Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

Abstract

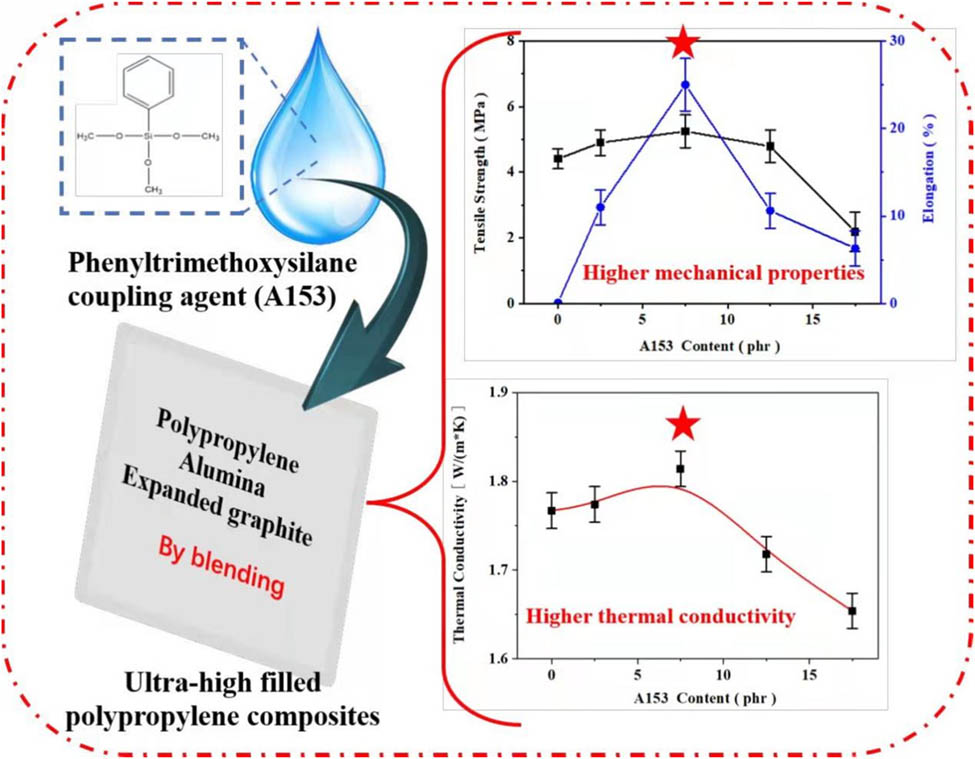

The improvement of mechanical properties, electrical properties, and processing properties of ultra-high-filled thermal insulation polypropylene (PP) composites has been plagued by high filling amount of heat-conducting fillers such as alumina powder (Al2O3) and expanded graphite. In order to improve its properties, this article uses a high-temperature-resistant coupling agent (A153) to modify the PP composite. The results of this study show that when the content of A153 reaches 7.5 phr, the tensile strength of PP composite can reach 5 MPa, the elongation at break can reach 25%, and the volume resistivity can reach 12.8 × 1012 Ω·m, and the maximum thermal conductivity is 1.82 W·m−1·K−1. The processability also shows that the introduction of A153 can increase the melt flow rate and effectively improve the processability of the material.

Graphical abstract

1 Introduction

With the development of science and technology, the requirements for the thermal conductivity of materials in the fields of microelectronic packaging, automobile, aerospace, electrical insulation, and so on are becoming higher and higher, especially the electronic components, which have high-precision, high integration, and high power, but the volume has gradually become smaller, which leads to a large amount of heat gathering in a narrow space and cannot be dissipated (1,2). If the heat is not dissipated on time, the continuous high temperature will overload or even fail the electronic components, which will shorten the service life of the electronic components and may cause serious harm. In order to ensure the continuous and efficient operation of electronic components, effective heat transfer and heat dissipation have become urgent problems to be solved (3,4,5). Therefore, the direct contact between high thermal conductivity polymer materials and electronic components to realize heat transfer has attracted extensive attention.

Polymers have the advantages of excellent electrical insulation, good processing performance, high chemical stability, and low cost. They are very suitable as the base material of thermal conductive materials (6). However, the thermal conductivity of common polymer materials is poor, and the thermal conductivity coefficient is generally lower than 0.2 W·m−1·K−1 (7,8). Adding ceramic, metal, and carbon materials with excellent heat conductivity to the polymer can effectively improve the thermal conductivity of the material. There is no doubt that the thermal conductivity of thermal conductive fillers is an important factor affecting the thermal conductivity of composites. In addition, the shape of the filler will also have an important impact on thermal conductivity. Weidenfeller and Kirchberg (9) studied the thermal conductivity of PP filled with Fe3O4, glass fiber, talc powder, and copper powder. It was found that when the volume fraction of filler reached 30%, the thermal conductivity of PP/TAIC powder composite could be as high as 2.5 W·m−1·K−1, which was significantly higher than that of PP/copper powder composite, which was 1.25 W·m−1·K−1, while the thermal conductivity of copper was about 40 times that of talc powder. Further study of this result shows that talc powder has flake structure, large aspect ratio, and good interfacial compatibility with PP, which is conducive to phonon heat transfer. This study proves that the thermal conductivity of the composite is related to not only the thermal conductivity of the filler itself but also the shape and interface structure of the filler.

Inorganic fillers with high thermal conductivity, such as alumina, aluminum nitride, silicon carbide, boron nitride, and expanded graphite (EG), can improve the thermal conductivity of composites in polymers while retaining the high insulation properties of materials (10,11,12). Alumina has excellent physicochemical properties, such as high temperature resistance, strong insulation, corrosion resistance, high thermal conductivity, and high strength. It can play an auxiliary role when two-dimensional fillers are connected to a thermal conduction network, which helps reduce anisotropy and is of low price. Therefore, it is widely used in ceramics, medicine, microelectronics, electrical machinery, and other industries. Compared with ordinary graphite, EG has a series of advantages: good chemical stability, low density, softness, and easy processing (13). In addition, its surface has a rich honeycomb pore structure to absorb other substances, so as to form a two-dimensional network heat conduction path and realize rapid heat transfer. EG has many excellent characteristics, is of low cost, and easy to manufacture, and so it is often used as a functional reinforcing filler to composite with other materials (11,12). The thermal conductivity of polymer materials is generally poor, whereas EG has good thermal conductivity and good compatibility with organic matter. It can be evenly dispersed in the matrix material with less addition, so as to significantly improve the thermal conductivity of polymer materials. Heat conductivity fillers have different shapes. the alumina mentioned above is granular and EG is flake, and this kind of multi-shape matching filler is easier to form heat conductivity path (14–16).

According to the research results of thermal conductivity and insulation properties and physical and mechanical properties of the composites filled with hybrid filler system, the prepared composites have better thermal conductivity and insulation properties only when the content of hybrid filler exceeds 50 wt% (17–19). However, at this time, the physical and mechanical properties of the composites will be significantly reduced, so that they cannot meet the requirements of some applications. Therefore, in the design of thermal conductive and insulating composites, we should consider not only the thermal conductive and insulating properties of the materials but also how to maintain good mechanical properties, especially the toughness of the materials. The toughening methods of PP include copolymerization modification, blending modification, and filling modification. Silane coupling agent has excellent chemical stability and is often used as a compatible modification component of plastics. The method of modifying PP with a silane coupling agent is simple and easy and is widely used at present. There are many kinds of silane coupling agents, and different silane coupling agents have different modification effects (20,21). Phenyltrimethoxysilane coupling agent (A153) has excellent chemical stability and high boiling point, which can meet the needs of PP processing.

In this study, PP with high temperature resistance was used as the basic material, and alumina powder (Al2O3) and EG PP/Al2O3/EG composite with better thermal conductivity and insulation and low cost were chosen as the research objects. In order to overcome the processing difficulties, poor mechanical properties, and weak electrical properties of high-filled polypropylene (PP) composites, A153 was used as the modified component of the composite system, and the effects of A153 content on the mechanical properties, thermal conductivity and insulation properties, and processability of PP thermal conductivity composite were discussed, which will provide a reference for practical application.

2 Experimental

2.1 Materials and instruments

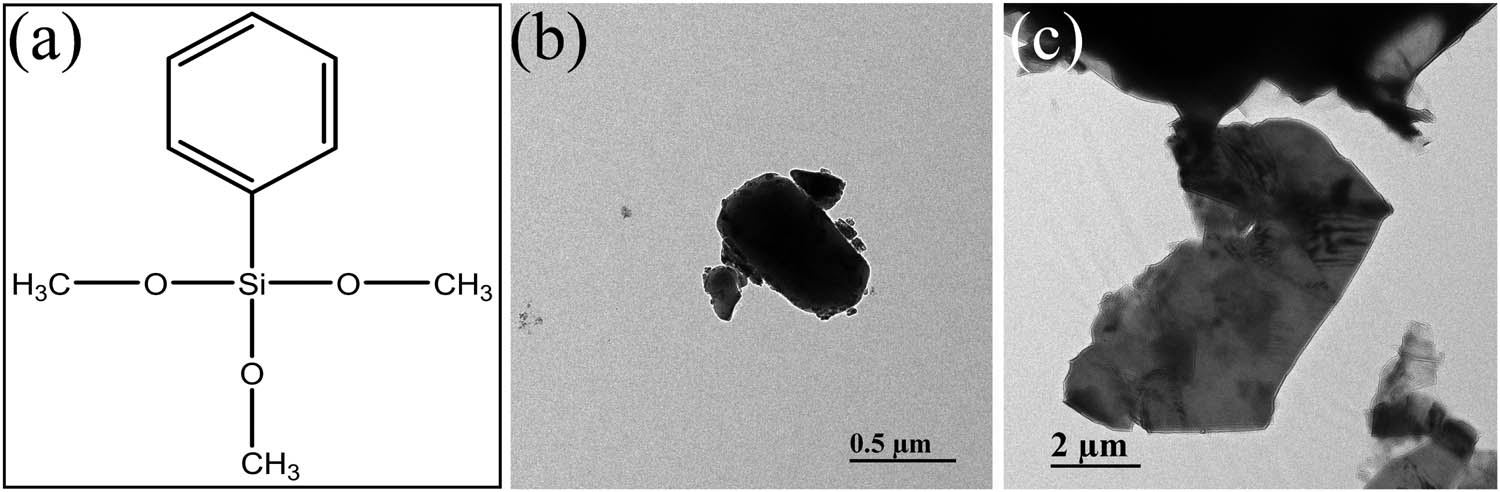

PP, whose brand name is T30s, was purchased from Mitsui chemical company in Japan, and its physical parameters are shown in Table 1. Phenyltrimethoxysilane coupling agent (A153) was purchased from Shanghai Zhanyun Chemical Co., Ltd, whose molecular formula is shown in Figure 1a. Alumina powder (Al2O3), with an average size of about 1 μm as can be seen in Figure 1b, was obtained from Dongguan Dongchao New Material Technology Co., Ltd. EG, with the average size of about 20 μm as can be seen in Figure 1c, was supplied by Qingdao Yanhai carbon material Co., Ltd.

Physical parameters of pure PP

| Physical parameters | PP |

|---|---|

| MFR (g·min−1) | 2.3–3.7 |

| Tensile strength (MPa) | ≥29 |

| Aggregate ash (%) | ≤0.03 |

| Isotactic index (%) | ≥96 |

Molecular structure formula of A153 (a); the TEM diagrams of Al2O3 (b), and EG (c).

2.2 Sample preparation

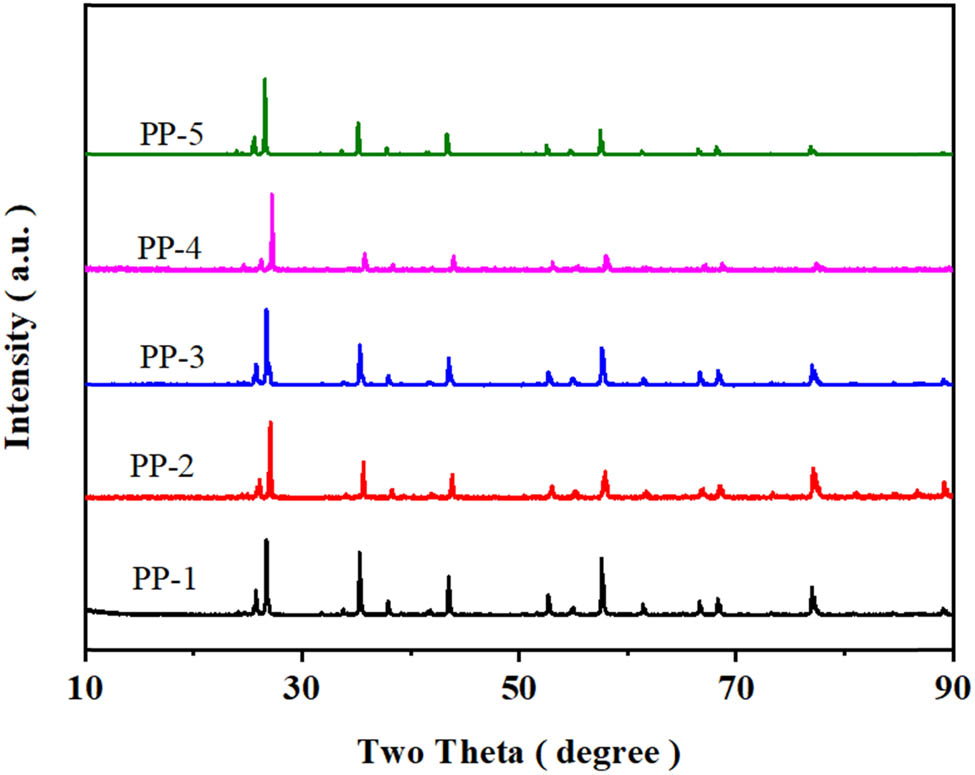

In order to prepare ultra-high filling and ultra-high thermal conductivity PP composites, we designed relevant formulas (Table A1 in Appendix) and carried out pre-experiments. The results of the thermal conductivity experiment depicted in Figure A1 (in Appendix) show that when 10 parts of EG and 290 parts of Al2O3 are added to 40 parts of PP, the thermal conductivity of PP composites can reach up to 1.75 W·m−1·K−1, which is increased by 600% compared with pure PP. Therefore, this proportion is selected as the ratio for subsequent research. At the same time, we also tested the prepared PP composites by X-ray diffraction (XRD) and FTIR (Figures A2 and A3). The results show that no new impurities or other compounds are introduced in the processing process, which further proves that this ratio can produce good synergistic thermal conductivity. The composite materials were prepared by blending 40 phr PP (phr = parts per hundred), 10 phr EG, and 290 phr Al2O3 with different amounts of A153 by using an internal mixer with 60 rpm−1 and 190°C for 8 min (22,23). Afterward, the composite materials were kept under conditions of 15 MPa and 190°C for 5 min to form the plane sheets in the tablet press (yst-100t; Dongguan Tin Testing Instrument Co., Ltd). Details of the compositions in this work are listed in Table 2.

Formula

| Sample code | PP (phr) | EG (phr) | Al2O3 (phr) | A153 (phr) |

|---|---|---|---|---|

| PP-1 | 40 | 10 | 290 | 0 |

| PP-2 | 40 | 10 | 290 | 2.5 |

| PP-3 | 40 | 10 | 290 | 7.5 |

| PP-4 | 40 | 10 | 290 | 12.5 |

| PP-5 | 40 | 10 | 290 | 17.5 |

2.3 Characterizations

2.3.1 Mechanical properties

Put the dumbbell type sample on the electronic universal testing machine (ETM-A; Shenzhen Wance Testing Equipment Co., Ltd) and test it according to GB/T 1040-1992. The rate is 50 mm·min−1. Test each sample five times and take the average value.

2.3.2 Melt flow rate (MFR)

Measure the mass of the sample melt flowing out of the die with the specified diameter within 10 min at 230°C and 21.6 kg in a melt index meter (SRZ-400E; Shenzhen Wance Test Equipment Co., Ltd).

2.3.3 Volume resistivity

Test according to GB/T 1410-2006 in a high resistance meter (ZC-36 type; Shanghai Qiangjia Electric Co., Ltd).

2.3.4 Fourier transform infrared spectroscopy

The test conditions are as follows: resolution, 4 cm−1; scanning times, 32 times; and scanning range, 3,500–700 cm−1 in a Fourier infrared spectrometer (TENSOR II, Brooke, Germany).

2.3.5 Thermal conductivity

Thermal conductivity was determined according to ISO 8301 in an LFA 1000 XFA500 (Linseis, Germany) with dry N2 flowing at a rate of 20 mL·min−1.

2.3.6 Rheological properties

The rotational speed of torque rheometer is 70 rpm and the processing temperature is 180–200°C in a torque rheometer (RM-200A; Harbin Hapu Electric Technology Co., Ltd).

2.3.7 Scanning electron microscopy (SEM)

The surface of the sample was sprayed with gold and then observed under the scanning electron microscope (Phenom Pro, Phenom-World B.V., the Netherlands) (12,13,24,25).

2.3.8 Dielectric strength

Place the sample on the dielectric strength tester and test it according to GB/T 1408.1-2006 in a dielectric mass spectrometer (IDAX300, Megger Company).

2.3.9 XRD

The crystal structures of the PP composites were characterized by XRD, which was performed with a rotating anode X-ray diffractometer (Japan Rigaku D/Max-Ra, Tokyo, Japan) equipped with a Cu Kα (λ = 0.1542 nm) radiation at 2θ values ranging from 5° to 60°.

3 Results and discussion

3.1 Mechanical properties

Figure 2a is a graph showing the change of elongation at break and breaking strength with A153 content. It can be seen from Figure 2a that when A153 is not added, the elongation at break of PP sample is almost 0%. With the increase of A153 addition, the elongation at break of PP sample first increases and then decreases. The elongation at break reaches its maximum when A153 addition is 7.5 phr and then continues to add A153, and the elongation at break begins to decrease. The breaking strength increases slightly with the increase in the amount of A153. When the amount of A153 is 7.5 phr, it reaches its maximum value, and if it continues to increase, then the strength decreases. This may be because A153 can promote the combination of EG particles and PP material surface, and a small amount of addition will significantly improve its tensile strength (26,27). When the amount of A153 is greater than 7.5 phr, excessive A153 begins to agglomerate, hindering the transmission of force and reducing the strength. The intermolecular elongation of A153 is also reduced. As an auxiliary agent with organic–inorganic hybrid structure, the silane coupling agent can improve the interfacial compatibility between PP and inorganic fillers, play the role of building a bridge, facilitate the transfer of force, and improve the mechanical properties in the macro.

Figure 2b is a graph showing the variation of shore A hardness with A153 content. As can be seen from Figure 2b, it increases with the increase of the addition amount of A153, but the increasing trend slows down when the addition amount of A153 exceeds 2.5 phr, which shows that a small amount of A153 can effectively improve the interfacial compatibility between PP and thermal conductivity additives and improve the properties of PP composites, while the influence of excessive A153 on it decreases gradually, so the changing trend of hardness slows down obviously (28).

Effect of different content of A153 on mechanical properties of PP composites: (a) elongation at break and tensile strength and (b) hardness.

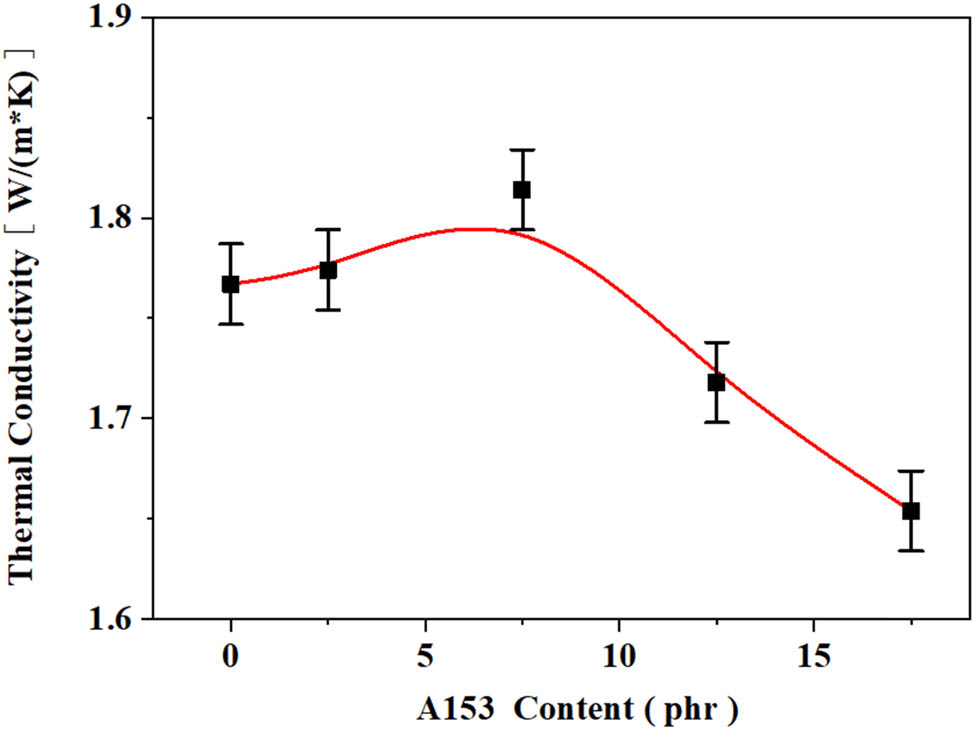

3.2 Thermal conductivity

Figure 3 is a graph showing the variation of thermal conductivity with A153 content. It can be seen from Figure 3 that the measured thermal conductivity of the sample is between 1.65 and 1.82 W·m−1·K−1, which first increases slowly and then decreases with the increase of A153 addition. This may be because when A153 is introduced to a low content, A153 improves the bonding degree between continuous phase PP resin and inorganic particles in the composite, which then improves the interfacial compatibility between polymer and inorganic powder. At this stage, the heat conduction medium is mainly polymer resin matrix and powder complex (29,30). With the increase in the introduction amount of A153, a transition layer of A153 is gradually formed between the polymer matrix and the inorganic powder, which hinders the heat transfer between the powder and the polymer matrix. Although, due to the good thermal conductivity of the powder itself, the stable thermal conductivity channel can be formed between each other and occupies a dominant position in the influence on the thermal conductivity, the influence of the addition amount of A153 on the thermal conductivity is not obvious.

Effect of A153 content on thermal conductivity of PP composites.

3.3 Volume resistivity

Figure 4 shows the curve of volume resistivity with A153 content. As can be seen from the figure, the volume resistivity first increases and then decreases with the increase of A153 addition. A small amount of A153 will significantly improve the volume resistivity of the sample, which shows that A153 in the material will significantly improve the insulation performance of the material. When the addition amount of A153 exceeds 7.5 phr, continue to increase A153, and the volume resistivity of the sample begins to decrease slowly (31,32). This may be because excessive addition of A153 will lead to molecular aggregation of A153, which will affect the overall volume resistivity of the material. When insulating materials are used in various parts of the electrical system, it is generally expected that the materials have as high insulation resistance as possible, and the appropriate addition of A153 can enhance the mechanical properties of the materials and improve the insulation properties of PP composites at the same time (33).

Effect of A153 content on volume resistivity of PP composites.

3.4 Processing performance

In order to study the effect of A153 on the processability of thermally conductive PP materials, MFR and rheological properties were tested, respectively. Figure 5a shows the variation curve of MFR with A153 content. It can be seen from Figure 5a that MFR increases with the increase of A153 content, from 0 to 0.9 g/10 min, which shows that A153 has a lubrication function and effectively reduces the huge friction resistance between PP and inorganic powder particles, so that PP composites can flow more easily in the melting process and are not prone to the sudden increase of torque (34). The higher the content of A153 in PP composites, the lower the friction resistance and the higher the MFR. The increase of MFR means that the energy consumption in industrial extrusion and molding process is reduced and the production efficiency is improved, which means that the addition of A153 makes PP composites show advantages in processing energy consumption and cost.

Effect of A153 content on processability of PP composites: (a) MFR, (b) viscosity, and (c) dielectric loss.

The viscosity curve in Figure 5b first decreases and then increases at low speed, because the addition of A153 hinders the relative fluidity between PP molecular chains and reduces the melt flow performance. At the same time, it can also be seen that the melt shear viscosity of PP blend decreases rapidly with the increase of shear rate and then gradually becomes slow (35). This is because, with the further increase of the shear rate, the conformation of the molecular chain changes from slow to fast, and the long-chain macromolecules deviate from the equilibrium conformation. Under the action of a high shear rate, the orientation of PP molecular chain reaches the limit state. At the same time, higher shear rate will break the melt and destroy the polymer structure. Therefore, when blending and melting, it is very important to select an appropriate melt shear rate to ensure the stable flow of the melt in the processing process.

Figure 5c shows the dielectric loss curve of samples with different A153 content. In the curve, there is a less obvious peak at 2.5 phr after the addition of component A153, which may be caused by the relaxation of ordered structure in the system after the addition of two-dimensional filler graphite (36). From the full frequency range, the curve of tan δ first increased and then decreased with the increase of A153 content. This is because the addition of A153 makes the whole system form a micro-order (37). However, when the content of A153 is greater than 7.5 phr, this micro-order is broken and tan δ decreases.

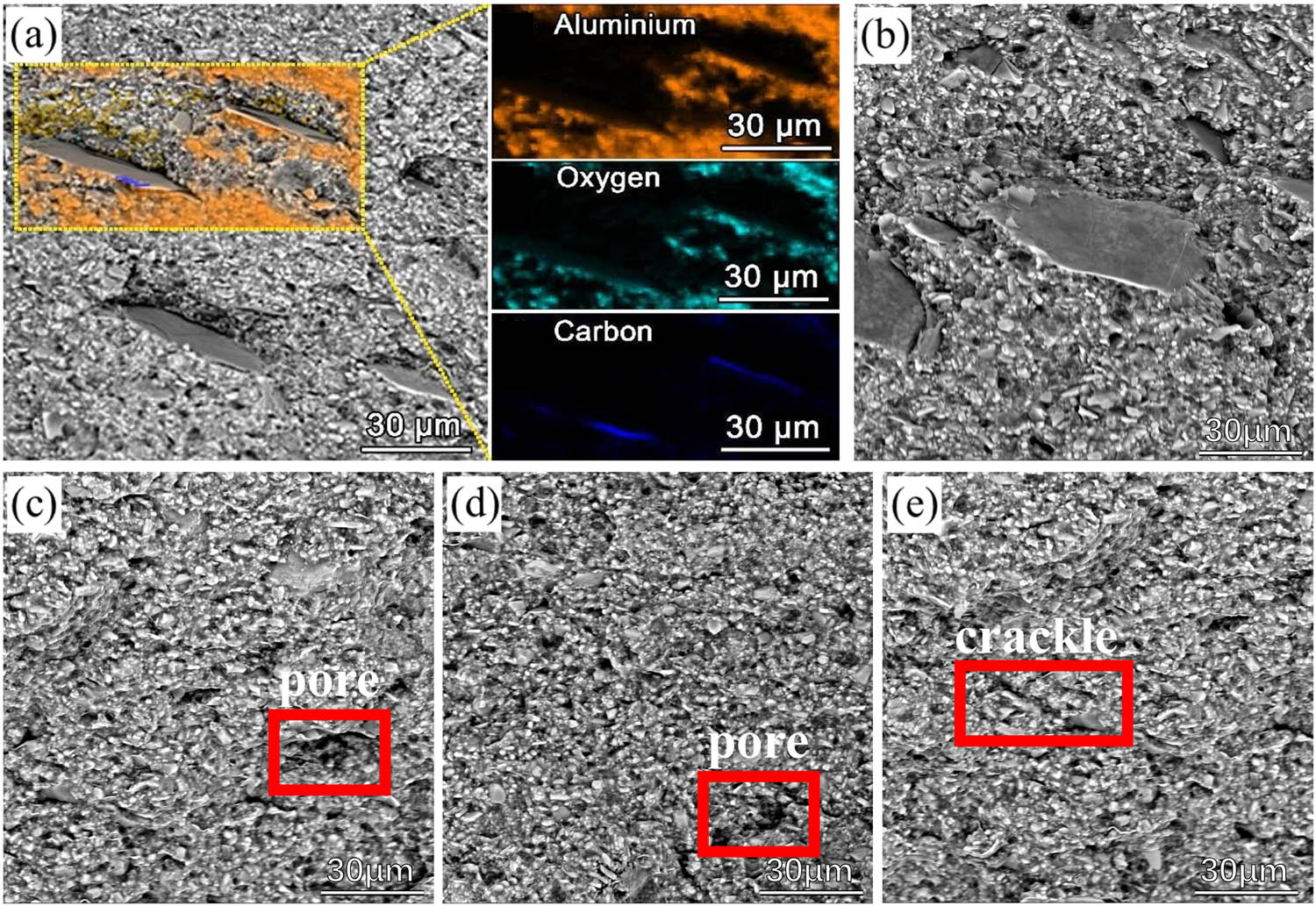

3.5 SEM

Figure 6 shows the cross-sectional morphology of PP samples with different A153 content. It can be seen from the figure that the section without A153 sample is relatively loose and has more pores. With the increase of A153 content, the structure of the sample gradually becomes compact and the pores gradually decrease (38,39). This shows that the proper addition of A153 can improve the interfacial compatibility between EG and PP, and the incompatible two materials are adsorbed by the organic–inorganic structure contained in A153, so as to reduce the internal cracks of PP composites. Therefore, its mechanical properties and processing properties are improved macroscopically. In addition, when the content of A153 exceeds 9 phr, the agglomeration phenomenon of alumina gradually appears, and cracks appear. This may be because too much A153 covers the inorganic filler, which makes the agglomeration phenomenon obvious, while the bonding between aggregates is weakened and cracks appear, thus affecting the properties of PP composites.

SEM cross section of PP samples with different A153 content: (a) PP-1, (b) PP-2, (c) PP-3, (d) PP-4, and (e) PP-5.

4 Conclusion

In order to improve the properties of high-filled thermal insulation PP composites, coupling agent A153 was used to modify it, and the effect of the number of A153 on PP composites was explored. The results of mechanical properties and insulation properties show that when the content of A153 reaches 7.5 phr, the tensile strength of PP composite can reach 5 MPa, the elongation at break can reach 25%, and the volume resistivity can reach 12.8 × 1012 Ω·m. Continuous addition of A153 will gradually increase the hardness, but the increase range decreases. The test results of thermal conductivity show that with the continuous addition of A153, the thermal conductivity first increases slowly and then decreases, and the maximum is 1.82 W·m−1·K−1 after the addition number reaches 7.5 phr. The results of the processing properties showed that with the increase of A153 content, MFR increased, the viscosity of PP composite decreased first and then increased at low speed, and the melt shear viscosity decreased rapidly and then gradually became slow with the increase of shear rate. The SEM results show that the pore structure of A153 gradually decreases as the A153 content increases.

Acknowledgments

We are grateful to the Collaborative Innovation Center of Radiological Medicine of Jiangsu Higher Education Institutions.

-

Funding information: Financial support from Nuclear Energy Development and Scientific Research Project of the State Administration of Science, Technology and Industry for National Defense, P.R. China (No. 2019-1342) and Jiangsu Natural Science Foundation (No. BK20211318) is highly appreciated.

-

Author contributions: Jianxi Li: writing – original draft, data curation; Shuya Zhang: writing – review and editing, methodology; Yaqin Fan: data curation, formal analysis; Aosong Wang: project administration, funding acquisition; Zhuang Miao: investigation, formal analysis; Peng Cheng: validation; Hanzhou Liu: conceptualization, funding acquisition, writing – review and editing, methodology.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

Appendix

Pre-experimental formula

| Code | PP (phr) | EG (phr) | Al2O3 (phr) |

|---|---|---|---|

| PP-1 | 40 | 0 | 200 |

| PP-2 | 40 | 0 | 300 |

| PP-3 | 40 | 5 | 295 |

| PP-4 | 40 | 10 | 290 |

| PP-5 | 40 | 15 | 285 |

Effect of different EG and Al2O3 ratios on thermal conductivity of PP composites.

Effect of different EG and Al2O3 ratios on XRD of PP composites.

Effect of different EG and Al2O3 ratios on FTIR of PP composites.

References

(1) Al Imran K, Lou J, Shivakumar KN. Enhancement of electrical and thermal conductivity of polypropylene by graphene nanoplatelets. J Appl Polym Sci. 2018;135(9):45833.10.1002/app.45833Search in Google Scholar

(2) Ahmadi M, Rouhi S, Ansari R. Evaluating the thermal conductivity coefficient of polypropylene/graphene nanocomposites: A hierarchical investigation. Proc Inst Mech Eng Part L-J Mater-Design Appl. 2021;235(12):2762–70.10.1177/14644207211035415Search in Google Scholar

(3) Du BX, Cui B. Effects of thermal conductivity on dielectric breakdown of micro, nano sized BN filled polypropylene composites. IEEE Trans Dielectr Electr Insulation. 2016;23(4):2116–25.10.1109/TDEI.2016.7556486Search in Google Scholar

(4) Batool F, Bindiganavile V. Evaluation of thermal conductivity of cement-based foam reinforced with polypropylene fibers. Mater Struct. 2020;53(1):13.10.1617/s11527-020-1445-7Search in Google Scholar

(5) Atagur M, Akyuz O, Sever K, Seki Y, Seydibeyoglu O, Isbilir A, et al. Investigation of thermal and mechanical properties of synthetic graphite and recycled carbon fiber filled polypropylene composites. Mater Res Express. 2019;6(6):065312.10.1088/2053-1591/ab0d34Search in Google Scholar

(6) Du H, Wu J, Liu G, Wu H, Yan R. Detection of thermophysical properties for high strength concrete after exposure to high temperature. J Wuhan Univ Technol-Mater Sci Ed. 2017;32(1):113–20.10.1007/s11595-017-1568-zSearch in Google Scholar

(7) Fukuyama Y, Senda M, Kawai T, Kuroda S, Toyonaga M, Taniike T, et al. The effect of the addition of polypropylene-grafted SiO2 nanoparticle on the thermal conductivity of isotactic polypropylene. J Therm Anal Calorim. 2014;117(3):1397–405.10.1007/s10973-014-3881-5Search in Google Scholar

(8) Ebadi-Dehaghani H, Reiszadeh M, Chavoshi A, Nazempour M, Vakili MH. The effect of zinc oxide and calcium carbonate nanoparticles on the thermal conductivity of polypropylene. J Macromol Sci Part B-Physics. 2014;53(1):93–107.10.1080/00222348.2013.810032Search in Google Scholar

(9) Weidenfeller B, Kirchberg S. Thermal and mechanical properties of polypropylene-iron-diamond composites. Compos Part B-Engineering. 2016;92:133–41.10.1016/j.compositesb.2016.02.011Search in Google Scholar

(10) King JA, Lopez Gaxiola D, Johnson BA, Keith JM. Thermal conductivity of carbon-filled polypropylene-based resins. J Composite Mater. 2010;44(7):839–55.10.1177/0021998309347578Search in Google Scholar

(11) Liu J, Shen L, Lin H, Huang Z, Hong H, Chen C. Preparation of Ni@UiO-66 incorporated polyethersulfone (PES) membrane by magnetic field assisted strategy to improve permeability and photocatalytic self-cleaning ability. J Colloid Interface Sci. 2022;618:483–95.10.1016/j.jcis.2022.03.106Search in Google Scholar PubMed

(12) Liu Y, Shen L, Huang Z, Liu J, Xu Y, Li R, et al. A novel in-situ micro-aeration functional membrane with excellent decoloration efficiency and antifouling performance. J Membr Sci. 2022;641:119925.10.1016/j.memsci.2021.119925Search in Google Scholar

(13) Han L, Chen C, Shen L, Lin H, Li B, Huang Z, et al. Novel membranes with extremely high permeability fabricated by 3D printing and nickel coating for oil/water separation. J Mater Chem A. 2022;10:12055–61.10.1039/D2TA01971JSearch in Google Scholar

(14) Nejad SJ, Golzary A. Investigation and modeling of the thermal conductivity of PP/clay nanocomposites and PP/MWCNT nanocomposites. E-Polymers. 2010;94(1). 10.1515/epoly.2010.10.1.1062.Search in Google Scholar

(15) Muratov DS, Kuznetsov DV, Il’inykh IA, Mazov IN, Stepashkin AA, Tcherdyntsev VV. Thermal conductivity of polypropylene filled with inorganic particles. J Alloy Compd. 2014;586:S451–4.10.1016/j.jallcom.2012.11.142Search in Google Scholar

(16) Liang J-Z. Estimation of thermal conductivity for polypropylene/hollow glass bead composites. Compos Part B-Eng. 2014;56:431–4.10.1016/j.compositesb.2013.08.072Search in Google Scholar

(17) Roh JU, Kim HS, Lee WI. Isotropic conductivities in chopped carbon fiber composites using expanded polypropylene. Adv Composite Mater. 2014;23(5–6):409–20.10.1080/09243046.2014.915096Search in Google Scholar

(18) Prakash V, Rai B, Tyagi VK, Niyogi UK. Dispersion and characterizations of nanofluids prepared with CuO and CNT nanoparticle. J Indian Chem Soc. 2015;92(8):1245–51.Search in Google Scholar

(19) Pehlivanli ZO. Manufacturing and characterization of polypropylene/boric acid composite. Polym Bull. 2021;78(7):4033–46.10.1007/s00289-021-03728-4Search in Google Scholar

(20) Wang J-L, Xiong G-P, Gu M, Zhang X, Liang J. A study on the thermal conductivity of multiwalled carbon nanotube/polypropylene composite. Acta Phys Sin. 2009;58(7):4536–41.10.7498/aps.58.4536Search in Google Scholar

(21) Vakili MH, Ebadi-Dehaghani H, Haghshenas-Fard M. Crystallization and thermal conductivity of CaCO3 nanoparticle filled polypropylene. J Macromol Sci Part B-Physics. 2011;50(8):1637–45.10.1080/00222348.2010.543033Search in Google Scholar

(22) Xu S, Zhou C, Li J, Shen L, Lin H. Simultaneously improving mechanical strength, hydrophobic property and flame retardancy of ethylene vinyl acetate copolymer/intumescent flame retardant/FeOOH by introducing modified fumed silica. Mater Today Commun. 2021;26:26.10.1016/j.mtcomm.2021.102114Search in Google Scholar

(23) Xu S, Li J, Ye Q, Shen L, Lin H. Flame-retardant ethylene vinyl acetate composite materials by combining additions of aluminum hydroxide and melamine cyanurate: Preparation and characteristic evaluations. J Colloid Interface Sci. 2021;589:525–31.10.1016/j.jcis.2021.01.026Search in Google Scholar PubMed

(24) Huang Z, Zeng Q, Liu Y, Xu Y, Li R, Hong H, et al. Facile synthesis of 2D TiO2@MXene composite membrane with enhanced separation and antifouling performance. J Membr Sci. 2021;640:640.10.1016/j.memsci.2021.119854Search in Google Scholar

(25) Chen B, Xie H, Shen L, Xu Y, Zhang M, Yu H, et al. Electroless Ni-Sn-P plating to fabricate nickel alloy coated polypropylene membrane with enhanced performance. J Membr Sci. 2021;18:640.10.1016/j.memsci.2021.119820Search in Google Scholar

(26) Chauhan SS, Aggarwal P, Karmarkar A. The effectiveness of m-TMI-grafted-PP as a coupling agent for wood polymer composites. J Composite Mater. 2016;50(25):3515–24.10.1177/0021998315622050Search in Google Scholar

(27) Aggarwal PK, Raghu N, Karmarkar A, Chuahan S. Jute-polypropylene composites using m-TMI-grafted-polypropylene as a coupling agent. Mater & Des. 2013;43:112–7.10.1016/j.matdes.2012.06.026Search in Google Scholar

(28) Das K, Ray D, Adhikary K, Bandyopadhyay NR, Mohanty AK, Misra M. Development of recycled polypropylene matrix composites reinforced with fly ash. J Reinforced Plast Compos. 2010;29(4):510–7.10.1177/0731684408099415Search in Google Scholar

(29) Deng S, Beehag A, Hillier W, Zhang D, Ye L. Kenaf-polypropylene composites manufactured from blended fiber mats. J Reinforced Plast Compos. 2013;32(16):1198–210.10.1177/0731684413485652Search in Google Scholar

(30) de la Orden MU, Gonzalez Sanchez C, Gonzalez Quesada M, Martinez Urreaga J. Effect of different coupling agents on the browning of cellulose-polypropylene composites during melt processing. Polym Degrad Stab. 2010;95(2):201–6.10.1016/j.polymdegradstab.2009.11.024Search in Google Scholar

(31) Madhavi S, Raju NV, Johns J. Characterization of bamboo – polypropylene composites: effect of coupling agent. Fibers Polym. 2021;22(11):3183–91.10.1007/s12221-021-0027-9Search in Google Scholar

(32) Lee M, Kim Y, Ryu H, Baeck S-H, Shim S. Effects of silane coupling agent on the mechanical and thermal properties of silica/polypropylene composites. Polymer-Korea. 2017;41(4):599–609.10.7317/pk.2017.41.4.599Search in Google Scholar

(33) Miyazaki K, Okazaki N, Terano M, Nakatani H. Preparation and characterization of cellulose/polypropylene composite using an oxidatively degraded polypropylene. J Polym Environ. 2008;16(4):267–75.10.1007/s10924-008-0111-xSearch in Google Scholar

(34) Ndiaye D, Tidjani A. Effects of coupling agents on thermal behavior and mechanical properties of wood flour/polypropylene composites. J Composite Mater. 2012;46(24):3067–75.10.1177/0021998311435675Search in Google Scholar

(35) Nourbakhsh A, Ashori A. Highly fiber-loaded composites: Physical and mechanical properties. Polym & Polym Compos. 2008;16(5):343–7.10.1177/096739110801600508Search in Google Scholar

(36) Subramaniam D, Natesan R, Shanmugavel BP. Development of storage bin using lantana camara flour reinforced polypropylene composites: Product performance study on the composite bin for pharmaceutical applications. J Polym Res. 2022;29(4):122.10.1007/s10965-022-02959-xSearch in Google Scholar

(37) Poletto M. Natural oils as coupling agents in recycled polypropylene wood flour composites: Mechanical, thermal and morphological properties. Polym Polym Compos. 2020;28(7):443–50.10.1177/0967391119886941Search in Google Scholar

(38) Wang Y, Cao J, Zhu L, Zhao G. Interfacial compatibility of wood flour/polypropylene composites by stress relaxation method. J Appl Polym Sci. 2012;126:E89–95.10.1002/app.36682Search in Google Scholar

(39) Vantsi O, Karki T. Different coupling agents in wood-polypropylene composites containing recycled mineral wool: A comparison of the effects. J Reinforced Plast Compos. 2015;34(11):879–95.10.1177/0731684415583524Search in Google Scholar

© 2022 Jianxi Li et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes

Articles in the same Issue

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes