Abstract

The heterogeneous nucleation process of polypropylene (PP)/high density polyethylene (HDPE)/thermoplastic elastomer (POE) composites was realized through blending modification, and characterization techniques, including scanning electron microscopy, differential scanning calorimetry, X-ray diffraction, and dynamic mechanical analysis, were used to analyze the pattern of the impact of modified dicyclohexyl-terephthalamide (TMB-5) on the mechanical properties and thermal stability of the PP/HDPE/POE composites. The results indicated that the modified TMB-5 was advantageous to the improvement of the mechanical properties and thermal stability of the high-temperature (cooking temperature)-resistant PP/HDPE/POE composites. When the amount of added modified TMB-5 was 0.4%, the impact strength and tensile strength of the PP/HDPE/POE composites increased to 36.3 kJ/m2 and 31.7 MPa, respectively, which were, respectively, 99.5% and 8.5% higher than those of the materials prepared when the amount of added modified TMB was 0.1%. The materials had higher storage modulus in room-temperature and high-temperature environments: 2,438.2 MPa (room temperature), 1,103.9 MPa (120°C), and 1,054.8 MPa (140°C). In addition, the capability of the PP/HDPE/POE composites to crystallize was improved continuously, and the crystallinity increased considerably. At the same time, the crystallization and melting temperatures increased, β-crystal formation was induced, and glass transition temperature increased, thus effectively improving the mechanical properties and thermal stability of the high-temperature (cooking temperature)-resistant PP/HDPE/POE composites.

1 Introduction

With the groundbreaking research of the plastics industry and medical technology and the growing concern about health problems, plastics have been extensively used in the medical field because of their excellent properties, convenient molding process, and relatively low cost. Polypropylene (PP) has characteristics of lightweight, low cost, hygienic properties, and easy molding process and is mainly used in the fields of small appliances, toys, washing machines, and auto parts. However, the traditional PP materials fail to produce the sterilization environments of high-temperature-resistant medical materials and sterile bags for agricultural products and meet the usage requirements of high-temperature (cooking temperature)-resistant materials, such as aluminum plastic film. Furthermore, the poor mechanical properties, along with the aforementioned drawbacks, severely restrict the promotion and application of PP in high-end industrial and agricultural fields.

At present, domestic and foreign scientific and technological workers have made a lot of research to improve the mechanical properties and thermal stability of high-temperature cooking-grade PP composites, mainly using blending modification, filler modification, and nucleating agent heterogeneous nucleation modification. Among them, blending modification is mainly based on polypropylene (PP)/high density polyethylene (HDPE), polypropylene (PP)/thermoplastic elastomer (POE), and PP/PE blends, while filling modification is mainly based on inorganic fillers, mainly SiO2, CaCO3, BaSO4, etc. Whether blending modification or filling modification can improve the mechanical properties of PP composites to a certain extent, but the improvement of thermal stability is still insufficient, and there are problems of dispersion (1,2,3,4,5,6). Nucleating agent modification can be used to improve the mechanical properties and thermal stability of PP composites. Nucleating agent modification can improve the mechanical and thermal stability properties by regulating heterophase nucleation, refining grain size, and enhancing interfacial adhesion (7,8). Kang et al. (9) modified PP using a combination of β nucleating agent and nano-scale CaCO3 to form a state in which α- and β-crystals coexist, enhancing the material toughness and heat resistance and realizing the high stiffness and high toughness of the modified material. Yi et al. investigated the effects of different catalyst systems on the PP structure. Li et al. (10) conducted detailed studies on the morphological structure, thermal stability, and mechanical properties of PP and propylene–ethylene copolymer blends with different ratios. Dong et al. (11) studied the effect of three α-nucleating agents on the mechanical and crystallization properties of PP. However, the aforementioned studies have all indicated that the thermal stability or mechanical properties of PP materials can be improved to a certain extent. However, the research on the ideal mechanical properties with high thermal stability in the field of high-temperature cooking is still lacking and not systematic but excellent mechanical properties with high thermal stability are still a technical challenge.

Therefore, in this study, PP was used as the base material, a dispersing agent was used to modify the nucleating agent, and the blending modification technique was used to prepare high-temperature (cooking temperature)-resistant PP/HDPE/POE composites and explore the pattern of the impact of modified nucleating agent dicyclohexyl-terephthalamide (TMB-5) on the mechanical properties and thermal stability of the PP/HDPE/POE composites.

2 Experimental section

2.1 Raw materials

PP was F08M, 3.8 wt% ethylene content, melt index 8 g/10 min (230°C, 2.16 kg), from China Petroleum & Chemical Corporation Maoming Branch. Polyolefin elastomer was 8200, 25 wt% octene content, melt index 5.0 g/10 min (190°C, 2.16 kg), from Dow Chemical, USA. High-density polyethylene was 5200B, melt index 0.35 g/10 min (190°C, 2.16 kg), from Sinopec Yanshan Petrochemical Company. β-nucleating agent was TMB-5, white powder, melting point >340°C, from Technology Innovation and Development Center, Shanxi Provincial Institute of Chemical Industry. The dispersing agent was N,N′-ethylenebis(stearamide), purity 99%, white powder, melting point 142°C, molecular weight 593, from Guangzhou Shanshan New Material Technology.

As presented in Table 1, N,N′-ethylenebis(stearamide) and TMB-5 were placed into a high-speed mixer at a specific ratio to carry out the modification, the duration was 30 min, the temperature was 100°C, and the rotation speed was 100 rpm.

Preparation of PP composites

| Raw material/% | Modified TMB-5 |

|---|---|

| N,N′-ethylenebis(stearamide) | 20 |

| TMB-5 | 80 |

2.2 Preparation of PP composite materials

As presented in Table 2, the PP/HDPE/POE composites were prepared using a twin-screw extruder, and the extrusion process was as follows: temperatures, 150°C, 190°C, 220°C, 220°C, 220°C, and 190°C; melting temperature, 220°C; main screw speed, 20 rpm. The extruded materials were dried in a heating blast drying oven at 60°C for 24 h and then cooled down for future use. The obtained materials were then placed in an injection molding machine to prepare the molded specimens. The injection molding process temperatures were as follows: 200°C, 220°C, 220°C, and 200°C. After being cooled down, the sample was characterized.

Formula

| Raw material/% | 1# | 2# | 3# | 4# | 5# |

|---|---|---|---|---|---|

| Modified TMB-5 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 |

| HDPE | — | 2 | 2 | 2 | 2 |

| POE | — | 6 | 6 | 6 | 6 |

| PP | 99.9 | 91.8 | 91.7 | 91.6 | 91.5 |

3 Characterization

3.1 Measurement of the mechanical properties

The tensile properties were measured according to GB/T 1040.2-2006. The impact strength was measured according to GB/T 1843-2008.

3.2 Crystallization behavior

According to GB/T 19466.1-2004, 3–5 mg of the specimen was cut and placed into an aluminum crucible. A differential scanning calorimeter (DSC) was used for the measurement, which was performed in a nitrogen environment with a heating rate of 10°C·min−1.

The method to calculate the crystallinity X DSC is as follows (12):

where X

DSC is the crystallinity, ΔH

m is the heat enthalpy of the melting process,

3.3 Crystalline structure

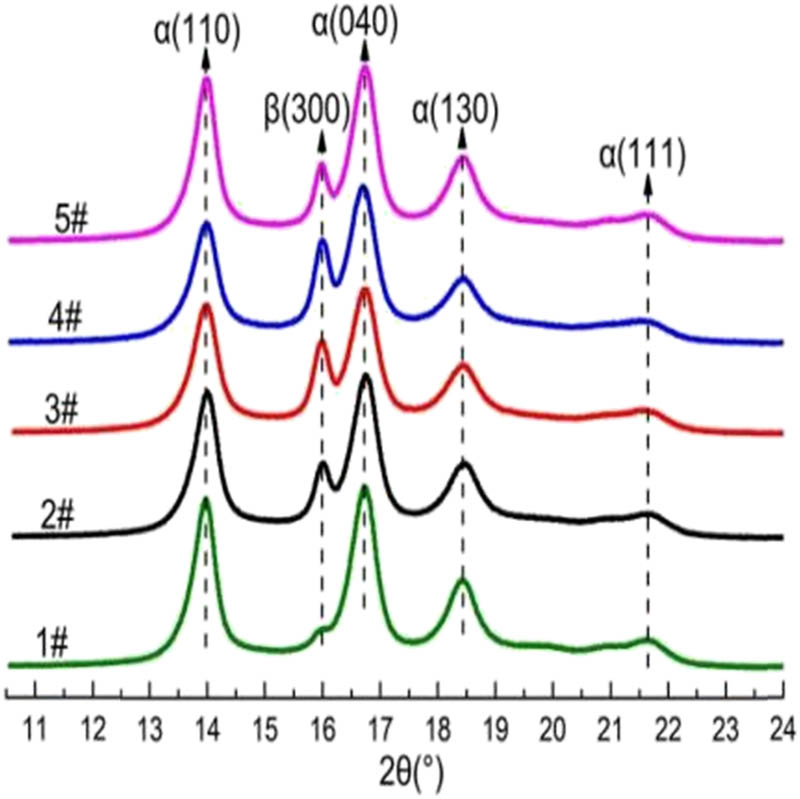

The samples were cut in blocks, and a Cu-Kα X-ray diffraction (XRD) system was used for the measurement, with a scan rate of 5°·min−1, X-ray wavelength of 0.154 nm, a voltage of 40 kV, a current of 40 mA, and a scan range of 10–30°. The method to calculate the crystallinity X XRD is as follows (14):

where

The crystallinity of the β-crystal form was calculated according to Eq. 3 (15):

where

where I α(110), I α(040), and I α(130) represent the intensities of three characteristic diffraction peaks (110) of α-crystal, and the corresponding 2θ values were 14°, 16.7°, and 18.4°, respectively. I β(300) represents the intensity of the crystal (300) diffraction peak formed by β-crystal at 2θ = 16.0°. There was a β(301) diffraction peak at 2θ = 21.6° for PP, but because it overlapped with α(111) crystal plane diffraction peak, I(301) and I(111) were not included when calculating K β.

3.4 Dynamic mechanical analysis

In the nitrogen atmosphere, the measurement was taken under dual cantilever bending mode at a heating rate of 5°C·min−1, the measurement range was −120°C to 140°C, the measurement frequency was 1 Hz, and the specimen size was 60 mm × 10 mm × 2 mm.

3.5 Characterization of the microstructure

The PP/HDPE/POE material sample was chilled in liquid nitrogen and then placed on an impact strength tester to carry out a rapid fracture. Subsequently, the fracture surface was sprayed with gold, and a field emission scanning electron microscope was used to record the fracture surface morphology of the sample under specific acceleration voltage conditions.

4 Results and discussion

4.1 Discussion on the mechanical properties

Figure 1 presents the curves of changes in the impact strength and tensile strength of the PP/HDPE/POE composites with different amounts of added modified TMB-5. As can be observed from the figure, with an increasing amount of added modified TMB-5, the impact strength exhibited a decreasing trend after the initial increase, and the tensile strength exhibited a small increase. When the amount of added modified TMB-5 was 0.1%, the impact strength was 18.2 kJ·m−2 and the tensile strength was 29.2 MPa (Specimen1# in Figure 1). When the amount of added modified TMB-5 was 0.4% (Specimen4# in Figure 1), the impact strength and the tensile strength were 36.3 kJ·m−2 and 31.7 MPa, respectively, which were, respectively, 99.5% and 8.5% higher than those of the specimen obtained when the amount of added modified TMB-5 was 0.1%. This is mainly because HDPE/POE elastomer particles can serve as stress concentration points. Furthermore, an increase in the amount of added modified TMB-5 promotes the generation of numerous shear bands, consuming the impact energy and enhancing the impact strength (17,18). Additionally, the nucleating agent not only plays a role in blocking, diverting, and terminating the growth of small cracks but also can enhance the compatibility of the composite material, form strong interfacial adhesion and refined particles, and promote the composite material to possess higher impact strength while maintaining excellent tensile properties (19,20). As the amount of added modified TMB-5 increased to 0.5% (Specimen5# in Figure 1), the impact strength decreased and the tensile strength increased. The aforementioned results suggested that the use of the heterogeneous nucleation effect of modified TMB-5 could achieve a relatively ideal result of enhancing the strength and toughness of the PP/HDPE/POE composites. Among them, when the amount of added modified TMB-5 was 0.4%, the most ideal comprehensive mechanical properties of the PP/HDPE/POE composites were obtained.

Effect of modified dicyclohexyl-terephthalamide (TMB-5) on the impact strength and tensile strength of the PP/HDPE/POE composites.

4.2 Analysis of the microstructure

Figure 2 displays the microstructural characteristics of the PP/HDPE/POE composites. As can be observed from the figure, with an increasing amount of added modified TMB-5, the fracture surface of the material was rough, and the thicknesses of the stress-whitening region and interface layer increased, but a smooth fracture surface also existed and exhibited the characteristics of coexistence of ductile–brittle fracture that was dominated by ductile fracture. These findings demonstrated that modified TMB-5 could promote the conversion of the fracture characteristics of the PP/HDPE/POE composites from complete brittle fracture to a certain ratio of ductile fracture. Among them, when the amount of added modified TMB-5 was 0.4% (Specimen(c) in Figure 2), the impact sections all exhibited strong interfacial adhesion and stress-whitening areas. Therefore, more energy dissipation is induced when the material is subjected to external impact force, thus greatly enhancing the comprehensive mechanical properties of the material. However, when the amount of added modified TMB-5 continued to increase to 0.5% (Specimen(e) in Figure 2), the degree of interfacial adhesion of the PP/HDPE/POE composites substantially weakened or even disappeared, and the characteristics of coexistence of ductile–brittle fracture changed, which was consistent with the result of the analysis of the mechanical properties. Therefore, when the amount of added modified TMB-5 was 0.4%, the best comprehensive mechanical properties of the PP/HDPE/POE composites were obtained. The underlying mechanism is that because of the addition of a nucleating agent, the interfacial adhesion and stress-whitening phenomenon of the material can induce extensive crazing and shear yielding when the external force is applied, thus promoting the energy dissipation of the polymer (21,22). Furthermore, an increase in the amount of added modified nucleating agent and an enhancement in dispersity can effectively promote the appearance of interfacial adhesion and stress-whitening phenomenon, which plays a critical role in improving the comprehensive mechanical properties of the material. However, there is a maximum dispersity value of the modified nucleating agent, so it has a limited value on the interfacial adhesion and stress-whitening. This indicated that when the amount of added modified TMB-5 was 0.4%, the PP/HDPE/POE composites could possess relatively ideal comprehensive mechanical properties, which was consistent with the aforementioned results.

