Abstract

The surface of nano-TiO2 was modified by a silane coupling agent KH570, and the photosensitive resin was modified by blending the modified nano-TiO2 with three-dimensional (3D) printing light-curing resin. The modified nano-TiO2 powder was characterized by infrared spectrum, X-ray diffraction, contact angle test, and scanning electron microscope. The effects of different content of modified TiO2 on the viscosity, curing shrinkage, tensile strength, elongation at break, hardness, thermal stability, and cross-section morphology of 3D printing photosensitive resin were studied. The results showed that the mechanical properties of epoxy resin were improved obviously after surface modification with a silane coupling agent. When the mass fraction of TiO2 was 1.5%, the mechanical properties of the molded parts were the best. The tensile strength, impact strength, and elongation at break were increased by 51.1, 43.8, and 10.8%, respectively, and the hardness value was maintained at 81–83 HD. The addition of modified TiO2 can improve the heat resistance of the epoxy resin. When the amount of TiO2 is 1.5%, the T 50%, T max, and carbon residue rate of the epoxy resin are increased by 3.44°C, 6.34°C, and 25.3%, respectively.

1 Introduction

Three-dimensional (3D) printing technology is a significant leap in the field of manufacturing technology in the world in the past 30 years. It has reached the high complexity and high precision structure that traditional manufacturing is difficult to achieve. It is a unique dieless manufacturing concept. Stereolithography apparatus (SLA, i.e., stereoscopic light-curing molding technology) is the most mature 3D printing technology with the highest molding accuracy (1,2,3). SLA takes liquid photosensitive resin as raw material, which is rapidly transformed from liquid resin to solid material under the action of ultraviolet light. This process is accompanied by the shrinkage of material volume. Excessive volume shrinkage will affect the molding accuracy, and at the same time, it will cause serious deformation of the molding parts. The material properties are affected, resulting in the actual strength of the photosensitive resin being only 1/10 to 1/100 of the theoretical strength (4). In order to reduce the serious influence caused by internal stress, inorganic fillers are usually added as rigid nodes between molecular chains. Common inorganic fillers include Al2O3 (5,6), TiO2 (7,8,9,10,11), SiC (12), TiC (13), ZrC, and B4C (14). TiO2 is a common inorganic nano-filler, which has the advantages of non-toxic, large specific surface area, and good heat resistance. Compared with traditional fillers, nano-fillers can also improve the properties of polymer materials when the amount of nano-fillers is small (15,16,17,18,19). Nano titanium oxide is widely used in plastics, fine ceramics, composite materials, surface protection, aerospace industry, semiconductor, and other fields due to its good properties of high strength, high hardness, high resistivity, high-temperature resistance, and wear resistance (20,21,22). It is the most widely used material among oxides (23). With the increase in the volume fraction of nanoparticles, the strength of the composite increases, and the plastic toughness of the composite decreases (24). When the volume fraction exceeds 4%, the nanoparticles are easy to agglomerate, and no matter how much reinforcement is added, the mechanical properties of the composite will not be improved (25,26). Liu et al. (27) and Liu (28) used polyvinyl alcohol to encapsulate nanoparticles, and Liu Kai used polymer binder to encapsulate ceramic particles to improve the dispersion of nanoparticles, which is suitable for SLS (laser sintering technology) molding with short molding cycle, low molding accuracy, and poor green body density, but not for SLA molding with high accuracy requirements. Ning et al. (29) modified the nano powder with KH570 to obtain the composite resin with good dispersion. However, the mechanical properties and the influencing factors of SLA are not studied. In this article, silane coupling agent KH570 was used to modify the surface of TiO2, and the modified nano-TiO2 was mechanically blended with 3D printing photosensitive resin to modify the photosensitive resin. The effects of different content of modified TiO2 on the viscosity, curing shrinkage, tensile strength, elongation at break, hardness, thermal stability, and cross-section morphology of 3D printing photosensitive resin were studied.

2 Materials and methods

2.1 Raw materials

Nano-TiO2 (the particle size is 10 nanometers); 3100 a bisphenol A epoxy acrylate (EA); γ-methacryloxypropyl trimethoxysilane (KH570); 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO); 1,6-hexanediol diacrylate (HDDA); analytical pure absolute ethanol; and distilled water (self-made).

2.2 Surface modification of TiO2

About 100 mL mixed solution of anhydrous ethanol and deionized water was prepared according to the ratio of 1:1.5 and added to a 250 mL three-port flask with a spherical condenser and stirrer; the pH of the solution was adjusted to 10 with ammonia water, 20 g dry nano-TiO2 powder was weighed, added into a three-port flask, and stirred with a stirrer under the condition of 70°C constant temperature oil bath for 30 min, so that the powder can be evenly dispersed in the solution. After that, the mixed solutions of KH-570 and ethanol with different mass fractions (5, 10, 15, 20, and 25%) were added to three-port flasks. After the reaction at 70°C for 3 h, ultraviolet (UV) light was used to irradiate the reaction process. After the reaction, it was cooled to room temperature, filtered, washed, dried in a 100°C blow-drying oven, ground, sieved through 200 meshes, dried, and stored for standby. The mechanism of KH-570-modified TiO2 is shown in Figure 1.

Mechanism of KH-570-modified nano-TiO2.

2.3 Photosensitive resin molding

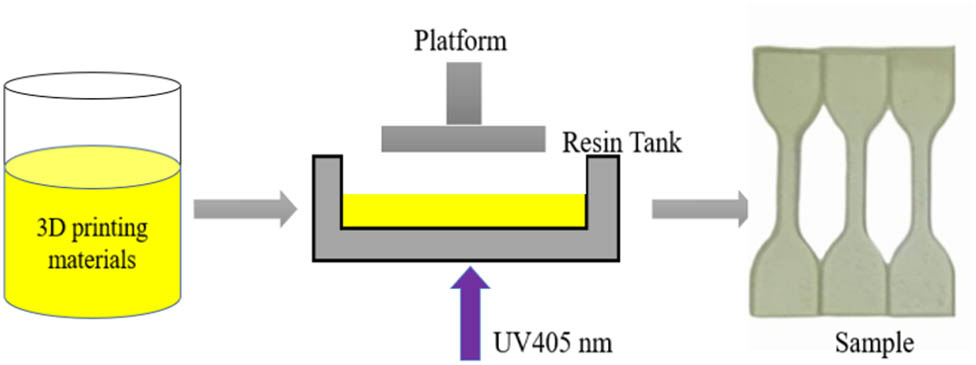

A certain amount of photoinitiator TPO was weighed and dissolved in the active diluent HDDA. It was stirred in a water bath at 40°C for 30 min to completely dissolve and then mixed with bisphenol A epoxy acrylic resin to obtain a mixed solution. The modified TiO2 was added to the mixed solution, magnetically stirred for 2 h at room temperature, and rotated at 1,000 rpm. After the stirring is completed, the mixture was allowed to stand for 12 h in the dark to defoam to obtain a 3D printing light-curing resin solution and stored in the dark at room temperature for later use. Using the Moai SLA 3D printer, the above mixed solution was poured into the resin tank. Setting parameters: the main emission wavelength is 405 nm, the layer thickness is 0.1 mm, the ultraviolet laser power is 58 W, and the printing speed is 40 mm·h−1. After selecting the digital model and printing, the sample size is 80 mm × 10 mm × 4 mm. Figure 2 shows the SLA 3D printing process. Figure 3 shows the curing process of 3D printing materials. The action mechanism of KH-570 modified TiO2 is shown in Figure 4.

SLA 3D printing process.

Curing process of 3D printing materials.

Curing mechanism of nano-TiO2-modified resin.

2.4 Testing and characterization

Moai-type SLA 3D printer (Hong Kong Peopoly Moai Company) is used for photosensitive resin molding. Setting parameters: the main emission wavelength is 405 nm, the layer thickness is 0.1 mm, the ultraviolet laser power is 58 W, the printing speed is 40 mm·h−1, and the sample size is 80 mm × 10 mm × 4 mm; S-4,800 field emission scanning electron microscope (Hitachi, Japan) was used to observe the morphology of TiO2. Samples of appropriate size were placed on the conductive adhesive, and the samples were sprayed with gold before observation; Bruker Fourier transform infrared spectrometer (Bruker company, Germany) was used to study the changes of organic functional groups in the samples, and the test range was 4,000–400 cm−1; XRD-7,000s X-ray diffractometer (Shimadzu company, Japan) was used to study the powder structure. The scanning angle was 10–80°, and the speed was 8°·min−1; Ndj-8s Digital Viscometer was used to measure the viscosity of the resin Shanghai (Yueping Scientific Instrument Co., Ltd.). About 100 mL of the evenly mixed resin was taken in a beaker, and the No. 2 rotor of the Ndj-8s digital viscometer was used to measure the resin viscosity, the speed was set at 12–60 rpm, and the temperature at 25°C. The viscosity of each sample was measured at five different points and averaged. Volume shrinkage: a pycnometer was used to measure the density ρ 1 of a uniformly mixed resin system at 25°C, then the resin system was put in the SLA 3D printer, the density ρ 2 of the resin system was tested after curing and molding, and the following formula was used to calculate volume shrinkage S V:

The resin glass transition temperature was measured using a DSC25 differential scanning calorimeter; the temperature rise and cooling rate were both 10°C·min−1, the test temperature range was from room temperature to 200°C; and the test was carried out in a nitrogen atmosphere with a nitrogen flowrate of 50 mL·min−1. According to GB/T 1040.2-2006 standard, a DL-D5000N rubber tensile test machine was used to test the spline, the tensile speed was 50 mm·min−1, and the determination temperature was room temperature.

3 Results and discussion

3.1 Characterization of modified nano-TiO2

Figure 5 shows the Fourier transform infrared (FT-IR) spectrum of nano-TiO2 before and after modification. Curves “a,” “b,” and “c” correspond to infrared spectrum curves of KH-570 and TiO2 before and after modification, respectively. At 2949.7 and 2841.7 cm−1 of the “a” curve are the stretching vibration absorption peaks of –CH3 and –CH2 in KH570, respectively. At 1086.2 and 823.0 cm−1 are the symmetric stretching vibration absorption peaks of Si–O–C, respectively. Compared with the “b” and “c” curves, there are obvious stretching vibration absorption peaks of –OH at 3426.5 and 3412.0 cm−1, which indicates that hydrophilic group –OH also exists on the surface of TiO2. After the surface organic modification of KH-570, the –OH on the surface of TiO2 particles is replaced by the organic group in the product silanol hydrolyzed by KH-570. The formation of silanol produces a part of –OH, which makes the position of –OH absorption peak shift red. Compared with “a” and “c” curves, the characteristic absorption peaks corresponding to KH-570 appeared at 1722.1 and 1638.2 cm−1 in “c” curve, which indicated that KH570 was successfully grafted onto the surface of TiO2. At the same time, the symmetric stretching vibration absorption peak of Si–O–C in KH-570 did not appear in “c” curve, which indicated that Si–O–C was replaced and formed a new structure with –OH on the surface of TiO2. The organic modification of nano-TiO2 was realized.

FT-IR diagram of nano-TiO2 before and after modification.

Figure 6 shows the X-ray diffraction (XRD) of nano-TiO2 before and after surface modification. The characteristic peaks of TiO2 are 25.281°, 37.8°, 48.049°, 53.89°, 55.06°, 68.76°, 70.30°, and 75.029°, respectively. Comparing the curves in the figure, it is found that the diffraction peak value and diffraction intensity of TiO2 before and after modification with KH-570 do not change, and with the gradual increase in KH-570 content, this result does not change, indicating that silane coupling agent KH-570 has little effect on the crystal form of TiO2.

XRD of nano-TiO2 before and after modification.

Figure 7 shows the static contact angle between the surface of modified nano-TiO2 and water. a–f is the static contact angle between the surface and water of nano-TiO2 modified by KH-570 with different mass fractions (0, 5, 10, 15, 20, and 25%). When the amount of silane coupling agent KH-570 is 0, the contact angle between the surface of the powder and water is 30° and the static contact angle between the surface of TiO2 and water increases with the increase of the content of KH-570, which achieves the transition from hydrophilic to superhydrophobic and can be better dispersed in the resin. When the mass fraction of KH-570 is 20%, it shows a good superhydrophobic property. When the mass ratio of KH-570 reaches 25%, the hydrophobic property of TiO2 decreases, which indicates that the content of the modifier should not be too much.

Static contact angle between modified nano-TiO2 surface and water: (a) 0% KH570, (b) 5% KH570, (c) 10% KH570, (d) 15% KH570, (e) 20% KH570, and (f) 25% KH570.

Figure 8 shows the scanning electron microscope observation of nano-TiO2 before and after modification. The morphology of nano-TiO2 modified by KH-570 with different mass fractions (0, 5, 10, 15, 20, and 25%) was studied. It can be seen from Figure 8a that the unmodified nano-TiO2 powder is irregular spherical particle stacking, and the agglomeration phenomenon is more serious. After being modified by KH570, the agglomeration phenomenon is improved, and with the increase in silane coupling agent KH570 content, the agglomeration gradually decreases.

Scanning electron microscopic photos of surface modified TiO2: (a) unmodified TiO2, (b) 5% KH570, (c) 10% KH570, (d) 15% KH570, (e) 20% KH570, and (f) 25% KH570.

3.2 Effect of nano-TiO2 content on curing shrinkage of resin

Figure 9 shows the effect of different content of TiO2 particles on the curing shrinkage of resin. It can be seen from the figure that with the increase of the content of nano-TiO2 particles, the curing shrinkage of the composite resin gradually decreases, and all keep below 6%. Before the curing of photosensitive resin, the main force between resins is the van der Waals force, and the intermolecular distance is van der Waals distance. After curing, the intermolecular distance changes from van der Waals distance to covalent bond distance, and the distance becomes shorter, so the resin shrinks. TiO2 is an inorganic non-shrinking component, which can be added to the resin to fill the gaps caused by the shrinkage of organic components.

Effect of different content of TiO2 particles on curing shrinkage of resin.

3.3 Effect of TiO2 content on resin viscosity

Figure 10 shows the effect of nano-TiO2 content on resin viscosity. It can be seen from the figure that the viscosity of the system increases with the increase in the content of TiO2 particles. The surface of the modified TiO2 contains organic groups. After mechanical blending with the resin, it is easy to form a cross-linking network between the molecular chains, which makes it difficult to slip between the molecular chains; thus, the viscosity of the system increases. On the other hand, because of the large specific surface area and high specific surface energy of nano-TiO2 particles, when the amount of nano-TiO2 particles is too high, it will interact with prepolymer and diluent monomer in the resin to form a physical cross-linking point, which hinders the movement of the molecular chain and increases the viscosity of the system.

Effect of TiO2 content on the viscosity of resin.

3.4 Effect of nano-TiO2 content on mechanical properties of molded parts

Figure 11 shows the change of mechanical properties of the resin-modified by adding different content of TiO2. It can be seen from the figure that the mechanical properties of the resin are enhanced by adding surface-treated TiO2. When the amount of TiO2 is 1.5 wt%, the comprehensive mechanical properties of the molded parts are the best. The tensile strength, impact strength, and elongation at break were increased by 51.1, 43.8, and 10.8, respectively. It can be seen from Figure 11d that with the increase in the amount of TiO2 in the system, the hardness has no obvious change, indicating that the mechanical properties of TiO2 itself will enhance the mechanical properties of the cured resin.

Effect of different TiO2 content on mechanical properties of molded parts: (a) tensile strength, (b) impact strength, (c) elongation at break, and (d) hardness.

3.5 Characterization of tensile fracture surface morphology of resin modified by nano-TiO2

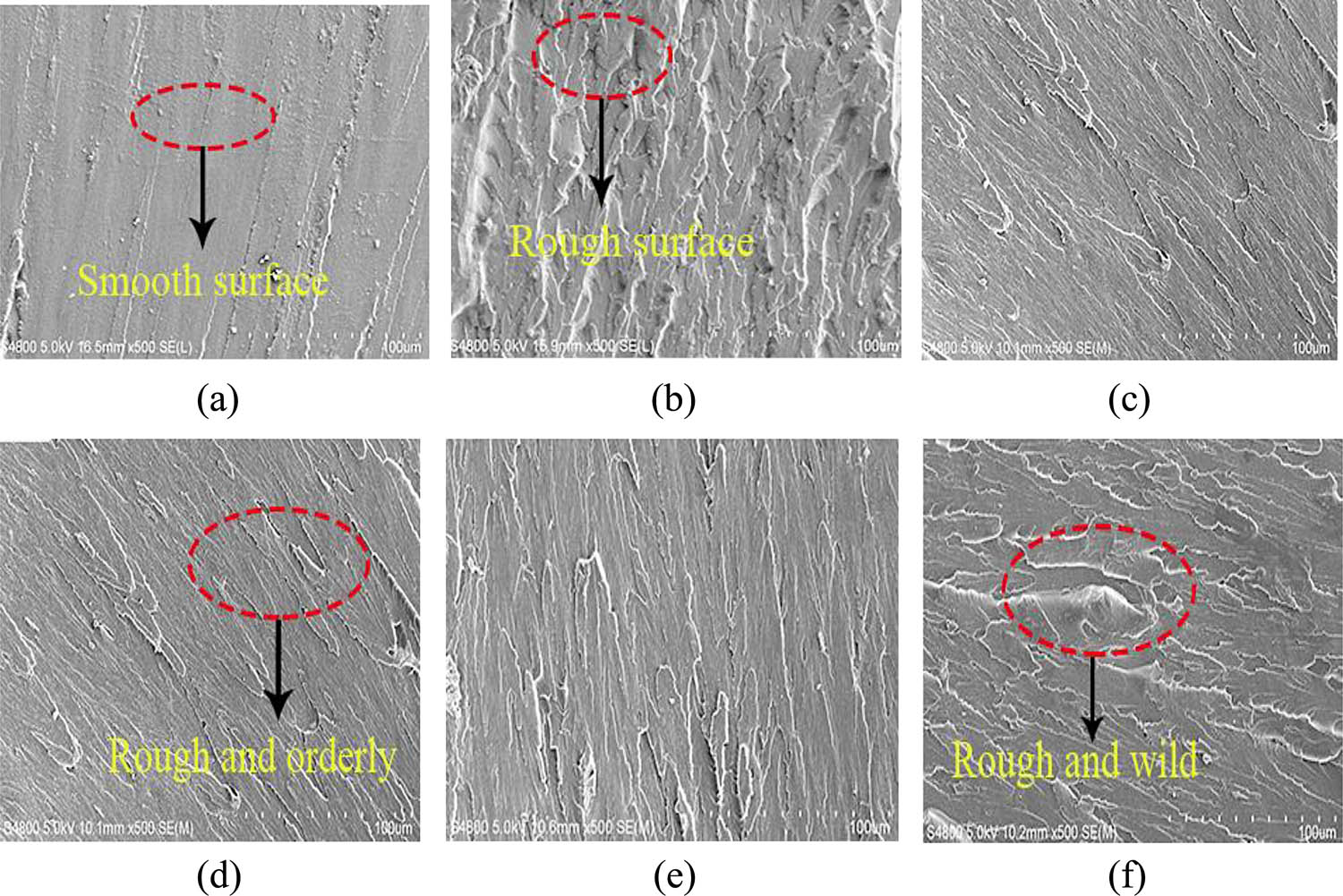

Figure 12 shows the micro-morphology of the tensile section of the modified resin. The fracture surface of pure epoxy resin is relatively flat and smooth, which is a typical characterization of brittle fracture. Compared with Figure 12a and b, after adding unmodified TiO2, the wrinkle and roughness of the cross-section increase, and an obvious delamination phenomenon appears, which is due to the poor dispersion of unmodified TiO2 particles in the resin. Compared with Figure 12a, c, and d, the cross-section becomes rough, the surface cracks and folds increase obviously, the crack arrangement direction is regular, the delamination of the cross-section decreases, and there is an obvious ductile depression area, which indicates that the addition of TiO2 blurs the interface of the printing layer and makes the cracks deflect. In Figure 12e and f, the cross-section of the resin has a large undulation, and the crack propagation direction is relatively concentrated because, with the increase of the content of TiO2 particles, the sedimentation and agglomeration phenomenon will occur, the viscosity of the system will gradually increase, and the transmittance of the printing time will be reduced.

Scanning electron microscopic of tensile section of the parts before and after modification: (a) blank resin, (b) unmodified TiO2, (c) 1 wt% TiO2, (d) 1.5 wt% TiO2, (e) 2 wt% TiO2, and (f) 2.5 wt% TiO2.

3.6 Effect of nano-TiO2 content on thermogravimetric behavior of resin

Figure 13 shows the TGA curve of EA and TiO2-modified photosensitive resin, corresponding to T 50%, T max, and residual mass data at 800°C. The decomposition of oligomers, photoinitiators, small molecular diluents, and modifiers that are not fully involved in the crosslinking UV curing reaction is mainly at room temperature −300°C, and the decomposition of EA segments is mainly at 300–500°C. Table 1 shows that the T max and carbon residue rate of the modified resin are relatively high when the TiO2 content is 1.5%, which is increased by 6.34°C and 25.3%, respectively. When the TiO2 content is 1.5%, the molded parts of the modified resin are higher than those of the unmodified resin at T 50% and T max.

Thermogravimetric curve of TiO2-modified resin: (a) TG and (b) DTG.

Thermogravimetric data of TiO2-modified resin

| Sample | T 50% (°C) | T max (°C) | Residue (%) |

|---|---|---|---|

| EA | 422 | 424 | 8 |

| EA/silicone | 424 | 430 | 8 |

| 0.5 wt% TiO2 | 420 | 428 | 11 |

| 1.0 wt% TiO2 | 424 | 432 | 10 |

| 1.5 wt% TiO2 | 425 | 432 | 10 |

| 2.0 wt% TiO2 | 425 | 432 | 10 |

| 2.5 wt% TiO2 | 422 | 430 | 9 |

3.7 Effect of nano-TiO2 content on glass transition temperature of resin

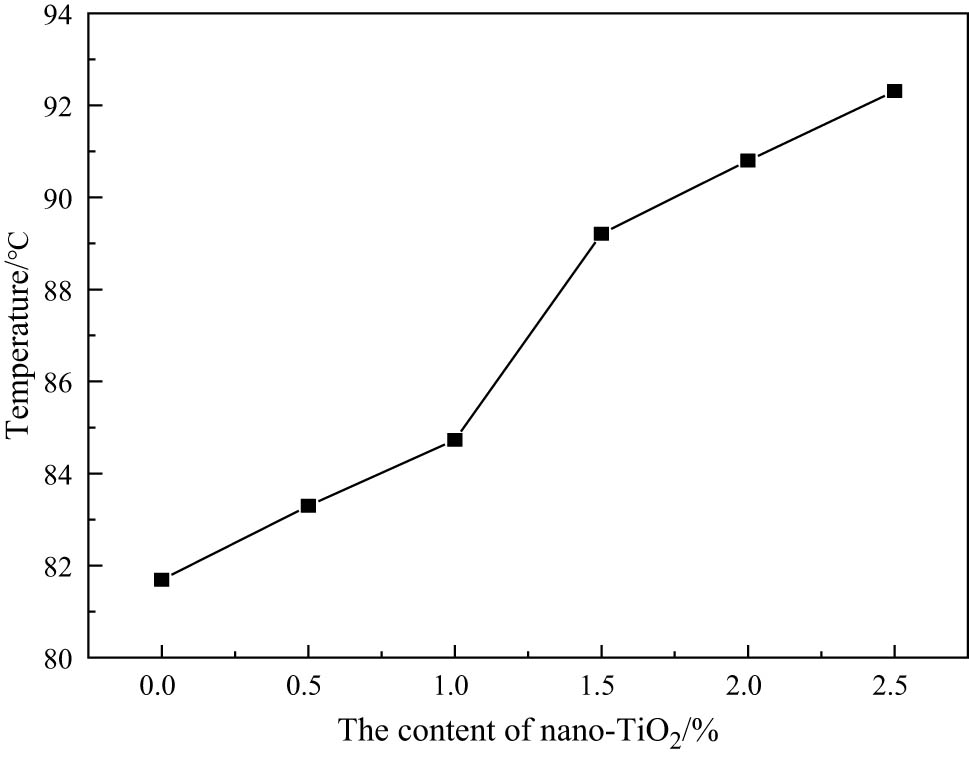

Figure 14 shows the influence curve of modified TiO2 on the glass transition temperature of the resin. It can be seen from the figure that with the increase of TiO2 content, the glass transition temperature of the molded parts increases after adding TiO2 particles. When the content of epoxy resin is 1.5%, the glass transition temperature is 92.31°C, which is 14.08°C higher than that of unmodified epoxy resin.

Glass transition temperature curve of TiO2-modified resin.

4 Conclusions

FT-IR and XRD analyses showed that KH570 was successfully grafted onto the surface of TiO2, and the crystal form of TiO2 did not change before and after modification. The hydrophobicity of the modified nano-TiO2 is obviously enhanced, and the agglomeration phenomenon of the particles is obviously weakened, so the nano-TiO2 has better dispersion performance. When the content of silane coupling agent is 20%, the agglomeration of TiO2 particles is less, the dispersion is better, and the contact angle is the largest. At this content, it has good two-phase compatibility with epoxy resin, improves its dispersion in the resin, and avoids the degradation of mechanical properties of cured materials due to phase separation.

The mechanical test shows that when the mass fraction of TiO2 is 1.5%, the mechanical properties of the molded parts are better. The tensile strength, impact strength, and elongation at break are increased by 51.1%, 43.8%, and 10.8%, respectively, and the hardness value is maintained at 81-83HD. It can be seen from the tensile cross-section morphology of the composite that when the mass fraction of TiO2 is within 1.5%, the cracks of the cross-section are more regular, and there are obvious ductile concave areas, which indicates that adding the appropriate amount of TiO2 can improve the fracture brittleness of the resin, ensure the printing accuracy, and play a certain role in toughening.

The analysis of thermal stability and glass transition temperature showed that the addition of modified TiO2 could improve the heat resistance of the resin. When the content of TiO2 is 1.5%, the T 50%, T max, and carbon residue of pure epoxy resin are increased by 3.44%, 6.34%, and 25.3%, respectively. The glass transition temperature reaches the maximum when the content of TiO2 is 2.5%, which is 14.08.

-

Funding information: Authors state no funding involved.

-

Author contributions: Yingying Liu: writing – original draft, writing – review and editing, methodology, formal analysis; Jin Chen: writing – original draft, visualization; Lei Ning: resources, formal analysis; Jianke Sun: project administration; Lu Liu: supervision, validation; Kun Zhao: software.

-

Conflict of interest: Authors state no conflict of interest.

References

(1) Ma XL. Research on application of SLA technology in the 3D printing technology. Appl Mech Mater. 2013;401–403:938–41.10.4028/www.scientific.net/AMM.401-403.938Search in Google Scholar

(2) Wang GC, Yuan Y, Liu DX. Application and progress of SLA rapid prototyping technology. Aeronautical Manuf Technol. 2011;06:26–9.Search in Google Scholar

(3) Mubarak S, Dhamodharan D, Divakaran N, Kale MB, Senthil T, Wu L, et al. Enhanced mechanical and thermal properties of stereolithography 3D printed structures by the effffects of incorporated controllably annealed anatase TiO2 nanoparticles. Nanomaterials. 2020;10:79.10.3390/nano10010079Search in Google Scholar

(4) Ding AX, Wang JK, Ni AQ, Sun LL, Li SX. A review of analytical prediction of cure-induced distortions in thermoset composites. Acta Materiae Compositae Sin. 2018;35:1361–76.Search in Google Scholar

(5) Ma SY, Guo Q, Zhang D. Research progress on nano-Al2O3 reinforced metal matrix composites. Mater China. 2019;06:577–87.Search in Google Scholar

(6) Sun YJ, Xun DX, Liu M. Research progress on preparing methods and technics of nano-aluma powder. Mater China. 2017;06:455–60.Search in Google Scholar

(7) Zhang K, Shen M-M, Wu K, Liu H-F, Zhang Y. Comparative study on flame retardancy and thermal degradation of phosphorus- and silicon-containing epoxy resin composites. J Polym Res. 2011;18:6–15.10.1007/s10965-011-9615-5Search in Google Scholar

(8) Garoushi S, Vallittu PK, Watts DC, Lassila L. Effect of nanofiller fractions and temperature on polymerization shrinkage on glass fiber reinforced filling material. Dental Mater. 2007;24:5–14.10.1016/j.dental.2007.06.020Search in Google Scholar

(9) Decker C, Nguyen Thi Viet T, Decker D, Weber-Koehl E. UV-radiation curing of acrylate/epoxide systems. Polymer. 2001;42:13–23.10.1016/S0032-3861(01)00065-9Search in Google Scholar

(10) Sumiyoshi T, Schnabel W, Henne A. Photolysis of acylphosphine oxides II: The influence of methyl substitution in benzoyldiphenylphosphine oxides. J Photochemistry. 1986;32:119–29.10.1016/0047-2670(86)85012-2Search in Google Scholar

(11) Mubarak S, Dhamodharan D, Kale MB, Divakaran N, Senthil T, Sathiyanathan P, et al. A novel approach to enhance mechanical and thermal properties of SLA 3D printed structure by incorporation of metal–metal oxide nanoparticles. Nanomaterials. 2020;10:217.10.3390/nano10020217Search in Google Scholar PubMed PubMed Central

(12) Song J, Guo Q, Ouyang Q, Su Y, Zhang J, Lavernia EJ. Influence of interfaces on the mechanical behavior of SiC particulate-reinforced Al–Zn–Mg–Cu composites. Mater Sci & Eng A. 2015;644:644–9.10.1016/j.msea.2015.07.050Search in Google Scholar

(13) Zhang L, Feng J, Li Z, Liu H. Interface structure and strength of brazed joints between TiC ceramic and iron. Sci Technol Weld Join. 2004;9:280–2.10.1179/136217104225012229Search in Google Scholar

(14) Yao Y, Chen L. Processing of B_4C Particulate-reinforced Magnesium-matrix composites by metal-assisted melt infiltration technique. J Mater Sci & Technol. 2014;07:661–5.10.1016/j.jmst.2014.06.005Search in Google Scholar

(15) Liu P, Gu A, Liang G, Guan Q, Yuan L. Preparation and properties of novel high performance UV-curable epoxy acrylate/hyperbranched polysiloxane coatings. Prog Org Coat. 2012;74:142–50.10.1016/j.porgcoat.2011.11.026Search in Google Scholar

(16) Rosso P, Ye L, Friedrich K, Sprenger S. A toughened epoxy resin by silica nanoparticle reinforcement. J Appl Polym Sci. 2006;101:2–3.10.1002/app.24543Search in Google Scholar

(17) Yu Z, Cui A, Zhao P, Wei H, Hu F. Preparation and properties studies of UV-curable silicone modified epoxy resin composite system. J Appl Biomater Funct Mater. 2018;16:170–6.10.1177/2280800017753053Search in Google Scholar PubMed

(18) Jin F‐L, Ma C‐L, Guo B‐T, Park S‐J. Effect of surface modification on thermal stability, flexural properties, and impact strength of epoxy/graphene nanocomposites. Bull Korean Chem Soc. 2019;40:991–6.10.1002/bkcs.11858Search in Google Scholar

(19) Shen Z, Xia Z, Zhang Y. Characterization and properties of epoxy resin (E-20) modified with silicone intermediate RSN-6018. Prog Org Coat. 2018;114:114–21.10.1016/j.porgcoat.2017.10.014Search in Google Scholar

(20) He L, Yongsheng L, Yansong L, Qingfeng Z, Yue G, Wenyan D, et al. Influence of sintering temperature and CVI time on mechanical properties of 3D-printed alumina ceramics. Mater Lett. 2021;285:129096.10.1016/j.matlet.2020.129096Search in Google Scholar

(21) Cardoso PHM, Oliveira MFL, Oliveira MG, da Silva MTRM. 3D printed parts of polylactic acid reinforced with carbon black and alumina nanofillers for tribological applications. Macromol Symposia. 2020;394:1–13.10.1002/masy.202000155Search in Google Scholar

(22) Akimov AS, Akimov AS, Sviridenko NN, Akimov AS. Synthesis and application of cobalt and polyoxomolybdate-containing alumina systems. J Physics: Conf Ser. 2020;1611:1–5.10.1088/1742-6596/1611/1/012027Search in Google Scholar

(23) Kadhim WA, Khalaf AL, Azeez RA, Hasany SF. Effect of doping alumina by nano Mn on the sensing applications. Mater Sci Forum. 2020;6127:6127–35.10.4028/www.scientific.net/MSF.1002.273Search in Google Scholar

(24) do Nascimento Silva M, Kassab E, Ginoble Pandoli O, Leite de Oliveira J, Pereira Quintela J, Bott IS. Corrosion behaviour of an epoxy paint reinforced with carbon nanoparticles. Corros Eng Sci Technol. 2020;55:8–13.10.1080/1478422X.2020.1767322Search in Google Scholar

(25) Pang WQ, Fan XZ, Zhang JQ. Research progress on agglomeration of nanoparticle in its preparation. J Chem Ind & Eng. 2008;03:19–23.Search in Google Scholar

(26) Solangi KH, Kazi SN, Luhur MR, Teng KH. A comprehensive review of thermo-physical properties and convective heat transfer to nanofluids. Energy. 2015;89:89–110.10.1016/j.energy.2015.06.105Search in Google Scholar

(27) Liu K, Shi Y, Li C, Wei Q. Indirect selective laser sintering of epoxy resin-Al2O3 ceramic powders combined with cold isostatic pressing. Ceram Int. 2014;40:5–12.10.1016/j.ceramint.2013.12.043Search in Google Scholar

(28) Liu K. Investigation on the hybrid technology of laser sintering/cold isostatic pressing about ceramic power. Doctoral Dissertation. Huazhong University of Science and Technology; 2014.Search in Google Scholar

(29) Ning HF, Yan XZ, Zhu Y. Research on viscosity and dispersity of aqueous ceramic suspension for stereolithography. Bull Chin Ceram Soc. 2017;11:3944–9.Search in Google Scholar

© 2022 Yingying Liu et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes

Articles in the same Issue

- Research Articles

- The effect of isothermal crystallization on mechanical properties of poly(ethylene 2,5-furandicarboxylate)

- The effect of different structural designs on impact resistance to carbon fiber foam sandwich structures

- Hyper-crosslinked polymers with controlled multiscale porosity for effective removal of benzene from cigarette smoke

- The HDPE composites reinforced with waste hybrid PET/cotton fibers modified with the synthesized modifier

- Effect of polyurethane/polyvinyl alcohol coating on mechanical properties of polyester harness cord

- Fabrication of flexible conductive silk fibroin/polythiophene membrane and its properties

- Development, characterization, and in vitro evaluation of adhesive fibrous mat for mucosal propranolol delivery

- Fused deposition modeling of polypropylene-aluminium silicate dihydrate microcomposites

- Preparation of highly water-resistant wood adhesives using ECH as a crosslinking agent

- Chitosan-based antioxidant films incorporated with root extract of Aralia continentalis Kitagawa for active food packaging applications

- Molecular dynamics simulation of nonisothermal crystallization of a single polyethylene chain and short polyethylene chains based on OPLS force field

- Synthesis and properties of polyurethane acrylate oligomer based on polycaprolactone diol

- Preparation and electroactuation of water-based polyurethane-based polyaniline conductive composites

- Rapeseed oil gallate-amide-urethane coating material: Synthesis and evaluation of coating properties

- Synthesis and properties of tetrazole-containing polyelectrolytes based on chitosan, starch, and arabinogalactan

- Preparation and properties of natural rubber composite with CoFe2O4-immobilized biomass carbon

- A lightweight polyurethane-carbon microsphere composite foam for electromagnetic shielding

- Effects of chitosan and Tween 80 addition on the properties of nanofiber mat through the electrospinning

- Effects of grafting and long-chain branching structures on rheological behavior, crystallization properties, foaming performance, and mechanical properties of polyamide 6

- Study on the interfacial interaction between ammonium perchlorate and hydroxyl-terminated polybutadiene in solid propellants by molecular dynamics simulation

- Study on the self-assembly of aromatic antimicrobial peptides based on different PAF26 peptide sequences

- Effects of high polyamic acid content and curing process on properties of epoxy resins

- Experiment and analysis of mechanical properties of carbon fiber composite laminates under impact compression

- A machine learning investigation of low-density polylactide batch foams

- A comparison study of hyaluronic acid hydrogel exquisite micropatterns with photolithography and light-cured inkjet printing methods

- Multifunctional nanoparticles for targeted delivery of apoptin plasmid in cancer treatment

- Thermal stability, mechanical, and optical properties of novel RTV silicone rubbers using octa(dimethylethoxysiloxy)-POSS as a cross-linker

- Preparation and applications of hydrophilic quaternary ammonium salt type polymeric antistatic agents

- Coefficient of thermal expansion and mechanical properties of modified fiber-reinforced boron phenolic composites

- Synergistic effects of PEG middle-blocks and talcum on crystallizability and thermomechanical properties of flexible PLLA-b-PEG-b-PLLA bioplastic

- A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater

- Simultaneously enhance the fire safety and mechanical properties of PLA by incorporating a cyclophosphazene-based flame retardant

- Fabrication of two multifunctional phosphorus–nitrogen flame retardants toward improving the fire safety of epoxy resin

- The role of natural rubber endogenous proteins in promoting the formation of vulcanization networks

- The impact of viscoelastic nanofluids on the oil droplet remobilization in porous media: An experimental approach

- A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption

- Fabrication of functional polyester fibers by sputter deposition with stainless steel

- Facile synthesis of core–shell structured magnetic Fe3O4@SiO2@Au molecularly imprinted polymers for high effective extraction and determination of 4-methylmethcathinone in human urine samples

- Interfacial structure and properties of isotactic polybutene-1/polyethylene blends

- Toward long-live ceramic on ceramic hip joints: In vitro investigation of squeaking of coated hip joint with layer-by-layer reinforced PVA coatings

- Effect of post-compaction heating on characteristics of microcrystalline cellulose compacts

- Polyurethane-based retanning agents with antimicrobial properties

- Preparation of polyamide 12 powder for additive manufacturing applications via thermally induced phase separation

- Polyvinyl alcohol/gum Arabic hydrogel preparation and cytotoxicity for wound healing improvement

- Synthesis and properties of PI composite films using carbon quantum dots as fillers

- Effect of phenyltrimethoxysilane coupling agent (A153) on simultaneously improving mechanical, electrical, and processing properties of ultra-high-filled polypropylene composites

- High-temperature behavior of silicone rubber composite with boron oxide/calcium silicate

- Lipid nanodiscs of poly(styrene-alt-maleic acid) to enhance plant antioxidant extraction

- Study on composting and seawater degradation properties of diethylene glycol-modified poly(butylene succinate) copolyesters

- A ternary hybrid nucleating agent for isotropic polypropylene: Preparation, characterization, and application

- Facile synthesis of a triazine-based porous organic polymer containing thiophene units for effective loading and releasing of temozolomide

- Preparation and performance of retention and drainage aid made of cationic spherical polyelectrolyte brushes

- Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing

- Mechanical properties and thermal analysis of graphene nanoplatelets reinforced polyimine composites

- Preparation and in vitro biocompatibility of PBAT and chitosan composites for novel biodegradable cardiac occluders

- Fabrication of biodegradable nanofibers via melt extrusion of immiscible blends

- Epoxy/melamine polyphosphate modified silicon carbide composites: Thermal conductivity and flame retardancy analyses

- Effect of dispersibility of graphene nanoplatelets on the properties of natural rubber latex composites using sodium dodecyl sulfate

- Preparation of PEEK-NH2/graphene network structured nanocomposites with high electrical conductivity

- Preparation and evaluation of high-performance modified alkyd resins based on 1,3,5-tris-(2-hydroxyethyl)cyanuric acid and study of their anticorrosive properties for surface coating applications

- A novel defect generation model based on two-stage GAN

- Thermally conductive h-BN/EHTPB/epoxy composites with enhanced toughness for on-board traction transformers

- Conformations and dynamic behaviors of confined wormlike chains in a pressure-driven flow

- Mechanical properties of epoxy resin toughened with cornstarch

- Optoelectronic investigation and spectroscopic characteristics of polyamide-66 polymer

- Novel bridged polysilsesquioxane aerogels with great mechanical properties and hydrophobicity

- Zeolitic imidazolate frameworks dispersed in waterborne epoxy resin to improve the anticorrosion performance of the coatings

- Fabrication of silver ions aramid fibers and polyethylene composites with excellent antibacterial and mechanical properties

- Thermal stability and optical properties of radiation-induced grafting of methyl methacrylate onto low-density polyethylene in a solvent system containing pyridine

- Preparation and permeation recognition mechanism of Cr(vi) ion-imprinted composite membranes

- Oxidized hyaluronic acid/adipic acid dihydrazide hydrogel as cell microcarriers for tissue regeneration applications

- Study of the phase-transition behavior of (AB)3 type star polystyrene-block-poly(n-butylacrylate) copolymers by the combination of rheology and SAXS

- A new insight into the reaction mechanism in preparation of poly(phenylene sulfide)

- Modified kaolin hydrogel for Cu2+ adsorption

- Thyme/garlic essential oils loaded chitosan–alginate nanocomposite: Characterization and antibacterial activities

- Thermal and mechanical properties of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/calcium carbonate composite with single continuous morphology

- Review Articles

- The use of chitosan as a skin-regeneration agent in burns injuries: A review

- State of the art of geopolymers: A review

- Mechanical, thermal, and tribological characterization of bio-polymeric composites: A comprehensive review

- The influence of ionic liquid pretreatment on the physicomechanical properties of polymer biocomposites: A mini-review

- Influence of filler material on properties of fiber-reinforced polymer composites: A review

- Rapid Communications

- Pressure-induced flow processing behind the superior mechanical properties and heat-resistance performance of poly(butylene succinate)

- RAFT polymerization-induced self-assembly of semifluorinated liquid-crystalline block copolymers

- RAFT polymerization-induced self-assembly of poly(ionic liquids) in ethanol

- Topical Issue: Recent advances in smart polymers and their composites: Fundamentals and applications (Guest Editors: Shaohua Jiang and Chunxin Ma)

- Fabrication of PANI-modified PVDF nanofibrous yarn for pH sensor

- Shape memory polymer/graphene nanocomposites: State-of-the-art

- Recent advances in dynamic covalent bond-based shape memory polymers

- Construction of esterase-responsive hyperbranched polyprodrug micelles and their antitumor activity in vitro

- Regenerable bacterial killing–releasing ultrathin smart hydrogel surfaces modified with zwitterionic polymer brushes