Abstract

In this article, water-based polyurethane (PU) with different concentrations and partial alcoholysis polyvinyl alcohol (PVA) were used to coat polyester (PET) harness cord in turn. The surface and mechanical properties of harness cord before and after coating were evaluated by performing the tests of dynamic contact angle, morphology observation, bending properties, tensile properties, and wearability. It was found that the surface properties of 1.5% PU-coated harness cord tended to be stable, and the mechanical properties of PU(1.5%)/PVA-coated harness cord were optimal. Compared with PVA-coated harness cord, the wearability of PU(1.5%)/PVA-coated harness cord showed a great increment up to 135.7%. This was because the PU coating effectively improved the interfacial properties between the PVA coating and the hydrophobic PET fibers and enhanced the adhesion of the PVA coating to the PET fibers.

1 Introduction

Harness cord is widely used in the industries of trademark, carpet, home textile, and towel. It is also the most important lifting part in the Jacquard loom when forming a shed. When the loom is in operation at high speed, the abrasion of harness cord will occur due to the friction between the harness cord and the comber board. This abrasion will affect the appearance and properties of the harness cord and consequently, reduce the productive efficiency (1,2). Therefore, the wearability of the harness cord is of great importance. The wearability of harness cord is mainly dependent on the types of fiber, structure, surface coating, lubricant, and interfacial properties between coating and fibers (3,4,5). The braided PET harness cord, compared with the traditional twisted structure, is a torque balanced construction which conduces to increase the uniformity and stability of stress distribution as well as the wearability (6,7). After the development of such materials as cotton, flax, vinylon, aramid, ultra-high molecular weight polyethylene, etc., the fiber type used for harness cord has been gradually replaced by polyester (PET) due to its excellent wearability, tensile property, heat resistance, fatigue resistance, and low moisture regain (8). The harness cords manufactured by these fibers require sizing, such as partial alcoholysis polyvinyl alcohol (PVA), polytetrafluoroethylene emulsion, polyacrylate, etc., and the additives, including oils, waxes, etc., to improve their wearability (3,9,10). However, the interfacial properties depend on the adhesion of the coating to the fiber, which plays a critical role in the mechanical properties of the harness cord, especially the wearability.

Because of the symmetrical molecular structure, rigid molecular chain, high orientation, and crystallinity as well as less polar groups (except for a small amount of carboxyl and hydroxyl), the PET fiber presents high hydrophobicity and chemical inertness, which makes it difficult to coat (11,12,13). In general, surface treatment is an effective method to improve the interfacial properties between the coating and PET fiber (14). Alkali decrement treatment can increase the surface roughness and enhance the adhesion of the coating to the PET fiber, but it will reduce the fiber’s mechanical properties (15,16,17). Corona discharge, plasma treatment, or ultraviolet irradiation can introduce free radicals to improve the surface activity of PET fiber (18,19,20,21,22,23), but the extensive application of these methods in actual production is limited. However, dipping treatment with resin can not only introduce polar groups to improve the adhesion of the coating to PET fiber but also avoid the disadvantages mentioned above, which is widely used in the manufacture of tire cord (24).

PVA, possessing good hydrophilicity, film-forming property, and adhesion, is one of the most common polymers used for sizing textile materials. Besides, PVA film presents high strength and excellent wearability (25). However, the rich hydroxyl in PVA molecular chains is easy to associate into hydrogen bonds, and the content of acetate groups is low, so that the adhesion of PVA to hydrophobic PET fiber is still insufficient (26). Water-based polyurethane (PU) is environmental friendly and has close solubility parameter to PET fiber. In order to improve the adhesion of PVA to PET fibers, PU was used to pre-coat PET harness cord. At present, only limited research has been conducted on the manufacture of twisted harness cord. However, the study on manufacture and property of braided harness cord has not yet been reported in research articles except for several patents. Therefore, in this article, the composite coating method was used to coat the PET harness cord with PU and PVA in turn. The surface and mechanical properties of harness cord before and after coating were evaluated by carrying out the tests of dynamic contact angle (DCA), morphology observation, Fourier transform infrared (FTIR), bending properties, tensile properties, and wearability. These findings can not only present the effect of PU/PVA coating on harness cord’s properties but will also be helpful to develop harness cord with high wearability, which will potentially be used on Jacquard looms widely.

2 Materials and methods

2.1 Experimental materials

The PET harness cord was braided by using the two-dimensional braiding machine KBL-16-2-90 with 16 spindles (Xuzhou Henghui, China), as shown in Figure 1. The PET industrial filament, 250D/72F, with high tenacity and low elongation, was supplied by Jinjiang Wester Special Fiber Co., Ltd, China. Table 1 lists the basic characteristics of braided harness cord.

Braiding of harness cord.

Characteristics of braided harness cord

| Diameter (mm) | Braiding pitch (mm) | Breaking force (N) | Elongation at break (%) | Bending rigidity (gf·cm2) | Bending hysteresis moment (gf·cm) | Wearability (times) |

|---|---|---|---|---|---|---|

| 0.9 | 3.8 | 258.55 | 33.32 | 0.48 | 0.97 | 125,876 |

The water-based PU (solid content was 65%) and partial alcoholysis PVA (degree of alcoholysis was 88%) were kindly supplied by Shanghai C&D international chemical (China). Sodium carboxyl methyl cellulose (CMC, pH 6.0–8.5, viscosity 800–1,200 mPa·s, and CAS 9004-32-4) and diammonium hydrogen citrate (DAHC, content ≥ 99.0%, molecular weight 226.18, and CAS 3012-65-5) were used as the rheological agent and anionic surfactant separately, which were commercially available from Sinopharm Chemical Reagent Co., Ltd (China). The wear resistance additive nano-TiO2 (99.8% metal basis, 100 nm, anatase, hydrophilic, and CAS 13463-67-7) and penetrant 8601 (pH 7.5–8.5) were purchased from Shanghai Aladdin Bio-Chem Technology Co., Ltd, (China) and Jiangsu Haian Petroleum Chemical Factory (China), respectively.

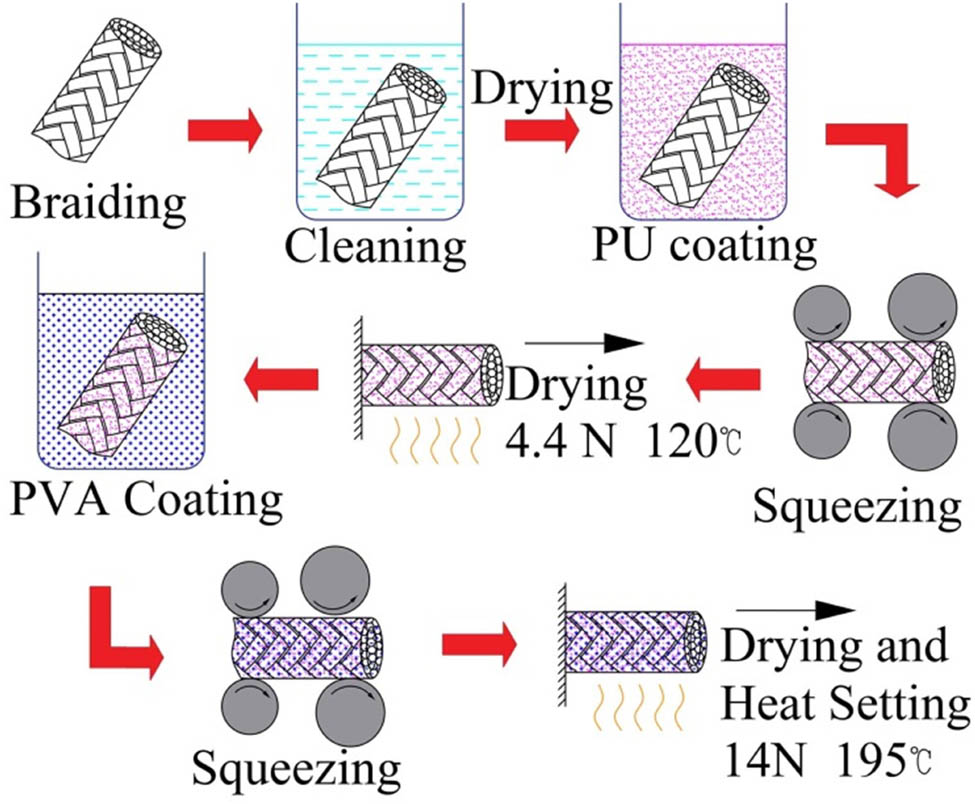

2.2 Manufacture of coated harness cord

The manufacture of composite coating harness cord (first method) used the PU and PVA in turn as shown in Figure 2. First, 75% alcohol and ultrasonic instrument (80°C, 80 kHz, 500 W, and 30 min) were employed to remove the spinning oil from the filament surface of the braided harness cords, followed by washing with deionized water, and drying in an oven at 60°C. The cleaned harness cord was immersed in PU solution (solvent was deionized water, 0.5%, 1.0%, and 1.5% concentration) for 0.5 min and squeezed by a double-roller device developed in our lab, followed by heat setting under 4.4 N tension and 120°C temperature for 3 min. Then, the PU coated harness cord was immersed in the prepared PVA size for 0.5 min and squeezed by the double-roller device. The PVA size formula for coating harness cord is presented in Table 2. Subsequently, the PU/PVA-coated harness cord was heat set under 14 N tension and 195°C temperature for 3 min. The tension was applied to ensure that the harness cord was stretched 6 ± 1% and it was maintained constant until the harness cord was cooled down. The second method used PVA size to coat harness cord directly. The subsequent operation was same as the first method.

Manufacture of composite coated harness cord with PU/PVA.

PVA size formula for coating harness cord

| PVA1788 (%) | CMC (%) | DAHC (%) | Penetrant 8601 (%) | Nano-TiO2 (%) | Deionized water (%) | Size viscosity (mPa·s) |

|---|---|---|---|---|---|---|

| 6 | 0.4 | 0.08 | 0.2 | 2 | 91.32 | 441.0 |

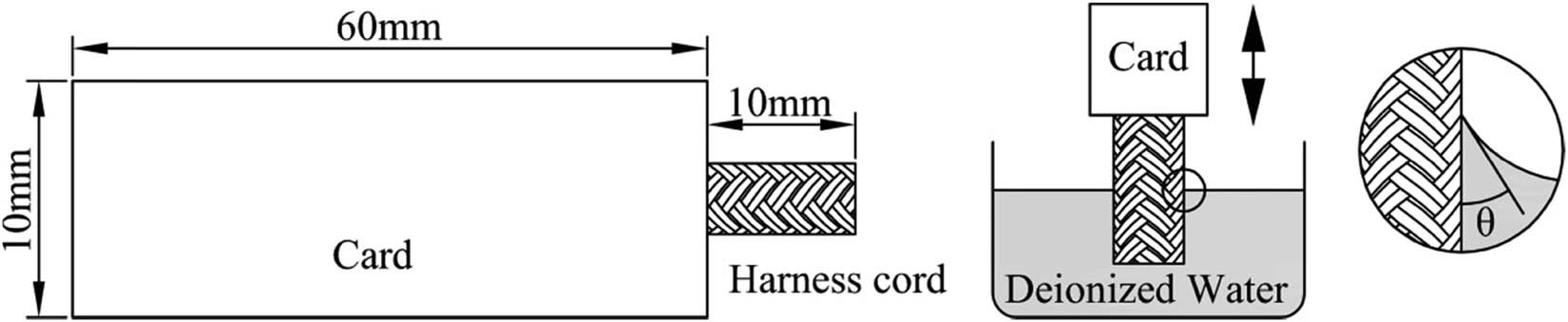

2.3 DCA tests

The surface tensiometer model DCAT 11 (Dataphysics, Germany) was employed to measure the DCA and study the surface properties of the harness cord before and after PU coating. Wilhelmy method was extensively used to test the advancing angle (θ A), receding angle (θ R), and contact angle hysteresis (Δθ) (27), and the Δθ was the difference between θ A and θ R. The test specimen and schematic diagram are presented in Figure 3. The harness cord was stuck between two paper cards of 60 mm × 10 mm with an extension length of 10 mm. The prepared specimen was immersed into the deionized water with a depth of 3 mm and a constant speed of 0.2 mm·s−1. When the specimen was immersed into or withdrawn out of the deionized water, the angle θ between the gas-liquid section and the solid–liquid interface was θ A and θ R, respectively. The ambient temperature was 20 ± 3°C. The total six specimens of each sample were tested for obtaining the average DCA.

Test specimen and schematic diagram of DCA.

2.4 Morphology observation

The surface morphology of the uncoated and coated harness cords was observed by a scanning electron microscope (SEM) model TM3000 (Hitachi, Japan). The accelerating voltage was 15 kV. To avoid charge-build-up problems, the samples were previously coated with a thin layer of gold by employing a sputter coater.

2.5 FTIR spectroscopy analysis

The FTIR spectra of the uncoated and coated harness cords were recorded on a spectrometer model Nicolet 6700 (Thermo Fisher, USA) in the range of 500–4,000 cm−1. The harness cords spectra were obtained using KBr pellets at room temperature, respectively.

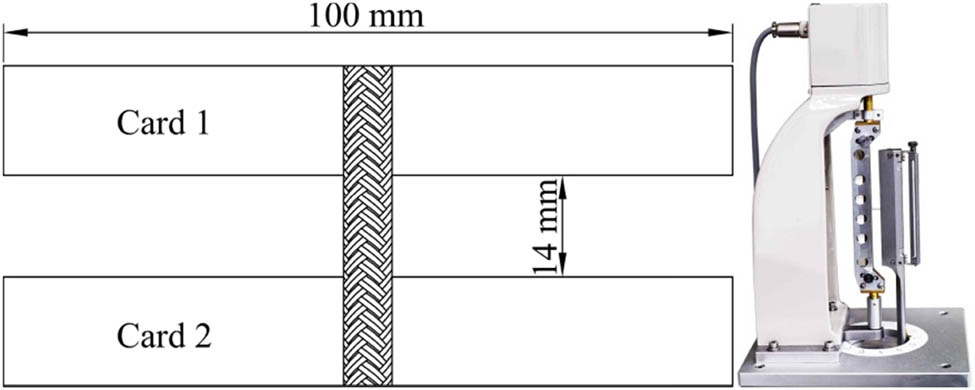

2.6 Bending properties tests

KES-FB-2 bending tester (Kato Tech, Japan) was employed to test the bending rigidity and bending hysteresis moment for evaluating the flexibility and elasticity of the PU/PVA coated harness cords (28). The prepared specimen and determination of bending rigidity are shown in Figure 4. The harness cord was stuck in the center of two paper cards spacing 14 mm. The temperature and the relative humidity were 20 ± 3°C and 65 ± 5%, respectively. To reduce the error, five different specimens of each sample were measured so as to obtain the mean bending properties.

Specimen and determination of bending properties.

2.7 Tensile properties tests

The tensile tests of PU/PVA-coated harness cords were carried out using universal electronic strength tester model WDW-20 (Shanghai Hualong, China) according to FZ 65002-1995 with 100 mm·min−1 speed and 20 cm clamp distance. The temperature and the relative humidity were 20 ± 3°C and 65 ± 5%, respectively. The final result of each sample was expressed with an average value of five specimens.

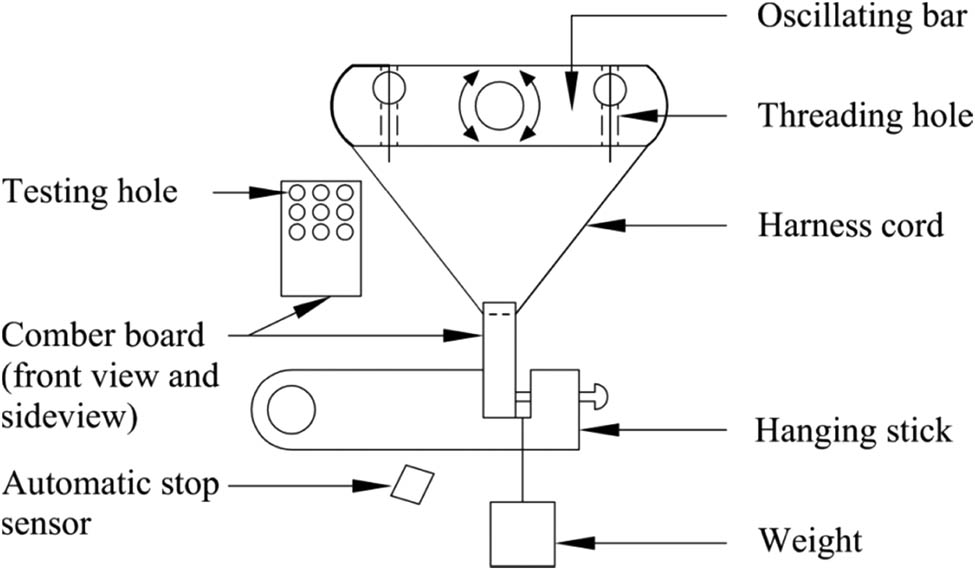

2.8 Wearability tests

The wearability of harness cord was tested by using the wearing test device developed in our lab to evaluate the effect of PU/PVA coating on this property. Figure 5 presents the schematic diagram of the test. The harness cord was fastened on the two ends of the oscillating bar that can reciprocate. The friction action would occur between the harness cord and the comber board. In most practical applications, the load on harness cord is about 150 g; the speed of harness cord moving up and down is no more than 450 times·min−1; the friction length of harness cord ranges from 45 to 120 mm; the angle between harness cord and comber board is not less than 60°. For improving the experimental efficiency, the tests were conducted under more severe conditions to accelerate the abrasion of the harness cord. Based on a large number of tests, the parameters of the wearing test device including the load, speed, friction length, and angle were set to 1,410 g, 440 rpm, 16 mm, and 38°, respectively (1). Three repeated wearability tests of each sample were undertaken. The temperature and the relative humidity were 20 ± 3°C and 65 ± 5%, respectively.

Schematic diagram of wearability test for harness cord.

3 Result and discussion

3.1 DCA

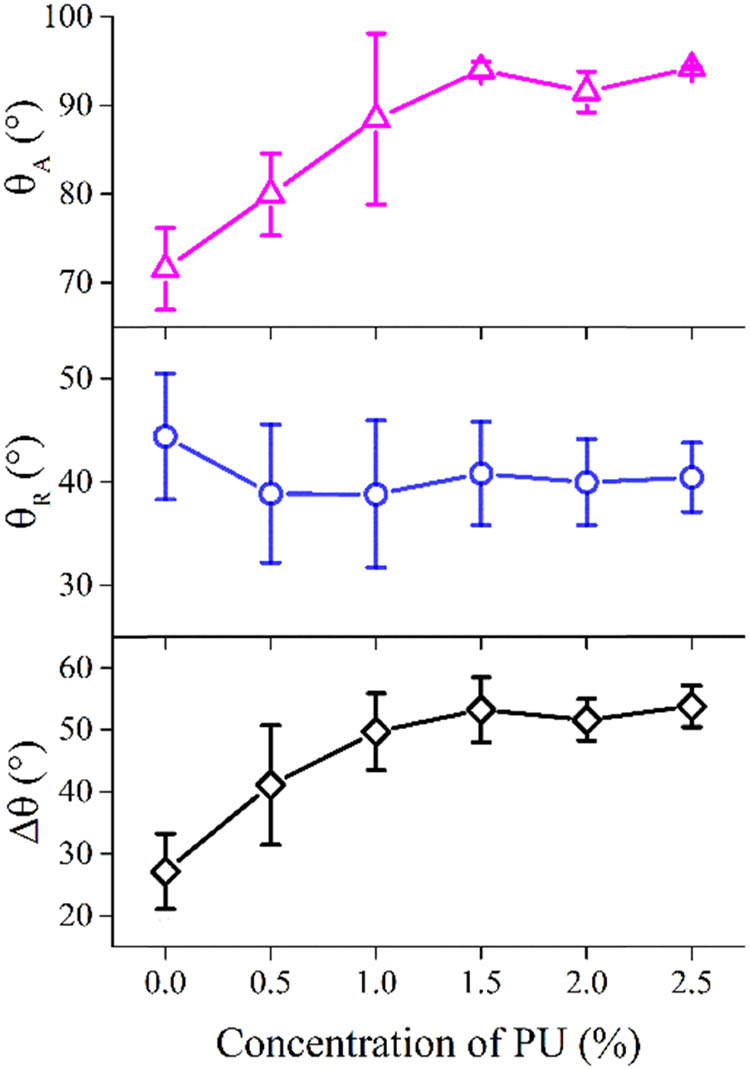

The DCA of harness cord before and after PU coating is shown in Figure 6.

Advancing angle (θ A), receding angle (θ R), and contact angle hysteresis (Δθ) of harness cord before and after PU coating.

As we can see from Figure 6, the θ A and Δθ of the coated harness cord increase gradually with the increase in the PU concentration. However, the θ R presents a slight decrease with a stable amplitude. Compared with the uncoated harness cord, the increased ratio (11.79–38.27%) of coated harness cords’ θ A are higher than the decreased ratio (4.03–12.58%) of harness cords’ θ R. The DCA difference of PU-coated harness cord can be ascribed to the change in the surface roughness. After the PU coating, the surface roughness of the harness cord was increased. When the coated harness cord was immersed into and withdrawn out of the deionized water, the concave-convex structure on harness cord surface could pin the contact line (i.e., solid–liquid–air interface line) and hinder the relative movement of water on the surface of the harness cord, which eventually resulted in the increase in θ A and the decrease in θ R (29,30,31). Moreover, the higher surface roughness will lead to the greater difference between θ A and θ R as well as the significant hysteresis. Besides, when the PU concentration increases to 1.5%, θ A, θ R, and Δθ no longer present striking variation, indicating that the surface properties of the coated harness cord tended to be stable.

3.2 Morphology observation

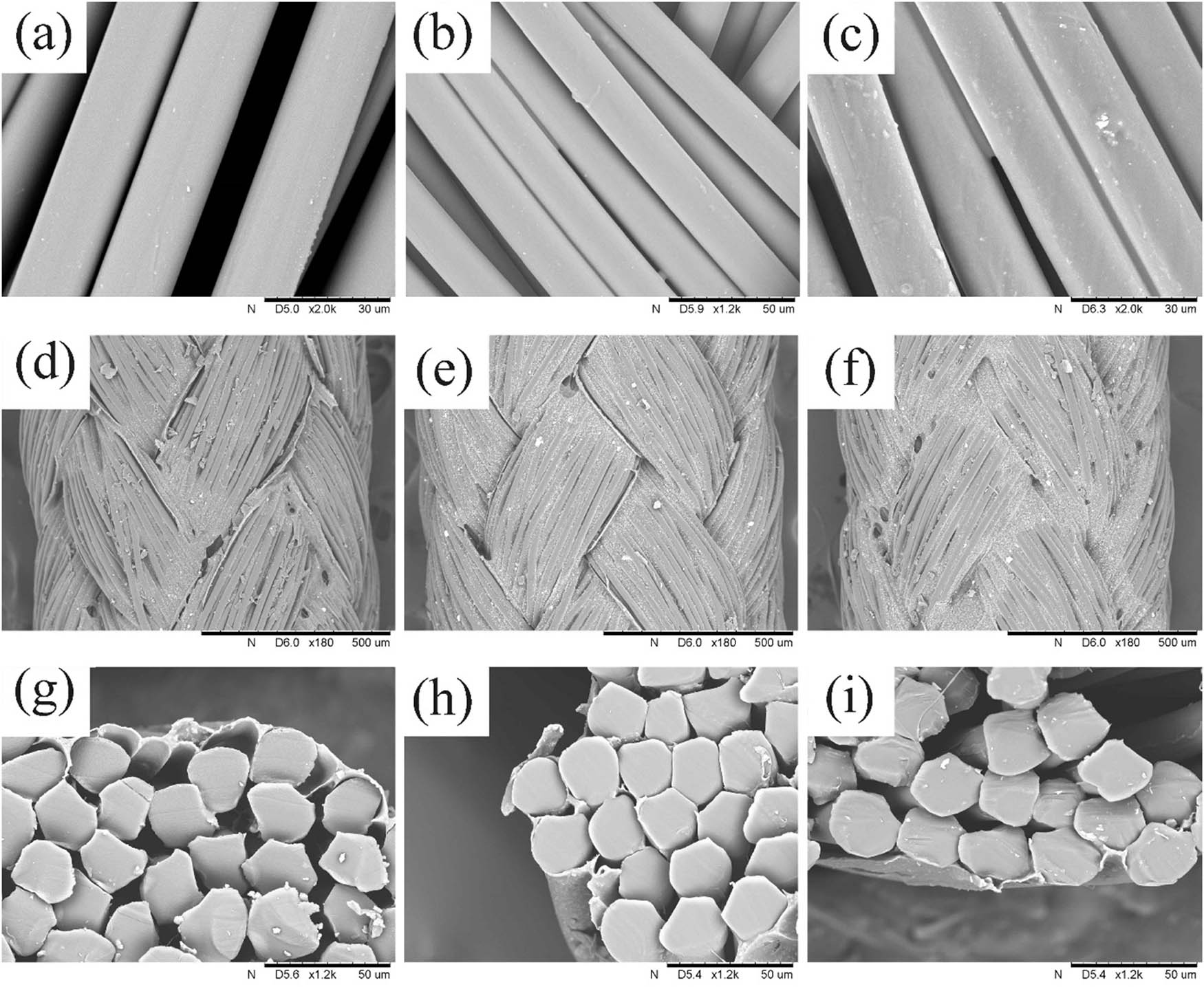

Figure 7 presents the electron photomicrographs of the harness cord before and after PU/PVA coating. Quite a smooth surface of PET fibers can be seen in the uncoated harness cord, as shown in Figure 7a. The white matting agent TiO2 which is used to scatter light can be observed on the fibers’ surface. In Figure 7b and c, the PU on the fibers’ surface, especially in the gap between the fibers, is clearly visible. When the concentration of PU increases from 0.5% to 1.5%, more PU adheres to the PET fibers.

(a) Uncoated harness cord. (b) 0.5% PU-coated harness cord. (c) 1.5% PU-coated harness cord. (d) Surface morphology of coated harness cord with PVA. (e) Surface morphology of coated harness cord with PU(0.5%)/PVA. (f) Surface morphology of coated harness cord with PU(1.5%)/PVA. (g) Cross section of coated harness cord with PVA. (h) Cross section of coated harness cord with PU(0.5%)/PVA. (i) Cross section of coated harness cord with PU(1.5%)/PVA.

The surface morphology of the coated harness cord with PVA and PU/PVA is shown in Figure 7d–f. In Figure 7d, the large cracks observed at the interlacing point of strands reveal the poor adhesion of PVA coating to the PET fibers. After 0.5% PU coating, as shown in Figure 7e, the cracks between PVA coating and PET fibers become small. When the concentration of PU increases to 1.5%, no cracks can be seen as shown in Figure 7f. The PU/PVA coating can adhere uniformly to the surface of the harness cord, indicating PU can improve the adhesion of PVA coating to PET fibers.

The cross section of the coated harness cord with PVA and PU/PVA is presented in Figure 7g–i. The separation observed in Figure 7h also reveals the poor adhesion of PVA coating to the PET fibers. This is because fewer ester groups exist in the macromolecules of PVA coating and the large difference in the solubility parameter between PVA (>52 (J·cm−3)1/2) and PET (44.8 (J·cm−3)1/2). After the PU coating, the PVA coating is closely bonded to PET fibers, as shown in Figure 7h and i. It is well known that the interaction of the two polymers is high when the solubility parameter value of them is close to each other (32,33). The solubility parameter of PU (43.1 (J·cm−3)1/2) is very close to that of PET, thus PU presents excellent adhesion to PET fibers. PU can act as “bridge” between PVA coating and hydrophobic PET fibers, therefore effectively improving the interfacial properties between them, and enhancing the adhesion of PVA coating to PET fibers.

3.3 Structural information from FTIR spectra

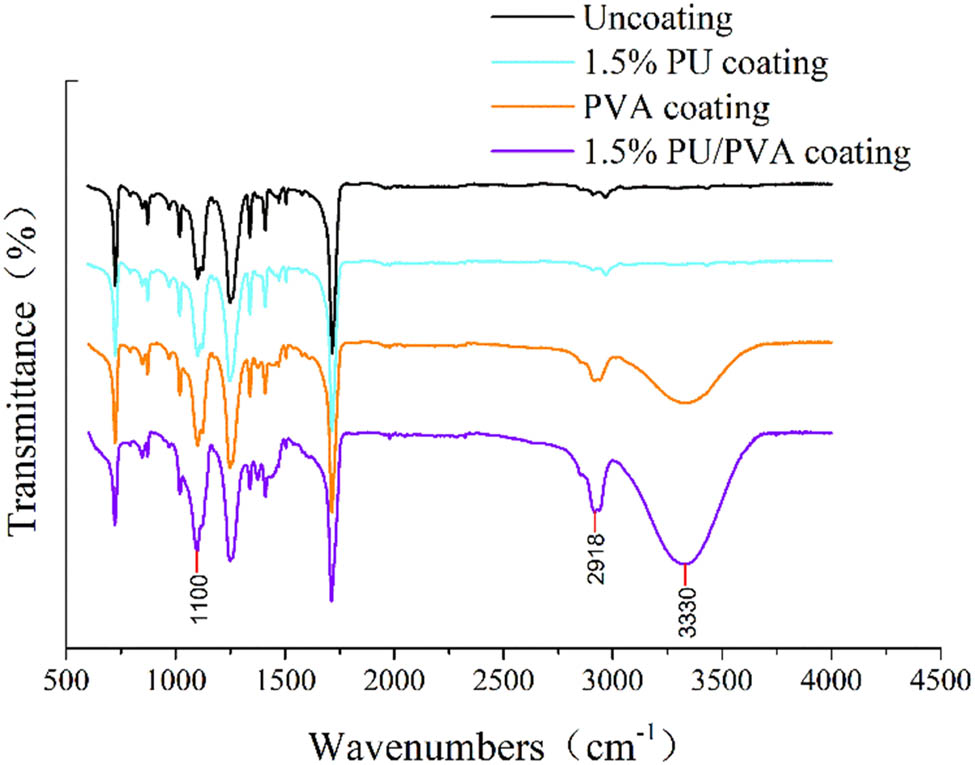

Figure 8 shows the FTIR spectra of uncoated harness cord and coated harness cords with PU(1.5%), PVA, and PU(1.5%)/PVA.

FTIR spectra of uncoated harness cord and coated harness cords with PU(1.5%), PVA, and PU(1.5%)/PVA.

In Figure 8, the same FTIR spectra of uncoated and 1.5% PU-coated harness cords can be observed. There is no striking change in the characteristic peaks and absorption intensity, which is responsible for the low concentration of PU, resulting in its structural information that cannot be shown in the FTIR spectra. The characteristic peaks of PET harness cord at wavenumbers of 725, 873, 1,102, 1,248, 1,409, 1,716, and 2,969 cm−1 can be attributed to the C–H rocking in long chain methylene, two adjacent C–H bending on benzene ring, C–OH stretching, C–O asymmetric stretching, C–H bending on benzene ring, C═O stretching of carbonyl, and CH2 stretching of methylene, respectively (34,35,36).

As we can see from Figure 8, compared with uncoated harness cord, the FTIR spectrum of PVA-coated harness cord changes significantly around wavenumber of 3,000 cm−1. The broad and blunt characteristic peak at 3,330 cm−1 is attributed to the stretching of associating hydroxyl, which is involved in intramolecular and intermolecular hydrogen bonds. The characteristic peak at 2,918 cm−1 is because of the CH2 stretching. At 1,100 cm−1, the absorption intensity of the characteristic peak is also enhanced, indicating that PVA increases the hydroxyl content in the coated harness cord. Although 1.5% PU/PVA-coated harness cord is only 1.5% more PU than PVA-coated harness cord, the absorption intensity of infrared spectrum is further enhanced at the above three wavenumbers. This suggested that the hydrogen bonds are formed between PU and PVA, which enhances the hydroxyl content of the coated harness cord. Therefore, PU can play a real “bridge” role between PVA and PET fibers to improve their interface performance and make them adhere more closely.

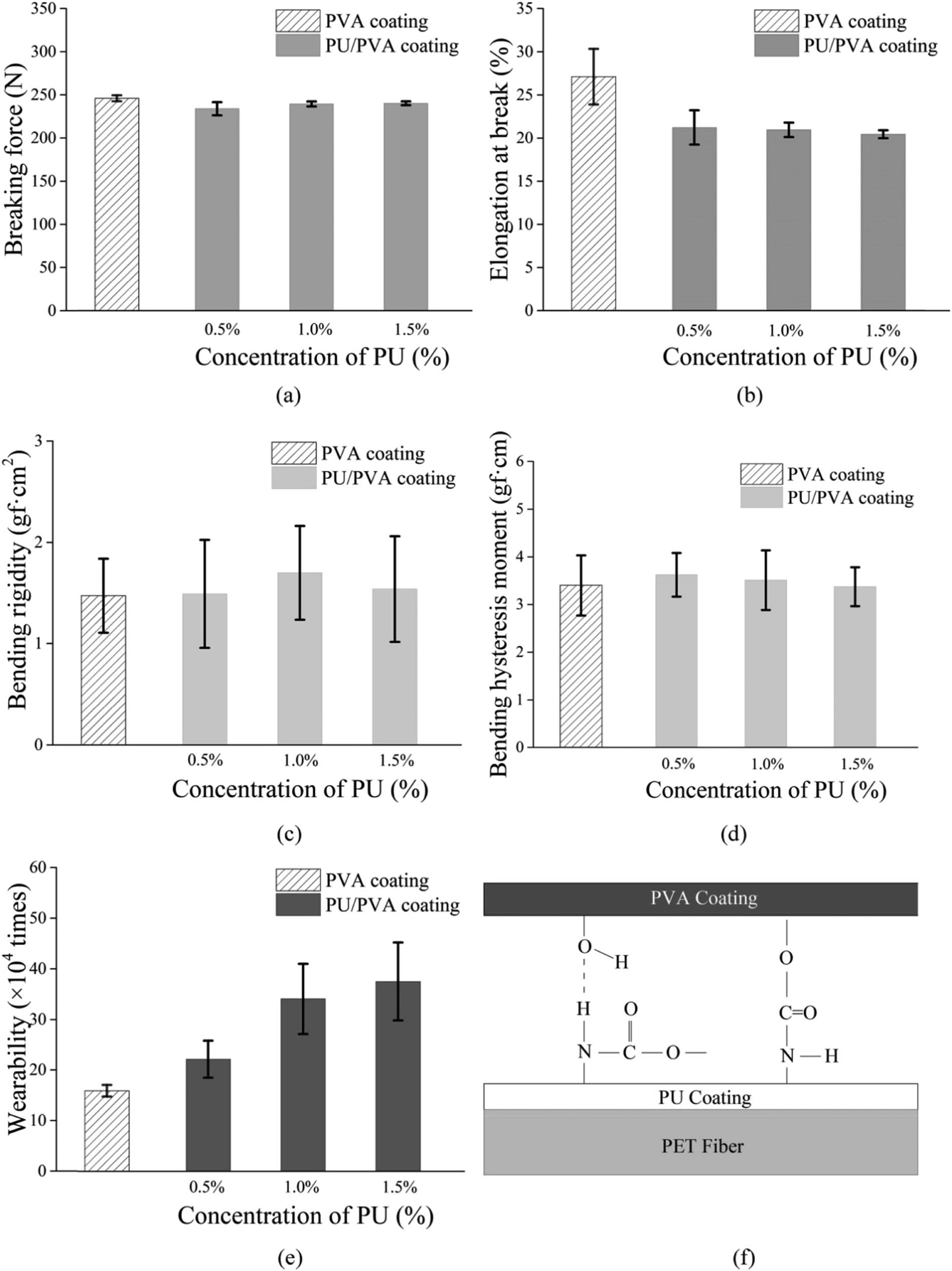

3.4 Tensile properties

Figure 9a and b shows the tensile properties of the coated harness cord with PVA and PU/PVA. It suggests that the breaking force of PU/PVA-coated harness cord presents a tiny reduction, ranging from 2.4% to 4.9%, compared with that of PVA-coated harness cord. However, the elongation at break decreases in larger extent as the PU concentration increases. For example, the elongation of PU/PVA-coated harness cord reduces as much as 24.6% when the concentration of PU is 1.5%. The reduction in tensile properties of PU/PVA-coated harness cord can be explained in the following two aspects. Firstly, the PU/PVA coating will bond the surface fibers of the harness cord together. It is difficult to adjust the angle between the surface fibers and the harness cord’s axis when the load is applied, which results in a low strength efficiency of the fibers in the axial direction of the harness cord. Secondly, the inner fibers in the coated harness cord are first subjected to the load, and the bonded fibers are hard to deform to share the load, which leads to ununiform stress distribution of fibers in harness cord and the occurrence of fibers’ breakage without simultaneously.

(a) Breaking force of coated harness cord with PVA and PU/PVA. (b) Elongation at break of coated harness cord with PVA and PU/PVA. (c) Bending rigidity of coated harness cord with PVA and PU/PVA. (d) Bending hysteresis moment of coated harness cord with PVA and PU/PVA. (e) Wearability of coated harness cord with PVA and PU/PVA. (f) Intermolecular interaction between PU and PVA.

3.5 Bending properties

Figure 9c and d depicts the bending properties of the coated harness cord with PVA and PU/PVA. Bending rigidity is the ability of the harness cord to resist bending deformation. A low value of bending rigidity means the harness cord has good flexibility. The bending hysteresis moment represents the magnitude of viscosity of harness cord during bending deformation. The high bending hysteresis moment denotes the low elasticity of the harness cord.

As illustrated in Figure 9c and d, the bending rigidity and bending hysteresis moment of PU/PVA-coated harness cord are slightly increased compared with the PVA-coated harness cord, and the increased ratios are within 15.3% and 6.6%, respectively. After the PVA coating, the surface fibers of the harness cord are bonded together, which limits the movement of fibers. During the bending test, the bonded fibers cannot slide against each other easily and adjust the angle between them and the harness cord’s axis to conform to the bending stress. Since the PU is a block polymer composed of soft segments and rigid segments alternately, a uniform flexible and elastic film can be formed on the surface of the harness cord. Therefore, the existence of PU does not significantly reduce the flexibility and elasticity of PU/PVA-coated harness cord.

3.6 Wearability

The wearability of the coated harness cord with PVA and PU/PVA is shown in Figure 9e. It is found that the wearability of PU/PVA-coated harness cord is significantly improved compared with that of PVA-coated harness cord. When the PU concentration is 0.5%, the wearability of PU/PVA-coated harness cord is increased by 39.1%. However, the wearability can be improved up to 135.7% if the PU concentration is increased to 1.5%.

Because the content of ester groups in PVA macromolecules is low and a large number of hydroxyl groups cannot form hydrogen bonds with smooth hydrophobic PET fibers, mechanical interlocking force and van der Waals force are insufficient to ensure the good adhesion of PVA coating to PET fibers. The excellent adhesion of PU to PET fibers is attributed to their similar solubility parameters. PU can form a film on the surface of PET harness cord and increase its surface roughness, thus improving the adhesion strength between PVA coating and PET fibers. The PU coating can also introduce such polar groups as carbamate group and isocyanate group on the surface of the PET fibers, which can form hydrogen bonds or chemical bonds with hydroxyl groups in PVA macromolecules (as shown in Figure 9f) so as to improve the interaction between PVA coating and PET fibers (37,38). In addition, according to diffusion theory, when the coating process is carried out at high temperature, the end or middle of PU, PET, and PVA macromolecular chains are easier to diffuse and entangle each other, which is also helpful to form the interface layers with high adhesion strength. The excellent interfacial properties can prevent the PVA coating from being peeled off by the shearing force of the comber board, which protects the PET fibers from directly being worn by the comber board, thereby improving the wearability of the harness cord. During the wearability test, the coated harness cord is also subjected to repeated bending forces. Because the bending properties of PU/PVA-coated harness cord do not change significantly, and PU itself has excellent wearability and toughness (39), the wearability of PU/PVA-coated harness cord has been greatly improved.

4 Conclusion

In this article, the PET harness cord with uniform PU/PVA coating and excellent performance was manufactured by using composite coating method. The bending and tensile properties of the PU(1.5%)/PVA-coated harness cord were only slightly decreased compared with that of PVA-coated one. However, its wearability was greatly improved by 135.7%. The PU coating could not only increase the surface roughness of the harness cord, but also improve the interfacial properties between the PVA coating and the hydrophobic PET fibers by introducing the polar groups, thus enhancing the adhesion of the PVA coating to the PET fibers.

-

Funding information: Natural Science Foundation of Hunan Province (2020JJ4245).

-

Author contributions: Kaifang Xie: writing – original draft and investigation; Xinjun Bao: writing – review and editing; Hengshu Zhou: writing – methodology and formal analysis; Bin He: project administration; Yuegang Liu: supervision; Guangbiao Xu: resources; Hua Shen: writing – grammar and language and visualization.

-

Conflict of interest: Authors state no conflict of interest.

References

(1) Xie KF, Xu YF, Shen H, Xu GB. Study on the wearability and abrasion mechanism of braided harness cord. Text Res J. 2019;89(14):2961–9. 10.1177/0040517518805377.Search in Google Scholar

(2) Behera BK. Assessing the wearability of technical yarns. In: Alagirusamy R, Das A, editors. Technical Textile Yarns. England: Woodhead Publishing; 2010. p. 215–6.10.1533/9781845699475.1.215Search in Google Scholar

(3) Fan WC, Zhu YH, Xi GH, Huang MQ, Liu XD. Wear-resistant cotton fabrics modified by PU coatings prepared via mist polymerization. J Appl Polym Sci. 2016;133(7):43024. 10.1002/app.43024.Search in Google Scholar

(4) Gurarda A, Yukseltan E, Kaplangiray BM, Kanik M. The effects of various lubricants on the friction properties of sewing threads. Text Res J. 2013;83(12):1273–82. 10.1177/0040517512470199.Search in Google Scholar

(5) Reifler FA, Sánchez FAL, Clemens FJ, Varga K, Hufenus R. Flexible ceramic-reinforced polyurethane composite coatings on synthetic fibres: process of continuous liquid film coating and its influence on the coating thickness. Compos Sci and Technol. 2010;70(8):1207–13. 10.1016/j.compscitech.2010.03.008.Search in Google Scholar

(6) Xie KF, Zhang ZY, Shen H, Xu GB. Analysis on property discrepancy between core and sheath fibers in braided harness cords. Fiber Polym. 2019;20(6):1311–6. 10.1007/s12221-019-8206-z.Search in Google Scholar

(7) Davies P, Durville D, Vu TD. The influence of torsion on braided rope performance, modelling and tests. Appl Ocean Res. 2016;59:417–23. 10.1016/j.apor.2016.07.003.Search in Google Scholar

(8) Xie KF, Shen H, Xu GB. Effect of temperature on tensile and creep-recovery properties of braided polyester harness cord. J Appl Polym Sci. 2019;136(33):47864. 10.1002/app.47864.Search in Google Scholar

(9) Hsieh JC, Li JH, Huang CH, Lou CW, Lin JH. Statistical analyses for tensile properties of nonwoven geotextiles at different ambient environmental temperatures. J Ind Text. 2017;47(3):331–47. 10.1177/1528083716647199.Search in Google Scholar

(10) Vassallo JC. Spun sizing chemicals and their selection. AATCC Rev. 2005;5(12):25–8. 10.1002/adma.200500685.Search in Google Scholar

(11) Krump H, Šimor M, Hudec I, Jaššo M, Luyt AS. Adhesion strength study between plasma treated polyester fibres and a rubber matrix. Appl Surf Sci. 2005;240(1–4):268–74. 10.1016/j.apsusc.2004.06.109.Search in Google Scholar

(12) Ibrahim NA, Eid BM, Youssef MA, Ameen HA, Salah M. Surface modification and smart functionalization of polyester-containing fabrics. J Ind Text. 2012;42(4):353–75. 10.1177/1528083712440899.Search in Google Scholar

(13) Venkatachalam S, Nayak SG, Labde JV, Gharal PR, Rao K, Kelkar AK. Degradation and recyclability of poly (Ethylene Terephthalate). In: Saleh HEM, editor. Polyester. London: Intech Open Science; 2012. p. 76–7.10.5772/48612Search in Google Scholar

(14) Lu J, Li M, Li YY, Li XQ, Gao Q, Ge MQ. Synthesis and sizing performances of water-soluble polyester based on bis(2-hydroxyethyl) terephthalate derived from depolymerized waste poly(ethylene terephthalate) fabrics. Text Res J. 2018;89(4):572–9. 10.1177/0040517517750652.Search in Google Scholar

(15) Ma PB, Huang JR, Huang J, Xu WL. Improving the adhesive property of polyester fabric with sodium hydroxide and corona discharge treatment. J Adhes Sci Technol. 2011;25(14):1647–57. 10.1163/016942410X537161.Search in Google Scholar

(16) Zhang ZY, Xie KF, Xu GB. Influence study on coating effect of polyester harness cord with alkali treatment. J Text Sci Eng. 2018;35(1):61–5.Search in Google Scholar

(17) Haghighatkish M, Yousefi M. Alkaline hydrolysis of polyester fibers structural effects. Iran J Polym Sci Technol. 1992;1(2):56–61.Search in Google Scholar

(18) Brzeziński S, Tracz A, Połowiński S, Kowalczyk D. Effect of corona discharge on the morphology of polyester fiber top layer. J Appl Polym Sci. 2010;116(6):3659–67. 10.1002/app.31926.Search in Google Scholar

(19) Šimor M, Ráheľ J, Černák M, Imahori Y, Štefečka M, Kando M. Atmospheric-pressure plasma treatment of polyester nonwoven fabrics for electroless plating. Surf Coat Tech. 2003;172(1):1–6. 10.1016/S0257-8972(03)00313-X.Search in Google Scholar

(20) Zhang CM, Zhao MH, Wang LB, Qu LJ, Men YJ. Surface modification of polyester fabrics by atmospheric-pressure air/He plasma for color strength and adhesion enhancement. Appl Surf Sci. 2017;400(APR.1):304–11. 10.1016/j.apsusc.2016.12.096.Search in Google Scholar

(21) Xu WL, Liu X. Surface modification of polyester fabric by corona discharge irradiation. Eur Polym J. 2003;39(1):199–202. 10.1016/S0014-3057(02)00169-6.Search in Google Scholar

(22) Razavizadeh M, Jamshidi M. Adhesion of nitrile rubber (NBR) to polyethylene terephthalate (PET) fabric. Part 1: PET surface modification by methylenediphenyl di-isocyanate (MDI). Appl Surf Sci. 2016;360(Part A):429–35. 10.1016/j.apsusc.2015.10.137.Search in Google Scholar

(23) Gorenšek M, Gorjanc M, Bukošek V, Kovač J, Petrović ZL, Puač N. Functionalization of polyester fabric by Ar/N2 plasma and silver. Text Res J. 2010;80(16):1633–42. 10.1177/0040517510365951.Search in Google Scholar

(24) Niroomand M, Hejazi SM, Sheikhzadeh M, Alirezazadeh A. Pull-out analysis of laser modified polyamide tire cords through rubber matrix. Eng Fai Anal. 2017;80:431–43. 10.1016/j.engfailanal.2017.07.013.Search in Google Scholar

(25) Xie KF, Xu YF, Shen H, Xu GB, Ma YX. Effect of coating process on morphology, bending rigidity and wearability of polyester harness cords. J Ind Text. 2019;50(5):187–204. 10.1177/1528083718819865.Search in Google Scholar

(26) Raeisi A, Shabanian M, Faghihi K. Preparation of beta-cyclodextrin-ester network and new organo-modified LDH as dual additives of PVA: thermal, dynamic-mechanical and migration study. Prog Org Coat. 2017;111:402–15. 10.1016/j.porgcoat.2017.06.022.Search in Google Scholar

(27) Karim AM, Kavehpour HP. Effect of viscous force on dynamic contact angle measurement using wilhelmy plate method. Colloid Surface A. 2018;548:54–60. 10.1016/j.colsurfa.2018.03.058.Search in Google Scholar

(28) Wang FM. The performance design of garment fabric. 1st edn. Shanghai: China Textile University Press; 2000.Search in Google Scholar

(29) Iliev S, Pesheva N, Iliev P. Contact angle hysteresis on doubly periodic smooth rough surfaces in Wenzel’s regime: The role of the contact line depinning mechanism. Phys Rev E. 2018;97(4):042801. 10.1103/PhysRevE.97.042801.Search in Google Scholar PubMed

(30) Sauer BB, Carney TE. Dynamic contact angle measurements on glass fibers: influence of fiber diameter on hysteresis and contact line pinning. Langmuir. 1990;6(5):1002–7. 10.1021/la00095a020.Search in Google Scholar

(31) Tretinnikov ON, Ikada Y. Dynamic wetting and contact angle hysteresis of polymer surfaces studied with the modified wilhelmy balance method. Langmuir. 1994;10(5):1606–14. 10.1021/la00017a047.Search in Google Scholar

(32) Uzun M, Govarthanam KK, Rajendran S, Sancak E. Interaction of a non-aqueous solvent system on bamboo, cotton, polyester and their blends: the effect on abrasive wear resistance. Wear. 2015;322–323(10):10–6. 10.1016/j.wear.2014.10.006.Search in Google Scholar

(33) Wang LL, Cui SS, Ni HG, Wu MH. Preparation and application of polyacrylate binder for washing-free printing on polyester with disperse dyes. Text Res J. 2018;89(13):2721–8. 10.1177/0040517518801193.Search in Google Scholar

(34) Cole KC, Guèvremont J, Ajji A, Dumoulin MM. Characterization of surface orientation in poly(ethylene terephthalate) by front-surface reflection infrared spectroscopy. Appl Spectrosc. 1994;48(12):1513–21. 10.1366/0003702944027877.Search in Google Scholar

(35) Bashir T, Ali M, Persson NK, Ramamoorthy SK, Skrifvars M. Stretch sensing properties of conductive knitted structures of PEDOT-coated viscose and polyester yarns. Text Res J. 2015;84(3):323–34. 10.1177/0040517513494253.Search in Google Scholar

(36) Zhou YF, Jiang L, Guo Y, Sun ZH, Jiang ZQ, Chen SJ, et al. Rapid fabrication of silver nanoparticle/polydopamine functionalized polyester fibers. Text Res J. 2019;89(19–20):3968–78. 10.1177/0040517519826893.Search in Google Scholar

(37) Zhou CC, Li ZD, Wang ZJ, Ju GL. Research progress in performance of terylene-TPU coated fabric interface. Chem Propell Polym Mater. 2011;9(4):53–7.Search in Google Scholar

(38) Xu PL, Zhang SQ. Polyurethane materials manual. 1st edn. Beijing: Chemical Industry Press; 2002.Search in Google Scholar

(39) Chen SB, Wang QH, Wang TM. Friction and wear behaviors of two kinds of hydroxyl-terminated polydimethylsiloxane-modified PU/EP IPN composites under dry sliding conditions. Tribol Lett. 2011;43(3):319–27. 10.1007/s11249-011-9816-4.Search in Google Scholar

© 2022 Kaifang Xie et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes

Articles in the same Issue

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes