Abstract

Polyurethane-based retanning agents with antimicrobial properties were synthesized by the chemical incorporation of ciprofloxacin (CPFX) units into polyurethane chains. The chemical structures were characterized by Fourier transform infrared (FTIR) and gel permeation chromatography (GPC). Then, the retanning agents were applied in the leather retanning process. Owing to the conjugation of CPFX into polyurethane chains, the molecular weight increases, further leading to the decrease in hydroxyl value and increase in particle size. The shrinkage temperature was improved after retanning. Owing to the filling of retanning agents in the gap of collagen fibers, the average thickness of leather increased by 65.8%. The mechanical properties of leather were visibly improved because of the large number of –COOH coordinate with Cr3+ and more hydrogen crosslinking with carboxyl group, amino group, and hydroxyl group of leather collagen. Furthermore, leather retanned by these polyurethane-based retanning agents presented good antimicrobial properties. The antibacterial activity could be conserved above 89% even after rinsing for ten times.

1 Introduction

Leather is a collagen fibrous material produced by tanning the collagen fiber network of animal hides and skins, and its productions can be seen almost everywhere in our life (1,2,3). As a natural material, leather can serve as a carbon and nitrogen source for microbial growth. Moreover, the collagen fibrous network of leather can provide suitable temperature, moisture, and oxygen for the growth and rapid colonization of bacteria. As a result, the formation of a biofilm will severely reduce the service life of the leather products (4,5,6). Hence, it is of great importance to inhibit bacteria growth on leather.

Antimicrobial properties of leather can be achieved through retanning process. As one of the significant steps in leather manufacturing process, retanning process can overcome some drawbacks of chrome tannage, improve leather shrinkage temperature, assist dyeing performance, and more importantly, endow some functional properties to the final leather, such as antimicrobial, antifouling, waterproof, fire-retardancy, and so on (7,8,9). For example, a chromotropic acid grafted amphoteric polyurethane was synthesized and then applied in the retanning process of the aldehyde tanned leather (10). The reaction between chromotropic acid and formaldehyde occurred between two naphthalene rings, effectively reducing the free formaldehyde content in leather.

Among the retanning agents, hyperbranched polyurethane has attracted increasing attention because of its novel structures and unique properties. A great number of active groups in hyperbranched polyurethane can coordinate with groups of collagen fiber macromolecules (such as hydroxyl, amino, and carboxyl), and form stable interaction (11,12,13). For instance, Ren and coworkers synthesized a hydroxyl-terminated hyperbranched retanning agent. All the leather samples retanned by it exhibited better tearing strength, tensile strength, cracking strength, dry rub fastness, and surface properties (12). Another research found that hyperbranched polymer retanning agent can effectively improve the shrinkage temperature of hide and chrome uptake (13). In particular, the structure of hyperbranched polyurethane can be easily designed by changing the types of raw materials during the manufacturing process to meet the desired performances (14,15). For example, a phosphorous polyol and expandable graphite were incorporated into polyurethane. The obtained hyperbranched polyurethane not only possesses high physical performances, but also significantly reduces the release of contaminative smoke CO and NOx in fires (16). Therefore, the antimicrobial moieties can be covalently conjugated into the chains of hyperbranched polyurethane. However, to the best of our knowledge, no research has been done on preparing hyperbranched polyurethane with antimicrobial properties for leather retanning.

Ciprofloxacin (CPFX), a low-molecular-weight antimicrobial agent, is one of the new generation of fluorinated quinolones structurally related to nalidixic acid (17,18). Its primary mechanism is inhibition of bacterial DNA gyrase. It is a broad-spectrum antibacterial drug to which most Gram-negative bacteria are highly susceptible in vitro and many Gram-positive bacteria are susceptible or moderately susceptible. Blending CPFX with retanning agents might cause its migration during the following leather manufacturing process (19,20). So, it is better to chemically incorporate CPFX into chains of retanning agents. In this study, we aim to endow leather antimicrobial properties in retanning process. Polyurethane-based retanning agents were prepared by chemically incorporating CPFX units into polyurethane chains. Then, they were applied in the leather retanning process. The shrinkage temperature, average thickness, and mechanical properties of final leather were measured. Besides, the antimicrobial properties of leather after retanning were investigated in detail. It was found that these retanning agents endowed leather with good bacteriostatic effect on Gram-positive and Gram-negative bacteria.

2 Materials and methods

2.1 Materials

1,1,1-Tris(hydroxymethyl)propane (TMP), hexamethylene diisocyanate (HDI), 2, 2-bis(hydroxymethyl)propionic acid (DMPA), CPFX, and N,N-dimethylformamide (DMF) were purchased from Shanghai Macklin Biochemical Co., Ltd (Shanghai, China). Formic acid (HCOOH), sodium formate (NaCOOH), and sodium bicarbonate (NaHCO3) were acquired from Aladdin Industrial Corporation (Shanghai, China). Hexamethylene-1,6-diisocyanate trimer (HDIT) was supplied by Bayer Co. Ltd (Germany). Other chemicals were used as received.

2.2 Preparation of polyurethane-based retanning agents (PUR) and PUR-CPFXs

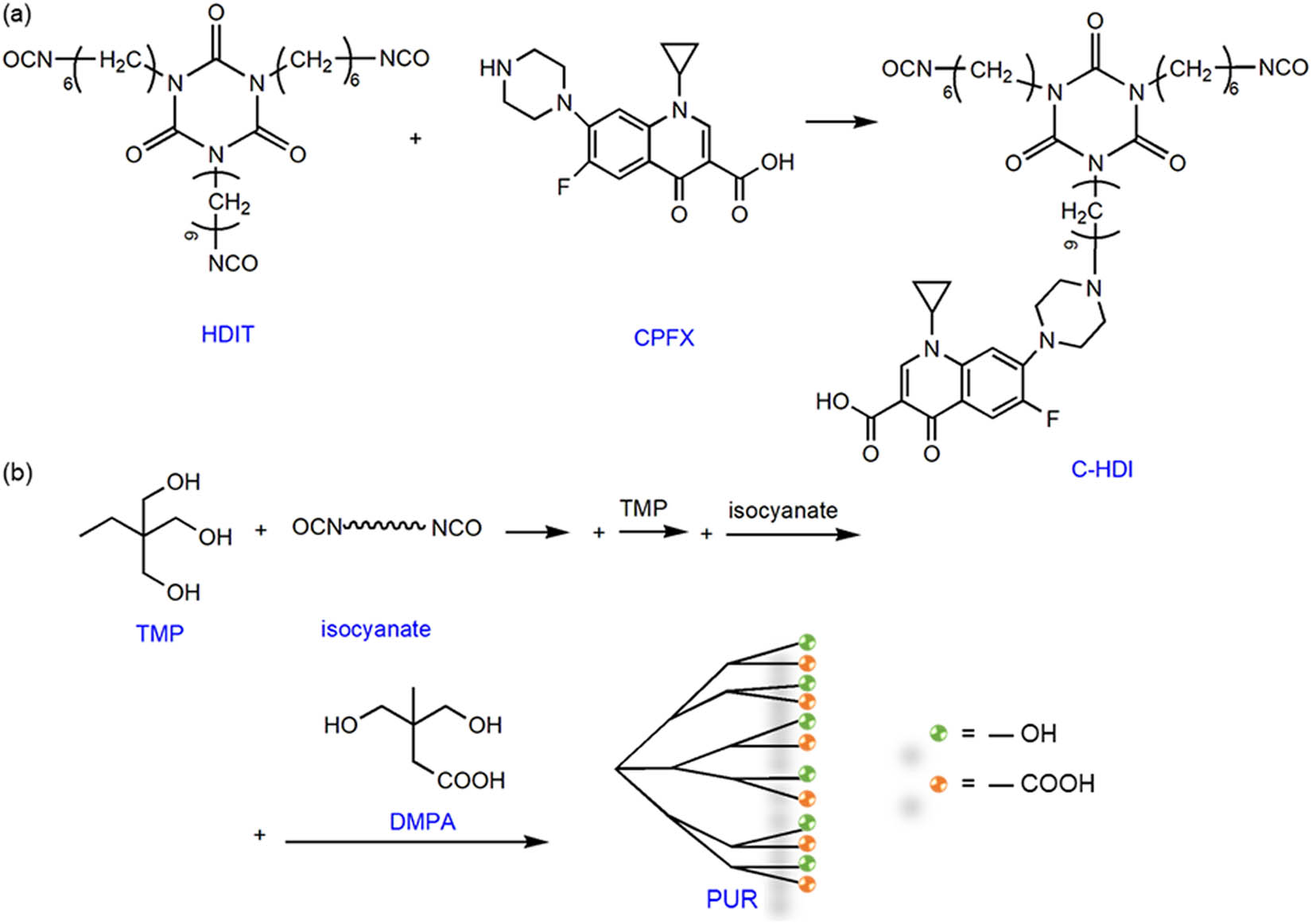

First, HDIT (0.011 mol), CPFX (0.01 mol), and appropriate DMF were added into a three-necked separable reaction flask equipped with a nitrogen inlet. The reaction was stirred at room temperature until the molar ratio of –NCO reached the theoretical value (0.02 mol) (21). The mixture was filtered, and then washed by DMF several times. Finally, it was dried at 30°C in the oven. The prepared isocyanate with two-NCO groups was named C-HDI (Scheme 1a). TMP (0.001 mol) and isocyanate (0.003 mol) were added to the mixture to form the branched structures. HDI was applied as isocyanate in the preparation process. In the meantime, appropriate DMF was poured in case of crosslink reaction. Next more TMP (0.003 mol) was charged into the reactor and kept stirring. After that, isocyanate (0.006 mol) was added for continued reaction. Subsequently, DMPA (0.006 mol) was added to react with the residual –NCO groups. Then, the DMF was removed at room temperature by rotary vacuum evaporation under reduced pressure. The obtained polymer was dissolved in ethanol and centrifuged at high speed. The supernatant after centrifugation was evaporated at room temperature by rotary vacuum evaporation under the reduced pressure, and the polyurethane-based retanning agents (PUR) were obtained (Scheme 1b). To acquire PUR with antimicrobial properties, C-HDI was utilized as isocyanate to replace part of HDI. Polyurethane-based retanning agents with antimicrobial properties were abbreviated as PUR-CPFX-x, and x represents the weight concentrations of C-HDI used in Scheme 1b as isocyanate.

Preparation of (a) C-HDI and (b) PUR.

2.3 Retanning technology

The wet blue is cattlehide tanned by Cr3+ of tanning agents and was retanned according to the technology reported in our previous work, as listed in Table 1 (22). PUR and PUR-CPFX were applied to treat the wet blue with the same technology. All chemicals were used based on the weight of evenly shaved wet blue.

Retanning process

| Process | Chemicals | Weight (%) | Time |

|---|---|---|---|

| Weighing | |||

| Bleaching | Water (35°C) | 200 | 15 min |

| HCOOH | 0.2 | ||

| Discharging the solution | |||

| Neutralizing | Water (30°C) | 150 | |

| HCOONa | 1 | 40 min, pH 4–4.5 | |

| NaHCO3 | 0.4–0.5 | 60 min, pH 5–5.5 | |

| Discharging the solution | |||

| Retanning | Water (35°C) | 100 | 60 min |

| PUR/PUR–CPFX | 8 | ||

| Horse up | |||

2.4 Measurements

2.4.1 Fourier transform infrared (FTIR)

FTIR (Thermo Fisher Nicolet Is5, USA) Spectroscopy measurements were performed, and the spectra of each sample were acquired at a resolution of 2 cm−1 in a wavelength range of 400–4,000 cm−1 with 32 scans.

2.4.2 Gel permeation chromatography (GPC)

Gel permeation chromatography was conducted on an Agilent Technologies 1260 Infinity chromatograph (United States) to determine the relative molecular weight and polydispersity of the polymers. All the tests were performed at 35°C and tetrahydrofuran (chromatographic grade) was used as an organic solvent.

2.4.3 Hydroxyl value

Hydroxyl value was measured using the acetic anhydride/pyridine refluxing method (23).

2.4.4 Particle sizes

Particle sizes were obtained by laser particle size analyzer (Mastersizer 3000E). Each sample was tested three times, and its average value was taken.

2.4.5 Shrinkage temperature

The shrinkage temperature (T s) of leather samples was measured by MSW–YD4 shrinkage meter (Yangguang Research Institute of Shanxi University of Science and Technology) according to the Chinese Industrial Standard (QB/T 2713-2005). Different parts of leathers were tested, and the average T s was calculated.

2.4.6 Thickness

A leather thickness gauge (Dongyan, DY-701) was applied to test the leather thickness. Different parts of the leather were tested, and the average thickness value was calculated.

2.4.7 Mechanical properties

Mechanical properties were determined using a universal testing machine (model tensiTECH, Woodstock, USA). Before measurement, samples were dried in an oven for 24 h at 60°C. Each sample was cut into dumbbell-shaped specimens of 50 mm length and 10 m neck width and measured with a 50 mm‧min−1 cross-head speed at 25°C. Measurements were taken five times for each sample.

2.4.8 Antimicrobial properties

Gram-negative bacterium E. coli (ATCC 29213) and Gram-positive bacterium S. aureus (ATCC 25922) were used as the indicator microorganisms to evaluate the antimicrobial properties of leather. The measurement process for the antimicrobial properties of leather retanned by PUR and PUR-CPFXs is shown in Scheme 2. First, E. coli and S. aureus were inoculated into three 12 mL bacterial culture tubes with 3 mL fluid Luria-Bertani (LB) medium, respectively. These bacteria were shaking cultured at 37°C for 15 h. Meanwhile, leather samples retanned by PUR and PUR-CPFXs were cut into specimens of 20 mm × 20 mm and sterilized by UV-irradiation for 1 h. Afterward, the concentration of both E. coli and S. aureus bacteria solution was diluted to 106 CFU‧mL−1. Flesh side was selected as the representative to measure the antimicrobial properties in this study. Next 50 μL of bacteria solution was dropped on the flesh layer of each leather sample, respectively, and was covered by sterile PVC film. Then, they were put into boxes with constant humidity (relative humidity ≥90%) and incubated for 24 h at 37°C. After that, the flesh layer of each sample was washed with 5 mL of sterile phosphate buffered saline (PBS) solution. After washing, each PBS solution was collected and diluted 103, 104, 105 times, respectively. Finally, 100 μL of diluted solution was dropped on the solid LB medium and put into a constant temperature incubator at 37°C for 18 h.

Measurement process for the antimicrobial properties of leather retanned by PUR and PUR-CPFXs.

3 Results and discussion

3.1 Preparation and characterization

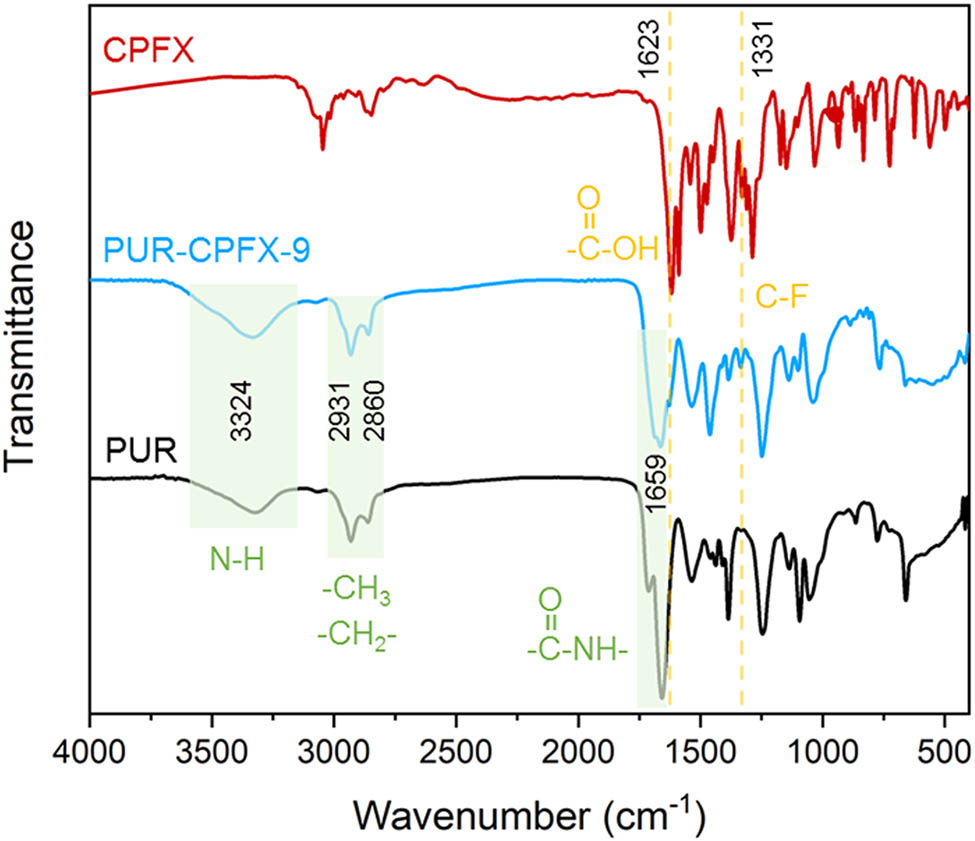

The presence of CPFX moieties in the polymer could be verified by FTIR analysis (Figure 1). PUR-CPFX-9 was chosen as a representative example. In the spectra of PUR and PUR-CPFX-9, absorption peaks at 3,324 cm−1 (N–H) and 1,659 cm−1 (C═O) were found, which were attributed to the urethane bond in polyurethane chains. Besides, peaks at 2,931 and 2,860 cm−1 corresponded to the stretching vibration of C–H in –CH3 and –CH2– (24,25,26), respectively. These peaks proved the polyurethane structure of PUR and PUR-CPFX-9. As for the spectrum of CPFX, the strong absorption peak at 1,623 cm−1 can be assigned to the –COOH (27) and C–F (28), respectively. These two peaks were found in the spectrum of PUR-CPFX-9, but not appeared in that of PUR. As a result, the CPFX was successfully introduced to PUR-CPFX-9.

FTIR spectra of CPFX, PUR-CPFX-9, and PUR.

GPC measurement was applied to obtain the molecular weight of PUR and PUR-CPFXs (Table 2). With the content of CPFX increased, both the M w and M n of PUR-CPFXs gradually increased. Because of the covalent conjugation of CPFX into polyurethane chains, the molecular weight inevitably grew larger. However, the polydispersity was not distinctly influenced after incorporating antimicrobial moieties. The hydroxyl value decreased when the molecular weights of the PUR increased. With the increase in molecular weights, the number of terminal hydroxyl groups increased simultaneously, but the increasing extent of the former was more significant than the latter. Therefore, the hydroxyl value decreased. Besides, with the increasing content of DPA, the particle size accordingly increased. In summary, owing to the conjugation of CPFX into polyurethane chains, the molecular weight increases, further leading to the decrease in hydroxyl value and increase in particle size.

GPC data, hydroxyl value as well as particle size of PUR and PUR-CPFXs

| Sample | M n (g‧mol−1) | M w (g‧mol−1) | M w/M n | [OH]m (mg KOH‧g−1) | d (nm) |

|---|---|---|---|---|---|

| PUR | 1,856 | 2,153 | 1.16 | 153.61 | 33.6 |

| PUR–CPFX–3 | 1,963 | 2,316 | 1.18 | 132.54 | 38.4 |

| PUR–CPFX–6 | 2,046 | 2,476 | 1.21 | 131.04 | 41.1 |

| PUR–CPFX–9 | 2,098 | 2,497 | 1.19 | 126.59 | 43.9 |

| PUR–CPFX–12 | 2,173 | 2,521 | 1.16 | 128.49 | 44.8 |

3.2 Application in retanning process

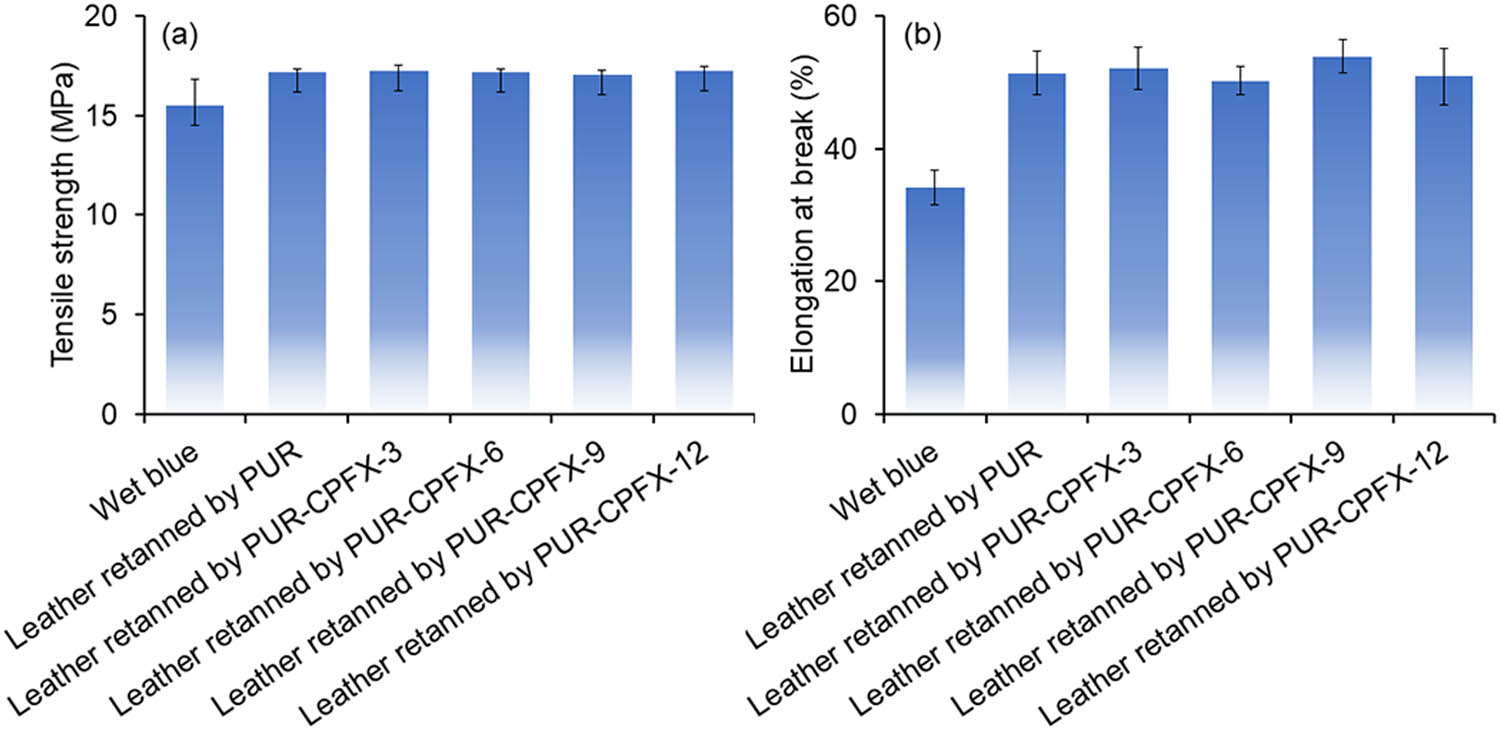

As a significant parameter to appraise the hydrothermal stability of leather (29,30), the T s of leather before and after retanning was acquired (Figure 2a). After retanned by PUR and PUR-CPFXs, the T s is obviously increased. The average thickness of leather was also measured (Figure 2b). Before the test, the wet blue and retanned leather were dried at room temperature. The thickness of leather after retanning by polyurethane was dramatically increased. Furthermore, the SEM images of leather before and after retanning are presented in Figure 2c and d, respectively. Before retanning, the leather fibers were dense, and only small gaps could be found between collagen fiber bundles. However, evident gaps were investigated, and the fibers were separated from each other after being retanned. On the one hand, quantities of –OH in the polyurethane chains can form hydrogen bonds with the –NH2 in the side chains of collagen fibers. On the other hand, a large quantity of –COOH in PUR can coordinate with Cr3+ of tanning agents (8). As a result, the higher crosslinking effectively improved the T s of leather (Figure 2e) (31). Owing to the filling of retanning agents in the gap of collagen fibers, the average thickness of leather increased by 65.8%. The mechanical properties of leather before and after retanning by PUR and PUR-CPFXs were also measured (Figure 3). The mechanical properties of leather were visibly improved after retanning. This was on account of the large number of –COOH and –OH in the PUR forming coordination with Cr3+ and more hydrogen crosslinking with carboxyl group, amino group and hydroxyl group of leather collagen (11,32). The elongation at break is visibly improved due to the outstanding lubricating and filling of polyurethane between collagen fibers (22).

(a) T s, (b) average thickness of Wet blue and leather retanned by PUR and PUR-CPFXs. SEM images of leather (c) before and (d) after retanning. (e) Schematic diagram of retanning by PUR.

(a) Tensile strength and (b) elongation at break of Wet blue and leather retanned by PUR and PUR-CPFXs.

3.3 Antimicrobial properties of retanned leather

The antimicrobial properties of retanned leather were evaluated using Gram-negative bacterium E. coli and Gram-positive bacterium S. aureus according to the previous reports (33,34,35,36) (Figure 4). Both E. coli and S. aureus grew well in the flesh layer of leather retanned by PUR. However, no bacterial colony was found in the medium with the PBS solution after washing flesh layer of leather retanned by PUR-CPFXs. After incorporated into polyurethane chains, the antibacterial properties of CPFX were reserved but not destroyed. The CPFX units in retanning agents effectively inhibited bacterial DNA gyrase. This result showed that the PUR-CPFX retanning agents endowed leather with good bacteriostatic effect on Gram-positive and Gram-negative bacteria (37,38). Nowadays, antimicrobial resistance has been a growing problem in microorganisms. It is of great importance to fabricate antimicrobial polymers by incorporating micromolecular antibacterial agents into polymer chains.

Antibacterial activity against (a) E. coli and (b) S. aureus of leather retanned by PUR and PUR-CPFXs. (c) Antibacterial efficiency against E. coli and S. aureus vs rinsing cycle.

Compared with low-molecular-weight antimicrobial agents, antimicrobial polyurethane-based retanning agents are seldom leached out from the leather because of their interaction with collagen fibers, which promises their long-lasting function. In this study, E. coli and S. aureus were selected as indicators to quantitatively investigate the long-lasting antibacterial property of leather retanned by PUR-CPFXs. PUR-CPFX-9 was chosen as a representative example. As could be seen in Figure 4c, leather retanned by PUR-CPFX-9 displayed excellent antimicrobial properties against both strains, demonstrating a desirable antibacterial efficiency. It was found that the antibacterial activity could be conserved even after rinsing ten times, and the antibacterial efficiency against both strains remained above 89%. Only a slight decline was found, which could be due to the loss of retanning agents among collagen fibers. PUR-CPFX can endow leather products stable antimicrobial properties.

4 Conclusion

In this study, we designed and synthesized polyurethane-based retanning agents (PUR-CPFXs) with antimicrobial properties via chemically conjugating CPFX into polyurethane branched chains. Then, the PUR-CPFX was utilized as retanning agents in the leather manufacturing process. After the conjugation of CPFX into polyurethane chains, the molecular weight increases, further leading to the decrease in hydroxyl value and increase in particle size. As for wet blue, after being retanned, the shrinkage temperature is obviously increased. After retanning, the leather fibers were separated from each other, owing to the filling of retanning agents in the gap of fibers. Hence, the average thickness of leather increased by 65.8%. The mechanical properties of leather were visibly improved after retanning, on account of the large number of –COOH in the PUR coordinating with Cr3+ and more hydrogen crosslinking with carboxyl group, amino group, and hydroxyl group of leather collagen. Particularly, leather retanned by PUR-CPFX exhibited good antimicrobial properties against Gram-positive or Gram-negative bacteria. The antibacterial activity could be conserved above 89% even after rinsing for ten times. These results suggested the potential application of PUR-CPFX as an antimicrobial retanning agent for leather manufacturing.

Acknowledgment

The authors greatly thank the financial support from Department of Education of Zhejiang Province (Y202043348).

-

Funding information: This work was funded by Department of Education of Zhejiang Province (Y202043348).

-

Author contributions: Sheng Ding: methodology, formal analysis, and writing – original draft; Jinxing Zhu: formal analysis; Saiqi Tian: writing – review and editing, resources, and project administration.

-

Conflict of interest: Authors state no conflict of interest.

References

(1) Zeng H, Xu W, Zhou J, Shi B. Two-stage temperature change chrome tanning: a more sustainable tanning process. J Am Leather Chem Assoc. 2019;114:153–62.Search in Google Scholar

(2) Li Q, Zhong R, Xiao X, Liao J, Shi B. Lightweight and flexible Bi@Bi-La natural leather composites with superb x-ray radiation shielding performance and low secondary radiation. ACS Appl Mater Interfaces. 2020;12:54117–26.10.1021/acsami.0c17008Search in Google Scholar PubMed

(3) Wang Y, Ding P, Xu H, Li Q, Guo J, Liao X, et al. Advanced X-ray shielding materials enabled by the coordination of well-dispersed high atomic number elements in natural leather. ACS Appl Mater Interfaces. 2020;12:19916–26.10.1021/acsami.0c01663Search in Google Scholar PubMed

(4) Xiang J, Ma L, Su H, Xiong J, Li K, Xia Q, et al. Layer-by-layer assembly of antibacterial composite coating for leather with cross-link enhanced durability against laundry and abrasion – ScienceDirect. Appl Surf Sci. 2018;458:978–87.10.1016/j.apsusc.2018.07.165Search in Google Scholar

(5) Wang C, Wu J, Li L, Mu C, Lin W. A facile preparation of a novel non-leaching antimicrobial waterborne polyurethane leather coating functionalized by quaternary phosphonium salt. J Leather Sci Eng. 2020;2:1–12.10.1186/s42825-019-0014-8Search in Google Scholar

(6) Ramesh RR, Murali S, Jonnalagadda RR. Research advances in the fabrication of biosafety and functional leather: a way-forward for effective management of COVID-19 outbreak. J Clean Prod. 2021;310:127464.10.1016/j.jclepro.2021.127464Search in Google Scholar PubMed PubMed Central

(7) Liu X, Yue O, Wang X, Hou M, Zheng M, Jiang H. Preparation and application of a novel biomass-based amphoteric retanning agent with the function of reducing free formaldehyde in leather. J Clean Prod. 2020;265:121796.10.1016/j.jclepro.2020.121796Search in Google Scholar

(8) Xu W, Chai X, Zhao G, Li J, Wang X. Preparation of reactive amphoteric polyurethane with multialdehyde groups and its use as a retanning agent for chrome-free tanned leather. J Appl Polym Sci. 2019;136:47940.10.1002/app.47940Search in Google Scholar

(9) Huang W, Song Y, Yu Y, Wang YN, Shi B. Interaction between retanning agents and wet white tanned by a novel bimetal complex tanning agent. J Leather Sci Eng. 2020;2:8.10.1186/s42825-020-00023-2Search in Google Scholar

(10) Wang X, Yan Z, Liu X, Qiang T, Chen L, Guo P, et al. An environmental polyurethane retanning agent with the function of reducing free formaldehyde in leather. J Clean Prod. 2019;207:679–88.10.1016/j.jclepro.2018.10.056Search in Google Scholar

(11) Qiang TT, Gao X, Ren J, Chen XK, Wang XC. A chrome-free and chrome-less tanning system based on the hyperbranched polymer. Acs Sustain Chem Eng. 2016;4:701–7.10.1021/acssuschemeng.5b00917Search in Google Scholar

(12) Ren LF, Zhao YX, Zhang H. Synthesis and Properties of Hydroxyl-terminated Hyperbranched Poly Isocyanurate-ester Retanning Agents. J Am Leather Chem Assoc. 2017;112:240–9.Search in Google Scholar

(13) Yao Q, Li CY, Huang HH, Chen HL, Liu BL. The Relationship between the structure of hyper-branched polymer and its effect on high exhaust chrome in reduced chrome tanning. J Am Leather Chem Assoc. 2017;112:153–61.Search in Google Scholar

(14) Zhang J, Ren HJ, Chen PP, Zhang Z, Hu CP. Preparation and properties of waterborne polyurethane with star-shaped hyperbranched structure. Polymer. 2019;180:180.10.1016/j.polymer.2019.121690Search in Google Scholar

(15) Fang L, Qiu T, Yang Q, Kong L, Ao Y. A novel hyperbranched polyurethane/nTiO2 waterborne sizing agent for improving UV-resistance and interfacial properties of SCF/PA6 composites. Compos Commun. 2021;23:100591.10.1016/j.coco.2020.100591Search in Google Scholar

(16) Ma C, Qiu S, Xiao Y, Zhang K, Zheng Y, Xing W, et al. Fabrication of fire safe rigid polyurethane foam with reduced release of CO and NOx and excellent physical properties by combining phosphine oxide-containing hyperbranched polyol and expandable graphite. Chem Eng J. 2022;431:431.10.1016/j.cej.2021.133347Search in Google Scholar

(17) Chang JM, Yang GF, Zeng Q, Wang ZH, Xu Z, Chen Y, et al. Poly(N-acryloyl ciprofloxacin-co-acrylic acid)-incorporated waterborne polyurethane leather coating with long-lasting antimicrobial property. J Am Leather Chem Assoc. 2017;112:15–22.Search in Google Scholar

(18) Wen HT, Yu GF, Zheng X, Chen YN, Dan NAH, Dan WH. Improving the antibacterial properties of wet leather based on grafting beta-cyclodextrin and inclusion with ciprofloxacin hydrochloride. J Soc Leather Technol Chem. 2021;105:217–30.Search in Google Scholar

(19) LeBel M. Ciprofloxacin: chemistry, mechanism of action, resistance, antimicrobial spectrum, pharmacokinetics, clinical trials, and adverse reactions. Pharmacotherapy J Hum Pharmacol Drug Ther. 1988;8:3–30.10.1002/j.1875-9114.1988.tb04058.xSearch in Google Scholar PubMed

(20) Sanders CC. Ciprofloxacin: in vitro activity, mechanism of action, and resistance. Rev Infect Dis. 1988;10:516–27.10.1093/clinids/10.3.516Search in Google Scholar PubMed

(21) Ji WJ, Song W, Zheng YY, He XZ. Improvement of method for determination of isocyanate group content in polyurethane prepolymer. Appl Mech & Mater. 2013;303:2533–6.10.4028/www.scientific.net/AMM.303-306.2533Search in Google Scholar

(22) Tian S, Zhang P, Fan H, Chen Y, Yan J, Shi B. A polyurethane-based retanning agent with fluorescent effect. J Am Leather Chem Assoc. 2016;111:148–54.Search in Google Scholar

(23) Fritz JS, Schenk GH. Chapter 19: Acid-catalyzed acetylation of organic hydroxyl groups††reprinted from analytical chemistry, 31, 1808 (1959). In: Schenk GH, editor. Copyright 1959 by the American chemical society and reprinted by permission of the copyright owner. Pergamon: Organic Functional Group Analysis; 1968. p. 205–15.10.1021/ac60155a034Search in Google Scholar

(24) Tian S, Chen Y, Zhu Y, Fan H. A fluorescent polyurethane with covalently cross-linked rhodamine derivatives. Polymers. 2020;12:1989.10.3390/polym12091989Search in Google Scholar PubMed PubMed Central

(25) Siesler HW. Rheo-optical Fourier transform IR (FTIR) spectroscopy of polyurethane elastomers. Polym Bull. 1983;9:417–78.10.1007/BF00307878Search in Google Scholar

(26) Wang GC, Wang JX, Zhang ZP. Reaction kinetics of irradiation-prepolymerized methyl methacrylate-polyurethane interpenetrating polymer networks by FTIR. Polym Int. 1991;25:237–43.10.1002/pi.4990250407Search in Google Scholar

(27) Hanna DH, Saad GR. Encapsulation of ciprofloxacin within modified xanthan gum- chitosan based hydrogel for drug delivery. Bioorganic Chem. 2019;84:115–24.10.1016/j.bioorg.2018.11.036Search in Google Scholar PubMed

(28) Breitbarth FW, Berg D, Dumke K, Tiller HJ. Investigation of the low-pressure plasma-chemical conversion of fluorocarbon waste gases. Plasma Chem Plasma Process. 1997;17:39–57.10.1007/BF02766821Search in Google Scholar

(29) Marcinkowska E, Zielinska G. Do leather anisotropic properties have an effect on shrinkage temperature? J Am Leather Chem Assoc. 2018;113:163–72.Search in Google Scholar

(30) Esteban B, Baquero G, Cuadros R, Morera JM. Proposal and application of a new method to determine leather shrinkage temperature. Thermochim Acta. 2021;698:178880.10.1016/j.tca.2021.178880Search in Google Scholar

(31) Ma JZ, Gao JJ, Wang HD, Lyu B, Gao DG. Dissymmetry gemini sulfosuccinate surfactant from vegetable oil: a kind of environmentally friendly fatliquoring agent in the leather industry. Acs Sustain Chem Eng. 2017;5:10693–701.10.1021/acssuschemeng.7b02662Search in Google Scholar

(32) Wells HC, Edmonds RL, Kirby N, Hawley A, Mudie ST, Haverkamp RG. Collagen Fibril Diameter and Leather Strength. J Agric Food Chem. 2013;61:11524–31.10.1021/jf4041854Search in Google Scholar PubMed

(33) Elsayed H, Hasanin M, Rehan M. Enhancement of multifunctional properties of leather surface decorated with silver nanoparticles (Ag NPs). J Mol Structure. 2021;1234:130130.10.1016/j.molstruc.2021.130130Search in Google Scholar

(34) Pollini M, Paladini F, Licciulli A, Maffezzoli A, Sannino A, Nicolais L. Antibacterial natural leather for application in the public transport system. J Coat Technol Res. 2013;10:239–45.10.1007/s11998-012-9439-1Search in Google Scholar

(35) Xiang J, Ma L, Su H, Xiong J, Li K, Xia Q, et al. Layer-by-layer assembly of antibacterial composite coating for leather with cross-link enhanced durability against laundry and abrasion. Appl Surf Sci. 2018;458:978–87.10.1016/j.apsusc.2018.07.165Search in Google Scholar

(36) Liu G, Haiqi G, Li K, Xiang J, Lan T, Zhang Z. Fabrication of silver nanoparticle sponge leather with durable antibacterial property. J Colloid Interface Sci. 2018;514:338–48.10.1016/j.jcis.2017.09.049Search in Google Scholar PubMed

(37) Alavi M, Nokhodchi A. Antimicrobial and wound healing activities of electrospun nanofibers based on functionalized carbohydrates and proteins. Cellulose. 2022;29:1331–47.10.1007/s10570-021-04412-6Search in Google Scholar

(38) Alavi M. Modifications of microcrystalline cellulose (MCC), nanofibrillated cellulose (NFC), and nanocrystalline cellulose (NCC) for antimicrobial and wound healing applications. e-Polymers. 2019;19:103–19.10.1515/epoly-2019-0013Search in Google Scholar

© 2022 Sheng Ding et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes

Articles in the same Issue

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes