Abstract

Polybutylene terephthalate (PBT) elastomers generated via the copolymerization of 3,3-bis(azidomethyl) oxetane and tetrahydrofuran have been widely used as a matrix for solid engines in rockets, missiles, and spacecraft because of their positive standard enthalpies of formation. This study investigates how the decomposition of PBT elastomers impacts their interactions with plasticizers during long-term storage and aging. We apply molecular dynamics to calculate the parameters (e.g., glass transition temperature, mechanical properties, diffusion, and compatibility) of PBT elastomers that influence the aging performance of PBT. The computational results indicate that as the degree of thermal-oxidative aging decomposition increases, the radius of gyration, peak value of radial distribution function, and free volume fraction of the aging model all decrease. The concomitant increase in defects and the weakening of the interactions between molecular chains in the aging model lead to a continuous reduction in the mechanical properties and glass transition temperature of the aging model. In general, the plasticizer exhibits enhanced diffusion and reduced compatibility. Overall, this article establishes models representing different degrees of thermal-oxidative aging of PBT elastomers, thereby revealing the interactions between plasticizers and PBT elastomers under thermal-oxidative aging conditions. The results provide a theoretical basis for evaluating the changes in the macroscopic aging performance of PBT elastomers from a microstructural perspective.

1 Introduction

Tactical missiles require propellants with high energy output, rapid combustion, high stability, and low characteristic signals (1,2). Polybutylene terephthalate (PBT) elastomers synthesized by copolymerizing 3,3-bis(azidomethyl) oxetane (BAMO) and tetrahydrofuran (THF) are widely used in modern military and aerospace applications owing to their advantageous energy and mechanical properties and their low characteristic signals. They are currently one of the most promising energetic propellant adhesives (3,4,5,6,7).

During the long-term storage of solid propellants, environmental factors (e.g., temperature and oxygen content) can trigger chemical reactions at weak points in the chain structure of the adhesive. Chen et al. (8) and Loyer et al. (9) experimentally demonstrated that the aging of PBT elastomers generally occurs in three stages: (i) disordered hydrogen bonding and decomposition/destruction of polyurethane polyether soft segments, (ii) sustained destruction of ordered hydrogen bonds and polyurethane polyether soft segments, and (iii) oxidative crosslinking of the main chain and generation of disordered hydrogen bonds. The decomposition and destruction of the polyurethane polyether soft segment during the first stage has a particularly significant impact on the macroscopic properties of the propellant. During this process, the relative molecular weight, relative molecular weight distribution, and branching degree of PBT elastomers all undergo appreciable changes. These changes alter the microstructure and mechanical properties of the propellant and affect the migration and diffusion of plasticizer components in the propellant toward the grain/liner and liner/insulation interfaces. As a result, the thermal stability and energy index of the propellant decrease rapidly, and the insulation ability and erosion resistance of the lining and insulation layers are significantly weakened. Moreover, the ballistic performance of the missile decreases, and in severe cases, explosions may occur during the launch process (10,11).

Research regarding the interactions between the matrix and plasticizers of aging PBT propellants has generally focused on changes in the aging performance at the macroscopic level based on experimental investigations involving mechanical, thermal, spectral, and chromatographic analyses; meanwhile, studies probing the microscopic mechanisms that cause the macroscopic changes in performance are relatively rare (8,12,13,14,15). With the continuous advancements in molecular dynamics (MD) simulation technology, it has become possible to observe changes in the chain structure under different aging states from a microscopic perspective, thereby enabling researchers to predict the aging performance of propellants. This approach supports propellant formulation design and manufacturing (16,17).

This article is based on the COMPASS force field and uses MD simulations to calculate various aging performance parameters of models representing different degrees of aging of PBT. We evaluate the impacts of molecular structural changes during the aging process on the macroscopic aging properties of PBT (e.g., its glass transition temperature, mechanical properties, diffusion, and compatibility). Simulating different PBT models and blended aging models provides a deeper understanding of the impact of microstructural changes on macroscopic properties during propellant aging.

2 Computational methods

2.1 Construction of molecular models

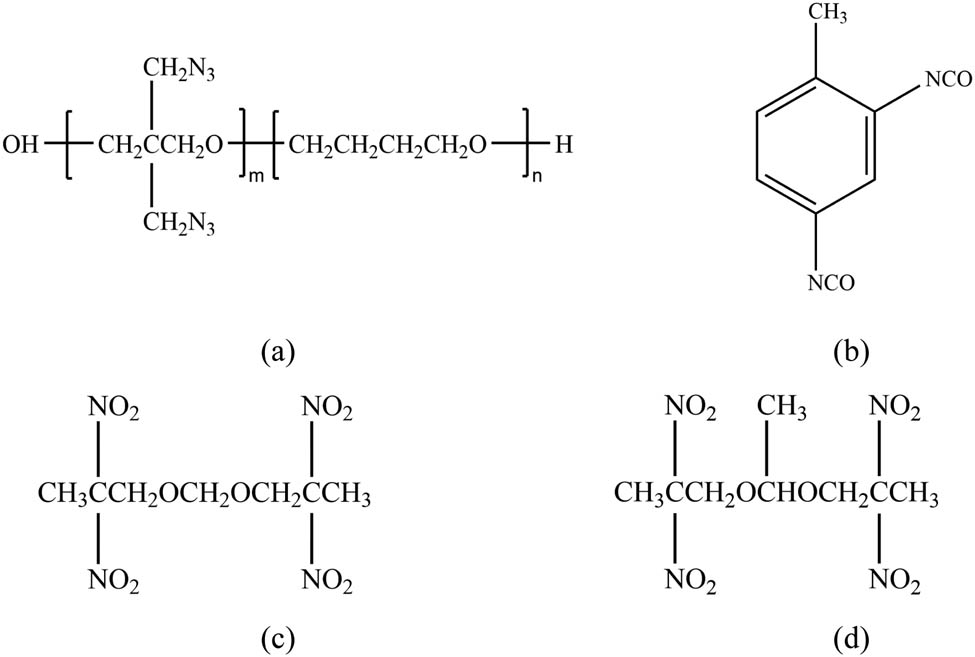

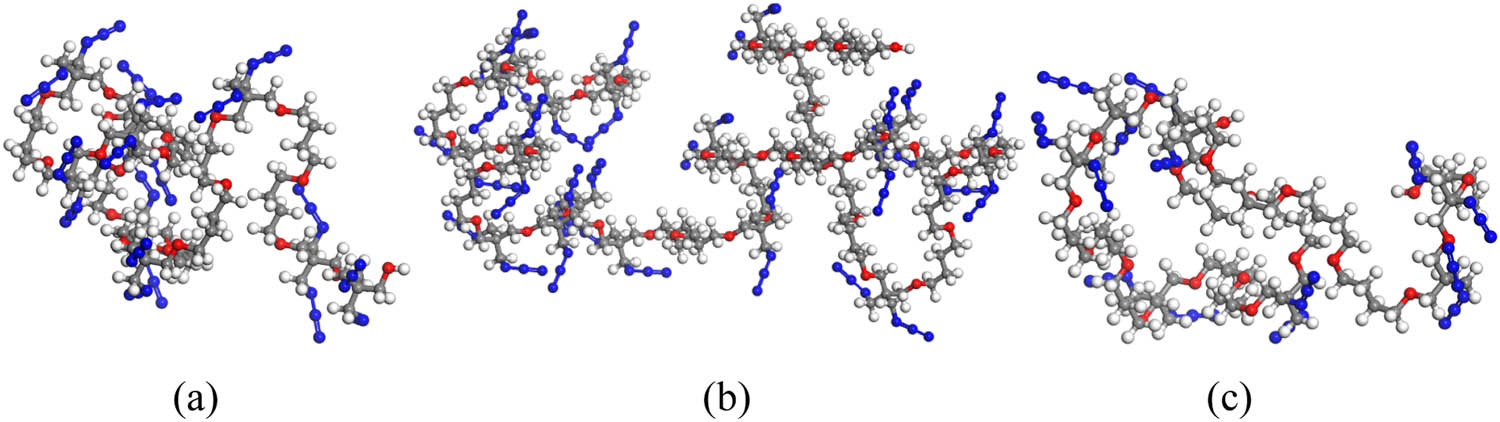

Molecular models of PBT-toluene diisocyanate (TDI; i.e., PT) and plasticizers “A3” (bis(2,2-dinitropropyl)-acetal [BDNPA] and bis(2,2-dinitropropyl)-formal [BDNPF]) were constructed using the Visualizer module in the Materials Studio (MS) software package. The molecular structures of PBT, TDI, BDNPF, and BDNPA are shown in Figure 1. The A3 plasticizer comprised a mixture of BDNPF and BDNPA in a 1:1 mass ratio. PBT is a random copolymer terminated by hydroxyl groups with a 1:1 molar ratio of m(BAMO):m(THF) monomers (18). To simultaneously optimize computational accuracy and resource consumption, the number of repeat units of PBT molecules was set to 38. Based on the PT molecular chain and the experimental and computational results reported by Chen et al. (8) and Kong et al. (19), the carbamate in the cured structure of PBT-TDI was selected as the point of decomposition reaction initiation during thermal-oxidative aging. The structure of the fragment after chemical bond cleavage is shown in Figure 2.

Molecular structural formulas of (a) PBT, (b) TDI, (c) BDNPF, and (d) BDNPA.

Segments of the decomposition reaction during thermal oxidative aging: (a) Segment_1, (b) Segment_2, and (c) Segment_3.

Considering the molecular formula of PBT, as well as the efficiency and scale constraints of molecular simulations, the mass ratio (i.e., plasticization ratio) of A3 to PT was set to 1:1.2. The temperature and pressure conditions were set to 298 K and 0.101 MPa, respectively. The amorphous cell module was used to construct 3D periodic models of PT pure substances containing different aging fragments, as well as 3D periodic blended models of PT and A3. The compositions of the assessed aging PT pure material models and PT/A3 blended models are presented in Table 1. The dimensions of the models were 42.94 × 42.94 × 42.94 Å and 54.19 × 54.19 × 54.19 Å, and the initial densities of the models were set to 1.12 and 1.26 g·cm−3, respectively.

Compositions of the assessed aging models

| PBT-TDI | Segment_1 | Segment_2 | Segment_3 | BDNPA | BDNPF | |

|---|---|---|---|---|---|---|

| Unaged | 6 | − | − | − | 107 | 112 |

| Aged_1 | 3 | 3 | 3 | − | 107 | 112 |

| Aged_2 | − | 9 | 3 | 3 | 107 | 112 |

| Aged_3 | − | 12 | − | 6 | 107 | 112 |

First, the Visualizer module was used to optimize the geometry and energy of the constructed model. The configuration with the lowest energy was selected to further construct the amorphous model.

2.2 Simulation details

The structurally optimized model was subjected to 10 NPT annealing treatments using the Forcite module in MS, with annealing temperatures between 298 and 598 K (18). Following each annealing process, geometric optimization was performed to fully relax the internal stresses in the models. After selecting the configuration with the lowest energy from annealing optimization, MD calculations were carried out at 100 and 220 ps under the NVT and NPT ensemble, respectively. The COMPASS (20,21) force field was used in both the optimization and MD calculations, with simulation steps of 1 fs. Reports by Anderson (22) and Parrinello and Rahman (23) were used to define the temperature controller and the pressure controller, respectively. Atom-based (24) and Ewald (25) methods were used to analyze van der Waals and electrostatic interactions, respectively. The entire trajectory was saved at 1 ps intervals throughout the simulation.

3 Results and discussion

First, we analyzed the molecular properties of PBT pure substances. Separately assessing the changes in the radius of gyration, radial distribution function, glass transition temperature, and mechanical properties of PBT pure substances during the aging process enabled a comprehensive analysis of the interactions between plasticizers and PBT under thermal-oxidative aging conditions. Overall, this helped us understand the specific impact of aging PBT on plasticizers while revealing the microscopic mechanism governing changes in the macroscopic performance parameters of the blended model.

3.1 Aging characteristics of pure PBT

3.1.1 Mean-squared radius of gyration

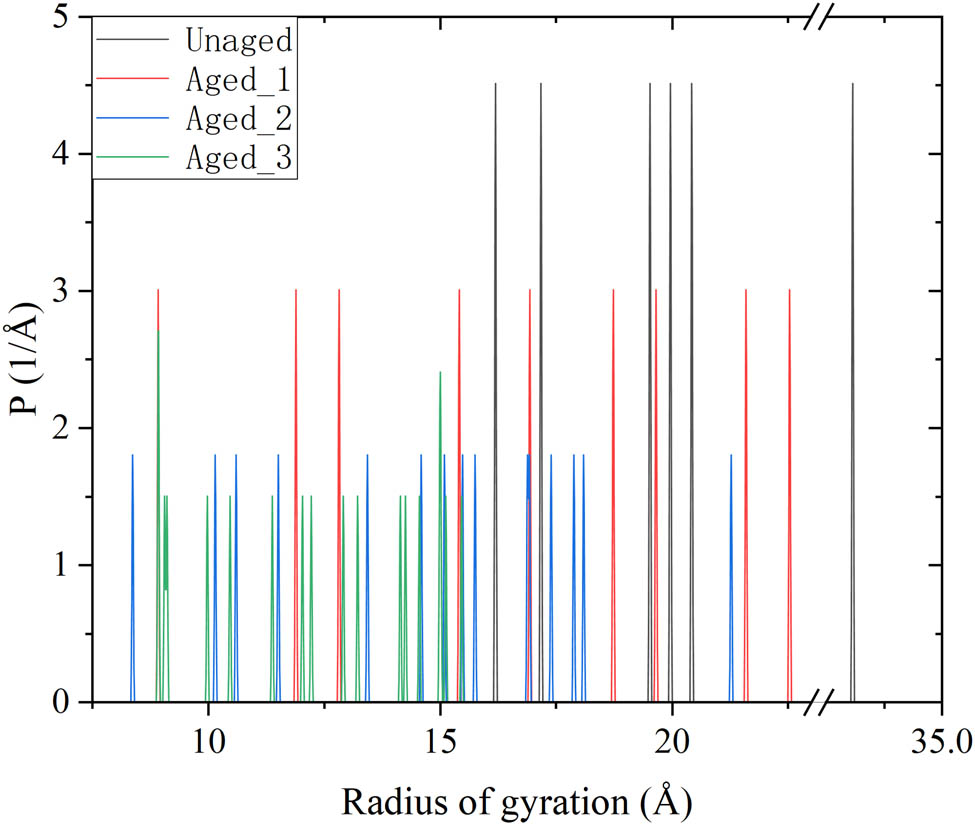

The mean-squared radius of gyration for different aging models at 298 K was calculated, and the results are shown in Figure 3.

Mean-squared radius of gyration for all analyzed models.

As the number of broken chain segments increased, the overall mean-squared radii of gyration of the aging models decreased, indicating that as the decomposition reaction proceeded, the molecular weights of PT molecules decreased, the network structure between molecules was disrupted, the volume of molecular chain clusters decreased, the interactions within molecules became stronger, and the volume occupied in space decreased; these phenomena resulted in a tighter and more constrained conformation of molecular chains. Unlike the Unaged model, the aged model exhibited an increased number of soft segments, suggesting that the tensile strength of the model decreased gradually during the aging process.

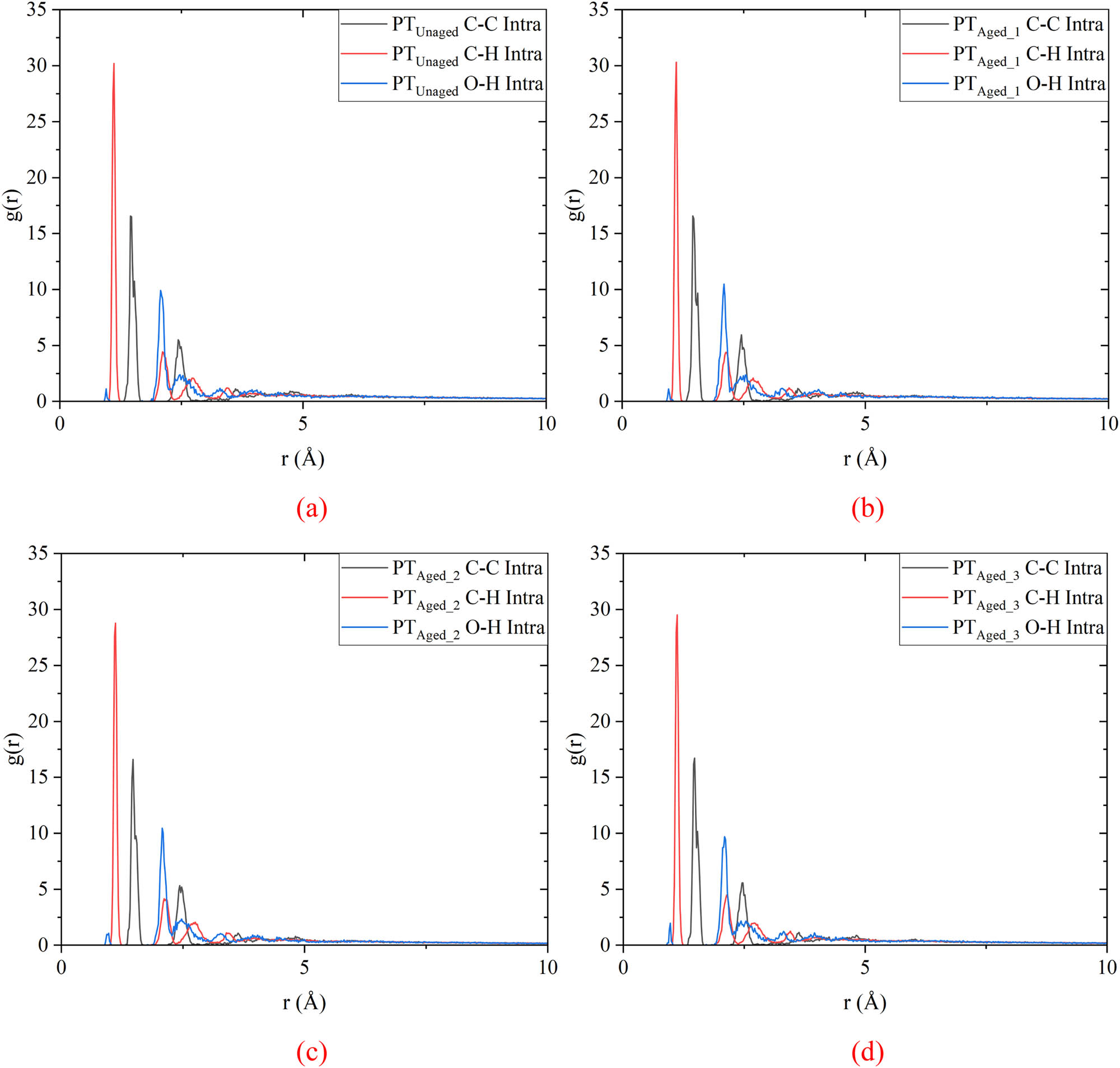

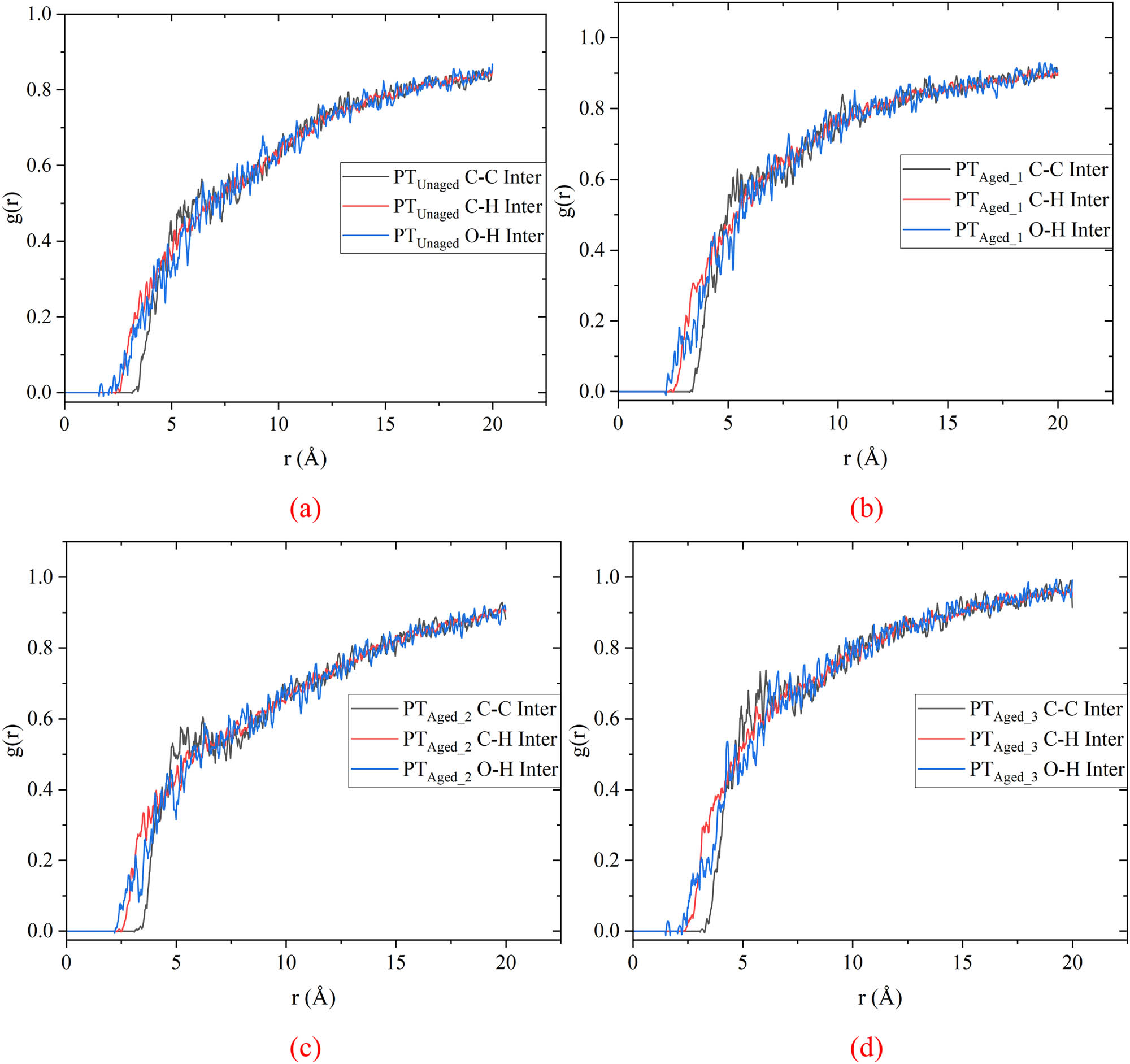

3.1.2 Radial distribution function

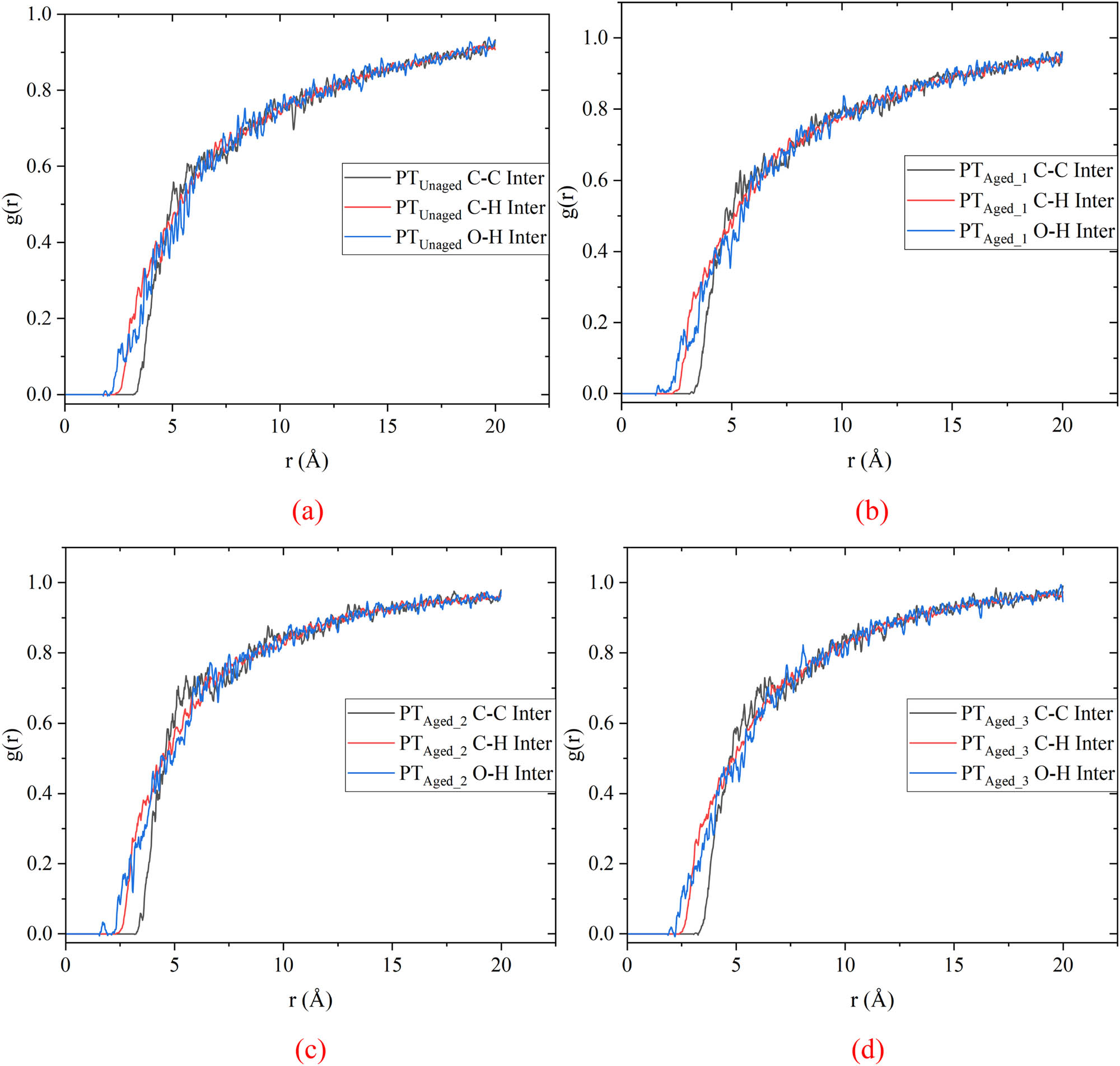

The radial distribution function of different aging models can be used to help verify the veracity and reliability of different aging models. Pure PT substances contain mainly C, H, and O elements, where the C and O atoms in the main chain are surrounded by H atoms; thus, the intramolecular radial distribution functions for C–C, C–H, and O–H moieties were calculated to study of the interactions involving the molecules of pure PT substances. The intra- and intermolecular radial distribution function of C–C, C–H, and O–H bonds in different models were computed, and the results are presented in Figures 4 and 5, respectively.

Intramolecular radial distribution functions of investigated models: (a) Unaged, (b) Aged_1, (c) Aged_2, and (d) Aged_3.

Intermolecular radial distribution functions of investigated models: (a) Unaged, (b) Aged_1, (c) Aged_2, and (d) Aged_3.

The intramolecular radial distribution function provides information about the microscale order of simulated systems. A peak appearing at <3 Å in the intramolecular radial distribution function indicates a model with short-range disorder and an amorphous structure; accordingly, a peak appearing at >3 Å indicates that the model is long-range ordered and has a crystalline structure. Figure 4 shows that for the pure PT substances, the peaks corresponding to C–C, C–H, and O–H are concentrated within the range of the first neighbor peak (1.5–2.1 Å). Stronger peaks do not appear above 3.0 Å, and at further distances, the curve saturates to a constant, indicating that the atomic positions of atoms in the model at long distances are random, with no apparent periodic structure. In summary, the model is a short-range disordered amorphous structure, which further demonstrates the veracity and reliability of the aging model.

Several aging models contained strong characteristic peaks at approximately 1.45, 1.10, and 2.07 Å, corresponding to the C–C, C–H, and O–H bonds in the PT molecular chain, respectively. The peaks at approximately 2.43, 2.11, and 2.47 Å correspond to the interactions between non-bonded neighboring C, H, and O atoms within the PT molecular chain, respectively. Sometimes, the intermolecular radial distribution function can reveal the types of intermolecular non-bonding interactions. Figure 5 shows that there are hydrogen bonding (r = 2.6–3.1 Å) and van der Waals interactions (r = 3.1–5.1 Å) in different aging models. The peak corresponding to hydrogen bonding interactions is small, indicating that van der Waals interactions represent the main mode of intermolecular interactions in the models. Moreover, non-bonding interactions are strengthened by the increased mobility of PT molecules upon increasing the degree of aging.

3.1.3 Glass transition temperature

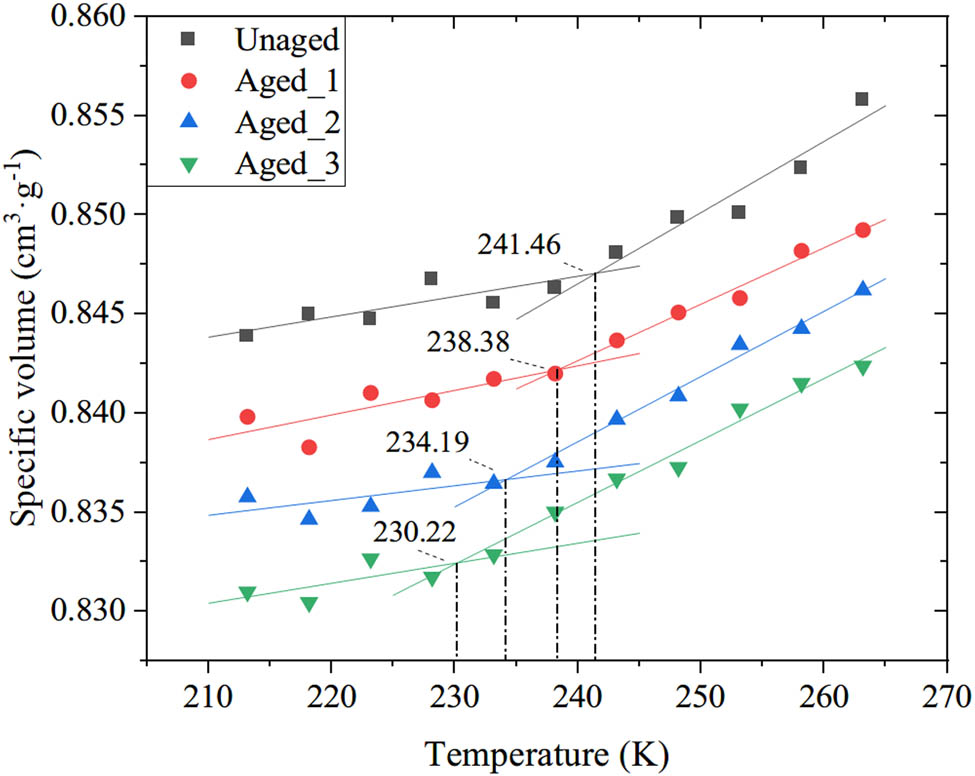

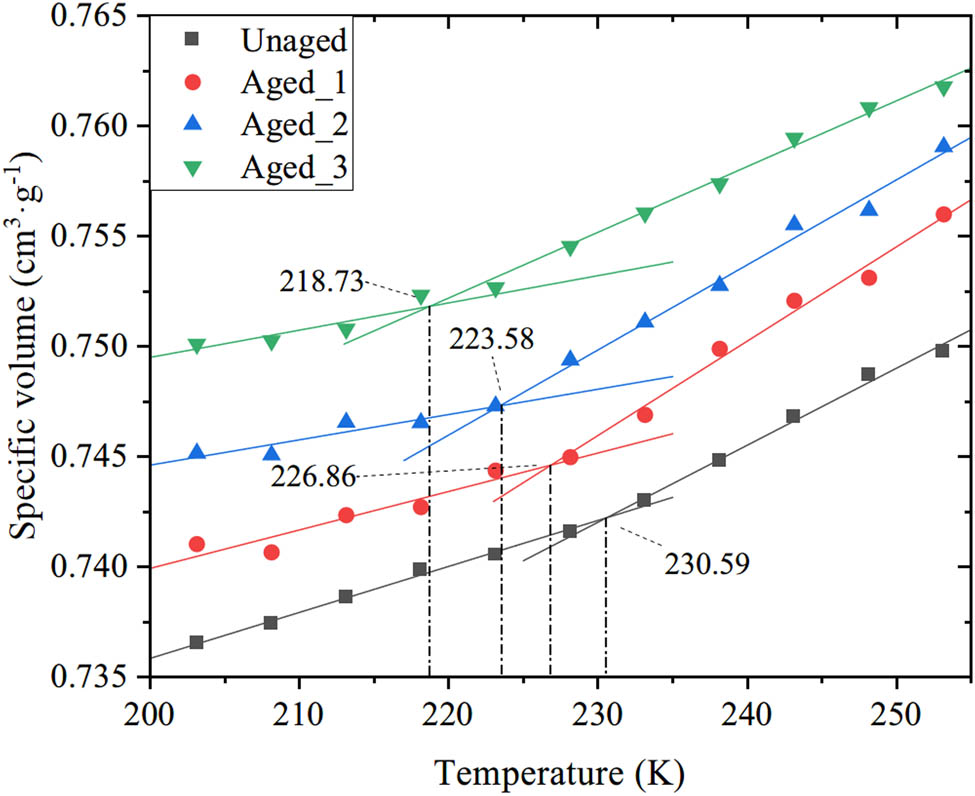

The glass transition temperature is a thermal property indicator of amorphous polymers, which is crucial for evaluating the mechanical properties of PBT elastomers, especially under low-temperature conditions. It can be used to determine the working temperature range of the propellant in a given environment. Based on the free volume theory introduced by Fox and Flory, there is a sharp change in the system’s free volume (or specific volume) before versus after the glass transition temperature (26). MD simulations were used to calculate the specific volumes of the different models at 213–263 K. Linear fitting was performed on the data points both before and after the abrupt change in specific volume. Figure 6 displays the specific volume–temperature curves for the various models. The glass transition temperatures of these models were obtained by calculating the intersection points of the specific volume–temperature fitting lines, as shown in Table 2.

Glass transition temperatures of PT models.

Glass transition temperatures of different simulated systems

| Model | Unaged | Aged_2 | Aged_3 | Aged_4 |

|---|---|---|---|---|

| T g (K) | 241.46 | 238.38 | 234.19 | 230.22 |

Figure 6 indicates that between 230 and 245 K, there was a significant change in specific volume for the different aging models. Table 2 indicates that the glass transition temperature of the unaged model (241.46 K) is similar to that of PBT-TDI, as measured by Chen et al. (8) via dynamic mechanical analysis (DMA) tests (216.65 K), and the error is within an acceptable range. The addition of plasticizers, such as A3 and various additives, leads to a difference between the actual glass transition temperature of PBT elastomers and the simulation results (27). As the decomposition reaction intensifies, the glass transition temperature of the simulated aging models shows a downward trend. There are two proposed reasons for this reduction in the glass transition temperature of the aging models. First, PT molecules are mainly composed of soft segments (i.e., the PBT), which have a glass transition temperature lower than room temperature, and hard segments (i.e., the TDI), which have a glass transition temperature higher than room temperature. As the long-chain PT molecules gradually degrade, the proportion of soft segments in the simulation system increases, and as a result, the rigidity decreases. Second, decomposition reactions lead to reduced size and increased mobility of molecular chains in aging models. Under the combined influence of flexibility and molecular weight, the glass transition temperatures of the models show a downward trend as the degree of decomposition due to aging increases.

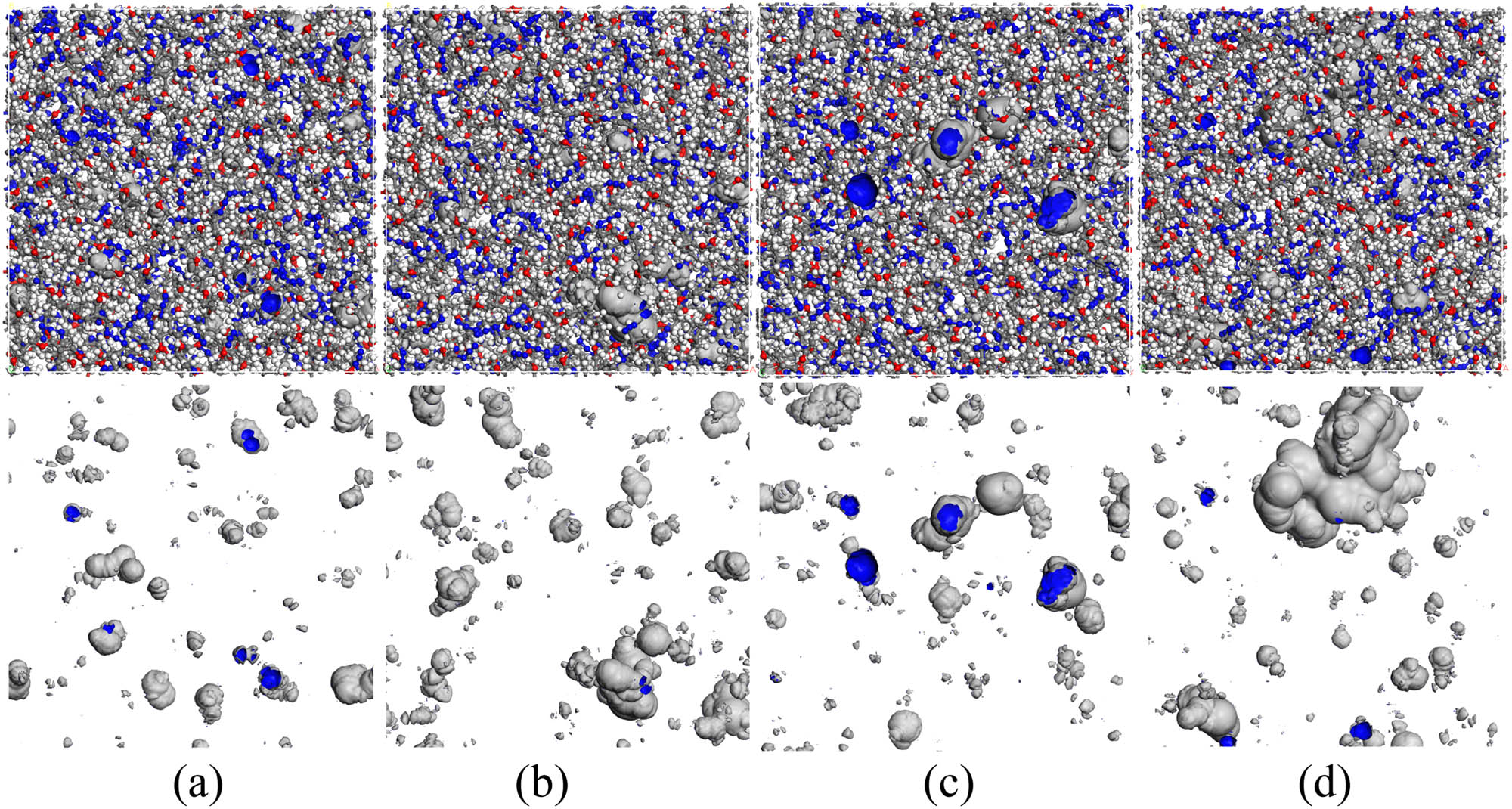

To further explore the reasons behind the changes in the glass transition temperature, the surface analysis module (atom volumes and surfaces) in MS was employed based on the hard-sphere probe method to calculate the free volume and occupied volume in the aging models. The free volume, occupied volume, and free volume fraction of the investigated models and their distributions are shown in Table 3 and Figure 7.

Free volume, occupied volume, and free volume fraction of investigated models

| Unaged | Aged_1 | Aged_2 | Aged_3 | |

|---|---|---|---|---|

| V 0 (Å3) | 76,423.91 | 76,678.26 | 77,033.97 | 76,948.61 |

| V f (Å3) | 489.83 | 858.18 | 1,050.74 | 2,250.53 |

| FFV (%) | 0.64 | 1.11 | 1.35 | 2.84 |

Free volume distribution of investigated models of (a) Unaged, (b) Aged_1, (c) Aged_2, and (d) Aged_3.

For the decomposition reaction aging model under a constant probe radius, the free volume fraction in the model gradually increases as the decomposition reaction proceeds, indicating that even under low-temperature conditions, the molecular chains in the model have sufficient space to overcome the rotation barrier and move. This reduces the glass transition temperature of the model with the continuous cleavage of molecular chains. In summary, the simulated law governing the free volume fraction is consistent with the simulated glass transition temperatures.

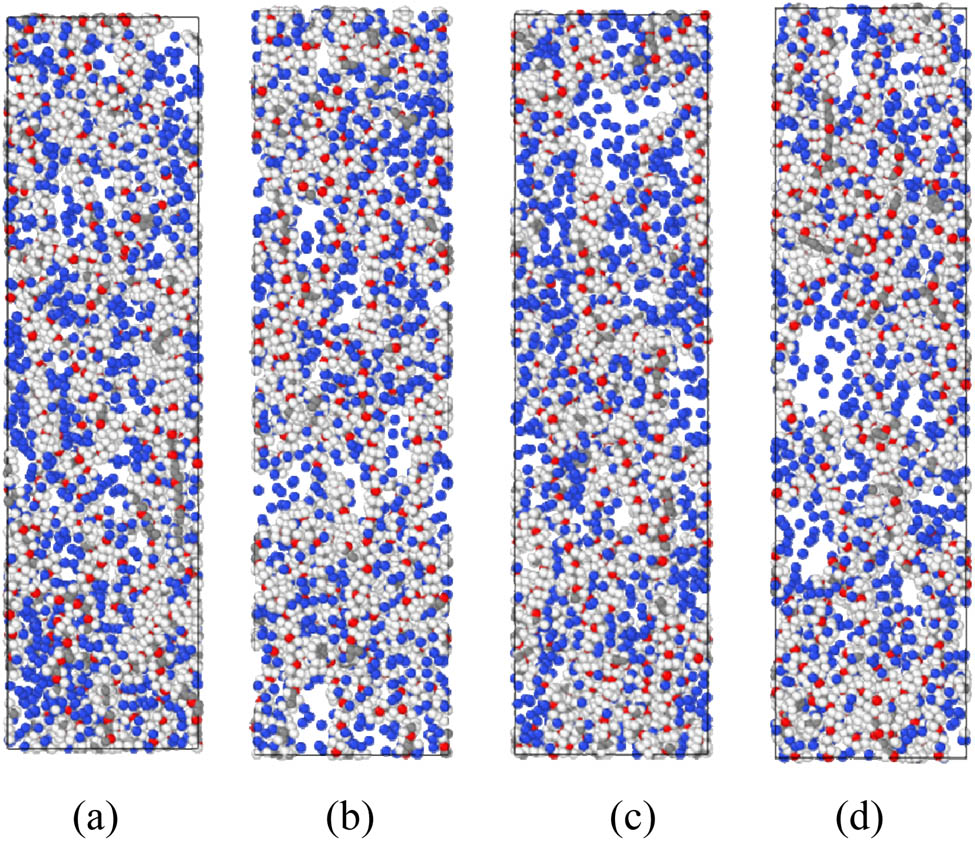

3.1.4 Mechanical properties

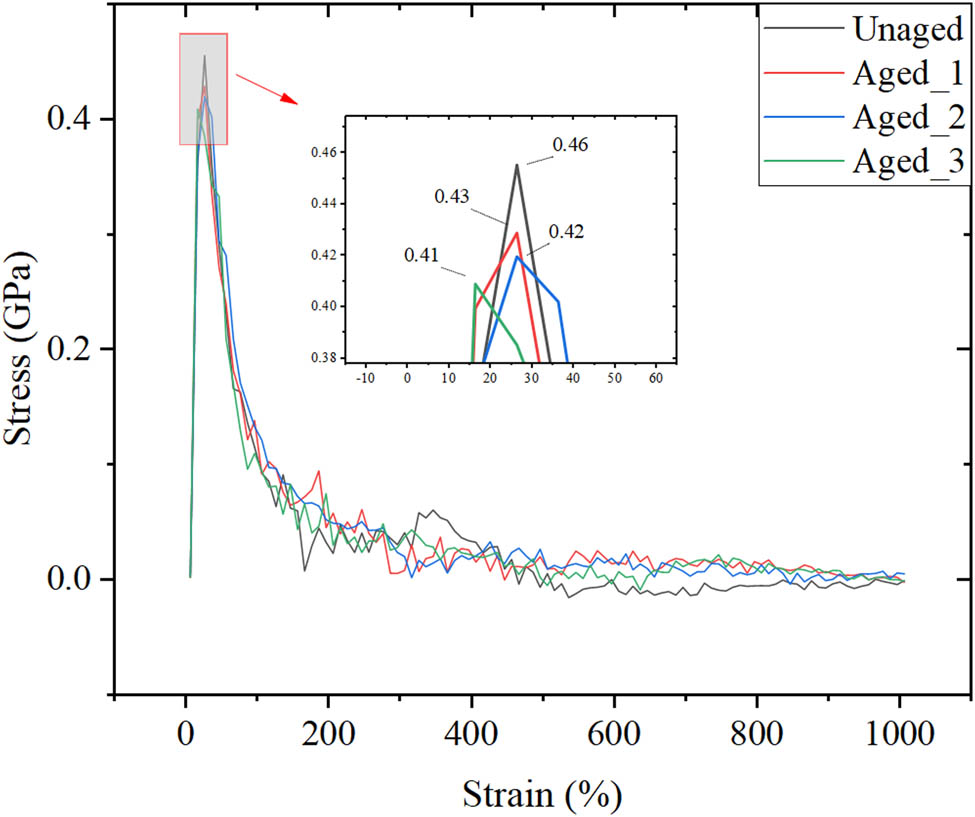

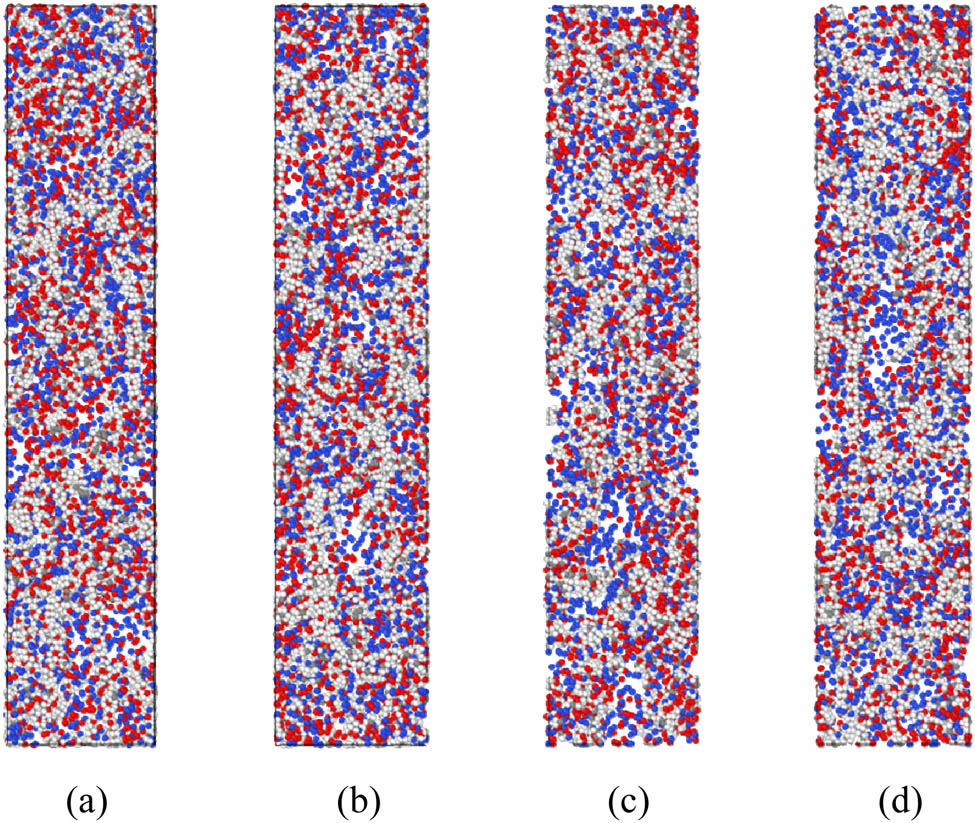

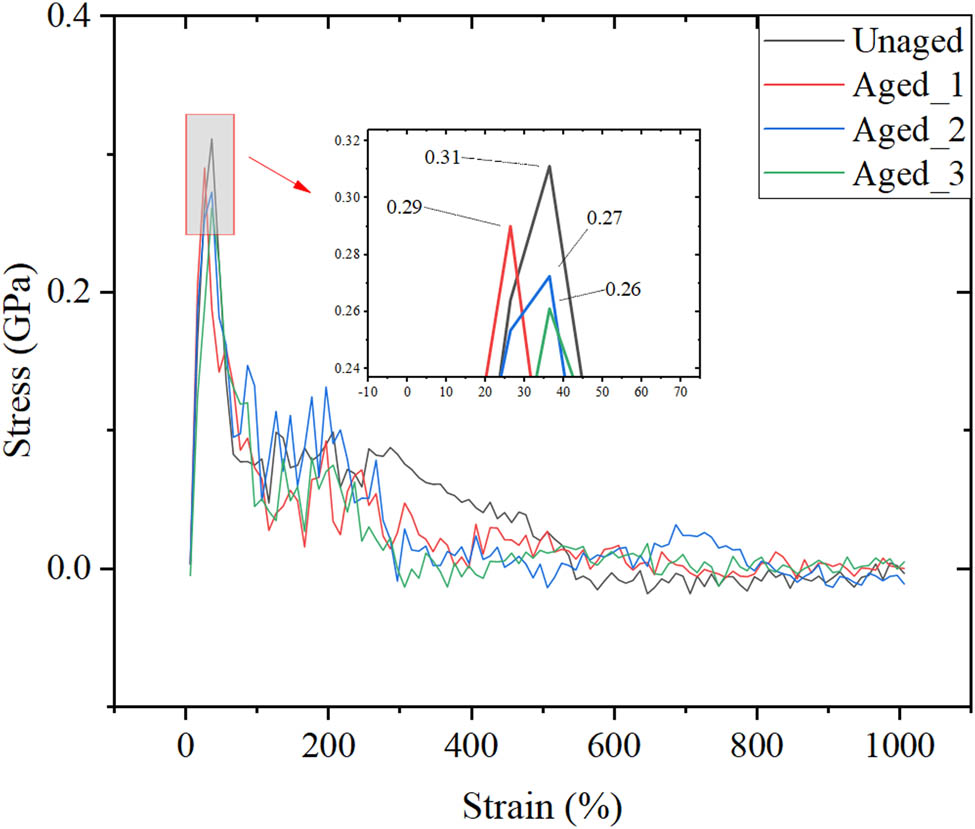

MD simulations were conducted on different aging models under uniaxial tensile conditions to analyze changes in their mechanical properties. Figures 8 and 9 show snapshots and stress–strain curves, respectively, corresponding to the uniaxial tensile deformation of PT models at different stages of aging. The temperature and strain rate conditions were 298 K and 0.001 Å·ps−1, respectively.

Snapshots of the uniaxial tensile deformation processes of PT models at different stages of aging: (a) Unaged, (b) Aged_1, (c) Aged_2, and (d) Aged_3.

Stress–strain curves corresponding to the uniaxial tensile deformation of PT models at different stages of aging.

The stress–strain curves exhibit significant stress oscillations under all aging conditions due to thermal fluctuations. As the strain on the simulation system continues to increase, the stress of all models increases linearly, begins to fluctuate, decreases after reaching the maximum stress point, and finally stabilizes. In the initial stage of uniaxial stretching, PT molecular chains are tightly entangled with one another. As the PT molecular chains continue to elongate, they gradually change their structural mode from curling to stretching under stress, and the molecular chains separate from one another. Meanwhile, pores and filaments gradually appeared in the models. As the decomposition reaction continues, the maximum stress and elongation of the simulated system continuously decrease. Compared with the Unaged model, the Aged_3 model showed a significant increase in the number of pores and filaments after 3 ns of stretching. The mobility of the PT molecular chains increases upon increasing the number of chain-breaking segments in the model. Additionally, the polymer chains undergo curling agglomeration, which reduces the tensile strength and limits the elongation of the PT model as the degradation and chain-breaking aging reactions continue. Notably, owing to computational limitations, the tensile strain rate of the MD simulation of uniaxial stretching is much larger than that of macroscopic quasi-static tensile tests. For this reason, the yield stress and elastic modulus of the simulated model are much larger than those measured in macroscopic experiments.

As seen in Figures 8 and 9, no typical polymer behavior was observed during the tensile process. Upon analysis, we believe that the absence of necking in MD simulations during polymer stretching can be attributed to several factors. First, the limitations of time and spatial scales in MD simulations play a significant role. Necking is a relatively slow process that involves large-scale reorganization and displacement of polymer chains, which may not be fully captured within the short simulation timescales. Second, the boundary conditions in MD simulations are unrealistic compared to actual tensile experiments. In real experiments, stress tends to concentrate in specific regions during deformation, leading to localized deformation and necking. However, due to the boundary conditions and relatively uniform stress distribution in MD simulations, such localized stress concentrations may not occur, making it difficult to observe necking. Third, the insufficient length of polymer chains in the simulation could also contribute to this issue. Short chains may not fully exhibit the complex behavior of long-chain polymers during stretching (such as chain entanglement, disentanglement, and melt flow), which are fundamental to the necking phenomenon. Finally, there are differences in temperature and strain rate between simulations and experiments. The strain rate in MD simulations is typically much higher than in experiments, which may result in polymers showing different deformation mechanisms, thereby preventing the formation of necking. These factors together explain why the macroscopic necking behavior observed in experiments cannot be replicated in simulations.

3.2 Interactions between aged PBT matrix and plasticizer

3.2.1 Glass transition temperature

MD simulations were used to calculate the specific volumes of different models between 203 and 253 K, and the data were subjected to linear fitting before and after the abrupt change in specific volume. The volume–temperature curves for the blended models are shown in Figure 10. The glass transition temperatures of different models were determined by calculating the intersection points of the volume–temperature fitting lines, and the results are shown in Table 4.

Glass transition temperatures of PT/A3 models.

Glass transition temperatures of blended models

| Model | Unaged | Aged_2 | Aged_3 | Aged_4 |

|---|---|---|---|---|

| T g (K) | 230.59 | 226.86 | 223.58 | 218.73 |

The glass transition temperature of the Unaged model (230.59 K) was closer to that of the PBT propellant reported by Chen et al. based on DMA experiments (233.4 K) (15). The specific volumes of the different aging models each showed an increasing trend with increasing temperature, with a sharp change between 215 and 235 K. The glass transition temperatures of the investigated blended models increased in the order: Aged_3 < Aged_2 < Aged_1 < Unaged.

The computational results presented in Section 3.1.3 suggest that the addition of BDNPA or BDNPF did not impact the law governing changes in glass transition temperature. Specifically, for the decomposition reaction aging system, as the number of chain-breaking fragments increased, the glass transition temperature of the model showed a decreasing trend. Moreover, the addition of BDNPA or BDNPF reduced the glass transition temperature of the matrix/plasticizer blended aging model as a whole. To investigate the reason for the reduced glass transition temperatures after the addition of these plasticizers and to elucidate the mechanism governing A3 interactions with PBT elastomers, the intermolecular radial distribution functions of C, O, and H atoms on the PT molecular chain were calculated for the different aging models of PT/A3; the results are shown in Figure 11.

Intermolecular radial distribution functions of blended aging models: (a) Unaged, (b) Aged_1, (c) Aged_2, and (d) Aged_3.

Comparing the radial distribution functions of the models in Figure 5 (Section 3.1.2) reveals that the addition of BDNPA or BDNPF greatly reduced the intensity of the peaks in the intermolecular radial distribution functions of C–C, C–H, and O–H moieties in PT, indicating reduced strength of hydrogen bonds and van der Waals interactions. The analysis suggests that the polar small molecules of BDNPA and BDNPF will be dispersed into the intermolecular PT polymer networks (which comprise PT molecular chains containing polar groups) via diffusion during the simulation process. This weakens the intermolecular interactions among PT molecules and increases the spacing between PT molecular chains, which increases the PT molecular mobility, thereby reducing the glass transition temperatures of the blended matrix/plasticizer models.

3.2.2 Mechanical properties

MD simulations of blended models under uniaxial tensile conditions revealed key changes in the mechanical properties of the blended models. Figures 12 and 13 show snapshots and stress–strain curves, respectively, of the uniaxial tensile deformation of PT/A3 models at different stages of aging at 298 K and a strain rate of 0.001 Å·ps−1.

Snapshots of the uniaxial tensile deformation of PT/A3 models at different stages of aging. (a) Unaged, (b) Aged_1, (c) Aged_2, and (d) Aged_3.

Stress–strain curves corresponding to the uniaxial tensile deformation of the PT/A3 blended models at different stages of aging.

The stress–strain curves of the PT/A3 blended models were similar to those presented in Section 3.1.4, showing the same significant stress oscillation under all aging conditions due to thermal fluctuations. With increasing strain, the stress of different models first increases linearly, start to fluctuate, decreases after reaching the yield point, and finally stabilizes. The variations in the stress–strain curves of the blended models are generally consistent with those of the PT pure material aging models. Comparing Figures 7 and 8 (Section 3.1.4) indicates that the addition of BDNPA or BDNPF significantly reduces the non-bonding interactions between PT molecular chains. Under the same aging conditions, the blend aging systems containing BDNPA and BDNPF exhibited stronger plasticity and higher elongation.

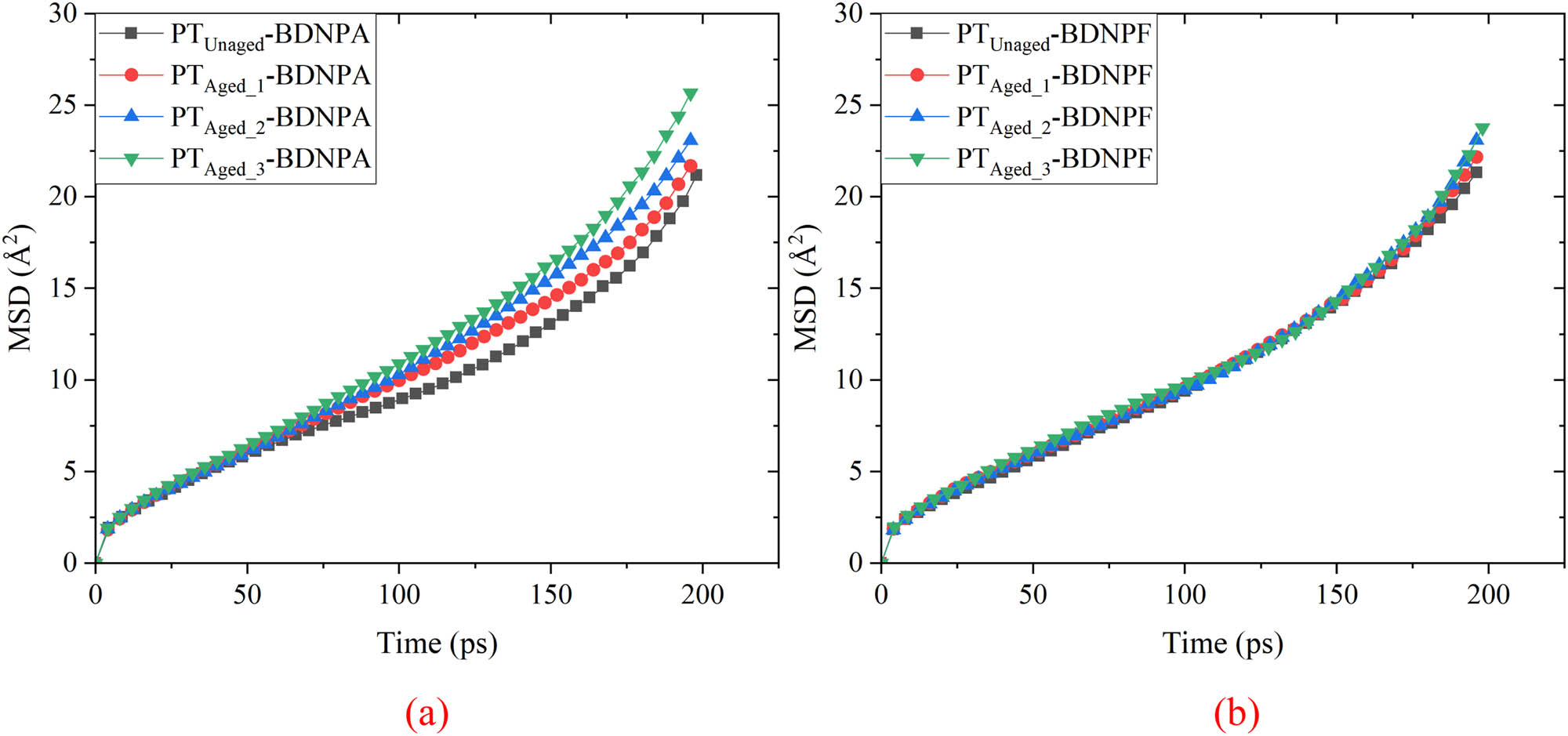

3.2.3 Diffusivity

The experimental study conducted by Yu demonstrated that plasticizers in PBT elastomers slowly migrate toward the surrounding interface during storage due to the concentration gradient force and microphase separation (28). This may have a negative impact on the adhesive performance of the propellant interface. Moreover, it will reduce the mechanical properties of the propellant. MD simulations were performed at 220 ps under NPT conditions for the blended aging models; after optimization and relaxation, the trajectories of the mean-squared displacement (MSD) of BDNPA and BDNPF over time are shown in Figure 14.

MSD vs time curves of A3 plasticizers: (a) BDNPA and (b) BDNPF.

During the initial 5 ps, the MSD curves for all blended aging models exhibited a rapid and nonlinear increase; between 5 and 200 ps, the MSD curves of the blended aging models exhibited a linear increase, with a lower growth rate than in the first 5 ps. As the simulation time increases, the MSDs of the aged models (Aged_1–Aged_3) change significantly, whereas that of the Unaged model changes the least. To further quantify the diffusion performance of BDNPA and BDNPF in the blended aging models, the diffusion coefficients of BDNPA and BDNPF were obtained by fitting the slopes of the respective MSD–time curves (Tables 5 and 6, respectively).

Diffusion coefficients of BDNPA in different aging models

| Model | Unaged | Aged_1 | Aged_2 | Aged_3 |

|---|---|---|---|---|

| D(BDNPA) | 1.885 × 10−2 | 1.951 × 10−2 | 2.093 × 10−2 | 2.405 × 10−2 |

Note: D = diffusion coefficient in units of 10−10 m2·s−1.

Diffusion coefficients of BDNPF in different aging models

| Model | Unaged | Aged_1 | Aged_2 | Aged_3 |

|---|---|---|---|---|

| D(BDNPF) | 1.979 × 10−2 | 2.075 × 10−2 | 2.218 × 10−2 | 2.261 × 10−2 |

Note: D = diffusion coefficient in units of 10−10 m2·s−1.

The diffusion coefficient of BDNPA was smaller than that of BDNPF in each model. The diffusion coefficients of both BDNPA and BDNPF generally increased, and the diffusion rate was accelerated with increasing numbers of broken chains in the aging models. Although the higher negative potential near the ends of the broken chains endows the molecular chain fragments with appreciable dipole moments, it has less of an impact on the diffusion of BDNPA and BDNPF than the size and number of molecular chains. With increased aging, the mobility of the PT molecular chain segments was gradually enhanced, and the free volume in the model increased. Due to the combined effects of non-bonding interactions and increased free volume, the available space for the motion of BDNPA and BDNPF increased, resulting in enhanced diffusion.

3.2.4 Component compatibility

Yu and Tian (29) and Zhang et al. (30) analyzed the causes of recent accidents involving solid missile engines and found that the compatibility between plasticizers and the propellant matrix had a significant impact on the stability of the propellant. The separation of propellant components due to plasticizer aggregation increases the propellant burning surface area after engine ignition, and in severe cases, this may cause engine explosion.

The models comprising PT and either BDNPA or BDNPF are multimixed models, and therefore, the cohesive energy density of the model components is calculated, along with the corresponding solubility (δ), van der Waals (δ v), and electrostatic (δ e) parameters for each component, to assess the compatibility between PT and BDNPA or BDNPF. MD simulations for 220 ps under NPT conditions using the optimized model enabled the determination of the cohesive energy density, solubility parameter, van der Waals parameter, and electrostatic parameter for different components in the investigated aging systems; the results are presented in Tables 7 and 8.

Cohesive energy density, van der Waals component, and electrostatic component of different PT/A3 aging models

| Model | Total | van der Waals | Electrostatic |

|---|---|---|---|

| Unaged | 2.56 × 108 | 2.13 × 108 | 3.51 × 107 |

| Aged_1 | 2.82 × 108 | 2.33 × 108 | 4.02 × 107 |

| Aged_2 | 3.02 × 108 | 2.51 × 108 | 4.25 × 107 |

| Aged_3 | 3.25 × 108 | 2.69 × 108 | 4.73 × 107 |

| BDNPA | 2.52 × 108 | 1.36 × 108 | 1.12 × 108 |

| BDNPF | 2.70 × 108 | 1.36 × 108 | 1.30 × 108 |

Solubility parameters for different PT/A3 aging models

| Model | δ T | δ v | δ e | Δδ PT/BDNPA | Δδ PT/BDNPF |

|---|---|---|---|---|---|

| Unaged | 16.008 | 14.595 | 5.924 | 0.143 | 0.418 |

| Aged_1 | 16.783 | 15.266 | 6.341 | 0.918 | 0.357 |

| Aged_2 | 17.370 | 15.837 | 6.517 | 1.505 | 0.944 |

| Aged_3 | 18.020 | 16.397 | 6.877 | 2.155 | 1.594 |

| BDNPA | 15.865 | 11.647 | 11.647 | — | — |

| BDNPF | 16.426 | 11.653 | 11.419 | — | — |

In the Unaged model, the Δδ of PT, BDNPA, and BDNPF are all less than 2.05 (J·cm−3)0.5, indicating that PT is compatible with both BDNPA and BDNPF; overall, the compatibility between PT and BDNPA is better than that between PT and BDNPF. The differences in solubility parameters between PT, BDNPA, and BDNPF in different aging systems decreased in the order, Aged_3 > Aged_2 > Aged_1(BDNPA)/Unaged(BDNPF) > Unaged(BDNPA)/Aged_1(BDNPF). Thus, with increasing degradation of PT molecular chains, the Δδ between PT and BDNPA or BDNPF gradually increased, and the compatibility gradually changed from compatibility to partial compatibility. These results suggest that the decomposition reaction generates broken chains containing hydroxyl groups at the ends. Notably, the calculated intermolecular radial distribution functions presented in Section 3.1.2 showed that the decomposition reaction had a limited effect on the non-polar interactions between atoms. However, with the continuous increase in the number of broken chains and reduction in the size of those broken chains, the resulting polar chain ends and weakened intermolecular interactions lead to increased van der Waals and electrostatic components of the PT solubility parameter. Ultimately, the difference in solubility parameters between PT and BDNPA or BDNPF gradually increased.

4 Conclusions

In simulations of PBT pure substances, as the thermal oxidative aging reaction proceeded, both the glass transition temperature and the mechanical properties of the pure substance decreased. Analyzing the radius of rotation, radial distribution function, and free volume fraction of pure substances revealed that the main reason for the observed changes was that the decomposition reaction destroyed the network structure of the PBT elastomer. As the number of soft segments in the simulation system increased, the intermolecular interactions were strengthened, the volume of molecular coils decreased, and their mobility increased. This led to gradual increases in the number of defects and the free volume fraction in the system.

For the simulation systems comprising PBT pure substances blended with plasticizers, as the thermal oxidative aging reaction proceeded, the glass transition temperature and mechanical properties of the blended systems remained generally consistent with those of the corresponding pure substance simulation systems. The diffusion coefficients and solubility parameters of the plasticizers continued to increase primarily because the chain segment size continued to decrease, thereby allowing a larger space for plasticizer movement in the simulation system. In addition, the non-polar and dipole interactions between the plasticizer and PBT molecules became stronger, which enhanced the plasticizer’s diffusion in PBT and reduced its compatibility. This phenomenon may facilitate the migration of plasticizers from the PBT matrix, thereby further exacerbating material aging and reduction in mechanical properties. Comparing the radial distribution functions of pure substances revealed that the addition of plasticizers reduced the strength of interactions between PBT molecular chains. This increased the mobility of PBT molecular chains in the blended systems, resulting in stronger plasticity, greater elongation, and an overall reduction in glass transition temperature.

This study elucidated the microscale mechanism governing the macroscopic changes in the performance of PBT propellants during thermal-oxidative aging using MD simulations. The results provide an important theoretical basis for understanding the aging mechanisms of PBT propellants and offer new ideas for improving the aging resistance of propellants. Future research should focus on experimental verifications of simulated results. Additionally, it would be valuable to design new graded antioxidants or explore unique strategies (e.g., crosslinking modifications, copolymerization) for improving the thermal oxidative stability of PBT propellants to support their long-term use.

Acknowledgement

The authors are grateful for the support provided by the School of Physics and Optoelectronic Engineering of Ludong University, especially in regard to the utilization of the MS software.

-

Funding information: Authors state no funding involved.

-

Author contributions: Lingze Kong: writing – original draft, writing – review & editing, methodology, formal analysis; Weiqi Sun: formal analysis; Hongqiang Zhao: visualization; Wei Zhou: project administration; Feng Guo: supervision; Bin Zhou: validation; Yumin Shi: validation; Li Li: methodology; Kun Li: visualization; Ruiqi Zhong: visualization.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article (and its supplementary information files).

References

(1) Cong K, He JY, Yang RJ. Facile synthesis of three diazido compounds and their application in polyether polytriazido elastomers as solid propellant binders. Polym Adv Technol. 2021;32(12):4940–50. 10.1002/pat.5488.Search in Google Scholar

(2) Zou XB, Zhang WG, Gu YJ, Fu XC, Zhang ZH, Ge Z, et al. A study on the effect of four thermoplastic elastomers on the properties of double-base propellants. RSC Adv. 2020;10(70):42883–9. 10.1039/D0RA08370D.Search in Google Scholar

(3) Frontini PM, Rink M, Pavan A. Development of polyurethane engineering thermoplastics. I. Preparation and structure. J Appl Polym Sci. 1993;48(11):2003–22. 10.1002/app.1993.070481114.Search in Google Scholar

(4) Tang G, Zhang ZJ, Li XY, Luo YJ. BAMO-THF copolymer-based energetic thermoplastic polyurethanes with a decent bonding property. Energ Mater Front. 2021;2(1):32–9. 10.1016/j.enmf.2021.01.007.Search in Google Scholar

(5) Cheradame H, Andreolety JP, Rousset E. Synthesis of polymers containing pseudohalide groups by cationic polymerization, 1. Homopolymerization of 3, 3‐bis (azidomethyl) oxetane and its copolymerization with 3-chloromethyl-3-(2, 5, 8‐trioxadecyl) oxetane. Macromol Chem Phys. 1991;192(4):901–18. 10.1002/macp.1991.021920414.Search in Google Scholar

(6) Kanti Sikder A, Reddy S. Review on energetic thermoplastic elastomers (ETPEs) for military science. Propell Explos Pyrot. 2013;38(1):14–28. 10.1002/prep.201200002.Search in Google Scholar

(7) Luo Y, Chen P, Zhao FQ, Hu RZ, Li SW, Gao Y. Kinetics and mechanism of the thermal decomposition reaction of 3, 3-Bis (azidomethyl) oxetane/tetrahydrofuran copolymer. Chin J Chem. 2004;22(11):1219–24. 10.1002/cjoc.20040221102.Search in Google Scholar

(8) Chen C, Pan H, Tu J, Chen J, Zhang XY, Mao C, et al. Thermal aging mechanism of PBT energetic elastomer based on the evolution of microstructure. Mater Today Chem. 2023;32:101655. 10.1016/j.mtchem.2023.101655.Search in Google Scholar

(9) Loyer C, Régnier G, Duval V, Ould Y, Richaud E. PBT plasticity loss induced by oxidative and hydrolysis ageing. Polym Degrad Stab. 2020;181:109368. 10.1016/j.polymdegradstab.2020.109368.Search in Google Scholar

(10) Wang J, Cui H, Ma W, Xu J. Investigation on aging model of solid propellant using the degree of crosslinking. Int J Aerosp Eng. 2022;2022:1–8. 10.1155/2022/2700740.Search in Google Scholar

(11) Sun YL, Ren H, Jiao QJ. Comparison of thermal behaviors and decomposition kinetics of NEPE propellant before and after storage. J Therm Anal Calorim. 2018;131(1):101–11. 10.1007/s10973-017-6525-8.Search in Google Scholar

(12) Yang DL, Edgar AS, Torres JA, Adams JC, Kress JD. Thermal stability of a eutectic mixture of bis(2, 2-dinitropropyl) acetal and formal: Part C. Kinetic compensation effect. Propell Explos Pyrot. 2021;46(1):134–49. 10.1002/prep.202000042.Search in Google Scholar

(13) Yang DL, Pacheco R, Edwards S, Henderson K, Wu RL, Labouriau A, et al. Thermal stability of a eutectic mixture of bis (2, 2-dinitropropyl) acetal and formal: Part B. Degradation mechanisms under water and high humidity environments. Polym Degrad Stab. 2016;130:338–47. 10.1016/j.polymdegradstab.2016.06.007.Search in Google Scholar

(14) Yang DL, Pacheco R, Edwards S, Henderson K, Wu RL, Labouriau A, et al. Thermal stability of a eutectic mixture of bis (2, 2-dinitropropyl) acetal and formal: Part A. Degradation mechanisms in air and under nitrogen atmosphere. Polym Degrad Stab. 2016;129:380–98. 10.1016/j.polymdegradstab.2016.05.017.Search in Google Scholar

(15) Chen C, Wang YX, Chen JF, Deng L, Mao CL, Zhou X. Study on thermal aging properties of PBT energetic elastomer. Propell Explos Pyrot. 2023;48(7):e202200233. 10.1002/prep.202200233.Search in Google Scholar

(16) Peter C, Kremer K. Multiscale simulation of soft matter systems. Faraday Discuss. 2009;144:9–24. 10.1039/B919800H.Search in Google Scholar PubMed

(17) Chernatynskiy A, Phillpot SR, LeSar R. Uncertainty quantification in multiscale simulation of materials: A prospective. Annu Rev Mater Res. 2013;43(1):157–82. 10.1146/annurev-matsci-071312-121708.Search in Google Scholar

(18) Li MM, Sun QF, Gan XD, Guo XD. Mesoscopic dynamic simulationon compatibility of PBT/plasticizers blends. Aerosp Shanghai. 2015;32(4):63–7. 10.19328/j.cnki.1006-1630.2015.04.013.Search in Google Scholar

(19) Kong L, Dong K, Tang Y, Yang CL, Xiao YD. Molecular simulation study on the aging mechanism of NEPE propellant matrix. Molecules. 2023;28(4):1792. 10.3390/molecules28041792.Search in Google Scholar PubMed PubMed Central

(20) Sun H, Ren P, Fried JR. The COMPASS force field: Parameterization and validations for polyphosphazenes. Comput Theor Polym Sci. 1998;8(1–2):229–46. 10.1016/S1089-3156(98)00042-7.Search in Google Scholar

(21) Sun H. COMPASS: An ab Initio force-field optimized for condensed-phase applicationsoverview with details on alkane and benzene compounds. J Phys Chem B. 1998;102(38):7338–64. 10.1021/jp980939v.Search in Google Scholar

(22) Andersen HC. Molecular dynamics simulations at constant pressure and/or temperature. J Chem Phys. 1980;72(4):2384–93. 10.1063/1.439486.Search in Google Scholar

(23) Parrinello M, Rahman A. Strain fluctuations and elastic constants. J Chem Phys. 1982;76(5):2662–6. 10.1063/1.443248.Search in Google Scholar

(24) Karasawa N, Goddard III WA. Force fields, structures, and properties of poly(vinylidene fluoride) crystals. Macromolecules. 2002;25(26):7268–81. 10.1021/ma00052a031.Search in Google Scholar

(25) Ewald P. Evaluation of optical and electrostatic lattice potentials. Ann Phys. 1921;64:253–87.10.1002/andp.19213690304Search in Google Scholar

(26) Fox Jr TG, Flory PJ. Second-order transition temperatures and related properties of polystyrene. I. Influence of molecular weight. J Appl Phys. 1950;21(6):581–91. 10.1063/1.1699711.Search in Google Scholar

(27) Paul W. Molecular dynamics simulations of the glass transition in polymer melts. Polymer. 2004;45(11):3901–5. 10.1016/j.polymer.2004.01.079.Search in Google Scholar

(28) Yu ZF. Investigation of physical compatibility of related components in novel high energy solid propellant by molecular simulation. Dissertation. Beijing: Beijing Institute of Technology; 2016.Search in Google Scholar

(29) Yu ZY, Tian WP. Analysis of test failure reason on solid rocket motor. J Solid Rocket Technol. 1999;22(4):18–22.Search in Google Scholar

(30) Zhang L, Chen C, Tang X, Zhou X. Mesoscale mechanics investigation of multi-component solid propellant systems. E-Polymers. 2024;24(1):20240006. 10.1515/epoly-2024-0006.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Flame-retardant thermoelectric responsive coating based on poly(3,4-ethylenedioxythiphene) modified metal–organic frameworks

- Highly stretchable, durable, and reversibly thermochromic wrapped yarns induced by Joule heating: With an emphasis on parametric study of elastane drafts

- Molecular dynamics simulation and experimental study on the mechanical properties of PET nanocomposites filled with CaCO3, SiO2, and POE-g-GMA

- Multifunctional hydrogel based on silk fibroin/thermosensitive polymers supporting implant biomaterials in osteomyelitis

- Marine antifouling coating based on fluorescent-modified poly(ethylene-co-tetrafluoroethylene) resin

- Preparation and application of profiled luminescent polyester fiber with reversible photochromism materials

- Determination of pesticide residue in soil samples by molecularly imprinted solid-phase extraction method

- The die swell eliminating mechanism of hot air assisted 3D printing of GF/PP and its influence on the product performance

- Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes

- The effects of property variation on the dripping behaviour of polymers during UL94 test simulated by particle finite element method

- Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets

- Synthesis, characterization and evaluation of a pH-responsive molecular imprinted polymer for Matrine as an intelligent drug delivery system

- Twist-related parametric optimization of Joule heating-triggered highly stretchable thermochromic wrapped yarns using technique for order preference by similarity to ideal solution

- Comparative analysis of flow factors and crystallinity in conventional extrusion and gas-assisted extrusion

- Simulation approach to study kinetic heterogeneity of gadolinium catalytic system in the 1,4-cis-polyisoprene production

- Properties of kenaf fiber-reinforced polyamide 6 composites

- Cellulose acetate filter rods tuned by surface engineering modification for typical smoke components adsorption

- A blue fluorescent waterborne polyurethane-based Zn(ii) complex with antibacterial activity

- Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading

- Preparation and application research of composites with low vacuum outgassing and excellent electromagnetic sealing performance

- Assessing the recycling potential of thermosetting polymer waste in high-density polyethylene composites for safety helmet applications

- Mesoscale mechanics investigation of multi-component solid propellant systems

- Preparation of HTV silicone rubber with hydrophobic–uvioresistant composite coating and the aging research

- Experimental investigation on tensile behavior of CFRP bolted joints subjected to hydrothermal aging

- Structure and transition behavior of crosslinked poly(2-(2-methoxyethoxy) ethylmethacrylate-co-(ethyleneglycol) methacrylate) gel film on cellulosic-based flat substrate

- Mechanical properties and thermal stability of high-temperature (cooking temperature)-resistant PP/HDPE/POE composites

- Preparation of itaconic acid-modified epoxy resins and comparative study on the properties of it and epoxy acrylates

- Synthesis and properties of novel degradable polyglycolide-based polyurethanes

- Fatigue life prediction method of carbon fiber-reinforced composites

- Thermal, morphological, and structural characterization of starch-based bio-polymers for melt spinnability

- Robust biaxially stretchable polylactic acid films based on the highly oriented chain network and “nano-walls” containing zinc phenylphosphonate and calcium sulfate whisker: Superior mechanical, barrier, and optical properties

- ARGET ATRP of styrene with low catalyst usage in bio-based solvent γ-valerolactone

- New PMMA-InP/ZnS nanohybrid coatings for improving the performance of c-Si photovoltaic cells

- Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites

- Preparation of cardanol-based curing agent for underwater drainage pipeline repairs

- Preparation of lightweight PBS foams with high ductility and impact toughness by foam injection molding

- Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study

- Experimental study on impact and flexural behaviors of CFRP/aluminum-honeycomb sandwich panel

- Normal-hexane treatment on PET-based waste fiber depolymerization process

- Effect of tannic acid chelating treatment on thermo-oxidative aging property of natural rubber

- Design, synthesis, and characterization of novel copolymer gel particles for water-plugging applications

- Influence of 1,1′-Azobis(cyclohexanezonitrile) on the thermo-oxidative aging performance of diolefin elastomers

- Characteristics of cellulose nanofibril films prepared by liquid- and gas-phase esterification processes

- Investigation on the biaxial stretching deformation mechanism of PA6 film based on finite element method

- Simultaneous effects of temperature and backbone length on static and dynamic properties of high-density polyethylene-1-butene copolymer melt: Equilibrium molecular dynamics approach

- Research on microscopic structure–activity relationship of AP particle–matrix interface in HTPB propellant

- Three-layered films enable efficient passive radiation cooling of buildings

- Electrospun nanofibers membranes of La(OH)3/PAN as a versatile adsorbent for fluoride remediation: Performance and mechanisms

- Preparation and characterization of biodegradable polyester fibers enhanced with antibacterial and antiviral organic composites

- Preparation of hydrophobic silicone rubber composite insulators and the research of anti-aging performance

- Surface modification of sepiolite and its application in one-component silicone potting adhesive

- Study on hydrophobicity and aging characteristics of epoxy resin modified with nano-MgO

- Optimization of baffle’s height in an asymmetric twin-screw extruder using the response surface model

- Effect of surface treatment of nickel-coated graphite on conductive rubber

- Experimental investigation on low-velocity impact and compression after impact behaviors of GFRP laminates with steel mesh reinforced

- Development and characterization of acetylated and acetylated surface-modified tapioca starches as a carrier material for linalool

- Investigation of the compaction density of electromagnetic moulding of poly(ether-ketone-ketone) polymer powder

- Experimental investigation on low-velocity-impact and post-impact-tension behaviors of GFRP T-joints after hydrothermal aging

- The repeated low-velocity impact response and damage accumulation of shape memory alloy hybrid composite laminates

- Exploring a new method for high-performance TPSiV preparation through innovative Si–H/Pt curing system in VSR/TPU blends

- Large-scale production of highly responsive, stretchable, and conductive wrapped yarns for wearable strain sensors

- Preparation of natural raw rubber and silica/NR composites with low generation heat through aqueous silane flocculation

- Molecular dynamics simulation of the interaction between polybutylene terephthalate and A3 during thermal-oxidative aging

- Crashworthiness of GFRP/aluminum hybrid square tubes under quasi-static compression and single/repeated impact

- Review Articles

- Recent advancements in multinuclear early transition metal catalysts for olefin polymerization through cooperative effects

- Impact of ionic liquids on the thermal properties of polymer composites

- Recent progress in properties and application of antibacterial food packaging materials based on polyvinyl alcohol

- Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters

- Rapid Communication

- Design, synthesis, characterization, and adsorption capacities of novel superabsorbent polymers derived from poly (potato starch xanthate-graft-acrylamide)

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Development of smart core–shell nanoparticles-based sensors for diagnostics of salivary alpha-amylase in biomedical and forensics

- Thermoplastic-polymer matrix composite of banana/betel nut husk fiber reinforcement: Physico-mechanical properties evaluation

- Special Issue: Electrospun Functional Materials

- Electrospun polyacrylonitrile/regenerated cellulose/citral nanofibers as active food packagings

Articles in the same Issue

- Research Articles

- Flame-retardant thermoelectric responsive coating based on poly(3,4-ethylenedioxythiphene) modified metal–organic frameworks

- Highly stretchable, durable, and reversibly thermochromic wrapped yarns induced by Joule heating: With an emphasis on parametric study of elastane drafts

- Molecular dynamics simulation and experimental study on the mechanical properties of PET nanocomposites filled with CaCO3, SiO2, and POE-g-GMA

- Multifunctional hydrogel based on silk fibroin/thermosensitive polymers supporting implant biomaterials in osteomyelitis

- Marine antifouling coating based on fluorescent-modified poly(ethylene-co-tetrafluoroethylene) resin

- Preparation and application of profiled luminescent polyester fiber with reversible photochromism materials

- Determination of pesticide residue in soil samples by molecularly imprinted solid-phase extraction method

- The die swell eliminating mechanism of hot air assisted 3D printing of GF/PP and its influence on the product performance

- Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes

- The effects of property variation on the dripping behaviour of polymers during UL94 test simulated by particle finite element method

- Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets

- Synthesis, characterization and evaluation of a pH-responsive molecular imprinted polymer for Matrine as an intelligent drug delivery system

- Twist-related parametric optimization of Joule heating-triggered highly stretchable thermochromic wrapped yarns using technique for order preference by similarity to ideal solution

- Comparative analysis of flow factors and crystallinity in conventional extrusion and gas-assisted extrusion

- Simulation approach to study kinetic heterogeneity of gadolinium catalytic system in the 1,4-cis-polyisoprene production

- Properties of kenaf fiber-reinforced polyamide 6 composites

- Cellulose acetate filter rods tuned by surface engineering modification for typical smoke components adsorption

- A blue fluorescent waterborne polyurethane-based Zn(ii) complex with antibacterial activity

- Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading

- Preparation and application research of composites with low vacuum outgassing and excellent electromagnetic sealing performance

- Assessing the recycling potential of thermosetting polymer waste in high-density polyethylene composites for safety helmet applications

- Mesoscale mechanics investigation of multi-component solid propellant systems

- Preparation of HTV silicone rubber with hydrophobic–uvioresistant composite coating and the aging research

- Experimental investigation on tensile behavior of CFRP bolted joints subjected to hydrothermal aging

- Structure and transition behavior of crosslinked poly(2-(2-methoxyethoxy) ethylmethacrylate-co-(ethyleneglycol) methacrylate) gel film on cellulosic-based flat substrate

- Mechanical properties and thermal stability of high-temperature (cooking temperature)-resistant PP/HDPE/POE composites

- Preparation of itaconic acid-modified epoxy resins and comparative study on the properties of it and epoxy acrylates

- Synthesis and properties of novel degradable polyglycolide-based polyurethanes

- Fatigue life prediction method of carbon fiber-reinforced composites

- Thermal, morphological, and structural characterization of starch-based bio-polymers for melt spinnability

- Robust biaxially stretchable polylactic acid films based on the highly oriented chain network and “nano-walls” containing zinc phenylphosphonate and calcium sulfate whisker: Superior mechanical, barrier, and optical properties

- ARGET ATRP of styrene with low catalyst usage in bio-based solvent γ-valerolactone

- New PMMA-InP/ZnS nanohybrid coatings for improving the performance of c-Si photovoltaic cells

- Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites

- Preparation of cardanol-based curing agent for underwater drainage pipeline repairs

- Preparation of lightweight PBS foams with high ductility and impact toughness by foam injection molding

- Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study

- Experimental study on impact and flexural behaviors of CFRP/aluminum-honeycomb sandwich panel

- Normal-hexane treatment on PET-based waste fiber depolymerization process

- Effect of tannic acid chelating treatment on thermo-oxidative aging property of natural rubber

- Design, synthesis, and characterization of novel copolymer gel particles for water-plugging applications

- Influence of 1,1′-Azobis(cyclohexanezonitrile) on the thermo-oxidative aging performance of diolefin elastomers

- Characteristics of cellulose nanofibril films prepared by liquid- and gas-phase esterification processes

- Investigation on the biaxial stretching deformation mechanism of PA6 film based on finite element method

- Simultaneous effects of temperature and backbone length on static and dynamic properties of high-density polyethylene-1-butene copolymer melt: Equilibrium molecular dynamics approach

- Research on microscopic structure–activity relationship of AP particle–matrix interface in HTPB propellant

- Three-layered films enable efficient passive radiation cooling of buildings

- Electrospun nanofibers membranes of La(OH)3/PAN as a versatile adsorbent for fluoride remediation: Performance and mechanisms

- Preparation and characterization of biodegradable polyester fibers enhanced with antibacterial and antiviral organic composites

- Preparation of hydrophobic silicone rubber composite insulators and the research of anti-aging performance

- Surface modification of sepiolite and its application in one-component silicone potting adhesive

- Study on hydrophobicity and aging characteristics of epoxy resin modified with nano-MgO

- Optimization of baffle’s height in an asymmetric twin-screw extruder using the response surface model

- Effect of surface treatment of nickel-coated graphite on conductive rubber

- Experimental investigation on low-velocity impact and compression after impact behaviors of GFRP laminates with steel mesh reinforced

- Development and characterization of acetylated and acetylated surface-modified tapioca starches as a carrier material for linalool

- Investigation of the compaction density of electromagnetic moulding of poly(ether-ketone-ketone) polymer powder

- Experimental investigation on low-velocity-impact and post-impact-tension behaviors of GFRP T-joints after hydrothermal aging

- The repeated low-velocity impact response and damage accumulation of shape memory alloy hybrid composite laminates

- Exploring a new method for high-performance TPSiV preparation through innovative Si–H/Pt curing system in VSR/TPU blends

- Large-scale production of highly responsive, stretchable, and conductive wrapped yarns for wearable strain sensors

- Preparation of natural raw rubber and silica/NR composites with low generation heat through aqueous silane flocculation

- Molecular dynamics simulation of the interaction between polybutylene terephthalate and A3 during thermal-oxidative aging

- Crashworthiness of GFRP/aluminum hybrid square tubes under quasi-static compression and single/repeated impact

- Review Articles

- Recent advancements in multinuclear early transition metal catalysts for olefin polymerization through cooperative effects

- Impact of ionic liquids on the thermal properties of polymer composites

- Recent progress in properties and application of antibacterial food packaging materials based on polyvinyl alcohol

- Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters

- Rapid Communication

- Design, synthesis, characterization, and adsorption capacities of novel superabsorbent polymers derived from poly (potato starch xanthate-graft-acrylamide)

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Development of smart core–shell nanoparticles-based sensors for diagnostics of salivary alpha-amylase in biomedical and forensics

- Thermoplastic-polymer matrix composite of banana/betel nut husk fiber reinforcement: Physico-mechanical properties evaluation

- Special Issue: Electrospun Functional Materials

- Electrospun polyacrylonitrile/regenerated cellulose/citral nanofibers as active food packagings