Abstract

A series of high temperature vulcanization (HTV) silicone rubbers with TiO2 ultraviolet (UV) shielding layer and polytetrafluoroethylene (PTFE) hydrophobic layer were prepared via stepwise spray method. It was found that the hydrophobic PTFE liquid emulsion (PTFEL) could steadily and tightly adhere to the HTV silicone rubber surface by spray method after pre-mixing with permanent room temperature vulcanized (PRTV) silicone rubber during the first step spray. And the subsequent introduction of TiO2 and PTEF solid powder (PTFES) could improve the UV shielding ability and further increase the hydrophobicity of HTV silicone rubber during the second step spray after pre-blending. The accelerated hygrothermal aging process and UV aging process were used to analyze the effect of coating structure and composition on anti-aging performance. And the results indicated that the HTV silicone rubber with PRTV-PTFEL/TiO2-PTFES composite coating showed a favorable UV shielding ability and also possessed an excellent hydrophobicity due to the introduction of low surface energy matter and the building of coarse micro-nano hydrophobic structure. After the aging process, the cracked micro-surface, increased water absorption and decreased mechanical property were displayed for the neat HTV silicone rubber, and these aging phenomena got dramatically improved for PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubber.

Graphical abstract

High temperature vulcanization silicone rubber with hydrophobic–uvioresistant composite coating built by stepwise spray method showed a micro-nano structure and displayed the favorable hydrophobicity and ultraviolet shielding capability.

1 Introduction

High temperature vulcanization (HTV) silicone rubber is a kind of polymer material with silicon oxygen chain as the main chain, and its side chain is usually dimethyl or methyl vinyl structure, which has the advantages of high-low temperature resistance, corrosion resistance and pollution flash resistance, etc. Silicone rubber materials have a very wide application in industrial field due to its outstanding electrical properties and pollution resistance and hydrophobicity, such as the fields of automotive electronics, aerospace and insulated power transmission, etc. (1,2,3). However, the HTV silicone rubber is easy to be aged during the long-term outdoor operation, especially under the condition with high humidity, high temperature and intense ultraviolet (UV) radiation (4,5). Generally, the aging phenomena includes the break of molecular chain, the deterioration of hydrophobicity, the hardening and cracking of surface and the decrease in mechanical property, which will cause severe security incident (6). Therefore, it is important to develop the new HTV silicone rubbers with favorable anti-aging performance.

Many attempts have been made to improve the anti-aging performance of HTV silicone rubber by introducing UV absorbent (7). Zhang et al. (8) doped nano-TiO2 particles in silicone rubber matrix to prepare silicone rubber composite through blending to improve the anti-aging performance under UV radiation. Peng et al. (9) added three kinds of organic UV absorbers into silicone rubber to improve its anti-UV aging ability. Except the effect of UV radiation, the existence of water can also facilitate the break of Si–O molecular chain and accelerate the aging process of HTV silicone rubber, especially in high temperature conditions (10,11). Thus, it is workable to improve the hygrothermal aging performance of HTV silicone rubber by increasing hydrophobicity. Presently, surface etching or surface fluorination is the main technique to increase its surface hydrophobicity. Chen et al. (12) constructed a micro-nano hierarchical structure and mastoid structure on the HTV silicone rubber surface to increase its roughness by femtosecond laser etching technology, which could effectively improve its hydrophobicity. Gao et al. (13) used coupled plasma technology to carry out low temperature plasma etching and fluoride treatment on the surface of HTV silicone rubber for hydrophobic modification. However, the equipment of current technology is expensive and inconvenient. And the etching method itself is also a destructive force for the HTV silicone rubber surface which will reduce the anti-UV aging performance, in spite of the improvement of hydrophobicity. The reported literature were focused on the single hydrophobic research or UV resistance research (14,15). It is important to develop a technology to prepare the HTV silicone rubber with excellent hygrothermal aging resistance and UV aging resistance simultaneously.

The increase in surface roughness is an effective method to improve the material’s hydrophobicity which has been verified and well known (16,17,18). Nano-TiO2 particle is a kind of remarkable anti-UV agent and has been widely applied in anti-UV fields (19,20). Fluorine is one of the most electronegative elements and fluorine materials such as the polytetrafluoroethylene (PTFE) are usually used to decrease the surface energy and increase the hydrophobicity of other materials (21,22). Usually, the traditional methods used to introduce TiO2 nanoparticles (NPs) or PTFE into the HTV silicone rubber matrix include blending modification and in situ growth in surface, etc. However, for HTV silicone rubber materials, the anti-UV function and hydrophobic effect should occur on the surface preferentially. Generally, the blending modification needs more content of additive and the surface coating layer generated by in situ growth is not very steady. Besides, the TiO2 NPs and PTFE are difficult to adhere to the surface of HTV silicone rubber without other assistant adhesive. Permanent room temperature vulcanized (PRTV) silicone rubber is a kind of silicone rubber which has a good hydrophobicity and can be cured under room temperature. Because of its molecular chain structure being similar to that of HTV silicone rubber, the PRTV can tightly adhere to the surface of HTV silicone rubber. Thus, in this work, the TiO2 NPs and PTFE were complementarily combined and introduced onto the surface of HTV silicone rubber by stepwise spray method to build the composite coating with hydrophobic and UV resistant characteristic using PRTV as the binding layer. The microstructure and composition of the composite coating were analyzed to study the effect on aging resistance performance. The Scanning electron microscopy (SEM), water absorption, water contact angle (CA), mechanical property, etc., were used to characterize the performance changes after aging process, and the X-Ray diffraction (XRD), Fourier-transform infrared (FTIR) and UV-visible diffuse reflectance spectroscopy ((UV-Vis DRS) were used to analyze the mechanism.

2 Materials and methods

2.1 Materials

The commercial high temperature vulcanized (HTV) silicone rubber was supplied by China Southern Power Grid (Guangzhou, China). The PTFE solid powder (PTFES) and PTFE liquid emulsion (PTFEL) were purchased from Zhenxing Plastic Co., Ltd (Dongguan, China), the PRTV silicone rubber was purchased from Hebei Guangbei Electric Power Technology Co., Ltd (Handan, China). The analytical reagent acetone and ethyl alcohol were purchased from Sinopharm Chemical Reagent Co., Ltd (Shanghai, China). And the rutile TiO2 NPs and Trichloro(1H,1H,2H,2H-tridecafluoro-n-octyl) silane (C8H4Cl3F13Si) were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd (Shanghai, China).

2.2 Preparation

2.2.1 Fluorination modification of TiO2 NPS

According to Wu et al. (23), a certain amount of TiO2 NPS were dispersed in ethanol-water (volume ratio 8:2) mixture under ultrasound for 30 min, and then 2 wt% Trichloro(1H, 1H, 2H, 2H-tridecafluoro-n-octyl) silane was added and stirred. Then, the NaOH aqueous solution was dropwise added to adjust the solution pH to 8.0. Subsequently, the reaction was performed at 60°C for 4 h. After the reaction, the mixture was centrifuged and the residue was washed with water and ethanol orderly. Finally, the fluorination modified TiO2 (F–TiO2) NPS were acquired after freeze-drying. For convenience, the TiO2 particles used in this work and described in later section were fluorination modified TiO2.

2.2.2 Preparation of composite coatings HTV silicone rubber

The HTV silicone rubbers with different composite coatings were prepared by stepwise spray method. Using the PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubber as an example, the specific preparation process is shown in Figure 1. First, the PRTV and PTFEL with 2:1 mass ratio were pre-mixed to prepare mixture A with 50 wt% concentration using acetone as solvent. At the same time, the F–TiO2 NPS and PTFES with 2:1 ratio were also pre-blended to prepare mixture B with 50 wt% concentration using acetone as dispersant. Then, the mixture A was sprayed to the surface of neat HTV silicone rubber to pre-cure for 30 min under room temperature. Subsequently, the mixture B was also sprayed to the above HTV silicone rubber surface and kept for another 30 min to volatilize the solvent under room temperature. The average coating thickness on HTV silicone rubber was about 12 μm. Then, this silicone rubber was cured under 80°C for 6 h to obtain the PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubber. In this work, other HTV silicone rubbers with PRTV/TiO2 coating, PRTV-PTFEL/TiO2 coating and PRTV/TiO2-PTFES coating were also prepared by similar stepwise spray method.

Schematic of the preparation process for PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubber. (a) Neat HTV silicone rubber. (b) PRTV-PTFEL coating HTV silicone rubber. (c) PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubber.

2.3 Measurements

2.3.1 Aging experiment

2.3.1.1 Hygrothermal aging experiment

The hygrothermal aging process of different HTV silicone rubbers was performed in a thermal-humidity test chamber (ST-80L, Xiamen Yishite Instruments Co., Ltd, China) under 70°C and 93% RH for 1, 2, 3 and 4 weeks, respectively.

2.3.1.2 UV aging experiment

The UV aging process of different HTV silicone rubbers was performed in a UV aging test chamber (ASR-ZW-151A, Guangdong Aisry Instrument Technology Co., Ltd, China) under 40°C and 200–280 nm UVC radiation for 200, 400 and 600 h, respectively.

2.3.2 FTIR spectrometer analysis

The structure of prepared F–TiO2 NPS was analyzed by Fourier-transform infrared spectrometer (Nicolet iS10 USA). The scanning range was 400–4,000 cm−1 and the scanning rate was 20 min−1.

2.3.3 XRD analysis

The crystal structure of prepared composite coatings HTV silicone rubbers was tested by TD-3500 X-ray diffractometer (China) under room temperature. The testing range of diffraction angle 2θ was 10–75°.

2.3.4 UV-vis DRS analysis

The UV light response performance of prepared composite coatings HTV silicone rubbers was analyzed by UV-vis DRS (Shimadzu UV-3600i Plus, Japan) within 200–800 nm wavelength range.

2.3.5 SEM analysis

The microstructure of the surface for prepared composite coatings HTV silicone rubbers before aging process was observed by ZEISS Sigma 300 SEM (Germany). And after aging process, the microstructure was observed by Hitachi TM3030 SEM (Japan).

2.3.6 Contact angle (CA) analysis

The hydrophily or hydrophobicity of the prepared composite coatings HTV silicone rubbers before and after aging was tested by CA meter (Dataphysics OCA20, Germany).

2.3.7 Moisture content and water absorption analysis

The moisture content of the prepared composite coatings HTV silicone rubbers after different aging time was measured by the mass change and could be calculated with the following formula (24):

where m 0 is the mass of HTV silicone rubbers before drying, and m 1 is the mass of HTV silicone rubbers after drying.

Water absorption of the prepared composite coatings HTV silicone rubbers after different aging time was also measured by the mass change and could be calculated with the following formula (24):

where m 0 is the mass of HTV silicone rubbers before absorbing water, and m 1 is the mass of HTV silicone rubbers after absorbing water.

2.3.8 Mechanical property

The mechanical property of prepared composite coatings HTV silicone rubbers after different aging time was measured by electronic universal testing machine (Shimadzu AGS-X-50N, Japan).

3 Results and discussion

3.1 Preparation and structure analysis of modified TiO2 NPs

In order to make good interface compatibility between inorganic TiO2 NPs with organic PRTV phase, and also to improve the hydrophobicity of TiO2 particles, the pure TiO2 NPs were modified by coupling agent Trichloro(1H,1H,2H, 2H-tridecafluoro-n-octyl) silane to graft the hydrophobic organic chains. The modification mechanism is shown in Figure 2. The chlorine groups of trichlorosilane can readily generate silanol groups through hydrolysis under alkaline conditions, which subsequently undergo dehydration synthesis to form Ti–O–Si bonds by reacting with the hydroxyl groups on the surface of TiO2 particles.

Coupling modification mechanism and preparation of fluorinated TiO2.

The structure of TiO2 nano particles before and after fluorinating modification was characterized by FTIR analysis. As shown in Figure 3, compared with the spectrum of pure TiO2 NPs, there were four new absorption peaks appeared in the spectrum of F–TiO2 particles at 1,249, 1,216, 1,142 and 1,120 cm−1, respectively. According to the literature (25), the absorption peaks at 1,249 and 1,216 cm−1 were attributed to the asymmetric stretching vibration mode of F–C–F (νasCF2), and the absorption peaks at 1,142 and 1,120 cm−1 were attributed to the symmetrical stretching vibration mode of F–C–F (νsCF2). The FTIR result indicated the successful preparation of F–TiO2 particles.

FTIR spectrum analysis of TiO2 particles before and after fluorating modification.

3.2 Microstructure observation of HTV silicone rubbers

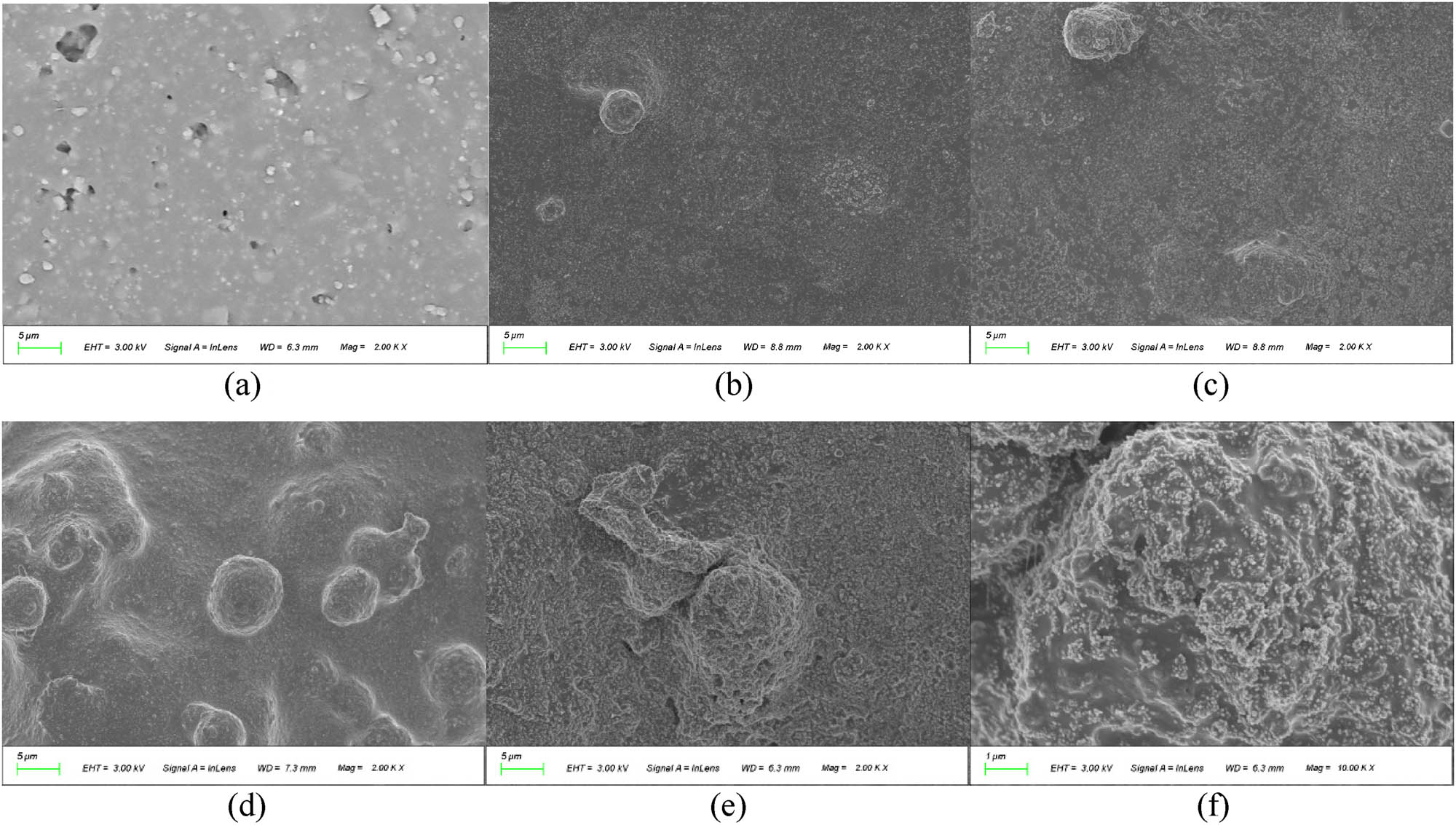

The microstructures of prepared HTV silicone rubbers with different coatings were observed by electron scanning microscope as shown in Figure 4. It could be clearly seen that the microscopic surface of neat HTV silicone rubber (Figure 4a) was porous and relatively smooth. Many exposed white particulate matters could be found in silicone rubber matrix which might be the inorganic reinforced fillers like SiO2, Al(OH)3, Al2O3, etc. However, this phenomenon disappeared after the introduction of composite coatings because of its covering function. Besides, the TiO2 NPs were dispersed uniformly on the surface by spray method in Figure 4b except for a little agglomeration. The PTFEL phase was compatible with PRTV and no evident phase separation could be found between them in Figure 4c. After the further introduction of PTFES, many big and spherical particles could be observed in Figure 4d and e. Enlarging the microstructure image of PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubber further, a typically coarse micro-nano composite structure could be clearly seen in Figure 4f, which was beneficial to the UV shielding and hydrophobicity promotion.

SEM microstructure of different HTV silicone rubber: (a) Neat HTV silicone rubber, (b) + PRTV/TiO2 coating, (c) + PRTV-PTFEL/TiO2 coating, (d) + PRTV/TiO2-PTFES coating, (e) + PRTV-PTFEL /TiO2-PTFES coating, and (f) enlargement of image (e). (a)–(e) ×2.0 k and (f) ×10.0 k.

3.3 UV-vis DRS analysis of HTV silicone rubbers

The UV-visible diffuse reflection spectrum was used to analyze the shielding effect of HTV silicone rubber on UV radiation. As shown in Figure 5, the neat HTV silicone rubber showed extremely low reflectance on UV radiation within the 200–550 nm regions, indicating a strong absorption on UV. However, this reflectance for composite coatings HTV silicone rubbers was increased markedly during the whole 200–800 nm test region. High reflectance meant low absorption. The increase in UV reflectance for composite coatings HTV silicone rubbers can be attributed to two reasons. First, the nano TiO2 is an excellent UV shielding agent and can scatter the UV radiation. Besides, the formation of large coarse surface on the composite coatings HTV silicone rubbers can also effectively reflect and scatter the UV radiation. Thus, the shielding effect of HTV silicone rubber on UV radiation was dramatically improved after the introduction of composite coatings. And in this work, the UV shielding effect for prepared HTV silicone rubbers with different composite coatings was hardly different, which may be resulted by their alike coarse surface and similar composition.

UV-visible diffuse reflection spectra of different HTV silicone rubber.

3.4 Analysis of crystallization properties of HTV silicone rubbers

The X-ray spectra of HTV silicone rubbers with different composite coatings before and after hygrothermal aging or UV aging are shown in Figure 6. An evident diffraction peak at 2θ = 17.4° corresponding to the (1,0,0) plane could be observed for the neat PTFES particles (26), and which could also be observed in the XRD spectra for the HTV silicone rubbers with PRTV/TiO2-PTFES coating and PRTV-PTFEL/TiO2-PTFES coating. As to the HTV silicone rubbers with PRTV-PTFEL/TiO2 coating, the PTFEL component was amorphous phase, and no PTFE diffraction peak could be observed. Some main diffraction peaks at 2θ = 20.4°, 35.9°, 41.0°, 54.1°, 56.5° and 68.9° corresponded to the (1,1,0), (1,01), (1,1,1), (2,1,1), (2,2,0) and (3,0,1) planes could be observed for the neat rutile phase TiO2 NPs, respectively (27). And these diffraction peaks could also be observed in the spectra of composite coating HTV silicone rubbers. As to the neat HTV silicone rubber, many evident diffraction peaks could be observed. HTV silicone rubber is a kind of composite material prepared by the blending of polymethylvinylsiloxane and inorganic reinforcement fillers like SiO2, Al(OH)3, pigment, etc. Generally, the primary matrix polymethylvinylsiloxane was amorphous phase, and lots of observed diffraction peaks at 2θ = 20.6°, 26.4°, 36.4°, 39.3°, 40.2°, 42.3°, 45.6°, 49.9°, 54.7°, 59.8°, 63.8°, 67.9° etc., for the neat HTV silicone rubber belonged to the filler’s crystalline phase. Thus, these inherent diffraction peaks could also be observed in the XRD spectra for other composite coating HTV silicone rubbers. Comparing the XRD spectra before and after hygrothermal aging process for the composite coating HTV silicone rubbers in Figure 6a, no obvious difference could be observed, including the diffraction peak intensity and location. However, this state was different for neat HTV silicone rubber, the diffraction peak intensity for inorganic reinforcement fillers increased dramatically after the aging process. At the same time, similar phenomenon was also displayed in the XRD spectra of different HTV silicone rubbers after the UV aging process in Figure 6b. The diffraction peaks hardly changed after the aging process for any composite coating HTV silicone rubbers. However, the diffraction peak intensity for neat HTV silicone rubber increased very obviously after the UV aging process which was similar to the result after hygrothermal aging. The increase in diffraction peak intensity was perhaps caused by more exposure of inorganic fillers, which was due to the fracture and breakage of polymer on the surface of neat HTV matrix after the aging process. The XRD spectra result indicated that neat HTV silicone rubber was easy to be aged while the prepared HTV silicone rubbers with composite coatings were much more stable under the same aging condition irrespective of hygrothermal environment or UV radiation.

XRD spectra of different HTV silicone rubber before and after aging process. (a) Hygrothermal aging 4 weeks and (b) UV aging 600 h.

3.5 Analysis of mechanical properties of HTV silicone rubbers

Mechanical property is an important feature to evaluate the material’s applicability. Figure 7 shows the stress–strain curves for different HTV silicone rubbers after different aging processes. It could be seen from the stress–strain curves that the breaking strength for HTV silicone rubbers with composite coating was almost the same and was higher than that for neat HTV silicone rubber after the 4 week hygrothermal aging (Figure 7a) or 600 h UV aging (Figure 7b). The increase in strength can be attributed to two reasons. One is that the introduction of TiO2 NPs can play as inorganic junctions in composite coating and can improve the mechanical property. The other is the effective improvement of anti-aging performance after the building of hydrophobic–uvioresistant composite coating on the surface of HTV silicone rubber.

Mechanical property of different HTV silicone rubber after aging process. (a) Hygrothermal aging 4 weeks, and (b) UV aging 600 h.

The effect of aging method and aging time were further studied to evaluate the anti-aging performance of neat HTV silicone rubber and the PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubber. As shown in Figure 8a, the UV aging process showed a greater influence on the breaking strength of neat HTV silicone rubber than hygrothermal aging process by comparison. The breaking strength of neat HTV silicone rubber decreased dramatically after the UV aging process and just showed a little decrease after hygrothermal aging process. The worsening of mechanical property is due to the break of silicone rubber molecular chains after the aging process. On the contrary, the effect of aging method on the breaking strength for PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubber was not very obvious as shown in Figure 8b. The result further indicated that the PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubber were much more stable than neat HTV silicone rubber under aging process irrespective of the hygrothermal aging or UV aging.

