Abstract

This article aims to evaluate the effects of mesh size change on the mechanical properties of GFRP laminates, via low-velocity impact and compression-after-impact (CAI) test, and the failure mechanism was analyzed. Through vacuum-assisted resin infusion, wire meshes with different mesh numbers and wire diameters were incorporated into GFRP. Based on response history and failure morphology, the results show that the addition of wire mesh can disperse the incident energy from the impact center to the outer region, thereby improving the impact resistance of GFRP. It is worth noting that increasing the number of mesh could improve the stiffness of the panels and enhance their ability in CAI events compared with increasing the diameter of wires, their failure evolution was presented from the perspective of digital image correlation (DIC). For example, the maximum displacement of 0.50–40 J decreased by 10.6% from 2.5 to 2.26 mm compared with 20–60 J.

1 Introduction

With its excellent specific stiffness, specific strength, and corrosion resistance, glass fiber is widely used in aviation, ship, and vehicle engineering (1,2,3). In the process of service, GFRP may be damaged in various forms, among which the common forms of failure are impact, tension, compression, etc. (4,5,6,7,8). GFRP materials can suffer various damages during use, among which low-velocity impact (LVI) is one of the most important injuries (9,10,11,12,13,14). Due to the high plasticity and ductility of metal materials, steel wire mesh can be added to GFRP materials to absorb impact energy by improving the overall plastic deformation ability, so that the overall properties of the material can be improved (15,16,17,18,19,20,21). The sandwich structure of the composite material is greatly affected by its own performance, and the mechanical properties of the material are improved by combining two or even a variety of different materials, which is conducive to its normal use during the remaining service period.

Metal materials have excellent impact resistance and durability, which can make up for the shortcomings that fiber-reinforced polymer (FRP) is prone to fracture and delaminate under low-speed impact. In practical applications, FRPs are susceptible to impact. Due to the complex damage mechanism, damage interference, and impact response of FRP composite components. Metallic materials can be inserted into FRP to improve their impact resistance, which gives it excellent energy-absorbing characteristics and improves the performance of FRP under compressive loads. It is possible to insert metal materials into FRP to improve its impact resistance, which gives it excellent energy absorption characteristics and improves the performance of FRP under compressive loads.

The purpose of this study is to fully understand the ability of FRP materials to cope with impact loads in practical engineering applications, as well as the residual compressive properties exhibited after impact. Such research is essential to ensure the reliability and safety of the components in practical use. Different layup methods of GFRP composites have been extensively studied (22,23,24,25). Krishnasamy et al. (26) studied the properties of metal mesh and epoxy resin-reinforced composites and analyzed the fracture surface microstructure of metal mesh materials using scanning electron microscopy. Megahed et al. (27) embedded aluminum mesh in glass fiber, and carried out tensile and bending tests with or without the notch, and the results showed that the specific tensile strength and specific flexural strength decreased as the number of aluminum mesh layers increased, and the thickness, position, and orientation of the aluminum mesh significantly affected the properties of the hybrid laminates. Previously, Wu et al. (28) embedded wire mesh into a glass fiber polymer laminate to observe the impact response and residual strength of tensile, and studied the effects of wire mesh and hole spacing in specimen. Sadoun et al. (29) tested fiberglass laminates for tensile, bending, by mixing an extremely thin layer of aluminum wire mesh, and showed that the use of aluminum wire mesh instead of glass fibers had a significant effect on the mechanical properties, toughness, and ductility of the GFRP laminates. Tu et al. (30) modified the pore diameter of the specimen using vacuum-assisted resin injection as part of the fabrication process. This modification was implemented for the purpose of studying the impact and compression after impact (CAI) behavior of a perforated sandwich panel comprising a foam core and a glass fiber-reinforced epoxy hybrid panel. In our study, we manufacture GFRP laminate with two types of mesh by VARI. Then, the impact response and damage morphology of the specimen under the LVI test were studied. Subsequently, the DIC system is employed to observe the damage evolution of the specimens during the LVI tests and the residual compressive strength is discussed in detail. Finally, some significant conclusions are drawn. These research results have potential application value in aerospace, automotive, and other fields, reducing accident risk and improving system reliability.

2 Experiment

2.1 Fabrication of specimens

In the experiment, vinyl resin (supplied by China Langfang Products Co., Ltd., Hebei, China), accelerator (cobalt isooctanoate), and curing agent (methyl ethyl ketone peroxide) are mixed by a mass ratio of 100:1:1 and cured at room temperature. The vacuum-assisted resin injection process (VARI) prepared twelve layers of woven glass fibers, and steel wire meshes with different mesh numbers and wire diameters were inserted at the intermediate interface between the sixth and seventh layers to improve the strength. The specific process of VARI is as follows: preparing various auxiliary materials, glass fiber, release cloth, diversion net, and steel wire mesh. Lay them on the work table in order, seal them with vacuum glue, place them in vacuum bags, and pump out the air to fully saturate the resin into the glass fiber as shown in Figure 1. Two groups of different wire mesh specimens were prepared, with a mesh number of 20 meshes, and five wire diameters of 0.12/0.23/0.3/0.4/0.5 mm were used as the control group in Figure 2(b). The wire diameter was 0.4 mm, and the mesh number of five kinds was 12/14/16/18/20 mesh control group as shown in Figure 2(a). Detailed details of the quality and thickness of the different types of specimens are shown in Tables 1 and 2. After undergoing a 24-h room temperature curing process, the specimen is precisely cut into 150 × 100 mm size rectangles.

Fabrication of GFRP laminate.

Specimen diagram of (a) different mesh numbers and (b) different wire diameters.

Comparison of specimen thickness and mass with different mesh numbers

| Specimen (J) | Mass (g) | Thickness (mm) |

|---|---|---|

| 12–60 | 81.3 | 4.37 |

| 14–60 | 84.1 | 4.37 |

| 16–60 | 90.7 | 4.37 |

| 18–60 | 93.9 | 4.37 |

| 20–60 | 102 | 4.37 |

| G–60J | 81.1 | 3.95 |

Comparison of specimen thickness and mass with different wire diameters

| Specimen (J) | Mass (g) | Volume (cm3) |

|---|---|---|

| 0.12–40 | 82.5 | 4.07 |

| 0.23–40 | 86.5 | 4.19 |

| 0.30–40 | 91.8 | 4.27 |

| 0.40–40 | 98.7 | 4.37 |

| 0.50–40 | 110.5 | 4.47 |

| G–40 | 81.1 | 3.95 |

2.2 Low-velocity impact test

LVI tests were conducted on an Instron Dynatup 9250HV drop-weight device, following the ASTM-D7136 standard as depicted in Figure 3. The specimen is placed on a fixed base with a spherical hammer that impacts the specimen in the center position, and four rubber grips are used to limit movement to prevent the specimen from moving during impact. Throughout the test, the speed, impact force, displacement, and impact time are recorded by the measuring system. After the test, a visual inspection is performed. In the impact test, each group of samples shall be tested at least three times. At the same time, the incident energies for the filament diameter group and the mesh number group were 40 and 60 J respectively. This is because compared with the wire diameter control group, the overall strength of the specimen in the mesh control group is higher than that in the wire diameter control group, so a greater energy is used to impact the specimen. Subsequently, their response modes and mechanical properties were analyzed. The specimens are named D-E, where D and E denote the specimen type and incident energy, respectively.

Setup of LVI testing.

2.3 Compression-after-impact test

To explore the residual strength of the specimen after impact, the specimen damaged by impact was subjected to a post-impact compression test. In general, the lower ends of the specimens were securely fixed, while the left and right boundaries constrained out-of-plane displacements. Compression-after-impact test are carried out on universal testing machine at a speed of 0.5 mm·min−1, according to the ASTM D7137 standard as shown in Figure 4. The digital image and its related technology were used to monitor and analyze the strain in the Y direction of the specimen.

Compression-after-impact test and DIC equipment.

3 Results and discussion

3.1 Effect of mesh diameter on hybrid structure

3.1.1 Damage mechanisms under low‐velocity impact

Figure 5(a) and (b) present a comparative analysis of the impact response histories, including contact force-time and contact force displacement, between composite laminates composed of glass fiber and steel mesh, and those composed of glass fiber alone. The results demonstrate that the former exhibit notable differences from the latter. Besides, the rebound occurred in all specimens, and those without steel wire rebounded more than those with steel wire mesh. In Figure 5(c), compared with pure GFRP samples, the peak displacement of the 0.50–40 J decreased by 23.1%, while the maximum force increased by 37.5%.

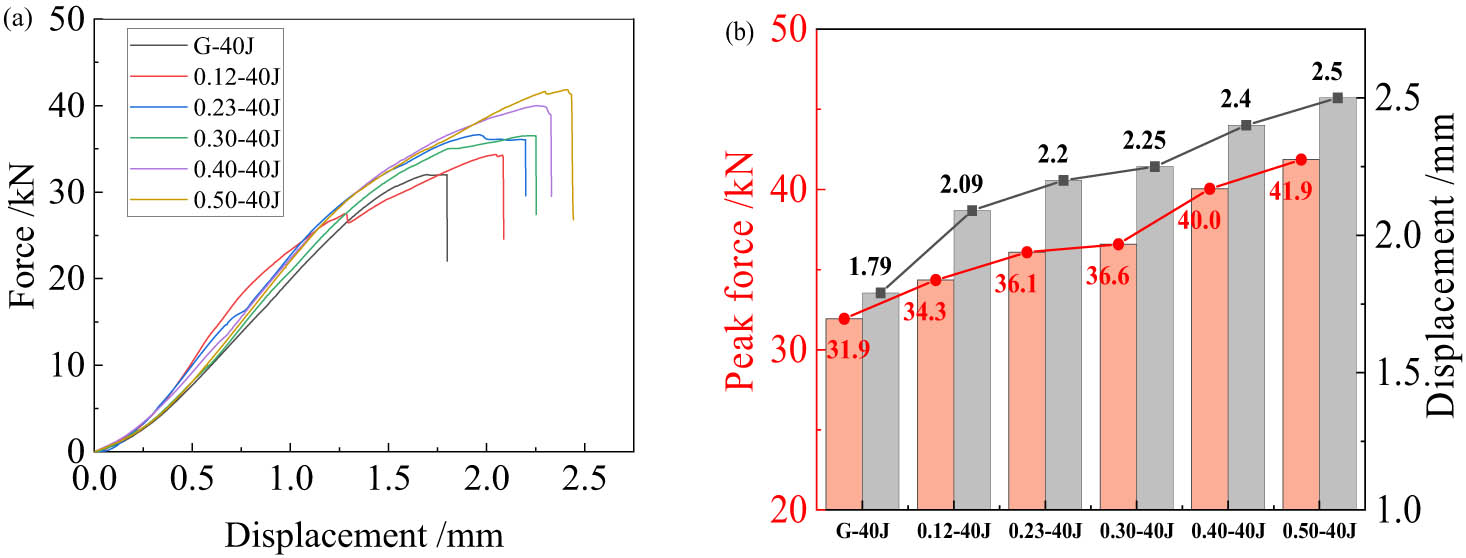

Comparison of six types of specimens on (a) force–displacement curve; (b) force–time curve; and (c) dual y-axis plots of peak load and maximum displacement.

After impact, both types of specimens show cross-shape fiber breakage along two directions of the layer as in Figure 6. When subjected to impact, the steel wire mesh absorbs the impact energy through plastic deformation, which increases the load and deformation degree and causes the deformation of the surrounding glass fibers, resulting in a larger delamination area than the pure GFRP specimen. Interestingly, the area of destruction decreases with the increase of the steel mesh. This suggests that steel mesh is a suitable material to be used in conjunction with GFRP in order to improve mechanical properties. The stiffness and impact resistance of specimens increase due to the impact energy absorbed through plastic deformation during impact, and the mechanical properties of the specimen increase.

Damage condition of different wire diameters samples at the LVI test.

3.1.2 Residual strength of GFRP laminates with different mesh diameter

As shown in Figure 7(a), it can be summarized into three phases. First, the graph commences with a similar slope while the deformation is concentrated at the point of impact. As the crack initiates in the laminate and the force increases, the slope of the force–displacement curve changes. Finally, the specimen experiences a sharp drop in contact force due to crack propagation. As a result, the samples were totally unqualified. The primary damage modes are fiber breakage interlaminar delamination, and 45° shear failure. Steel wire mesh absorbs impact energy through plastic deformation, increasing the load and degree of deformation in Figure 7(b). Large wire diameters absorb more impact energy and reduce damage.

Comparison of compression curves of specimens with different mesh numbers: (a) displacement-load; (b) peak load and maximum displacement.

In the beginning, the specimens in state uniform stress, with the increase of loading, the deformation is mainly concentrated at the point of impact as shown in Figure 8. It is noted that due to the increase in wire diameter, symmetrical stress is progressively concentrated in the superior portion of the specimen, ultimately leading to its failure which is different from pure-GFRP samples. From the damaged morphology of the laminate, destruction mostly happens where it is impacted as shown in Figure 9. Moreover, interlaminar delamination, fiber breakage, and 45° shear failure are the primary failure modes of the specimens.

CAI strain contour diagram of specimens with different wire diameters.

Damage morphology on the back and side of all cases after the CAI test.

3.2 Effect of mesh number on hybrid structure

3.2.1 Damage mechanisms under low‐velocity impact

Combined with the damage morphology’s appearance, the mechanical response of the LVI tests is analyzed in detail. The typical curves of samples with varying numbers of mesh in the LVI test are compared in Figure 10. As shown in Figure 10, the G–60 J shows relatively poor impact resistance. Compared to different meshes, high-density meshes will cause the peak force to increase while displacement decreases when the specimen is impacted, which means that the mechanical properties of the samples will be enhanced significantly. For example, compared with 20–60 and G–60 J, the specimen peak displacement decreased by 20.0%, while the ultima force increased by 43.7%.

Comparison of six types of specimens on (a) force–displacement curve; (b) force–time curve; and (c) dual y-axis plots of peak load and maximum displacement.

The number of meshes affects the stability and impact resistance of the specimen, so it is an important index to measure the density of steel wire mesh. For specimens with a small number of meshes, the energy needs to diffuse a larger area to the outside of the impact point, resulting in a larger damage area on both sides. After impact, all types of specimens show permanent cross-shape failures as shown in Figure 11. The GFRP layers are interconnected by filling epoxy resin into the wire net holes, which enhances the interface strength. Consequently, the hybrid laminates exhibit improved performance in withstanding LVI.

Damage condition of different mesh number samples at the LVI test.

3.2.2 Residual strength of GFRP laminate with different mesh number

In Figure 12, with the increase in the number of meshes embedded in the sample, the mechanical properties of the specimen after exposure to CAI are improved. Further, the performance of laminate increases with the increase of wire diameter. The specimen is evenly stressed as a whole, and as the compression process continues, the deformation is mainly concentrated at the impact point, and with the increase of the wire diameter, the originally symmetrical stress is gradually concentrated in the upper part of the specimen and destroyed at the end, which is the opposite of G–40 J.

Comparison of compression curves of specimens with different mesh numbers: (a) displacement-load; (b) peak load and maximum displacement.

The residual strength of CAI is critical for assessing the safety of the structure, and the strain distribution curve detected by DIC is shown in Figure 13. The overall shape of the strain is symmetrical, and both the form of delamination expansion and the final profile change significantly with increasing mesh, which reflects the complexity of the damage forms. Within the thickness direction, multiple damage modes are observed, including fiber fracture, fiber delamination, and 45° shear failure as shown in Figure 14. Besides, the difference in mesh does alter the final damage mode of the laminates and affects the initiation location and the extent of damage.

CAI strain contour diagram of specimens with different mesh numbers.

Damage morphology on the back and side of all cases after the CAI test.

4 Conclusion

In the experiment, it is shown how composite laminates with different meshes respond to LVI and CAI. The damage mechanism of the composites was studied by comparing the response history, visual inspection, and DIC technique. The main findings of this study are summarized as follows:

The significant ascent of impact strength and stiffness of GFRP laminate embedded with mesh is reflected in a drop in peak force and an increase in failure displacement. Further, the performance of laminate increases with the increase of wire diameter. Compared with 0.50–40 J in LVI, the peak force of G–40 J decreased by 30.9%, while the failure displacement increased by 10.9%.

The damage area of laminates under LVI decreases with the increase of mesh. Because epoxy resin is filled in the holes of steel wire mesh, the GFRP layers are connected together, and the interface strength is improved. The incident energy is absorbed and transferred through plastic deformation, which increases the failure area but improves the mechanical properties of the specimen.

The residual strength of the laminate embedded in the mesh is improved compared with that of the pure GFRP plate, and the failure mode is fiber delamination, fiber breakage, and 45° shear failure. During the failure process, the strain of the specimen is symmetrical, and most of the specimens are damaged at the impact point, and the cracks extend from the impact point to the edge of the specimen. Compared to increasing the wire diameter, increasing the mesh number will improve the mechanical properties of the specimen. For example, the peak force of 0.50–40 J increased by 10.5% from 41.9 to 37.5 kN compared with 20–60 J.

Acknowledgments

This work was sponsored by the National Natural Science Foundations of China (12362016).

-

Author contributions: Hongyuan Huang: conceptualization, methodology, software validation, formal analysis, writing – original draft, writing – review & editing, visualization, supervision, project administration, funding acquisition. Xuan Gao: formal analysis, investigation, and resources. Yilin Tu: data curation, writing – original draft, writing – review & editing, visualization, supervision, and project administration. Jiajun Lou: investigation, resources, and data curation. Ye Wu: conceptualization, methodology, investigation, resources, data curation, writing – review & editing. Shenshen Chen: data curation, writing – original draft, writing – review & editing, and visualization. Yun Wan: visualization, supervision, project administration, and funding acquisition.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The data that support the findings of this study are available on request from the corresponding author upon reasonable request.

References

(1) Xu M, Ji H, Wu Y, Meng X, Di J, Yang J, et al. Recovering glass fibers from waste wind turbine blades: Recycling methods, fiber properties, and potential utilization. Renewable Sustainable Energy Rev. 2024;202:114690.10.1016/j.rser.2024.114690Search in Google Scholar

(2) Wei J, Ke L, Wang P, Li W, Leung CKY. Microstructure, mechanical properties and interaction mechanism of seawater sea-sand engineered cementitious composite (SS-ECC) with glass fiber reinforced polymer (GFRP) bar. Compos Struct. 2024;343:118302.10.1016/j.compstruct.2024.118302Search in Google Scholar

(3) Wu Y, Wan Y. The low-velocity impact and compression after impact (CAI) behavior of foam core sandwich panels with shape memory alloy hybrid face-sheets. 2019;26(1):517–30.10.1515/secm-2019-0034Search in Google Scholar

(4) Yang T, Zhu D, Chen C. Mechanical properties and failure patterns of sandwich panels with AR-glass textile reinforced concrete face sheets subjected to quasi-static load. Thin-Walled Struct. 2023;193:111286.10.1016/j.tws.2023.111286Search in Google Scholar

(5) Jia M, Qian K, Yu K. Acoustic emission characteristics and failure patterns of basalt fiber and basalt textile reinforced concrete under flexural load. J Nat Fibers. 2022;19(16):14725–43.10.1080/15440478.2022.2068728Search in Google Scholar

(6) Huang Z, Cao S, Yilmaz E. Investigation on the flexural strength, failure pattern and microstructural characteristics of combined fibers reinforced cemented tailings backfill. Constr Build Mater. 2021;300:124005.10.1016/j.conbuildmat.2021.124005Search in Google Scholar

(7) Li X, Zhang Y, Shi C, Chen X. Experimental and numerical study on tensile strength and failure pattern of high performance steel fiber reinforced concrete under dynamic splitting tension. Constr Build Mater. 2020;259:119796.10.1016/j.conbuildmat.2020.119796Search in Google Scholar

(8) Zhang L, Wang X, Lu S, Jiang X, Ma C, Lin L, et al. Fatigue damage monitoring of repaired composite wind turbine blades using high-stability buckypaper sensors. Compos Sci Technol. 2022;227:109592.10.1016/j.compscitech.2022.109592Search in Google Scholar

(9) Zhang L, Wang X, Lu S, Guo Y, Wang Y, Liu X, et al. Strain and crack growth monitoring of aluminum alloy sheet using high-sensitivity buckypaper film sensors. Sensors Actuators A Phys. 2023;363:114697.10.1016/j.sna.2023.114697Search in Google Scholar

(10) Zaleha M, Mahzan S, Fitri M, Kamarudin KA, Eliza Y, Tobi ALM. Wave velocity characteristic for Kenaf natural fibre under impact damage. IOP Conf Ser Mater Sci Eng. 2017;165(1):012018.10.1088/1757-899X/165/1/012018Search in Google Scholar

(11) Xu W, Chen J, Cui X, Wang D, Pu Y. ow-velocity impact analysis and multi-objective optimization of hybrid carbon/basalt fibre reinforced composite laminate. Compos Struct. 2024;343:118305.10.1016/j.compstruct.2024.118305Search in Google Scholar

(12) Krishna Prasad A, Natrayan L. Compression and impact investigation of GFRP epoxy with novel hybrid Banana-Prosopis Juliflora GFRP composite. Mater Today Proc. 2022;69:1369–74.10.1016/j.matpr.2022.09.004Search in Google Scholar

(13) Lyu Q, Wang B, Guo Z. Predicting post-impact compression strength of composite laminates under multiple low-velocity impacts. Compos Part A: Appl Sci Manuf. 2023;164:107322.10.1016/j.compositesa.2022.107322Search in Google Scholar

(14) Wang K, Taheri F. Experimental and numerical analysis of low-velocity impact and compression after impact responses of novel 3D hybrid composites. Compos Struct. 2024;338:118133.10.1016/j.compstruct.2024.118133Search in Google Scholar

(15) Xiao H, Liu T, Li T, Duan Y. Design of damage-resistant hybrid lay-up structures for fiber-reinforced composites based on interface properties. Compos Struct. 2023;319:117210.10.1016/j.compstruct.2023.117210Search in Google Scholar

(16) Nag MK, Kumar P. Fabrication and characterization of laminated natural fibers and SS303 wire mesh reinforced epoxy-based hybrid composite. Proc Inst Mech Eng Part L. 2023;238(1):73–99.10.1177/14644207231183966Search in Google Scholar

(17) Kumar A, Singh A. Mechanical characterization of pineapple leaf fiber epoxy composites with steel wire mesh. Key Eng Mater. 2023;960:205–17.10.4028/p-cpZe1oSearch in Google Scholar

(18) Singh CQJ, Rajamurugan G. Effect of resin on mechanical and wear performance of wire mesh-reinforced hydrophilic fiber composite. Trans Indian Inst Met. 2021;74(11):2853–67.10.1007/s12666-021-02359-7Search in Google Scholar

(19) Bahl S. Axisymmetric finite element analysis of single fiber push-out test for stainless steel wire reinforced aluminum matrix composites. Mater Today: Proc. 2020;28:1605–11.10.1016/j.matpr.2020.04.848Search in Google Scholar

(20) Liu B, Wang W, Sutherland L. Experimental and numerical response and failure of laterally impacted carbon/glass fibre-reinforced hybrid composite laminates. Int J Impact Eng. 2023;179:104654.10.1016/j.ijimpeng.2023.104654Search in Google Scholar

(21) Nassir NA, Birch RS, Cantwell WJ, Guan ZW. The response of glass fibre reinforced PEKK laminates subjected to single and multiple impact loading. Polym Test. 2024;131:108323.10.1016/j.polymertesting.2023.108323Search in Google Scholar

(22) Nagumo Y, Hamanaka M, Shirasu K, Ryuzono K, Yoshimura A, Tohmyoh H, et al. Fracture mechanism of carbon fiber-reinforced thermoplastic composite laminates under compression after impact. J Compos Mater. 2024;58(11):1377–90.10.1177/00219983241240622Search in Google Scholar

(23) Seamone A, Davidson P, Waas AM, Ranatunga V. Low velocity impact and compression after impact of thin and thick laminated carbon fiber composite panels. Int J Solids Struct. 2024;292:112745.10.1016/j.ijsolstr.2024.112745Search in Google Scholar

(24) de Paiva JMF, Hosokawa MN, Montagna LS, Rezende MC. Effect of hygrothermal conditioning on compressive strength after impact in carbon fiber/epoxy composites. J Appl Polym Sci. 2024;141(16):e55237.10.1002/app.55237Search in Google Scholar

(25) Li H, Yu Z, Tao Z, Liu K. Experimental investigations on the repeated low velocity impact and compression-after-impact behaviors of woven glass fiber reinforced composite laminates. Polym Compos. 2024;45(2):1884–97.10.1002/pc.27896Search in Google Scholar

(26) Krishnasamy P, Rajamurugan G, Thirumurugan M. Dynamic mechanical characteristics of jute fiber and 304 wire mesh reinforced epoxy composite. J Ind Text. 2019;51(4):540–58.10.1177/1528083719883057Search in Google Scholar

(27) Megahed AA, Abd El-Wadoud F, Wagih A, Kabeel AM. Effect of incorporating aluminum wire mesh on the notched and un-notched strengths of glass fiber/epoxy composites. Compos Struct. 2021;263:113695.10.1016/j.compstruct.2021.113695Search in Google Scholar

(28) Wu Y, You P, Hua W, Liu C, Zhang S, Liu Y. Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading. e-Polymers. 2024;24(1):20240002.10.1515/epoly-2024-0002Search in Google Scholar

(29) Sadoun AM, El-Wadoud FA, Fathy A, Kabeel AM, Megahed AA. Effect of through-the-thickness position of aluminum wire mesh on the mechanical properties of GFRP/Al hybrid composites. J Mater Res Technol. 2021;15:500–10.10.1016/j.jmrt.2021.08.026Search in Google Scholar

(30) Tu Y, Li X, Huang H, Chen C, Liu G, Liu Y, et al. Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets. e-Polymers. 2024;24(1):20240021.10.1515/epoly-2024-0021Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Flame-retardant thermoelectric responsive coating based on poly(3,4-ethylenedioxythiphene) modified metal–organic frameworks

- Highly stretchable, durable, and reversibly thermochromic wrapped yarns induced by Joule heating: With an emphasis on parametric study of elastane drafts

- Molecular dynamics simulation and experimental study on the mechanical properties of PET nanocomposites filled with CaCO3, SiO2, and POE-g-GMA

- Multifunctional hydrogel based on silk fibroin/thermosensitive polymers supporting implant biomaterials in osteomyelitis

- Marine antifouling coating based on fluorescent-modified poly(ethylene-co-tetrafluoroethylene) resin

- Preparation and application of profiled luminescent polyester fiber with reversible photochromism materials

- Determination of pesticide residue in soil samples by molecularly imprinted solid-phase extraction method

- The die swell eliminating mechanism of hot air assisted 3D printing of GF/PP and its influence on the product performance

- Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes

- The effects of property variation on the dripping behaviour of polymers during UL94 test simulated by particle finite element method

- Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets

- Synthesis, characterization and evaluation of a pH-responsive molecular imprinted polymer for Matrine as an intelligent drug delivery system

- Twist-related parametric optimization of Joule heating-triggered highly stretchable thermochromic wrapped yarns using technique for order preference by similarity to ideal solution

- Comparative analysis of flow factors and crystallinity in conventional extrusion and gas-assisted extrusion

- Simulation approach to study kinetic heterogeneity of gadolinium catalytic system in the 1,4-cis-polyisoprene production

- Properties of kenaf fiber-reinforced polyamide 6 composites

- Cellulose acetate filter rods tuned by surface engineering modification for typical smoke components adsorption

- A blue fluorescent waterborne polyurethane-based Zn(ii) complex with antibacterial activity

- Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading

- Preparation and application research of composites with low vacuum outgassing and excellent electromagnetic sealing performance

- Assessing the recycling potential of thermosetting polymer waste in high-density polyethylene composites for safety helmet applications

- Mesoscale mechanics investigation of multi-component solid propellant systems

- Preparation of HTV silicone rubber with hydrophobic–uvioresistant composite coating and the aging research

- Experimental investigation on tensile behavior of CFRP bolted joints subjected to hydrothermal aging

- Structure and transition behavior of crosslinked poly(2-(2-methoxyethoxy) ethylmethacrylate-co-(ethyleneglycol) methacrylate) gel film on cellulosic-based flat substrate

- Mechanical properties and thermal stability of high-temperature (cooking temperature)-resistant PP/HDPE/POE composites

- Preparation of itaconic acid-modified epoxy resins and comparative study on the properties of it and epoxy acrylates

- Synthesis and properties of novel degradable polyglycolide-based polyurethanes

- Fatigue life prediction method of carbon fiber-reinforced composites

- Thermal, morphological, and structural characterization of starch-based bio-polymers for melt spinnability

- Robust biaxially stretchable polylactic acid films based on the highly oriented chain network and “nano-walls” containing zinc phenylphosphonate and calcium sulfate whisker: Superior mechanical, barrier, and optical properties

- ARGET ATRP of styrene with low catalyst usage in bio-based solvent γ-valerolactone

- New PMMA-InP/ZnS nanohybrid coatings for improving the performance of c-Si photovoltaic cells

- Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites

- Preparation of cardanol-based curing agent for underwater drainage pipeline repairs

- Preparation of lightweight PBS foams with high ductility and impact toughness by foam injection molding

- Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study

- Experimental study on impact and flexural behaviors of CFRP/aluminum-honeycomb sandwich panel

- Normal-hexane treatment on PET-based waste fiber depolymerization process

- Effect of tannic acid chelating treatment on thermo-oxidative aging property of natural rubber

- Design, synthesis, and characterization of novel copolymer gel particles for water-plugging applications

- Influence of 1,1′-Azobis(cyclohexanezonitrile) on the thermo-oxidative aging performance of diolefin elastomers

- Characteristics of cellulose nanofibril films prepared by liquid- and gas-phase esterification processes

- Investigation on the biaxial stretching deformation mechanism of PA6 film based on finite element method

- Simultaneous effects of temperature and backbone length on static and dynamic properties of high-density polyethylene-1-butene copolymer melt: Equilibrium molecular dynamics approach

- Research on microscopic structure–activity relationship of AP particle–matrix interface in HTPB propellant

- Three-layered films enable efficient passive radiation cooling of buildings

- Electrospun nanofibers membranes of La(OH)3/PAN as a versatile adsorbent for fluoride remediation: Performance and mechanisms

- Preparation and characterization of biodegradable polyester fibers enhanced with antibacterial and antiviral organic composites

- Preparation of hydrophobic silicone rubber composite insulators and the research of anti-aging performance

- Surface modification of sepiolite and its application in one-component silicone potting adhesive

- Study on hydrophobicity and aging characteristics of epoxy resin modified with nano-MgO

- Optimization of baffle’s height in an asymmetric twin-screw extruder using the response surface model

- Effect of surface treatment of nickel-coated graphite on conductive rubber

- Experimental investigation on low-velocity impact and compression after impact behaviors of GFRP laminates with steel mesh reinforced

- Development and characterization of acetylated and acetylated surface-modified tapioca starches as a carrier material for linalool

- Investigation of the compaction density of electromagnetic moulding of poly(ether-ketone-ketone) polymer powder

- Experimental investigation on low-velocity-impact and post-impact-tension behaviors of GFRP T-joints after hydrothermal aging

- The repeated low-velocity impact response and damage accumulation of shape memory alloy hybrid composite laminates

- Exploring a new method for high-performance TPSiV preparation through innovative Si–H/Pt curing system in VSR/TPU blends

- Large-scale production of highly responsive, stretchable, and conductive wrapped yarns for wearable strain sensors

- Preparation of natural raw rubber and silica/NR composites with low generation heat through aqueous silane flocculation

- Molecular dynamics simulation of the interaction between polybutylene terephthalate and A3 during thermal-oxidative aging

- Crashworthiness of GFRP/aluminum hybrid square tubes under quasi-static compression and single/repeated impact

- Review Articles

- Recent advancements in multinuclear early transition metal catalysts for olefin polymerization through cooperative effects

- Impact of ionic liquids on the thermal properties of polymer composites

- Recent progress in properties and application of antibacterial food packaging materials based on polyvinyl alcohol

- Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters

- Rapid Communication

- Design, synthesis, characterization, and adsorption capacities of novel superabsorbent polymers derived from poly (potato starch xanthate-graft-acrylamide)

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Development of smart core–shell nanoparticles-based sensors for diagnostics of salivary alpha-amylase in biomedical and forensics

- Thermoplastic-polymer matrix composite of banana/betel nut husk fiber reinforcement: Physico-mechanical properties evaluation

- Special Issue: Electrospun Functional Materials

- Electrospun polyacrylonitrile/regenerated cellulose/citral nanofibers as active food packagings

Articles in the same Issue

- Research Articles

- Flame-retardant thermoelectric responsive coating based on poly(3,4-ethylenedioxythiphene) modified metal–organic frameworks

- Highly stretchable, durable, and reversibly thermochromic wrapped yarns induced by Joule heating: With an emphasis on parametric study of elastane drafts

- Molecular dynamics simulation and experimental study on the mechanical properties of PET nanocomposites filled with CaCO3, SiO2, and POE-g-GMA

- Multifunctional hydrogel based on silk fibroin/thermosensitive polymers supporting implant biomaterials in osteomyelitis

- Marine antifouling coating based on fluorescent-modified poly(ethylene-co-tetrafluoroethylene) resin

- Preparation and application of profiled luminescent polyester fiber with reversible photochromism materials

- Determination of pesticide residue in soil samples by molecularly imprinted solid-phase extraction method

- The die swell eliminating mechanism of hot air assisted 3D printing of GF/PP and its influence on the product performance

- Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes

- The effects of property variation on the dripping behaviour of polymers during UL94 test simulated by particle finite element method

- Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets

- Synthesis, characterization and evaluation of a pH-responsive molecular imprinted polymer for Matrine as an intelligent drug delivery system

- Twist-related parametric optimization of Joule heating-triggered highly stretchable thermochromic wrapped yarns using technique for order preference by similarity to ideal solution

- Comparative analysis of flow factors and crystallinity in conventional extrusion and gas-assisted extrusion

- Simulation approach to study kinetic heterogeneity of gadolinium catalytic system in the 1,4-cis-polyisoprene production

- Properties of kenaf fiber-reinforced polyamide 6 composites

- Cellulose acetate filter rods tuned by surface engineering modification for typical smoke components adsorption

- A blue fluorescent waterborne polyurethane-based Zn(ii) complex with antibacterial activity

- Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading

- Preparation and application research of composites with low vacuum outgassing and excellent electromagnetic sealing performance

- Assessing the recycling potential of thermosetting polymer waste in high-density polyethylene composites for safety helmet applications

- Mesoscale mechanics investigation of multi-component solid propellant systems

- Preparation of HTV silicone rubber with hydrophobic–uvioresistant composite coating and the aging research

- Experimental investigation on tensile behavior of CFRP bolted joints subjected to hydrothermal aging

- Structure and transition behavior of crosslinked poly(2-(2-methoxyethoxy) ethylmethacrylate-co-(ethyleneglycol) methacrylate) gel film on cellulosic-based flat substrate

- Mechanical properties and thermal stability of high-temperature (cooking temperature)-resistant PP/HDPE/POE composites

- Preparation of itaconic acid-modified epoxy resins and comparative study on the properties of it and epoxy acrylates

- Synthesis and properties of novel degradable polyglycolide-based polyurethanes

- Fatigue life prediction method of carbon fiber-reinforced composites

- Thermal, morphological, and structural characterization of starch-based bio-polymers for melt spinnability

- Robust biaxially stretchable polylactic acid films based on the highly oriented chain network and “nano-walls” containing zinc phenylphosphonate and calcium sulfate whisker: Superior mechanical, barrier, and optical properties

- ARGET ATRP of styrene with low catalyst usage in bio-based solvent γ-valerolactone

- New PMMA-InP/ZnS nanohybrid coatings for improving the performance of c-Si photovoltaic cells

- Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites

- Preparation of cardanol-based curing agent for underwater drainage pipeline repairs

- Preparation of lightweight PBS foams with high ductility and impact toughness by foam injection molding

- Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study

- Experimental study on impact and flexural behaviors of CFRP/aluminum-honeycomb sandwich panel

- Normal-hexane treatment on PET-based waste fiber depolymerization process

- Effect of tannic acid chelating treatment on thermo-oxidative aging property of natural rubber

- Design, synthesis, and characterization of novel copolymer gel particles for water-plugging applications

- Influence of 1,1′-Azobis(cyclohexanezonitrile) on the thermo-oxidative aging performance of diolefin elastomers

- Characteristics of cellulose nanofibril films prepared by liquid- and gas-phase esterification processes

- Investigation on the biaxial stretching deformation mechanism of PA6 film based on finite element method

- Simultaneous effects of temperature and backbone length on static and dynamic properties of high-density polyethylene-1-butene copolymer melt: Equilibrium molecular dynamics approach

- Research on microscopic structure–activity relationship of AP particle–matrix interface in HTPB propellant

- Three-layered films enable efficient passive radiation cooling of buildings

- Electrospun nanofibers membranes of La(OH)3/PAN as a versatile adsorbent for fluoride remediation: Performance and mechanisms

- Preparation and characterization of biodegradable polyester fibers enhanced with antibacterial and antiviral organic composites

- Preparation of hydrophobic silicone rubber composite insulators and the research of anti-aging performance

- Surface modification of sepiolite and its application in one-component silicone potting adhesive

- Study on hydrophobicity and aging characteristics of epoxy resin modified with nano-MgO

- Optimization of baffle’s height in an asymmetric twin-screw extruder using the response surface model

- Effect of surface treatment of nickel-coated graphite on conductive rubber

- Experimental investigation on low-velocity impact and compression after impact behaviors of GFRP laminates with steel mesh reinforced

- Development and characterization of acetylated and acetylated surface-modified tapioca starches as a carrier material for linalool

- Investigation of the compaction density of electromagnetic moulding of poly(ether-ketone-ketone) polymer powder

- Experimental investigation on low-velocity-impact and post-impact-tension behaviors of GFRP T-joints after hydrothermal aging

- The repeated low-velocity impact response and damage accumulation of shape memory alloy hybrid composite laminates

- Exploring a new method for high-performance TPSiV preparation through innovative Si–H/Pt curing system in VSR/TPU blends

- Large-scale production of highly responsive, stretchable, and conductive wrapped yarns for wearable strain sensors

- Preparation of natural raw rubber and silica/NR composites with low generation heat through aqueous silane flocculation

- Molecular dynamics simulation of the interaction between polybutylene terephthalate and A3 during thermal-oxidative aging

- Crashworthiness of GFRP/aluminum hybrid square tubes under quasi-static compression and single/repeated impact

- Review Articles

- Recent advancements in multinuclear early transition metal catalysts for olefin polymerization through cooperative effects

- Impact of ionic liquids on the thermal properties of polymer composites

- Recent progress in properties and application of antibacterial food packaging materials based on polyvinyl alcohol

- Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters

- Rapid Communication

- Design, synthesis, characterization, and adsorption capacities of novel superabsorbent polymers derived from poly (potato starch xanthate-graft-acrylamide)

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Development of smart core–shell nanoparticles-based sensors for diagnostics of salivary alpha-amylase in biomedical and forensics

- Thermoplastic-polymer matrix composite of banana/betel nut husk fiber reinforcement: Physico-mechanical properties evaluation

- Special Issue: Electrospun Functional Materials

- Electrospun polyacrylonitrile/regenerated cellulose/citral nanofibers as active food packagings