Abstract

Large amounts of textile waste are generated every year and disposed of through landfill or incineration, leading to numerous environmental and social issues. In this study, waste hybrid polyethylene terephthalate (PET)/cotton fibers were used directly to reinforce high density polyethylene (HDPE) to prepare composites. In order to give full play to the fiber’s reinforcing characteristics, the PET/cotton fibers were further modified with the modifier using a novel synthesized tetraethyl orthosilicate/3-aminopropyl triethoxysilane (KH550)/polyethylene (PE)-g-MAH (MPE) hybrid (TMPE). Fourier transform infrared and scanning electron microscopy (SEM) confirmed that the TMPE was successfully coated on the surface of fibers. Furthermore, compared with the original and the MPE-modified fibers, the thermal stability of TMPE-modified fibers was significantly increased. SEM and mechanical test indicated that the compatibility of the modified fibers with HDPE had been significantly improved, which led to the improvement of mechanical properties. Compared with the original and MPE-modified fibers-reinforced HDPE composites, the bending strength, bending modulus, and impact strength of TMPE-modified fiber-reinforced HDPE composites were improved obviously by 31.7%, 25.7%, and 89.1%, respectively.

1 Introduction

Due to the increase of world population, the rapid change of fashion cycle, and the improvement of people’s quality of life, waste fabrics have been increasing steadily in the past few decades. If the fabrics are in the pure form, e.g., cotton or PET, different recycling or reuse techniques can be developed on a large scale. However, waste textiles are generally hybrid PET/cotton fabrics (a general term for blended fabrics of PET and cotton). In most countries, people choose to bury waste textiles in land (landfill) in order to dispose them (1), which not only is a waste of resources, but also pollutes the environment. Compared with landfill, recycling and reuse of PET/cotton fabrics are obviously much preferable (2).

In previous studies, the recycling and reuse of hybrid PET/cotton fabrics were mainly to separate the waste PET/cotton fabrics into different products. This may be done by depolymerizing or dissolving one component while maintaining the other. For example, to maintain the PET, people can degrade the cotton either with acid or microbes (3,4,5). Then the maintained PET can be melted and woven into new products in textile manufactures. It is also possible to maintain the cotton and depolymerize or dissolve the PET (6,7). However, cotton fibers with cellulose as the main component are easy to be damaged to a certain extent after mechanical or chemical treatment. Therefore, recycled cotton fibers can only be used for low-value textiles, such as carpets, fillers, and nonwoven fabrics (8,9). In addition, the use of solvents and the generation of hazardous wastes in the process of separation inevitably bring new environmental problems, and the fibers being separated may have incomplete separation or mechanical property deterioration caused by damages. Therefore, their reuse value is relatively low (10). That is to say, the recycling might cost far more than the value of the recovered material.

However, if the PET/cotton fibers can be used directly, the problems caused by the preceding method can be avoided. In fact, the PET/cotton fibers have certain strength and modulus; therefore, making PET/cotton fibers into reinforced composite materials may be a potential method for recycling them. However, two problems should be considered before using them directly as the reinforcing materials. One is how to choose the suitable processing temperature because of the differences of thermal stability between cotton fibers and PET fibers. The temperature used to process the composite materials is lower than the heat resistance temperature of recycled cotton (140–150°C) to ensure the integrity of PET and cotton fiber to strengthen the composite. However, when it reaches the processing temperature of the PET fiber (180–220°C), the cotton fiber might have been carbonized. So, it is necessary to improve the thermal stability of the hybrid PET/cotton fibers in order to use them in the composites. In fiber-reinforced polymers, the interfacial adhesion between the fiber and the polymer matrix determines the key to the stress transfer efficiency of high-performance fiber-reinforced materials. Therefore, it is necessary that the fibers be modified to improve the chemical bonding and mechanical interlocking between the fiber and the polymer matrix (11,12,13). So, the other problem is how to choose the suitable modification method to modify the hybrid PET/cotton fibers. Most of previous studies were based on surface chemical etching (alkali treatment), graft modification (14), plasma modification (15), and coating method (16). These studies have shown that alkali treatment can easily control the reaction time and temperature. In addition, it is possible to design and predict the decrease in fiber strength and weight loss. Therefore, alkali treatment is usually the basic treatment and grafting and coating treatment further functional treatment (17,18).

In our previous study (19), through the sol–gel method, SiO2 was connected to the polypropylene-g-MAH molecular chains through a silane coupling agent, which was used to coat PET fibers to form an inorganic–organic film on the surface of the glass fibers. The results have proved that the modification effect is obvious, and the properties of PP composites have been significantly improved. So the same modification method was used to modify the surface of hybrid PET/cotton fibers, for the purpose of improving the thermal stability of the fibers and the compatibility of the fibers with high density polyethylene (HDPE), so as to further improve the performance of the composite material and provide an optional method for reusing the hybrid PET/cotton fibers.

2 Experimental

2.1 Materials

The 10-count PET/cotton yarn (provided by Weifang Xinhui Textile Co., Ltd) was made of 65% polyester and 35% cotton fiber twisted. The matrix material was HDPE with a density of 0.96 g·cm−3, and melt flow rate = 7.3 g·10 min−1 (2.16 kg, 230°C, PetroChina Company Limited). Maleic anhydride grafted polyethylene (PE-g-MAH, MPE) was provided by Ningbo Nengzhiguang New Material Technology Co., Ltd., with a density of 0.96 g‧cm−3 and a free maleic anhydride content of less than 1.0%. Other materials were of analytical grade and all materials were used according to the received dose.

2.2 Synthesis of modifier

The hybrid modifier was synthesized by referring to the process of previous work (19): PE-g-MAH powder was added to a boiling xylene solution until the powder dissolved (solution A). Tetraethyl orthosilicate (TEOS), P-toluene sulfonic acid (PTSA), and xylene were mixed at room temperature according to the mass ratio of 1:0.01:20, and the mixture was continuously stirred (solution B). KH550 was mixed with xylene at room temperature in the mass ratio of 0.5:20, and the mixture was continuously stirred (solution C). Then, solution A, B, and C were mixed at 130°C for 1 h. The fiber modifier named TMPE was accomplished. It should be noted that the entire process of synthesizing the modifier should be in an anhydrous environment to prevent the hydrolysis reaction of TEOS from precipitation of SiO2, destroying the stability of the colloid.

2.3 Surface treatment of PET/cotton fibers

The PET/cotton fibers were soaked in a mixed solution of acetone and water (volume ratio 1:1) for 2 h, then washed with deionized water for 3–4 times, and finally dried at 85°C. Then the dried fibers were soaked in NaOH (0.01 mol·L−1) solution at 80°C for 1 h and dried again. Thereafter, they were dried and modified by MPE and TMPE solution by impregnation methods, respectively. Finally, the modified fibers were placed at room temperature for 3 days. When the modifier was completely hydrolyzed, SiO2/MPE composite powders were formed on the surface of the PET/cotton fibers. The reaction mechanism was shown in Eqs. (1)–(6):

The hydrolysis reaction of TEOS:

The hydrolysis reaction of KH550:

The reaction of TEOS and KH550 hydrolyzate:

The generation of silica groups with amine groups:

Interaction between MPE and amine groups

Synthesis of TMPE on the fiber surface:

2.4 Preparation of composites

The HDPE and fibers were mixed for 8 min in the mass ratio of 70:30 in the HAAKE at 180°C under the rotor speed of 60 rad·s−1. And then the mixture was pressed into 4 mm thick plate at 180°C for 6 min under the pressure of 7.5 MPa. According to the modification of PET/cotton fibers, these composites were divided into HDPE, HDPE reinforced with original fibers, HDPE reinforced with MPE-modified fibers, and HDPE reinforced with TMPE-modified fibers.

2.5 Characterizations

2.5.1 Scanning electron microscope

Scanning electron microscopy (SEM, S-4800N, Hitachi, Tokyo, Japan) was used to examine the morphology of the modified fibers and the impact cross-section of the PET/cotton fibers/HDPE composites. Samples were treated with spray gold craft before observation.

2.5.2 Fourier transform infrared spectroscopy

Fourier transform infrared (FTIR, Nicolet Magna-IR550, Thermo Electron, New York, USA) was used to characterize the modifier powders. The samples were loaded onto potassium bromide tablets.

2.5.3 Thermogravimetric analysis

The thermal stability of the modified fibers was tested by thermogravimetric analysis (TGA, Pyris6, Perkin-Elmer, Waltham, MA, USA). The samples were heated from ambient temperature to 800°C at a heating rate of 10°C·min−1 under the nitrogen atmosphere with a flow rate of 50 mL·min−1.

2.5.4 Color difference analysis

Color difference meter (SC-10, 3nh, Shenzhen, China) was used to analyze the color of the prepared PET/cotton fibers/HDPE composite material. The colorimeter uses the L, a, b color system, and the color change can be represented by Eq. 7:

where ΔE: degree of discoloration; L: from 0 to 100, +ΔL means white, −ΔL means black; a: from −150 to +150, +Δa means red, −Δa means green; b: from −150 to +150, +Δb means yellow, −Δb means blue.

2.5.5 Mechanical properties

The breaking force of a single yarn was tested with a universal tensile machine (XQ-1, Shanghai) in accordance with GB/T 14337-2008. The bending properties of the PET/cotton fibers/HDPE composites were tested by a universal tensile machine (CMT-20KN, Shenzhen). The test sample was prepared according to GB/T 9341-2008. The impact strength of the composites was measured by the cantilever beam impact tester (CEAST-9050, Italy), which was prepared according to GB/T 1834-2008.

3 Results and discussion

3.1 FTIR of modifier

The FTIR spectra of MPE and TMPE are shown in Figure 1. Absorption peaks at 3,421, 2,740, and 1,100 cm−1 are absent in MPE, but present in TMPE. Among them, 3,421 cm−1 is the N–H stretching vibration belonging to the amide group, 2,740 cm−1 is the stretching vibration belonging to the amine salt, and 1,100 cm−1 is speculated to be the antisymmetric stretching vibration peak of Si–O–Si. It can be seen from the figure that TMPE has only one peak between 3,300 and 3,500 cm−1, and the number of peaks in this wave number corresponds to the number of N–H bonds, so there is an imine group peak at 3,411 cm−1. The characteristic peak of the amine salt at 2,740 cm−1 indicates that part of the amine group reacts with PTSA.

FTIR spectra of MPE and TMPE modifiers.

Based on the structures of KH550, TEOS, and MPE, it can be concluded that the amine group in KH550 reacts with the anhydride in MPE to form an imino group (amide) close to the carbonyl group, and the alkoxy group of KH550 is hydrolyzed. Then, it reacts with TEOS hydrolyzed hydroxyl group to form a strong silicon–oxygen bond to form an organic–inorganic hybrid layer.

3.2 Modified PET/cotton fibers

3.2.1 Dimensional changes of PET/cotton fibers in microstructure

Figure 2 shows the SEM figures of hybrid PET/cotton fibers. PET fibers and cotton fibers are randomly distributed among the hybrid fibers (Figure 2a). PET fiber is regular and has a smooth surface, while cotton fiber has wrinkled and irregular surface due to its bending in the natural growth process (Figure 2b and c).

SEM images of (a) hybrid PET/cotton fibers, (b) PET fiber, and (c) cotton fiber in hybrid fibers.

Figure 3 shows the effects of modifiers on the surface morphology of PET fibers and cotton fibers, respectively. Apparently, the surface of the fibers is not uniformly packed with MPE particles (Figure 3a and b). However, compared with the MPE-modified fibers, the surface of TMPE-modified fibers is uniformly modified with a coating (Figure 3c and d). This not only protects the fibers to some extent, but also increases the contact area between the fibers and the matrix. By comparing the morphology characteristics of MPE-modified fiber and TMPE-modified fiber, it can be concluded that the modified coatings on the surface of the fibers are composed of silicon-oxygen bonds and MPE, and SiO2 with amino groups inhibits the agglomeration of MPE. In addition, SiO2 provides a nucleating agent for MPE and disperses MPE, thereby increasing the probability of contact between the modifier and the terminal hydroxyl groups on the fiber surface, which make the reaction more completely and the modified coating more closely combined.

SEM images of (a and b) MPE-modified fibers and (c and d) TMPE-modified fibers.

3.2.2 Thermal stability analysis of PET/cotton fibers

The TGA curves of original fibers, MPE-modified fibers, and TMPE-modified fibers are shown in Figure 4. Figure 4 shows that there appear two stages of weight loss and decomposition. The first stage is the decomposition of cotton fibers, and the second stage is the decomposition of PET fibers. Table 1 shows the temperature of every stage of weight loss and decomposition. It can be clearly seen from Table 1 that compared with the original fibers and the MPE-modified fibers, the decomposition temperatures of TMPE-modified cotton fibers and PET fibers are both significantly increased by 30°C and 33°C, respectively. This shows that TEOS and KH550 formed a dense inorganic layer on the surface of fibers by the amine-based SiO2 layer formed by the mutual reaction between their hydrolyzed products, thereby improving the thermal stability of PET/cotton fibers. In addition, the thermal conductivity of SiO2 is much higher than that of the fibers. After heat enters the modified fibers, it will first be transferred between SiO2, thus temporarily protecting other components.

TGA curves of (a) original fibers, (b) MPE-modified fibers, and (c) TMPE-modified fibers.

The temperatures of every stage of weight loss and decomposition

| Sample | The temperature of the first stage (°C) | The temperature of the second stage (°C) |

|---|---|---|

| Original fibers | 320–360 | 370–450 |

| MPE-modified fibers | 325–365 | 375–455 |

| TMPE-modified fibers | 350–390 | 403–483 |

3.2.3 Mechanical test of PET/cotton yarn

According to Figure 5, the breaking force of TMPE-modified fibers is much higher than that of original fibers and MPE-modified fibers. After the fiber is alkali-treated, many terminal hydroxyl groups will be produced on the surface. These active groups can react with MPE to connect MPE and fiber together. The experimental raw materials are polyester and cotton fibers twisted together. The distance between them is very close, and these fibers are connected to form a whole through MPE, thereby effectively improving the strength of the yarn. Due to the addition of TEOS in TMPE modifier, the fiber’s surface was coated with a modified coating, and the agglomeration of MPE was inhibited and the dispersion was more uniform. This covering structure can not only repair the defects on the fiber surface, but also increase the stress transmission between the fibers to further enhance the strength of the TMPE-modified yarn.

Breaking force of PET/cotton yarn.

3.3 Analysis of PET/cotton fibers/HDPE composite material

3.3.1 Microstructure of composite material section

Figure 6 shows the microscopic morphology of the impact section of the HDPE composite reinforced with fibers. The original fibers apparently separate from the HDPE matrix (Figure 6a). Compared with the original fibers-filled HDPE, the gap between the fibers and matrix in the MPE-modified fibers-filled HDPE got smaller (Figure 6b) for improving the compatibility between the MPE-modified fibers and the matrix. In Figure 6c, the fibers and the HDPE matrix are tightly combined into a whole, which proves that TMPE modifiers are advantageous to improve the compatibility of the fibers and the HDPE matrix.

SEM images of impact cross-sections of (a) original fibers/HDPE, (b) MPE-modified fibers/HDPE, and (c) TMPE-modified fibers/HDPE.

3.3.2 Analysis of color difference of composite materials

Figure 7 shows the specimen surface photos of HDPE filled with the original fibers, MPE-modified fibers, and TMPE-modified fibers. In the process of composite material processing, cotton fibers are partially carbonized, so the color of the composite material is brown (Figure 7a). However, the surface of the composites filled with modified fibers changes progressively to chalky white but in a different whitening rate (Figure 7b and c). In order to further understand the surface whitening, the color difference meter was used to observe the whitening area, as shown in Table 2. As can be seen from the Table 2, the value with the biggest change of the three samples is L value, and L represents the change of black and white color. Table 2 shows that the color of the material filled with the TMPE-modified fibers is the lightest, which shows that TMPE has a significant improvement in the thermal stability of the fibers. The compatibility of the MPE-modified fibers with HDPE has been enhanced to a certain extent, so that the matrix can better cover the fibers during processing, thereby reducing the contact between fibers and air, which inhibit the carbonization of fibers. For the TMPE-modified fibers, the compatibility of the fibers and the matrix was increased significantly for the uniform distribution of the denser modifier, resulting in the filled composite materials having the lightest color.

Composite specimen surface photos of (a) original fibers/HDPE, (b) MPE-modified fibers/HDPE, and (c) TMPE-modified fiber/HDPE.

Data of composites measured by the color difference meter

| Sample | L | a | b | ΔL | Δa | Δb |

|---|---|---|---|---|---|---|

| Original fibers/HDPE | 47.61 | 6.22 | 11.29 | 0 | 0 | 0 |

| MPE-modified fibers/HDPE | 54.14 | 4.92 | 11.87 | 6.53 | −1.3 | 0.58 |

| TMPE-modified fibers/HDPE | 55.97 | 5.21 | 12.65 | 8.36 | −1.01 | 1.36 |

3.3.3 Mechanical analysis of composite materials

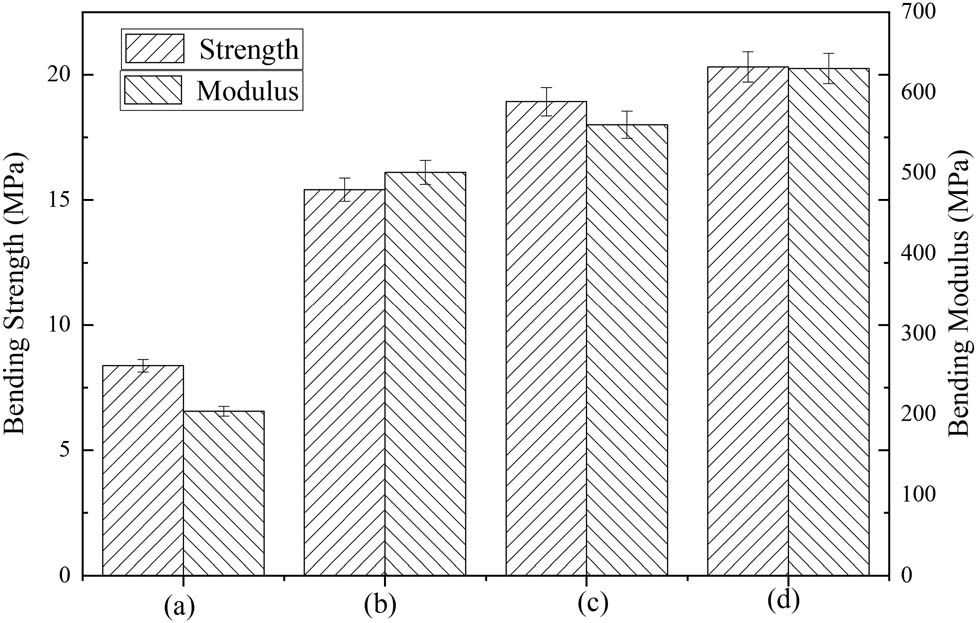

Figure 8 shows the bending strength and modulus of HDPE filled with fibers, respectively. Compared with HDPE, the bending strength and modulus of composites filled with PET/cotton fibers improved significantly. Moreover, the performance of the composites filled with TMPE-modified fibers is the best among all the samples. Compared to the composites filled with the original fibers, the bending strength and modulus of composites filled with TMPE-modified fibers increased by 4.89 and 129.03 MPa, respectively. Figure 9 shows the impact performance of the composite material. It can be seen from the figure that the impact strength of unmodified fiber-reinforced HDPE is 14.78 kJ·m−2, and the impact strength of MPE and TMPE-modified fiber-reinforced HDPE are 23.64 and 27.95 kJ·m−2, an increase of 60.0% and 89.1%, respectively.

Bending performance of (a) HDPE and HDPE composites filled with (b) original fibers, (c) MPE-modified fibers, and (d) TMPE-modified fibers.

Impact performance of HDPE composites filled with PET/cotton fibers.

The reinforcing effect of TMPE-modified fibers is much higher than that of unmodified fibers, which indicates that TMPE modifier has obvious improvement effect on the properties of composites. On the one hand, the modified coating makes the surface of the fibers rougher and increases the contact area between the fibers and the matrix, which can increase the compatibility of the fibers and the matrix; on the other hand, the modified coating protects the fibers and reduces the carbonization degree of the fibers, thereby significantly improving the mechanical properties of the conforming material.

4 Conclusion

In summary, the direct utilization of hybrid PET/cotton hybrid fibers was studied to enhance HDPE composites, so as to avoid the separation of the fibers and attendant environmental problems. Also, the surface modification of the fibers was carried out successfully to improve their thermal stability and strengthen their enhancing. TGA and color difference analysis showed the synthesized TMPE modifier increased the thermal stability of the fibers and the fibers-filled HDPE composites. Moreover, the breaking force of TMPE-modified fibers is also improved. Compared with the original fibers-filled composites, the bending strength, modulus, and impact strength of TMPE-modified fibers/HDPE composites were increased by 31.7%, 25.7%, and 89.1%, respectively.

-

Funding information: Authors state no funding involved.

-

Author contributions: Wei Cao: writing – original draft, conceptualization, data curation, software, methodology; Qiuying Li: conceptualization, formal analysis, validation, visualization, project administration, writing – review and editing; Chifei Wu: resources, supervision, funding acquisition, validation, investigation.

-

Conflict of interest: Authors state no conflict of interest.

References

(1) Nørup N , Pihl K , Damgaard A , Scheutz C . Evaluation of a European textile sorting centre: material flow analysis and life cycle inventory. Resou Conserv Recy. 2019;143(32):310–9.10.1016/j.resconrec.2019.01.010Suche in Google Scholar

(2) Haslinger S , Hummel M , Anghelescu A , Määttänen M , Sixta H . Upcycling of cotton polyester blended textile waste to new man-made cellulose fibers. Waste Manage. 2019;97(25):88–96.10.1016/j.wasman.2019.07.040Suche in Google Scholar PubMed

(3) Sun XW , Lu CH , Zhang W , Tian D , Zhang XX . Acetone-soluble cellulose acetate extracted from waste blended fabrics via ionic liquid catalyzed acetylation. Carbohyd Polym. 2013;93(1):405–11.10.1016/j.carbpol.2013.05.089Suche in Google Scholar PubMed

(4) Shi S , Zhang ML , Ling C , Hou WS , Yan ZF . Extraction and characterization of microcrystalline cellulose from waste cotton fabrics via hydrothermal method. Waste Manage. 2018;82(30):139–46.10.1016/j.wasman.2018.10.023Suche in Google Scholar PubMed

(5) Felice Q , Sara V , Simone W , Klemens K , Lukas S , Alessandro P , et al. Highly selective enzymatic recovery of building blocks from wool-cotton-polyester textile waste blends. Polymers. 2018;10(10):1107.10.3390/polym10101107Suche in Google Scholar PubMed PubMed Central

(6) Palme A , Peterson A , Motte H , Theliander H , Brelid H . Development of an efficient route for combined recycling of PET and cotton from mixed fabrics. Text Cloth Sustainabil. 2017;3(1):26–35.10.1186/s40689-017-0026-9Suche in Google Scholar

(7) Li Z . Separation of waste cotton-polyester blended fabric. Mater Sci Eng. 2020;768(2):022062–7.10.1088/1757-899X/768/2/022062Suche in Google Scholar

(8) Haule LV , Carr CM , Rigout M . Preparation and physical properties of regenerated cellulose fibers from cotton waste garments. J Clean Prod. 2016;112(5):4445–51.10.1016/j.jclepro.2015.08.086Suche in Google Scholar

(9) Stoeva K , Alriksson S . Influence of recycling programmers on waste separation behaviour. Waste Manage. 2017;68(1):732–41.10.1016/j.wasman.2017.06.005Suche in Google Scholar PubMed

(10) Haslinger S , Hummel M , Anghelescu-Hakala A , Määttänen M , Sixta H . Upcycling of cotton polyester blended textile waste to new man-made cellulose fibers. Waste Manage. 2019;97(31):88–96.10.1016/j.wasman.2019.07.040Suche in Google Scholar

(11) Yang G , Park M , Park S-J , Li Z . Recent progresses of fabrication and characterization of fibers-reinforced composites: a review. Compos Commu. 2019;14(4):34–42.10.1016/j.coco.2019.05.004Suche in Google Scholar

(12) Lertwassana W , Parnklang T , Mora P , Jubsilp C , Rimdusit S . High performance aramid pulp/carbon fiber-reinforced polybenzoxzine composites as friction materials. Compos Part B-Eng. 2019;177(24):107280–90.10.1016/j.compositesb.2019.107280Suche in Google Scholar

(13) Raphael NA , Namratha KA , Chandrashekar BNB , Sadasivuni KKC , Ponnamma DD , Smitha ASE , et al. Surface modification and grafting of carbon fibers: a route to better interface. Prog Cryst Growth Ch. 2018;64(3):75–101.10.1016/j.pcrysgrow.2018.07.001Suche in Google Scholar

(14) Lucas L , Victor HC , Sílvia HPB . Reuse of p-aramid from industrial waste as reinforcement fiber in polyamide 6.6. Polym Test. 2016;56(37):124–30.10.1016/j.polymertesting.2016.10.002Suche in Google Scholar

(15) Li S , Han KQ , Rong HP , Li XZ , Yu MH . Surface modification of aramid fibers via ammonia-plasma treatment. J Appl Polym Sci. 2014;131(10):40250–6.10.1002/app.40250Suche in Google Scholar

(16) Chen JR , Zhu YF , Ni QQ , Fu YQ , Fu XS . Surface modification and characterization of aramid fibers with hybrid coating. Appl Surf Sci. 2014;321(1):103–8.10.1016/j.apsusc.2014.09.196Suche in Google Scholar

(17) Vasilica P , Augustin M , Ovidiu C , Gabriela L , Emil IM , Corneliu M , et al. Tinctorial response of recycled PET fibers to chemical modifications during saponification and aminolysis reactions. Ind Eng Chem Res. 2014;53(43):16652–63.10.1021/ie5028974Suche in Google Scholar

(18) Fang YC , Liu XH , Tao XC . Intumescent flame retardant and anti-dripping of PET fabrics through layer-by-layer assembly of chitosan and ammonium polyphosphate. Prog Org Coat. 2019;134(48):162–8.10.1016/j.porgcoat.2019.05.010Suche in Google Scholar

(19) Mao YP , Li QY , Wu CF . Surface modification of PET fiber with hybrid coating and its effect on the properties of PP composites. Polymers. 2019;11(10):1726–41.10.3390/polym11101726Suche in Google Scholar PubMed PubMed Central

© 2022 Wei Cao et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes

Artikel in diesem Heft

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes