Abstract

The microstructure design of hydrogel materials offers a broad range of practical applications and is extensively used in flexible sensors, polymer microneedles, microfluidic chips, and other biomedical engineering fields. Among the bio-sourced hydrogels, oligomeric hyaluronic acid (HA) possesses wound healing, anti-tumor, and angiogenesis properties. However, micropatterning soft hydrogels, such as HA-relative hydrogels containing 90% water by weight, continue to pose difficulties for both high precision and micro-scale lithography. The purpose of this study was to compare the photolithography and light-cured inkjet printing methods of methacryloyl HA hydrogel (HAMA-gel) to those for synthetic light-curable polymer resins. Photolithography and light-cured inkjet printing methods with designed scale, high resolution, and little processing times were used to effectively prepare micropatterns of HAMA-gel. The well-shaped micropatterns consisted of parallel channels in tens of micrometers and strip/grid lines in the hundreds of micrometers. Human vein endothelial cells cultured on the material’s surface demonstrated that HAMA-gel had good biocompatibility. The width of the flow channel (10 and 20 µm) was regulated on the surface of the microstructure to allow for simultaneous control of cell growth along the flow channel and groove directions.

1 Introduction

Biomedical polymer materials are the most rapidly evolving and widely used class of medical materials. They include natural polymer materials such as chitin (1,2), cellulose (3,4), hyaluronic acid (HA) (5,6,7), chitosan, as well as synthetic polymer materials such as polydimethylsiloxane (8), polyvinyl alcohol (PVA) (9), polyacrylate (10), polycaprolactone (PCL) (11), and polylactic acid (PLA) (12,13). Nearly all mammalian cells contain HA, which can be destroyed by the enzyme hyaluronidase. Cells easily adhere to and grow on it, retaining their biological properties and sensitivity to the environment. Hydrogel products may be used as an extracellular matrix to provide a favorable environment for cells and are a hot research material in biological fields such as tissue-engineering scaffolds, postoperative repair, and immune regulation (14,15,16).

The viscosity of the aqueous solution of HA increases rapidly as the molecular weight increases. For example, a solution of one million molecular weight HA achieves a high viscosity at a mass fraction of 2%, while a solution of 100,000 molecular weight HA reaches a high viscosity at a mass fraction of more than 5%. At the same time, a high molecular weight maximizes the acid groups on the chain between the embedding, reduces the likelihood of the modified materials colliding with a reactive group, and decreases the reaction efficiency during the modification process. In addition, the traditional technique of preparing hydrogels through free radical polymerization has high water and oxygen requirements, which makes polymerization difficult to achieve under normal conditions. Due to the mild reaction conditions, high yield, and low environmental requirements, the “click” reaction has become a popular technique for preparing hydrogels. Zhang et al. (17) synthesized four-arm maleimide grafted polyethylene glycol (PEG) and four-arm thiol-grafted PEG, as well as acrylic acid-modified nucleic acid aptamers, using the sulfhydryl-olefins click reaction. The preparation of a PEG hydrogel, capable of orthogonal reaction and the selective curing of a photomask, resulted in a patterned structure. We recently reported fast-cured PCL-derived micropatterns using a UV-initiated thiol-ene “click” reaction (18).

Furthermore, we successfully prepared HA micropatterns using photolithography and thiol-ene “click” reaction, which resulted in the regulated release of VEGF protein (19). This work demonstrated the simultaneous or sequential control of protein immobilization and released in a hydrogel at different times and concentrations, which can be used to create a more biomimetic three-dimensional microenvironment for cells or act as a kind of intelligence for controlled release protein carriers. As HA hydrogels have excellent molding properties and the ability to retain a certain shape after gelation, they may be used for precise microstructure molding and have good application prospects in cell and tissue engineering.

The most widely used micromachining is photolithography (20) and printing technology (21), with the development of electron beams (22), UV nano-imprint (23), 3D printing (24,25,26) as novel branches, in addition to microstructure preparation techniques of many biological materials such as soft lithography (27), micro-contact printing, and inkjet printing have been constantly reflected in the micro-machined molding of biological materials. Srimongkon et al. (28) successfully printed the PVA hydrogel and calcium alginate (CA) hydrogel using modified inkjet printers. The two-dimensional surface micropatterning of the polymer gel may be produced by inkjet printing, and the ink used is available in the fields of biomedicine and cell engineering. So far, the use of photo clamps or printing techniques for micro-processed research on hydrogel, particularly those with high water content and with precision typically measured in centimeters, has been unable to meet the demand for bioengineering and tissue engineering. The use of inkjet printing to print HA is very difficult, primarily due to solution viscosity and curing time. Moreover, the concentration of the solution affects the strength of the gel after curing, and only the appropriate concentration can maintain a good microstructure in the gel.

In this study, the double-bond-modified HA (HAMA) was synthesized by methacrylate modification of oligomeric HA followed by the esterification reaction between pentaerythritol and N-acetyl-l-cysteine to form the bioactive crosslinking agent (SH-CA) with multi-arm mercapto group grafting. Rapid photocurable HA hydrogels (HAMA-gel) were synthesized by a simple, mild, and fast “click” reaction between “mercapto-olefin.” The potential performance of oligomeric HAMA as a framework for precise microstructure formation was investigated in this study, and the light-curing performance of HAMA-gel was evaluated using photolithography and inkjet printing. Then, we investigated the effect of surface microstructure on the growth morphology of human umbilical vein endothelial (HUVE) cells. We compared two UV-cured resins, commercial polyethylene glycol diacrylate (PEGDA) and PCL–PEG–PCL triblock copolymer (PCEC), to determine the light-curing process and cell adhesion growth properties. This offers a theoretical justification for the design of photocurable microstructures on the surfaces of biological hydrogel materials.

2 Experimental

2.1 Preparation of photocurable materials

2.1.1 HAMA photocurable hydrogel

In this work, HA (M n = 5,000) was selected as the biogel precursor. Methylacrylated hyaluronic acid (HAMA), a multi-thiol crosslinking agent (SH-CA), and HAMA-gel light-curing material were prepared as previously described (19). HAMA-gel with a 5% crosslinking agent was selected for micropattern design on the surface due to its mechanical strength and minimal variations in forming changes. Briefly, the double-bond modified HAMA raw material was dissolved in deionized water to form a 6% HAMA solution, and the photocurable gel prepolymer solution was prepared by adding 5 wt% SH-CA crosslinking agent and 1 wt% Irgacure 2959. The structure of (A) HAMA and (B) SH-CA is shown in Figure 1. Figure 1a illustrates a schematic reaction diagram for HAMA-gel.

Chemical structures of methacrylated hyaluronic acid (HAMA), multi-thiol crosslinking agent (SH-CA), PEGDA, and acrylated PCL–PEG–PCL triblock copolymer (ene-PCEC).

2.1.2 PEGDA photocurable resin

In a 5 mL vial, 5 mmol PEGDA (M n = 400, 2.0 g) was added. Based on the ratio of double bonds to sulfhydryl group 1:1, 2.5 mmol tetra (3-mercaptopropionic acid) pentaerythritol ester (PETMP, 0.61 g) and 1 wt‰ initiator benzoin dimethyl ether (DMPA, 1.6 mg) were added. During curing, a sufficient quantity of solution was injected into the mold, and the colorless transparent PEGDA photocurable material was obtained by UV curing (OmniCure S1500, 365 nm) for 10 min. Figure 1c shows the chemical structure of PEGDA.

2.1.3 PCEC-derived photocurable resin

The PCL–PEG–PCL hydroxy-terminated triblock copolymer (PCEC-OH) was synthesized using a technique described in the literature (29), and the end groups of PCEC-OH were modified through double bonding with acryl chloride to obtain ene-PCEC (18). Figure 1d shows the chemical structure of ene-PCEC. Around 0.1 mmol double-bonded terminated PCL block copolymers (ene-PCEC, M n = 1,700, 0.17 g) and 2.5 mmol PEGDA (M n = 400, 1.0 g) were added to a 5 mL vial in the ratio of double bonds to sulfhydryl group 1:1, and 1.3 mmol tetra (3-mercaptopropionic acid) pentaerythritol ester (PETMP, 0.32 g), 1 wt‰ initiator benzoin dimethyl ether (DMPA, 1.6 mg), and a small amount of dichloromethane (CH2Cl2) were added to obtain a homogenous solution. To obtain white opaque PCEC-derived materials, a suitable amount of solution was placed in the mold during curing and UV curing (OmniCure S1500, 365 nm) for 10 min.

2.2 Photocurable resin surface microstructure pattern design

2.2.1 Photolithography method

Photomasks with light transmittance may be produced on the surface of the glass using lithography technology. A chrome-plated opaque mask template was used in this experiment. The template surface was heavily chrome-plated and impervious to light, while the transmittance region was designed as a parallel striped structure with a width of 10 or 20 µm and spacings of 100 µm. UV curing (OmniCure S1500, 365 nm) was performed in the transmittance region to cure the photocurable matrix material under the mask through ultraviolet light to produce a material with a strip-like flow channel structure on the surface, thus forming the material’s surface microstructure.

The schematic of the photomask-prepared surface microstructure material is shown in Figure 2b. The curing structure was segmented into three layers: upper, middle, and lower layers. The upper layer was a chrome-plated photomask, while the middle layer was a 5 mm thick and soft silica gel sheet. Excess silica gel was cut off from the 5 mm × 5 mm square region of the direct photomask’s transparent area, and the prepolymer solution of HAMA-gel was injected. The lower layer was a quartz glass substrate that served as a carrier for the integral curing unit. The polymer solution of HAMA-gel was placed into the hole of the silica gel sheet before curing, covered with a light mask, and irradiated under ultraviolet light for a certain period to obtain the material with strip microstructure on the surface.

(a) Schematic of reaction for HAMA-gel; (b) surface microstructure fabricated by the photolithography method; and (c) well-zigzag microstructure printed by the light-cured inkjet printing method.

2.2.2 Light-curd inkjet printing method

Three procured polymer solutions of PEGDA, PCEC/PEGDA mixture, and HAMA-gel were inkjet printed on glass substrates using a micro-nano material deposition inkjet printer system (Microplotter Proto). Figure 2c illustrates the inkjet printing technique used to prepare the well-shaped microstructure. The release voltage was set to 14.0 V, and inkjet printing on a glass substrate was performed using the HAMA-gel precursor’s light-curing material. Following printing, the print was shaped using UV curing (OmniCure S1500, 365 nm).

2.3 Microstructure surface morphology

A fluorescence inversion microscope (ZEISS AXIO OBSERVER AI) was used to examine the microstructures of HAMA-gel, PEGDA, and PCEC-derived materials using photolithography and inkjet printing techniques, respectively.

2.4 Surface contact angle and surface tension energy

A contact angle measuring device (OCA-15, DataPhysics, Germany) was used to measure the contact angle between water and photocurable primary solution (PEGDA, HAMA-gel) on the different substrates (glass, PTFE, and PET). In a liquid–solid interface system, the relationship between liquid–solid interface tension and solid–phase surface tension was as follows:

The contact angle θ on each substrate was determined using Eq. (2), as was the gas-up interface of PET, PTFE, and glass. Tension γ SG according to water, PEGDA, HAMA-gel could determine the surface tension of three water, PEGDA, HAMA-gel solutions on each substrate γ LG. Finally, Eq. (1) was sued to calculate the liquid-solid interface tension γ SL.

2.5 Immunofluorescence staining

2.5.1 Cell culture

HUVE cells (5,000 cells per well) were seeded into 24-well plates on the sample surface and supplemented with 10% fetal bovine serum, 1.5 g·L−1 sodium bicarbonate, 100 U·mL−1 penicillin and 100 µg·mL−1 streptomycin, and DMEM cell medium. The cells were cultured at 37°C and 5% CO2 for 48 h.

2.5.2 Cell fixation and staining

Each well was rinsed three times with PBS buffer for 3 min each and then fixed with paraformaldehyde for 15 min. After rinsing thrice with PBS buffer, 0.05% Triton 100 was added and allowed to stand for 5 min to enhance membrane permeability. The wells were rinsed thrice with PBS buffer, 5% goat serum was added, and the plates were incubated for 1 h. After adding DAPI for 1 min, PBS was rinsed three times, and an anti-fluorescence quenching agent was added.

2.5.3 Observation of cell morphology

Inverted fluorescence microscopy (ZEISS AXIO OBSERVER AI) was used to investigate the impact of surface microstructure on cell growth morphology.

3 Results and discussion

3.1 Photolithography performances

The UV-cured photolithography technique was successfully used to prepare micron-scale channel patterns on the surfaces of HAMA-gel, PEGDA, and PCEC-derived materials. Figure 3 illustrates periodic channel micropatterns on the surfaces of HAMA-gel, PEGDA, and PCEC-derived materials, respectively, that were prepared using the photolithography technique. The top surface morphology was characterized by parallel gaps with uniform widths of about 20 and 10 µm. As can be observed, all three types of materials exhibited a regular elevated surface flow channel morphology following the light-curing procedure. The channel width of the three materials was significantly increased when cured with a 20 µm photomask compared to those treated with a 10 µm photomask. The channel’s edges and boundaries were both clear. On the surfaces of HAMA-gel, PEGDA, and PCEC-derived materials, the flow channels were smooth and regular, with complete micro-channel morphology and regular spacing. This demonstrates the possibility of using photolithography to prepare the surface microstructure of both hard photocurable materials and soft HAMA-gel hydrogel materials. In addition, photocurable materials with a variety of surface microstructures may be obtained by altering the morphology of the transmittance part of the photomask.

The channel micropatterns on the top surfaces of (a) HAMA-gel, (b) PEGDA, and (c) PCEC-derived materials prepared by photolithography and observed by fluorescence inverted microscope. The gap widths of three materials were designed for 20 and 10 µm, with scale bars of 200 and 100 µm, respectively. (d) The regularity of micro-channel on the top surface of the three materials.

To characterize the micro-channel formation accuracy of materials, the width of each channel and the spacing between channel intervals were measured. Figure 3d shows the regularity of micro-channels on the surface of the three materials. The surface channel width of HAMA-gel, PEGDA, and PCEC-derived materials was 17.7, 20.5, and 25.7 µm, respectively, when light-cured micropatterns were used with a 20 µm photomask. In contrast, the surface channel width of HAMA-gel, PEGDA, and PCEC-derived materials was 8.8, 14.0, and 18.1 µm, respectively, when cured with a 10 µm photomask. As can be observed, the size variations of the surface microstructure of PEGDA and PCEC-derived materials were much larger than those of HAMA-gel. On the one hand, due to UV light scattering through the mask, the portion of the mask closest to the light transmittance generated unnecessary crosslinking, while the crosslinking reaction transformed the liquid precursor into a solid state, resulting in negligible volume shrinkage and an inconsistent set value for the channel width. The channel width of HAMA-gel was found to be somewhat narrower than the channel width specified in the design. It can be explained by the fact that the soft modulus (<75 kPa) and higher water content (94 wt%) resulted in slight deformation of crosslinked HAMA hydrogel.

Similarly, the channel spacing of HAMA-gel, PEGDA, and PCEC-derived materials was 95.8, 98.3, and 73.2 µm, respectively, when cured with the 20 µm photomask. The channel spacing of HAMA-gel, PEGDA, and PCEC-derived materials were 95.9, 94.1, and 79.1 µm, respectively, when cured using a 10 µm photomask template. The reason for the derivation of the channel spacing and width in the PCEC-derived micropattern is that PCEC was a semi-crystallized and rubber-like polymer at room temperature, which increased the surface stress of the material and warped the thin film.

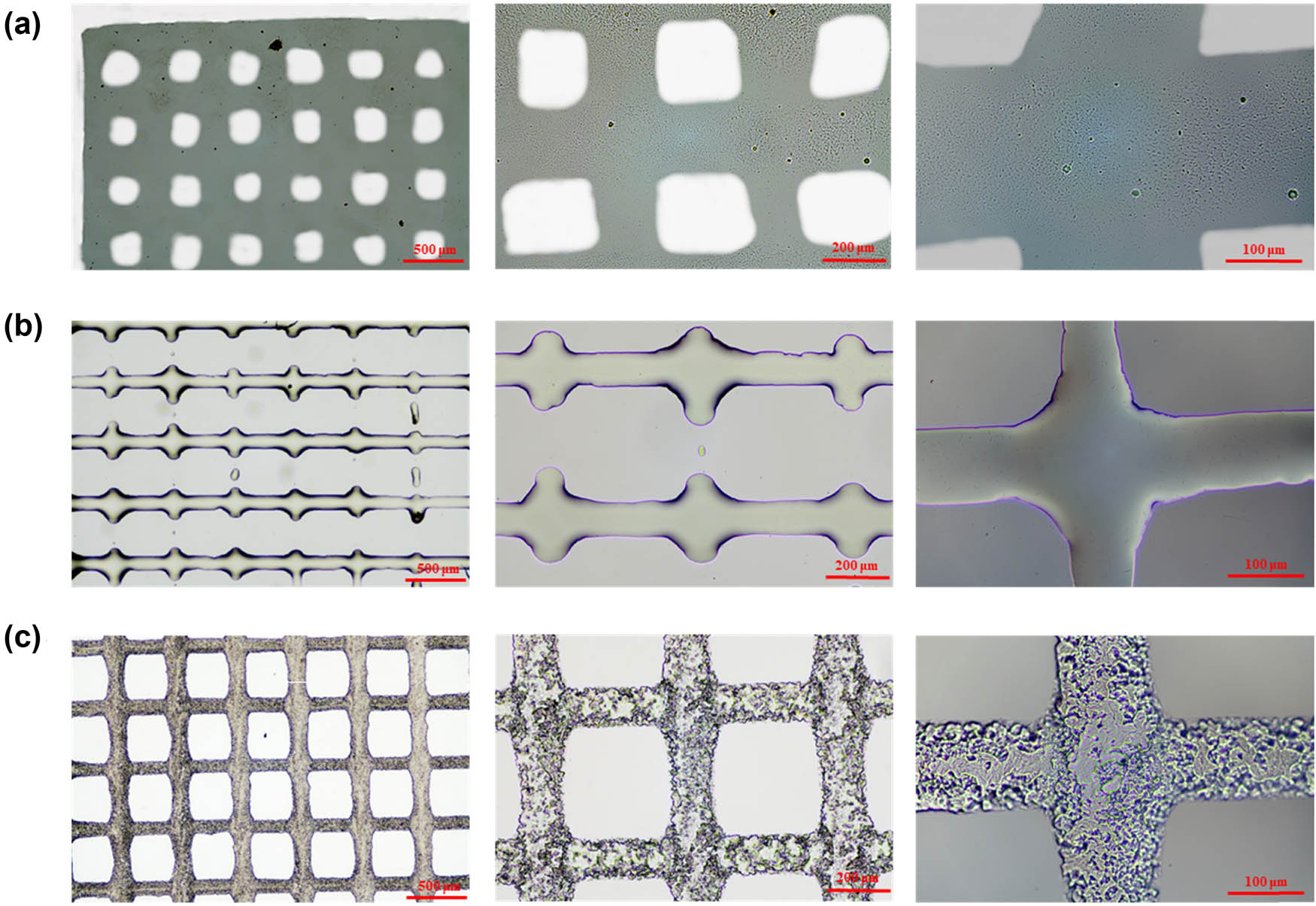

3.2 Light-cured inkjet printing

The microstructure of the HAMA-gel PEGDA and PCEC-derived precursor solution was printed on the glass substrate using a micro-nano inkjet printing system, followed by a UV light curing process to fix the material morphology on the substrate. HAMA-gel was capable of printing smoothly on a glass substrate and delineating strip and grid patterns with ease. Figure 4 shows the morphology of the various precursors printed on the glass substrate, demonstrating that the micropattern of light-curable precursors could be successfully doped into the flat surface through the nuzzle and subsequently set in two dimensions via the UV light curing process. The width of the pattern varied depending on the wettability and shape-holding ability of the precursor and substrate. Due to the high affinity of glass for the hydrophilic solution, the width of HAMA-gel was about 220 µm (Figure 4a), while the widths of PEGDA and PCEC-derived patterns were approximately 50–60 µm, and the pattern structures were inaccurate and defective (Figure 4b and c). Inkjet printing, as a two-dimensional printing technique, is capable of designing and fabricating two-dimensional patterns of HAMA-gel efficiently to meet specific needs and opens up a diverse range of application areas due to the nature of the printing materials.

Morphology of (a) HAMA-gel, (b) PEGDA, and (c) PCEC-derived micropatterns by inkjet printing. The scales are 500, 200, and 100 µm, respectively.

To explain the pattern deformation, the surface contact angles and relative surface tension of HAMA-gel, PEGDA, and PCEC-derived precursors were investigated and shown in Figure 5. Because the PCEC-derived precursor comprised 83% PEGDA, its surface contact angle and surface tension were comparable to those of the PEGDA precursor. Figure 5a shows the photographing of different solutions on a variety of substrates. The hydrophilic HAMA-gel exhibited good wettability on glass surfaces but spread poorly on plastic surfaces. Due to its increased hydrophobicity, PEGDA had a larger contact angle and surface tension than HAMA-gel (Figure 5b and c). As a result, it is preferable to print micropatterns on the hydrophilic glass surface rather than on a hydrophobic plastic surface.

(a) The surface contact angle images of water, HAMA-gel, and PEGDA precursor on different substrates, respectively. The data of (b) surface contact angle and (c) surface tension were calculated in detail.

3.3 The effect of surface microstructure on the development of cell adhesion

Optical microscopy was used to examine the effect of the surface microstructure of HAMA-gel, PEGDA, and PCEC-derived materials on cell growth. Figure 6a shows the HUVE cells’ growth on the surface of the three microstructure materials after 48 h of incubation. The cell morphology on the surface of HAMA-gel was normal spindle-shaped in both the control group and microstructure groups, and cell growth was excellent. In contrast to the PEGDA and PCEC control groups, the HUVE cells could not spread out on the smooth surface of PEGDA, and the cell morphologies were nearly spherical. Nonetheless, HUVE cell adhesion to the surface of PCEC/PEGDA was poor, and the number of cells was minimal. However, no cells were observed on the surface of PEGDA and PCEC/PEGDA microstructures, suggesting that the microstructures made it more difficult for cells to attach and grow normally on the surface of materials with low cell adhesion. HAMA-gel surface microstructure, on the other hand, demonstrated excellent cell adherence, suggesting its high biocompatibility and prominence as a scaffold for cell growth.

Influence of surface microstructure on cell growth morphology. (a) Growth of HUVE cells on the smooth surface and microstructure surface of HAMA-gel, PEGDA, and PCEC-derived materials after 48 h culture. (b) Effects of different channel widths on the surface of HAMA-gel on cell growth and morphology by immunofluorescence staining, the right pictures are the magnifications of the left. (c) Culture of HUVE cells on inkjet printer HAMA-gel materials, cell growth after 48 h: (left) strip structure; (right) grid-like structure.

To investigate the impact of surface microstructure on cell growth, cells on the surface of HAMA-gel material were stained with immunofluorescence, and the cytoskeleton and cells were colored with phantom cyclic peptide and DAPI, respectively, to obtain the complete cell morphology. Figure 6b shows cell growth morphology on the surface of HAMA-gel with smooth surface, 10 µm channel structure, and 20 µm channel structure, respectively. Furthermore, HUVE cells were cultured on inkjet-printed HAMA-gel lines, and Figure 6c shows cell growth after 48 h. In the printed strip structure, the cells adhered and grew along with the strip structure, while in the printed grid-like structure, cells adhered and grew sparsely along with the grid-like structure on glass sheets without microstructures, suggesting that cell growth was material selective. Cells were more likely to adhere to and proliferate on a hydrophilic surface and stiff matrix in comparison with the 3D-printed structure of synthesized resin like PLA (30).

In the control group, cell growth was irregular with a smooth surface and cell morphology was complete. The channel width in the 10 µm channel structure was slightly smaller than that of the endothelial cells. Most cells could not cross the channel barrier and grow in the groove between the two channels. In the 20 µm channel structure, the cells grew along the channel because the channel width was sufficient to support cell climbing and growth. The results indicated that channel width affects cell growth direction, causing the majority of cells to grow along the direction of the flow channel orientation. By controlling the flow channel width to a value less than that of the cells, one can control the majority of cells in the groove-oriented growth. By controlling the flow channel width to a value greater than the cells, one can control cell growth orientation along the flow channel and the direction of the grooves. These findings have significant implications in regulating cells’ directed growth and differentiation.

4 Conclusion

In this study, the micro-patterns of HAMA-gel were successfully fabricated using both photolithography and UV-cured inkjet printing methods. To achieve high resolution and exquisite microstructure, a thiol-ene “click” reaction was designed. As a consequence, photolithography was used to design parallel channels (gap width ∼ 10 µm) with the precious structure while maintaining a high-water content (94 wt%). In contrast, the commercial photocurable resin PEGDA and its PCEC-modified resin demonstrated low accuracy and large deformation. Moreover, due to the exceptional stickiness of HAMA-gel on the glass substrate, inkjet printing and UV light curing processes were used to create a two-dimensional design of HAMA-gel with a sub-millimeter scale. PEGDA and PCEC-derived precursors, on the other hand, could not be smoothly printed under the same conditions. HAMA-gel micropatterns, both channels, and lines, aided adhesion cell growth. It was shown that the HUVE cells were successfully cultured and grew with the orientation of the micropatterns.

-

Funding information: This research was conducted thanks to the Natural Science Foundation of China (Nos. 52173046 and 81970398), Natural Science Foundation of Zhejiang Province (Nos. LZ21E030002 and LY19E030007), Key R&D Program of Zhejiang Province (No. 2021C01064), Ningbo Scientific and Technological Innovation 2025 Major Project (No. 2020Z097), and the Fundamental Research Funds for the Provincial Universities of Zhejiang (No. RF-A2020008).

-

Author contributions: Feng Chen: Investigation, conceptualization, methodology, writing – original draft, writing – review and editing, supervision; Shaochun Gu: investigation, formal analysis; Qianmin Zhang: investigation, formal analysis; Tong Liu: formal analysis; Zhenjie Liu: formal analysis, supervision; Tairong Kuang: formal analysis, writing – original draft, writing – review and editing, supervision.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

(1) Yang F, Yang J, Qiu S, Xu W, Wang Y. Tannic acid enhanced the physical and oxidative stability of chitin particles stabilized oil in water emulsion. Food Chem. 2021;346(21):128762.10.1016/j.foodchem.2020.128762Suche in Google Scholar PubMed

(2) Chen B, Wu S, Ye Q. Fabrication and characterization of biodegradable KH560 crosslinked chitin hydrogels with high toughness and good biocompatibility. Carbohydr Polym. 2021;259:117707.10.1016/j.carbpol.2021.117707Suche in Google Scholar PubMed

(3) Luebbert C, Stoyanov E, Sadowski G. Phase behavior of ASDs based on hydroxypropyl cellulose. Int J Pharma X. 2021;3:100070.10.1016/j.ijpx.2020.100070Suche in Google Scholar PubMed PubMed Central

(4) Dai L, Cheng T, Duan C, Zhao W, Zhang W, Zou X, et al. 3D printing using plant-derived cellulose and its derivatives: A review. Carbohydr Polym. 2019;203:71–86.10.1016/j.carbpol.2018.09.027Suche in Google Scholar PubMed

(5) Gao H, Yu C, Li Q, Cao X. Injectable DMEM-induced phenylboronic acid-modified hyaluronic acid self-crosslinking hydrogel for potential applications in tissue repair. Carbohydr Polym. 2021;258:117663.10.1016/j.carbpol.2021.117663Suche in Google Scholar PubMed

(6) Zhan W, Li H, Guo Y, Yang L, Pang L, Zhang C. Hyaluronic acid functionalized biodegradable mesoporous silica nanocomposites for efficient photothermal and chemotherapy in breast cancer. Nanotechnology. 2021;32(16):165703.10.1088/1361-6528/abda74Suche in Google Scholar PubMed

(7) Xue F, Zhang H, Hu J, Liu Y. Hyaluronic acid nanofibers crosslinked with a nontoxic reagent. Carbohydr Polym. 2021;259:117757.10.1016/j.carbpol.2021.117757Suche in Google Scholar PubMed

(8) Shin EA, Lee SB, Kim GH, Jung J, Lee CK. Enhanced interfacial adhesion of polydimethylsiloxane (PDMS) by control of the crosslink density. J Nanosci Nanotechnol. 2020;20(11):6768–75.10.1166/jnn.2020.18804Suche in Google Scholar PubMed

(9) Jiang WB, Ji LJ, Chen K, Wu B, Wu VY, Zhu J. Cross-linking reaction kinetics of polyvinyl alcohol with glutaraldehyde. J East China Univ Sci Technol (Nat Sci Ed). 2016;42(5):625–9.Suche in Google Scholar

(10) Skwarczynski M, Zaman M, Urbani CN, Lin IC, Jia Z, Batzloff MR, et al. Polyacrylate dendrimer nanoparticles: A Self-adjuvanting vaccine delivery system. Angew Chem Int Ed. 2010;49(33):5742–5.10.1002/anie.201002221Suche in Google Scholar PubMed

(11) Kuang TR, Chen SW, Gu ZP, Shen ZS, Hejna A, Saeb MR, et al. A facile approach to fabricate load-bearing porous polymer scaffolds for bone tissue engineering. Adv Compos Hybrid Mater. 2022. 10.1007/s42114-022-00418-1.Suche in Google Scholar

(12) Kuang TR, Ju JJ, Liu T, Hejna A, Saeb MR, Zhang S, et al. A facile structural manipulation strategy to prepare ultra-strong, super-tough, and thermally stable polylactide/nucleating agent composites. Adv Compos Hybrid Mater. 2022. 10.1007/s42114-021-00390-2.Suche in Google Scholar

(13) Kuang TR, Zhang ML, Lian XH, Zhang JB, Liu T, Zhang S, et al. External flow-induced highly oriented and dense nanohybrid shish-kebabs: A strategy for achieving high performance in poly (lactic acid) composites. Compos Commun. 2022;29:101042.10.1016/j.coco.2021.101042Suche in Google Scholar

(14) Chen J, Yang J, Wang L, Zhang X, Heng BC, Wang D, et al. Modified hyaluronic acid hydrogels with chemical groups that facilitate adhesion to host tissues enhance cartilage regeneration. Bioact Mater. 2021;6(6):1689–98.10.1016/j.bioactmat.2020.11.020Suche in Google Scholar PubMed PubMed Central

(15) Tang S, Chi K, Xu H, Yong Q, Yang J, Catchmark JM. A covalently cross-linked hyaluronic acid/bacterial cellulose composite hydrogel for potential biological applications. Carbohydr Polym. 2021;252:117123.10.1016/j.carbpol.2020.117123Suche in Google Scholar PubMed

(16) Zhang K, Yang J, Sun Y, Wang Y, Liang J, Luo J, et al. Gelatin-based composite hydrogels with biomimetic lubrication and sustained drug release. Friction. 2022;10(2):232–46.10.1007/s40544-020-0437-5Suche in Google Scholar

(17) Zhang Z, Du J, Li Y, Wu J, Yu F, Chen Y. An aptamer-patterned hydrogel for the controlled capture and release of proteins via biorthogonal click chemistry and DNA hybridization. J Mater Chem B. 2017;5(30):5974–82.10.1039/C7TB00883JSuche in Google Scholar

(18) Zhu Y, Shen J, Yin L, Wei X, Chen F, Zhong M, et al. Directly photopatterning of polycaprolactone-derived photocured resin by UV-initiated thiol-ene “click” reaction: Enhanced mechanical property and excellent biocompatibility. Chem Eng J. 2019;366:112–22.10.1016/j.cej.2019.02.045Suche in Google Scholar

(19) Zhang Q, Wei X, Ji Y, Yin L, Dong Z, Chen F, et al. Adjustable and ultrafast light-cured hyaluronic acid hydrogel: Promoting biocompatibility and cell growth. J Mater Chem B. 2020;25(8):5441–50.10.1039/C9TB02796CSuche in Google Scholar

(20) Nakashima Y, Yamamoto Y, Hikichi Y, Nakanishi Y. Creation of cell micropatterns using a newly developed gel micromachining technique. Biofabrication. 2016;8(3):035006.10.1088/1758-5090/8/3/035006Suche in Google Scholar PubMed

(21) Yu CC, Chen HL. Nanoimprint technology for patterning functional materials and its applications. Microelectron Eng. 2015;132:98–119.10.1016/j.mee.2014.10.015Suche in Google Scholar

(22) Okazaki S. High resolution optical lithography or high throughput electron beam lithography: The technical struggle from the micro to the nano-fabrication evolution. Microelectron Eng. 2015;133:23–35.10.1016/j.mee.2014.11.015Suche in Google Scholar

(23) Kim B, Lee JS. Thermally reversible shape transformation of nano-patterned PNIPAAm hydrogel. Polym Bull. 2021;78:3353–61.10.1007/s00289-020-03276-3Suche in Google Scholar

(24) Panwar A, Tan L. Current Status of Bioinks for micro-extrusion-based 3D bioprinting. Molecules. 2016;21(6):685.10.3390/molecules21060685Suche in Google Scholar PubMed PubMed Central

(25) Ouyang L, Highley CB, Sun W, Burdick JA. A generalizable strategy for the 3D bioprinting of hydrogels from nonviscous photo‐crosslinkable inks. Adv Mater. 2017;29(8):1604983.10.1002/adma.201604983Suche in Google Scholar PubMed

(26) Derakhshanfar S, Mbeleck R, Xu K, Zhang X, Zhong W, Xing M. 3D bioprinting for biomedical devices and tissue engineering: A review of recent trends and advances. Bioact Mater. 2018;3(2):144–56.10.1016/j.bioactmat.2017.11.008Suche in Google Scholar PubMed PubMed Central

(27) Zhou S, Zhou Q, Lu C, Zhang Z, Ren L. Design and preparation of 3D printing intelligent poly N,N-dimethylacrylamide hydrogel actuators. E-Polymers. 2020;20(1):273–81.10.1515/epoly-2020-0033Suche in Google Scholar

(28) Srimongkon T, Mandai S, Enomae T. Application of biomaterials and inkjet printing to develop bacterial culture System. Adv Mater Sci Eng. 2015;2015(2):1–9.10.1155/2015/290790Suche in Google Scholar

(29) Liu CB, Gong CY, Huang MJ, Wang JW, Pan YF, De Zhang Y, et al. Thermo reversible gel-sol behavior of biodegradable PCL–PEG–PCL triblock copolymer in aqueous solutions. J Biomed Mater Res Part B-Appl Biomater. 2008;84B(1):165–75.10.1002/jbm.b.30858Suche in Google Scholar PubMed

(30) Donate R, Monzón M, Alemán-Domínguez ME. Additive manufacturing of PLA-based scaffolds intended for bone regeneration and strategies to improve their biological properties. E-Polymers. 2020;20(1):571–99.10.1515/epoly-2020-0046Suche in Google Scholar

© 2022 Feng Chen et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes

Artikel in diesem Heft

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes