Naheed S. Synthesis and characterization of carboxymethyl cellulose from pineapple leaf and kenaf core biomass: a comparative study of new raw materials. Biomass Convers Biorefin. 2024;14:14653–63. 10.1007/s13399-022-03700-w.Suche in Google Scholar

[13] Suryanto H, Kurniawan F, Syukri D. Characteristics of cellulose acetate from bacterial cellulose made of pineapple waste. AIP Conf Proc. 2024;2991(1):040033.10.1063/5.0198560Suche in Google Scholar

[14] Rini, Suryanto H, Hari PD, Syukri D, Jaswandi, Kurniawan F, et al. Application of nanocellulose biofilter from pineapple peel waste for water microbes removal. J Environ Public Health. 2023;2023:5823207. 10.1155/2023/5823207. PMID: 36747499; PMCID: PMC9899142.Suche in Google Scholar PubMed PubMed Central

[15] Syukri D, Suryanto H, Faridah A, Refdi CW, Diliarosta S, Rini, et al. Fabrication of carboxymethyl cellulose (CMC) derived from themeda gigantea cellulose with various concentrations of sodium monochloroacetate. OnLine J Biol Sci. 2025;25(1):104–14. 10.3844/ojbsci.2025.104.114.Suche in Google Scholar

[16] Suryadi H, Sutriyo, Fauziah G. Characterization sodium carboxymethyl cellulose from alpha cellulose betung bamboo (Dendrocalamus asper). Pharmacogn J. 2019;11(5):894–900.10.5530/pj.2019.11.143Suche in Google Scholar

[17] Klunklin W, Jantanasakulwong K, Phimolsiripol Y, Leksawasdi N, Seesuriyachan P, Chaiyaso T, et al. Synthesis, characterization, and application of carboxymethyl cellulose from asparagus stalk end. Polymers (Basel). 2020;13(1):81. 10.3390/polym13010081. PMID: 33379203; PMCID: PMC7795991.Suche in Google Scholar PubMed PubMed Central

[18] Khamidov G, Hazman Ö, Erol I. Thermal and biological properties of novel sodium carboxymethylcellulose-PPFMA nanocomposites containing biosynthesized Ag-ZnO hybrid filler. Int J Biol Macromol. 2024;257(Pt 1):128447. 10.1016/j.ijbiomac.2023.128447. Epub 2023 Nov 30. Erratum in: Int J Biol Macromol. 2024 Jun;269(Pt 2):132180. doi: 10.1016/j.ijbiomac.2024.132180. PMID: 38040162.Suche in Google Scholar PubMed

[19] Fouda-Mbanga BG, Tywabi-Ngeva Z. Application of pineapple waste to the removal of toxic contaminants: A review. Toxics. 2022;10(10):561. 10.3390/toxics10100561. PMID: 36287842; PMCID: PMC9610545.Suche in Google Scholar PubMed PubMed Central

[20] Meena L, Sengar AS, Neog R, Sunil CK. Pineapple processing waste (PPW): Bioactive compounds, their extraction, and utilisation: A review. J Food Sci Technol. 2022;59(11):4152–64. 10.1007/s13197-021-05271-6. Epub 2021 Oct 8. PMID: 36193474; PMCID: PMC9525513.Suche in Google Scholar PubMed PubMed Central

[21] Awasthi MK, Azelee NIW, Ramli ANM, Rashid SA, Manas NHA, Dailin DJ, et al. Microbial biotechnology approaches for conversion of pineapple waste in to emerging source of healthy food for sustainable environment. Int J Food Microbiol. 2022;373:109714. 10.1016/j.ijfoodmicro.2022.109714. Epub 2022 May 7. PMID: 35567891.Suche in Google Scholar PubMed

[22] Leneveu-Jenvrin C, Quentin B, Assemat S, Hoarau M, Meile JC, Remize F. Changes of quality of minimally-processed pineapple (Ananas comosus, var. ‘Queen Victoria’) during cold storage: Fungi in the leading role. Microorganisms. 2020;8(2):185. 10.3390/microorganisms8020185. PMID: 32012867; PMCID: PMC7074791.Suche in Google Scholar PubMed PubMed Central

[23] Syukri D, Thammawong M, Naznin HA, Nakano K. Role of raffinose family oligosaccharides in respiratory metabolism during soybean seed germination. Environ Control Biol. 2019;57:107–12.10.2525/ecb.57.107Suche in Google Scholar

[24] Liu S-F, Zhu K-X, Guo X-N. The effect of carboxymethyl cellulose sodium on the proofing tolerance and quality of frozen dough steamed bread. Foods. 2024;13(6):870. 10.3390/foods13060870.Suche in Google Scholar PubMed PubMed Central

[25] Frei-Rutishauser B, Christian M, Gernot W, Watson T. Factors affecting sterile filtration of sodium-carboxymethylcellulose-based solutions. BioProcess Int. 2016;14.Suche in Google Scholar

[26] Churam T, Usubharatana P, Phungrassami H. Sustainable production of carboxymethyl cellulose: A biopolymer alternative from sugarcane (Saccharum officinarum L.) leaves. Sustainability. 2024;16(6):2352. 10.3390/su16062352.Suche in Google Scholar

[27] Nanda RF, Kasim A, Rini, Syukri D, Rahmi ID, Koja R, et al. Effect of storage duration of pineapple on the quality of the bromelain produced. J Glob Innov Agric Sci. 2024;12.Suche in Google Scholar

[28] Mondal MI, Yeasmin MS, Rahman MS. Preparation of food grade carboxymethyl cellulose from corn husk agrowaste. Int J Biol Macromol. 2015;79:144–50. 10.1016/j.ijbiomac.2015.04.061. Epub 2015 May 1. PMID: 25936282.Suche in Google Scholar PubMed

[29] Gibis M, Valerie S, Jochen W. Effects of carboxymethyl cellulose (CMC) and microcrystalline cellulose (MCC) as fat replacers on the microstructure and sensory characteristics of fried beef patties. Food Hydrocoll. 2015;45:236–46. 10.1016/j.foodhyd.2014.11.021.Suche in Google Scholar

[30] Fouad H, Mohammad J, Zoheb K, Aatikah M, Basim A, Mohamed N, et al. Preparation and characterization of carboxymethyl microcrystalline cellulose from pineapple leaf fibre. Sci Rep. 2024;14:23286. 10.1038/s41598-024-73860-4.Suche in Google Scholar PubMed PubMed Central

[31] Wagner P, Różańska S, Warmbier E, Frankiewicz A, Różański J. Rheological properties of sodium carboxymethylcellulose solutions in dihydroxy alcohol/water mixtures. Materials (Basel). 2023;16(1):418. 10.3390/ma16010418. PMID: 36614757; PMCID: PMC9822266.Suche in Google Scholar PubMed PubMed Central

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Optimization of sustainable corn–cattle integration in Gorontalo Province using goal programming

- Competitiveness of Indonesia’s nutmeg in global market

- Toward sustainable bioproducts from lignocellulosic biomass: Influence of chemical pretreatments on liquefied walnut shells

- Efficacy of Betaproteobacteria-based insecticides for managing whitefly, Bemisia tabaci (Hemiptera: Aleyrodidae), on cucumber plants

- Assessment of nutrition status of pineapple plants during ratoon season using diagnosis and recommendation integrated system

- Nutritional value and consumer assessment of 12 avocado crosses between cvs. Hass × Pionero

- The lacked access to beef in the low-income region: An evidence from the eastern part of Indonesia

- Comparison of milk consumption habits across two European countries: Pilot study in Portugal and France

- Antioxidant responses of black glutinous rice to drought and salinity stresses at different growth stages

- Differential efficacy of salicylic acid-induced resistance against bacterial blight caused by Xanthomonas oryzae pv. oryzae in rice genotypes

- Yield and vegetation index of different maize varieties and nitrogen doses under normal irrigation

- Urbanization and forecast possibilities of land use changes by 2050: New evidence in Ho Chi Minh city, Vietnam

- Organizational-economic efficiency of raspberry farming – case study of Kosovo

- Application of nitrogen-fixing purple non-sulfur bacteria in improving nitrogen uptake, growth, and yield of rice grown on extremely saline soil under greenhouse conditions

- Digital motivation, knowledge, and skills: Pathways to adaptive millennial farmers

- Investigation of biological characteristics of fruit development and physiological disorders of Musang King durian (Durio zibethinus Murr.)

- Enhancing rice yield and farmer welfare: Overcoming barriers to IPB 3S rice adoption in Indonesia

- Simulation model to realize soybean self-sufficiency and food security in Indonesia: A system dynamic approach

- Gender, empowerment, and rural sustainable development: A case study of crab business integration

- Metagenomic and metabolomic analyses of bacterial communities in short mackerel (Rastrelliger brachysoma) under storage conditions and inoculation of the histamine-producing bacterium

- Fostering women’s engagement in good agricultural practices within oil palm smallholdings: Evaluating the role of partnerships

- Increasing nitrogen use efficiency by reducing ammonia and nitrate losses from tomato production in Kabul, Afghanistan

- Physiological activities and yield of yacon potato are affected by soil water availability

- Vulnerability context due to COVID-19 and El Nino: Case study of poultry farming in South Sulawesi, Indonesia

- Wheat freshness recognition leveraging Gramian angular field and attention-augmented resnet

- Suggestions for promoting SOC storage within the carbon farming framework: Analyzing the INFOSOLO database

- Optimization of hot foam applications for thermal weed control in perennial crops and open-field vegetables

- Toxicity evaluation of metsulfuron-methyl, nicosulfuron, and methoxyfenozide as pesticides in Indonesia

- Fermentation parameters and nutritional value of silages from fodder mallow (Malva verticillata L.), white sweet clover (Melilotus albus Medik.), and their mixtures

- Five models and ten predictors for energy costs on farms in the European Union

- Effect of silvopastoral systems with integrated forest species from the Peruvian tropics on the soil chemical properties

- Transforming food systems in Semarang City, Indonesia: A short food supply chain model

- Understanding farmers’ behavior toward risk management practices and financial access: Evidence from chili farms in West Java, Indonesia

- Optimization of mixed botanical insecticides from Azadirachta indica and Calophyllum soulattri against Spodoptera frugiperda using response surface methodology

- Mapping socio-economic vulnerability and conflict in oil palm cultivation: A case study from West Papua, Indonesia

- Exploring rice consumption patterns and carbohydrate source diversification among the Indonesian community in Hungary

- Determinants of rice consumer lexicographic preferences in South Sulawesi Province, Indonesia

- Effect on growth and meat quality of weaned piglets and finishing pigs when hops (Humulus lupulus) are added to their rations

- Healthy motivations for food consumption in 16 countries

- The agriculture specialization through the lens of PESTLE analysis

- Combined application of chitosan-boron and chitosan-silicon nano-fertilizers with soybean protein hydrolysate to enhance rice growth and yield

- Stability and adaptability analyses to identify suitable high-yielding maize hybrids using PBSTAT-GE

- Phosphate-solubilizing bacteria-mediated rock phosphate utilization with poultry manure enhances soil nutrient dynamics and maize growth in semi-arid soil

- Factors impacting on purchasing decision of organic food in developing countries: A systematic review

- Influence of flowering plants in maize crop on the interaction network of Tetragonula laeviceps colonies

- Bacillus subtilis 34 and water-retaining polymer reduce Meloidogyne javanica damage in tomato plants under water stress

- Vachellia tortilis leaf meal improves antioxidant activity and colour stability of broiler meat

- Evaluating the competitiveness of leading coffee-producing nations: A comparative advantage analysis across coffee product categories

- Application of Lactiplantibacillus plantarum LP5 in vacuum-packaged cooked ham as a bioprotective culture

- Evaluation of tomato hybrid lines adapted to lowland

- South African commercial livestock farmers’ adaptation and coping strategies for agricultural drought

- Spatial analysis of desertification-sensitive areas in arid conditions based on modified MEDALUS approach and geospatial techniques

- Meta-analysis of the effect garlic (Allium sativum) on productive performance, egg quality, and lipid profiles in laying quails

- Optimizing carrageenan–citric acid synergy in mango gummies using response surface methodology

- The strategic role of agricultural vocational training in sustainable local food systems

- Agricultural planning grounded in regional rainfall patterns in the Colombian Orinoquia: An essential step for advancing climate-adapted and sustainable agriculture

- Perspectives of master’s graduates on organic agriculture: A Portuguese case study

- Developing a behavioral model to predict eco-friendly packaging use among millennials

- Government support during COVID-19 for vulnerable households in Central Vietnam

- Citric acid–modified coconut shell biochar mitigates saline–alkaline stress in Solanum lycopersicum L. by modulating enzyme activity in the plant and soil

- Herbal extracts: For green control of citrus Huanglongbing

- Research on the impact of insurance policies on the welfare effects of pork producers and consumers: Evidence from China

- Investigating the susceptibility and resistance barley (Hordeum vulgare L.) cultivars against the Russian wheat aphid (Diuraphis noxia)

- Characterization of promising enterobacterial strains for silver nanoparticle synthesis and enhancement of product yields under optimal conditions

- Testing thawed rumen fluid to assess in vitro degradability and its link to phytochemical and fibre contents in selected herbs and spices

- Protein and iron enrichment on functional chicken sausage using plant-based natural resources

- Fruit and vegetable intake among Nigerian University students: patterns, preferences, and influencing factors

- Bioprospecting a plant growth-promoting and biocontrol bacterium isolated from wheat (Triticum turgidum subsp. durum) in the Yaqui Valley, Mexico: Paenibacillus sp. strain TSM33

- Quantifying urban expansion and agricultural land conversion using spatial indices: evidence from the Red River Delta, Vietnam

- LEADER approach and sustainability overview in European countries

- Influence of visible light wavelengths on bioactive compounds and GABA contents in barley sprouts

- Assessing Albania’s readiness for the European Union-aligned organic agriculture expansion: a mixed-methods SWOT analysis integrating policy, market, and farmer perspectives

- Genetically modified foods’ questionable contribution to food security: exploring South African consumers’ knowledge and familiarity

- The role of global actors in the sustainability of upstream–downstream integration in the silk agribusiness

- Multidimensional sustainability assessment of smallholder dairy cattle farming systems post-foot and mouth disease outbreak in East Java, Indonesia: a Rapdairy approach

- Enhancing azoxystrobin efficacy against Pythium aphanidermatum rot using agricultural adjuvants

- Review Articles

- Reference dietary patterns in Portugal: Mediterranean diet vs Atlantic diet

- Evaluating the nutritional, therapeutic, and economic potential of Tetragonia decumbens Mill.: A promising wild leafy vegetable for bio-saline agriculture in South Africa

- A review on apple cultivation in Morocco: Current situation and future prospects

- Quercus acorns as a component of human dietary patterns

- CRISPR/Cas-based detection systems – emerging tools for plant pathology

- Short Communications

- An analysis of consumer behavior regarding green product purchases in Semarang, Indonesia: The use of SEM-PLS and the AIDA model

- Effect of NaOH concentration on production of Na-CMC derived from pineapple waste collected from local society

Artikel in diesem Heft

- Research Articles

- Optimization of sustainable corn–cattle integration in Gorontalo Province using goal programming

- Competitiveness of Indonesia’s nutmeg in global market

- Toward sustainable bioproducts from lignocellulosic biomass: Influence of chemical pretreatments on liquefied walnut shells

- Efficacy of Betaproteobacteria-based insecticides for managing whitefly, Bemisia tabaci (Hemiptera: Aleyrodidae), on cucumber plants

- Assessment of nutrition status of pineapple plants during ratoon season using diagnosis and recommendation integrated system

- Nutritional value and consumer assessment of 12 avocado crosses between cvs. Hass × Pionero

- The lacked access to beef in the low-income region: An evidence from the eastern part of Indonesia

- Comparison of milk consumption habits across two European countries: Pilot study in Portugal and France

- Antioxidant responses of black glutinous rice to drought and salinity stresses at different growth stages

- Differential efficacy of salicylic acid-induced resistance against bacterial blight caused by Xanthomonas oryzae pv. oryzae in rice genotypes

- Yield and vegetation index of different maize varieties and nitrogen doses under normal irrigation

- Urbanization and forecast possibilities of land use changes by 2050: New evidence in Ho Chi Minh city, Vietnam

- Organizational-economic efficiency of raspberry farming – case study of Kosovo

- Application of nitrogen-fixing purple non-sulfur bacteria in improving nitrogen uptake, growth, and yield of rice grown on extremely saline soil under greenhouse conditions

- Digital motivation, knowledge, and skills: Pathways to adaptive millennial farmers

- Investigation of biological characteristics of fruit development and physiological disorders of Musang King durian (Durio zibethinus Murr.)

- Enhancing rice yield and farmer welfare: Overcoming barriers to IPB 3S rice adoption in Indonesia

- Simulation model to realize soybean self-sufficiency and food security in Indonesia: A system dynamic approach

- Gender, empowerment, and rural sustainable development: A case study of crab business integration

- Metagenomic and metabolomic analyses of bacterial communities in short mackerel (Rastrelliger brachysoma) under storage conditions and inoculation of the histamine-producing bacterium

- Fostering women’s engagement in good agricultural practices within oil palm smallholdings: Evaluating the role of partnerships

- Increasing nitrogen use efficiency by reducing ammonia and nitrate losses from tomato production in Kabul, Afghanistan

- Physiological activities and yield of yacon potato are affected by soil water availability

- Vulnerability context due to COVID-19 and El Nino: Case study of poultry farming in South Sulawesi, Indonesia

- Wheat freshness recognition leveraging Gramian angular field and attention-augmented resnet

- Suggestions for promoting SOC storage within the carbon farming framework: Analyzing the INFOSOLO database

- Optimization of hot foam applications for thermal weed control in perennial crops and open-field vegetables

- Toxicity evaluation of metsulfuron-methyl, nicosulfuron, and methoxyfenozide as pesticides in Indonesia

- Fermentation parameters and nutritional value of silages from fodder mallow (Malva verticillata L.), white sweet clover (Melilotus albus Medik.), and their mixtures

- Five models and ten predictors for energy costs on farms in the European Union

- Effect of silvopastoral systems with integrated forest species from the Peruvian tropics on the soil chemical properties

- Transforming food systems in Semarang City, Indonesia: A short food supply chain model

- Understanding farmers’ behavior toward risk management practices and financial access: Evidence from chili farms in West Java, Indonesia

- Optimization of mixed botanical insecticides from Azadirachta indica and Calophyllum soulattri against Spodoptera frugiperda using response surface methodology

- Mapping socio-economic vulnerability and conflict in oil palm cultivation: A case study from West Papua, Indonesia

- Exploring rice consumption patterns and carbohydrate source diversification among the Indonesian community in Hungary

- Determinants of rice consumer lexicographic preferences in South Sulawesi Province, Indonesia

- Effect on growth and meat quality of weaned piglets and finishing pigs when hops (Humulus lupulus) are added to their rations

- Healthy motivations for food consumption in 16 countries

- The agriculture specialization through the lens of PESTLE analysis

- Combined application of chitosan-boron and chitosan-silicon nano-fertilizers with soybean protein hydrolysate to enhance rice growth and yield

- Stability and adaptability analyses to identify suitable high-yielding maize hybrids using PBSTAT-GE

- Phosphate-solubilizing bacteria-mediated rock phosphate utilization with poultry manure enhances soil nutrient dynamics and maize growth in semi-arid soil

- Factors impacting on purchasing decision of organic food in developing countries: A systematic review

- Influence of flowering plants in maize crop on the interaction network of Tetragonula laeviceps colonies

- Bacillus subtilis 34 and water-retaining polymer reduce Meloidogyne javanica damage in tomato plants under water stress

- Vachellia tortilis leaf meal improves antioxidant activity and colour stability of broiler meat

- Evaluating the competitiveness of leading coffee-producing nations: A comparative advantage analysis across coffee product categories

- Application of Lactiplantibacillus plantarum LP5 in vacuum-packaged cooked ham as a bioprotective culture

- Evaluation of tomato hybrid lines adapted to lowland

- South African commercial livestock farmers’ adaptation and coping strategies for agricultural drought

- Spatial analysis of desertification-sensitive areas in arid conditions based on modified MEDALUS approach and geospatial techniques

- Meta-analysis of the effect garlic (Allium sativum) on productive performance, egg quality, and lipid profiles in laying quails

- Optimizing carrageenan–citric acid synergy in mango gummies using response surface methodology

- The strategic role of agricultural vocational training in sustainable local food systems

- Agricultural planning grounded in regional rainfall patterns in the Colombian Orinoquia: An essential step for advancing climate-adapted and sustainable agriculture

- Perspectives of master’s graduates on organic agriculture: A Portuguese case study

- Developing a behavioral model to predict eco-friendly packaging use among millennials

- Government support during COVID-19 for vulnerable households in Central Vietnam

- Citric acid–modified coconut shell biochar mitigates saline–alkaline stress in Solanum lycopersicum L. by modulating enzyme activity in the plant and soil

- Herbal extracts: For green control of citrus Huanglongbing

- Research on the impact of insurance policies on the welfare effects of pork producers and consumers: Evidence from China

- Investigating the susceptibility and resistance barley (Hordeum vulgare L.) cultivars against the Russian wheat aphid (Diuraphis noxia)

- Characterization of promising enterobacterial strains for silver nanoparticle synthesis and enhancement of product yields under optimal conditions

- Testing thawed rumen fluid to assess in vitro degradability and its link to phytochemical and fibre contents in selected herbs and spices

- Protein and iron enrichment on functional chicken sausage using plant-based natural resources

- Fruit and vegetable intake among Nigerian University students: patterns, preferences, and influencing factors

- Bioprospecting a plant growth-promoting and biocontrol bacterium isolated from wheat (Triticum turgidum subsp. durum) in the Yaqui Valley, Mexico: Paenibacillus sp. strain TSM33

- Quantifying urban expansion and agricultural land conversion using spatial indices: evidence from the Red River Delta, Vietnam

- LEADER approach and sustainability overview in European countries

- Influence of visible light wavelengths on bioactive compounds and GABA contents in barley sprouts

- Assessing Albania’s readiness for the European Union-aligned organic agriculture expansion: a mixed-methods SWOT analysis integrating policy, market, and farmer perspectives

- Genetically modified foods’ questionable contribution to food security: exploring South African consumers’ knowledge and familiarity

- The role of global actors in the sustainability of upstream–downstream integration in the silk agribusiness

- Multidimensional sustainability assessment of smallholder dairy cattle farming systems post-foot and mouth disease outbreak in East Java, Indonesia: a Rapdairy approach

- Enhancing azoxystrobin efficacy against Pythium aphanidermatum rot using agricultural adjuvants

- Review Articles

- Reference dietary patterns in Portugal: Mediterranean diet vs Atlantic diet

- Evaluating the nutritional, therapeutic, and economic potential of Tetragonia decumbens Mill.: A promising wild leafy vegetable for bio-saline agriculture in South Africa

- A review on apple cultivation in Morocco: Current situation and future prospects

- Quercus acorns as a component of human dietary patterns

- CRISPR/Cas-based detection systems – emerging tools for plant pathology

- Short Communications

- An analysis of consumer behavior regarding green product purchases in Semarang, Indonesia: The use of SEM-PLS and the AIDA model

- Effect of NaOH concentration on production of Na-CMC derived from pineapple waste collected from local society