Abstract

The current review extensively discusses the effects of various natural fillers on mechanical, thermal, and tribological characteristics of polypropylene, polyethylene, poly(vinyl chloride), and polyester resin matrices. The discussion has considered all of the tensile, flexural, and impact properties along with the wear rate and thermogravimetric analysis of a wide range of natural reinforcements. Detailed comparative studies about the factors that influence the fillers’ performance in the polymeric composites were also conducted to give the reader a comprehensive understanding to enable a better selection of the optimized characteristics to develop a more sustainable design. This systematic review indicates that the majority of green fillers had an adverse effect on the tensile strength of the considered matrices, but generally improved the tensile modulus. Moreover, the studied fillers enhanced the flexural modulus property for all mentioned matrices. The impact strength was dramatically influenced by the intrinsic characteristic of the filler type.

Abbreviations

- µ

-

coefficient of friction

- BA

-

bamboo powder

- BA

-

basalt

- BC

-

precipitated bio-calcium carbonate

- BKWP

-

bleached kraft wood pulp

- CNF

-

cellulose nanofibril

- Es

-

eggshells

- FL

-

flax

- FLBA

-

flax-basalt

- FM

-

flexural modulus

- FS

-

flexural strength

- H

-

hardness

- HDPE

-

high-density polyethylene

- HE

-

hemp

- HEBA

-

hemp-basalt

- IMF

-

Indian mallon fiber

- IS

-

impact strength

- KE

-

Kenaf

- KEBA

-

Kenaf-basalt

- LCNF

-

lignocellulose nanofibril

- LL

-

lemon leaves

- OP

-

olive pits flour

- PCC

-

precipitated calcium carbonate

- PE

-

polyethylene

- PP

-

polypropylene

- PVC

-

polyvinyl chloride

- RE

-

reed straw powder

- RH

-

rice husk

- RI

-

rice straw powder

- SC

-

sugarcane

- T endset

-

the temperature at which the material finishes thermally decomposing

- TM

-

tensile modulus

- T max

-

the temperature at which the rate of mass loss touches the highest point

- T onset

-

the temperature at which the material starts thermally decomposing

- TS

-

tensile strength

- WF

-

wood flour

- WH

-

wheat straw powder

- WR

-

wear rate

1 Introduction

Synthetic polymers have been appealing to engineers to use them as alternatives to other types of materials such as metals and glass. The cause can be attributed to their desirable properties like resistance to chemicals, ease of processing, low cost, formability, flexibility, and toughness, in conjunction with lightness (1). This array of properties is exploited in many applications including industrial, medical, as well as environmental ones (2).

The ubiquitous usage of polymers leads to an enormous annual waste, which is predicted to touch 12 × 109 tons by 2050 only. Twelve percent of polymer waste has solely been incinerated, 9% has been reprocessed, and the remains have been trashed in oceans and landfills (3). The production of a vast amount of polymers has resulted in an authentic severe crisis, which is environmental contamination. For more illustration, the incineration process of polymeric waste produces 210 poisonous compounds including carbon dioxide, mercury, fluorides, and sulfuric acid which cause environmental pollution (4). On top of that, throwing plastic garbage into the oceans negatively affects marine animals. A lot of litter breaks down into small particles (micro and nanoparticles) due to exposure to natural factors like solar UV radiation. This debris is ingested by marine life, and subsequently affects their health (5). Moreover, the plastic trash in the scrapyard forms a harbor for insects, microbes, and rats along with damaging the esthetic value.

The tremendous depletion of polymers and their impacts on the environment have prompted researchers to innovate bio-polymeric composites, which are polymers matrices reinforced by eco-friendly fillers, as a viable substitute for synthetic ones. Natural fillers that have been used as a reinforcement in synthetic polymers are plentiful, and they may be either organic, such as olive leaves, grape fiber, parsley, hay, palm, lemon, reed, teas waste fiber, sugar palm, kenaf (KE), kombucha membranes, jute, pine, and cypress, (6,7,8,9,10,11,12,13,14) or inorganic, such as eggshells (15), talc (16), Catla fish scales (17), basalt powder (18), and seashell (19).

Apart from the eco-friendliness property of these fillers, they are also considered light, almost costless, and available (20), whereas the amount of annual waste from the agriculture sector only is 140,000 million comprising rice husk (RH), coconut shell, sugarcane, hemp (HE), jute, and so on (21). In addition, they have high specific strength (22).

Compounding waste of lignocellulosic and/or inorganic natural filler with polymer matrices to produce biocomposites achieves two goals by one shot. The first goal is declining the quantity of utilized synthetic polymers, and the second one is capsuling the disposal of natural fibers. Not only that but also such mixing may also improve the mechanical, thermal, or tribological performance of the produced composites. Consequently, the current review aims to characterize the effects of using different concentrations of natural fillers (organic and/or inorganic) on four types of synthetic polymers including polypropylene (PP), polyethylene (PE), poly(vinyl chloride), and polyester resin in a three-dimensional way. In other words, the analysis will be on mechanical, tribological, and thermal properties. It is worthwhile to mention that this review documented only the influences of untreated fillers on the aforementioned polymers in a unique tabulated form that has not been used before based on the best knowledge.

2 Natural filler-reinforced PP matrix

PP is referred to polyolefin family. It has the second-highest production rate among the other types of plastics after PE. Its production volume around the globe is expected to reach 88 million tons in 2026 (23). PP is mainly used for packaging applications. However, PP is one of the most popular thermoplastics used in automotive parts like gas cans, pumpers, lamp housing, cable insulations, door panels, chemical tanks, water reservoirs, and fluid brake reservoirs. The reason behind the frequent employment of PP is attributed to its properties. Besides its flexibility and recyclability, it relatively has low cost and density. In addition, PP can resist chemicals and harsh weather, and eventually, it has attractive water barrier characteristics (1,24). However, PP has poor strength and modulus properties (25). Despite the widespread applications of PP, it is still a petroleum-based polymer leading to environmental pollution. Therefore, engineers have been attempting to mitigate its effects and overcome its weakness points by coupling it with natural fillers. For example, AL‐Oqla et al. (9) used 10, 20, and 30 wt% of hay, lemon, palm, and reed fibers to reinforce PP via screw extruder followed by cold compression molding. Tribological and mechanical behaviors were investigated. The addition of these fibers has caused a decrease in the tensile strength (TS) of PP, but the decrease was severe when 30 wt% of reed fibers and 30 wt% of palm fibers were added where the TS of PP decreased from 26.2 to 9 MPa and 6.9 MPa, respectively. Regarding the tensile modulus (TM), it can be noted that it has generally improved except at 10 wt% of hay, 20 and 30 wt% of reed, and a significant decline is observed at 30 wt% of palm. The values of Charpy strength (un-notched) have fluctuated around the control value. In other words, the impact strength (IS) has decreased and increased regarding the type of fiber and the wt%. In any case, the IS has reached the maximum at 20 wt% of hay, while it has touched the lowest point at 30 wt% of reed. Turning to the coefficient of friction, it can be concluded that it has increased at all wt% regardless of the type of fiber (Table 1). Hayajneh et al. (26) employed a single screw extruder to produce three types of composite materials using three wt% (5, 10, and 20 wt%) of lemon leaves (LL), eggshell flakes (Es), and the hybridization of both eggshells and lemon leaves (Es-LL). The flexural and tensile properties are presented in Table 1. It can be noted that coupling Es, LL, and Es-LL fibers have decreased all values of the TS of PP, while they have increased the TM at all percentages except at 10 wt% LL. Also, it is easy to note that the Es filler has given better tensile properties compared to the LL and hybrid filler (Es-LL). The TM has reached the vertex at 10 wt% of Es. Regarding the effects of the fibers on flexural properties, it can be concluded that all wt% of Es filler still has the highest flexural strength (FS) and modulus in comparison to LL and LL-Es fibers. The flexural modulus (FM) value has touched a peak in the sample containing 20 wt% of Es, while it has the lowest one in the sample including 20 wt% of LL. Notwithstanding, the hybrid filler (Es-LL) has given intermediate flexural and tensile properties, Table 1. Oliveira et al. (27) investigated the effect of three wt% (10, 20, and 30 wt%) of three species of fillers (cellulose nanofibril (CNF), lignocellulose nanofibril (LCNF), and bleached kraft wood pulp (BKWP) extracted from Eucalyptus grandis on tensile, notched Izod impact and thermal properties. Solid-state shear pulverization was obtained for mixing cellulose aqueous suspension with PP and then followed by twin-screw extrusion and injection molding. They discovered that CNF, LCNF, and BKWP fibers have raised the TS and modulus at all wt%. However, BKWP has given the best results where it has reached the apex at 30 wt%. BKWP fiber has significantly improved the IS where it has culminated at 30 wt%. The values of IS of samples containing CNF and LCNF have risen and fallen irregularly around the value of the control sample. With regards to the thermal properties, it can be observed that BKWP has increased the maximum degradation rate temperature (T max) from 328°C to 351°C. In contrast, CNF has worsened (T max), while LCNF has enhanced slightly (T max) of PP. All these values are presented in Table 1. In addition, recycled PP was coupled with five wt% (2–20 wt%) of RH using the injection molding technique by Moreno et al. (28). They studied the effects of RH addition on Izod IS and tensile properties in addition to the thermogravimetric properties (TGA). Increasing the wt% of RH has led to a gradual decrease in the TS where it decreased from ∼30 MPa (at 0 wt%) to ∼20 MPa (at 20 wt%). Similarly, the TM has decreased continuously with the increasing fiber loading. On the contrary, RH has slightly enhanced the IS except at 2 wt%. As for thermal properties, it can be observed from Table 1 that the RH has a positive impact on T max, T onset, and T endset. Aradhyula et al. (17) developed three PP composites using (10, 20, and 30 wt%) Catla fish scales. The mixtures of Catla fish scales (CFS) and PP were pelletized, and then they were prepared by injection molding machine for mechanical tests (tensile, flexural, Shore-D hardness (H), and Izod impact). The influence of increasing the wt% of CFS on the TS is negative, whereas increasing the wt% from 0 to 30 has approximately halved the TS value. Conversely, CFS fillers have continuously heightened the TM along with the wt%. FS and modulus also have been improved except at 30 wt% of CFS. The IS has erratically increased and decreased. Regarding the H, it can be seen that CFS fillers have enhanced the H, and they culminated at 30 wt% CFS, Table 1. Saleem et al. (29) used a mixture of 50 wt% PP fibers (as a matrix) and 50 wt% of seven types of fiber, which are flax (FL), KE, HE, basalt (BA), flax-basalt (FLBA) (25 wt% for each), kenaf-basalt (KEBA) (25 wt% for each), and hemp-basalt (HEBA) (25 wt% for each) to produce a plate with a dimension of 190 mm × 200 mm for mechanical characterization. They used a multistage compression molding process to fabricate the composite. The effects of these diverse species of fibers on tensile, flexural, and Charpy impact properties were investigated. Their findings have revealed that the tensile and flexural properties (strength and modulus) of BA-PP have got the highest points. Conversely, the TM and FM of the FL-PP composite reached the nadir, while the TS and FS of KE-PP have touched the lowest points. In addition, the hybrid reinforcement, HEBA, has climaxed the IS at 54 kJ·m−2, whereas BA-PP has reached the lowest value at 22 kJ·m−2 as presented in Table 1. McGauran et al. (30) used different weight percentages of poultry eggshell (Es) (from 5 to 55 wt%) to develop PP composites by a twin-screw extruder. They attempted to reveal the TS, TM, FS, FM, and IS of produced composites. Their results indicate that the TS has gotten worse by increasing the wt% of Es. Oppositely, the TM has got better as the wt% increases except at the lowest percentage 5%. The FS and modulus have increased gradually simultaneously with increasing the wt% except at 55 wt%, where the TS has equaled the original value of PP. Turning to the IS, it is obvious that Es has risen the IS regardless of the wt%. All values are presented in Table 1. Nnodu et al. (31) produced four composites of PP exploiting four wt% (2.5–10 wt%) of pineapple leaves via an injection molding machine. They investigated the TS and Brinell H test. Diverse impacts on TS are observed in Table 1 when the pineapple leaves were added. The H values of the composites are just above the neat PP. Mark et al. (32) incorporated PP with powder of coconut shells (CNS). They used four wt% (10–40 wt%) of four sizes using the injection molding process, and then they examined TS, TM, FS, FM, and Rockwell H. According to Table 1, it is shown that the powder of CNS has gradually promoted all values of tensile properties (strength and modulus) and flexural properties (strength and modulus) with the increase of wt% of CNS regardless of the particle size. A similar trend is observed in the H property. It is worthwhile to mention that the sample containing 40 wt% of the particle size 63 µm has reached the vertex in all preceded properties. Hernández-Díaz et al. (33) injected PP matrix mixed with numerous wt% (20–50 wt%) of old newspaper fibers into a rectangular mold for the Charpy test. It is seen from Table 1 that old news fibers have adverse influences on the IS where it has decreased by increasing the wt% of old newspaper fibers. Aljnaid and Banat (34) used a twin screw extruder to compound PP with 20 wt% of olive pomace flour (OPF). They discovered that OFP improved the un-notched Izod IS. Conversely, the young modulus value decreased. Also, the FS and modulus declined due to the addition of 20 wt% OPF. The exact values of flexural, tensile, and IS are displayed in Table 1.

Mechanical, tribological, and thermal properties of PP composites reinforced by diverse natural fibers

| Filler | Size-length diameter | wt% | TS (MPa) | TM (MPa) | FS (MPa) | FM (MPa) | IS Izod/Charpy | H | WR/µ | T onset (°C) | T endset (°C) | T max (°C) | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| None | 0 | 26.2 | 1146.6 | — | — | 672.7 kJ·m−3 | — | 0.55 µ | — | — | — | (9) | |

| Hay | Length 8–12 mm | 10 | 19 | 1005.7 | — | — | 614.8 | — | 0.77 | — | — | — | |

| 20 | 20.9 | 1220.0 | — | — | 1030.9 | — | 0.76 | — | — | — | |||

| 30 | 15.9 | 1557.2 | — | — | 657.9 | — | 0.82 | — | — | — | |||

| Lemon | 10 | 23.6 | 1246.6 | — | — | 779.9 | — | 0.67 | — | — | — | ||

| 20 | 22.1 | 1167.9 | — | — | 806.5 | — | 0.76 | — | — | — | |||

| 30 | 17.9 | 1157.2 | — | — | 762.4 | — | 0.76 | — | — | — | |||

| Palm | 10 | 20.2 | 1275.9 | — | — | 842.7 | — | 0.59 | — | — | — | ||

| 20 | 22.8 | 1272.5 | — | — | 657.9 | — | 0.68 | — | — | — | |||

| 30 | 6.90 | 376.5 | — | — | 586.7 | — | 0.65 | — | — | — | |||

| Reed | 10 | 19.6 | 1252.2 | — | — | 631.1 | — | 0.59 | — | — | — | ||

| 20 | 23.5 | 1013.3 | — | — | 820.8 | — | 0.64 | — | — | — | |||

| 30 | 9 | 900 | — | — | 464.9 | — | 0.65 | — | — | — | |||

| None | 0 | 28.6 | 658.5 | 37.4 | 878 | — | — | — | — | — | — | (26) | |

| LL | LL midribs 21 ± 13.4 mm | 5 | 25.0 | 745.6 | 33.0 | 893 | — | — | — | — | — | — | |

| 10 | 17.4 | 605.0 | 32.1 | 931 | — | — | — | — | — | — | |||

| 20 | 18.5 | 658.8 | 28.5 | 766 | — | — | — | — | — | — | |||

| Es | LL laminates 6 ± 4.5 mm | 5 | 26.8 | 758.8 | 34.4 | 1,015 | — | — | — | — | — | — | |

| 10 | 24.0 | 797.7 | 35.4 | 1,030 | — | — | — | — | — | — | |||

| 20 | 19.4 | 707.8 | 33.1 | 1,180 | — | — | — | — | — | — | |||

| LL-Es | Es flakes 3.6 ± 1.5 | 5 | 22.0 | 783.1 | 34.8 | 995 | — | — | — | — | — | — | |

| 10 | 22.7 | 730.0 | 31.3 | 1,034 | — | — | — | — | — | — | |||

| 20 | 17.9 | 706.2 | 29.7 | 998 | — | — | — | — | — | — | |||

| None | 0 | 30 | 1,700 | — | — | 22 J·m−2 | — | — | 240 | 328 | (27) | ||

| CNF | Diameter 15–20 μm | 10 | 32 | 2,100 | — | — | 20 | — | — | — | — | — | |

| 20 | 33 | 2,400 | — | — | 22 | — | — | — | — | — | |||

| 30 | 33 | 2,600 | — | — | 21 | — | — | 230 | 321 | ||||

| LCNF | Length 1–2 mm | 10 | 33 | 2,300 | — | — | 23 | — | — | — | — | — | |

| 20 | 33 | 2,500 | — | — | 22 | — | — | — | — | — | |||

| 30 | 33 | 2,700 | — | — | 19 | — | — | 231 | — | 330 | |||

| BKWP | 10 | 33 | 2,100 | — | — | 28 | — | — | — | — | — | ||

| 20 | 37 | 2,500 | — | — | 31 | — | — | — | — | — | |||

| 30 | 51 | 3,500 | — | — | 48 | — | — | 240 | — | 351 | |||

| None | 0 | 30* | 575* | — | — | 2.4 kJ·m−2 | — | — | 295 | 464 | 445 | (28) | |

| RH | — | 2 | 30* | 600* | — | — | 2.25* | — | — | 298 | 474 | 446 | |

| 4 | 27* | 550* | — | — | 2.75* | — | — | 312 | 474 | 445 | |||

| 7 | 25* | 280* | — | — | 2.5* | — | — | 301 | 474 | 445 | |||

| 10 | 23.5* | 270* | — | — | 2.7* | — | — | 311 | 483 | 455 | |||

| 20 | 20.5* | 225* | — | — | 3.1* | — | — | 314 | 483 | 454 | |||

| None | 0 | 34.2 | 3,880 | 90.8 | 3,500 | 27 J·m−1 | 60N | — | — | — | — | (17) | |

| Catla fish scales | — | 10 | 28.9 | 3,960 | 95.7 | 3,520 | 21.8 | 65.3 | — | — | — | — | |

| 20 | 24.5 | 4,260 | 99 | 3,510 | 24.7 | 65.8 | — | — | — | — | |||

| 30 | 21 | 5,230 | 106 | 3,240 | 27.2 | 66.3 | — | — | — | — | |||

| None | 0 | 35.4 | 1,420* | 35* | 193 | — | 24 Rockwell | — | — | — | — | (32) | |

| FL | FL-KE-HE length 70–120 mm | 50 | 32 | 3,206 | 39 | 1,517 | 50 kJ·m−2 | — | — | — | — | — | (29) |

| KE | BA length 96 mm | 50 | 27 | 3,518 | 32 | 1,795 | 36 | — | — | — | — | — | |

| HE | 50 | 28 | 3,284 | 35 | 1,146 | 23 | — | — | — | — | — | ||

| BA | 50 | 98 | 6,717 | 55 | 3,560 | 22 | — | — | — | — | — | ||

| FLBA | 50 | 48 | 3,776 | 45 | 2,700 | 49 | — | — | — | — | — | ||

| KEBA | 50 | 40 | 4,632 | 37 | 2,478 | 51 | — | — | — | — | — | ||

| HEBA | 50 | 43 | 3,933 | 31 | 1,783 | 54 | — | — | — | — | — | ||

| None | 0 | 30* | 475* | 26* | 1,100* | 350 J·m−1 | — | — | — | — | — | (30) | |

| Es | — | 5 | 27.7* | 410* | 26.9* | 1,390* | 400* | — | — | — | — | — | |

| 10 | 27.8* | 485* | 27* | 1,350* | 450* | — | — | — | — | — | |||

| 25 | 24.5* | 540* | 28* | 1,420* | 530* | — | — | — | — | — | |||

| 40 | 21* | 615* | 30* | 1,910* | 790* | — | — | — | — | — | |||

| 55 | 16.5* | 600* | 25.9* | 2,650* | 610* | — | — | — | — | — | |||

| None | 0 | 40* | — | — | — | — | 30.1 HBN | — | — | — | (31) | ||

| Pineapple | 75 micron | 2.5 | 32* | — | — | — | — | 30.3* | — | — | — | ||

| 5 | 30* | — | — | — | — | 30.9* | — | — | — | ||||

| 7.5 | 25* | — | — | — | — | 30.9* | — | — | — | ||||

| 10 | 24* | — | — | — | — | 31.3* | — | — | — | ||||

| Coconut shell | 63 µm | 10 | 40.5* | 2,120* | 37.5* | 232* | — | 27* | — | — | — | — | |

| 20 | 43.5* | 2,580* | 38.3* | 257* | — | 29* | — | — | — | — | |||

| 30 | 48.3* | 2,970* | 40* | 270* | — | 31* | — | — | — | — | |||

| 40 | 50* | 3,080* | 42.5* | 288* | — | 34* | — | — | — | — | |||

| 150 µm | 10 | 38.5* | 1,700* | 36.8* | 223* | — | 26.5* | — | — | — | — | ||

| 20 | 39.3* | 2,200* | 37.5* | 240* | — | 28.5* | — | — | — | — | |||

| 30 | 44* | 2,600* | 39.2* | 257* | — | 30* | — | — | — | — | |||

| 40 | 45.8* | 2,770* | 41.8* | 270* | — | 32.6* | — | — | — | — | |||

| 300 µm | 10 | 37.5* | 1,650* | 35.5* | 215* | — | 26* | — | — | — | — | ||

| 20 | 38.5* | 2,000* | 36.7* | 232* | — | 28* | — | — | — | — | |||

| 30 | 41* | 2,300* | 38.3* | 247* | — | 29.2* | — | — | — | — | |||

| 40 | 43.5* | 2,400* | 40.8* | 258* | — | 31.5* | — | — | — | — | |||

| 425 µm | 10 | 37.2* | 1,600* | 35.2* | 205* | — | 26* | — | — | — | — | ||

| 20 | 39.5* | 1,970* | 35.8* | 218* | — | 27.8* | — | — | — | — | |||

| 30 | 40* | 2,250* | 37.5* | 232* | — | 29* | — | — | — | — | |||

| 40 | 41.2* | 2,380* | 40* | 245* | — | 31* | — | — | — | — | |||

| Old newspaper fiber | — | 20 | — | — | — | — | 12.7 kJ·m−2 | — | — | — | — | — | (33) |

| 30 | — | — | — | — | 8.7 | — | — | — | — | — | |||

| 40 | — | — | — | — | 7 | — | — | — | — | — | |||

| 50 | — | — | — | — | 6.1 | — | — | — | — | — | |||

| None | 0 | — | 681 | 22 | 2,400* | 21 J·m−1 | — | — | — | — | — | (34) | |

| OPF | 63–106 μm | 20 | — | 242 | 14 | 1,800* | 43 | — | — | — | — | — |

*Values are estimated from figures and tables from the original articles.

–Values are not available or cannot be estimated.

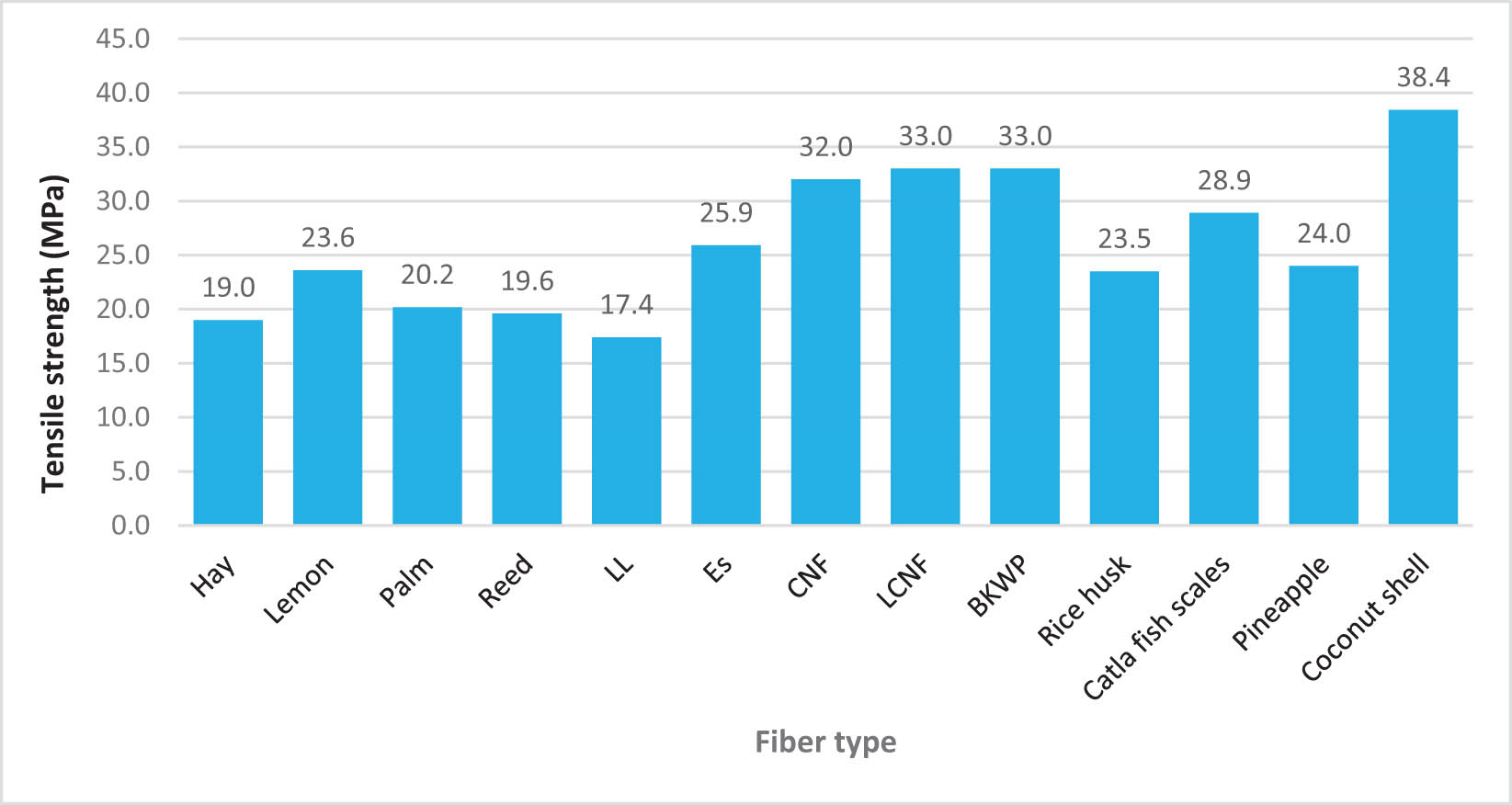

2.1 The effect of 10 wt% of different natural fillers on TS of PP matrix

Changing the sort of fiber in any polymeric matrix has influenced its TS. Therefore, Figure 1 compares the TS values of numerous types of fibers that were used to reinforce the PP matrix. The comparison is made at a constant wt% of 10 regardless of the fiber dimensions and the fabrication process. If there was more than one shape or size for the same fiber, the average of the strength was calculated. For example, several sizes of 10 wt% of coconut shells were used as stated in Table 1. Each size gave a diverse value of the TS. Consequently, the average value was taken.

TS values of PP composites at 10 wt% of different natural fillers.

As shown in Figure 1, it can be noted that coconut shells/PP composite has the highest TS, 38.4 MPa. In comparison, the LL-PP composite gets the lowest TS at 17.4 MPa. The other types of fibers gave an intermediate value between coconut shells and LL. The overall strength of natural fiber/PP composite on average is 26 ± 6.52 MPa.

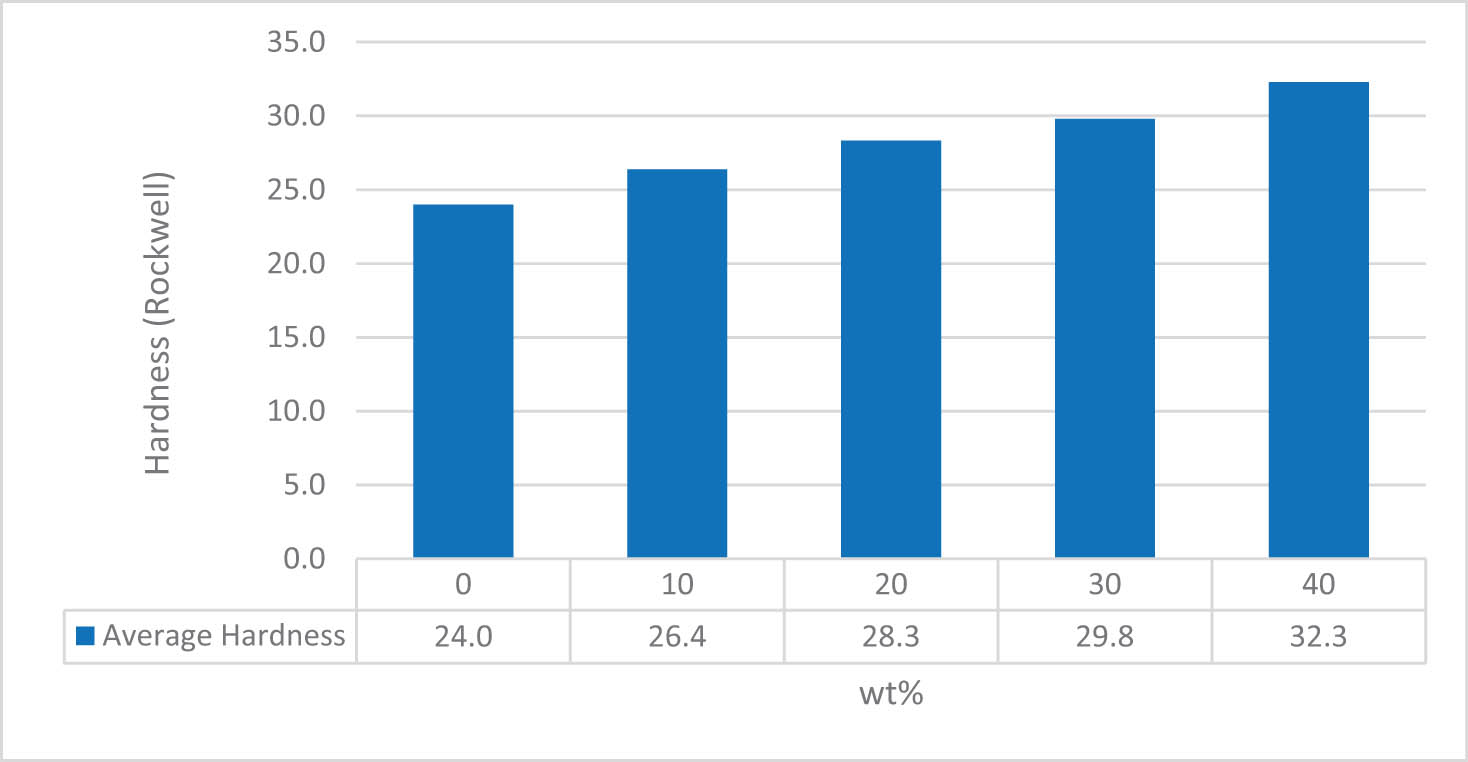

2.2 The effect of wt% of coconut shells on Rockwell H of PP matrix

Figure 2 displays the effect of wt% of coconut shells on the values of Rockwell H. The values at each wt% represent the average Rockwell H at four different sizes (63, 150, 300, and 425 µm) as presented in Table 1. It can be easily seen from Figure 2 that Rockwell H is proportional to the wt%, where 40 wt% increased the Rockwell by 33%.

Rockwell values of PP composites at different wt% of coconut shells.

2.3 The effects of natural fillers on tensile and flexural properties of PP composites

Based on the studies that have been conducted on the tensile test of PP, it can be concluded that most of the fibers have negative impacts at all concentrations on the TS of PP except for coconut shells, CNF, LCNF, and BKWP. The best TS of PP has been achieved by the addition of 30 wt% BKWP regardless of the shape or size of the fiber where it has reached the peak at 51 MPa (70% improvement). In comparison, 40 wt% coconut shells have approximately doubled the value of TM to reach a peak of 3,080 MPa from 1,420 MPa (116% improvement) when compared to Hay, Lemon, Palm, Reed, LL, Es, Es-LL, CNF, LCNF, BKWP, RH, and coconut shells. The FS has increased and decreased irregularly depending on the type of fiber. All researchers who have studied the fiber effect on FM have found that the FM has increased except at 30 wt% Catla fish scales and 20 wt% LL and olive pomace flour. The highest improvement (21%) in FS of PP occurred when PP was reinforced by 40 wt% coconut shells. By comparison, the best improvement of FM (140%) has obtained at 55 wt% Es.

3 Natural filler-reinforced high-density polyethylene matrix

PE is a thermoplastic material with a diverse crystalline structure. PE can be categorized as a branch of the polyolefin family. It has the largest production rate of plastics around the world due to its tremendous utilization in several applications (such as cable insulations, pipes, milk jugs, and containers) due to its advantages like toughness, chemically inertness, low friction, and strong electrical insulation (35).

PE is classified into different types including low-density polyethylene (LDPE), high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), ultrahigh molecular weight polyethylene (UHMWPE), and cross-linked polyethylene (XLPE). Nevertheless, LDPE and HDPE are the most common types (36). The compact structure with little branches of HDPE leads to higher density and hence higher TS, higher H, and high opacity incomparable with LDPE (37).

The excessive usage of HDPE, 4.16 million tons from 2019 to 2021 only in China, poses an intense threat to the environment. Therefore, researchers have been seeking to develop less environmental PE using natural fillers. For instance, Hejna et al. (38) obtained five wt% (1, 2, 5, 10, and 20 wt%) in the powder form of coffee silverskin to produce bio-HDPE composites. Both filler and matrix were subjected to a twin screw extruder to pelletize the composites. Then, the pellets were compressed at a temperature of 170°C. The impact of coffee silverskin on tensile properties of HDPE was reported in Table 2. Increasing the wt% up to 2% has risen the TS just above the original value of HDPE. However, the TM is improved continuously, and it hit the climax at 20 wt% with an improvement of 30%. Further, Khouaja et al. (39) employed 30, 40, and 50 wt% of bleached kraft and microcrystalline cellulose fibers in two sizes of powder form as a reinforcement for HDPE. To improve the bonding behavior between HDPE and fibers, 3 wt% of maleic anhydride grafted PE was used. Compression molding was utilized to fabricate the composites after they had extruded to granules by a twin screw extruder. The thermal stability of the composites was analyzed by TGA. The results indicate that T onset has decreased by coupling both bleached kraft and microcrystalline cellulose fibers with HDPE, and T endset of HDPE is nearly the same as its composites, while T max of HDPE composites is changed randomly. These results are presented in Table 2. Mendes et al. (40) analyzed tensile, flexural, and thermal properties of spent coffee grounds–HDPE composites that were produced by the injection molding technique. They obtained 10, 20, and 30 wt% fiber loadings. From Table 2, it can be observed that spent coffee fiber has a positive influence on tensile and FM, whereas it has a negative impact on TS. In addition, this fiber has improved the FM only at 10 wt%. With regards to the TGA, it can be seen that the addition of spent coffee has decreased both the endset and the onset temperature. Daramola et al. (41), moreover, manufactured five composites using different wt% (2, 4, 6, 8, and 10 wt%) of chitosan particles. The composites were fabricated by a single screw extruder and then molded using a laboratory press at 230°C for mechanical characterization (tensile, flexural, and Charpy impact). It can be concluded from Table 2 that chitosan particles have slightly improved the TS except at 10 wt% percent, whereas chitosan particles have enhanced the TM at 2 wt%. By comparison, the FS improved regardless of the wt%, and it culminated in 2 wt% chitosan-HDPE sample at 57 MPa. Similarly, the FM and the impact of HDPE have also been enhanced by chitosan except at 10 wt%, and it has decreased again. On top of that, Negawo et al. (42) used 15, 20, 25, and 30 wt% of enset fiber, extracted from the Ventricosum plant, as a filler for HDPE. The composites were granulated by a twin screw extruder and then hot pressed at 165°C in a square mold. Eventually, the tensile and flexural properties were assessed. Reinforcing HDPE by 30 wt% of enset fiber has approximately halved the TS. Conversely, enset fiber has increased the TM to reach the apex, 1,851 MPa, at the highest wt%. Generally, as presented in Table 2, it can be noted that the fiber has declined the FS and modulus. In addition to that, Koffi et al. (35) extracted wood fiber from birch trees to reinforce HDPE by the injection molding process with the help of maleic anhydride grafted PE as a coupling agent. They studied the effects of four wt% (10, 20, 30, and 40 wt%) on Izod IS, TS, TM, and H (Shore D). Table 2 reveals that birch fiber has increased the TS by 250%, and it has tripled the TM. Furthermore, the effect of birch fiber on IS is negative, while it is positive on the H property. In addition, two wt% (25 and 50 wt%) of distillers grains were mixed with virgin HDPE using a mixer at 160°C. The mixtures were hot pressed at 160°C for 3 min under 15 MPa by Wen et al. (43). They evaluated tensile and thermal stability properties. A negative influence of distillers grains has been observed on the TS of HDPE. Turning to thermal properties, it can be concluded that distillers grains have not significantly affected T endset and T onset, whereas this fiber has increased T max. Besides, HDPE matrix and Mangrove wood particles (10, 20, and 30 wt%) were compounded using a twin-screw extruder and poured by an injection molding machine into a rectangular mold for the thermogravimetric analysis (44). Table 2 presents that there is an improvement due to the addition of Mangrove wood particles on T endset and T max except at 30 wt%, where these temperatures have dropped. In addition, red pine wood flour (WF) with two wt% (15 and 30 wt%) was used as fillers for the HDPE matrix by Başboğa et al. (45). The samples were extruded and pelletized via a single screw extruder. Afterward, they were injected through an extruder with three zones (its temperature 180–190–200°C) for mechanical properties like flexural, tensile, Izod impact, and thermal stability. Maleic anhydrite grafted PE and paraffin wax were used as a coupling agent and a lubricant, respectively. Table 2 displays that both percentages have boosted FS and modulus and TS and modulus. However, it has decreased the IS. T endset has improved, while T max and T endset of HDPE composites have almost the same as the HDPE matrix. Furthermore, the effects of seven wt% (10, 20, 30, 40, 50, 60, and 70 wt%) of RH biochar on tensile, flexural, and thermal properties of HDPE were investigated. The composites were mixed by a twin screw extruder, and then the samples were injected at 180°C into a desired shaped mold (46). Table 2 shows that the TS and FM have reached the vertex at 40 wt% of RH biochar. The TM has touched the peak at 60 wt% of RH biochar, whereas the FS has climaxed at 50 wt% of RH biochar. With regards to TGA, it can be concluded that T endset, T max, and T endset have slightly fallen and risen with increasing the wt% of the fibers.

Mechanical, tribological, and thermal properties of HDPE composites reinforced by diverse natural fibers

| Filler | Size-length diameter | wt% | TS (MPa) | TM (MPa) | FS (MPa) | FM (MPa) | IS Izod/Charpy | H | WR/µ | T onset (°C) | T endset (°C) | T max (°C) | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| None | 0 | 21.25* | 860* | — | — | — | — | — | — | — | — | (38) | |

| Coffee silverskin | 400 μm | 1 | 22.25* | 935* | — | — | — | — | — | — | — | — | |

| 2 | 22.5* | 960* | — | — | — | — | — | — | — | — | |||

| 5 | 21.2* | 995* | — | — | — | — | — | — | — | — | |||

| 10 | 20* | 1,170* | — | — | — | — | — | — | — | — | |||

| 20 | 16* | 1,125* | — | — | — | — | — | — | — | — | |||

| None | 0 | — | — | — | — | — | — | — | 430 | 500 | 480* | (39) | |

| Bleached kraft | 120 μm | 30 | — | — | — | — | — | — | — | 280* | 490* | 475* | |

| 40 | — | — | — | — | — | — | — | 315* | 500* | 480* | |||

| 50 | — | — | — | — | — | — | — | 320* | 500* | 475* | |||

| Microcrystalline cellulose | 130 μm | 30 | — | — | — | — | — | — | — | 325* | 500* | 475* | |

| 40 | — | — | — | — | — | — | — | 330* | 500* | 475* | |||

| 50 | — | — | — | — | — | — | — | 330* | 500* | 470* | |||

| None | 0 | 17 | 453 | 24 | 250 | — | — | — | 420 | 456 | — | (40) | |

| Spent coffee grounds | 12 to 28 μm | 10 | 16 | 481 | 26 | 350 | — | — | — | 390 | 436 | — | |

| 20 | 15 | 530 | 21 | 420 | — | — | — | 384 | 472 | — | |||

| 30 | 14 | 675 | 21 | 520 | — | — | — | 392 | 463 | — | |||

| None | 0 | 20.5* | 680* | 21.66 | 1,050* | 210* kJ m−2 | — | — | — | — | — | (41) | |

| Chitosan particles | 90 μm | 2 | 23 | 828* | 41* | 1,200* | 229 | — | — | — | — | — | |

| 4 | 22.25* | 650* | 57* | 1,690 | 240* | — | — | — | — | — | |||

| 6 | 22* | 600* | 41* | 1,100* | 235* | — | — | — | — | — | |||

| 8 | 22* | 575* | 36* | 1,050* | 235* | — | — | — | — | — | |||

| 10 | 19 | 490* | 34* | 700* | 185* | — | — | — | — | — | |||

| None | 0 | 21.87 | 1,286 | 42.12 | 364.9 | — | — | — | — | — | — | (42) | |

| Enset fiber | 5–8 mm | 15 | 16.84 | 1,513 | 31.71 | 296.6 | — | — | — | — | — | — | |

| 20 | 13.65 | 1,748 | 33.02 | 366.3 | — | — | — | — | — | — | |||

| 25 | 13.47 | 1,898 | 30.24 | 347.9 | — | — | — | — | — | — | |||

| 30 | 12.81 | 1,851 | 27.50 | 307.3 | — | — | — | — | — | — | |||

| None | 0 | 18.8 | 1,510 | — | — | 6.2 kJ·m−2 | 50.6 Shore D | — | — | — | — | (35) | |

| Birch fiber | 20–60 mesh size | 10 | 25.08 | 1,660 | — | — | 4.43 | 62.6 | — | — | — | — | |

| 20 | 32.47 | 2,670 | — | — | 5.33 | 70.8 | — | — | — | — | |||

| 30 | 38.33 | 3,370 | — | — | 5.46 | 74.6 | — | — | — | — | |||

| 40 | 45.54 | 4,390 | — | — | 4.68 | 73.6 | — | — | — | — | |||

| None | 0 | 36* | — | — | — | — | — | — | 469.1 | 500* | 478.7 | (43) | |

| Distillers grains | Powder form | 25 | 28* | — | — | — | — | — | — | 467.2 | 500* | 486.0 | |

| 50 | 25.5* | — | — | — | — | — | — | 466.6 | 500* | 485.4 | |||

| None | 0 | — | — | — | — | — | — | — | 412.6 | — | 513.4 | (44) | |

| Mangrove wood particle | 500–1,000 μm | 10 | — | — | — | — | — | — | — | 436.3 | — | 517.5 | |

| 20 | — | — | — | — | — | — | — | 437.2 | — | 525.6 | |||

| 30 | — | — | — | — | — | — | — | 402.6 | — | 518.6 | |||

| None | 0 | 19.39 | 333.5 | 22.12 | 712.9 | 3.47 kJ·m−2 | — | — | 425 | 510 | 492.8 | (45) | |

| Red pine wood | 200 mesh size | 15 | 20.56 | 441.9 | 27.82 | 932.6 | 2.45 | — | — | 440 | 510 | 492.6 | |

| 30 | 22.19 | 635.7 | 35.24 | 1,494 | 2.28 | — | — | 446* | 510* | 491* | |||

| None | 0 | 23.54 | 1,330 | 14.16 | 880 | — | — | — | 450 | 500 | 480 | (46) | |

| RH biochar | <150 μm | 10 | 23.21 | 1,360 | 16.37 | 910 | — | — | — | 450* | 495* | 482* | |

| 20 | 24.88 | 1,470 | 18.3 | 1,290 | — | — | — | 450* | 498* | 484* | |||

| 30 | 25.2 | 1,690 | 19.33 | 1,320 | — | — | — | 450* | 500* | 486* | |||

| 40 | 29.05 | 1,700 | 28.15 | 1,790 | — | — | — | 450* | 505* | 482* | |||

| 50 | 26.25 | 1,870 | 34.95 | 1,760 | — | — | — | 450* | 500* | 486* | |||

| 60 | 24.9 | 2,030 | 29.19 | 1,300 | — | — | — | 450* | 498* | 486* | |||

| 70 | 19.02 | 980 | 18.08 | 1,110 | — | — | — | 450* | 498* | 480* |

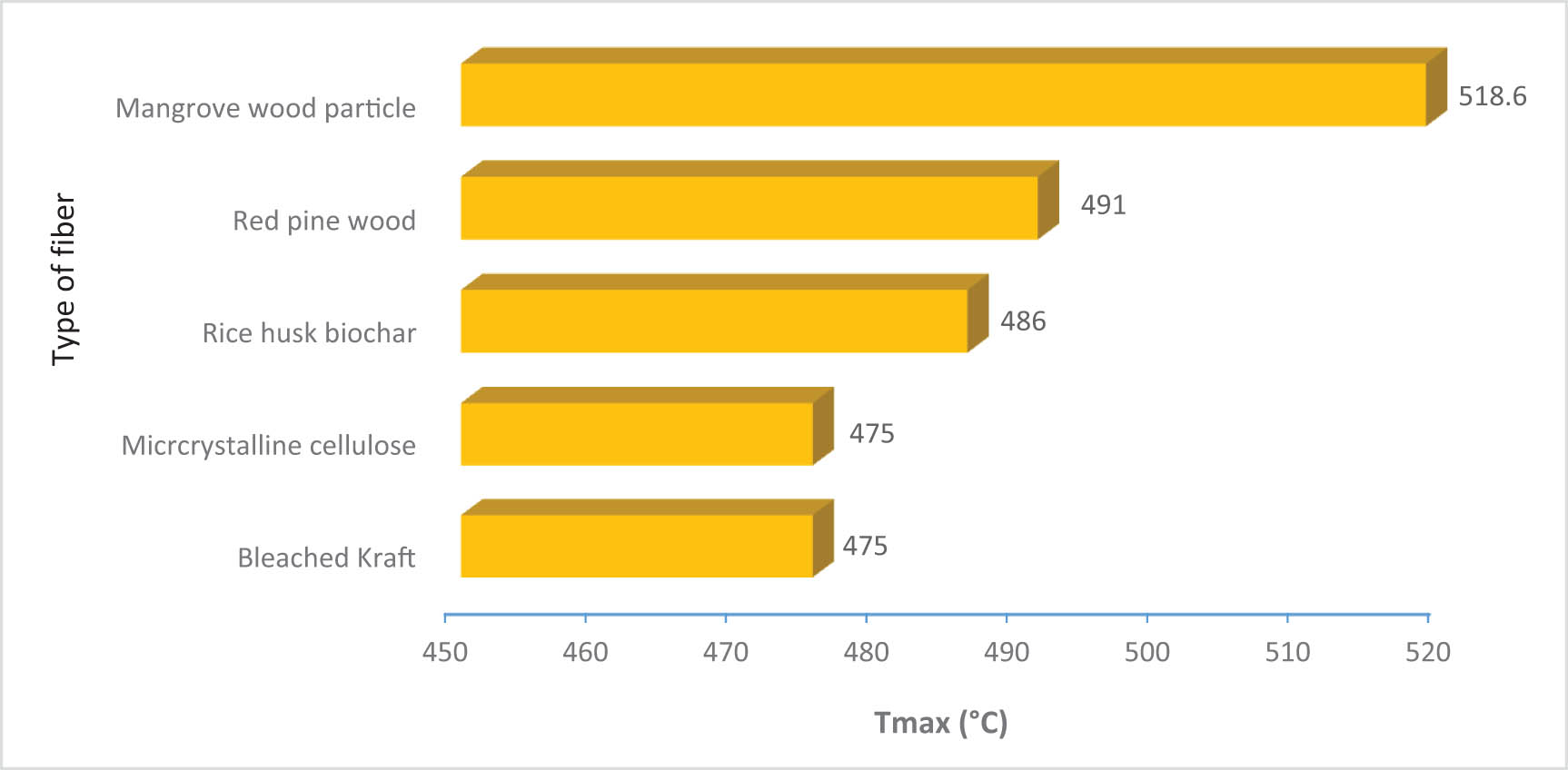

3.1 The effect of 30 wt% of different natural fillers on (T max) of HDPE composites

Figure 3 shows the effect of diverse natural fillers on the maximum degradation temperature of the HDPE matrix. The comparison was performed at 30 wt% of each filler. The comparison ignored the effect (if any) of the production process, the coupling agents, and the size and shape of the fiber. T max values were collected from several research articles as presented in the previous tables. It can be noticed from the figure that the mangrove wood-HDPE composite resists higher thermal degradation than its counterparts do. Microcrystalline cellulose and bleached Kraft fillers have the same impact on the T max of HDPE. In comparison to microcrystalline cellulose and bleached Kraft fillers, red pine wood and RH biochar gave higher values.

T max values of HDPE composites at 30 wt% of different types of fibers.

3.2 The effects of fibers on tensile and flexural properties of HDPE composites

The TS of the HDPE matrix has been improved by the addition of coffee silverskin, chitosan particles, red pine wood, and RH biochar, where these fibers have enhanced marginally the TS of HDPE matrix. However, birch fiber has roughly improved the TS. The TS of HDPE has reached the apex in 40 wt% birch-HDPE composite with 140% improvement. All fibers have positive effects on TM except for chitosan particles and RH biochar (at 70 wt% only). The best value of TM was obtained at 40 wt% birch with 190% enhancement. The FS values have fluctuated irregularly depending on the type of fiber and its wt%. In any case, it hits the vertex at 50 wt% of RH biochar (148% improvement). Regarding the FM, it can be deduced that it has climaxed at 30 wt% of spent coffee grounds with an improvement of nearly 100%.

4 Natural filler-reinforced poly vinyl chloride matrix

Vinyl chloride can be constituted from chloride and ethylene. The polymerization of vinyl chloride leads to poly vinyl chloride (PVC), which is one of the most common thermoplastic polymers (47). PVC has a long lifespan and high density (1.4 g·cm−3), and it is well resistant to moisture, fungi, and fire. The mechanical, thermal, and chemical properties of PVC can be controlled by additives such as stabilizer (increases thermal degradation), impact modifier (rises the IS), antioxidant (enhances thermal and optical stability), and light stabilizers (dissipates UV) (48). The exploitation of PVC is vast, and it is estimated that the worldwide consumption rate of polyvinyl chloride will reach a peak of 51 million tons by 2021. Seventy percent of PVC consumption is utilized in construction industries (www.statista.com) such as pipes, window profiles, sidings, and electric wires (48).

Like other types of petroleum-based polymers, PVC can lead to negative influences on the environment, which subsequently prompt engineers and researchers to mitigate its effects by using natural fillers. To exemplify, Naji et al. (18) kneaded diverse wt% (from 0 to 58.8 wt%, interval 10%) of BA rock powder with PVC matrix using a Brabender. A plasticizer (DEHP), stabilizer (DBLS), internal lubricant (COD), and heat stabilizer (ODA) were added to the mixture with a constant wt%. All heated premixed compounds were molded by a compressor. The effects of BA powder on the TS, H (Shore A), and thermal stability were assessed. Their results are presented in Table 3. BA rock powder has declined the TS of PVC. In contrast, it has increased the H property. Regarding the thermal properties, it is conspicuous that the addition of BA rock powder on PVC has decreased T max, which has changed erratically below the value of the control sample. Oppositely, BA filler has increased T onset. In addition, pine WF (1, 5, and 10 wt%) with powdered PVC were mixed via a twin roll mill at 145°C and extruded via a single screw extruder at 160°C. The influence of the pine WF filler on TS and H (Shore-A) was examined by Bendjaouahdou and Aidaoui (49). At any weight percent, pine WF has a detrimental impact on both tensile and H qualities as presented in Table 3. Moreover, decayed wood powder and sound wood powder from Pinus massoniana Lamb. were used as fillers in PVC. A total of 30, 40, and 50 wt% of each filler were mixed with PVC powder using a twin-screw extruder at 150°C. Subsequently, the produced granules were subjected to hot pressing at 170°C. TSs, TM, and thermogravimetric properties were investigated. The sound wood powder has outperformed decayed wood powder in terms of tensile and thermogravimetric properties at all wt%. The highest TS (25 MPa) was achieved at 40 wt% of sound wood powder as displayed in Table 3 (50). In addition, Abdellah Ali et al. (51) developed PVC composites using three types of bio-fillers, 60 wt% olive pits flour (OP), and 60 wt% of precipitated bio-calcium carbonate (BC) that is extracted from beet juice waste in the sugar, and 60 wt% of OP-BC. Other materials such as CPE, TBLS, DBLST, NLST, K120, Ca-stearate, stearic acid PE wax, and TiO2 as processing aids were added. Apart from the thermal properties, they further assessed the mechanical properties such as Izod IS, tensile and flexural properties, and H (Shore-D). It can be noted from Table 3 that all OP, BC, and OP-BC fibers have decreased the TS of the PVC matrix; however, if these fibers are compared to one another, it can be said that the hybrid filler (50 wt% OP–10 wt% BC) has the strongest TS, but it is still below the matrix. The FS and IS have also decreased with the addition of the fibers. In the case of the TM and the H, it can be observed that the modulus has always been improved regardless of the type of fiber and it hits the climax (2,198 MPa) at (50 wt% OP–10 wt% BC), and the H has culminated at 60 wt% OP for H. T endset has remained the same before and after the addition of the fibers except at 60 wt% OP, where it has been decreased. On the other hand, T onset has been dropped. Ali et al. (48) exploited the WF from the wood workshops and/or precipitated calcium carbonate (PCC) from sugar origin beet juices as fillers for PVC. They examined the effects of these fillers on impact (Izod) strength, H (Shore-D), FS, TS, and thermal properties. Stabilizers, lubricants, processing aids, photoactive pigments, and impact modifiers were also used with the PVC matrix. The composites were kneaded in a hot two-roll machine first. Then, in a square mold, they were hot compressed. The incorporation of 62 wt% of WF, PCC, or WF-PCC has diminished TS, IS, and FS. On the contrary, it has improved the H and the TM. In any case, the hybrid filler (52 wt% WF:10 wt% PCC) has the best values of all properties excluding T endset. Besides, the influences of 10–40 wt% of bamboo particles on mechanical properties of semi-rigid PVC have been investigated by Darus et al. (52). Plasticizer (diethylhexyl phthalate), lubricant (stearic-acid-based compound), tin stabilizer, and PVC were mixed in a brabender at 170°C. Afterward, PVC composites were crushed. Subsequently, they were hot pressed at 190°C. It can be concluded from Table 3 that the TS and IS of the PVC matrix have been decreased due to the addition of bamboo fiber. Conversely, the TM has erratically been increased where it has increased from 4.4 to 220 MPa. In addition, the FS and modulus have been tripled and quadrupled, respectively, at 40 wt% of the fiber. Zhong et al. (53) used 50 wt% of each of the following fibers, rice straw powder (RI), wheat straw powder (WH), reed straw (RE), and bamboo powder (BA), with PVC matrix. Ca/Zn stabilizer and PE wax were added. All ingredients were mixed and extruded at 165°C by a mixer and a twin screw extruder, respectively. The fabricated composites were mechanically investigated. It can be noted that the effects of WS, RP, and BP fibers on TS, FS, and IS are almost the same. RS fiber has the weakest properties in comparison with WS, RP, and BP fibers (Table 3). On top of that, the impacts of Areca fibers from Areca palm tree on PVC matrix have been explored by Nayak et al. (54) who valued the mechanical properties (flexural test, Izod impact test, and tensile test) in conjunction with the thermal ones. The wt% that were used were 10, 18, 20, 30, and 40 wt%. Plasticizer, stabilizer, and lubricant were added as processing aids with the matrix and the fiber. The compounds were injected after they had been mixed in a mixer. The results of the current study are presented in Table 3. There is a slight improvement in TS and FS up to 30 wt%. Then, the properties decreased again. The TM has significantly been enhanced. Regardless, the IS has declined to touch the lowest value at 40 wt%. Wang et al. (55) utilized 50 wt% of RH powder to reinforce PVC by a twin screw extruder. Some additives also were used to facilitate the composites fabrication. FS and Izod IS were evaluated. The FS value was 35 MPa, while the IS was 3.2 kJ·m−2. WR, Rockwell H, IS, and thermal properties of 50 wt% eucalyptus fiber-reinforced PVC have been explored by Zhang et al. (56). Coupling agent, stabilizer, and PE wax have been added to the composites. A mixer and a twin screw extruder have been used to manufacture the composites. A total of 50 wt% eucalyptus fibers gave better IS when compared to 50 wt% RH powder as presented in Table 3.

Mechanical, tribological, and thermal properties of PVC composites reinforced by diverse natural fibers

| Filler | Size-length diameter | wt% | TS (MPa) | TM (MPa) | FS (MPa) | FM (MPa) | IS Izod/Charpy | H | WR/µ | T onset (°C) | T endset (°C) | T max (°C) | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| None | 0 | 3.91 | — | — | — | — | 80.67 Shore-A | 239.5 | — | 273.5 | (18) | ||

| BA rock powder | 0.29–14.58 μm | 18.8 | 3.34 | — | — | — | — | 94.9 | — | 242.4 | — | 273.6 | |

| 28.8 | 3.09 | — | — | — | — | 98.6 | — | 242.4 | — | 253.0 | |||

| 38.8 | 2.40 | — | — | — | — | 99.5 | — | 248.6 | — | 260.0 | |||

| 48.8 | 2.27 | — | — | — | — | 103.3 | — | 249.6 | — | 225.0 | |||

| 58.8 | 1.88 | — | — | — | — | 104.2 | — | 254.3 | — | 260.0 | |||

| None | 0 | 12.40 | — | — | — | — | 70.35 Shore-A | — | — | — | — | (49) | |

| Pine WF | 60 mesh size | 1 | 10.60 | — | — | — | — | 69.45 | — | — | — | — | |

| 5 | 9.70 | — | — | — | — | 69.50 | — | — | — | — | |||

| 10 | 6.41 | — | — | — | — | 68.35 | — | — | — | — | |||

| Decayed wood powder | 60–80 mesh | 30 | 11.4 | 1,969 | — | — | — | — | — | — | — | — | (50) |

| 40 | 20.7 | 3,258 | — | — | — | — | — | 240* | 370* | 310* | |||

| 50 | 20.5 | 3,279 | — | — | — | — | — | — | — | — | |||

| Sound wood powder | 60–80 mesh | 30 | 22.0 | 3,233 | — | — | — | — | — | — | — | — | |

| 40 | 25.2 | 3,995 | — | — | — | — | — | 250* | 365* | 314* | |||

| 50 | 19.5 | 3,341 | — | — | — | — | — | — | — | — | |||

| None | 0 | 41.76 | 1,164 | 78.68 | — | 84.5 J·m−1 | 76 shore-D | — | 257 | 372 | — | (51) | |

| BC | BC-100 mesh | 60 | 22.78 | 1,455 | 44.74 | — | 44.62 | 79 | — | 238 | 372 | — | |

| OP-BC | 50:10 | 29.21 | 2,198 | 51.89 | — | 54.10 | 82 | — | 240 | 372 | — | ||

| 40:20 | 24.14 | 1,837 | 45.33 | — | 46.98 | 83 | — | 243 | 372 | — | |||

| 30:30 | 21.06 | 1,689 | 44.85 | — | 45.32 | 85 | — | 244 | 372 | — | |||

| OP | 60 | 20.85 | 1,617 | 49.56 | — | 49.75 | 86 | — | 246 | 357 | — | ||

| None | 0 | 41.76 | 1,164 | 78.68 | — | 84.5 J·m−1 | 76 Shore D | — | 257 | 372 | — | (48) | |

| WF WF-PCC | WF 243 μm | 62 | 19.89 | 1,453 | 44.69 | — | 44. | 77 | — | 238 | 372 | — | |

| PCC 100 mesh | 52:10 | 26.92 | 2,195 | 51.78 | — | 54.0 | 80 | — | 240 | 372 | — | ||

| 42:20 | 21.87 | 1,833 | 45.21 | — | 46.8 | 82 | — | 243 | 372 | — | |||

| 31:31 | 18.27 | 1,686 | 44.77 | — | 45.2 | 83 | — | 244.5 | 372 | — | |||

| PCC | 62 | 21.03 | 1,614 | 49.57 | — | 49.5 | 85 | — | 246 | 357 | — | ||

| None | 0 | 17 | 4.4 | 3 | 113.7 | 186.8 kJ·m−2 | — | — | — | — | — | (52) | |

| Bamboo particles | 45–180 µm | 10 | 13.66 | 155.5 | 7.15 | 312.7 | 137 | — | — | — | — | — | |

| 20 | 11.84 | 218.8 | 7.45 | 333.5 | 66.35 | — | — | — | — | — | |||

| 30 | 10.2 | 147.7 | 9.18 | 443.6 | 60.65 | — | — | — | — | — | |||

| 40 | 9.98 | 222 | 10.25 | 500.4 | 49.66 | — | — | — | — | — | |||

| RI | 100 mesh powder | 50 | 22 | — | 32 | — | 3.6 kJ·m−2 | — | — | — | — | — | (53) |

| WH | 50 | 24.9 | — | 35 | — | 4 | — | — | — | — | — | ||

| RE | 50 | 25.4 | — | 34.4 | — | 4.3 | — | — | — | — | — | ||

| BA | 50 | 24.25 | — | 33.8 | — | 4.1 | — | — | — | — | — | ||

| None | 0 | 20.18 | 1,570 | 10.58 | — | 12.24 kJ·m−2 | — | — | 240 | — | — | (54) | |

| Areca sheath | Length 1–5 cm | 10 | 26.67 | 1,950 | 12.21 | — | 10.11 | — | — | — | — | — | |

| Width 1–10 mm | 18 | — | — | — | — | — | — | — | 220 | — | — | ||

| 20 | 32.19 | 2,170 | 17.62 | — | 9.17 | — | — | — | — | — | |||

| 30 | 28.42 | 2,360 | 15.71 | — | 7.89 | — | — | — | — | — | |||

| 40 | 22.74 | 2,590 | 10.27 | — | 5.21 | — | — | — | — | — | |||

| Rice | |||||||||||||

| Husk | 100 mesh | 50 | — | — | 35 | — | 3.2 kJ·m−2 | — | — | — | — | — | (55) |

| Eucalyptus | |||||||||||||

| Fiber | 100 mesh | 50 | — | — | — | — | 4.95 kJ·m−2 | 62.3 HRR | 0.0001 mm3 N−1 m−1 | 254.6 | 326 | — | (56) |

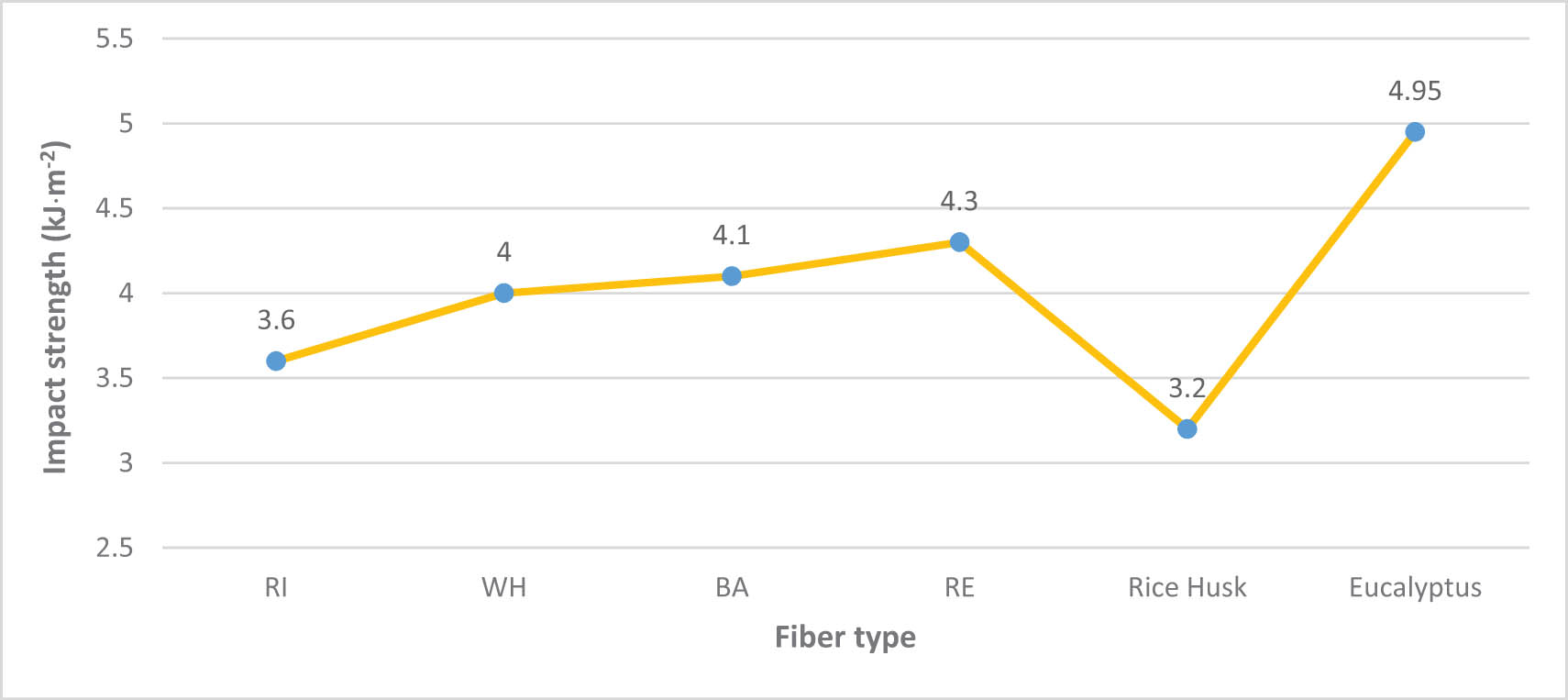

4.1 The effects of 50 wt% of natural fillers on the IS of PVC composites

A comparison of the IS of numerous PVC composite-based natural fillers is presented in Figure 4. This comparison was conducted at 50 wt% of each filler and at the size of 100 mesh. It can be observed from Figure 4 that the differences in the IS values are small. However, the IS of eucalyptus–PVC composite has hit the vertex at 4.95 kJ·m−2. In contrast, RH composite has reached the lowest point at 3.2 kJ·m−2.

IS values of PVC composites at 50 wt% of different natural fillers.

4.2 The effects of natural fillers on tensile and flexural properties of PVC composites

Based on the available properties, it can be said that all fibers have decreased the TS value of PVC except for Areca Sheath, where it has increased the tensile from 22 to 32 MPa at 20 wt%. On the contrary, the TM of PVC composites has increased regardless of the type of fiber and the wt%. The best improvement, ∼5,000%, has occurred on the modulus due to the addition of 40 wt% of bamboo fibers. In addition, the FS of 40 wt% bamboo-PVC composite has reached the vertex where it has tripled to reach 10.25 from 3 MPa. Moreover, the FS is quadrupled at the same wt% of bamboo.

5 Natural filler-reinforced polyester resin matrix

Polyester resin is a dense thermoset pale yellow liquid (57,58) produced basically from the chemical reaction between dibasic acid and glycol (59). Catalyst-like methyl ethyl ketone peroxide (MEKP) is added to the resin to perform the curing process. Cobalt as an accelerator also can be used to facilitate the curing process (60).

Polyester resin has become the most widely utilized thermoset in polymer-based composites in the 21st century. The versatility of polyester resin can be attributed to the ease of the treating process where it can be cured over a range of temperatures (even at room temperature) and under atmospheric pressure (58). Besides, mechanical and electrical properties along with the chemical ones and its good adherence with numerous fibers make polyester matrix widespread in different applications (61). It is widely used in the construction and transportation sectors (58). Polyester resin, like other types of polymers, can have a harmful impact on the environment. So, different studies have been conducted to alleviate its negative consequences by reinforcing polyester with natural filler rather than glass fiber and carbon fiber. To exemplify, different fiber loadings of Indian mallow fiber (10, 20, 30, 40, and 50 wt%) were used to produce polyester composites by the compression molding technique. The produced composites were evaluated through the flexural test, tensile test, Izod impact test, and Barcol H test by Vignesh et al. (62). With increasing the fiber loading from 10 to 50 wt%, the TS, TM, FS, IS, and H have increased to reach 46.5 MPa, 3,550 MPa, 112 MPa, 14.2 kJ·m−2, and 60 Barcol, respectively. Further, Büyükkaya et al. (63) mixed (5, 10, 15, and 20 wt%) of hazelnut shells, corn stalk, nettle stalk, and nettle fiber with polyester liquid and cobalt and methyl ethyl ketone peroxide as bonding agents. Mixtures were poured into molds. Then, they were cured in an oven for 24 h at 80°C. The FS and FM were tested. All these fibers have dramatically reduced FS. However, the lowest values of FS are obtained by corn stalk in comparison with their counterparts. In addition, the FM value has been changed irregularly up and down. Nevertheless, Nettle fibers have the highest FM as presented in Table 4. In addition, Das et al. (64) used five loadings of wood charcoal powder (4–20 wt%) to reinforce jute-polyester resin. Hand lay-up was used to fabricate the composites. 2 wt% of methyl ethyl ketone peroxide (MEKP) was added to the polyester resin. Then, the tensile and thermal properties were evaluated. Table 4 presents that the TS of polyester has been enhanced up to 8 wt% of charcoal and then it has dropped below the value of the polyester matrix. The TM presents a similar trend, but the TM started to decline at 12 wt%. Both T onset and T endset have been decreased at the singular per cent, 4 wt%. Furthermore, thermal and tensile properties of wheat straw–polyester composites were investigated by Haque et al. (65). The composites were fabricated by the hand mixing technique. The unsaturated resin was mixed with a methyl ethyl ketone peroxide as a cross-linker and hardener. Then, the mixtures were cured for 24 h at room temperature. The presence of wheat straw in polyester resin has improved marginally the tensile properties, while it has not affected both T onset and T endset as presented in Table 4.

Mechanical, tribological, and thermal properties of polyester composites reinforced by diverse natural fibers; note: (80:20) represents that 80 wt% of the whole percent (70) is feather while 20 wt% of the whole percent (70) is cotton

| Filler | Size-length diameter | wt% | TS (MPa) | TM (MPa) | FS (MPa) | FM (MPa) | IS Izod/Charpy | H | WR/µ | T onset (°C) | T endset (°C) | T max (°C) | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Indian mallow fiber | 30 mm length | 10 | 21.5 | 2,250* | 49* | — | 3.9* k·J m−2 | 24 Barcol | — | — | — | — | (62) |

| 20 | 26.7 | 3,200* | 56* | — | 5.8* | 35 | — | — | — | — | |||

| 30 | 33.5 | 3,400* | 58* | — | 8* | 44 | — | — | — | — | |||

| 40 | 42.5 | 3,450* | 92* | — | 9* | 52 | — | — | — | — | |||

| 50 | 46.5 | 3,550* | 112* | — | 14.2* | 60 | — | — | — | — | |||

| None | 0 | 102* | 2,800* | — | — | — | — | (63) | |||||

| Hazelnut shells | 425–600 µm | 5 | — | — | 32* | 3,000* | — | — | — | — | — | — | |

| 10 | — | — | 36* | 2,850* | — | — | — | — | — | — | |||

| 15 | — | — | 38* | 2,500* | — | — | — | — | — | — | |||

| 20 | — | — | 42* | 2,300* | — | — | — | — | — | — | |||

| Corn stalk | 5 | — | — | 20* | 2,850* | — | — | — | — | — | — | ||

| 10 | — | — | 18* | 2,550* | — | — | — | — | — | — | |||

| 15 | — | — | 22* | 2,250* | — | — | — | — | — | — | |||

| 20 | — | — | 24* | 2,200* | — | — | — | — | — | — | |||

| Nettle stalk | 5 | — | — | 38* | 2,900* | — | — | — | — | — | — | ||

| 10 | — | — | 26* | 2,650* | — | — | — | — | — | — | |||

| 15 | — | — | 27* | 2,200* | — | — | — | — | — | — | |||

| 20 | — | — | 28* | 2,050* | — | — | — | — | — | — | |||

| Nettle fiber | 5 | — | — | 27* | 3,600* | — | — | — | — | — | — | ||

| 10 | — | — | 34* | 3,800* | — | — | — | — | — | — | |||

| 15 | — | — | 28* | 3,150* | — | — | — | — | — | — | |||

| 20 | — | — | 28* | 3,000* | — | — | — | — | — | — | |||

| None | 0 | 27 | 1,100 | — | — | — | — | — | 350 | 400 | — | (64) | |

| Wood charcoal Powder | — | 4 | 34 | 1,200 | — | — | — | — | — | 290 | 375 | — | |

| 8 | 27.5 | 1,080 | — | — | — | — | — | — | |||||

| 12 | 26 | 1,140 | — | — | — | — | — | — | |||||

| 16 | 21 | 1,050 | — | — | — | — | — | — | |||||

| 20 | 16 | 790 | — | — | — | — | — | — | |||||

| None | 0 | 11.75 | 1005.4 | — | — | — | — | — | 210 | 430 | (65) | ||

| wheat straw | Length 2 mm | — | 14.45 | 1190.5 | — | — | — | — | — | 208 | 431 | ||

| None | 0 | 29.23 | — | 7.97 | — | 1 | 42.9 | 0.0006 | — | — | — | (60) | |

| J·m−2 | HV | mm3·N−1·m−1 | |||||||||||

| Chopped Agave | 10 mm Length | 5 | 52.19 | — | 12.35 | — | 1.6 | 63.6 | 0.00391 | — | — | — | |

| 10 | 78.56 | — | 17.56 | — | 3.2 | 60.3 | 0.00517 | — | — | — | |||

| 15 | 95.27 | — | 35.76 | — | 4.7 | 58.3 | 0.00629 | — | — | — | |||

| 20 | 84.67 | — | 32.35 | — | 2.7 | 54.2 | 0.00735 | — | — | — | |||

| Mat Agave | — | 5 | 31.35 | — | 8.25 | — | 3.67 | 61.2 | 0.01021 | — | — | — | |

| 10 | 60.6 | — | 15.65 | — | 4.1 | 59.8 | 0.01018 | — | — | — | |||

| 15 | 79.85 | — | 31.2 | — | 4.6 | 51.7 | 0.01102 | — | — | — | |||

| 20 | 72.58 | — | 29 | — | 2.1 | 51.6 | 0.01565 | — | — | — | |||

| Chopped HE | — | 3 | 60.5 | — | 5.62 | — | 1 | 56.9 HV | 0.0844 mm3·N−1·m−1 | — | — | — | (61) |

| 6 | 64.6 | — | 7.83 | — | 4.3 | 57.1 | 0.0728 | — | — | — | |||

| 9 | 69.9 | — | 10.15 | — | 5.7 | 50.1 | 0.0941 | — | — | — | |||

| Chopped Nettle | 3 | 74.6 | — | 5.46 | — | 3 | 67.8 | 0.0437 | — | — | — | ||

| 6 | 57.4 | — | 6.35 | — | 5.4 | 49.2 | 0.1 | — | — | — | |||

| 9 | 66.9 | — | 16 | — | 6.7 | 52.0 | 0.0831 | — | — | — | |||

| Chopped Nettle-Hemp | 18 | 71.5 | — | 14.21 | — | 6.2 | 59.1 | 0.0684 | — | — | — | ||

| Mat (Nettle - HE) | 3 | 67.3 | — | 16.50 | — | 2.6 | 44.5 | 0.109 | — | — | — | ||

| 6 | 58.5 | — | 18.35 | — | 3.4 | 51.7 | 0.0829 | — | — | — | |||

| 9 | 72.7 | — | 16.85 | — | 3.2 | 49.8 | 0.0822 | — | — | — | |||

| None | 0 | 72* | — | 440* | — | 50 J·m−1* | 82* Shore-A | — | (59) | ||||

| Rattan-Bamboo | Woven mat | 10 | 66* | — | 400* | — | 120* | 84* | — | — | — | — | |

| 20 | 73* | — | 370* | — | 260* | 88* | — | — | — | — | |||

| 30 | 76* | — | 345* | — | 390* | 92* | — | 345* | 427* | 402 | |||

| None | 0 | 24.48 | 2147.2 | — | — | — | — | — | — | — | — | (57) | |

| Cotton | Nonwoven | 70 | 19.34 | 2015 | — | — | — | — | — | — | — | — | |

| 50 | 4.000 | 2001.5 | — | — | — | — | — | — | — | — | |||

| Wool | Nonwoven | 70 | 21.13 | 1612.9 | — | — | — | — | — | — | — | — | |

| 50 | 6.52 | 1273.2 | — | — | — | — | — | — | — | — | |||

| Feathers-cotton | Feather length 10–30 mm | 70 1:1 | 25.90 | 1,799 | — | — | — | — | — | — | — | — | |

| 50 1:1 | 23.53 | 1657.04 | — | — | — | — | — | — | — | — | |||

| Feathers-cotton | 70 80:20 | 20.32 | 1638.87 | — | — | — | — | — | — | — | — | ||

| 50 80:20 | 16.93 | 1459.22 | — | — | — | — | — | — | — | — | |||

| Feather-wool | 70 1:1 | 11.4 | 1800.31 | — | — | — | — | — | — | — | — | ||

| 50 1:1 | 14.6 | 1634.71 | — | — | — | — | — | — | — | — | |||

| Feather-wool | 70 80:20 | 2.74 | 1417.56 | — | — | — | — | — | — | — | — | ||

| 50 80:20 | 12.55 | 1459.18 | — | — | — | — | — | — | — | — | |||

| Jute | Length 20–35 cm Diameter 0.09–0.25 mm Mat form | 30 | 46.61 | — | 114 | — | — | — | — | — | — | — | (66) |

| Bamboo | 30 | 53.87 | — | 133.9 | — | — | — | — | — | — | — | ||

| Jute-bamboo | 30 15:15 | 53.16 | — | 124 | — | — | — | — | — | — | — | ||

| 30 20:10 | 55.63 | — | 121 | — | — | — | — | — | — | — | |||

| 30 10:20 | 72.03 | — | 131.5 | — | — | — | — | — | — | — | |||

| None | 0 | 17* | 200* | — | — | 25* | — | — | — | — | — | (67) | |

| Bamboo | Length ∼5–8 mm | 10 | 21* | 225* | — | — | 27* | — | — | — | — | — | |

| Diameter ∼250–500 μm | 20 | 22* | 625* | — | — | 36* | — | — | — | — | — | ||

| 30 | 20* | 555* | — | — | 38* | — | — | — | — | — | |||

In addition, four wt% (5, 10, 15, and 20) of chopped and mat Rambans fiber (agave) with balanced wt% (2 wt%) of hardener (methyl ethyl ketone peroxide) and 2 wt% accelerator (cobalt) were added to polyester resin. The composites were subjected to the compression molding process at a constant load after the curing process had started. The Vickers H property in addition to the strength of tensile, flexural, and notched Charpy impact was characterized by Prasad et al. (60). All these characteristics have been improved except for the WR where it has worsened. Coupling 15% of agave fiber with polyester has culminated the TS, FS, and IS as it is displayed in Table 4. H property has reached the climax at 5 wt% of the fiber with the improvement of 50%. When comparing chopped agave with mat agave at the same weight percentage, it is worthwhile to note that chopped agave has often produced better outcomes. On top of that, Prasad et al. (61) studied the effects of reinforcing two forms (chopped fibers and matted fibers) of diverse types of fibers (HE, nettle and hemp-nettle) at different wt% (3, 6, and 9 wt%) on specific WR, Charpy impact, H Vickers, FS, and TS. The composites were prepared by the manual layout process. Table 4 presents that the FS and IS of chopped HE and chopped nettle have been enhanced along with the increase of wt%. The TS of chopped HE-polyester composite has also been increased, while it has been changed irregularly when the chopped nettle fibers have been added. The H has been reduced when chopped nettle and chopped HE were introduced to the polyester matrix. The WR of both fibers has fluctuated irregularly. With turning to the hybrid filler (mat of HE and nettle), it can be noted that most of the properties have fluctuated slightly. Munshi et al. (59) assessed flexural, tensile, H, and impact properties of polyester composites. Besides, thermogravimetric properties were also investigated. The composites were reinforced by different fiber loadings (10, 20, and 30 wt%) of a uniform ratio of rattan and bamboo ratio (1:1). The fibers were in the woven mat form. The Hand lay-up process was used for manufacturing the composites. The ratio of polyester to the methyl ethyl ketone peroxide (MEKP) as hardener was (98:2). Table 4 displays that the FS has negatively been affected by adding the fiber to the matrix. Conversely, the IS has substantially been boosted. A slight improvement has been noted in the H and TS. Mrajji et al. (57), in addition, reinforced polyester with four species of filler (cotton, wool, feathers-cotton, and feathers-wool). The used wt% of the fibers were 50 and 70, but the ratios within the wt% itself of the hybrid reinforcement of feather-cotton and feather-wool were 1:1 and 80:20, respectively. The vacuum molding process was used to fabricate nonwoven composites. As the previous fabrication processes, MEKP and cobalt were used for the same goals. The TS and modulus have been investigated. The outcomes in Table 4 display that nonwoven cotton has improved the TS, but at the same time, it has decreased the TM. With regards to nonwoven wool, it can be concluded that both TS and TM have been reduced. Also, the TM and strength of the hybrid filler (cotton-feather and cotton-feather) have declined regardless of the way of hybridization except at 70 wt% (1:1) Feathers-cotton where the TS has improved marginally. Mekonnen and Mamo (66) utilized the hand lay-up process to fabricate jute–polyester, bamboo–polyester, and jute–bamboo–polyester composites. Six grams of MEKP were added to the polyester matrix as a catalyst. The tensile and FS of the produced composites were investigated. Table 4 presents that the best effect on TS was obtained by reinforcing polyester with the hybrid jute–bamboo fiber with a ratio of 10:20 compared to individual jute or bamboo. By comparison, bamboo has given the best TM at the same weight percent. In addition, bamboo fiber with different loadings (10, 20, and 30) are mixed for 30 min with the polyester resin and then the mixtures are poured into a mold of steel. MEKP and cobalt were used as a hardener and accelerator. Charpy impact and tensile properties of bamboo polyester composites were assessed by Abdul Karim et al. (67). The TS and TM have been enhanced up to 20 wt% and then they have been decreased again. In any case, the TM is tripled at 20 wt% of bamboo, while the effect of this fiber on the TS is insignificant. In the case of the IS, it can be noted that it has improved to hit the peak at 30 wt% of bamboo fiber as presented in Table 4.

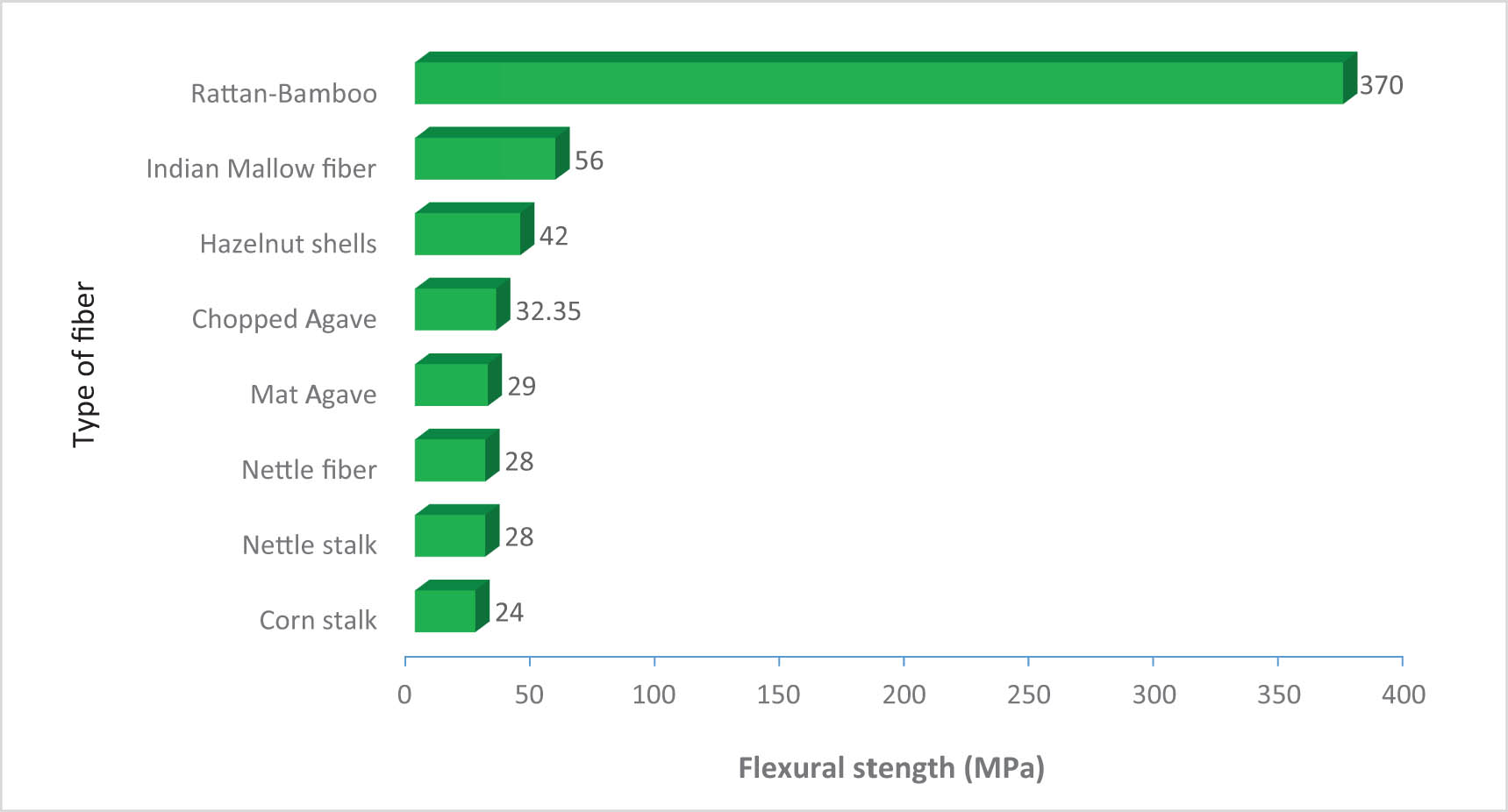

5.1 The effects of 20 wt% of natural fillers on FS of polyester composites

Figure 5 illustrates the FS of polyester resin composite at 20 wt% of natural filler. It can be seen that FS values of nettle stalk, nettle fiber, and mat gave composites are almost the same. This means that they can substitute each other in polyester resin. In addition, the strength of hazelnut shells and chopped agave composites are just over than nettle stalk, nettle fiber, and mat gave composites. The hybrid fiber (rattan-bamboo) has erratically raised the FS erratically, where its value has reached 370 kJ·m−2. However, the FS of corn stalk has touched the lowest value at 24 kJ·m−2.

FS values of polyester at 20 wt% of different natural fillers.

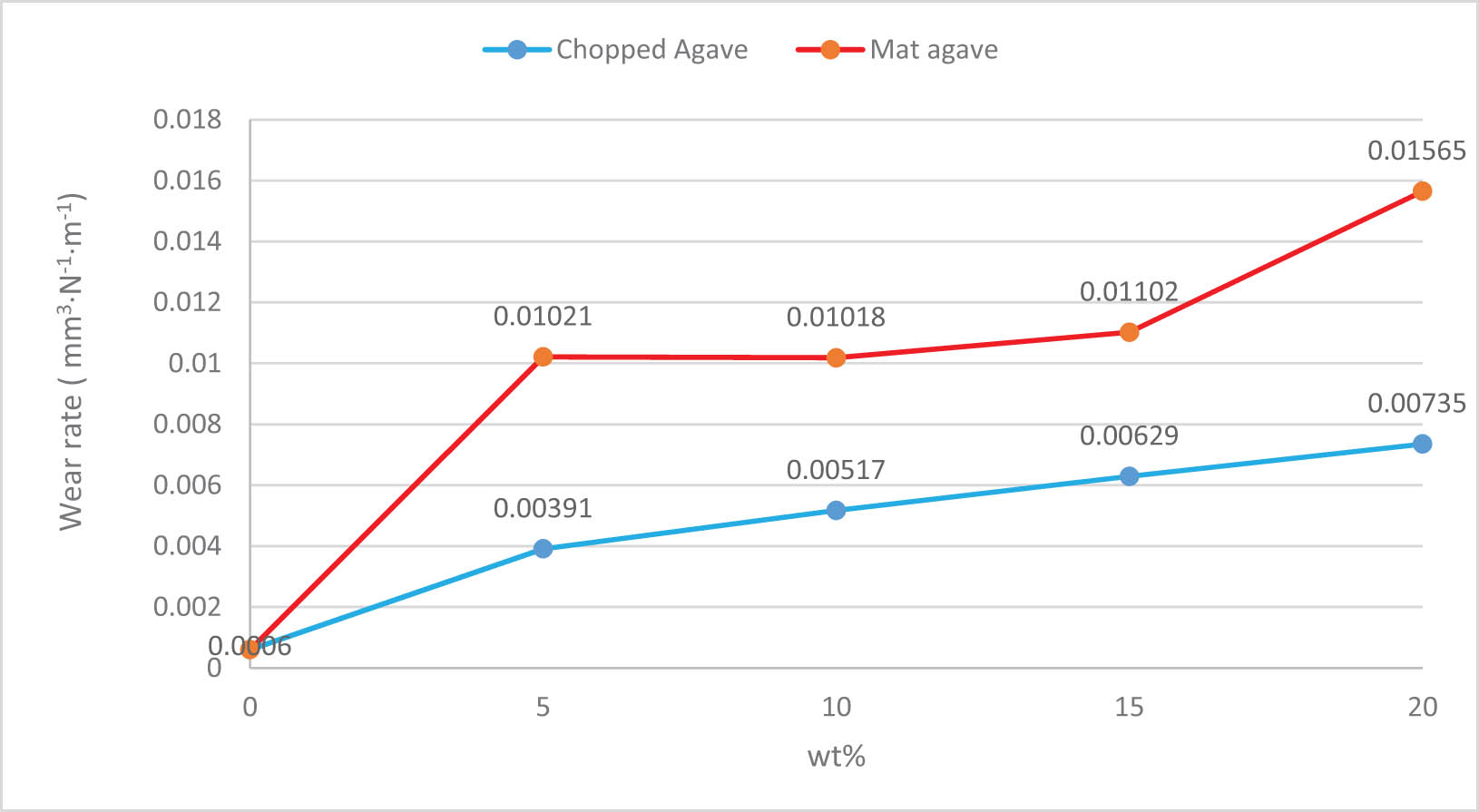

5.2 The effects of wt% and agave fiber forms on the WR of polyester composites

Figure 6 presents the effect of both wt% and the forms of agave fibers on the WR of PVC composite. It can be easily noticed that increasing the wt% of agave fiber in PVC matrix leads to a gradual increase in the WR. In other words, 0 wt% gave better wear resistance than 20 wt%. This is valid for chopped and mat agave forms. Regarding the forms of fiber, it can be observed that mat agave form worsened the WR at the same wt%. For example, at 10 wt% of chopped fiber, the WR is 0.00391 mm3·N−1·m−1, while the rate is 0.01021 mm3·N−1·m−1.

The WR of agave fiber–polyester composite at diverse wt% and forms.

5.3 The effects of the fiber type on tensile and flexural properties of polyester composites

The values of TS have changed irregularly depending on the type of fiber and the wt%. However, agave (mat or chopped form) has approximately tripled the TS at 15 wt%. Also, wheat straw, wood charcoal powder, bamboo, and rattan-bamboo have improved the TS, but their effects on the TS were marginal. Wheat straw and wood charcoal Powder have insignificantly strengthened the TM, while bamboo fiber (length ∼5–8 mm) has tripled the TM (Table 4). The majority of researchers have not studied FS. Nevertheless, rattan-bamboo, hazelnut shells, corn stalk, nettle stalk, and nettle fiber have decreased the FS of the polyester matrix. Conversely, agave (mat or chopped) has increased the FS to 35.76 from 7.97 MPa. Turning to FM, it can be noted that the effects of fibers on FM have not been studied extensively, but hazelnut shells, corn stalk, nettle stalk, and nettle fiber have adversely affected the FM.

6 Conclusions

The current review has compiled in the tabular form the influences of different wt% of various natural fillers either organic or inorganic on tensile, flexural, impact properties in conjunction with the WR and thermogravimetric of PE, HDPE, PVC, and polyester resin. Based on the present overview, the following points can be concluded:

The majority of those fillers has an adverse effect on the TS of the PP, PE, poly(vinyl chloride), and polyester resin. They generally improved the TM.

The influences of the natural fillers on the FS are better than their effects on TS. Despite that, some of the fillers have dramatically decreased the FS.

All utilized fillers in this research have positive impacts on FM of PP, HDPE, PVC, and polyester resin.

Some of the fillers do preserve the TS in conjunction with decreasing the amount of plastic, while few types of filler have enhanced the TS.

The IS decreased and increased irregularly depending on the type of fiber and wt% with the same fiber.

Both Izod and Charpy impact tests can be used with bio-polymeric composites.

Most of the studies focused on the mechanical properties (tensile, flexural, and impact), whereas the research that has been conducted on WR and thermal properties is very limited.

Generally, the very high wt% of fibers decreases the properties of the composite. The highest wt% of fiber was 70%, which was used for RH biochar in HDPE. Also, 70% of cotton, 70% wool, 70% feathers-cotton, and 70% feathers-cotton were used for polyester resin.

It can be observed that bio-HDPE composites touched the highest values of the maximum degradation temperature (T max) followed by bio-PP composites, which were followed by bio-PVC composites.

Among all the composites, the maximum degradation temperature (T max) of mangrove wood-HDPE composite reached the apex at 20 wt%, whereas BA rock powder-PVC has the lowest T max at 48.8 wt%.

Very limited studies have been reported regarding the tribological properties of bio-polymeric composites. Therefore, it is recommended to expand studies on this particular characterization of such biomaterials to enhance developing more sustainable materials. Among the studied fillers, it can be noted that eucalyptus fiber/PVC composite hit the lowest WR.

The increase in the wt% of agave fiber influenced adversely the wear resistance of the PVC matrix. Mat form had higher WR than chopped from regardless of the wt%.

All studied types of fillers had beneficial impacts on Rockwell H regardless of the type of the matrix. Coconut shells increased the H of the PP matrix by 33% at 40 wt% of coconut shells.

Acknowledgment

This work was supported by a grant from the Deanship of Scientific Research at the Jordan University of Science and Technology (JUST) with grant no. 448/2019.

-

Funding information: This work was supported by a grant from the Deanship of Scientific Research at the Jordan University of Science and Technology (JUST) with grant no. 448/2019.

-

Author contributions: Mohammed T. Hayajneh: funding acquisition, investigation, and supervision; Mu’ayyad M. Al-Shrida: conceptualization, methodology, and writing –original draft; Faris M. AL-Oqla: visualization, validation, and writing – review and editing.

-

Conflict of interest: The authors state no conflict of interest.

References

(1) Nuruddin M, Korani DM, Jo H, Chowdhury RA, Montes FJ, Howarter JA, et al. Gas and water vapor barrier performance of cellulose nanocrystal–citric acid-coated polypropylene for flexible packaging. ACS Appl Polym Mater. 2020;2(11):4405–14. 10.1021/acsapm.0c00483.Search in Google Scholar

(2) Tabasum S, Younas M, Zaeem MA, Majeed I, Majeed M, Noreen A, et al. A review on blending of corn starch with natural and synthetic polymers, and inorganic nanoparticles with mathematical modeling. Int J Biol Macromol. 2019;122:969–96. 10.1016/j.ijbiomac.2018.10.092.Search in Google Scholar PubMed

(3) Karan H, Funk C, Grabert M, Oey M, Hankamer B. Green bioplastics as part of a circular bioeconomy. Trends Plant Sci. 2019;24(3):237–49. 10.1016/j.tplants.2018.11.010.Search in Google Scholar PubMed

(4) Rahman MT, Mohajerani A, Giustozzi F. Recycling of waste materials for asphalt concrete and bitumen: A review. Materials. 2020;13(7):1495. 10.3390/ma13071495.Search in Google Scholar PubMed PubMed Central

(5) Thevenon F, Carroll C, Sousa J. Plastic debris in the ocean: the characterization of marine plastics and their environmental impacts, situation analysis report. Gland, Switzerland: IUCN; 2014. p. 52.10.2305/IUCN.CH.2014.03.enSearch in Google Scholar

(6) Al-Oqla FM. Flexural characteristics and impact rupture stress investigations of sustainable green olive leaves bio-composite materials. J Polym Environ. 2021;29(3):892–9.10.1007/s10924-020-01889-3Search in Google Scholar

(7) Al-Oqla FM. Performance trends and deteriorations of lignocellulosic grape fiber/polyethylene biocomposites under harsh environment for enhanced sustainable bio-materials. Cellulose. 2021;28(4):2203–13.10.1007/s10570-020-03649-xSearch in Google Scholar

(8) AL-Oqla F, Thakur VK. Toward chemically treated low-cost lignocellulosic parsley waste/polypropylene bio-composites for resourceful sustainable bio-products. Int J Environ Sci Technol. 2021;19(7):6681–90.10.1007/s13762-021-03601-xSearch in Google Scholar

(9) AL‐Oqla FM, Hayajneh MT, Aldhirat A. Tribological and mechanical fracture performance of Mediterranean lignocellulosic fiber reinforced polypropylene composites. Polym Compos. 2021;42:5501–11. 10.1002/pc.26241.Search in Google Scholar

(10) Alaaeddin M, Sapuan S, Zuhri M, Zainudin E, Al-Oqla FM. Physical and mechanical properties of polyvinylidene fluoride-short sugar palm fiber nanocomposites. J Clean Prod. 2019;235:473–82. 10.1016/j.jclepro.2019.06.341.Search in Google Scholar

(11) AL-Oqla FM. Investigating the mechanical performance deterioration of Mediterranean cellulosic cypress and pine/polyethylene composites. Cellulose. 2017;24(6):2523–30.10.1007/s10570-017-1280-3Search in Google Scholar

(12) Sypaseuth FD, Gallo E, Çiftci S, Schartel B. Polylactic acid biocomposites: approaches to a completely green flame retarded polymer. e-Polymers. 2017;17(6):449–62.10.1515/epoly-2017-0024Search in Google Scholar

(13) Arteaga-Ballesteros BE, Guevara-Morales A, San Martín-Martínez E, Figueroa-López U, Vieyra H. Composite of polylactic acid and microcellulose from kombucha membranes. e-Polymers. 2021;21(1):015–26.10.1515/epoly-2021-0001Search in Google Scholar

(14) Salem TF, Tirkes S, Akar AO, Tayfun UJe-P. Enhancement of mechanical, thermal and water uptake performance of TPU/jute fiber green composites via chemical treatments on fiber surface. e-Polymers. 2020;20(1):133–43.10.1515/epoly-2020-0015Search in Google Scholar

(15) Bello SA, Raji NK, Kolawole MY, Adebayo MK, Adebisi JA, Okunola KA, et al. Eggshell nanoparticle reinforced recycled low-density polyethylene: A new material for automobile application. J King Saud Univ-Eng Sci. 2021. 10.1016/j.jksues.2021.04.008.Search in Google Scholar

(16) Jha NS, Rathod P, Wagh S, Pande S. Investigation on the mechanical, thermal propertiesof polyamide 6/polypropylene blends with natural talc as filler. AIP Conference Proceedings. AIP Publishing LLC; 2019.10.1063/1.5100387Search in Google Scholar

(17) Aradhyula TV, Bian D, Reddy AB, Jeng Y-R, Chavali M, Sadiku ER, et al. Compounding and the mechanical properties of catla fish scales reinforced-polypropylene composite–from biowaste to biomaterial. Adv Compos Mater. 2020;29(2):115–28. 10.1080/09243046.2019.1647981.Search in Google Scholar

(18) Naji AM, Mohammed IY, AL-BAYATY SA. Mechanical and thermal degradation kinetic study of basalt filled polyvinyl chloride composite material. Egypt J Chem. 2021;64(2):4–5. 10.21608/ejchem.2020.35343.2739.Search in Google Scholar

(19) Balan GS, Kumar VS, Rajaram S, Ravichandran M. Investigation on water absorption and wear characteristics of waste plastics and seashell powder reinforced polymer composite. J Tribologi. 2020;27:57–70.Search in Google Scholar

(20) Hayajneh M, AL-Oqla FM, Aldhirat A. Physical and mechanical inherent characteristic investigations of various Jordanian natural fiber species to reveal their potential for green biomaterials. J Nat Fibers. 2021;1–14. 10.1080/15440478.2021.1944432.Search in Google Scholar

(21) Fayomi O, Owodolu T, Agboola O, Oyebanji J, Popoola A. A paradigm shift on the impact of synthetic Agro waste nanoparticles materials for engineering diversity: A mini overview. AIP Conference Proceedings. AIP Publishing LLC; 2020. p. 020041.10.1063/5.0033733Search in Google Scholar

(22) Ramu P, Kumar CJ, Palanikumar K. Mechanical characteristics and terminological behavior study on natural fiber nano reinforced polymer composite–a review. Mater Today Proc. 2019;16:1287–96. 10.1016/j.matpr.2019.05.226.Search in Google Scholar

(23) www.statista.com. Global polypropylene resin production volume 2018 & 2026. [cited 2021 Otcober 22]; https://www.statista.com/statistics/1103529/global-polypropylene-production/#statisticContainer.Search in Google Scholar

(24) Norrrahim M, Norizan M, Ilyas R, Sapuan M, Jenol M. Performance evaluation of cellulose nanofiber reinforced polypropylene biocomposites for automotive applications. Amsterdam, The Netherland: Woodhead Publishing; 2020.10.1016/B978-0-12-820559-4.00007-9Search in Google Scholar

(25) Kada D, Koubaa A, Tabak G, Migneault S, Garnier B, Boudenne A. Tensile properties, thermal conductivity, and thermal stability of short carbon fiber reinforced polypropylene composites. Polym Compos. 2018;39(S2):E664–70. 10.1002/pc.24093.Search in Google Scholar

(26) Hayajneh MT, AL-Oqla FM, Al-Shrida MaM. Hybrid green organic/inorganic filler polypropylene composites: Morphological study and mechanical performance investigations. e-Polymers. 2021;21(1):710–21. 10.1515/epoly-2021-0074.Search in Google Scholar

(27) Oliveira GHM, Maia TH, Talabi SI, Canto LB, Lucas AA. Characterization of cellulose nano/microfibril reinforced polypropylene composites processed via solid‐state shear pulverization. Polym Compos. 2021;42(3):1371–82. 10.1002/pc.25907.Search in Google Scholar

(28) Moreno DDP, de Camargo RV, dos Santos Luiz D, Branco LTP, Grillo CC, Saron C. Composites of recycled polypropylene from cotton swab waste with pyrolyzed rice husk. J Polym Env. 2021;29(1):350–62. 10.1007/s10924-020-01883-9.Search in Google Scholar

(29) Saleem A, Medina L, Skrifvars M. Mechanical performance of hybrid bast and basalt fibers reinforced polymer composites. J Polym Res. 2020;27(3):1–13. 10.1007/s10965-020-2028-6.Search in Google Scholar

(30) McGauran T, Dunne N, Smyth BM, Cunningham E. Incorporation of poultry eggshell and litter ash as high loading polymer fillers in polypropylene. Composites Part C:Open Access. 2020;3:100080. 10.1016/j.jcomc.2020.100080.Search in Google Scholar

(31) Nnodu OG, Igwe IO, Ojingwa MA, Nwapa C, Oragwu PI, Okonkwo SN. Effects of chemical modifications of pineapple leaf fibre on the properties of polypropylene composites. J Polym Sci Technol. 2020;5(1):25–37.Search in Google Scholar

(32) Mark UC, Madufor IC, Obasi HC, Mark U. Influence of filler loading on the mechanical and morphological properties of carbonized coconut shell particles reinforced polypropylene composites. J Compos Mater. 2020;54(3):397–407. 10.1177/2F0021998319856070.Search in Google Scholar