Abstract

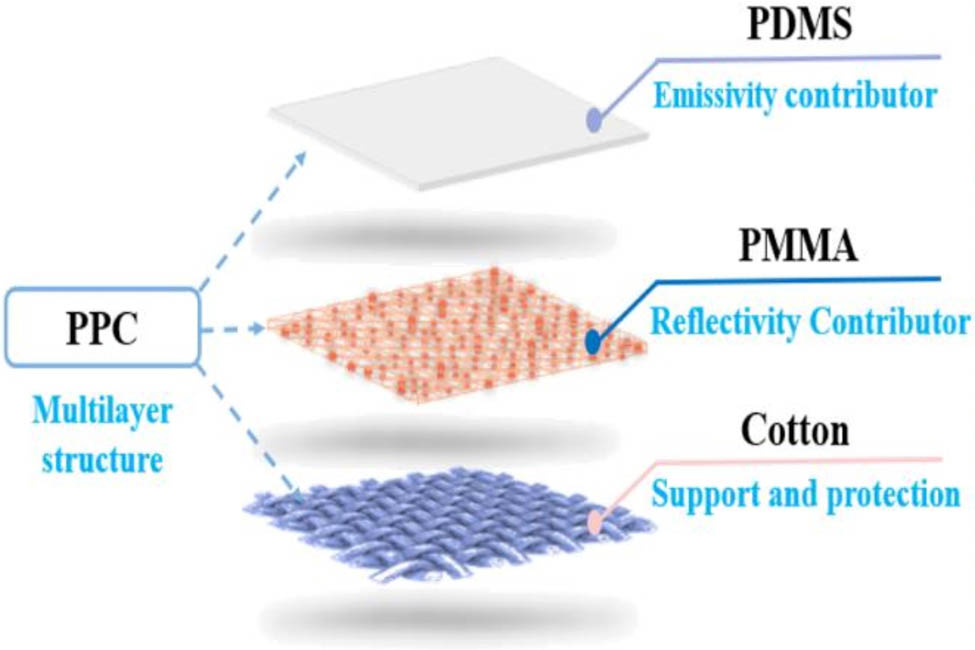

To address the excessive energy consumption of building cooling, the coverage of passive radiation cooling materials on the surface of buildings can effectively save the global refrigeration power resources and reduce the greenhouse gas emissions generated by refrigeration equipment. In this work, passive radiation hydrophobic fabric cooling materials with three functional layers (i.e., top polydimethylsiloxane [PDMS] film layer for solar emissivity, middle polymethylmethacrylate [PMMA] film layer for solar reflectivity, and bottom cotton fabric layer for support) were prepared. This passive radiation cooling material with optimized thickness of PDMS (1.5 mm) and PMMA (3.5 mm) have a rich uneven filament structure and ideal internal bonding structure, which enabled 94% of solar reflectivity and 93.4% of atmospheric window emissivity (8–14 μm). Top layer of the composite film was hydrophobic (a contact angle of 117°) and allowed the rolling of water droplets to remove most of the surface dust. Moreover, these composites presented an excellent cooling of 7.7–15.0°C in the outdoor real cooling test. For medium-sized houses, the roof covered with composite was expected to reduce the emission CO2 by 17% every year. The findings of this work indicated that the prepared three-layered radiation cooling materials have great potentials in thermal energy storage buildings.

1 Introduction

As the temperature of buildings increases and is higher than the upper critical temperature of the thermal neutral zone, the human body’s oxygen consumption increases, metabolism is strengthened, heat production increases, and body temperature rises. However, excessive body temperature is very harmful to human body (1,2). Therefore, it is particularly important to implement refrigeration measures for buildings in high temperature environment. Common building cooling measures are composed of active and passive building cooling measures according to whether power resources are needed. Although active building refrigeration measures are efficient, they consume a lot of power resources. Passive refrigeration is a design method or technical method that does not consume power resources (3,4). The traditional building ventilation technology generally needs to be designed before construction, and the ventilation system of the formed building needs to be reconstructed, which has a large amount of work and is inconvenient. Green wall technology mainly refers to covering the building surface with green plants to achieve cooling effect (5–7). Although it can cool down, the maintenance and cleaning of green plants also consume a lot of manpower and material resources. The new evaporation technology is no longer simply spraying water mist directly, but choosing materials with strong water storage capacity. This can not only effectively save water resources, but also greatly extend the cooling time. The radiation refrigeration technology does not use any other resources, and can be used continuously for a long time. The radiation material itself can directly radiate part of the heat of sunlight from the atmospheric window into the universe, so that the total amount of sunlight heat absorbed by the earth is reduced (8). Therefore, the application of evaporation refrigeration technology and radiation refrigeration technology, which are relatively unrestricted, energy saving, environmentally friendly, and low cost, has aroused great concern.

In recent years, passive radiation cooling is an excellent choice to attract great attention at home and abroad. With the deepening of scholars’ research, the properties of passive daytime radiation cooling materials reported in recent years have been greatly improved, mainly because the material structure has been improved or some nanoparticles have been added (9–11). At present, daytime radiation cooling materials can be roughly divided into metamaterials, polymer films, coatings, fabrics and blocks (12,13). Polymer films presented attractive radiation cooling properties due to their stable structure and hence, they have attracted the attention of many researchers. For example, a kind of polyethylene oxide nanofiber-based film was designed by layers through the extensible electrostatic spinning process, exhibited 96.3% of reflectivity in the wavelength range from 0.3 to 2.5 μm and 78% of selective emissivity in the wavelength range from 8 to 14 μm (14). A polyvinylidene fluoride/tetraethoxysilane (PVDF/TEOS) film with numerous nanopores was prepared by electrospinning technique. The surface of electrospun PVDF/TEOS film was distributed with SiO2 microspheres uniformly (15). The film could achieve an average infrared emissivity of more than 96% and a reflectivity of about 97%. The average radiation cooling power of PVDF/TEOS film was 62 W·m−2 with 7°C of cooling effect. A kind of polyethylene aerogel was reported, which has 92.2% of solar reflectance and 93.4% of average infrared emissivity (16). This aerogel had a good heat insulation effect, achieving 13°C of cooling effect. However, the tests of the above materials were carried out in low humidity environments. In high humidity environments, there is more water in the air, which would decrease the transmittance of the atmospheric window significantly, exerting a distinct influence to the cooling performance. For the tropical high temperature areas, many materials are not suitable. Therefore, a kind of polymethylmethacrylate (PMMA) film with hydrophobic surface and modified hierarchical structure was reported. The solar reflectivity of this film was 95% and the infrared emissivity was 98% (17). Even in the case of relative humidity of ∼64%, it could realize the environmental cooling at ∼5.5°C. In addition, the performance of radiation cooling materials would decrease due to their vulnerability to pollution including the coverage of solid dust and erosion of microorganisms (18). Given that, an ethylene–propylene–diene copolymer composite film was fabricated with a super-hydrophobic and self-cleaning porous structure. Numerous silica microspheres were embedded in film pores, which could achieve the optical properties of 96% solar reflectivity and 95% average emissivity (19). Under the direct sunlight, Wang et al. loaded polytetrafluoroethylene on cellulose-based paper materials by the jet spinning technology to obtain radiation cooling materials with super-hydrophobic properties (20). Specifically, the as-prepared radiation cooling material could achieve the cooling effect of 5°C for 834 W·m−2 of solar irradiance. Its radiation cooling power was 104 W·m−2 for 671 W·m−2 of solar irradiance. In addition, if the paper was dyed, it could meet the needs of color radiation cooler.

Since the passive radiation cooling effect is highly dependent on the structure of radiation cooling materials when they are applied to building refrigeration, how to design the material structure skillfully to enable high reflectivity in visible-near infrared wavelength and excellent emissivity (8–14 μm of atmospheric window) is still the focus of research (21–25). For the absorption of visible-near infrared sunlight and emissivity (8–14 μm of atmospheric window), the existence thermal emitters including Si−O−Si, −CF3 C−O−C, and C−O−H vibration absorption bonds played an essential role from the view of material composition (26–28). Thus, performances of passive radiation cooling materials including weather resistance, structural stability, waterproof, and self-cleaning should be undoubtedly taken into consideration. For this reason, polydimethylsiloxane (PDMS) has been applied to prepare radiation cooling materials. First of all, PDMS is a polymer mainly formed by Si−O−Si bond arrangement, which has good emissivity in theory, and it has also been confirmed by previous literature reports (29–31). Second, PDMS membrane is hydrophobic, which means that it is expected to achieve radiation cooling and self-cleaning characteristics in high temperature and high humidity environment. However, PDMS film is transparent and has low reflectivity. If a layer of high reflectivity material is added at its bottom, its cooling ability will be greatly improved. Spray-assisted prepared PMMA film might address this issue (32,33). On the one hand, the high whiteness of PMMA exhibits a high reflectivity in theory. On the other hand, it contains C−O−C bond, which is helpful to improve the emissivity of the whole composite. However, spray-assisted prepared PMMA is fragile and is difficult to transport. Hence, a supporting material is needed to protect and support it. We choose cotton fabric as the supporting material. On the one hand, cotton fabric is inexpensive and easy to obtain. On the other hand, cotton fabric is a flexible material, which can be replaced by other more suitable textile materials according to the needs in practical application.

In this work, passive radiation cooling composite films with three-layered structure were prepared. Specifically, composite films were constructed with top PDMS layer, middle PMMA layer, and bottom cotton fabric layer. The thicknesses of PDMS layer and PMMA layer, as well as the hierarchical order, were optimized. The internal structure and surface hydrophobicity were evaluated. Through the indoor cooling simulation test, outdoor cooling real test, and infrared camera shooting, the cooling abilities of hydrophobic multilayered fabrics were quantitatively determined. The annual power saving of buildings as well as the emission decrease of CO2 using these three-layered composite films was estimated.

2 Materials and methods

2.1 Materials

PDMS, PMMA, curing agent of PDMS, and ethyl acetate were purchased from Aladdin Chemistry Co. Ltd (Shanghai, China). Woven cotton fabric (gram weight 112.0 g·m−2) was obtained from the local cotton factory. All chemicals were of analytical grade and used as received without further purification.

2.2 Fabrication of three-layered passive radiation cooling materials

The preparation of three-layered passive radiation cooling materials included two steps (Figure 1). First, an ethyl acetate solution with 10% solute mass fraction of PMMA was prepared. A spray gun with 0.2 mm of diameter and 10 cm of height was applied to spray PMMA solution onto a cotton fabric. Second, a solution of PDMS and its curing agent (with mass ratio of 10:1) was scraped on a glass plate and heated at 90°C at a duration of 3 h. Then the formed PDMS film was covered onto the PMMA film to fabricate a three-layered passive radiation cooling composite materials. Given the specific layered structure of multilayered passive radiation cooling fabrics, i.e., PDMS as the top layer, PMMA as the middle layer, and cotton fabric as the bottom layer, the as-prepared multilayered passive radiation fabrics were termed as PPC materials. The thicknesses of PMMA film and PDMS film were adjusted to optimize the passive radiation cooling property of PPC materials.

Structural diagram of three-layered PPC materials.

2.3 Characterization

Scanning electron microscope (SEM; HITACHI, TM1000) was used to characterize the morphology of PPC materials. To enhance its conductivity, gold was sprayed under vacuum for 20 s with a current of 10–15 A. The magnification during testing was regulated from 30 to 5,000 times. The surface hydrophobicity of PPC materials was tested by the contact angle analyzer (DSA30, Kruss, Germany), and the hydrophobicity of PPC material was reflected by the contact angle of surface water. The water drop volume was 5 μL, and the sample was measured at three different positions. The spectral reflectance (ρ(λ)) was recorded by a UV-Vis-NIR spectrophotometer (UV-3600 PLUS, Shimadzu, Japan). Functional groups on PPC surface were analyzed using an ATR-FTIR measurement (Spectrum Two, PerkinElmer, USA).

2.4 Passive radiation cooling performance evaluation

The spectral absorption (α(λ)) and emissivity (ε(λ)) are equal for any object in the thermal equilibrium according to the Kirchhoff’s law. The calculation formula for ε(λ) could be expressed as ε(λ) = 1 – ρ(λ) – τ(λ), where τ(λ) is the transmittance. Fourier infrared spectrometer with an integrating sphere (iS10, Thermo Fisher Scientific, USA) was applied to determine the reflectivity. The emissivity of samples was calculated through the above formula. In the self-cleaning performance experiment, crushed soil was used as the pollution source, which was randomly sprinkled on the surface of PPC materials. The dropper was used to drop water onto the sample to simulate the real situation of rain or accumulated dew, and the removal status of pollutants before and after the application of PPC materials was compared. In the outdoor cooling test experiment, a tin foil covered box was applied to reduce or eliminate the outside impact. A glass plate (5 cm × 5 cm) was applied to hold PPC materials. The temperature of PPC materials was monitored via an attached probe. For the real evaluation of PPC materials, the outdoor test was conducted in Yibin City (Sichuan province of China) at 10:00 on June 12 (36°C of air temperature, 44% of humidity, and 2 m·s−1 of wind). The temperatures of both control and sample groups were recorded every minute.

Moreover, the electrical energy savings were calculated as the following equation, i.e.,

where the irradiated time was 6 h, the roof heat transfer coefficient was 0.64 W·m−2·K−1, and the irradiated surface area of house was 98 m2. Supposed summer days were 100 days every year, the electricity fee was $0.15 (kW·h)−1, and the coefficient of performance of an air conditioner was 3. CO2 emission per kW·h was 0.563 kg.

3 Results and discussion

3.1 Morphology and microstructure of PPC materials

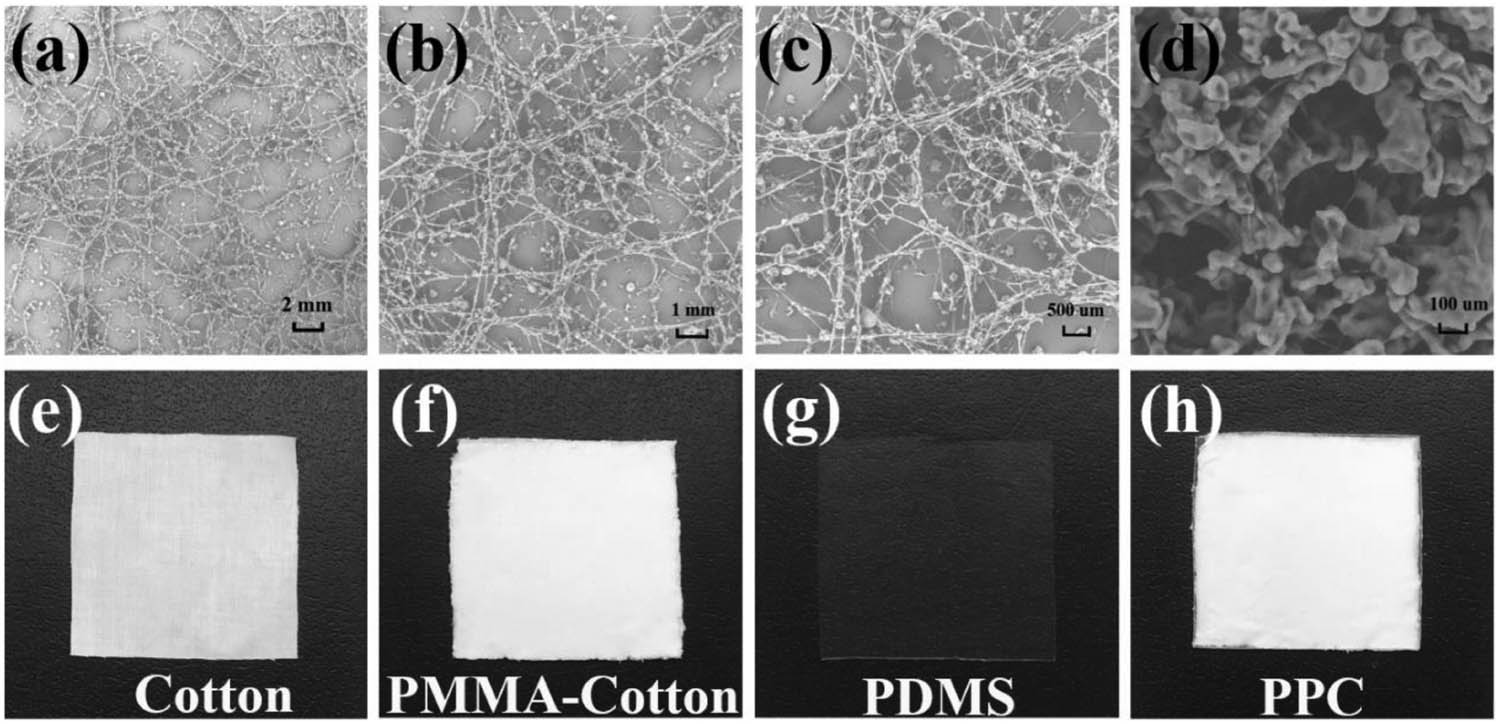

White is the most popular color for today’s industrial products. Nature offers a variety of white surfaces that are built without pigment particles. Such natural white colors are caused by scattering layers which consist of highly disordered nanostructures. The emissivity of materials is related to the functional groups of their surfaces, while the reflectivity of materials is closely dependent on the microstructure of materials. In this work, the specific microstructure (Figure 2a–d) enabled the white color of sprayed PMMA film (Figure 2f). After the PMMA solution was spun with a pen, the ethyl acetate solvent which had certain viscidity and water absorption characteristic would evaporate relatively slowly, allowing the formation of disordered filaments. These filaments displayed an unsmooth surface after being enlarged. Compared with smooth filaments, irregular filaments were more available for the refection of sunlight because of their larger specific surface areas. The physical drawings of PPC materials at different stages are also presented in Figure 2e–h. First, a clean cotton fabric was placed, and then PMMA solution was sprayed on the cotton fabric to form PMMA–cotton composite. The prepared pure PDMS film was covered on PMMA–cotton composite to form the target radiation PPC material. In the practical application process, it is necessary to fix around the material to ensure a long-term usage.

SEM images of PMMA film with four magnifications including ×50 (a), ×100 (b), ×200 (c), and ×1,000 (d). Photographs of samples at different preparing stages including cotton (e), PMMA–cotton (f), PDMS (g), and PCC (h).

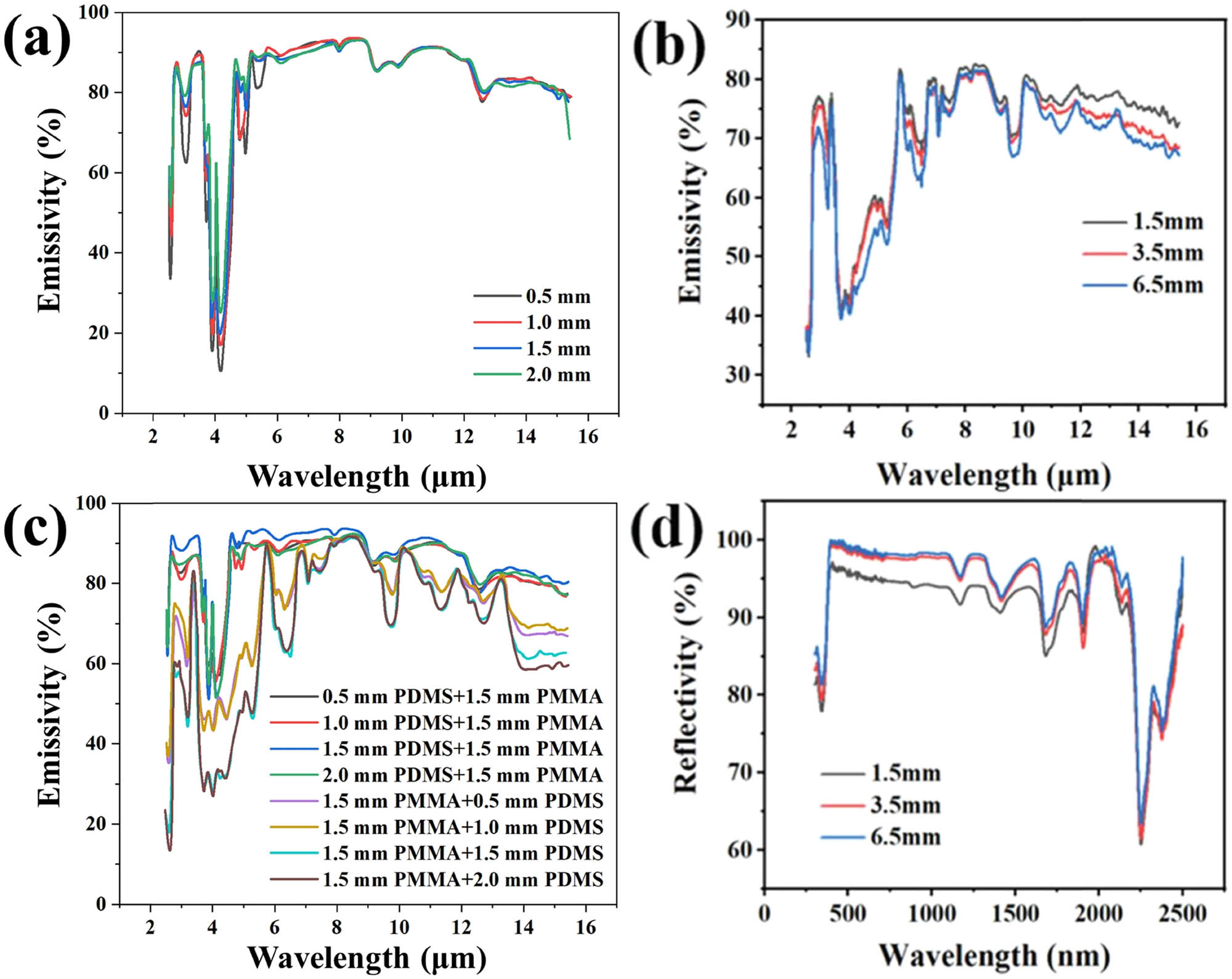

3.2 Structural optimization of PCC materials as a function of film thickness

Since the thickness of radiation cooling materials presented a great influence on the radiation cooling performance, the emissivity of PDMS film as a function of thickness is shown in Figure 3a and b. The influence of PDMS thickness on emissivity was slight in the thickness range of 0.5–2 mm. As shown in Figure 3a, the emissivity values (8–14 µm of the atmospheric window) of PMMA film of 1.5 and 2.0 mm presented higher values at 363–556 and 1,209–1,295 nm, while the emissivity values (8–14 µm of the atmospheric window) of PMMA film of 0.5 and 1.0 mm presented higher values at 320–363, 560–763, and 1,312–1,428 nm. The average emissivity (8–14 µm of the atmospheric window) of PMMA films showed variable trends for different wavelengths with the thickness of films. As shown in Figure 3c, PDMS (1.5 mm) + PMMA (1.5 mm) presented a high average emissivity value of 93.4% (8–14 μm of atmospheric window). The high emissivity of PDMS was mainly attributed to the telescopic vibration of numerous Si−O−Si bonds in PDMS (34). Since the volume of liquid storage tank of the pen was fixed, PMMA films with three thicknesses were prepared with the addition of 1, 2, and 3 cans of PMMA solution, respectively. In the process of jet spinning, PMMA filaments float too lightly and were greatly influenced by the airflow, which led to the disproportionate thickness of final film formed.

Emissivity of PPC components as a function of film thickness: (a) PDMS films, (b) PMMA films, and (c) PDMS–PMMA composite films. (d) Reflectivity curves of PMMA films as a function of film thickness.

PDMS films with different thicknesses were compounded with PMMA film (1.5 mm). The emissivity curves of these composite films are shown in Figure 3c. The average emissivity values of these composite materials (8–14 μm of atmospheric window) were higher than that of PMMA film on the PDMS film. Among these, the average emissivity of PDMS film (1.5 mm) combined with PMMA film was the highest. Therefore, PDMS film of 1.5 mm was appropriate as the top layer of PPC materials. After determining the top layer of three-layered composite materials, it is necessary to optimize the second layer to improve the overall reflectivity. As displayed in Figure 3d, the reflectivity of PMMA film increased with the rising thickness of PMMA. The reflectivity could reach >94% from 500 to 2,000 nm for 3.5 mm of PMMA film. As the thickness of PMMA film increased to 6.5 mm further, its reflectivity value improved with a percentage of 5%. Considering the cost and performance of passive radiation cooling materials comprehensively, 3.5 mm of thickness for PMMA film was appropriate as the optimized thickness in the following experiments.

3.3 Optical properties of PPC materials

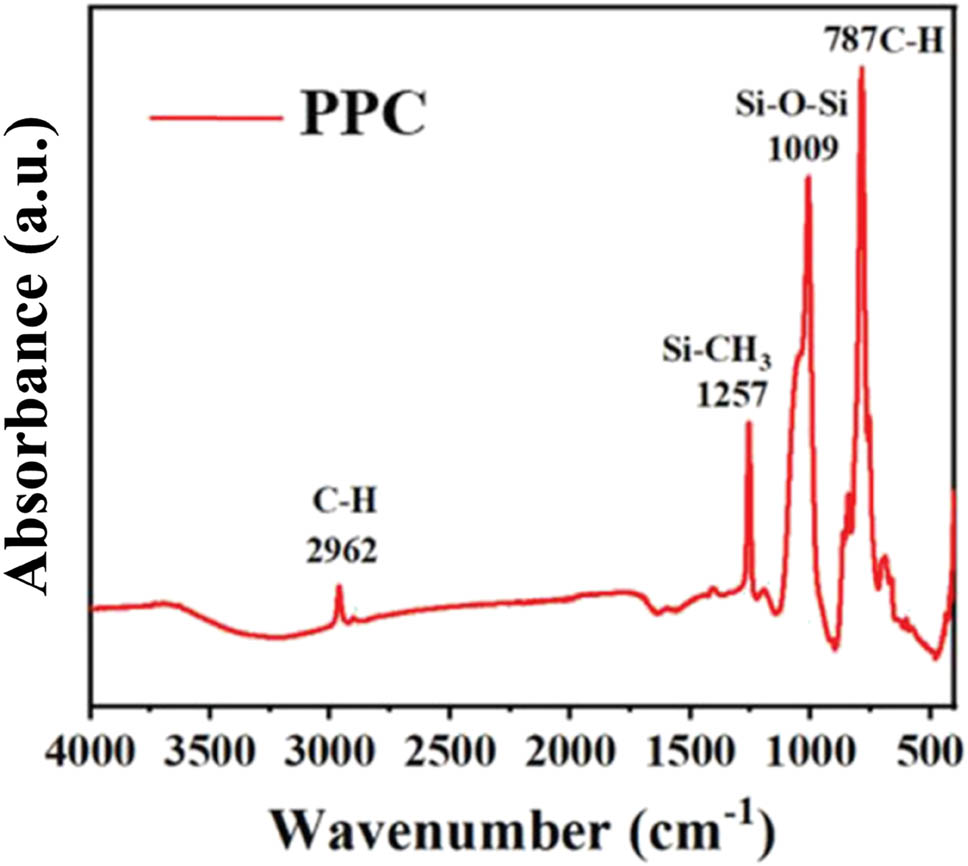

Since pure PMMA film is easy to be broken and deformed, it is urgently necessary to provide a supporter for the integrity of PPC materials. Herein, the designed three-layered structure of PPC materials was proposed as displayed in Figure 1. The emissivity property of PPC materials should be attributed to PDMS film component. The reflectivity property of PPC materials should be attributed to PMMA film component. The supporter of PDMS and PMMA should be ascribed to cotton fabric. From the ATR-FTIR spectra illustrated in Figure 4, the stretching vibration absorption band of C–H bond (alkyl group) and Si−O−Si were observed at 2,963 and 1,010 cm−1, respectively. The bending vibration absorption band of Si–CH3 and out of the plane of C–H were displayed at 1,257 and 786 cm−1 (35). Taken together, the preparation of PPC materials conformed to the ideal concept of heat emitter in the selection of chemical bonds.

Infrared absorption spectrum curve of PPC material.

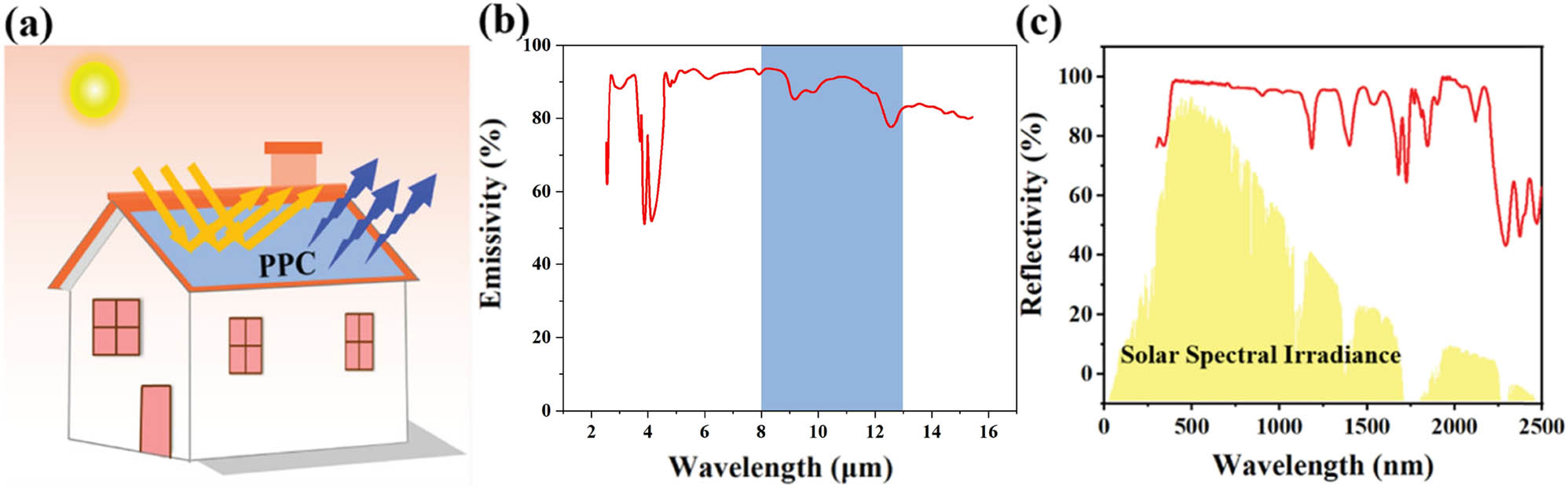

For materials used in the building cooling, the emissivity and the reflectivity are the two most critical cooling properties to be evaluated (Figure 5a). As shown in Figure 5b and c, PPC material presented a high average emissivity values of 93.4% (8–14 μm of atmospheric window) and high reflectivity values over 94% in the sunlight, indicating that PPC was an ideal material for the passive radiation cooling application.

Schematic diagram of building cooling (a). Emissivity curve (b) and reflectance curve (c) of PPC material.

3.4 Flexibility and hydrophobic self-cleaning performance of PPC materials

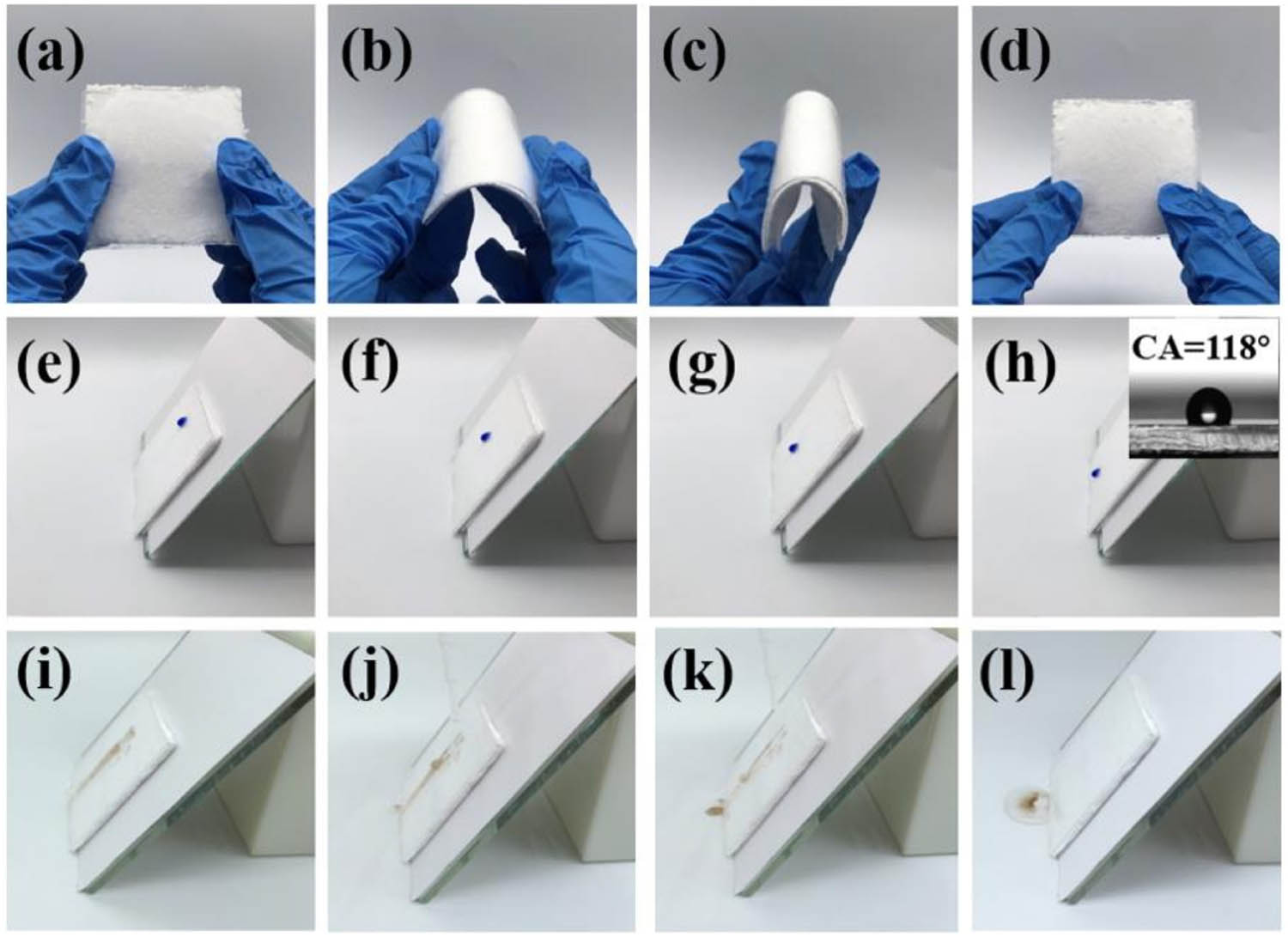

Since polymers containing one or more of these bonds have a certain radiation effect in the atmospheric window, most radiation cooling materials have two major problems in the practical application with the deepening of the research. First, small water droplets are easily formed on the surface of radiation cooling materials, which seriously affects the cooling capacity in hot and humid circumstance. Second, the surface of radiation cooling materials is easily polluted by dust and other pollution sources. A relatively simple and effective solution to solve these two problems is to endow the radiation cooling material with a hydrophobic surface. The hydrophobic surface can not only make small droplets roll down automatically, but also take away some surface dirt when the droplets roll down, enabling the self-cleaning characteristic of radiation cooling materials. The flexibility of PPC is shown in Figure 6a–d. After being bent for many times, the surface of PPC would not crack, and could still be quickly returned to pristine matrix without external applied force. As shown in the photographs of Figure 6e–h, a droplet of water flowed smoothly and automatically through the surface of PPC material as the included angle between the inclined plane and the horizontal plane was set to 45°. The contact angle of PPC material was ∼117°, which was larger than 90°, indicating that the surface of PCC material was hydrophobic (36). PDMS is sticky and easily absorbs dust. However, comparing with the coverage of dust on the surface of PPC materials, the force induced by dropping or flowing water would be enough to remove most of the dust as shown in Figure 6. The dirt or soil located on the surface of PPC could be wiped off easily with the flow of water droplets as illustrated in Figure 6i–l, presenting a self-cleaning performance. The surface hydrophobicity of PPC material could prevent dew or rain from damaging PMMA film, as well as prevent the dust effectively. The dust fell onto PPC would be wiped off through the naturally falling raindrops. The hydrophobic characteristic of PPC was expected to solve the problem of poor cooling ability in high temperature and high humidity environment, and prolong the service life of radiation cooling materials.

Pictures of PPC flexibility including before bending (a), bending (b) and (c), and after bending (d). Pictures of falling liquid droplet (e)–(h). Pictures of self-cleaning phenomenon for dust washed away by running water (i–l).

3.5 Cooling performance of PPC materials

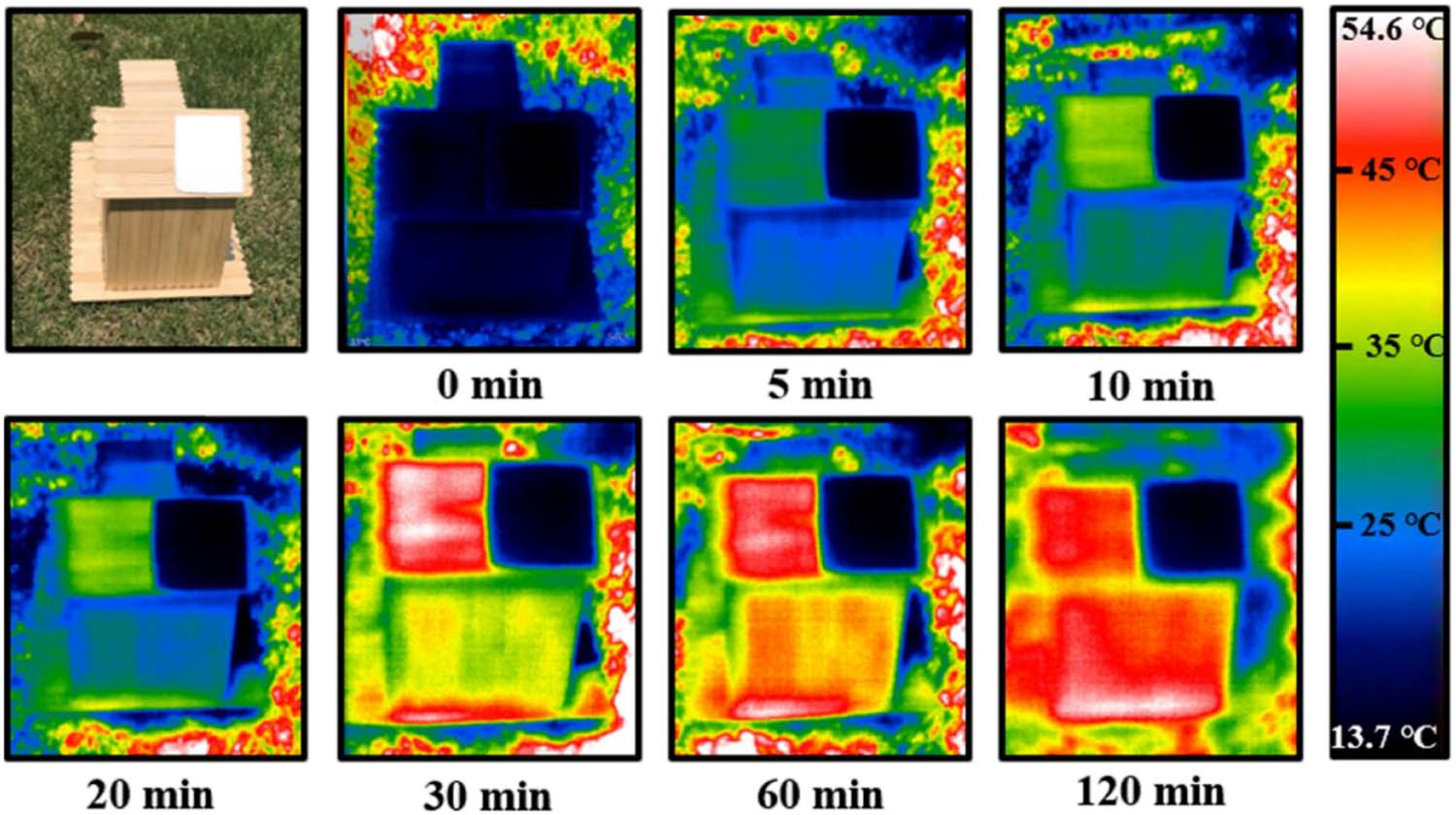

Infrared radiography was applied to monitor the heat-up situation of wooden roof covered with or without PPC materials in the simulated extra ventricular test (Figure 7). With the increase of irradiation time from 0 to 120 min, PPC covered wooden roof presented a slight temperature enhancement at a low level. It is worth noting that the bare wooden roof presented a significant heat-up tendency from the initial 9.7°C to the final 43.6°C. During the irradiation period, the temperature of some bare wooden roofs reached above 50°C at 30 and 60 min, and then the temperature dropped. This is because the light intensity of the sun changed obviously during the outdoor experiment. The constantly shifting sunlight directly affected the angle of sunlight irradiating cooling materials, thus affecting the temperature change of the roof surface.

Images of PPC materials taken with an infrared camera in the outdoor simulation application.

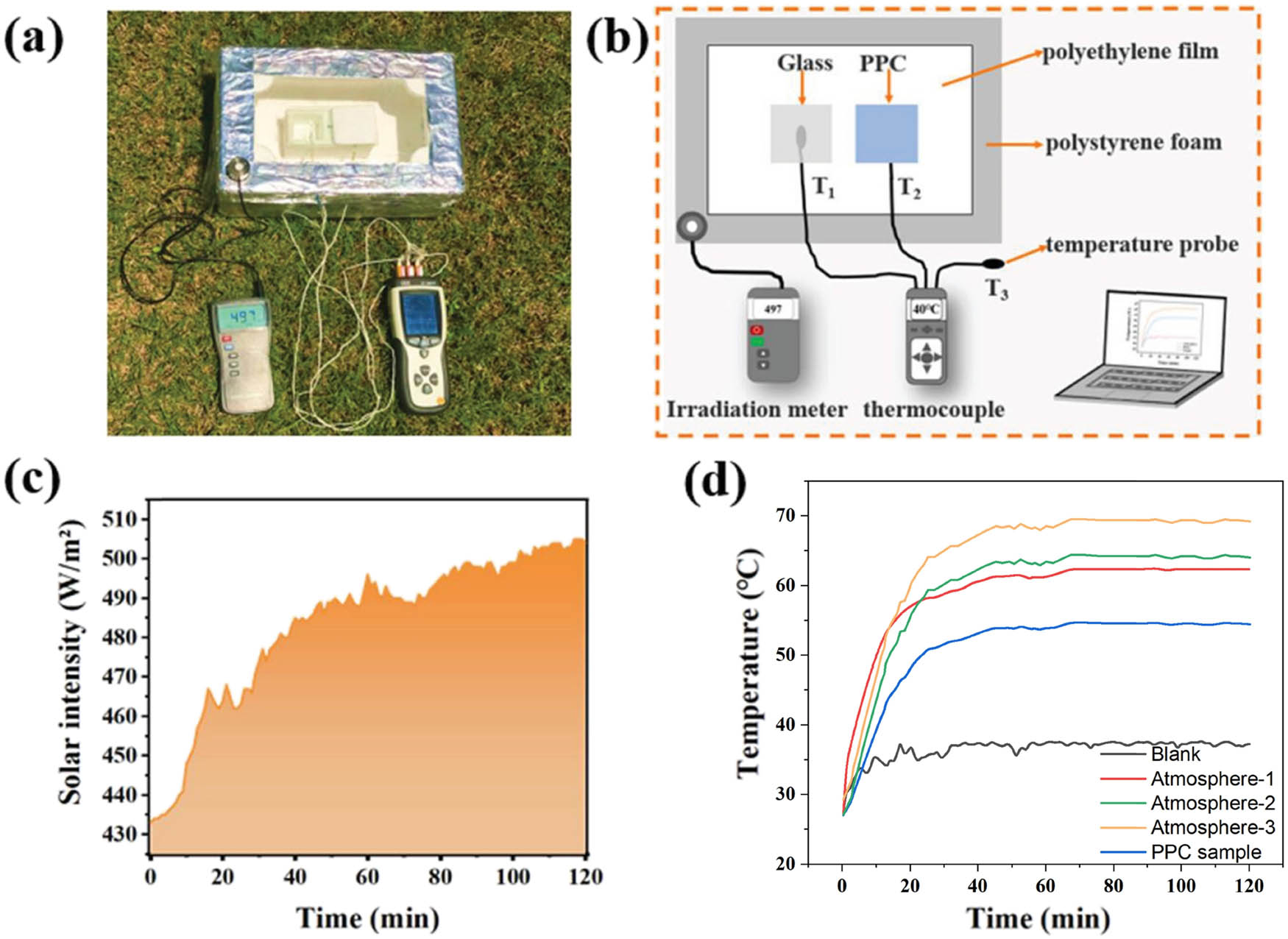

The physical diagram of devices used in the radiation cooling exponent is provided in Figure 8a. To eliminate the influence of circumstance efficiently during the whole experimental process, a tin foil was fully wrapped around the box, and a plastic coverage was wrapped on the top surface of the box, which allowed the full transmission of sunlight as well as the negative influence of environment. The passive radiation cooling effect of PPC material was monitored for the variation of solar intensity from 10:00 to 12:00 in Yibin City (Sichuan province of China) on June 12, 2024. The sunshine intensity rose continuously from 433 to 505 W·m−2 at the investigated time period. As shown in Figure 8d, the temperature of atmosphere-1 sample (i.e., glass plate without the coverage of PPC) increased to 55°C rapidly in the first 18 min, and then rose to 62.3°C slowly until 60 min, achieving the equilibrium of thermal energy. For other references, a glass was placed onto the polyethylene film directly as the atmosphere-2 sample and the Al foil was placed onto the polyethylene film directly as the atmosphere-3 sample. The temperatures of these two atmosphere samples increased to 64.2°C and 69.6°C, respectively, arriving at the thermal equilibrium of solar energy. For the glass plate covered with PPC, the temperature increased obviously in the first 25 min, and then rose to 54.6°C with the equilibrium of thermal energy. On the one hand, the final temperature of glass plate with PPC coverage was distinctly lower than that of glass without PPC coverage. On the other hand, the heating rate of glass plate with PPC coverage was also significantly higher than that of glass without PPC coverage. The above results demonstrated that PPC material had an excellent cooling ability, and the cooling effect was about 7.7–15.0°C. This cooling effect was in the middle-upper position among the numerous reported radiation cooling materials. Given the efficient heat absorption and conduct of PPC-covered glass plate under the sunlight irradiation, it was urgently necessary to apply the cooling materials for glass buildings in summer.

Picture and illustration of radiation cooling devices (a) and (b). Sunlight intensity (c). Temperature curves of cooling measurement (d).

According to the estimation of power saving and corresponding carbon dioxide emission reduction of medium-sized houses, the wooden roof temperature under the sunlight could reach about 65°C, and that of PPC-covered roof could stay stable at about 55°C. The circumstance of Yibin City (Sichuan province China) was 34°C. To maintain the indoor temperature at 20°C, the electricity consumption for a medium-sized house was about 574 kW·h/year, while that for PC-covered medium-sized house was 474 kW·h/year. Given that, PPC-covered wooden roof for medium-sized houses could reduce the electricity consumption efficiently. According to the equation listed in Table 1, the calculated reduced ratio of CO2 emission was 17%/year.

Electrical energy savings and corresponding reduction in CO2 emissions for medium-sized homes with or without PPC-covered roofs

| T roof (°C) | T air (°C) | T inside (°C) | Heat uptake/day (MJ) | Electricity costs/year ($) | CO2 emission/year (kg) | |

|---|---|---|---|---|---|---|

| Exposed roof | 65 | 36 | 21 | 62 | 86 | 323 |

| PCC coating roof | 58 | 36 | 21 | 52 | 72 | 268 |

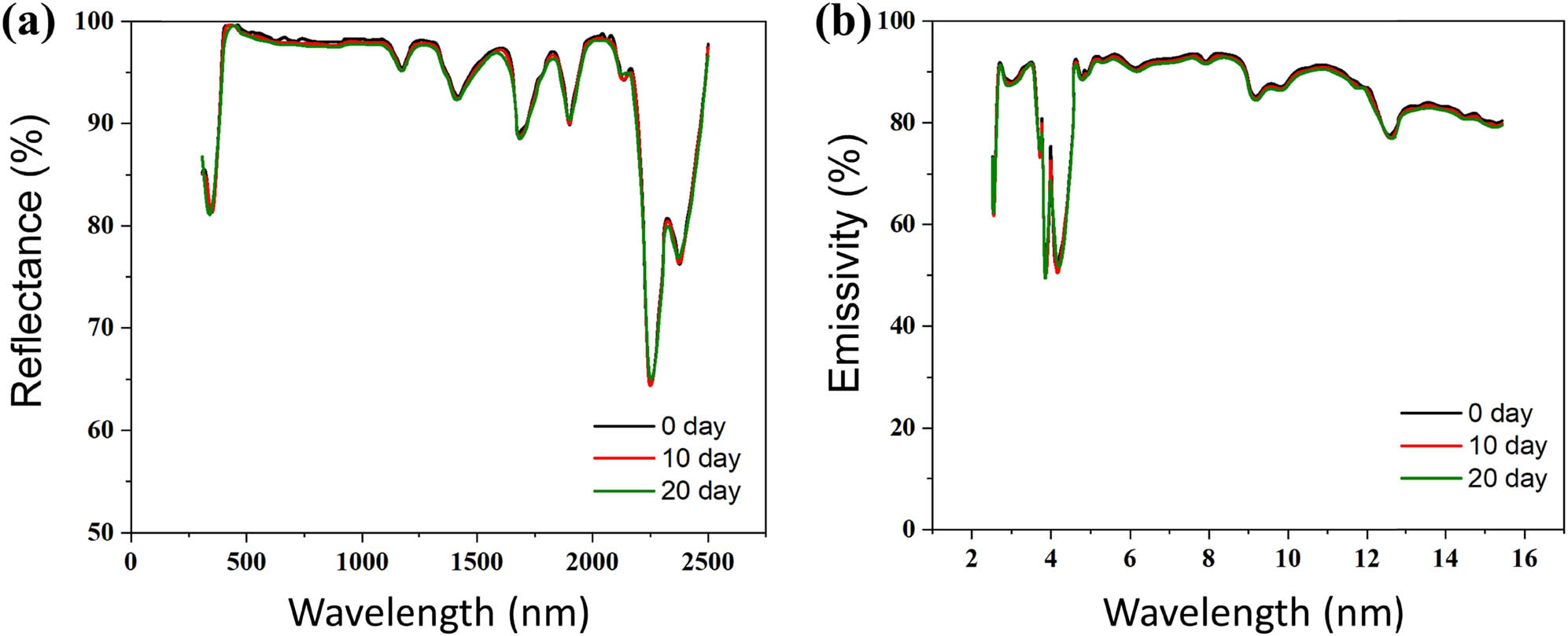

The three-layered films had a good durability. The accelerated weathering test of the three-layered films was carried out for 20 days (4 h of UV irradiation with intensity of 0.71 W·m−2 at 310 nm and 4 h of water spray at 60°C on a continuous cycle). The solar reflectance spectrum showed that the reflectance of the film was slightly reduced after a long period of accelerated aging, but still over 90% of incident sunlight is reflected after 20 days’ accelerated weathering treatment. The long-wave infrared emissivity was almost unaffected (Figure 9).

Reflectance and emissivity spectra of PPC materials with accelerated weathering time. (a) Reflectance spectra and (b) emissivity spectra.

4 Conclusions

In summary, three-layered PPC materials with hydrophobic surface and randomly distributed filaments were designed and prepared for the efficient passive radiation cooling during the day. While PDMS film exhibited higher emissivity than spray-prepared PMMA film, spray-prepared PMMA film exhibited higher reflectivity than PDMS film. PPC material presented a rich uneven filament structure (1.5 mm of PMMA and 3.5 mm of PDMS) and an ideal internal bonding structure, which endowed it with high solar reflectivity (94%) and excellent emissivity (93.4%). The top PDMS layer of PPC material was hydrophobic (117°). PPC material could remove most of the dust under the rolling of water droplets, exhibiting an excellent self-cleaning performance. PPC material also presented a good cooling ability with a cooling effect of 7.7–15.0°C in the simulated outdoor cooling test. For medium-sized houses, PPC-covered wooden roof declined 17% of CO2 emission every year.

-

Author contributions: Yi Guo: investigation, conceptualization, data curation, validation, writing – original draft preparation, and writing – reviewing and editing.

-

Conflict of interest: The author declares that he has no known competing financial interest or personal relationships that could have appeared to influence the work reported in this article.

References

(1) Chowdhury FI, Xu QW, Sinha K, Wang X. Cellulose-upgraded polymer films for radiative sky cooling. J Quant Spectrosc Radiat Transf. 2021;272:107824. 10.1016/j.jqsrt.2021.107824.Suche in Google Scholar

(2) Yang K, Liu M, Du N, Huo Z, Chen Y, Yang Z, et al. Performance analysis of a novel phase-change wall of wood structure coupled with sky-radiation cooling. Energy Convers Manage. 2014;307:118329. 10.1016/j.enconman.2024.118329.Suche in Google Scholar

(3) Xu F, Hang J, Wang H, Gao Z, Zhang JJ, Yang J. An experimental study of the effects of using cool materials at different building heights on the indoor and outdoor environment. Build Environ. 2024;259:111664. 10.1016/j.buildenv.2024.111664.Suche in Google Scholar

(4) Xie H, Du Y, Li X, Zhang C, Zhou W, Yang X, et al. Chinese architecture inspired smart roof tile integrating radiation cooling, water harvesting, and energy recycling. Nano Energy. 2024;127:109709. 10.1016/j.nanoen.2024.109709.Suche in Google Scholar

(5) Jiang L, Gong M, Sun J, Lin Y, Tu K, Chen Y, et al. The design and performance research of PTFE/PVDF/PDMS superhydrophobic radiative cooling composite coating with high infrared emissivity. Mater Today Commun. 2024;38:108406. 10.1016/j.mtcomm.2024.108406.Suche in Google Scholar

(6) Zhao B, Hu M, Xuan Q, Kwan TH, Dabwan YN, Pei G. Tunable thermal management based on solar heating and radiative cooling. Sol Energy Mater Sol Cell. 2022;235:111457. 10.1016/j.sol,at.2021.111457.Suche in Google Scholar

(7) Wu W, Lin S, Wei M, Huang J, Xu H, Lu Y, et al. Flexible passive radiative cooling inspired by Saharan silver ants. Sol Energy Mater Sol Cell. 2020;210:110512. 10.1016/j.solmat.2020.110512.Suche in Google Scholar

(8) Pirvaram A, Cooper T, Leung SN, O’Brien PG. A comprehensive study on using underside infrared reflectors to enhance the performance of radiative cooling structures. Energy Convers Manage. 2024;304:118180. 10.1016/j.enconman.2024.118180.Suche in Google Scholar

(9) Liu P, Wang S. Color and reflective properties of magnesium phosphate cement grouting material for cooling pavement. Sol Energy Mater Sol Cell. 2024;275:113008. 10.1016/j.solmat.2024.113008.Suche in Google Scholar

(10) Altiokka ABG, Arslan O. Performance analysis of residential hybrid cooling and heating system operating under low solar radiation. Process Saf Environ. 2024;189:246–66. 10.1016/j.psep.2024.06.036.Suche in Google Scholar

(11) Wang T, Wu Y, Shi L, Hu X, Chen M, Wu L. A structural polymer for highly efficient all-day passive radiative cooling. Nat Commun. 2021;12:365. 10.1038/s41467-020-20646-7.Suche in Google Scholar PubMed PubMed Central

(12) Wang T, Zhang Y, Chen M, Gu M, Wu L. Scalable and waterborne titanium-dioxide-free thermochromic coatings for self-adaptive passive radiative cooling and heating. Cell Rep Phys Sci. 2022;3:365. 10.1016/j.xcrp.2022.100782.Suche in Google Scholar

(13) Wang T, Zhang S, Zhu Q, Zhang J, Zhang Y, Du Y, et al. A trilayer structure with surface binary microsphere array for radiative cooling and heating regulation. ACS Photonics. 2024;11:2815–23. 10.1021/acsphotonics.4c00833.Suche in Google Scholar

(14) Mei X, Wang T, Zhang Y, Huang T, Chen M, Wu L. Scalable bilayer thin coatings with enhanced thermal dissipation for passive daytime radiative cooling. Chem Eng J. 2024;495:153182. 10.1016/j.cej.2024.153182.Suche in Google Scholar

(15) Chae D, Lee SY, Lim H, Son S, Ha J, Park J, et al. Vivid colored cooling structure managing full solar spectrum via near-infrared reflection and photoluminescence. ACS Appl Mater Interfaces. 2023;15:58274–85. 10.1021/acsami.3c08790.Suche in Google Scholar PubMed

(16) Mandal J, Yang Y, Yu N, Raman AP. Paints as a scalable and effective radiative cooling technology for buildings. Joule. 2020;4:1350–6. 10.1016/j.joule.2020.04.010.Suche in Google Scholar

(17) Alnajideen M, Gao M. A new configuration of V-trough concentrator for achieving improved concentration ratio of > 3.0x. Sol Energy Mater Sol Cell. 2022;245:111877. 10.1016/j.solmat.2022.111877.Suche in Google Scholar

(18) Gong Q, Wong HC, Chen J, Li P, Lu L. Solar-driven adaptive radiative cooling coating with polymer carbon dots-enhanced photoluminescence for urban skin. Chem Eng J. 2024;494:153262. 10.1016/j.cej.2024.153262.Suche in Google Scholar

(19) Niu J, Zhou W, Bai J, Wang S, Ma X, Li S, et al. A multi-scale particles doped ETFE based self-cleaning coating for passive daytime radiative cooling. Mater Today Commun. 2024;37:108918. 10.1016/j.mtcomm.2024.108918.Suche in Google Scholar

(20) Wang M, Li H, You R, Kong W, Tao Z. Experimental research on high-temperature radiation characteristics of film-cooled plate of gas turbines. Energy. 2024;303:132005. 10.1016/j.energy.2024.132005.Suche in Google Scholar

(21) Xia G, Zhou T, Zhang Y, Dai S, Jiao G. Operating characteristics analysis and optimization of loop heat pipe radiation cooling system in space reactor. Nucl Eng Des. 2024;420:113043. 10.1016/j.nucengdes.2024.113043.Suche in Google Scholar

(22) Salih SM, Jalil JM, Najim SE. Experimental and numerical analysis of double-pass solar air heater utilizing multiple capsules PCM. Renew Energy. 2019;143:1053–66. 10.1016/j.renene.2019.05.050.Suche in Google Scholar

(23) Chen ZH, Liu JX, Zhang HL, Kuang HP, Zhao MT, Zhang S. Comparative investigation of mechanical and cooling performance between thermochromic road materials prepared by wet/dry process: for low-carbon production and sustainable service. J Clean Prod. 2022;360:132158. 10.1016/j.jclepro.2022.132158.Suche in Google Scholar

(24) Shin MS. Investigations of flow and heat transfer characteristics in a channel impingement cooling configuration with a single row of water jets. Energies. 2021;14:4327. 10.3390/en14144327.Suche in Google Scholar

(25) Zhang Z, Liu J, Zhang N, Cao X, Yuan Y, Sultan M, et al. Coupling effect of radiative cooling and phase change material on building wall thermal performance. J Build Eng. 2024;82:108344. 10.1016/j.jobe.2023.108344.Suche in Google Scholar

(26) Alshammari A, Almatrafi E, Rady M. Radiative coatings for solar cell cooling: materials, and applications. Sol Energy. 2024;273:112545. 10.1016/j.solener.2024.112545.Suche in Google Scholar

(27) Li Z, Chen Q, Song Y, Zhu B, Zhu J. Fundamentals, materials, and applications for daytime radiative cooling. Adv Mater Technol. 2020;5:1901007. 10.1002/admt.201901007.Suche in Google Scholar

(28) Pirvaram A, Talebzadeh N, Leung SN, O’Brien PG. Radiative cooling for buildings: a review of techno-enviro-economics and life-cycle assessment methods. Renew Sustain Energy Rev. 2022;162:112415. 10.1016/j.rser.2022.112415.Suche in Google Scholar

(29) Yilmaz S, Ozcalik HR, Kesler S, Dincer F, Yelmen B. The analysis of different PV power systems for the determination of optimal PV panels and system installation – a case study in Kahramanmaras, Turkey. Renew Sustain Energy Rev. 2015;52:1015–24. 10.1016/j.rser.2015.07.146.Suche in Google Scholar

(30) Shaeli MN, Jalil JM, Baccar M. Improving the performance of solar photovoltaic thermal cells using jet impingement and phase change materials cooling technology. Renew Energ. 2024;227:120536. 10.1016/j.renene.2024.120536.Suche in Google Scholar

(31) Chen Z, Zhang H, Yang X, Leng Z, Tang Y. Cooling efficiency of thermochromic asphalt pavement material and its contribution to field performance enhancement of asphalt mixture. Constr Build Mater. 2024;411:134562. 10.1016/j.conbuildmat.2023.134562.Suche in Google Scholar

(32) Sun YR, Du C, Gong HR, Li YH, Chen JY. Effect of temperature field on damage initiation in asphalt pavement: a microstructure based multiscale finite element method. Mech Mater. 2020;144:103367. 10.1016/j.mechmat.2020.103367.Suche in Google Scholar

(33) Champagne VK, Pisaturo GP, Clarke DR. High temperature oxides for selective absorption of thermal radiation. J Eur Ceram Soc. 2023;43:7656–67. 10.1016/j.jeurceramsoc.2023.07.075.Suche in Google Scholar

(34) Hasan A, Sarwar J, Alnoman H, Abdelbaqi S. Yearly energy performance of a photovoltaic-phase change material (PV-PCM) system in hot climate. Sol Energy. 2017;146:417–29. 10.1016/j.solener.2017.01.070.Suche in Google Scholar

(35) Koutsakis G, Clarke DR. Optical absorption effects in thermal radiation barrier coating materials. Surf Coat Technol. 2024;487:130974. 10.1016/j.surfcoat.2024.130974.Suche in Google Scholar

(36) Koutsakis G, Begley M, Hutchinson J, Ghandhi J. Fracture-based transient thermo-mechanical analysis of reciprocating engine thermal barrier coatings. Eng Fract Mech. 2022;270:108568. 10.1016/j.engfracmech.2022.108568.Suche in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Flame-retardant thermoelectric responsive coating based on poly(3,4-ethylenedioxythiphene) modified metal–organic frameworks

- Highly stretchable, durable, and reversibly thermochromic wrapped yarns induced by Joule heating: With an emphasis on parametric study of elastane drafts

- Molecular dynamics simulation and experimental study on the mechanical properties of PET nanocomposites filled with CaCO3, SiO2, and POE-g-GMA

- Multifunctional hydrogel based on silk fibroin/thermosensitive polymers supporting implant biomaterials in osteomyelitis

- Marine antifouling coating based on fluorescent-modified poly(ethylene-co-tetrafluoroethylene) resin

- Preparation and application of profiled luminescent polyester fiber with reversible photochromism materials

- Determination of pesticide residue in soil samples by molecularly imprinted solid-phase extraction method

- The die swell eliminating mechanism of hot air assisted 3D printing of GF/PP and its influence on the product performance

- Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes

- The effects of property variation on the dripping behaviour of polymers during UL94 test simulated by particle finite element method

- Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets

- Synthesis, characterization and evaluation of a pH-responsive molecular imprinted polymer for Matrine as an intelligent drug delivery system

- Twist-related parametric optimization of Joule heating-triggered highly stretchable thermochromic wrapped yarns using technique for order preference by similarity to ideal solution

- Comparative analysis of flow factors and crystallinity in conventional extrusion and gas-assisted extrusion

- Simulation approach to study kinetic heterogeneity of gadolinium catalytic system in the 1,4-cis-polyisoprene production

- Properties of kenaf fiber-reinforced polyamide 6 composites

- Cellulose acetate filter rods tuned by surface engineering modification for typical smoke components adsorption

- A blue fluorescent waterborne polyurethane-based Zn(ii) complex with antibacterial activity

- Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading

- Preparation and application research of composites with low vacuum outgassing and excellent electromagnetic sealing performance

- Assessing the recycling potential of thermosetting polymer waste in high-density polyethylene composites for safety helmet applications

- Mesoscale mechanics investigation of multi-component solid propellant systems

- Preparation of HTV silicone rubber with hydrophobic–uvioresistant composite coating and the aging research

- Experimental investigation on tensile behavior of CFRP bolted joints subjected to hydrothermal aging

- Structure and transition behavior of crosslinked poly(2-(2-methoxyethoxy) ethylmethacrylate-co-(ethyleneglycol) methacrylate) gel film on cellulosic-based flat substrate

- Mechanical properties and thermal stability of high-temperature (cooking temperature)-resistant PP/HDPE/POE composites

- Preparation of itaconic acid-modified epoxy resins and comparative study on the properties of it and epoxy acrylates

- Synthesis and properties of novel degradable polyglycolide-based polyurethanes

- Fatigue life prediction method of carbon fiber-reinforced composites

- Thermal, morphological, and structural characterization of starch-based bio-polymers for melt spinnability

- Robust biaxially stretchable polylactic acid films based on the highly oriented chain network and “nano-walls” containing zinc phenylphosphonate and calcium sulfate whisker: Superior mechanical, barrier, and optical properties

- ARGET ATRP of styrene with low catalyst usage in bio-based solvent γ-valerolactone

- New PMMA-InP/ZnS nanohybrid coatings for improving the performance of c-Si photovoltaic cells

- Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites

- Preparation of cardanol-based curing agent for underwater drainage pipeline repairs

- Preparation of lightweight PBS foams with high ductility and impact toughness by foam injection molding

- Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study

- Experimental study on impact and flexural behaviors of CFRP/aluminum-honeycomb sandwich panel

- Normal-hexane treatment on PET-based waste fiber depolymerization process

- Effect of tannic acid chelating treatment on thermo-oxidative aging property of natural rubber

- Design, synthesis, and characterization of novel copolymer gel particles for water-plugging applications

- Influence of 1,1′-Azobis(cyclohexanezonitrile) on the thermo-oxidative aging performance of diolefin elastomers

- Characteristics of cellulose nanofibril films prepared by liquid- and gas-phase esterification processes

- Investigation on the biaxial stretching deformation mechanism of PA6 film based on finite element method

- Simultaneous effects of temperature and backbone length on static and dynamic properties of high-density polyethylene-1-butene copolymer melt: Equilibrium molecular dynamics approach

- Research on microscopic structure–activity relationship of AP particle–matrix interface in HTPB propellant

- Three-layered films enable efficient passive radiation cooling of buildings

- Electrospun nanofibers membranes of La(OH)3/PAN as a versatile adsorbent for fluoride remediation: Performance and mechanisms

- Preparation and characterization of biodegradable polyester fibers enhanced with antibacterial and antiviral organic composites

- Preparation of hydrophobic silicone rubber composite insulators and the research of anti-aging performance

- Surface modification of sepiolite and its application in one-component silicone potting adhesive

- Study on hydrophobicity and aging characteristics of epoxy resin modified with nano-MgO

- Optimization of baffle’s height in an asymmetric twin-screw extruder using the response surface model

- Effect of surface treatment of nickel-coated graphite on conductive rubber

- Experimental investigation on low-velocity impact and compression after impact behaviors of GFRP laminates with steel mesh reinforced

- Development and characterization of acetylated and acetylated surface-modified tapioca starches as a carrier material for linalool

- Investigation of the compaction density of electromagnetic moulding of poly(ether-ketone-ketone) polymer powder

- Experimental investigation on low-velocity-impact and post-impact-tension behaviors of GFRP T-joints after hydrothermal aging

- The repeated low-velocity impact response and damage accumulation of shape memory alloy hybrid composite laminates

- Exploring a new method for high-performance TPSiV preparation through innovative Si–H/Pt curing system in VSR/TPU blends

- Large-scale production of highly responsive, stretchable, and conductive wrapped yarns for wearable strain sensors

- Preparation of natural raw rubber and silica/NR composites with low generation heat through aqueous silane flocculation

- Molecular dynamics simulation of the interaction between polybutylene terephthalate and A3 during thermal-oxidative aging

- Crashworthiness of GFRP/aluminum hybrid square tubes under quasi-static compression and single/repeated impact

- Review Articles

- Recent advancements in multinuclear early transition metal catalysts for olefin polymerization through cooperative effects

- Impact of ionic liquids on the thermal properties of polymer composites

- Recent progress in properties and application of antibacterial food packaging materials based on polyvinyl alcohol

- Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters

- Rapid Communication

- Design, synthesis, characterization, and adsorption capacities of novel superabsorbent polymers derived from poly (potato starch xanthate-graft-acrylamide)

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Development of smart core–shell nanoparticles-based sensors for diagnostics of salivary alpha-amylase in biomedical and forensics

- Thermoplastic-polymer matrix composite of banana/betel nut husk fiber reinforcement: Physico-mechanical properties evaluation

- Special Issue: Electrospun Functional Materials

- Electrospun polyacrylonitrile/regenerated cellulose/citral nanofibers as active food packagings

Artikel in diesem Heft

- Research Articles

- Flame-retardant thermoelectric responsive coating based on poly(3,4-ethylenedioxythiphene) modified metal–organic frameworks

- Highly stretchable, durable, and reversibly thermochromic wrapped yarns induced by Joule heating: With an emphasis on parametric study of elastane drafts

- Molecular dynamics simulation and experimental study on the mechanical properties of PET nanocomposites filled with CaCO3, SiO2, and POE-g-GMA

- Multifunctional hydrogel based on silk fibroin/thermosensitive polymers supporting implant biomaterials in osteomyelitis

- Marine antifouling coating based on fluorescent-modified poly(ethylene-co-tetrafluoroethylene) resin

- Preparation and application of profiled luminescent polyester fiber with reversible photochromism materials

- Determination of pesticide residue in soil samples by molecularly imprinted solid-phase extraction method

- The die swell eliminating mechanism of hot air assisted 3D printing of GF/PP and its influence on the product performance

- Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes

- The effects of property variation on the dripping behaviour of polymers during UL94 test simulated by particle finite element method

- Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets

- Synthesis, characterization and evaluation of a pH-responsive molecular imprinted polymer for Matrine as an intelligent drug delivery system

- Twist-related parametric optimization of Joule heating-triggered highly stretchable thermochromic wrapped yarns using technique for order preference by similarity to ideal solution

- Comparative analysis of flow factors and crystallinity in conventional extrusion and gas-assisted extrusion

- Simulation approach to study kinetic heterogeneity of gadolinium catalytic system in the 1,4-cis-polyisoprene production

- Properties of kenaf fiber-reinforced polyamide 6 composites

- Cellulose acetate filter rods tuned by surface engineering modification for typical smoke components adsorption

- A blue fluorescent waterborne polyurethane-based Zn(ii) complex with antibacterial activity

- Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading

- Preparation and application research of composites with low vacuum outgassing and excellent electromagnetic sealing performance

- Assessing the recycling potential of thermosetting polymer waste in high-density polyethylene composites for safety helmet applications

- Mesoscale mechanics investigation of multi-component solid propellant systems

- Preparation of HTV silicone rubber with hydrophobic–uvioresistant composite coating and the aging research

- Experimental investigation on tensile behavior of CFRP bolted joints subjected to hydrothermal aging

- Structure and transition behavior of crosslinked poly(2-(2-methoxyethoxy) ethylmethacrylate-co-(ethyleneglycol) methacrylate) gel film on cellulosic-based flat substrate

- Mechanical properties and thermal stability of high-temperature (cooking temperature)-resistant PP/HDPE/POE composites

- Preparation of itaconic acid-modified epoxy resins and comparative study on the properties of it and epoxy acrylates

- Synthesis and properties of novel degradable polyglycolide-based polyurethanes

- Fatigue life prediction method of carbon fiber-reinforced composites

- Thermal, morphological, and structural characterization of starch-based bio-polymers for melt spinnability

- Robust biaxially stretchable polylactic acid films based on the highly oriented chain network and “nano-walls” containing zinc phenylphosphonate and calcium sulfate whisker: Superior mechanical, barrier, and optical properties

- ARGET ATRP of styrene with low catalyst usage in bio-based solvent γ-valerolactone

- New PMMA-InP/ZnS nanohybrid coatings for improving the performance of c-Si photovoltaic cells

- Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites

- Preparation of cardanol-based curing agent for underwater drainage pipeline repairs

- Preparation of lightweight PBS foams with high ductility and impact toughness by foam injection molding

- Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study

- Experimental study on impact and flexural behaviors of CFRP/aluminum-honeycomb sandwich panel

- Normal-hexane treatment on PET-based waste fiber depolymerization process

- Effect of tannic acid chelating treatment on thermo-oxidative aging property of natural rubber

- Design, synthesis, and characterization of novel copolymer gel particles for water-plugging applications

- Influence of 1,1′-Azobis(cyclohexanezonitrile) on the thermo-oxidative aging performance of diolefin elastomers

- Characteristics of cellulose nanofibril films prepared by liquid- and gas-phase esterification processes

- Investigation on the biaxial stretching deformation mechanism of PA6 film based on finite element method

- Simultaneous effects of temperature and backbone length on static and dynamic properties of high-density polyethylene-1-butene copolymer melt: Equilibrium molecular dynamics approach

- Research on microscopic structure–activity relationship of AP particle–matrix interface in HTPB propellant

- Three-layered films enable efficient passive radiation cooling of buildings

- Electrospun nanofibers membranes of La(OH)3/PAN as a versatile adsorbent for fluoride remediation: Performance and mechanisms

- Preparation and characterization of biodegradable polyester fibers enhanced with antibacterial and antiviral organic composites

- Preparation of hydrophobic silicone rubber composite insulators and the research of anti-aging performance

- Surface modification of sepiolite and its application in one-component silicone potting adhesive

- Study on hydrophobicity and aging characteristics of epoxy resin modified with nano-MgO

- Optimization of baffle’s height in an asymmetric twin-screw extruder using the response surface model

- Effect of surface treatment of nickel-coated graphite on conductive rubber

- Experimental investigation on low-velocity impact and compression after impact behaviors of GFRP laminates with steel mesh reinforced

- Development and characterization of acetylated and acetylated surface-modified tapioca starches as a carrier material for linalool

- Investigation of the compaction density of electromagnetic moulding of poly(ether-ketone-ketone) polymer powder

- Experimental investigation on low-velocity-impact and post-impact-tension behaviors of GFRP T-joints after hydrothermal aging

- The repeated low-velocity impact response and damage accumulation of shape memory alloy hybrid composite laminates

- Exploring a new method for high-performance TPSiV preparation through innovative Si–H/Pt curing system in VSR/TPU blends

- Large-scale production of highly responsive, stretchable, and conductive wrapped yarns for wearable strain sensors

- Preparation of natural raw rubber and silica/NR composites with low generation heat through aqueous silane flocculation

- Molecular dynamics simulation of the interaction between polybutylene terephthalate and A3 during thermal-oxidative aging

- Crashworthiness of GFRP/aluminum hybrid square tubes under quasi-static compression and single/repeated impact

- Review Articles

- Recent advancements in multinuclear early transition metal catalysts for olefin polymerization through cooperative effects

- Impact of ionic liquids on the thermal properties of polymer composites

- Recent progress in properties and application of antibacterial food packaging materials based on polyvinyl alcohol

- Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters

- Rapid Communication

- Design, synthesis, characterization, and adsorption capacities of novel superabsorbent polymers derived from poly (potato starch xanthate-graft-acrylamide)

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Development of smart core–shell nanoparticles-based sensors for diagnostics of salivary alpha-amylase in biomedical and forensics

- Thermoplastic-polymer matrix composite of banana/betel nut husk fiber reinforcement: Physico-mechanical properties evaluation

- Special Issue: Electrospun Functional Materials

- Electrospun polyacrylonitrile/regenerated cellulose/citral nanofibers as active food packagings