Mechanical property of HTV silicone rubber after different aging processes. (a) Different aging of neat HTV and (b) different aging of +PRTV-PTFEL/TiO2-PTFES.

3.6 Moisture content and water absorption analysis of HTV silicone rubbers

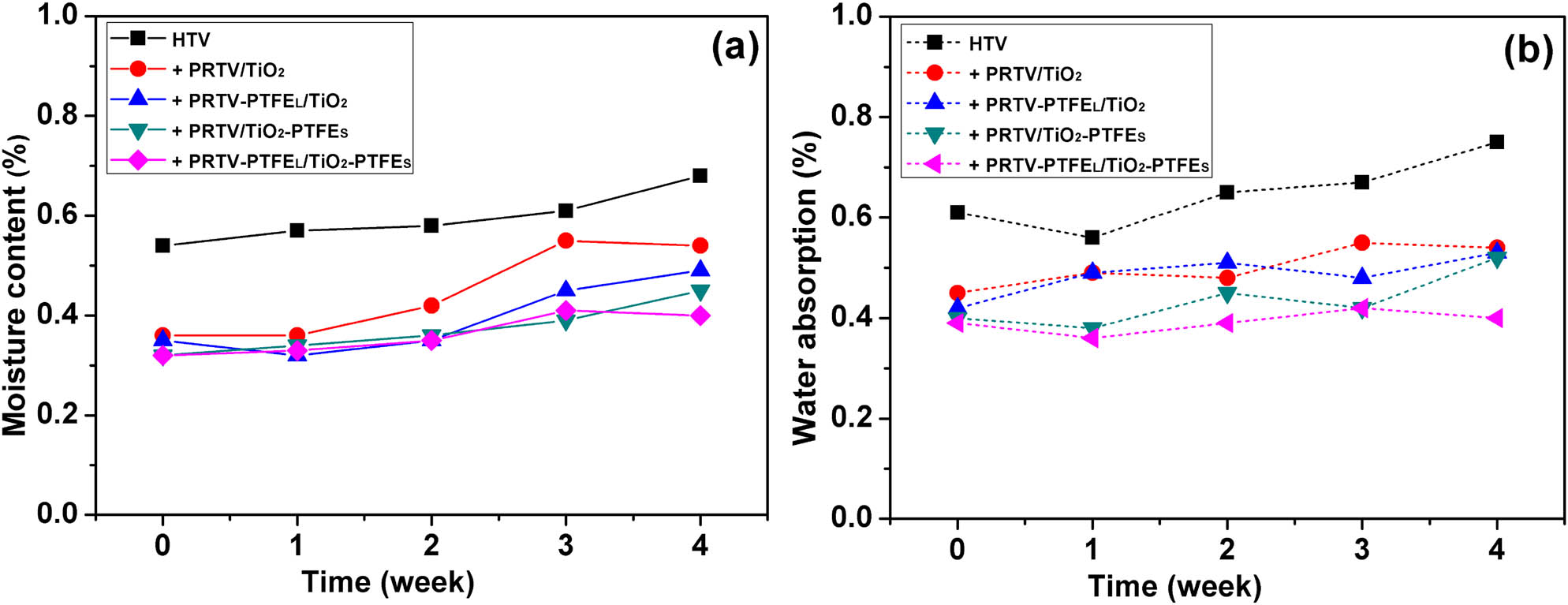

The effect of hygrothermal aging time on moisture content for HTV silicone rubber with different coatings were studied as shown in Figure 9a. It could be seen that the moisture content for all HTV silicone rubbers were increased gradually, ignoring the experimental errors, the moisture content began to increase obviously when the hygrothermal aging time reached 3 weeks. At the same time, the water absorption of different HTV silicone rubbers after hygrothermal aging was also researched as shown in Figure 9b. On the whole, the water absorption was in an increasing trend with the increase in the hygrothermal aging time. Besides, it could be seen that the moisture content and water absorption increased slowly during the first 3 weeks and then increased obviously. In a large part, the increase in moisture content or water absorption for different HTV silicone rubbers was due to the worse hydrophobicity of the material surface. Thus, it can be deduced that the cracks and breakages may have occurred and some hydrophilic inorganic fillers were exposed on the surface during the aging process which can accommodate water and is beneficial for the improvement of moisture content and water absorption. In addition, comparing among the silicone rubbers, the neat HTV material presented the highest moisture content and water absorption, while PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubbers showed the lowest value during the entire hygrothermal aging process. The variation trends of moisture content or water absorption for different HTV silicone rubbers were kept nearly consistent with their hydrophilicity performance. The result indicated that the hygrothermal aging performance for HTV silicone rubber was strongly affected by its hydrophilicity. Under the hygrothermal aging condition, the materials with good hydrophobicity will show a good anti-aging performance because it is difficult for water to adhere on the material’s surface largely and for long-time, which can slow down the hygrothermal aging rate.

Moisture content (a) and water absorption (b) of HTV silicone rubber after hygrothermal aging.

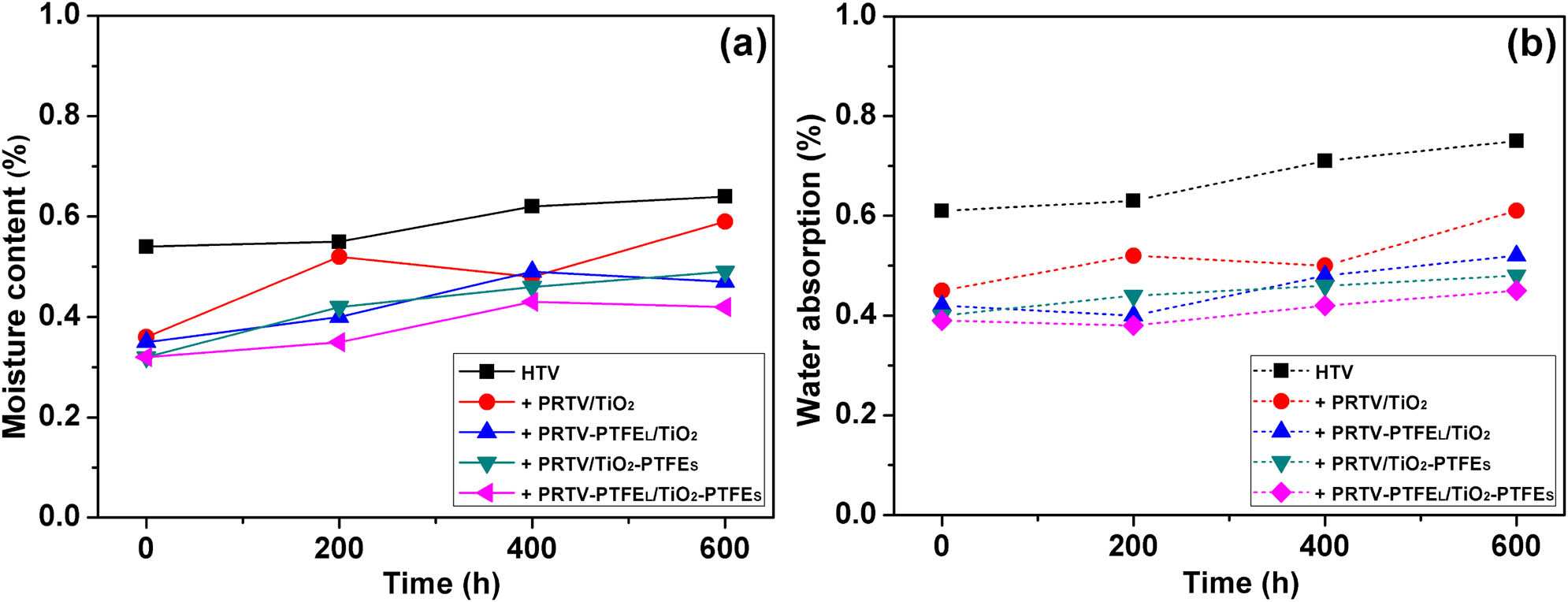

The effects of UV aging time on moisture content and water absorption for HTV silicone rubber with different coatings were also studied as shown in Figure 10. It could be seen form Figure 10a that the moisture content for all HTV silicone rubbers were increased slowly before the first 200 h, and which increased evidently when the UV aging time reached 400 h. And the water absorption in Figure 10b showed similar tendency. The result indicated that the 400 h UV aging time could cause a relatively obvious aging phenomenon. Moreover, among the all HTV silicone rubber materials, the moisture content and water absorption for neat HTV silicone rubber were higher than others, and which increased obviously with the increase in UV aging time. By contrast, the moisture content and water absorption were little different for all coated HTV silicone rubbers. The result indicated that the anti-UV capability of HTV silicone rubber was dramatically improved after the introduction of composite coating containing TiO2 NPs.

Moisture content (a) and water absorption (b) of HTV silicone rubber after UV aging.

3.7 Hydrophobicity analysis of HTV silicone rubbers

The water CA of different HTV silicone rubbers after different aging methods and aging time was studied as shown in Figure 11. It could be clearly seen that the hydrophobicity of neat HTV was not very good before the aging process and that obviously increased after the introduction of hydrophobic PTFE component or the building of micro-nano coarse structure. Among which, the HTV silicone rubber with PRTV-PTFEL/TiO2-PTFES composite coating displayed the best hydrophobicity with the highest water CA due to the combined function of hydrophobic component and micro-nano coarse structure. After the aging process, the water CAs for these HTV silicone rubbers were declined with varying degrees. But on the whole, the water CAs for neat HTV silicone rubber decreased markedly after the aging process, especially under the UV aging process. By contrast, the HTV silicone rubbers with composite coatings showed a relatively stable hydrophobicity with a slight decrease in water CAs irrespective of the hygrothermal aging or UV aging. Moreover, the HTV silicone rubber with PRTV-PTFEL/TiO2-PTFES composite coating still remained the best hydrophobicity after any aging process. The result indicated that the prepared HTV silicone rubber with PRTV-PTFEL/TiO2-PTFES composite coating possessed a favorable anti-aging performance.

CA of HTV silicone rubber after different aging processes.

3.8 Micromorphology and anti-aging mechanism analysis of HTV silicone rubbers

The microstructure of different HTV silicone rubbers after hygrothermal aging was observed by SEM as seen in Figure 12. The obvious big air holes and fragments could be found for neat HTV silicone rubber which might be generated due to the aging process (Figure 12a and b). By contrast, the aging phenomenon of surface micromorphology was improved remarkably for those prepared coating HTV silicone rubbers. Among which, just a few and small air holes were generated and no obvious fragments could be found for the PRTV/TiO2 coating HTV silicone rubber because of its increased hydrophobicity (Figure 12c). With the further introduction of low surface energy matter PTFEL or PTFES, the steady surface was presented for composite coating HTV silicone rubber after hygrothermal aging (Figure 12d–f). Comparing this surface with Figure 1 before hygrothermal aging, the microstructure for composite coating HTV silicone rubber was hardly changed. The SEM observation result indicated that the prepared composite coating HTV silicone rubber had favorable hygrothermal aging resistance due to the introduction of inorganic rigid TiO2 NPs and low surface energy matter PTFE and also the significant improvement of hydrophobicity.

Microstructure of different HTV rubber after 4 weeks hygrothermal aging. (a) Neat HTV silicone rubber (×2.0 k), (b) neat HTV silicone rubber (×5.0 k), (c) + PRTV/TiO2 coating, (d) + PRTV-PTFEL/TiO2 coating, (e) + PRTV/TiO2-PTFES coating, and (f) PRTV-PTFEL /TiO2-PTFES coating.

The microstructure of different HTV silicone rubbers after UV aging was also observed by SEM as seen in Figure 13. As to the neat HTV silicone rubber in Figure 13a and b, the clear surface exfoliations and visible cracks could be observed after long-term UV radiation, indicating the poor UV resistance. Similarly, the UV aging phenomenon of the surface for those composite coating HTV silicone rubbers was improved dramatically. The surface was steady except for some small pores after UV aging process, and no obvious exfoliations or cracks could be observed in Figure 13c and d. Moreover, the small pores even disappeared in Figure 13e and f for the HTV silicone rubbers with PRTV/TiO2-PTFES coating or PRTV-PTFEL/TiO2-PTFES coating. The SEM result indicated that the prepared HTV silicone rubber with composite coating possessed an excellent UV aging resistance.

Microstructure of different HTV rubber after 600 h UV aging. (a) Neat HTV silicone rubber (×2.0 k), (b) neat HTV silicone rubber (×5.0 k), (c) + PRTV/TiO2 coating, (d) + PRTV-PTFEL/TiO2 coating, (e) + PRTV/TiO2-PTFES coating, and (f) PRTV-PTFEL /TiO2-PTFES coating.

According to the above tests and results analysis, the possible anti-aging mechanism for prepared PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubber is explored and deduced as shown in Figure 14. As to the neat HTV silicone rubber, its surface is porous and hydrophilic. Under the condition of high humidity and temperature or strong UV radiation, moisture easily adheres to the surface and induces the aging reaction like degradation, cross-linking, etc. Similarly, the UV radiation will be majorly absorbed by silicone rubber matrix and then the aging reaction will be induced, which causes the cracks and exfoliations. However, this circumstance is different for the PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubber. Comparing with the smooth surface of neat HTV silicone rubber, the building of coarse micro-nano structure and the existing of low surface energy matter can prevent the moisture droplet to adhere to the surface silicone rubber, and then will delay the hygrothermal aging process. At the same time, a part of UV light can be absorbed by TiO2 NPs in coating layer and another part of UV light can be scattered by increasing roughness of surface, so, the direct UV irradiation to silicone rubber molecular chains can be avoided or reduced. Thus, the stability of PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubber gets promoted dramatically under UV aging process.

Simulation of anti-aging mechanism of PRTV-PTFEL/TiO2-PTFES coating HTV silicone rubber.

4 Conclusion

In order to improve the anti-aging performance of HTV silicone rubber under the condition with high humidity, high temperature and intense UV radiation, in this work, the TiO2 UV shielding layer and PTFE hydrophobic layer were introduced onto the surface of HTV silicone rubber via stepwise spray method to prepare different coating HTV silicone rubber. The 4 weeks accelerated hygrothermal aging experiment and 600 h accelerated UV aging experiment were used to analyze the anti-aging performance of the prepared HTV silicone rubber with different coating structures and compositions. The results of aging experiment showed that the anti-aging performance of neat HTV was baddish under long-term damp and hot condition or long-term UV radiation. By SEM observation, many clearly visible cracks and breakages could be found on the micro-surface of neat HTV silicone rubber after aging process, especially the UV aging. And the XRD result confirmed that the content of exposed inorganic filler in the exterior surface of neat HTV silicone rubber increased after aging process. Its water absorption increased and water CA decreased gradually with the increase in aging time, indicating the deterioration of hydrophobicity. However, these aging phenomena were vastly alleviated for those coating HTV silicone rubbers. Comparing with the neat HTV silicone rubber, the CA of composite coating HTV silicone rubber increased obviously, among which, the PRTV-PTFEL/TiO2-PTFES composite coating showed the best improvement in hydrophobicity than other coatings like PRTV/TiO2, PRTV-PTFEL/TiO2 or PRTV/TiO2-PTFES. Besides, the coating HTV silicone rubber showed an increased UV reflectance than neat HTV silicone rubber. After the hygrothermal aging or UV aging, the water absorption increased slowly, and the hydrophobicity and mechanical property degraded tardily. The XRD spectra hardly changed after aging process, which indicated the favorable aging stability of coating HTV silicone rubber. Among all the prepared coating silicone rubbers, the HTV silicone rubbers with PRTV-PTFEL/TiO2-PTFES composite coating presented the best hygrothermal aging resistance due to its strongest hydrophobicity resulted by the coaction between low surface energy matter and micro-nano hierarchical mastoid structure. And this coating HTV silicone rubber also showed an excellent UV aging resistance due to strong shielding effect of TiO2 NPs on UV radiation. The results of accelerated aging experiment indicated that the PRTV-PTFEL/TiO2-PTFES composites coating prepared by stepwise spray method could be used as the aging-resistant HTV silicone rubber materials’ preparation.

-

Funding information: This work was supported by the Key Technology Project of China Southern Power Grid (110002022030301SJ00011).

-

Author contributions: Mingdong Lei: data curation; Ziyou Li: software; Qiang Gan: methodology; Weizhen Zhou: investigation; and Qiang Li: writing and project administration.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The authors confirm that the data and materials supporting the findings of this study are available within the article.

References

(1) Argha KP, Arijit B, Abhijit L. Studies on prospect of HTV silicone rubber as dielectric material when reinforced with TiO2 nanoparticles. IET Sci Meas Technol. 2021;15(3):292–301. 10.1049/smt2.12030.Search in Google Scholar

(2) Muhammad ZS, Mohammad A, Shahid A. Corona-aged performance of nano-filled HTV silicone rubber. Plasma Process Polym. 2022;19(11):2200033. 10.1002/PPAP.202200033.Search in Google Scholar

(3) Christos-Christodoulos AK, Vassiliki TK, Ioannis FG. A proposal for the evaluation of HTV silicone rubber composite insulators. Polymers. 2021;13(21):3610. 10.3390/POLYM13213610.Search in Google Scholar

(4) Huang H, Liang T, Li B, Ma XD, Mao XY, Lü QY. Effect of acidic-fog on performances of HTV silicone rubber with AC energized. Eng Fail Anal. 2022;132:105880. 10.1016/J.ENGFAILANAL.2021.105880.Search in Google Scholar

(5) Gou B, Xie CZ, Xu HS, Du Y, Wang R, Li LC, et al. Cracking mechanism and degradation performances of HTV silicone rubber with interfacial defects under acid and thermal stress. Eng Fail Anal. 2021;127:105468. 10.1016/J.ENGFAILANAL.2021.105468.Search in Google Scholar

(6) Rahmat U, Rahisham AR, Rizwan A, Khan W, Israr U. Aging mechanism of HTV silicone rubber loaded with hybrid nano/micro silica and alumina exposed to concurrent multistress. Polym Test. 2023;121:107985. 10.1016/J.POLYMERTESTING.2023.107985.Search in Google Scholar

(7) Zhang H, Yang H, Shentu BQ. Effect of surface modification of titanium dioxide on the UV-C aging behavior of silicone rubber. J Appl Polym Sci. 2019;136(10):47170. 10.1002/app.47170.Search in Google Scholar

(8) Zhang H, Yang H, Shentu BQ, Chen SJ, Chen M. Effect of titanium dioxide on the UV-C ageing behavior of silicone rubber. J Appl Polym Sci. 2018;135(14):46099. 10.1002/app.46099.Search in Google Scholar

(9) Peng XY, Wang C, Luo WC, Huang Z, Fang PF. Study on UV absorber effect on the mechanical and surface properties of silicone rubber. J Wuhan Univ Technol. 2016;38(5):34–9. 10.3963/j.issn.1671-4431.2016.05.007.Search in Google Scholar

(10) Mohamed GS, Vijayarekha K. Investigation of surface degradation of aged high temperature vulcanized (HTV) silicone rubber insulators. Energies. 2019;12(19):3769. 10.3390/en12193769.Search in Google Scholar

(11) Chen C, Jia ZD, Ye WA, Guan ZC, Li YZ. Thermo-oxidative aging analysis of HTV silicone rubber used for outdoor insulation. IEEE Trans Dielectr Electr Insul. 2017;24(3):1761–72. 10.1109/tdei.2017.005751.Search in Google Scholar

(12) Chen L, Nie QL, Guo F, Hu T, Wang YT, Liu D. Aging characteristics of superhydrophobic silicone rubber surfaces etched by femtosecond laser. Chin J Lasers. 2022;49(10):1002606. 10.3788/CJL202249.1002606.Search in Google Scholar

(13) Gao SH, Zhou KS. Hydrophobic Modification on the Surface of Silicone Rubber Insulator by CF4 RF Plasma. Polym Mater Sci Eng. 2013;29(8):101–4. 10.1111/odi.12144.Search in Google Scholar PubMed

(14) Zhang RB, Han QT, Xia Y, Li S. Plasma jet array treatment to improve the hydrophobicity of contaminated HTV silicone rubber. Plasma Sci Tech. 2017;19(10):105505. 10.1088/2058-6272/aa7c16.Search in Google Scholar

(15) He WJ, Zhang FY, Zhang FW, He Q. Effect of CeO2 on UV aging of composite insulators prepared by template-spraying method. J Appl Polym Sci. 2023;140(1):e53274. 10.1002/APP.53274.Search in Google Scholar

(16) Vazirinasab E, Jafari R, Momen G. Evaluation of atmospheric-pressure plasma parameters to achieve superhydrophobic and self-cleaning HTV silicone rubber surfaces via a single-step, eco-friendly approach. Surf Coat Tech. 2019;375:100–11. 10.1016/j.surfcoat.2019.07.005.Search in Google Scholar

(17) Zhang RB, Zhou XL, Xia Y, Su SC, Guan ZC, Chen J, et al. Hydrophobicity improvement of contaminated HTV silicone rubber by atmospheric plasma jet treatment. IEEE Trans Dielectr Electr Insul. 2016;23(1):377–84. 10.1109/TDEI.2015.005117.Search in Google Scholar

(18) Liu ML, Luo YF, Jia DM. Synthesis of mechanically durable superhydrophobic polymer materials with roughness-regeneration performance. Compos Part A Appl S. 2020;133:105861. 10.1016/j.compositesa.2020.105861.Search in Google Scholar

(19) Naveen R, Kumar M, Enhancing UV. Resistance of TiO2 reinforced Kevlar 29 fiber using Sol-Gel & Low-temperature hydrothermal Processes. Polym Plast Tech Mat. 2023;62(1):117–28. 10.1080/25740881.2022.2096469.Search in Google Scholar

(20) Wang H, Wang YY, Fu FB, Qian Y, Xiao YH, Yang DJ, et al. Controlled preparation of lignin/titanium dioxide hybrid composite particles with excellent UV aging resistance and its high value application. Int J Biol Macromol. 2020;150:371–9. 10.1016/j.ijbiomac.2019.12.185.Search in Google Scholar PubMed

(21) Yang SM, Wang JQ, Wang Y, Ding YJ, Zhang WL, Liu F. Interfacial polymerized polyamide nanofiltration membrane by demulsification of hexane-in-water droplets through hydrophobic PTFE membrane: Membrane performance and formation mechanism. Sep Purif Technol. 2021;275:119227. 10.1016/J.SEPPUR.2021.119227.Search in Google Scholar

(22) Zhou T, Zhong Q, Li JD, Yao YY, Xiang RL, Zhu PX. Superhydrophobic polytetrafluoroethylene nanofiber membranes prepared by vacuum sintering and their application in vacuum membrane distillation. J Appl Polym Sci. 2020;137(36):49060. 10.1002/app.49060.Search in Google Scholar

(23) Wu WC, Wang XL, Wang DA, Chen M, Zhou F, Liu WM, et al. Alumina nanowire forests via unconventional anodization and super-repellency plus low adhesion to diverse liquids. Chem Commun. 2009;9:1043–5. 10.1039/b818633b.Search in Google Scholar PubMed

(24) Xu S, Zhao XW, Ye L. Effect of heat treatment on the structure and properties of MC Nylon 6. Polym Plast Technol Eng. 2012;51(7):689–95. 10.1080/03602559.2012.661902.Search in Google Scholar

(25) Yu HW, Han WR, Liu L, Gu DD, Mu W, Chen N. Two-dimensional infrared spectroscopy study on polytetrafluoroethylene F-C-F stretching vibration. Mater Rev. 2014;28(24):95–8. 10.11896/j.issn.1005-023X.2014.24.022.Search in Google Scholar

(26) Sato K, Tominaga Y, Imai Y, Yoshiyama T, Aburatani Y. Deformation capability of poly(tetrafluoroethylene) materials: Estimation with X-ray diffraction measurements. Polym Test. 2022;113:107690. 10.1016/J.POLYMERTESTING.2022.107690.Search in Google Scholar

(27) Zhu ZG, Long YF, Xue X, Yin Y, Zhu B, Xu BJ. Phase-transition kinetics of calcium-doped TiO2: A high-temperature XRD study. Ceram Int. 2022;48(17):25056–63. 10.1016/J.CERAMINT.2022.05.160.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Flame-retardant thermoelectric responsive coating based on poly(3,4-ethylenedioxythiphene) modified metal–organic frameworks

- Highly stretchable, durable, and reversibly thermochromic wrapped yarns induced by Joule heating: With an emphasis on parametric study of elastane drafts

- Molecular dynamics simulation and experimental study on the mechanical properties of PET nanocomposites filled with CaCO3, SiO2, and POE-g-GMA

- Multifunctional hydrogel based on silk fibroin/thermosensitive polymers supporting implant biomaterials in osteomyelitis

- Marine antifouling coating based on fluorescent-modified poly(ethylene-co-tetrafluoroethylene) resin

- Preparation and application of profiled luminescent polyester fiber with reversible photochromism materials

- Determination of pesticide residue in soil samples by molecularly imprinted solid-phase extraction method

- The die swell eliminating mechanism of hot air assisted 3D printing of GF/PP and its influence on the product performance

- Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes

- The effects of property variation on the dripping behaviour of polymers during UL94 test simulated by particle finite element method

- Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets

- Synthesis, characterization and evaluation of a pH-responsive molecular imprinted polymer for Matrine as an intelligent drug delivery system

- Twist-related parametric optimization of Joule heating-triggered highly stretchable thermochromic wrapped yarns using technique for order preference by similarity to ideal solution

- Comparative analysis of flow factors and crystallinity in conventional extrusion and gas-assisted extrusion

- Simulation approach to study kinetic heterogeneity of gadolinium catalytic system in the 1,4-cis-polyisoprene production

- Properties of kenaf fiber-reinforced polyamide 6 composites

- Cellulose acetate filter rods tuned by surface engineering modification for typical smoke components adsorption

- A blue fluorescent waterborne polyurethane-based Zn(ii) complex with antibacterial activity

- Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading

- Preparation and application research of composites with low vacuum outgassing and excellent electromagnetic sealing performance

- Assessing the recycling potential of thermosetting polymer waste in high-density polyethylene composites for safety helmet applications

- Mesoscale mechanics investigation of multi-component solid propellant systems

- Preparation of HTV silicone rubber with hydrophobic–uvioresistant composite coating and the aging research

- Experimental investigation on tensile behavior of CFRP bolted joints subjected to hydrothermal aging

- Structure and transition behavior of crosslinked poly(2-(2-methoxyethoxy) ethylmethacrylate-co-(ethyleneglycol) methacrylate) gel film on cellulosic-based flat substrate

- Mechanical properties and thermal stability of high-temperature (cooking temperature)-resistant PP/HDPE/POE composites

- Preparation of itaconic acid-modified epoxy resins and comparative study on the properties of it and epoxy acrylates

- Synthesis and properties of novel degradable polyglycolide-based polyurethanes

- Fatigue life prediction method of carbon fiber-reinforced composites

- Thermal, morphological, and structural characterization of starch-based bio-polymers for melt spinnability

- Robust biaxially stretchable polylactic acid films based on the highly oriented chain network and “nano-walls” containing zinc phenylphosphonate and calcium sulfate whisker: Superior mechanical, barrier, and optical properties

- ARGET ATRP of styrene with low catalyst usage in bio-based solvent γ-valerolactone

- New PMMA-InP/ZnS nanohybrid coatings for improving the performance of c-Si photovoltaic cells

- Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites

- Preparation of cardanol-based curing agent for underwater drainage pipeline repairs

- Preparation of lightweight PBS foams with high ductility and impact toughness by foam injection molding

- Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study

- Experimental study on impact and flexural behaviors of CFRP/aluminum-honeycomb sandwich panel

- Normal-hexane treatment on PET-based waste fiber depolymerization process

- Effect of tannic acid chelating treatment on thermo-oxidative aging property of natural rubber

- Design, synthesis, and characterization of novel copolymer gel particles for water-plugging applications

- Influence of 1,1′-Azobis(cyclohexanezonitrile) on the thermo-oxidative aging performance of diolefin elastomers

- Characteristics of cellulose nanofibril films prepared by liquid- and gas-phase esterification processes

- Investigation on the biaxial stretching deformation mechanism of PA6 film based on finite element method

- Simultaneous effects of temperature and backbone length on static and dynamic properties of high-density polyethylene-1-butene copolymer melt: Equilibrium molecular dynamics approach

- Research on microscopic structure–activity relationship of AP particle–matrix interface in HTPB propellant

- Three-layered films enable efficient passive radiation cooling of buildings

- Electrospun nanofibers membranes of La(OH)3/PAN as a versatile adsorbent for fluoride remediation: Performance and mechanisms

- Preparation and characterization of biodegradable polyester fibers enhanced with antibacterial and antiviral organic composites

- Preparation of hydrophobic silicone rubber composite insulators and the research of anti-aging performance

- Surface modification of sepiolite and its application in one-component silicone potting adhesive

- Study on hydrophobicity and aging characteristics of epoxy resin modified with nano-MgO

- Optimization of baffle’s height in an asymmetric twin-screw extruder using the response surface model

- Effect of surface treatment of nickel-coated graphite on conductive rubber

- Experimental investigation on low-velocity impact and compression after impact behaviors of GFRP laminates with steel mesh reinforced

- Development and characterization of acetylated and acetylated surface-modified tapioca starches as a carrier material for linalool

- Investigation of the compaction density of electromagnetic moulding of poly(ether-ketone-ketone) polymer powder

- Experimental investigation on low-velocity-impact and post-impact-tension behaviors of GFRP T-joints after hydrothermal aging

- The repeated low-velocity impact response and damage accumulation of shape memory alloy hybrid composite laminates

- Exploring a new method for high-performance TPSiV preparation through innovative Si–H/Pt curing system in VSR/TPU blends

- Large-scale production of highly responsive, stretchable, and conductive wrapped yarns for wearable strain sensors

- Preparation of natural raw rubber and silica/NR composites with low generation heat through aqueous silane flocculation

- Molecular dynamics simulation of the interaction between polybutylene terephthalate and A3 during thermal-oxidative aging

- Crashworthiness of GFRP/aluminum hybrid square tubes under quasi-static compression and single/repeated impact

- Review Articles

- Recent advancements in multinuclear early transition metal catalysts for olefin polymerization through cooperative effects

- Impact of ionic liquids on the thermal properties of polymer composites

- Recent progress in properties and application of antibacterial food packaging materials based on polyvinyl alcohol

- Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters

- Rapid Communication

- Design, synthesis, characterization, and adsorption capacities of novel superabsorbent polymers derived from poly (potato starch xanthate-graft-acrylamide)

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Development of smart core–shell nanoparticles-based sensors for diagnostics of salivary alpha-amylase in biomedical and forensics

- Thermoplastic-polymer matrix composite of banana/betel nut husk fiber reinforcement: Physico-mechanical properties evaluation

- Special Issue: Electrospun Functional Materials

- Electrospun polyacrylonitrile/regenerated cellulose/citral nanofibers as active food packagings

Articles in the same Issue

- Research Articles

- Flame-retardant thermoelectric responsive coating based on poly(3,4-ethylenedioxythiphene) modified metal–organic frameworks

- Highly stretchable, durable, and reversibly thermochromic wrapped yarns induced by Joule heating: With an emphasis on parametric study of elastane drafts

- Molecular dynamics simulation and experimental study on the mechanical properties of PET nanocomposites filled with CaCO3, SiO2, and POE-g-GMA

- Multifunctional hydrogel based on silk fibroin/thermosensitive polymers supporting implant biomaterials in osteomyelitis

- Marine antifouling coating based on fluorescent-modified poly(ethylene-co-tetrafluoroethylene) resin

- Preparation and application of profiled luminescent polyester fiber with reversible photochromism materials

- Determination of pesticide residue in soil samples by molecularly imprinted solid-phase extraction method

- The die swell eliminating mechanism of hot air assisted 3D printing of GF/PP and its influence on the product performance

- Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes

- The effects of property variation on the dripping behaviour of polymers during UL94 test simulated by particle finite element method

- Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets

- Synthesis, characterization and evaluation of a pH-responsive molecular imprinted polymer for Matrine as an intelligent drug delivery system

- Twist-related parametric optimization of Joule heating-triggered highly stretchable thermochromic wrapped yarns using technique for order preference by similarity to ideal solution

- Comparative analysis of flow factors and crystallinity in conventional extrusion and gas-assisted extrusion

- Simulation approach to study kinetic heterogeneity of gadolinium catalytic system in the 1,4-cis-polyisoprene production

- Properties of kenaf fiber-reinforced polyamide 6 composites

- Cellulose acetate filter rods tuned by surface engineering modification for typical smoke components adsorption

- A blue fluorescent waterborne polyurethane-based Zn(ii) complex with antibacterial activity

- Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading

- Preparation and application research of composites with low vacuum outgassing and excellent electromagnetic sealing performance

- Assessing the recycling potential of thermosetting polymer waste in high-density polyethylene composites for safety helmet applications

- Mesoscale mechanics investigation of multi-component solid propellant systems

- Preparation of HTV silicone rubber with hydrophobic–uvioresistant composite coating and the aging research

- Experimental investigation on tensile behavior of CFRP bolted joints subjected to hydrothermal aging

- Structure and transition behavior of crosslinked poly(2-(2-methoxyethoxy) ethylmethacrylate-co-(ethyleneglycol) methacrylate) gel film on cellulosic-based flat substrate

- Mechanical properties and thermal stability of high-temperature (cooking temperature)-resistant PP/HDPE/POE composites

- Preparation of itaconic acid-modified epoxy resins and comparative study on the properties of it and epoxy acrylates

- Synthesis and properties of novel degradable polyglycolide-based polyurethanes

- Fatigue life prediction method of carbon fiber-reinforced composites

- Thermal, morphological, and structural characterization of starch-based bio-polymers for melt spinnability

- Robust biaxially stretchable polylactic acid films based on the highly oriented chain network and “nano-walls” containing zinc phenylphosphonate and calcium sulfate whisker: Superior mechanical, barrier, and optical properties

- ARGET ATRP of styrene with low catalyst usage in bio-based solvent γ-valerolactone

- New PMMA-InP/ZnS nanohybrid coatings for improving the performance of c-Si photovoltaic cells

- Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites

- Preparation of cardanol-based curing agent for underwater drainage pipeline repairs

- Preparation of lightweight PBS foams with high ductility and impact toughness by foam injection molding

- Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study

- Experimental study on impact and flexural behaviors of CFRP/aluminum-honeycomb sandwich panel

- Normal-hexane treatment on PET-based waste fiber depolymerization process

- Effect of tannic acid chelating treatment on thermo-oxidative aging property of natural rubber

- Design, synthesis, and characterization of novel copolymer gel particles for water-plugging applications

- Influence of 1,1′-Azobis(cyclohexanezonitrile) on the thermo-oxidative aging performance of diolefin elastomers

- Characteristics of cellulose nanofibril films prepared by liquid- and gas-phase esterification processes

- Investigation on the biaxial stretching deformation mechanism of PA6 film based on finite element method

- Simultaneous effects of temperature and backbone length on static and dynamic properties of high-density polyethylene-1-butene copolymer melt: Equilibrium molecular dynamics approach

- Research on microscopic structure–activity relationship of AP particle–matrix interface in HTPB propellant

- Three-layered films enable efficient passive radiation cooling of buildings

- Electrospun nanofibers membranes of La(OH)3/PAN as a versatile adsorbent for fluoride remediation: Performance and mechanisms

- Preparation and characterization of biodegradable polyester fibers enhanced with antibacterial and antiviral organic composites

- Preparation of hydrophobic silicone rubber composite insulators and the research of anti-aging performance

- Surface modification of sepiolite and its application in one-component silicone potting adhesive

- Study on hydrophobicity and aging characteristics of epoxy resin modified with nano-MgO

- Optimization of baffle’s height in an asymmetric twin-screw extruder using the response surface model

- Effect of surface treatment of nickel-coated graphite on conductive rubber

- Experimental investigation on low-velocity impact and compression after impact behaviors of GFRP laminates with steel mesh reinforced

- Development and characterization of acetylated and acetylated surface-modified tapioca starches as a carrier material for linalool

- Investigation of the compaction density of electromagnetic moulding of poly(ether-ketone-ketone) polymer powder

- Experimental investigation on low-velocity-impact and post-impact-tension behaviors of GFRP T-joints after hydrothermal aging

- The repeated low-velocity impact response and damage accumulation of shape memory alloy hybrid composite laminates

- Exploring a new method for high-performance TPSiV preparation through innovative Si–H/Pt curing system in VSR/TPU blends

- Large-scale production of highly responsive, stretchable, and conductive wrapped yarns for wearable strain sensors

- Preparation of natural raw rubber and silica/NR composites with low generation heat through aqueous silane flocculation

- Molecular dynamics simulation of the interaction between polybutylene terephthalate and A3 during thermal-oxidative aging

- Crashworthiness of GFRP/aluminum hybrid square tubes under quasi-static compression and single/repeated impact

- Review Articles

- Recent advancements in multinuclear early transition metal catalysts for olefin polymerization through cooperative effects

- Impact of ionic liquids on the thermal properties of polymer composites

- Recent progress in properties and application of antibacterial food packaging materials based on polyvinyl alcohol

- Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters

- Rapid Communication

- Design, synthesis, characterization, and adsorption capacities of novel superabsorbent polymers derived from poly (potato starch xanthate-graft-acrylamide)

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Development of smart core–shell nanoparticles-based sensors for diagnostics of salivary alpha-amylase in biomedical and forensics

- Thermoplastic-polymer matrix composite of banana/betel nut husk fiber reinforcement: Physico-mechanical properties evaluation

- Special Issue: Electrospun Functional Materials

- Electrospun polyacrylonitrile/regenerated cellulose/citral nanofibers as active food packagings