Abstract

Silicon carbide (SiC) was modified by melamine polyphosphate (MPP)-modified silicone to form SiC-MPP, then incorporated into epoxy resin (EP) for developing thermally resistant composites, which showed thermal conductivity and flame retardancy performance. The EP/SiC-MPP composites were prepared by blending and cured under 60°C for 2 h and 150°C for 8 h. The grafting degree of SiC-MPP was analyzed using Fourier transform Infrared, scanning electron microscope, and thermogravimetric measurements. The flame retardancy of the EP/SiC-MPP composites was studied by UL-94 vertical combustion and cone calorimetry test. The results showed that for EP/SiC-MPP containing 20 wt%, the UL-94 was case V1. Also compared to pure epoxy, the peak heat release rate (PHRR) of composites was reduced from 800 to 304 kW·m−2. The thermal conductivity of EP/SiC-M20 composites was 0.53 W·m−1·K−1, almost 2.5-fold higher than pure epoxy (0.21 W·m−1·K−1). The as-prepared EP/SiC-MPP composites exhibited enhanced flame retardancy and thermal conductivity. Based on analyses performed, these composites took credit-related applications.

1 Introduction

Epoxy resin (EP) is a versatile thermosetting resin possessing electrical insulation, high mechanical properties, and high bonding strength. Moreover, its solvent resistance is outstanding, which was the reason why epoxy has been widely used in the preparation of electronic and electrical composites (1,2,3). On the other hand, owing to its low thermal conductivity and active chemical properties at high temperatures, the flame retardancy of EP materials is poor, which limits its application in the field of electronic packaging to a certain extent. It is very necessary and valuable to enhance the epoxy composites’ thermal conductivity and flame retardancy (4,5,6,7,8,9).

At present, EP is widely used in the field of display and lighting, such as large-scale display screens and white light lighting. At the same time, the high-speed and high-density enrichment of integrated circuit board have become more demanding for the flame retardancy and thermal conductivity of EP (10,11,12). Therefore, improving the thermal conductivity and flame retardancy of EP has practical application value and theoretical research significance. The traditional thermal conductive epoxy materials are prepared by adding one or more high thermal conductive fillers such as nanotubes, boron nitride, graphene, alumina, and silicon carbide (SiC) into the EP matrix to increase the thermal conductivity of the composites (13,14,15,16,17,18). The traditional flame-retardant EP also needs to add various flame retardants into the matrix like thermal conductive EP, to improve the flame retardancy of the composites (19,20,21,22,23). However, few researchers have studied flame retardancy and thermal conductivity at the same time.

The focus of thermally conductive materials was on the selection, compounding, and orientation of thermally conductive fillers, while the research on flame retardant also focuses on the selection, compounding, and addition of flame retardant itself (24,25). If the flame retardant is directly involved in the polymer matrix, the migration and leakage of the flame retardant will occur in varying degrees during its use, which will pollute the place where the composites are used. Meanwhile, the migration and leakage of the flame retardant will reduce the flame-retardant effect of the composites (26,27). There will be some problems when the fillers of thermal conductivity are directly added to the polymer matrix, such as the interface thermal resistance between heat conductive fillers and polymer matrix and the thermal resistance between fillers and fillers (28,29).

Properties and performance of epoxy-based composites depend largely on the crosslinking/curing behavior/kinetics (30,31). In general, a well-cured epoxy composite has a high thermal degradation resistance, along with anti-corrosion and flame retardancy performance. However, finding a relationship between network formation in terms of curing/crosslinking and with properties and performance of epoxy composites necessitates using some universal and well-established measures (32,33,34,35). More technically, the classification of epoxy composites because of curability, flame retardancy, and conductivity is a complex task, which needs experts as well as using some indices that make understanding of network formation and network degradation, besides performance characteristics such as flame retardancy and thermal and electrical conductivity (35).

This work will try to solve the above vital problems about flame retardant leakage and interface thermal resistance between thermal conductive filler and matrix based on these two aspects. In this study, SiC particles are selected, which have outstanding advantages in thermal conductivity, hardness, toughness, and wear resistance, and can be used as thermal conductive filler of the EP. In this work, the coupling agent (KH-560) was used to modify the surface of SiC particles, and the melamine polyphosphate (MPP) was used to bond and graft MPP onto the surface of SiC particles through the ring opening reaction of the epoxy group. The functional filler integrating flame retardant and thermal conductivity was designed and prepared. Then the functional particles were involved to the epoxy matrix, and the EP/SiC composites was processed and formed by blending and curing. Then, the thermal conductivity and flame retardancy of the composites were studied by adjusting the proportion of SiC in order to solve the related problems of thermal conductivity and flame retardancy.

2 Experimental

2.1 Reagents

SiC particles, with a particle size of about 50 microns, were purchased from the Weifang Kaihua SiC powder company. MPP was supplied by Shanghai Mclean Biochemical Technology Co., Ltd. Silane coupling agent (KH560) was bought from Shanghai Yuanye Biotechnology Co., Ltd. The epoxy value of bisphenol A EP was 0.51, which was purchased from the EP plant of Yueyang Petrochemical Plant. 2-Ethyl-4-methylimidazole (EMI-2,4) was purchased from shanghai Mclean Biochemical Technology Co., Ltd. N-N Dimethylformamide (DMF) was supplied from Sinopharm Chemical Reagent Co., Ltd. Absolute ethanol was supplied from Tianjin Yongda Chemical Reagent Co., Ltd.

2.2 Experimental

2.2.1 SiC modified by silane coupling agent KH560

SiC (20 g) was washed in the distilled water 2–3 times and then washed in absolute ethanol once. After suction filtration, SiC particles were obtained. The washed SiC was involved in a certain amount of ethanol solution containing 10 wt% KH560, heated at 45°C via water bath and stirred magnetically for 8 h, filtered after the reaction, washed the filter cake alternately and repeatedly with ethanol and distilled water for three times, and freeze-dried the filter cake for 24 h to obtain KH560-modified SiC particles (SiC-KH560).

2.2.2 MPP-modified SiC-KH560 particles

SiC-KH560 (10 g) particles were involved in DMF solution containing 15 wt% MPP and heated in an oil bath at 85°C and stirred by magnetic force for 24 h. The mixed solution was filtered using suction, and the filter cake was washed in DMF thrice. Finally, the washing product was freeze-dried for 24 h to obtain the SiC particles modified with MPP (SiC-KH560-MPP), it was abbreviated as SiC-M.

2.2.3 Preparation of EP/SiC-M composites

SiC-M was involved in the ethanol, and after ultrasonic dispersion and magnetic stirring for half an hour, EP was added to the solution. After ultrasonic stirring for half an hour, the temperature was raised to 60°C, and the ethanol was removed by vacuum distillation under the condition of magnetic stirring. The complete volatilization of ethanol in the system was determined using constant weight method. After cooling to room temperature in an ice water bath, the curing agent EMI-2,4 according to 6 wt% of the mass of EP was added to the mixture. After stirring and mixing evenly, vacuuming, and defoaming in a 40°C vacuum-drying oven, this process was repeated three times. Finally, the resin mixing system was poured into the stainless-steel mold coated with vacuum silicone grease and cured at 60°C for 2 h and at 150°C for 8 h. EP and EP/SiC-M composites (EP/SiC-M) were also prepared according to this process. The filling amount of SiC-M in the composite EP/SiC-M was 3 wt%, 10 wt%, and 20 wt% of the total mass of the composite, respectively; the corresponding composites were abbreviated as EP/SiC-M3, EP/SiC-M10, and EP/SiC-M20.

2.3 Characterization

The infrared (IR) spectrum analysis was carried out on the tensor 37 Fourier transform IR spectrum of Bruker company in Germany. The test was carried out after the mixture of the substance was tested and KBr was pressed. The scanning range of the spectrum was 400–4,000 cm−1. The synchronous thermal analysis test was carried out on the Q600 thermogravimetric analyzer of TA company in the United States. In the nitrogen atmosphere, the temperature range was 30–800℃, and the heating rate was 10°C·min−1. The sample morphology was observed using SU8010 field emission scanning electron microscope (FE-SEM Hitachi high-tech company of Japan), and the scanning voltage was 1.0 kV. The powder sample was pasted on the sample table with conductive adhesive, and the block sample was wrapped on the special sample loading table with conductive adhesive and then tested to observe its micro-morphology. Based on GB/T 2408-2008 standard, a UL94-x horizontal and vertical combustion tester (MODIS China Combustion Technology Co., Ltd.) was used to determine the combustion grade of the sample, and the sample size was 127 mm × 12.7 mm × 2.7 mm. Based on the GB/T 2406-2009 standard, the HC-2C oxygen index tester of Nanjing Shangyuan Analytical Instrument Co., Ltd. was used to determine the limiting oxygen index of the sample. The sample size was 100 mm × 10 mm × 4 mm. Based on GB/T 16172-2007 standard, the combustion performance of the sample was measured using the cone calorimeter (CC) of the FTT company in the UK. The sample size was 100 mm × 100 mm × 2.7 mm, and radiant heat flux was 35 kW·m−2. DLF-1200 laser thermal conductivity instrument (American TA instrument company) was used to test the thermal conductivity of the sample – sample size: disc with a diameter of 25.4 mm and a thickness of 2.30 mm. The sample was sprayed with graphite to treat the surface, and the test temperature was 30°C.

3 Results and discussion

3.1 Characterization of functionalized SiC particles

3.1.1 IR spectrum

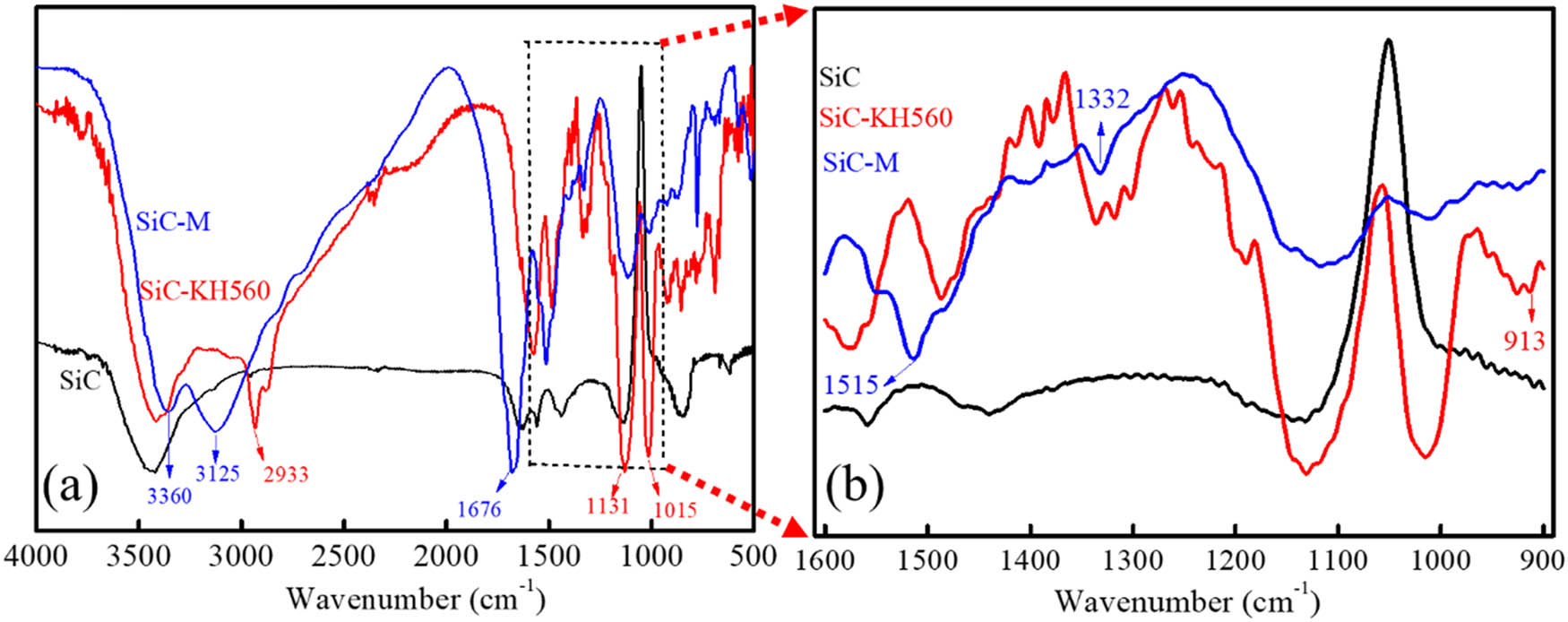

Figure 1a exhibits the IR spectrum of SiC particles, silane coupling agent–modified SiC (SiC-KH560), and MPP-modified SiC particles (SiC-M), and Figure 1b presents a partially enlarged view of 900–1,600 cm−1. It is obvious that the absorption peak of the SiC-KH560 curve is at 913 cm−1, which is the characteristic absorption peak of the epoxy group in Figure 1b. As shown in Figure 1a, the IR absorption curve of SiC-KH560 exhibits strong absorption peaks at 1,015 and 1,131 cm−1 compared with the IR absorption curve of SiC particles, which was the antisymmetric stretching vibration absorption of Si–O–Si bond. At the same time, there was a strong absorption peak at 2,933 cm−1 on the IR absorption curve of SiC-KH560, which was the stretching vibration peak of methylene. In conclusion, the IR absorption curve of SiC particles was compared with that of SiC-KH560, which proved the modification of silane coupling agent KH560 on the surface of SiC particles was successful.

IR spectrum of SiC, SiC-KH-560, and SiC-M; (a) original curve picture, (b) partial enlarged view of picture (a).

Comparing the IR absorption curves of red SiC-KH560 and blue SiC-M in Figure 1, it was found that the double shoulder peak of –NH2 appeared in the curve of SiC-M at 3,100–3,400 cm−1, the stretching peak of

3.1.2 Thermogravimetric analysis

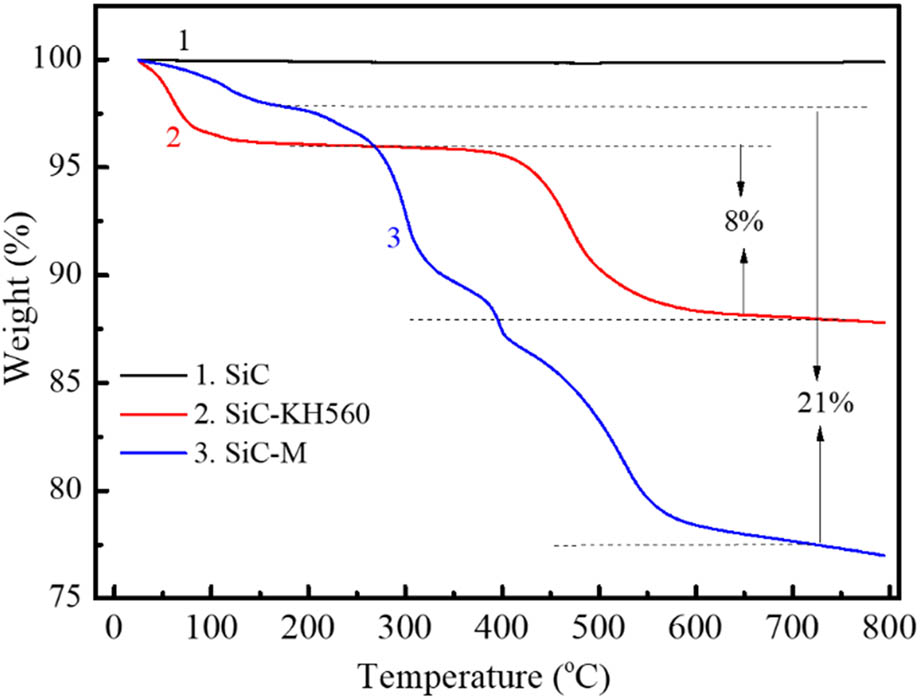

Figure 2 shows the thermal weight loss curve of SiC, SiC-KH560, and SiC-M, in which the weight loss curve of SiC had little change in the whole temperature range. The weight loss of SiC-KH560 represented by curve 2 was absorbed water within the first 100°C, there was almost no weight loss within the range of 100–450°C, the weight loss was about 8% in the range of 450–600°C, and curve 2 was no longer weight loss above 600°C. It can be seen from the comparison between curve 1 and curve 2 that the weight loss of SiC-KH560 was 8% higher than that of pure SiC. This indicates that the grafting degree of coupling agent KH560 on the surface of SiC particles was about 8 g/100 g. It can be seen from curve 3 in Figure 2 that the total weight loss of SiC-M reached 21% in the range of 100–700°C. Compared with SiC-KH560 represented by curve 2, the grafting degree of MPP was 13%, which means the MPP bonded to the surface of SiC particles reached 13 g/100 g (37).

TGA curves of SiC, SiC-KH-560, and SiC-M.

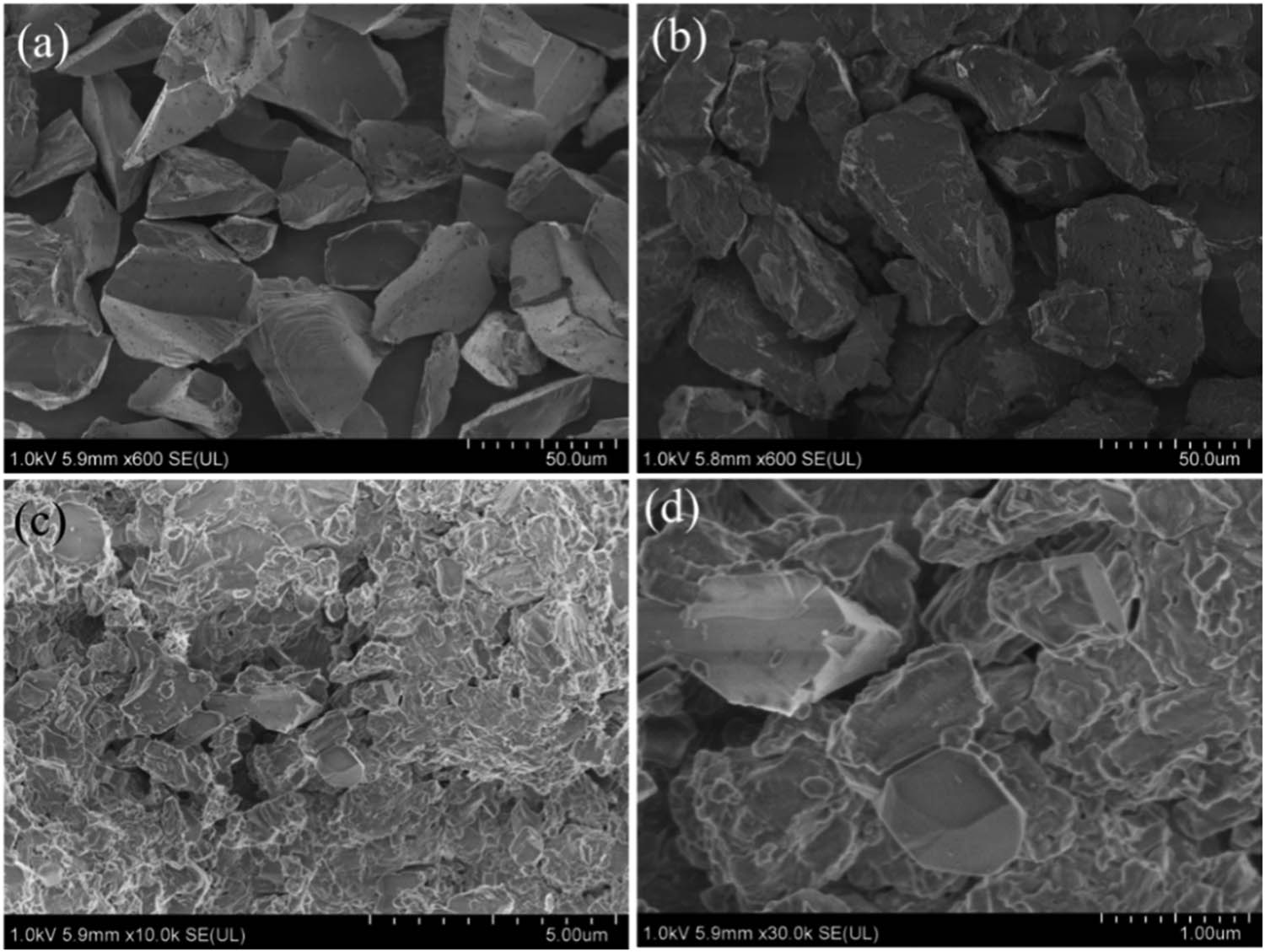

3.1.3 SEM of SiC and its modified particles and composites

Figure 3 shows the SEM diagram of SiC and their modified particles. Figure 3a is the SEM diagram of SiC; it shows that the particle size of SiC used in this study is about 50 μm. Figure 3b is after modification by silane coupling agent KH560. Comparing the Figure 3a and b, it can be seen that the surface of SiC was covered with a layer of materials, combined with thermogravimetric (TGA) and IR analyses, and that this layer of material was a silane coupling agent KH560 grafted on the surface of SiC. Figure 3c and d is both functional SiC particles grafted and modified by MPP. Compared with Figure 3b, the surface of Figure 3c was covered with a layer of material different from the silane coupling agent, which made the surface of SiC particles significantly different from unmodified SiC and SiC particles modified by the coupling agent. Combined with TGA and IR analyses, the material covered on the surface of SiC particles is MPP.

SEM images of (a) SiC; (b) SiC-KH560; (c and d) SiC-M with different amplification ratios.

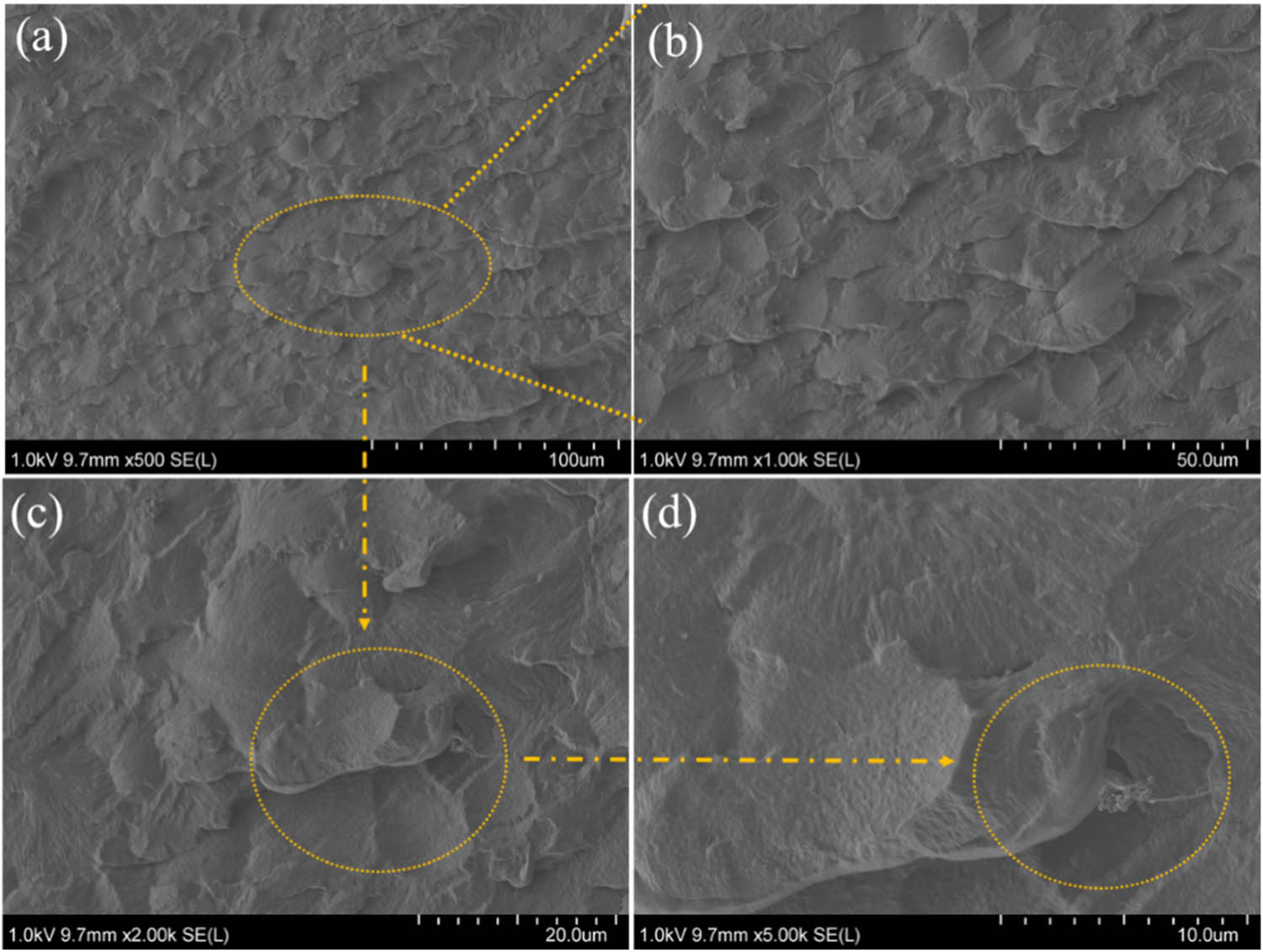

Figure 4 shows the SEM magnification of the cross-section of composites EP/SiC-M3 at different times. As shown in Figure 4a, the cross-section of the composite presents a shell-like texture, which was not the brittle fracture of pure EP, showing a smooth and flat cross-section morphology. After the magnification of Figure 4b was 1,000 times, Figure 4c was 2,000 times, and Figure 4d was 5,000 times. It is clearly shown that after the EP matrix was involved with modified SiC particles, there were broken flocculent wires in the yellow line frame area in Figure 4d. It proved that the fracture mode of the composites had been changed from brittle fracture of pure EP to ductile fracture.

SEM images of EP/SiC-M3 with different amplification ratios.

3.2 Thermal stability of composites

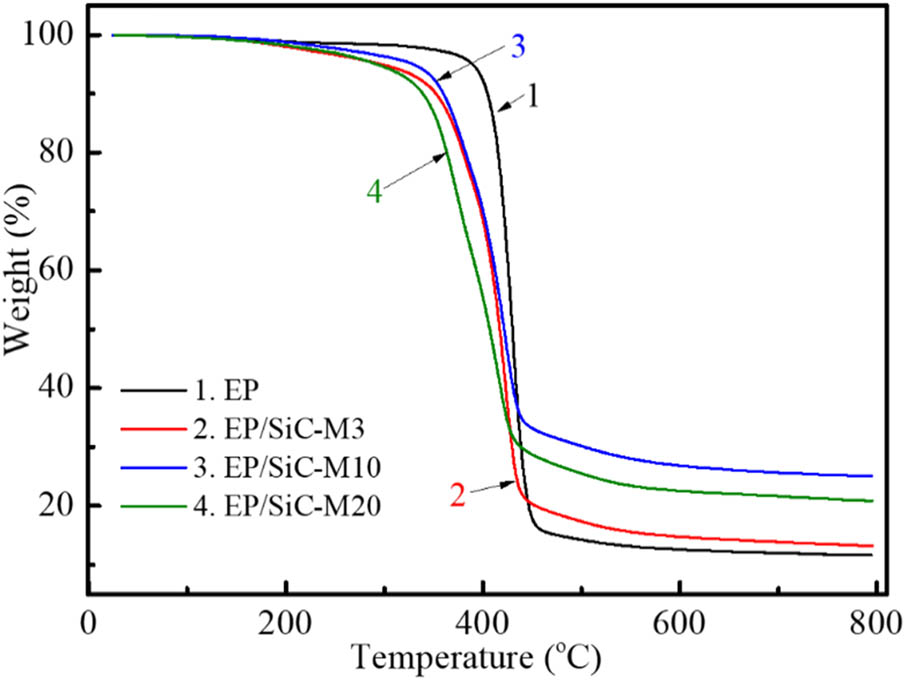

Figure 5 reveals the thermogravimetric curve of EP, and its SiC composites with different contents under a nitrogen atmosphere. It can be seen from the four curves in the figure that with the increase of SiC content, the residual amount of the composite in the high-temperature zone was higher. And the initial decomposition temperature of the composite EP/SiC-M showed a downward trend with the increase of SiC content from 3 to 20 wt%, which may be due to the influence of the addition of SiC particles on the curing crosslinking degree of EP and the reduction of its crosslinking density. At the same time, it may also be that the decomposition speed of the flame retardant modified on the surface of SiC particles was accelerated at about 300%, resulting in the accelerated mass loss of the composites. It could produce more non-combustible gases and play to the intumescent flame-retardant effect of melamine salt flame retardant.

TGA curves of EP and composites EP/SiC-M.

3.3 Combustion performance of composites

CC is one of the effective tools to characterize the combustion performance parameters of materials in a real fire environment (38,39,40,41,42). In this work, the flame retardancy of composites was studied from four aspects: energy change, smoke output, harmful gas, and mass loss rate via the CC test.

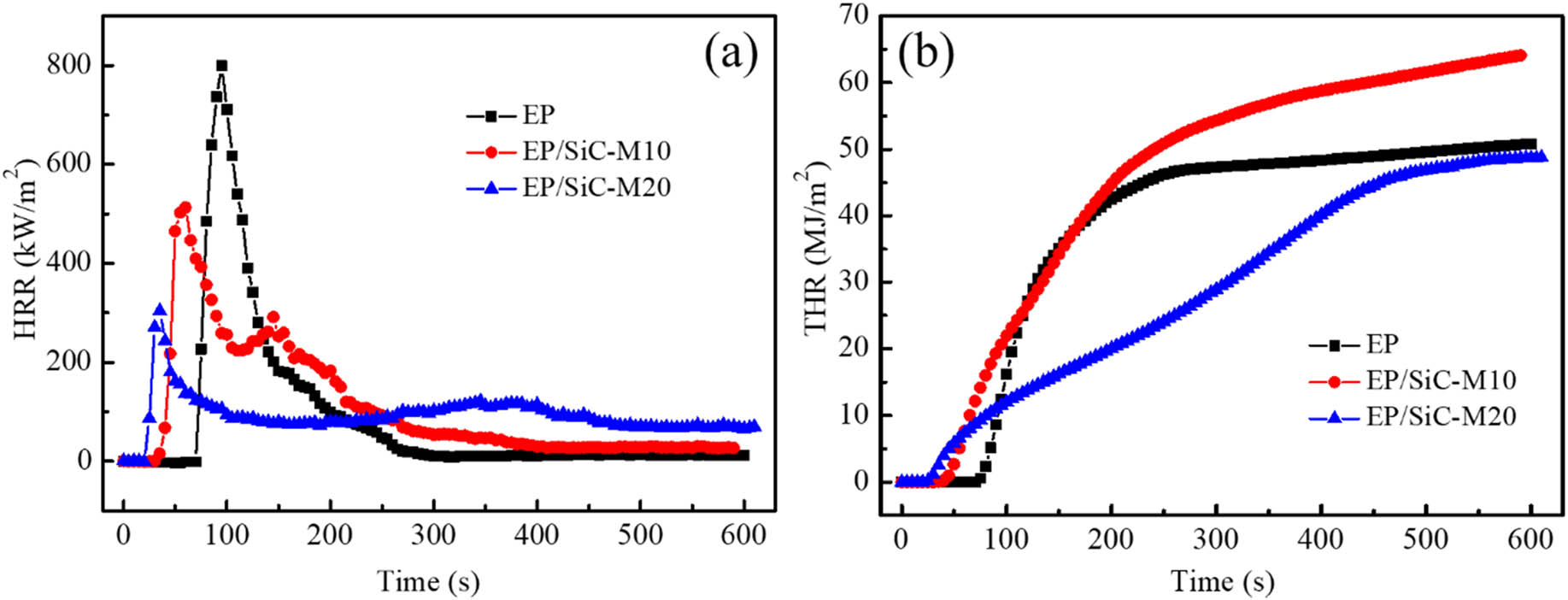

3.3.1 Research in terms of heat release

Figure 6 is a graph showing the variation of heat release rate (HRR) and total heat release (THR) of EP, composite EP/SiC-M10, and EP/SiC-M20 with combustion time. As shown in Figure 6a, pure EP was easy to burn, and its peak heat release rate (PHRR reached 800 kW·m−2, while the PHRR of composite EP/SiC-M10 was decreased to 513 kW·m−2. The PHRR of composite EP/SiC-M20 was decreased to 304 kW·m−2, which was decreased by 36% and 62%, respectively, compared with the pure EP. The flame-retardant properties of the composites can be effectively improved by the flame retardant of MPP grafted SiC.

Heat release rate (a) and total heat release (b) versus time curves of EP and composites EP/SiC-M.

It is shown in Figure 6b that the THR of composite EP/SiC-M20 was much lower than that of pure EP during the 400 s of combustion. With the progress of the combustion process, the flame retardant in composite EP/SiC-M20 was consumed. At the end of combustion, the heat release of composites was almost close to that of pure EP, which was further proved that the SiC modified by flame-retardant MPP played a flame-retardant role in the composites.

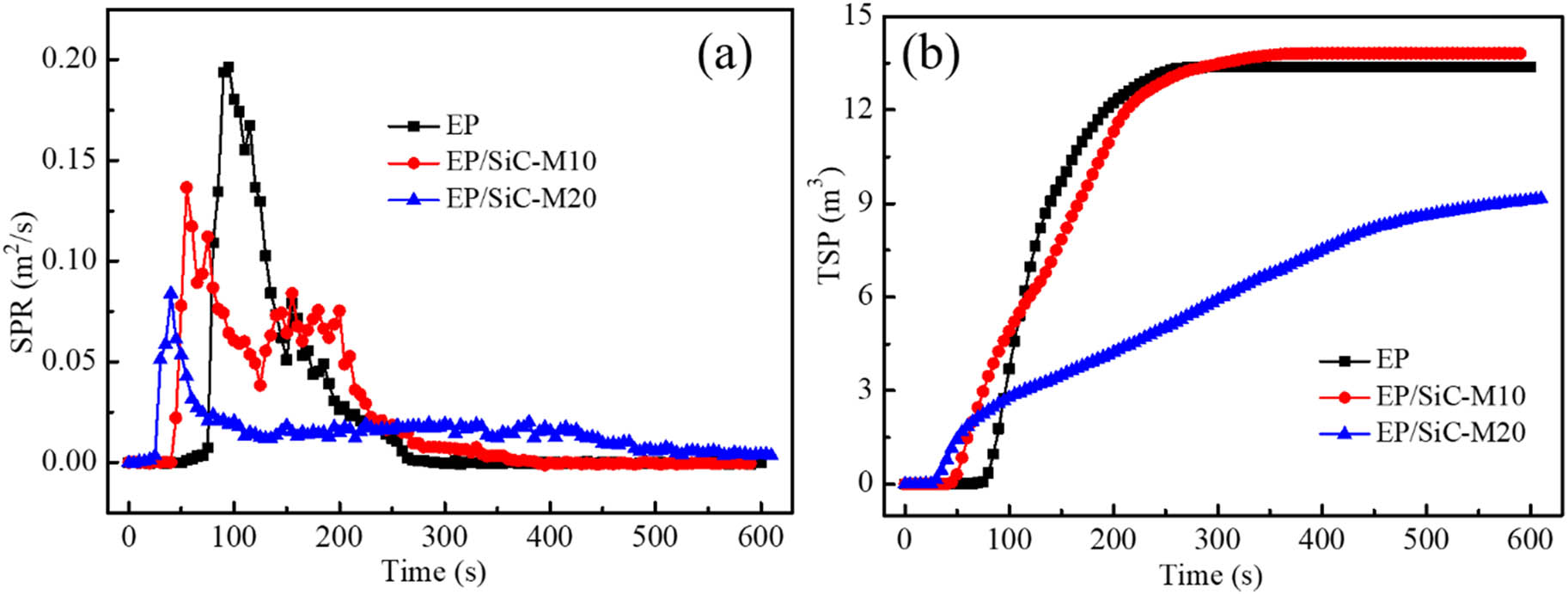

3.3.2 Study on smoke production

Figure 7 is a graph showing the variation of smoke production rate (SPR) and total smoke production (TSP) of EP, composite EP/SiC-M10, and EP/SiC-M20 with combustion time. As shown in Figure 7a, compared with pure EP, the smoke production rate of the composite was significantly reduced. When the content of SiC was 20 wt%, the peak smoke production rate of the composite EP/SiC-M20 was reduced from 0.196 to 0.083 m2·s−1, a decrease of 57%. The peak smoke production rate of the composite EP/SiC-M10 also decreased to 0.136 m2·s−1, which once again proved that the SiC particles grafted with flame retardant can effectively improve the flame-retardant performance.

Smoke production rate (a) and total smoke production (b) versus time curves of EP and composites EP/SiC-M.

In Figure 7b, the total smoke production of composite EP/SiC-M20 was higher than that of pure EP in the first 100 s, which may be due to the function of flame retardant grafted on the surface of SiC particles in the composite. In the initial stage of combustion, the flame retardant decomposes rapidly, producing a large number of non-combustible gases (nitrogen, ammonia, water vapor, etc.) to dilute the air on the surface of combustibles. At the same time, polyphosphate also dehydrates rapidly under the action of high temperature to form polyphosphate, which promotes the dehydration and carbonization of EP matrix to form an isolation layer and prevent the combustion of composites. Therefore, in the combustion process after 100 s, the total smoke production of composite EP/SiC-M20 (9 m3) was always lower than that of pure EP (13 m3).

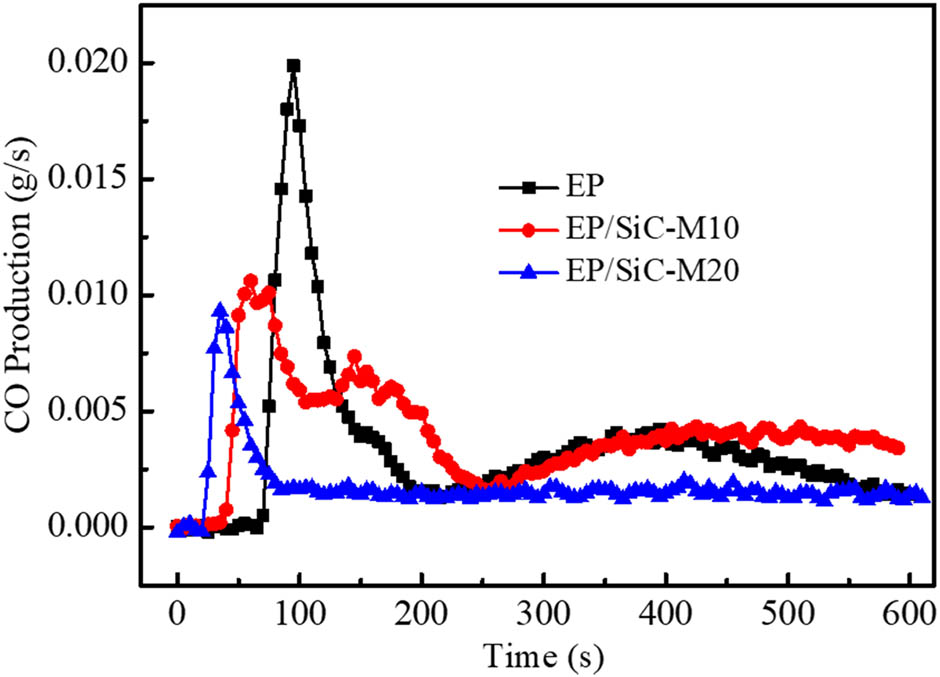

3.3.3 Research on harmful gases

Figure 8 is the variation curve of the CO production rate of EP, composite EP/SiC-M10, and EP/SiC-M20 during combustion. It can be seen from the figure that the peak value of CO gas produced by composite EP/SiC-M10 and EP/SiC-M20 was earlier than that of pure EP, which may be due to the early decomposition of surface grafted flame retardant MPP with SiC particles to produce a large amount of incombustible gas, which inhibits the combustion of the composite and causes its insufficient combustion. The peak values of CO gas produced by EP/SiC-M10 and EP/SiC-M20 composites were 0.011 and 0.009 g·s−1, respectively. It was greatly reduced compared with the peak value of CO gas produced by the pure EP of 0.02 g·s−1. It proved that the SiC particles modified by MPP flame retardant can exert their flame-retardant effect in the composite system from the aspect of harmful gas generation rate.

CO production rate versus time curves of EP and composites EP/SiC-M.

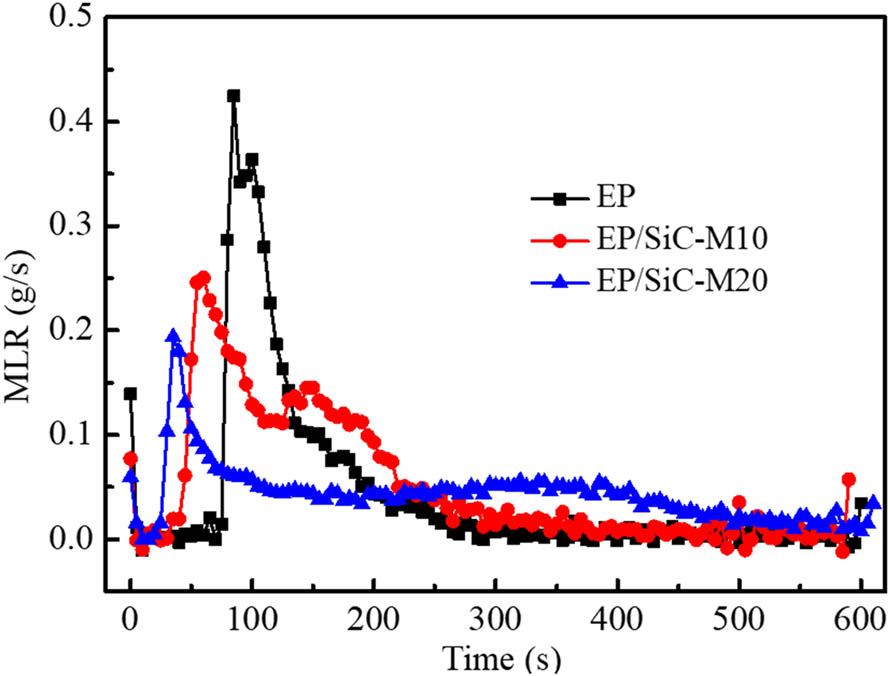

3.3.4 Research on mass loss

Figure 9 is the variation curve of the mass loss rate of EP, composite EP/SiC-M10, and EP/SiC-M20 during combustion. It can be seen from the figure that the peak mass losses of composite EP/SiC-M10 and EP/SiC-M20 were 0.24 and 0.19 g·s−1, respectively, which was much lower than the peak mass loss rate of pure EP of 0.43 g·s−1, and the composite EP/SiC-M20 was reduced by about 56%. This showed that adding flame retardant modified SiC particles to EP was an effective method to inhibit the combustion of composites.

Mass loss rate versus time curves of EP and composites EP/SiC-M.

To sum up, the CC test analyzes the flame-retardant performance of the material from four aspects: energy change, smoke output, harmful gas generation rate, and mass loss rate. The results showed that the addition of SiC grafted with flame retardant MPP can significantly inhibit the combustion of the composite and achieve the effect of flame retardancy.

3.4 Flame retardancy test of composites

The test results of limiting oxygen index and UL-94 flame retardant grade of composite EP/SiC-M are listed in Table 1. The experimental results showed that the limiting oxygen index of pure EP was 25.1, and the oxygen index of the composite was improved with the increase in the amount of flame-retardant modified SiC; at the same time, the flame-retardant grade was also increased with the increase of SiC content. When the content of SiC increases to 20 wt% and above, the flame-retardant grade of EP/SiC-M20 composites reached V1. This showed that the results of the limiting oxygen index test and UL-94 flame-retardant level test were consistent with those of CC, which proved that the flame-retardant design scheme was feasible.

The limiting oxygen index (LOI) and UL-94 rating of EP and composite EP/SiC-M

| Samples | EP | EP/SiC-M3 | EP/SiC-M10 | EP/SiC-M20 |

|---|---|---|---|---|

| LOI (vol%) | 25.1 | 26.4 | 28.6 | 30.3 |

| UL-94 rating | NR | NR | V2 | V1 |

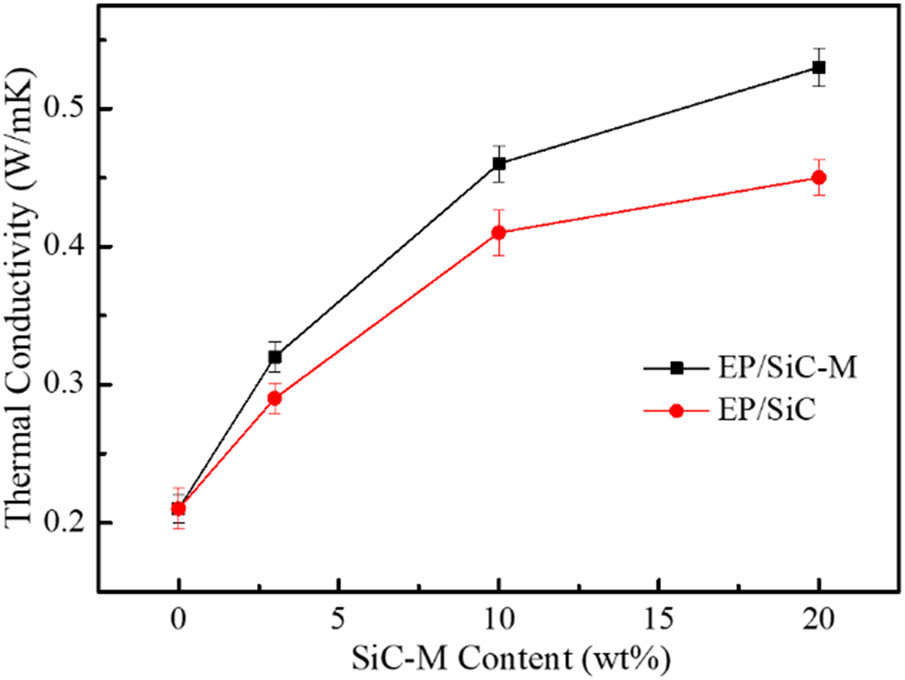

3.5 Thermal conductivity of composites

Figure 10 is a graph showing the variation of thermal conductivity of EP and composite EP/SiC-M with the content of modified SiC particles. It can be seen from the figure that the thermal conductivity of pure EP was 0.21 W·m−1·K−1, while the thermal conductivity of composites with SiC-M and SiC was all improved. When the content of SiC was 20 wt%, the thermal conductivity of composites EP/SiC was enhanced to 0.45 W·m−1·K−1, which was more than two times higher than the pure EP. And thermal conductivity of composites EP/SiC-M was enhanced to 0.53 W·m−1·K−1 when the content of SiC was 20 wt%. The thermal conductivity of EP/SiC-M was higher than that of EP/SiC. This may be due to the modified MPP on the SiC surface of EP/SiC-M and reduced interface thermal resistance between the SiC-M and epoxy matrix (43).

Thermal conductivity of EP and composites EP/SiC-M with different contents of SiC-M.

This showed that adding thermal conductive particles to EP matrix can effectively improve the thermal conductivity of composites. At the same time, it also proved that it was feasible to modify flame retardant on the surface of thermally conductive particles SiC to realize the initial thermal conductive flame-retardant strategy.

4 Conclusion

SiC particles were modified by a silane coupling agent with the epoxy group at the end, and the epoxy functional group was grafted on the surface. The flame-retardant MPP was bonded to the surface of SiC particles with functional modified particles by the amino group of MPP-initiated ring opening reaction. Then, the functional SiC particles were added to the epoxy matrix through blending and compounding to form the composite EP/SiC-M. A series of composites were obtained by adjusting the amount of SiC. According to the test results of the conical calorimeter of the composite, the flame retardancy of the composite was analyzed from four aspects: energy change, smoke output, harmful gas generation rate, and mass loss rate. The results showed that the addition of SiC particles grafted and modified by MPP can significantly inhibit the combustion of the composite and play a flame-retardant effect. When the addition amount of SiC was 20 wt%, the UL 94 test of composite materials reached V1 rating. The thermal conductivity of composite EP/SiC-M20 was 0.53 W·m−1·K−1, which was three times higher than that of pure EP. These results demonstrate that it can simultaneously achieve enhanced thermal conductivity and flame retardancy via modifying the flame retardant on the surface of heat conduction particle SiC.

-

Funding information: The funding was provided by the Project of Henan Provincial Department of Education (21B430013), China.

-

Author contributions: Xuejun Shi: writing – original draft; Baoting Wei: writing – review and editing, Xiangxiang Du: methodology; Guoxu He: formal analysis, Yongjun Han: resources.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The data presented in this study are available on request from the corresponding author.

References

(1) Chen C, Xue Y, Li Z, Wen Y, Li X, Wu F, et al. Construction of 3D boron nitride nanosheets/silver networks in epoxy-based composites with high thermal conductivity via in-situ sintering of silver nanoparticles. Chem Eng J. 2019;369:1150–60.10.1016/j.cej.2019.03.150Suche in Google Scholar

(2) Xiao C, Chen L, Tang Y, Zhang X, Zheng K, Tian X. Enhanced thermal conductivity of silicon carbide nanowires (SiCw)/epoxy resin composite with segregated structure. Compos Part A-Appl S. 2019;116:98–105.10.1016/j.compositesa.2018.10.023Suche in Google Scholar

(3) Shi XJ, Shi GL, Li ST, Du XX, Han YJ. Sound insulation properties of hollow polystyrene spheres/polyethylene glycol/epoxy composites. Polymers. 2022;14(7):1388.10.3390/polym14071388Suche in Google Scholar PubMed PubMed Central

(4) Feng Y, He C, Wen Y, Zhou X, Xie X, Ye Y, et al. Multifunctional interface tailoring for enhancing thermal conductivity, flame retardancy and dynamic mechanical property of epoxy/Al2O3 composites. Compos Sci Technol. 2018;160:42–9.10.1016/j.compscitech.2018.03.009Suche in Google Scholar

(5) Feng Y, He C, Wen Y, Ye Y, Zhou X, Xie X, et al. Superior flame retardancy and smoke suppression of epoxy-based composites with phosphorus/nitrogen co-doped graphene. J Hazard Mater. 2018;346:140–51.10.1016/j.jhazmat.2017.12.019Suche in Google Scholar PubMed

(6) Liu C, Huang K, Liu R, Li Y, Dai L, Wang W. A multi-element flame retardant on the basis of silicon-phosphorus-nitrogen for combustibility suppressing of epoxy. Polym Test. 2022;111:107582.10.1016/j.polymertesting.2022.107582Suche in Google Scholar

(7) Liu C, Chen T, Yuan C, Chang Y, Chen G, Zeng B, et al. Highly transparent and flame-retardant epoxy composites based on a hybrid multi-element containing POSS derivative. RSC Adv. 2017;7(73):46139–47.10.1039/C7RA09327FSuche in Google Scholar

(8) Wang W, Li Y, Wei J, Luo Z, Pan C, Liu C, et al. A novel polyhedral oligomeric silsesquioxanes derivative: Synthesis and characterization. J Mol Struct. 2021;1246:131255.10.1016/j.molstruc.2021.131255Suche in Google Scholar

(9) Liu C, Chen T, Yuan C, Song C, Chang Y, Chen Y, et al. Modification of epoxy resin through the self-assembly of a surfactant-like multi-element flame retardant. J Mater Chem A. 2016;4(9):3462–70.10.1039/C5TA07115ASuche in Google Scholar

(10) Vahabi H, Jouyandeh M, Cochez M, Khalili R, Vagner C, Ferriol M, et al. Short-lasting fire in partially and completely cured epoxy coatings containing expandable graphite and halloysite nanotube additives. Prog Org Coat. 2018;123:160–7.10.1016/j.porgcoat.2018.07.014Suche in Google Scholar

(11) Rad ER, Vahabi H, de Anda AR, Saeb MR, Thomas S. Bio-epoxy resins with inherent flame retardancy. Prog Org Coat. 2019;135:608–12.10.1016/j.porgcoat.2019.05.046Suche in Google Scholar

(12) Vahabi H, Saeb MR, Formela K, Cuesta J. Flame retardant epoxy/halloysite nanotubes nanocomposite coatings: Exploring low-concentration threshold for flammability compared to expandable graphite as superior fire retardant. Prog Org Coat. 2018;119:8–14.10.1016/j.porgcoat.2018.02.005Suche in Google Scholar

(13) Jian RK, Pang FQ, Lin YC, Bai WB. Facile construction of lamellar-like phosphorus-based triazole-zinc complex for high-performance epoxy resins. J Colloid Inter Sci. 2022;609:513–22.10.1016/j.jcis.2021.11.054Suche in Google Scholar PubMed

(14) Zheng XT, Dong YQ, Liu XD, Xu YL, Jian RK. Fully bio-based flame-retardant cotton fabrics via layer-by-layer self-assembly of laccase and phytic acid. J Clean Prod. 2022;350:131525.10.1016/j.jclepro.2022.131525Suche in Google Scholar

(15) Ai YF, Liu XD, Bai WB, Lin Y, Xie R, Rong KJ. From herbicide to flame retardant: The lamellar-like phosphorus-bridged amitrole toward high fire safety epoxy resin with light smoke and low toxicity. Chemosphere. 2022;291(Pt 1):132704.10.1016/j.chemosphere.2021.132704Suche in Google Scholar PubMed

(16) Liu XD, Zheng XT, Dong YQ, He L, Chen F, Bai W, et al. A novel nitrogen-rich phosphinic amide towards flame-retardant, smoke suppression and mechanically strengthened epoxy resins. Polym Degrad Stabil. 2022;196:109840.10.1016/j.polymdegradstab.2022.109840Suche in Google Scholar

(17) Shao ZB, Cui J, Lin XB, Li XL, Jian RK, Wang DY. In-situ coprecipitation formed Fe/Zn-layered double hydroxide/ammonium polyphosphate hybrid material for flame retardant epoxy resin via synergistic catalytic charring. Compos Part A-Appl S. 2022;155:106841.10.1016/j.compositesa.2022.106841Suche in Google Scholar

(18) Liu L, Shen S, Wang Y. Enhanced thermal conductivity of flexible h-BN/polyimide composites films with ethyl cellulose. e-Polymers. 2019;19(1):305–12.10.1515/epoly-2019-0031Suche in Google Scholar

(19) Wen Y, Cheng Z, Li W, Li Z, Liao D, Hu X, et al. A novel oligomer containing DOPO and ferrocene groups: Synthesis, characterization, and its application in fire retardant epoxy resin. Polym Degrad Stabil. 2018;156:111–24.10.1016/j.polymdegradstab.2018.08.010Suche in Google Scholar

(20) Wei YX, Deng C, Chen H, Wang L, Wei WC, Wang YZ. Novel core-shell hybrid nanosphere towards the mechanical enhancement and fire retardance of polycarbonate. ACS Appl Mater Inter. 2018;10(33):28036–50.10.1021/acsami.8b07629Suche in Google Scholar PubMed

(21) Rao WH, Hu ZY, Xu HX, Xu YJ, Qi M, Liao W, et al. Flame-retardant flexible polyurethane foams with highly efficient melamine salt. Ind Eng Chem Res. 2017;56:7112–9.10.1021/acs.iecr.7b01335Suche in Google Scholar

(22) Tan Y, Shao ZB, Yu LX, Long JW, Qi M, Chen L, et al. Piperazine-modified ammonium polyphosphate as monocomponent flame-retardant hardener for epoxy resin: flame retardance, curing behavior and mechanical property. Polym Chem. 2016;7(17):3003–12.10.1039/C6PY00434BSuche in Google Scholar

(23) Qiu S, Ma C, Wang X, Zhou X, Feng X, Yuen RKK, et al. Melamine-containing polyphosphazene wrapped ammonium polyphosphate: A novel multifunctional organic inorganic hybrid flame retardant. J Hazard Mater. 2018;344:839–48.10.1016/j.jhazmat.2017.11.018Suche in Google Scholar PubMed

(24) Guo Y, Chang CC, Halada G, Cuiffo MA, Yuan X, Zuo X, et al. Engineering flame retardant biodegradable polymer nanocomposites and their application in 3D printing. Polym Degrad Stabil. 2017;137:205–15.10.1016/j.polymdegradstab.2017.01.019Suche in Google Scholar

(25) Vahabi H, Wu H, Saeb MR, Koo JH, Ramakrishna S. Electrospinning for developing flame retardant polymer materials: Current status and future perspectives. Polymer. 2021;217:123466.10.1016/j.polymer.2021.123466Suche in Google Scholar

(26) Feng Y, Li X, Zhao X, Ye YS, Zhou XP, Liu H, et al. Synergetic improvement in thermal conductivity and flame retardancy of epoxy/silver nanowires composites by incorporating “branch-like” flame-retardant functionalized graphene. ACS Appl Mater Inter. 2018;10(25):21628–41.10.1021/acsami.8b05221Suche in Google Scholar PubMed

(27) Guan YH, Huang JQ, Yang JC, Shao ZB, Wang YZ. An effective way to flame-retard biocomposite with ethanolamine modified ammonium polyphosphate and its flame retardant mechanisms. Ind Eng Chem Res. 2015;54(13):3524–31.10.1021/acs.iecr.5b00123Suche in Google Scholar

(28) Jiang Y, Li M, Chen C, Xie X, Xue ZG, Zhou XP, et al. Effect of elastic modulus mismatch of epoxy/titanium dioxide coated silver nanowire composites on the performance of thermal conductivity. Compos Sci Technol. 2018;165:206–13.10.1016/j.compscitech.2018.06.028Suche in Google Scholar

(29) Jiang Y, Shi X, Feng Y, Li S, Zhou XP, Xie XL. Enhanced thermal conductivity and ideal dielectric properties of epoxy composites containing polymer modified hexagonal boron nitride. Compos Part A-Appl S. 2018;107:657–64.10.1016/j.compositesa.2018.02.016Suche in Google Scholar

(30) Jouyandeh M, Shabanian M, Khaleghi M, Paran MR, Saeb MR. Acid-aided epoxy-amine curing reaction as reflected in epoxy/Fe3O4 nanocomposites: Chemistry, mechanism, and fracture behavior. Prog Org Coat. 2018;125:384–92.10.1016/j.porgcoat.2018.09.024Suche in Google Scholar

(31) Sabahi H, Khorami M, Rezayan AH, Jafari Y, Karami MH. Surface functionalization of halloysite nanotubes via curcumin inclusion. Colloid Surf A. 2018;538:834–40.10.1016/j.colsurfa.2017.11.038Suche in Google Scholar

(32) Zhou HC, Kitagawa S. Metal-organic frameworks (MOFs). Chem Soc Rev. 2014;43(16):5415–8.10.1039/C4CS90059FSuche in Google Scholar

(33) Jouyandeh M, Jazani OM, Navarchian AH, Shabanian M, Vahabi H, Saeb MR. Surface engineering of nanoparticles with macromolecules for epoxy curing: Development of super-reactive nitrogen-rich nanosilica through surface chemistry manipulation. Appl Surf Sci. 2018;447:152–64.10.1016/j.apsusc.2018.03.197Suche in Google Scholar

(34) Termonia Y. Structure property relationships in nanocomposites. Polymer. 2007;48(23):6948–54.10.1016/j.polymer.2007.09.025Suche in Google Scholar

(35) Sari MG, Saeb MR, Shabanian M, Khaleghi M, Vahabi H, Vagner C, et al. Epoxy/starch modified nano-zinc oxide transparent nanocomposite coatings: A showcase of superior curing behavior. Prog Org Coat. 2018;115:143–50.10.1016/j.porgcoat.2017.11.016Suche in Google Scholar

(36) Dong LP, Deng C, Li RM, Cao ZJ, Lin L, Chen L, et al. Poly (piperazinyl phosphamide): A novel highly-efficient charring agent for an EVA/APP intumescent flame retardant system. RSC Adv. 2016;6(36):30436–44.10.1039/C6RA00164ESuche in Google Scholar

(37) Zhang Y, Ni Y, He M, Wang X, Chen L, Wang YZ. Phosphorus-containing copolyesters: The effect of ionic group and its analogous phosphorus heterocycles on their flame-retardant and anti-dripping performances. Polymer. 2015;60:50–61.10.1016/j.polymer.2015.01.030Suche in Google Scholar

(38) Yang JC, Cao ZJ, Wang YZ, Schiraldi DA. Ammonium polyphosphate-based nanocoating for melamine foam towards high flame retardancy and anti-shrinkage in fire. Polymer. 2015;66:86–93.10.1016/j.polymer.2015.04.022Suche in Google Scholar

(39) Zhao HB, Wang YZ. Design and synthesis of pet-based copolyesters with flame-retardant and antidripping performance. Macromol Rapid Comm. 2017;38(23):1700451.10.1002/marc.201700451Suche in Google Scholar PubMed

(40) Shen D, Xu YJ, Long JW, Shi X, Chen L, Wang YZ. Epoxy resin flame-retarded via a novel melamine-organophosphinic acid salt: thermal stability, flame retardance and pyrolysis behavior. J Anal Appl Pyrol. 2017;128:54–63.10.1016/j.jaap.2017.10.025Suche in Google Scholar

(41) Dong JH. Flame Retardant of Epoxy Resin Composites. Adv Mater Res. 2012;450:688–91.10.4028/www.scientific.net/AMR.450-451.688Suche in Google Scholar

(42) Toldy A, Harakály G, Szolnoki B, Zimonyi M, Marosi G. Flame retardancy of thermoplastics polyurethanes. Polym Degrad Stabil. 2012;97(12):2524–30.10.1016/j.polymdegradstab.2012.07.015Suche in Google Scholar

(43) Henri V, Amin R, Mohammad F, Sonnier R, Saeb MR, Dumazert L, et al. Competitiveness and synergy between three flame retardants in poly (ethylene-co-vinyl acetate). Polym Degrad Stabil. 2017;143:164–75.10.1016/j.polymdegradstab.2017.07.005Suche in Google Scholar

© 2022 Xuejun Shi et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes

Artikel in diesem Heft

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes