Abstract

The demand for sustainable textiles has increased research on bio-based biopolymers. Fiber spinning from starch biopolymer and its blends was widely attempted using electro-spinning; however, it is less attempted using melt spinning which is an industrially feasible method. In this study, native tapioca starch is converted into thermoplastic starch (TPS), blended with polylactic acid (PLA), and is attempted for melt spinnability in its neat and blended form TPS/PLA (70/30) with the intention of checking the possibility of melt spinning. The results from characterization of the prepared biopolymers show that thermal analysis of neat TPS does not reveal clear thermal transitions, glass transition (T g), and melting (T m), in the second heating curve, rather it influenced crystallization behavior of PLA as seen from differential scanning calorimetry result and degradation temperature (T d) was found to be in the range of 296–352°C from thermogravimetric analysis showing that addition of PLA improved thermal stability of TPS. Morphology analysis with AFM images revealed the presence of granular starch in neat TPS and phase separation in TPS/PLA blends with finer phase distribution in the presence of additives. Fourier transform infrared spectroscopy result shows the interaction between starch, glycerol, and PLA showing the effect of thermoplasticization of starch which brings rupture or weakening of the strong glycosidic bonds in between starch molecules and interaction between TPS and PLA as it can be seen from peak shift and peak intensity. The melt spinning trials show the possibility of melt spinning TPS-based biopolymers into fibers even with higher content of TPS as well as neat TPS giving an insight and motivation for more research engagement. The melt-spun fibers were found to have a diameter in the range of 160.0–117.0 μm. However, additional experiments and investigations are required to improve the mechanical and other properties of the fibers.

1 Introduction

Petroleum-based polymers have been widely used in textile industries because of their light weight, good processability, good performances, low cost, and low energy consumption during their processing. Most of synthetic fibers used in the current market are obtained from petroleum-based polymers which are non-biodegradable and non-compostable. Recently, biodegradable bio-based plastics, such as polylactic acid (PLA), thermoplastic starch (TPS), and polyhydroxyalkanoates, have received attention in replacing petroleum-based plastics for textile and other industrial applications because of their advantage as eco-friendly polymers (1). TPS is classified as one of those materials extensively investigated for its use as an alternative to petroleum-based plastics for many applications such as films, shopping bags, food packaging, pharmaceuticals, tissue engineering, 3D printing filament, and many more due to its natural abundance and low cost (2,3). Starch can be obtained from many crops such as wheat, corn, rice, potato, and tapioca which are considered potential sources of starch (3).

Native starch is essentially composed of two major polysaccharides: (a) amylose and (b) amylopectin with traces of proteins, lipids, phosphorus, and ash. In most available starch granules, amylopectin is the largest component by weight, while amylose accounts 15–30 wt%, with numerous exceptions (4). Amylose is a linear or slightly branched polymer composed of glucose molecules interconnected primarily by (α-1,4) glycosidic linkages, whereas amylopectin is a highly branched polymer with (α-1,4) linkages found in the main polymer chains, and (α-1,6) linkages found in the side polymer chains at the branching points. The ratio of these two polysaccharides in granules depends on the starch source, and this variability leads to significant differences in the physicochemical, rheological, thermal, properties, and molecular entanglement during the processing of starches (5,6).

Physically, most native starches are semi-crystalline, having a crystallinity of about 20–45%. According to García-Cruz et al. (7), the higher the amylopectin content, the higher will be the crystallinity in starches. The short-branched chains in the amylopectin mainly lead to the main crystalline phase in granular starch (8). Amylose and the branching points of amylopectin form the amorphous phase. The amylose and amylopectin content of starches can vary based on the source of starches and it also has great influence on physicochemical properties as well as their thermal processability. For normal tapioca starch, the amylose content generally ranges from 15.2 to 26.5% (20.7% on average) according to Hsieh et al. (9).

Unfortunately, native starch does not own the thermoplastic properties needed for polymer-related applications (10). Native starch has to be modified to be melt-processable as a thermoplastic material because the melting temperature (T m) of pure dry starch is close to 220–240°C, which is higher than its degradation temperature of approximately (220°C), due to strong hydrogen bond together with cyclic structure of starch giving them highly ordered crystalline structure (11).

The thermal processing of starch-based polymers involves multiple chemical and physical reactions, e.g., water diffusion, granule expansion, gelatinization, decomposition, melting, and crystallization (12,13).

Among the various phase transitions, gelatinization is particularly important because it is closely related to the other phases mentioned above, and it is the basis for the conversion of starch into a thermoplastic (14,15). Gelatinization is the process in which starch granules undergo an irreversible transformation when subjected to thermo-mechanical treatment in the presence of water (16). During this process, the amorphous region (amylose) hydrates and swells first, due to weaker hydrogen bonds in this region. As a result, the crystalline regions (amylopectin) are stretched and torn away (17). The established concept of “gelatinization” refers to the destruction of crystalline structure of starch granules, melting of native crystals, and molecular solubilization (16). The starch gelatinization degree can be mainly affected by the amount of moisture in starch and the applied temperature (18). The degree of gelatinization increases with increasing moisture content until it reaches a maximum value at a certain moisture content (19).

Starch can be modified into thermoplastic material by the addition of plasticizers, heat, and shear stress to give it thermoplastic properties. In this way, the starch granules lose a large part of their original structure, and a new continuous phase is formed in the form of viscous, meltable materials known as TPS. The efficiency of converting native starch to TPS depends on several variables such as plasticization technique, plasticizer type, plasticizer concentration, plasticizer combination, process parameters, and moisture content of the starch (11,20,21). Water, glycerol, sorbitol, sugar, ionic liquids, and compounds that have functional groups such as urea, formaldehyde, anhydride, or acetamide are applicable as plasticizers (22,23). The plasticizer breaks the strong inter- and intra-molecular interactions forming hydrogen bonds with the starch, resulting in the plasticization of starch (24).

These plasticizers which are less volatile compounds with polar groups, such as OH, COOH, and NH2, are also capable of forming hydrogen bonds and interrupting molecular interactions between starch chains (25). Among the plasticizers, the commonly used is glycerol which has relatively low molecular weight.

To produce TPS, an extrusion process is used, because it is a scalable process widely used in the plastics industry. In addition, it offers great advantages such as excellent mixing capacity, operational flexibility, and low infrastructure (25).

During starch extrusion, the loss of the crystalline structure of the starch is caused by the mechanical breaking of the molecular bonds due to the conditions of high shear, pressure, and temperature inside the extruder (26). Obtaining TPS by extrusion has been less researched, probably because this process is more complex with starch than with other polymers, due to the multiple phase transitions that occur during processing (13,25).

According to Smits et al. (27) heat treatment during extrusion leads to the strong interaction between starch and glycerol, most likely caused by the formation of H-bonds. When the mixture of amylose or amylopectin, either crystalline or amorphous, with glycerol is heated, a strong exothermal interaction enthalpy can be detected by differential scanning calorimetry (DSC). The transition enthalpy is proportional to the amounts of glycerol added, suggesting that the plasticizer is responsible for the observed exothermic phenomenon (28).

Although products made from TPS exhibit good oxygen barrier properties, biodegradability, and compostability, some poor properties like strong water absorption, relatively weak mechanical properties, and low thermal stability limit their uses (29,30). To improve these poor properties, several strategies have been used, including chemical modification of starch, melt blending of TPS with other conventional or biodegradable polymers, reinforcement of TPS with fibers, and development of TPS/nanofiller composites (11,31).

There are several researches that attempted to spin fibers from biopolymers like cellulose, lignin, starch, and others. It is very important to know that the fabrication of biopolymer fibers is not straightforward and not as scalable as synthetic polymers or thermoplastic polymers, which can be extruded into fibers via melt-blowing or wet-laid processes (32). Research efforts made in fiber spinning from starch mainly focused on electro-spinning (33,34), which is not an industrially feasible method. Melt spinning is the most appropriate and economic process for polymer fiber manufacturing at industrial scales (35). It is more eco-friendly method with a high speed production and it is also a solvent-free process. Other spinning methods like electrospinning, dry spinning, and wet spinning require the use of certain solvents which are usually toxic and difficult to recycle. The solution-spun fibers cannot be directly used for healthcare textiles and medical products, which are two important applications. Hence, melt spinning which is solvent-free spinning method will be the best choice for fiber spinning from biopolymers (36). In addition, as compared to fibers spun with other technologies, the melt spun fibers can have versatile applications due to the possibility of processing melt spun fibers in weaving, knitting, no-woven, and other applications which can diversify the areas of application of this fibers.

Even though melt spinning is an industrially feasible method for fiber spinning, it is less utilized for fiber spinning from biopolymers, particularly for starch spun fibers. The current article attempts the use of melt spinning for spinning biopolymer fibers from starch and starch/biopolymer blends. The authors of this research work believe that achieving successful melt spinnability of TPS-based biopolymers can have great contribution toward the development of biopolymer fibers with characteristics of biodegradability and biocompatibility as well in the utilization of the abundant starch biopolymer for textile applications. This article deals in particular with structural, thermal, and morphological characterization of starch-based melt spinnable compounds and properties of melt spun fibers.

2 Materials and methods

2.1 Materials

Tapioca starch sample SimPure™ 99600 with a moisture content of 11% was supplied by (Cargill, Inc.) as free sample. PLA Luminy® LX530, a medium flow fiber-grade resin with (98% l-isomer content, density of 1.24 g·cm−3, and melt flow index (MFI) of 23 g per 10 min), was purchased from Total Corbion. Licocare® RBW wax, a white crystal with melting point of 78.3°C, is purchased from Clariant Plastics and Coatings GmbH. Glycerol of 99.5% purity having a molecular weight of 92.04 g·ml−1 was purchased from chemiekontor.de GmbH and it has industrial-grade specifications.

2.2 Methods

2.2.1 Plasticization and extrusion of starch

Conversion of starch into thermoplastic material was done using a co-rotating twin screw melt extruder available in the Institute for Circular Economy of Bio:Polymers at Hof University (ibp), Germany. The plasticizer glycerol was used for the plasticization of starch to convert it into thermoplastic material. The proportion of glycerol used was 28.6% w/w (starch dry mass basis). Starch powder and plasticizer of predetermined proportion were premixed and kept for 1 day before extrusion to enhance the diffusion of plasticizer into starch molecules. In case of TPS prepared with wax addition, predetermined amount of starch and Licocare® RBW 102 wax powder (1.5% based on starch mass) were dry-mixed, then a predetermined amount of glycerol was added, and mixing took place. The premixing was done using a kitchen mixer (BOSCH MUM4, Germany) where the predetermined amount of starch and plasticizer was mixed for about 1 h using a medium speed level of the mixer.

The melt extrusion was done on co-rotating twin screw extruder from Lab Tech Engineering Co., Ltd, Thailand, having a screw length-to-diameter ratio (L/D) of 44 and a screw diameter of 20 mm.

The premixed starch and glycerol with or without wax is fed into the hopper of the twin-screw extruder and subsequently melt-extruded. The melt-extruded strands were air cooled, cut, and pelletized using the associated granulator on the twin screw extruder.

2.2.2 Blending of TPS with PLA

The TPS pellets were dried for 6 h at 60°C by using a LUXOR CAS compressed air dryer (Motan Holding GmbH, Konstanz, Germany) before melt mixing with PLA. The PLA pellets were also dried before melt mixing for 6 h at 80°C using the above-mentioned dryer. Following the drying process, TPS/PLA pellets with a mass ratio of 70/30, respectively, were fed into the hopper of the twin-screw extruder and were melt-extruded. Finally, the extrudates from the blends were air-cooled, pelletized, and used for melt spinning as well as for further analyses.

Figure 1 shows an illustration of the process used for melt blending of TPS and PLA compounds.

Illustration of melt blending process of the compounds.

2.2.3 Blend proportions and extrusion parameters for neat TPS and TPS/PLA compounds on twin screw melt extruder

Blend proportions, recipe preparation, and process parameters for TPS neat and TPS/PLA blend preparation on twin screw extruder are given in Table 1.

Blend proportion, recipe of preparation, and process parameters for TPS (based on tapioca starch) and TPS/PLA melt extrusion

| Sample code | Starch (% w/w) | Glycerol (% w/w) | Wax (% w/w) | TPS/PLA proportion (w/w) | Screw speed (rpm) | Feed rate (kg·h−1) |

|---|---|---|---|---|---|---|

| Neat TPS | 71.4 | 28.6 | 0 | 100/0 | 225 | 2 |

| TPS-w | 71.4 | 28.6 | 1.5 | 100/0 | 225 | 2 |

| TPS/PLA | 71.4 | 28.6 | 0 | 70/30 | 120 | 1 |

| TPSw/PLA | 71.4 | 28.6 | 1.5 | 70/30 | 120 | 1 |

| Screw temperature (°C) for TPS melt extrusion | ||||||

| Feed-100-110-110-120-120-130-130-130-130-125-125-Die | ||||||

| Screw temperature (°C) for TPS/PLA melt blending | ||||||

| Feed-130-130-140-140-150-150-160-160-150-150-140-Die | ||||||

The samples are coded as neat TPS, which represents TPS from native starch and glycerol, TPS/PLA, which represents a blend of TPS/PLA (70/30), and TPSw/PLA, which represents TPS/PLA (70/30) blends where TPS is prepared with wax addition.

2.2.4 Melt spinning

Since melt spinning does not require a solvent, as is the case with wet spinning and electro-spinning, it is considered an environmental friendly method of fiber spinning (33).

The current study is aimed at melt spinning of fibers based on native tapioca starch. The melt spinning of TPS-based compounds which are prepared by melt extrusion using a twin-screw extruder was done on the monofilament piston type melt spinning device available at Leibniz-Institut fuer Polymerforschung e.V. (Dresden), Germany.

The piston-type melt spinning device has a single piston barrel and is equipped with a diameter (D) of the capillary hole of 0.3 mm, and the ratio of the capillary length L to the capillary diameter (L/D) being 2. The pre-dried polymer samples (for 12 h at 40°C) were filled and melted in the heated cylinder with varying temperatures for the different sample compounds. Subsequently, the melted materials were forced by a piston through a single-hole die. A winder was used to collect the melt as-spun monofilaments with varying take-up speeds.

The material composition and parameters for melt spinning of fibers are given in Table 2.

Composition and parameters for pilot scale melt spinning of fibers

| Sample code | TPS/PLA blend proportion | Winding speed (m·min−1) | Spinning temperature (°C) |

|---|---|---|---|

| Neat TPS | 100/0 | 30–50 | 200 |

| TPS/PLA | 70/30 | 20–25 | 190 |

| TPSw/PLA | 70/30 | 30 | 200 |

2.3 Characterization

2.3.1 Thermal characterization

Thermal characterization of the samples was done with the aim of finding thermal transitions occurring and also finding out the thermal stability and degradation behavior of the compounds.

Thermal characterization of TPS-based compounds was done using the DSC 214 Polyma instrument from NETZSCH-Gerätebau GmbH and the thermogravimetric analysis (TGA) TG 209 F3 instrument also from NETZSCH-Gerätebau GmbH, Germany. TGA was carried out to evaluate the degradation characteristics of the TPS samples and TPS/PLA blend samples. For DSC measurement, a sample mass of 6–10 mg was used with a nitrogen gas atmosphere with a gas flow rate of 40 ml·min−1. The samples were heated at a constant heating rate of 10 K·min−1 within a temperature range of −80°C to 200°C for the first heating cycle followed by a cooling cycle from 200°C to −80°C and a second heating cycle from −80°C to 200°C.

In case of TGA, sample mass from 6 to 10 mg was used for measurement and a nitrogen gas atmosphere with a gas flow rate of 20 ml·min−1 was adjusted. The samples were heated at a constant heating rate of 10 K·min−1 in a temperature range of 35–500°C.

2.3.2 Morphology characterization

2.3.2.1 Atomic force microscopy (AFM) measurement

To characterize the surface morphology of the TPS and TPS/PLA blends, AFM was performed with core AFM from Nano surf, Switzerland, using a tapping mode. During tapping mode operation, the cantilever is oscillated near its resonance frequency resulting in a ‘free’ amplitude (37). Analysis of measurement data was done by using Gwyddion 2.59 version software.

2.3.2.2 Sample preparation

Neat TPS and TPS/PLA blend pellets are pressed into films on the thermo-pressing machine for morphology study. A press from Vogt Labormaschinen GmbH, Berlin, Germany, with heated upper and lower plates was used for this purpose. The parameters for pressing are temperature of 120°C, 140°C, 150°C, and 160°C for pure TPS and 160°C, 165°C, 170°C, and 180°C for TPS/PLA blends with pressure of 190 bar. The total time used for pressing in each case is 5 min with 0, 1, 2, and 2 min at each temperature, respectively, which was set based on pre-trials with different parameters and fixed based on better films obtained.

The pressed film samples are used for surface morphology observation using AFM, where phase images were taken of 2.5 μm² size.

2.3.2.3 Fiber diameter measurement

To measure the diameter of melt spun fibers, the digital microscope VHX-950 from Keyence Corporation was used. Fiber diameter measurement was done using an objective of 20 and a magnification power of 50×. Three tests per sample at different positions on the fiber surface were done and the average was taken as fiber sample diameter.

2.3.3 MFI measurement

MFI or melt flow rate (MFR) is a measure of a given polymers’ flow characteristics also known as the rheological properties in the molten state under a known pressure and temperature. In another way, it is a measure of the ease of flow of thermoplastic polymer melt. It can also be defined as the weight of polymer in grams flowing in 10 min through a die of a specific diameter with the application of pressure by a predetermined weight at a given temperature.

The MFI measurement was conducted on an MFI device (Karg Industrietechnik) according to the ISO 1133 standard test method using an applied load of 5 kg and a temperature of 160°C with a preheating time of 300 s.

2.3.4 Structural characterization

2.3.4.1 Fourier transform infrared spectroscopy (FTIR) characterization

The structural characterization of polymer compounds was performed using FTIR. In FTIR spectra, most molecules absorb light in the infrared region of the electromagnetic spectrum, converting it to molecular vibration. This absorption is characteristic of the nature of the chemical bonds present in a sample.

In this study, FTIR analysis was performed in ATR (attenuated total reflection) modality on polymer pellets and the ATR spectra were recorded using a Bruker Tensor 27 FT-IR spectrometer (Bruker, Germany). The samples were heated from 30°C to 250°C, with increments of 10°C, and their spectra were recorded every 10°C at a wavenumber ranging from 400 to 4,000 cm−1.

In ATR, infrared light passes through a crystal of a certain material (diamond, ZnSe, or germanium) and interacts with the sample. The sample is placed on ATR crystal, and IR light passes the crystal, is reflected internally, and is partially absorbed by the sample.

Typical infrared spectra for TPS have been studied by different researchers and a summary of wave number range and associated type of bond is given in Table 3.

| Wave number (cm−1) | Type of bond |

|---|---|

| 3,900–3,300 | O–H stretching |

| 2,950–2,850 | C–H stretching |

| 1,740–1,742 | C═O stretching |

| 1,650–1,645 | O–H bending |

| 1,640–1,645 | C═C stretching |

| 1,450–1,200 | C–H bending |

| 1,200–900 | C–O stretching and C–O–H vibration |

| 920–750 | C–O–C ring vibration |

3 Results and discussion

3.1 Processability of starch and TPS-based compounds via extrusion

During starch extrusion, it was observed that the output extrudates are highly influenced by the amount of glycerol and processing temperature used; hence, even smaller change in them results in extrudates with different colors and different surface uniformities. Due to the high starch thermal instability, thermal degradation was observed in some of the compounds as evidenced by extrudates color (not shown in this document). Finding the right proportion of plasticizer has great effect on processability, stretchability, and extrudate/pellet color.

Screw speed and feed rate are also found to have great influence on processability as seen from the output extrudate uniformity/diameter. Further pressed films were produced from the extruded material after granulating it into polymer pellets to check the conversion of native starch into thermoplastic material.

Finally, from experiments done on melt extrusion of starch, it was revealed that native starch is converted to TPS, the TPS pellets were successfully prepared and used for blending with PLA pellets in the next stage.

The following images from Figure 2 show starch powder, TPS filament, neat TPS granules/pellets, and TPS/PLA blend pellets obtained from twin screw melt extruder.

(a) tapioca starch powder, (b) neat TPS filament, (c) neat TPS pellets, and (d) TPS/PLA (70/30) pellets.

3.2 Characterizations

3.2.1 Flow characteristics

The MFR or MFI has important practical significance for polymer processing and their field of applications.

The MFR measurement results for pure TPS and TPS/PLA blends and neat commercial PLA polymers are given along with their error values in Figure 3.

MFR values for compounds prepared.

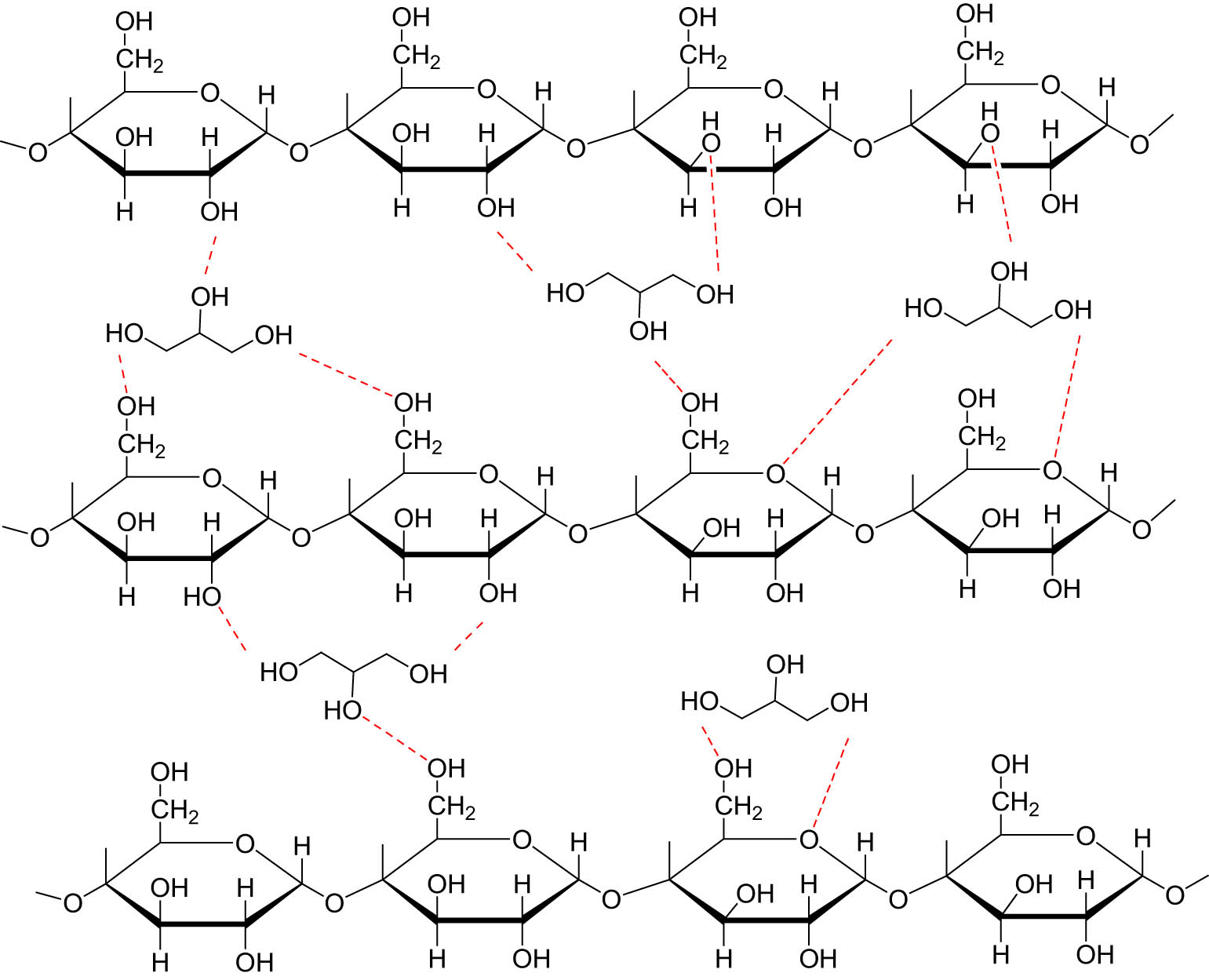

The results from the MFR measurement in Figure 3 show that neat TPS has an MFR value of 19.5 g per 10 min indicating the conversion of native starch into melt-flowing material with relatively sufficient melt flow character. Starch during heat treatment can undergo a transition from crystalline to amorphous structure and subsequent recrystallization when cooled and during storage. The addition of glycerol as plasticizer may have reduced starch crystallinity and intermolecular forces of starch improving mobility of starch and facilitating its conversion into amorphous material. At room temperature, glycerol interacts mainly with the amorphous regions of the starch (27). The interaction between starch and glycerol is shown in Figure 4. The relatively high MFR value of the TPSw/PLA (70/30) blend as compared to neat TPS, TPS/PLA (70/30) blends, and neat PLA may be due to the plasticization effect of glycerol on to PLA chains reducing intermolecular force in between PLA chains because of better interaction between TPS and PLA in the presence of wax, which in turn may indicate its effect as dispersion aid. Waxes have different physicochemical properties according to their sources and chemical composition enhancing the properties of wax-based composites and blends (42). The presence of interactions between components can alter the viscoelastic behavior of the PLA component because of the plasticization effect of wax on PLA resulting in further flexibility of the blends and favoring spinnability during melt spinning as well (43).

Interaction between starch and glycerol (re-produced with permission by (25), copyright 2024, John Wiley and Sons).

In the case of TPS/PLA (70/30) blends, the formation of physical network structure between TPS and PLA with large microstructure size due to relatively poor miscibility between the blends may have reduced the free volume and, hence, reduced the flow property due to higher interphase interaction which is also consistent with morphology analysis of the blends. In this study, higher content of TPS in the blends, i.e., 70/30 TPS/PLA, was used with the intention of evaluating melt spinnability of blends with higher TPS content. The proposed interaction between starch and glycerol during thermo-plasticization is given in Figure 4.

3.2.2 Morphology of pellets used for melt spinning

According to Ribeiro et al. (44), native starch exists in granular form during AFM observation without granule destruction. The AFM 3D image (Figure 5) for native cassava/tapioca starch as observed by them indicates the existence of large starch granules during AFM surface observation and during SEM observation according to others.

The results for microscopic images of pressed film samples obtained from AFM for the neat TPS, TPS/PLA (70/30 w/w), and TPSw/PLA (70/30 w/w) samples, as defined in Table 1, are shown in Figure 6.

AFM images (size 2.5 µm²) of (i) neat TPS, (ii) TPS/PLA (70/30), and (iii) TPSw/PLA (70/30); (a) phase image, (b) amplitude, and (c) topography.

During thermo-plasticization of starch, granular starch is converted into a homogeneous material, TPS, comprising a hard-elastic network and soft amorphous regions.

Figures 6(i, a) and 7(i, b) and (i, c) show the results of the phase image, amplitude, and topography, respectively, for neat TPS as observed from AFM image. As we can see from the images, granular crystalline starch is converted to homogeneous amorphous material comprising starch-rich and plasticizer-rich regions (13) as visible with darker and brighter phase areas. The previous research by Werner et al. (46) reported that the darker phase regions indicate soft regions and, therefore, in the phase image of Figure 6(i, a), the dark regions indicate plasticizer-rich regions that are softer.

Along starch transformation, the granular structure is disrupted, releasing mainly amylose chains because amylopectin has more intra- and intermolecular hydrogen bonds and less surface area, making it difficult to disrupt (47). Several physicochemical processes take place during starch thermo-plasticization such as fragmentation, de-structuration, plasticization, and melting. Consequently, TPS is constituted of a highly plasticized amorphous phase and a crystalline region associated with the remaining starch granule as reported by Castillo et al. (13).

In this research work, as indicated by the arrows in the phase and amplitude images in Figures 6(i, a) and 7(i, b), some starch granules are not fully de-structured, and they remain as granular crystalline structures in microscopic images indicating agreement with the above-mentioned previous researcher’s reports. The topography in Figure 6(i, c) also indicates rough surface of pressed films indicating a similar result to that of amplitude and phase images.

It is important to highlight that optimal processing conditions allow obtaining a high proportion of the TPS plasticized phase. More plasticization due to the dispersion effect provides a more plasticized phase and reduces the crystalline phase, associated with remaining or unplasticized granules, hence improving the performance of the resulting TPS in later stages.

The AFM image (size 2.5 μm2) results for TPS/PLA (70/30) blends are shown in Figure 6(ii).

The phase and amplitude images in Figure 6(ii, a) and (ii, b) indicate that there is a kind of phase separation between TPS and PLA phases. The PLA exists as a dispersed phase in TPS matrix with a large microstructure phase size indicating poor miscibility among the blends due to their thermodynamically immiscible nature. Here, the TPS-rich matrix in which PLA-rich domains appear randomly dispersed is evidenced by larger particle size, indicating a lack of miscibility. According to previous research works, existence of large particle domains in the blends indicates poor interphase interaction and poor miscibility between blends (48). The topography image in Figure 6(ii, c) shows surface roughness more evidenced in certain regions. This indicates that low miscibility among the components generates a microstructure with little cohesion between the phases. This poor miscibility and weak cohesion may be the reason for the weak mechanical property and poor performance of polymer pellets during melt spinning. These results are in accordance with previous AFM studies on Mater-Bi starch bioplastic (49) and others (46).

The AFM image results for TPSw/PLA (70/30) are shown in Figure 6(iii).

In the AFM phase image of Figure 6(iii, a), we can observe that there is relatively a homogeneous distribution of blend components with less microstructure size. The PLA is distributed as a dispersed phase with fine microstructure size with difficult to identify it as it is a minor phase, which may be due to relatively better dispersion (50) among the blends as compared to TPS/PLA (70/30). The finely dispersed and uniformly distributed PLA domains in the TPS matrix may give better cohesion and hence better overall properties which was also evidenced by relatively better melt spinnability of this compound. More interestingly, the amplitude image in Figure 6(iii, b) does not clearly show any large edge height difference, which was clearly visible in other blends, confirming a good distribution in this blend. The topography image in Figure 6(iii, c) also shows a smooth surface as compared to the other blends. This relatively better dispersion between the compounds could be due to wax addition during TPS preparation as a dispersion aid; however, the wax is not clearly visible in the AFM images observed due to its very low content of 1.5%. The higher cohesion achieved between phases in TPSw/PLA (70/30) resulted in relatively better melt spinnability of this compound as seen from melt spun fiber samples.

3.2.3 Thermal characterization

DSC has been widely used to characterize the phase transition of starch, such as gelatinization, retrogradation, and glass transition (T g). The thermal transitions like glass transition T g and melting temperature T m of neat TPS and TPS/PLA blends were determined using DSC.

The DSC first and second heating curve for native starch is given in Figure 7.

DSC, first, and second heating curve for native tapioca starch,.

From the diagram in Figure 7, we can see that the first heating DSC curve for native tapioca starch shows a broad endothermic reaction which begins with onset temperature T onset around 72°C and reaches its maximum peak value T p at 123°C. This transition is attributed to the gelatinization of starch, which is in accord with the literature (41,51). The gelatinization enthalpy was found to be 200.4 J·g−1 with broad area. The gelatinization process was facilitated by the presence of moisture in starch granules. This result agrees with previous work by Zuo et al. (52) who have found the maximum transitional peak to be 129°C, which is nearly similar to the result obtained in the present work. The second heating curve of native starch does not show any thermal transitions indicating its amorphous behavior after gelatinization during the first heating which is an expected result as the starch is converted to thermoplastic material possessing amorphous nature. In addition, T g of fully gelatinized starch is difficult to determine using DSC analysis because the heat capacity change is quite low at the T g and this result agrees with previous works (53).

During the gelatinization process, semi-crystalline starch granules undergo a change of state from an ordered to a completely or partially disordered structure (54). According to Ning et al., a combination of DSC with X-ray diffraction and small-angle X-ray scattering has shown that residual crystallinity and lamellar organization still remain after the gelatinization process (38).

The gelatinization of starch is not a sharp transition in the DSC curve. Instead, it appears as a large endothermic reaction due to the polydispersity of the granules (55) and a similar result is obtained in this work as well.

The DSC second heating curves for neat TPS, neat PLA, TPS/PLA, and TPSw/PLA blends are plotted in Figure 8. The corresponding characteristic thermal values like glass transition, crystallization, and melting temperatures are shown in Table 4.

DSC, second heating curves for neat TPS, neat PLA, and TPS/PLA (70/30) and TPSw/PLA (70/30).

DSC, second heating results for TPS and blend compounds

| Sample | T g (°C) | T m1 (°C) | T m2 (°C) | T cc (°C) |

|---|---|---|---|---|

| Neat TPS | −0.5 to 30.5 | — | — | — |

| TPS/PLA (70/30) | 61.3 | — | [155.6, 160.8] | 113.4 |

| TPSw/PLA (70/30) | 62.5 | 80.9 | [154.7, 160.2] | 111.5 |

| Neat PLA | 63.4 | 161 | — | — |

From the DSC curve for neat TPS in Figure 8, a small peak with an onset temperature at −0.5°C and ending at the temperature of about 30.5°C is observed which may indicate the glass transition range of TPS polymer. Glass transition T g is the temperature at which bounded amylose and amylopectin were loosened to lead a significant movement of the starch molecules (29). This agrees with the work from other researchers for example, according to work by Bergo et al. (56), the glass transition temperature (T g) of cassava starch films was decreased from 131.9°C to 42.1°C, when the glycerol content was increased from 0 to 45% w/w, respectively, and nearly similar result is obtained in our case. This may be an indication of the successful conversion of native starch into amorphous thermoplastic material.

During gelatinization, the plasticizer molecules eliminate starch–starch interactions and replace them with starch-plasticizer interactions, increasing the mobility of polymeric chains (57). There is no clear melting peak observed in our result, which also is in accord with work from other researchers for TPS polymers (29). The transformation of granular starch is influenced by process conditions such as temperature and plasticizer content (57).

Form the DSC curve for TPS/PLA 70/30, we can see that there are three endothermic peaks observed at a temperature of around 61.3°C, 155.6°C, and 161°C. The first peak at 61°C is attributed to the glass transition temperature T g of the amorphous phase of PLA in the blend. The endothermic peaks at 155.6°C and 161°C are associated with the melting of TPS and PLA phases in the blend indicating phase separation. However, these values are lower than neat PLA melting temperature T m of 165°C and T g of 64°C (from first heating curve not shown). This may be due to constraints induced by starch in crystallization of PLA, leading to thinner lamellae than the ones produced by pure PLA (51). The melting temperature of neat PLA from the second heating curve was found to be 161°C indicating reduction in T m as compared to the first heating curve and this is related to slow crystallization behavior of PLA during cooling. The lowering in T g and T m in case of TPS/PLA (70/30) may be a result of the plasticizer glycerol increasing segmental mobility in the polymeric chains as a result of interaction between TPS and PLA during melt blending. The exothermic peak found at the temperature of 113.4°C refers to the cold crystallization temperature of the blend polymer, indicating that TPS can facilitate PLA crystallization since this crystallization peak was not observed in the case of neat PLA.

From the DSC curve for TPSw/PLA 70/30, we can see four endothermic peaks observed at a temperature of 62.5°C, 81°C, 154.7°C, and 160.2°C. The first endothermic peak at 62.5°C corresponds to the T g of the blend where the amorphous phase of PLA is dominating (3) and this value is higher than T g for TPS/PLA (70/70) blend, assuring better miscibility in this case. The second endothermic peak at around 81°C is attributed to the melting of Licocare® RBW 102 wax used in TPS preparation. The overlapping peaks at 154.7°C and 160.2°C are attributed to melting of the crystals associated with starch and PLA phase, respectively. These melting temperature values are lower than the T m of pure PLA which is 165°C. This may be due to constraints induced by starch in the crystallization of PLA, leading to thinner lamellae than the ones produced by pure PLA (51). The slightly lower T m and slightly higher T g values of TPSw/PLA 70/30 as compared to TPS/PLA 70/30 indicate relatively better dispersion in this case. The exothermic peak found at the temperature of about 111.5°C refers to cold crystallization temperature of the blend polymers. The reduction in cold crystallization temperature in this case may be due to an increase in chain mobility associated with better TPS chain interaction with PLA increasing its rate of crystallization.

However, the presence of double melting peaks may indicate phase separation and poor miscibility between polymers in all blends, which may also be reason for poor melt spinnability associated with all blend polymers.

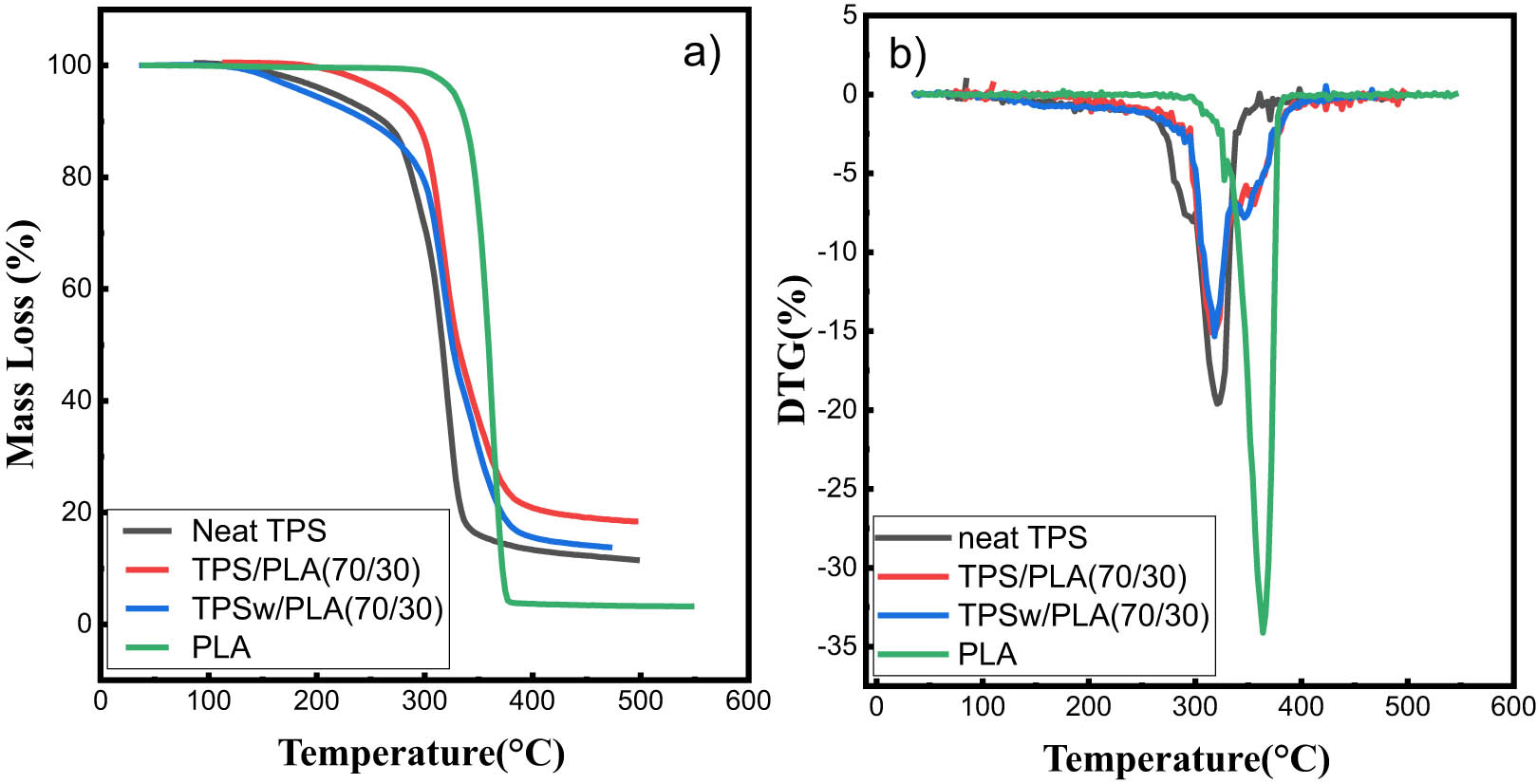

The results of thermal degradation and thermal stability for thermoplastic starch TPS from tapioca starch and blends of TPS/PLA are presented in plot curves of weight loss (%) of granulates as a function of temperature as shown in the diagrams of Figure 9 and Table 5. The onset of degradation T onset (°C), maximum degradation temperature or peak temperature T max (°C), 5% mass loss T 5%, and 80% mass loss T 80% are given in Table 5.

TGA (a) and DTG (b) curve for neat TPS, neat PLA, TPS/PLA (70/30), and TPSw/PLA (70/30).

Results of thermogravimetric analysis

| Material | T onset (°C) | T max (°C) | T 5% | T 80% | Residual mass (%) |

|---|---|---|---|---|---|

| Neat TPS | 296 | 334 | 215 | 334.7 | 11.42 |

| TPS/PLA | 295 | 352 | 265 | 416.7 | 18.30 |

| TPSw/PLA | 296 | 345 | 193 | 371.0 | 13.79 |

| PLA | 353 | 365 | 327 | 368.0 | 3.21 |

From the TGA thermogram for neat TPS (Figure 9a), we can see a gradual weight loss with temperature rising from room temperature up to 123°C and this is mainly due to moisture/loosely bound water removal (1,29,58).

The weight loss between 123°C and 296°C continues probably due to glycerol volatilization (reaching the step of starch decomposition which begins at about 296°C). The decomposition of starch occurs at the temperature of about 296°C as indicated by onset temperature and ends at the temperature of about 334°C. This phenomenon might be ascribed to the removal of hydrogen functional groups, degradation, and de-polymerization of the starch carbon chains in accordance with Tarique et al. (29). Furthermore, TGA analysis of neat TPS showed a gradual weight loss with the single-step polymer chain degradation and this means that TPS exists as a single phase (41). This finding is consistent with the AFM result from Figure 6i, which indicated only some crystalline starch granules without phase separation. The T 5% and T 80% mass loss for neat TPS occurred at temperature around 215°C and 334.7°C, respectively. The residual mass at a temperature of 497°C of the analyzed TPS was found to be 11.42%. The residual mass might be inorganic impurities or organic matters that could stand high temperatures. The result obtained by TGA in this study is in accordance with previous works (29,40,59,60).

From the TGA curve for TPS/PLA (70/30) in Figure 9a, we can see that there is a three-step degradation associated with mass loss with the temperature of nearly up to 295°C, from 295°C to nearly 352°C and above 352°C. The first mass loss in the temperature range of up to 296°C occurs due to removal of plasticizer, water, and other volatile compounds, and it was also observed during melt spinning of these polymers. The degradation of polymer starts at a temperature of around 295°C as can be seen from onset temperature T onset and ends at maximum temperature of 352°C. This indicates relatively good thermal stability of TPS/PLA blends as compared to neat TPS where maximum degradation occurred at a temperature of 334°C. The T 5% and T 80% mass loss occurred at a temperature of 265 and 416.7°C, respectively, which is a higher temperature as compared to neat TPS for the same amount of mass loss. The residual mass at a temperature of 497°C of the analyzed TPS/PLA (70/30) was found to be 18.3%. As compared to neat TPS, TPS/PLA (70/30) blend polymer pellets have higher thermal stability.

From the TGA curve for TPSw/PLA (70/30) blend (Figure 9a), we can see that the degradation of polymer begins at a temperature of around 296°C and ends at maximum temperature of about 345°C. The data reveal that the onset temperature for TPSw/PLA (70/30) compounds is nearly similar to the neat TPS and TPS/PLA (70/30), but maximum degradation which is at (345°C) occurs at a temperature lower than that of TPS/PLA (70/30) (352°C) and higher temperature than that for neat TPS (333°C). The T 5% and T 80% mass loss occurred at a temperature of 193 and 371°C, respectively. This value is higher than the values for neat TPS and lower than the values for TPS/PLA (70/30). The addition of wax as dispersion agent and lubricant reduced the thermal stability of polymers as miscibility is slightly better and the TPS phase is dominating.

Thermal stability of TPS is highly improved by the addition of PLA as it can be seen from all blend compounds analyzed.

Table 5 shows TGA thermal parameters for onset of degradation T onset, temperature for 5% mass loss (T 5%), temperature for 80% mass loss (T 80%), and residual mass for neat TPS, PLA, and TPS/PLA blend compounds.

Generally, from the TGA curves for neat TPS, PLA, TPS/PLA (70/30), and TPSw/PLA (70/30) we can observe that addition of PLA improved thermal stability of TPS and thermal degradation for blends starts nearly at the same temperature, which is associated to starch phase degradation and the degradation behavior is dominated by TPS phase due to its high proportion in the case of blends. However, the thermal stability of TPS/PLA blends is better than that of neat TPS which is probably due to higher thermal stability behavior of PLA. The data also reveal that slightly better interaction between TPS and PLA can influence the thermal stability and maximum degradation temperature of TPS/PLA blends.

3.2.4 Structural characterization

In this study, the ATR spectra were used to investigate the possible differences between spectra of starch and starch-based blends, which could indicate a change in chemical structure upon blending and plasticization.

The ATR spectra for native tapioca starch, neat PLA, neat TPS, TPS/PLA (70/30), and TPSw/PLA (70/30) are shown in Figure 10.

ATR spectra for native starch, neat TPS, neat PLA, TPS/PLA (70/30), and TPSw/PLA (70/30).

From the spectra for native starch, we can see that there is a broad peak at wavenumber 3,282 cm−1, which is attributed to O–H stretching (39,61,62). Other associated peaks observed here can be referred from Table 3 which indicates the peaks and associated bonds for starch. These results of native starch structural characterizations are used for comparative analysis of peak changes in starch after plasticization and blending with PLA.

The disruption of granular organization during starch thermal extrusion induces modifications in morphological characteristics, crystalline architecture, and chemical structure of native starch (13).

The ATR spectrum for neat TPS presents the typical absorption bands corresponding to the functional groups of starch and glycerol. The broad peak occurring at a wavenumber of 3,315 cm−1 is attributed to O–H stretching resulting from starch and glycerol, and this peak is shifted to higher wavenumbers as compared to the corresponding peak of native starch at 3,282 cm−1 indicating the effect of starch plasticization.

According to Paluch et al. (63), the shift of characteristic bands in TPS compared to native starch observed demonstrates the formation of more stable bonds and stronger interactions in the TPS between the –OH groups of the starch and plasticizer, compared to the bonds between OH groups in native starch chains. The interaction between starch and plasticizer can also be seen from peak shift of C–H stretching from 2,889 cm−1 (in native starch) to 2,927 cm−1 in TPS due to plasticization effect from glycerol. The small peak at 1,645 cm−1 is attributed to O–H bending associated with bound water or hydroxyl groups in starch (64).

The peak bands at 1,150 cm−1 are attributed to C–O–C asymmetric stretching and the peak band at 1,016 cm−1 is attributed to C–O stretching of starch molecules.

The representative bands of the glycerol plasticizer were displayed at 2,884 cm−1 (C–H) and 1,430 cm−1 corresponding to weak signal of CH2 symmetric deformation associated with glycerol.

According to Abdullah et al. (39), who studied different types of starches (corn, cassava, potato), all starches can possess OH, C–H, C–O–C, and C–O functional groups in wavenumber range of 3,300–3,600, ∼2,900, ∼1,150, and 1,000–1,100 cm−1, respectively, and peak at 926 cm−1 which corresponds to the C–O stretching of pyranose rings or C–O–C ring vibration of carbohydrate (38,39,40).

From the ATR spectra for TPS/PLA (70/30) in Figure 10, we can see that there is a wavenumber shift toward higher values in the region of O–H and C–H stretching, in case of TPS/PLA blends due to interaction between TPS and PLA. The new peak at 1,753 cm−1 is attributed to carbonyl (C═O) stretching in the PLA phase as this peak is not found in case of neat TPS and found in neat PLA at 1,747 cm−1. Another peak shift compared to neat TPS spectra, is the peak at 1,647 cm−1 which was at 1,645 cm−1 in neat TPS corresponding to O–H bending. The C–H bending peak shifted toward a lower wavenumber value of 1,361 cm−1 in case of TPS/PLA as compared to neat TPS which is 1,366 cm−1 and the C–O stretching peak shifted toward a higher value from 1,016 cm−1 in neat TPS to 1,018 cm−1 in TPS/PLA indicating an interaction between the blends.

From the ATR spectra for TPSw/PLA (70/30) in Figure 10 we can see there is peak shift at C–H region to lower value (2,920 cm−1) compared to TPS/PLA (70/30) indicating interaction or miscibility between TPS and PLA due dominance of TPS phase because of its higher proportion in the blend. This may be due to the addition of wax, which acted as dispersion agent facilitating miscibility between the blends. The high intensity peak at 1,751 cm−1 is attributed to carbonyl stretching in PLA phase and it shows downward shift from 1,753 cm−1 in case of TPS/PLA (70/30), indicating relatively better interaction between TPS and PLA in the presence of wax. Another peak that appeared at 1,646 cm−1 corresponds to O–H bending and it shifted to lower values as compared to neat TPS/PLA (70/30). The peak band at 1,079 cm−1 is attributed to C–O–C asymmetric stretching in PLA and the band at 1,020 cm−1 is attributed to C–O stretching. The C–O stretching bands shifted to higher value from 1,018 cm−1 in case of TPS/PLA (70/30) to 1,020 cm−1 in case of TPSw/PLA (70/30), indicating better interaction between TPS and PLA, which is also supported by AFM morphology images.

Generally, the FTIR analysis results indicate peak changes of native starch, associated to energy absorptions indicating the effect of starch plasticization and melt blending. The peak shifts due to plasticization and melt blending indicate the interactions between starch-glycerol and TPS-PLA, which is also in alignment with the results of morphology analysis.

3.3 Evaluation of the spinnability of the materials

Melt spinnability trial tests were done for polymer compounds prepared from neat TPS, TPS/PLA (70/30), and TPSw/PLA (70/30) using different take up speeds and the results are comparatively discussed.

The results of melt spun fibers diameter measurement are given in Table 6.

Result from fiber diameter measurement

| Sample | Spinning speed (m·min−1) | Average fiber diameter (μm) |

|---|---|---|

| Neat TPS | 30 | 160.67 ± 0.5 |

| 40 | 142.67 ± 0.5 | |

| TPS/PLA (70/30) | 20 | 460.30 ± 0.5 |

| TPSw/PLA (70/30) | 50 | 117.30 ± 0.5 |

As it was explained in Table 2, melt spinning trials were run at different spinning speeds to find out the maximum possible spinning speed and suitable processing temperature for each compound. Hence, for neat TPS, a spinning speed ranging from 30–50 m·min−1 at a temperature of 200°C was found to be suitable to form filament fibers and, hence, melt spun filament fibers are obtained. Fine continuous filaments with better appearance, but weak strength, have been successfully spun (Figure 11a). The result shows the possibility melt spinning of neat thermoplastic starch into fibers and it gives more insights to further work on the possibility of melt spinning thermoplastic starch into fibers with better performance and further look into their application areas. For TPS/PLA (70/30) blend compounds, a temperature of 190°C at a spinning speed of up to 25 m·min−1 was found to be suitable for filament fiber formation. However, it was not possible to form fine filaments or fibers from this compound and only very coarse filaments (Figure 11b) that are brittle were formed showing poor melt spinnability of this compound into fibers. Frequent breakage of filaments was observed during melt spinning indicating relatively weak interfacial tension between blends as a result of higher phase separation between the blends. For TPSw/PLA (70/30) blend compounds, the spinning speed of 30 m·min−1 was found to be a good one in forming relatively better melt spun filament fibers (Figure 11c) at a temperature of 200°C. This may be due to relatively better interfacial tension between the blends as a result of better interaction.

Optical microscope images of melt spun fibers of neat TPS; (a) spun at 30 m·min−1, (b) spun at 40 m·min−1, and (c) TPSw/PLA (70/30) spun at 50 m·min−1.

The diameter of melt spun fibers and the possible process parameters for the melt spinning of the compounds are given in Table 6.

Microscope images for melt spun fibers showing diameter measurement are shown in Figure 11. As we see from the figure, optical microscope surface images of melt spun fibers for neat TPS at different take up speeds and TPSw/PLA (70/30) fibers are given with three monofilaments from each sample for average fiber diameter measurement.

The average diameter of three filaments each of fibers spun from TPS at a winding speed of 30 m·min−1 is found to be 160.67 μm and the diameter of the fibers spun using a winding speed of 40 m·min−1 is 142.67 μm. Whereas the average diameter of fibers spun from TPSw/PLA (70/30) blends is found to be 117.3 μm having better fineness and appearance. The melt spun fibers from TPSw/PLA (70/30) have rough surface and non-uniform diameter as compared to neat TPS fibers. The TPS/PLA (70/30) filaments are very thick and short to be compared with continuous melt spun filament fibers in terms of diameter as well as the fibers were difficult to straighten and measure diameter under the same device; hence, optical microscope images are not given. Figure 12 shows images of melt spun fibers samples from different compounds.

Melt spun fiber samples; (a) neat TPS, (b) TPS/PLA (70/30), and (c and d) TPSw/PLA (70/30).

Generally, from the melt spun fiber samples shown in Figure 12, we can see that the melt spun fibers made from TPS/PLA (70/30) blends have very coarse diameter and more breakage was observed during melt spinning with difficulty in melt spinning of the blend into fibers. The melt spun fibers from TPSw/PLA (70/30) have fine diameter and better appearance while neat TPS fibers have medium diameter, and they are more brittle after spinning as compared to melt spun fibers from blend polymers.

The results from fiber diameter measurement show that finer and better fiber melt spinnability is possible whenever there is better miscibility between blends, which is seen in case of TPSw/PLA (70/30) blends where relatively better fibers (in terms of appearance) were spun. However, the melt spun fibers from all compounds are difficult for further analysis and tensile testing, indicating the need to improve the overall properties of compounds to get fibers with better performance and possibility of overall characterization.

4 Conclusion

In the current work, native tapioca starch was successfully converted into thermoplastic material using a co-rotating twin screw melt extruder and the thermoplastic starch pellets/granules were prepared for further analysis. The conversion of starch into thermoplastic material was evidenced by the possibility of producing pressed films by using thermo-pressing machine applicable to conventional thermoplastic polymers. Granular destruction of starch was observed during melt extrusion as evidenced by morphology study with AFM, with few starch granules remaining, which may affect the property of TPS. The phase images from TPS/PLA blends show that better interaction and cohesion of phases between blends can be achieved with the addition of additives, which can promote the formation of fine phase microstructure size and uniform dispersion of blend components. The slightly good dispersion of blend components contributed to relatively good melt spinnability in terms of appearance and fiber fineness. Besides this, interaction between starch-glycerol from FTIR study also confirms starch thermo-plasticization as evidenced by peak shifts due to intra- and intermolecular bond breakage in between starch molecules due to the effect of heat and shear force in the presence of plasticizer during starch melt extrusion.

Thermal study reveals that neat thermoplastic starch, TPS, has no clear melting point and its thermal stability is lower than that of PLA, and the addition of PLA improved thermal stability of blend polymers while TPS influenced crystallization characteristics of PLA. From this work possibility of filament, fiber production from neat TPS and TPS/PLA blends using melt spinning technology is observed. The possibility of melt spinning of fibers was better in case of compounds with better dispersion/miscibility. The melt spun fibers have diameter in the range of microns; however, it is evidenced that it needs further work to melt spin fibers with overall better performance. Hence, researchers of the current work are further investigating the possibilities of preparing melt spun biopolymer fibers suitable for certain applications from starch-based bio-polymer blend compounds.

Generally, the study shows the possibility of filament fiber formation from TPS as well as TPS/PLA blends which may give an insight for further research works engagement in this area of research to achieve a better melt spun fibers and to utilize the abundant starch bio-polymer for textile applications.

Acknowledgments

The authors of this research article would like to thank Leibniz-Institut fuer Polymerforschung (Dresden e.V.), Germany, for their cooperation on melt spinning trials and particularly Mr. Mathias Haeschel for his support.

-

Funding information: This research received no external funding.

-

Author contributions: All authors have contributed to this article. Selamu T.: writing original draft, experimental work, and analysis, Mirko R.: writing review and editing, Tamrat T: writing review and editing, Lucas G.: editing, visualization, and supervision, Michael Nase: writing review, editing, and supervision, Ines K.: writing review and editing, and Norbert S.: experimental work.

-

Conflict of interest: The authors can declare that there is no conflict of interest.

-

Data availability statement: The data sets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

(1) Noivoil N, Yoksan R. Compatibility improvement of poly(lactic acid)/thermoplastic starch blown films using acetylated starch. J Appl Polym Sci. 2021;138(2):49675. 10.1002/app.49675.Search in Google Scholar

(2) Haryńska A, Janik H, Sienkiewicz M, Mikolaszek B, Kucińska-Lipka J. PLA–potato thermoplastic starch filament as a sustainable alternative to the conventional PLA filament: Processing, characterization, and FFF 3D printing. ACS Sustainable Chem Eng. 2021;9(20):6923–38. 10.1021/acssuschemeng.0c09413.Search in Google Scholar

(3) Zhang Y, Rempel C, Liu Q. Thermoplastic starch processing and characteristics-a review. Crit Rev food Sci Nutr. 2014;54(10):1353–70. 10.1080/10408398.2011.636156 Search in Google Scholar

(4) Bertoft E. Understanding starch structure: recent progress. Agronomy. 2017;7(3):56. 10.3390/agronomy7030056.Search in Google Scholar

(5) Martinez Villadiego K, Arias Tapia MJ, Useche J, Ledesma Y, Leyton A. Thermal and morphological characterization of native and plasticized starches of sweet potato (ipomoea batatas) and diamante yam (dioscorea rotundata. J Polym Environ. 2021;29(3):871–80. 10.1007/s10924-020-01898-2.Search in Google Scholar

(6) Cao P, Wu G, Yao Z, Wang Z, Li E, Yu S, et al. Effects of amylose and amylopectin molecular structures on starch electrospinning. Carbohydr Polym. 2022;296:119959. 10.1016/j.carbpol.2022.119959.Search in Google Scholar

(7) García-Cruz HI, Jaime-Fonseca MR, Borries-Medrano E, von; Vieyra H. Extrusion parameters to produce a PLA-starch derived thermoplastic polymer. RMIQ. 2020;19(1):395–412. 10.24275/rmiq/Poly1529.Search in Google Scholar

(8) Liu H, Xie F, Yu L, Chen L, Li L. Thermal processing of starch-based polymers. Prog Polym Sci. 2009;34(12):1348–68. 10.1016/j.progpolymsci.2009.07.001.Search in Google Scholar

(9) Hsieh C-F, Liu W, Whaley JK, Shi Y-C. Structure, properties, and potential applications of waxy tapioca starches – A review. Trends Food Sci Technol. 2019;83:225–34. 10.1016/j.tifs.2018.11.022.Search in Google Scholar

(10) Altayan MM, Ayaso M, Al Darouich T, Karabet F. The effect of increasing soaking time on the properties of premixing starch–glycerol–water suspension before melt-blending process: Comparative study on the behavior of wheat and corn starches. Polym Bull. 2020;77(4):1695–706. 10.1007/s00289-019-02826-8.Search in Google Scholar

(11) Moghaddam MRA, Razavi SMA, Jahani Y. Effects of compatibilizer and thermoplastic starch (TPS) concentration on morphological, rheological, tensile, thermal and moisture sorption properties of plasticized polylactic acid/TPS blends. J Polym Environ. 2018;26(8):3202–15. 10.1007/s10924-018-1206-7.Search in Google Scholar

(12) Surendren A, Mohanty AK, Liu Q, Misra M. A review of biodegradable thermoplastic starches, their blends and composites: recent developments and opportunities for single-use plastic packaging alternatives. Green Chem. 2022;24(22):8606–36. 10.1039/D2GC02169B.Search in Google Scholar

(13) Castillo LA, López OV, García MA, Barbosa SE, Villar MA. Crystalline morphology of thermoplastic starch/talc nanocomposites induced by thermal processing. Heliyon. 2019;5(6):e01877. 10.1016/j.heliyon.2019.e01877.Search in Google Scholar

(14) Mo XZ, Zhong YX, Pang JY, Guo T, Qi X. Experimental investigation of the thermoplastic tapioca starch/sisal fiber composites. AMR. 2011;221:586–91. 10.4028/www.scientific.net/AMR.221.586.Search in Google Scholar

(15) Morán JI, Cyras VP, Giudicessi SL, Erra-Balsells R, Vázquez A. Influence of the glycerol content and temperature on the rheology of native and acetylated starches during and after gelatinization. J Appl Polym Sci. 2011;120(6):3410–20. 10.1002/app.33347.Search in Google Scholar

(16) Palanisamy A, Deslandes F, Ramaioli M, Menut P, Plana-Fattori A, Flick D. Kinetic modelling of individual starch granules swelling. Food Struct. 2020;26:100150. 10.1016/j.foostr.2020.100150.Search in Google Scholar

(17) Chakraborty I, N P, Mal SS, Paul UC, Rahman MH, Mazumder N. An insight into the gelatinization properties influencing the modified starches used in food industry: A review. Food Bioprocess Technol. 2022;15(6):1195–223. 10.1007/s11947-022-02761-z.Search in Google Scholar

(18) Lund D. Influence of time, temperature, moisture, ingredients, and processing conditions on starch gelatinization. Crit Rev Food Sci Nutr. 1984;20(4):249–73. 10.1080/10408398409527391.Search in Google Scholar

(19) Ke T, Sun X. Effects of moisture content and heat treatment on the physical properties of starch and poly(lactic acid) blends. J Appl Polym Sci. 2001;81(12):3069–82. 10.1002/app.1758.Search in Google Scholar

(20) Zuo Y, Gu J, Tan H, Zhang Y. Thermoplastic starch prepared with different plasticizers: Relation between degree of plasticization and properties. J Wuhan Univ Technol-Mat Sci Ed. 2015;30(2):423–8. 10.1007/s11595-015-1164-z.Search in Google Scholar

(21) Abera G, Woldeyes B, Demash HD, Miyake G. The effect of plasticizers on thermoplastic starch films developed from the indigenous Ethiopian tuber crop Anchote (Coccinia abyssinica) starch. Int J Biol Macromol. 2020;155:581–7. 10.1016/j.ijbiomac.2020.03.218.Search in Google Scholar

(22) Ivanič F, Kováčová M, Chodák I. The effect of plasticizer selection on properties of blends poly(butylene adipate-co-terephthalate) with thermoplastic starch. Eur Polym J. 2019;116:99–105. 10.1016/j.eurpolymj.2019.03.042.Search in Google Scholar

(23) MA X. The plastcizers containing amide groups for thermoplastic starch. Carbohydr Polym. 2004;57(2):197–203. 10.1016/j.carbpol.2004.04.012.Search in Google Scholar

(24) Estrada-Monje A, Alonso-Romero S, Zitzumbo-Guzmán R, Estrada-Moreno IA, Zaragoza-Contreras EA. Thermoplastic starch-based blends with improved thermal and thermomechanical properties. Polymers. 2021;13(23):4263. 10.3390/polym13234263.Search in Google Scholar

(25) Montilla‐Buitrago CE, Gómez‐López RA, Solanilla‐Duque JF, Serna‐Cock L, Villada‐Castillo HS. Effect of plasticizers on properties, retrogradation, and processing of extrusion‐obtained thermoplastic starch: A review. Starch – Stärke. 2021;73(9–10):2100060. 10.1002/star.202100060.Search in Google Scholar

(26) Arboleda GA, Montilla CE, Villada HS, Varona GA. Obtaining a flexible film elaborated from cassava thermoplastic starch and polylactic acid. Int J Polym Sci. 2015;2015:1–9. 10.1155/2015/627268.Search in Google Scholar

(27) Smits A, Kruiskamp P, van Soest J, Vliegenthart J. Interaction between dry starch and plasticisers glycerol or ethylene glycol, measured by differential scanning calorimetry and solid state NMR spectroscopy. Carbohydr Polym. 2003;53(4):409–16. 10.1016/S0144-8617(03)00119-X.Search in Google Scholar

(28) Pushpadass HA, Marx DB, Hanna MA. Effects of extrusion temperature and plasticizers on the physical and functional properties of starch films. Starch – Stärke. 2008;60(10):527–38. 10.1002/star.200800713.Search in Google Scholar

(29) Tarique J, Sapuan SM, Khalina A. Effect of glycerol plasticizer loading on the physical, mechanical, thermal, and barrier properties of arrowroot (Maranta arundinacea) starch biopolymers. Sci Rep. 2021;11(1):13900. 10.1038/s41598-021-93094-y.Search in Google Scholar

(30) Shapi’i RA, Othman SH, Basha RK, Naim MN. Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles. Nanotechnol Rev. 2022;11(1):1464–77. 10.1515/ntrev-2022-0094.Search in Google Scholar

(31) Jayarathna S, Andersson M, Andersson R. Recent advances in starch-based blends and composites for bioplastics applications. Polymers. 2022;14(21):4557. 10.3390/polym14214557 Search in Google Scholar

(32) Kakoria A, Sinha-Ray S. A Review on biopolymer-based fibers via electrospinning and solution blowing and their applications. Fibers. 2018;6(3):45. 10.3390/fib6030045.Search in Google Scholar

(33) Kong L, Ziegler GR. Fabrication of pure starch fibers by electrospinning. Food Hydrocoll. 2014;36:20–5. 10.1016/j.foodhyd.2013.08.021.Search in Google Scholar

(34) Hemamalini T, Giri Dev VR. Comprehensive review on electrospinning of starch polymer for biomedical applications. Int J Biol macromolecules. 2018;106:712–8. 10.1016/j.ijbiomac.2017.08.079.Search in Google Scholar

(35) El-Sayed H, Vineis C, Varesano A, Mowafi S, Andrea Carletto R, Tonetti C, et al. A critique on multi-jet electrospinning: State of the art and future outlook. Nanotechnol Rev. 2019;8(1):236–45. 10.1515/ntrev-2019-0022.Search in Google Scholar

(36) Yang Y, Zhang M, Ju Z, Tam PY, Hua T, Younas MW, et al. Poly(lactic acid) fibers, yarns and fabrics: Manufacturing, properties and applications. Text Res J. 2021;91(13–14):1641–69. 10.1177/0040517520984101.Search in Google Scholar

(37) Sergei NM, Darrell HR. Characterization of polymer surfaces with atomic force microscopy. Annu Rev Mater Sci. 1997;27:175–222. 10.1146/annurev.matsci.27.1.175.Search in Google Scholar

(38) Ning W, Xingxiang Z, Na H, Jianming F. Effects of water on the properties of thermoplastic starch poly(lactic acid) blend containing citric acid. J Thermoplast Composite Mater. 2010;23(1):19–34. 10.1177/0892705709096549.Search in Google Scholar

(39) Abdullah AHD, Chalimah S, Primadona I, Hanantyo MHG. Physical and chemical properties of corn, cassava, and potato starchs. IOP Conf Ser: Earth Environ Sci. 2018;160:12003. 10.1088/1755-1315/160/1/012003.Search in Google Scholar

(40) Turco R, Ortega-Toro R, Tesser R, Mallardo S, Collazo-Bigliardi S, Chiralt Boix A, et al. Poly (lactic acid)/thermoplastic starch films: Effect of cardoon seed epoxidized oil on their chemicophysical, mechanical, and barrier properties. Coatings. 2019;9(9):574. 10.3390/coatings9090574.Search in Google Scholar

(41) Altayan MM, Al Darouich T, Karabet F. On the plasticization process of potato starch: Preparation and characterization. Food Biophys. 2017;12(4):397–403. 10.1007/s11483-017-9495-2.Search in Google Scholar

(42) Mónica Elvira M-D, Iván Alziri E-M, Erika Ivonne L-M, Alejandro V-R. Effect of the addition of different natural waxes on the mechanical and rheological behavior of PLA—A comparative study. Polymers. 2023;15(2):305. 10.3390/polym15020305.Search in Google Scholar

(43) Beer-Lech K, Skic A, Skic K, Stropek Z. Characterization of the structural and physical properties of the thermoplastic starch film with kaolinite and beeswax addition. Adv Sci Technol Res J. 2022;16(5):312–23. 10.12913/22998624/155188.Search in Google Scholar

(44) Schnitzler E, Ribeiro LS, Cordoba LDP, Andrade MMP, Oliveira CS, Da Silva ÉC, et al. Thermoanalytical study on the action of nitric acid up cassava starch granules. Braz J Therm Anal. 2014;3(1–2):20. 10.18362/bjta.v3i1-2.25.Search in Google Scholar

(45) Yulianto A, Kayati FN, Novariawan B, Supriyanti A. The effect of extrusion temperature on changes of characteristics of partially pregelatinized cassava starch. IJCEA. 2020;11(2):67–70. 10.18178/ijcea.2020.11.2.782.Search in Google Scholar

(46) Werner E, Güth U, Brockhagen B, Döpke C, Ehrmann A. Examination of polymer blends by AFM phase images. Technologies. 2023;11(2):56. 10.3390/technologies11020056.Search in Google Scholar

(47) López OV, Ninago MD, Lencina MMS, García MA, Andreucetti NA, Ciolino AE, et al. Thermoplastic starch plasticized with alginate-glycerol mixtures: Melt-processing evaluation and film properties. Carbohydr poly. 2015;126:83–90. 10.1016/j.carbpol.2015.03.030.Search in Google Scholar

(48) Ferri JM, Garcia‐Garcia D, Carbonell‐Verdu A, Fenollar O, Balart R. Poly(lactic acid) formulations with improved toughness by physical blending with thermoplastic starch. J Appl Poly Sci. 2018;135(4):5751. 10.1002/app.45751.Search in Google Scholar

(49) Aldas M, Pavon C, López-Martínez J, Arrieta MP. Pine resin derivatives as sustainable additives to improve the mechanical and thermal properties of injected moulded thermoplastic starch. Appl Sci. 2020;10(7):2561. 10.3390/app10072561.Search in Google Scholar

(50) Huneault MA, Li H. Morphology and properties of compatibilized polylactide/thermoplastic starch blends. Polymer. 2007;48(1):270–80. 10.1016/j.polymer.2006.11.023.Search in Google Scholar

(51) Mano JF, Koniarova D, Reis RL. Thermal properties of thermoplastic starch/synthetic polymer blends with potential biomedical applicability. J Mater Sci Mater Med. 2003;14(2):127–35. 10.1023/a:1022015712170.Search in Google Scholar

(52) Zuo Y, He X, Li P, Li W, Wu Y. Preparation and characterization of hydrophobically grafted starches by In Situ solid phase polymerization. Polymers. 2019;11(1):72. 10.3390/polym11010072.Search in Google Scholar

(53) Orue A, Corcuera MA, Peña C, Eceiza A, Arbelaiz A. Bionanocomposites based on thermoplastic starch and cellulose nanofibers. J Thermoplast Compos Mater. 2016;29(6):817–32. 10.1177/0892705714536424.Search in Google Scholar

(54) Gamarano DdS, Pereira IM, Da Silva MC, Mottin AC, Ayres E. Crystal structure transformations in extruded starch plasticized with glycerol and urea. Polym Bull. 2020;77(9):4971–92. 10.1007/s00289-019-02999-2.Search in Google Scholar

(55) Liu Y, Yu J, Copeland L, Wang S, Wang S. Gelatinization behavior of starch: Reflecting beyond the endotherm measured by differential scanning calorimetry. Food Chem. 2019;284:53–9. 10.1016/j.foodchem.2019.01.095.Search in Google Scholar

(56) Bergo P, Sobral P, Prison JM. Effect of glycerol on physical properties of cassava starch films. J Food Process Preserv. 2010;34:401–10. 10.1111/j.1745-4549.2008.00282.x Search in Google Scholar

(57) Mohammadi Nafchi A, Moradpour M, Saeidi M, Alias AK. Thermoplastic starches: Properties, challenges, and prospects. Starch/Stärke. 2013;65(1–2):61–72. 10.1002/star.201200201.Search in Google Scholar

(58) Mendes JF, Paschoalin RT, Carmona VB, Sena Neto AR, Marques ACP, Marconcini JM, et al. Biodegradable polymer blends based on corn starch and thermoplastic chitosan processed by extrusion. Carbohydr poly. 2016;137:452–8. 10.1016/j.carbpol.2015.10.093.Search in Google Scholar

(59) Musa M, Yoo M, Kang T, Kolawole E, Ishiaku U, Yakubu M, et al. Characterization and thermomechanical properties of thermoplastic potato starch. Res Rev: J Eng Technol. 2013;2:2324.Search in Google Scholar

(60) Zahiruddin S, Othman SH, Tawakkal I, Talib RA. Mechanical and thermal properties of tapioca starch films plasticized with glycerol and sorbitol. Food Res. 2018;3(2):157–63. 10.26656/fr.2017.3(2).105.Search in Google Scholar

(61) Adamu AD, Jikan SS, Talip BHA, Badarulzaman NA, Yahaya S. Effect of glycerol on the properties of tapioca starch film. MSF. 2017;888:239–43. 10.4028/www.scientific.net/MSF.888.239.Search in Google Scholar

(62) Sacithraa R, MadhanMohan M, Vijayachitra S. Quantitative Analysis of Tapioca Starch using FT-IR Spectroscopy and Partial Least Squares. nternational Conference on Innovations In Intelligent Instrumentation, Optimization And Signal Processing “ICIIIOSP-2013”; 2013.Search in Google Scholar

(63) Paluch M, Ostrowska J, Tyński P, Sadurski W, Konkol M. Structural and thermal properties of starch plasticized with glycerol/urea mixture. J Polym Environ. 2022;30(2):728–40. 10.1007/s10924-021-02235-x.Search in Google Scholar

(64) Caicedo C, Pulgarin HLC. Study of the physical and mechanical properties of thermoplastic starch/poly(lactic acid) blends modified with acid agents. Processes. 2021;9(4):578. 10.3390/pr9040578.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Flame-retardant thermoelectric responsive coating based on poly(3,4-ethylenedioxythiphene) modified metal–organic frameworks

- Highly stretchable, durable, and reversibly thermochromic wrapped yarns induced by Joule heating: With an emphasis on parametric study of elastane drafts

- Molecular dynamics simulation and experimental study on the mechanical properties of PET nanocomposites filled with CaCO3, SiO2, and POE-g-GMA

- Multifunctional hydrogel based on silk fibroin/thermosensitive polymers supporting implant biomaterials in osteomyelitis

- Marine antifouling coating based on fluorescent-modified poly(ethylene-co-tetrafluoroethylene) resin

- Preparation and application of profiled luminescent polyester fiber with reversible photochromism materials

- Determination of pesticide residue in soil samples by molecularly imprinted solid-phase extraction method

- The die swell eliminating mechanism of hot air assisted 3D printing of GF/PP and its influence on the product performance

- Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes

- The effects of property variation on the dripping behaviour of polymers during UL94 test simulated by particle finite element method

- Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets

- Synthesis, characterization and evaluation of a pH-responsive molecular imprinted polymer for Matrine as an intelligent drug delivery system

- Twist-related parametric optimization of Joule heating-triggered highly stretchable thermochromic wrapped yarns using technique for order preference by similarity to ideal solution

- Comparative analysis of flow factors and crystallinity in conventional extrusion and gas-assisted extrusion

- Simulation approach to study kinetic heterogeneity of gadolinium catalytic system in the 1,4-cis-polyisoprene production

- Properties of kenaf fiber-reinforced polyamide 6 composites

- Cellulose acetate filter rods tuned by surface engineering modification for typical smoke components adsorption

- A blue fluorescent waterborne polyurethane-based Zn(ii) complex with antibacterial activity

- Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading

- Preparation and application research of composites with low vacuum outgassing and excellent electromagnetic sealing performance

- Assessing the recycling potential of thermosetting polymer waste in high-density polyethylene composites for safety helmet applications

- Mesoscale mechanics investigation of multi-component solid propellant systems

- Preparation of HTV silicone rubber with hydrophobic–uvioresistant composite coating and the aging research

- Experimental investigation on tensile behavior of CFRP bolted joints subjected to hydrothermal aging

- Structure and transition behavior of crosslinked poly(2-(2-methoxyethoxy) ethylmethacrylate-co-(ethyleneglycol) methacrylate) gel film on cellulosic-based flat substrate

- Mechanical properties and thermal stability of high-temperature (cooking temperature)-resistant PP/HDPE/POE composites

- Preparation of itaconic acid-modified epoxy resins and comparative study on the properties of it and epoxy acrylates

- Synthesis and properties of novel degradable polyglycolide-based polyurethanes

- Fatigue life prediction method of carbon fiber-reinforced composites

- Thermal, morphological, and structural characterization of starch-based bio-polymers for melt spinnability

- Robust biaxially stretchable polylactic acid films based on the highly oriented chain network and “nano-walls” containing zinc phenylphosphonate and calcium sulfate whisker: Superior mechanical, barrier, and optical properties

- ARGET ATRP of styrene with low catalyst usage in bio-based solvent γ-valerolactone

- New PMMA-InP/ZnS nanohybrid coatings for improving the performance of c-Si photovoltaic cells

- Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites

- Preparation of cardanol-based curing agent for underwater drainage pipeline repairs

- Preparation of lightweight PBS foams with high ductility and impact toughness by foam injection molding

- Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study

- Experimental study on impact and flexural behaviors of CFRP/aluminum-honeycomb sandwich panel

- Normal-hexane treatment on PET-based waste fiber depolymerization process

- Effect of tannic acid chelating treatment on thermo-oxidative aging property of natural rubber

- Design, synthesis, and characterization of novel copolymer gel particles for water-plugging applications

- Influence of 1,1′-Azobis(cyclohexanezonitrile) on the thermo-oxidative aging performance of diolefin elastomers

- Characteristics of cellulose nanofibril films prepared by liquid- and gas-phase esterification processes