Microstructural characteristics of the PP/HDPE/POE composites. Note: (a) 1#; (b) 2#; (c) 3#; (b) 4#; (e) 5#.

4.3 Analysis of the crystallization behavior

Figure 3 displays the effect of modified TMB-5 on the crystallization behavior (a) and melting behavior (b) of the PP/HDPE/POE composites. As presented in Figure 3(a) and Table 3, with increasing amount of added modified TMB-5, the crystallization temperature (T c) increased by 7.8%, manifested by an increase from 86.9°C to 93.7°C, whereas the half-peak width exhibited a gradient decrease (1#∼4# in Table 3). This is mainly because, with an increasing amount of added modified TMB-5, the crystallization rate further increases, which promotes an increase in the capability of crystallization, a decrease in intermolecular entanglement ability, increases in molecular chain flexibility and lattice stacking regularity, and optimization in the ratio of the crystalline region and amorphous region. As a result, crystallization is improved and comprehensive mechanical properties are enhanced (23). However, as the amount of added modified TMB-5 increased to 0.5% and T c decreased (5# in Table 3). The main reason is the metastability of polymer platelets. At a higher amount of added nucleating agent, the thickness of the material platelets gradually increased, thus leading to a decrease in T c (24). Additionally, as can be observed from Figure 3(b), as the amount of added modified TMB-5 increased, the melting temperature of the material exhibited an increasing trend. When the amount of added modified TMB-5 was 0.4%, the melting temperature of the material increased to 150.9°C (4# in Table 3). The heterogeneous nucleation effect generated from the nucleating agent optimizes the relaxation process and rearrangement intensity of the internal chain structure of the material, refines the grains, and improves the crystallization process of the material, thus increasing the melting temperature and improving the mechanical properties (25). When the amount of added modified TMB-5 continued to increase to 0.5%, the melting temperature greatly increased to 151.3°C, but the crystallization temperature decreased to 91.7°C (5# in Table 3). These findings suggest that an excessive amount of nucleating agent inhibits the increases in the crystallization rate and capability of crystallization so that the proportion of amorphous region increases, which reduces the mechanical properties of the material to a certain extent. Therefore, an excessive amount of nucleating agent was not advantageous to the enhancement of the comprehensive properties of the material.

Effect of modified dicyclohexyl-terephthalamide (TMB-5) on the crystallization behavior (a) and melting behavior (b) of the PP/HDPE/POE composites.

Crystallization and melting values of the PP/HDPE/POE composites

| Sample number | T c/°C | T f/°C | T m/°C | ΔH m/(J·g−1) | X DSC/% |

|---|---|---|---|---|---|

| 1# | 86.9 | 6.00 | 148.5 | 34.35 | 19.4 |

| 2# | 88.6 | 5.68 | 149.7 | 43.90 | 24.8 |

| 3# | 89.8 | 4.95 | 150.3 | 55.60 | 31.4 |

| 4# | 93.7 | 4.19 | 150.9 | 63.52 | 35.9 |

| 5# | 91.7 | 3.85 | 151.3 | 61.21 | 34.6 |

Note: T c, crystallization temperature; T f, half-peak width; T m, melting temperature; ΔH m, melting enthalpy; X DSC, crystallinity measured by differential scanning calorimetry.

In addition, as can be observed from Table 3, with an increasing amount of added modified TMB-5, the crystallinity of the PP/HDPE/POE composites increased substantially. When the amount of added modified TMB-5 was 0.4%, X DSC was 35.9%, which was 85.1% higher than 19.4% when the amount of added modified TMB-5 was 0.1% (1# and 4# in Table 3). This is mainly because an increase in the amount of added nucleating agent weakens the intermolecular forces, optimizes the internal molecular conformation of materials, and increases the molecular chain relaxation degree and reconstruction regularity so that the crystallization of the material tends to be complete, and the crystallinity increases (26,27). When the amount of added modified TMB-5 was 0.5%, the crystallinity decreased by 1.3% or 15.2% compared with that of the material obtained when the amount of added modified TMB-5 was 0.4% or 0.1% (1#, 4#, and 5# in Table 3). The main reason is that a further increase in the amount of added nucleating agents accelerates the intermolecular motion, causing a more compact stacking of molecular chains. Consequently, the molecular distance is restricted, and the material loses its crystallization structure, inhibiting a further increase in crystallinity (28). When the amount of added modified TMB-5 was 0.4%, the crystallization behavior of the material was good. This indicated that when the amount of added modified TMB-5 was 0.4%, the comprehensive mechanical properties were optimal, which was consistent with the result of the analysis of the mechanical properties.

4.4 XRD analysis

Figure 4 presents the XRD patterns of the PP/HDPE/POE composites. As can be observed from the figure, with the amount of added modified TMB-5 gradually increasing from 0.1% to 0.4% (1#∼4#in Figure 4), obvious diffraction peaks appeared at 2θ = 14°, 16.7°, 18.4°, and 21.6° in the PP composites, and they corresponded to the diffraction peaks of different crystal planes, which were α(110), α(040), α(130), and α(111), respectively. More importantly, a diffraction peak of β(300) crystal plane occurred at 2θ = 16°, suggesting that the addition of the nucleating agent induced the conversion of the α-crystal form to the β-crystal form. When the amount of added modified TMB-5 was 0.5%, the diffraction peak intensity of β(300) crystal plane decreased. In combination with Table 4, it can be observed that the crystallinity exhibited a decreasing trend after the initial increase as the amount of added modified TMB-5 increased, which was consistent with the result of the DSC analysis.

XRD patterns of the PP/HDPE/POE composites.

Values of the PP composites measured using XRD

| Sample number | X XRD (%) | X α (%) | X β (%) | R β (%) |

|---|---|---|---|---|

| 1# | 59.1 | 50.06 | 9.04 | 15.3 |

| 2# | 62.6 | 46.6 | 16 | 25.5 |

| 3# | 69.5 | 47.9 | 21.6 | 31.1 |

| 4# | 77.4 | 44.7 | 32.7 | 42.2 |

| 5# | 63.6 | 46.9 | 16.7 | 26.3 |

Note: X XRD, crystallinity measured by XRD; X α, α-crystal crystallinity; X β, β-crystal crystallinity; R β, relative content of β crystal; PP, polypropylene.

Furthermore, when the amount of added modified TMB-5 was 0.4% (4# in Table 4), the maximum Rβ value (42.2%) was obtained. An increase in the content of the β-crystal form can largely increase the impact energy dissipation, thus enhancing the toughness of the material. However, when the amount of added modified TMB-5 increased to 0.5% ((5# in Table 4), the content of the β-crystal form decreased dramatically, which further confirmed that the addition of an excessive amount of nucleating agent was not advantageous to the improvement of the crystal structure of the material but decreased the toughness of the material. This was consistent with the result of the analysis of the mechanical properties.

4.5 Dynamic mechanical analysis

Figure 5 presents the storage modulus–temperature curve of the PP/HDPE/POE composites. As can be observed, with an increasing amount of added modified TMB-5, the storage modulus first decreased slowly as the temperature rose and then decreased sharply before finally reaching the equilibrium state. One possible reason for this phenomenon is that when the initial low temperature increases to a certain temperature, the change in the environment in which the specimen exists leads to a slow decrease in the storage modulus of the composite material (29). The subsequent sharp decrease in the storage modulus is because during the glass transition process, the composite material shifts from a rigid state to an elastic state, which is accompanied by the release of modulus. Finally, the equilibrium state is reached. At this time, the rigid state weakens, manifested by the elastic state (29). As can be observed from Figure 5 and Table 5, when the amount of added modified TMB-5 was 0.1% ((1#in Figure 5), the stiffness of the material in a low-temperature environment was poor. As the environmental temperature increased to room temperature and high temperature, the modulus exhibited a large decrease, and the stiffness in the corresponding environment was not sufficient. When the amount of added modified TMB-5 was 0.4% (4# in Table 5), the glass transition temperature (T g) was −51°C, which was 32°C higher than that when the amount of added modified TMB-5 was 0.1% (1# in Table 5). The storage modulus in the room-temperature environment was higher (2,438.2 MPa); the storage moduli at high temperatures of 120°C and 140°C remained higher and were 1,103.9 and 1,054.8 MPa, respectively. These results indicated that the material still maintained excellent stiffness in a high-temperature environment, and the high-temperature stability was considerably improved. According to the Kelvin–Voigt model, when the storage modulus increases, the viscosity of the material increases, elastic deformation also becomes larger, and the stiffness increases (30). As can be observed from the results, when the amount of added modified TMB-5 was 0.4%, the specimen maintained a high storage modulus in a high-temperature environment, and an ideal high-temperature stability was obtained. When the amount of added modified TMB-5 was 0.5% (5# in Table 5), T g decreased to −61°C; the storage moduli at different environmental temperatures were lower than those of the specimen obtained when the amount of added modified TMB-5 was 0.4% (4# in Table 5). These findings indicated that as the amount of added nucleating agent increased, the thermal stability and stiffness of the material decreased and the tensile strength decreased, which was consistent with the result of the analysis of the mechanical properties.

Storage modulus–temperature curve of the PP/HDPE/POE composites.

Values of the PP/HDPE/POE composites measured by dynamic mechanical analysis

| Sample number | T g/°C | Storage modulus/MPa | |||

|---|---|---|---|---|---|

| −120°C | 25°C | 120°C | 140°C | ||

| 1# | −83 | 4,377.8 | 863.8 | 202.2 | 123.6 |

| 2# | −72 | 4,394.7 | 1,799.2 | 745.8 | 605.3 |

| 3# | −66 | 4,462.1 | 1,671.3 | 897.5 | 852.5 |

| 4# | −51 | 4,865.2 | 2,438.2 | 1,103.9 | 1,054.8 |

| 5# | −61 | 4,681.2 | 2,018.3 | 875 | 802 |

5 Conclusions

With an increasing amount of added modified TMB-5, the impact strength exhibited a decreasing trend after the initial increase and the tensile strength exhibited a small increase. When the amount of added modified TMB-5 was 0.4%, the impact strength and the tensile strength were 36.3 kJ·m−2 and 31.7 MPa, respectively, which were, respectively, 99.5% and 8.5% higher than those of the specimen obtained when the amount of added modified TMB-5 was 0.1%.

When the amount of added modified TMB-5 was 0.4%, the impact sections all exhibited strong interfacial adhesion and stress-whitening areas. Therefore, more energy dissipation is induced when the material is subjected to external impact force, thus greatly enhancing the comprehensive mechanical properties of the material.

With increasing amount of added modified TMB-5, the crystallization temperature (T c) increased by 7.8%, manifested by an increase from 86.9°C to 93.7°C, whereas the half-peak width exhibited a gradient decrease. When the amount of added modified TMB-5 was 0.4%, the melting temperature of the material increased to 150.9°C, and the comprehensive mechanical properties were optimal, which was consistent with the result of the analysis of the mechanical properties.

When the amount of added modified TMB-5 was 0.4%, the maximum R β value (42.2%) was obtained. An increase in the content of the β-crystal form can largely increase the impact energy dissipation, thus enhancing the toughness of the material.

When the amount of added modified TMB-5 was 0.4%, the specimen maintained a high storage modulus in a high-temperature environment, and an ideal high-temperature stability was obtained. When the amount of added modified TMB-5 was 0.5%, T g decreased to −60.8°C; the storage moduli at different environmental temperatures were lower than those of the specimen obtained when the amount of added modified TMB-5 was 0.4%. These findings indicated that as the amount of added nucleating agent increased, the thermal stability and stiffness of the material decreased, and the tensile strength decreased, which was consistent with the result of the analysis of the mechanical properties.

Acknowledgements

I would like to express my gratitude to all those who helped me during the writing of this thesis. I sincerely thank corresponding author Yi Zhang and Xiao-Xiao Huang for his help. In addition, I would like to thank Guizhou Institute of Metallurgy and Chemical Engineering for providing a learning platform. Finally, I would like to thank the editors of e-polymers for their help.

-

Funding information: The authors express their sincere thanks to the Guizhou Province Science and Technology Support Plan of China (Grant No. [2020] 4Y063), the Guizhou Basic Research Program of China (Nos.[2019]1448 and [2020]1Z043), and the Guiyang Science and Technology Plan Project of China (Nos. [2023]6-4 and [2021]43-21) for their financial support.

-

Author contributions: Yu-Long Ma and Kang Yang: designed and performed the experiments; Yu-Long, Kang Yang,Ju-Heng Wang and Shu Zeng: data curation and formal analysis; Yu-Long Ma: writing – original draft; Yi Zhang: writing – review and editing; Shu Zeng: funding acquisition. All authors have read and agreed to the published version of the manuscript.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The data presented in this study are available on request from the corresponding author.

References

(1) Li M, Zhang YW, Yuan CY, Quan M. Effect of viscosity ratio on morphology and mechanical properties of PP/HDPE blend. Suliao Gongye. 2009;34(9):51–4. 10.1061/(ASCE)0887-381X(2006)20:1(20).Search in Google Scholar

(2) Li CH, Wang JF, Guo JW, Wu H, Guo SY. The toughening behavior of the PP/POE alternating multilayered blends under EWF and impact tensile methods. Chin J Polym Sci. 2015;33:1477–90. 10.1007/s10118-015-1692-1.Search in Google Scholar

(3) Gao H, Song YM, Wang QW, Han Z, Zhang ML. Rheological and mechanical properties of wood fiber-PP/PE blend composites. J For Res. 2008;19:315–8. 10.1007/s11676-008-0057-9.Search in Google Scholar

(4) Sui Y, Cui Y, Cong CB, Meng XY, Zhou Q. Rheological and mechanical properties of automobile polypropylene/silica (PP/SiO2) nanocomposites. J Phys. 2022;2324:012004. 10.1088/1742-6596/2324/1/012004.Search in Google Scholar

(5) Parhizkar M, Shelesh-Nezhad K, Rezaei A. Mechanical and thermal properties of Homo-PP/GF/CaCO3 hybrid nanocomposites. Adv Mater Res-Int J. 2016;5(2):121–30. 10.12989/amr.2016.5.2.121.Search in Google Scholar

(6) Kohandel F, Sararoudi S, Shafiei, Barangi L. Rheological and mechanical properties of highly filled polyolefin based on PP/barium sulfate. Adv Mater Res-Int J. 2016;5(2):121–30. 10.1063/1.4942326.Search in Google Scholar

(7) Kang WL, Gong XL, Gai JG. Toughening effect of ultrahigh molecular weight polyethylene and compounded α/β nucleation agents on isotactic polypropylene by different processing methods. Polym Sci Ser A. 2015;57(6):811–8. 10.1134/S0965545X15070056.Search in Google Scholar

(8) Liu BJ, Xing JF, Jiang TH, You YJ, Zeng X, Gong W. Lightweight and tough polypropylene/silica nanoparticle composite foam nucleated from nanoparticles with intrinsic cavities for plastic structural components. ACS Appl Nano Mater. 2023;6(16):14967–79. 10.1021/acsanm.3c02523.Search in Google Scholar

(9) Kang SR, Ma LB, Yan P, Ma W. Study on preparation and properties of nano modification β-crystalline polypropylene high-performance materials. Chem Manag. 2023;145–7. 10.19900/j.cnki.ISSN1008-4800.2023.16.041.Search in Google Scholar

(10) Li Y, Han CY, Yu YC, Zhang HL, Wang Z. Study on blending modification of polypropylene and propylene ethylene copolymer. Plastic Technol. 2018;46(7):22–8. 10.15925/j.cnki.issn1005-3360.2018.07.005.Search in Google Scholar

(11) Dong L, Li L, Duan HY, Zhang DJ, Yang SY. Effect of α nucleating agent on mechanical and crystallization properties of PP(Article). Synth Resin Plastic. 2019;36(2):53–6. CNKI:SUN:HCSZ.0.2019-02-016.Search in Google Scholar

(12) Tan H, Guo X, Tan H, Zhang QL, Liu CH. Crystallization and mechanical properties of carbon nanotube/continuous carbon fiber/metallocene polypropylene composites. Mater Res Express. 2021;9(1):015302. 10.1088/2053-1591/ac46e6.Search in Google Scholar

(13) Scoti M, Stefano FD, Girolamo RD, Malafronte A, Talarico G. Model of crystallization behavior of isotactic polypropylene: The role of defects. Macromol Chem Phys. 2023;224(2):1–17. 10.1002/macp.202200262.Search in Google Scholar

(14) Liu G, Zhang X, Liu Y, Li X, Chen H, Walton K, et al. Effect of elastomer on crystalline transition and deformation behavior of isotactic polypropylene. Polymer. 2013;54(4):1440–7. 10.1016/j.polymer.2013.01.012.Search in Google Scholar

(15) Gu YX, Liu YX, Fan ZR, Gui JF, Liu P, Wang HM. Influence of β-nucleating compound agents on the mechanical properties and crystallization behavior of polypropylene random copolymer. J Wuhan Univ Technol-Mater. 2023;38(1):237–43. 10.1007/s11595-023-2687-7.Search in Google Scholar

(16) Ma YL, Wang JH, Zhang Y, Huang XX, Zeng S. Preparation and properties of high light and high transmittance CPP films. Plastic Ind. 2020;48(4):157–60, CNKI: SUN: SLGY.0.2020-04-032.Search in Google Scholar

(17) Ma YL, Huang XX, Wang JH, Zhang Y, Zeng S. Effect of erucic acid amide on properties of ternary PP membrane materials. Plastic Ind. 2018;(1):91–4. 10.3969/j.issn.1005-5770.2018.01.022.Search in Google Scholar

(18) Bahrami R, Bagher R. Effect of hybridization on crystallization behavior, mechanical properties, and toughening mechanisms in rubber-modified polypropylene flax fiber composites. J Composite Mater. 2022;56(17):2677–93. 10.1177/00219983221101.Search in Google Scholar

(19) Jiang WJ, Song XD, Zhou R, Wu ZK, Xiang M. Influences of molecular structure on the isothermal crystallization behavior and mechanical properties of β-nucleated isotactic polypropylene. Polym Technol Mater. 2020;59(17):1724–35. 10.1080/25740881.2020.1765388.Search in Google Scholar

(20) Zhang X, Zhao SC, Meng X, Xin Z. The mechanical properties, crystallization and rheological behavior of isotactic polypropylene with nucleating agent supported on polyhedral oligomeric silsesquioxanes (POSS). J Polym Res. 2020;27(10):2105–12. 10.1007/s10965-020-02260-9.Search in Google Scholar

(21) Simanke AG, Cangussú ME, Nyland L, Correia GF. Microstructure characterization of amorphous phase of polypropylene impact copolymers. Macromol Symposia. 2020;391(1):2000133. 10.1002/masy.202000133.Search in Google Scholar

(22) Ge Q, Wu T, Ding L, Yang F, Xiang M. Effect of annealing on microstructure and mechanical properties of polypropylene random copolymer. Soft Mater. 2019;17(1):1–13. 10.1080/1539445X.2018.1528456.Search in Google Scholar

(23) Tian HF, Zhang S, Ge X, Xiang AM. Crystallization behaviors and mechanical properties of carbon fiber-reinforced polypropylene composites. J Therm Anal Calorim. 2017;128(3):1495–540. 10.1007/s10973-016-5996-3.Search in Google Scholar

(24) Yang R, Ding L, Zhang X, Li JC. Nonisothermal crystallization, melting behaviors, and mechanical properties of isotactic polypropylene nucleated with a liquid crystalline polymer. Ind Eng Chem Res. 2018;57(6):2083–93. 10.1021/acs.iecr.7b04115.Search in Google Scholar

(25) Bandyopadhyay J, Mekoa R, Skosana S, Ray SS. Thermal properties and nonisothermal crystallization behaviour of polypropylene nanocomposite. Fract Damage Mech: Theory Simul Exp. 2020;2289(1):1–5. 10.1063/5.0029040.Search in Google Scholar

(26) Liu JR, Pan YT. Nucleation and crystallization behavior of isotactic polypropylene induced by zinc tetrahydrophthalate. Polym Bull. 2022;79(7):4563–80. 10.1007/s00289-021-03717-7.Search in Google Scholar

(27) Shi WJ, Xu Y, Qin J, Li X, Lv Q, Chen X, et al. Isothermal crystallization behaviors of isotactic polypropylene with ultrasonically-modified calcium sulfate whisker as β-nucleating agent. Polym Eng Sci. 2022;62(7):2219–29. 10.1002/pen.26002.Search in Google Scholar

(28) Luo SS, Wei LQ, Sun J, Huang AR, Qin SH, Luo H, et al. Crystallization behavior and optical properties of isotactic polypropylene filled with α-nucleating agents of multilayered distribution. RSC Adv. 2020;10(1):387–97. 10.1039/C9RA09485G.Search in Google Scholar

(29) Li YC, He S, He H, Yu P, Wang DQ. Study on low temperature toughness and crystallization behavior of polypropylene random copolymer(Article). J Polym Eng. 2017;37(7):715–27. 10.1515/polyeng-2016-0169.Search in Google Scholar

(30) Stan F, Turcanu Constantinescu A-M, Fetecau C. Analysis of viscoelastic behavior of polypropylene/carbon nanotube nanocomposites by instrumented indentation. Polymers. 2020;12(11):E2535. 10.3390/polym12112535.Search in Google Scholar PubMed PubMed Central

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Flame-retardant thermoelectric responsive coating based on poly(3,4-ethylenedioxythiphene) modified metal–organic frameworks

- Highly stretchable, durable, and reversibly thermochromic wrapped yarns induced by Joule heating: With an emphasis on parametric study of elastane drafts

- Molecular dynamics simulation and experimental study on the mechanical properties of PET nanocomposites filled with CaCO3, SiO2, and POE-g-GMA

- Multifunctional hydrogel based on silk fibroin/thermosensitive polymers supporting implant biomaterials in osteomyelitis

- Marine antifouling coating based on fluorescent-modified poly(ethylene-co-tetrafluoroethylene) resin

- Preparation and application of profiled luminescent polyester fiber with reversible photochromism materials

- Determination of pesticide residue in soil samples by molecularly imprinted solid-phase extraction method

- The die swell eliminating mechanism of hot air assisted 3D printing of GF/PP and its influence on the product performance

- Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes

- The effects of property variation on the dripping behaviour of polymers during UL94 test simulated by particle finite element method

- Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets

- Synthesis, characterization and evaluation of a pH-responsive molecular imprinted polymer for Matrine as an intelligent drug delivery system

- Twist-related parametric optimization of Joule heating-triggered highly stretchable thermochromic wrapped yarns using technique for order preference by similarity to ideal solution

- Comparative analysis of flow factors and crystallinity in conventional extrusion and gas-assisted extrusion

- Simulation approach to study kinetic heterogeneity of gadolinium catalytic system in the 1,4-cis-polyisoprene production

- Properties of kenaf fiber-reinforced polyamide 6 composites

- Cellulose acetate filter rods tuned by surface engineering modification for typical smoke components adsorption

- A blue fluorescent waterborne polyurethane-based Zn(ii) complex with antibacterial activity

- Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading

- Preparation and application research of composites with low vacuum outgassing and excellent electromagnetic sealing performance

- Assessing the recycling potential of thermosetting polymer waste in high-density polyethylene composites for safety helmet applications

- Mesoscale mechanics investigation of multi-component solid propellant systems

- Preparation of HTV silicone rubber with hydrophobic–uvioresistant composite coating and the aging research

- Experimental investigation on tensile behavior of CFRP bolted joints subjected to hydrothermal aging

- Structure and transition behavior of crosslinked poly(2-(2-methoxyethoxy) ethylmethacrylate-co-(ethyleneglycol) methacrylate) gel film on cellulosic-based flat substrate

- Mechanical properties and thermal stability of high-temperature (cooking temperature)-resistant PP/HDPE/POE composites

- Preparation of itaconic acid-modified epoxy resins and comparative study on the properties of it and epoxy acrylates

- Synthesis and properties of novel degradable polyglycolide-based polyurethanes

- Fatigue life prediction method of carbon fiber-reinforced composites

- Thermal, morphological, and structural characterization of starch-based bio-polymers for melt spinnability

- Robust biaxially stretchable polylactic acid films based on the highly oriented chain network and “nano-walls” containing zinc phenylphosphonate and calcium sulfate whisker: Superior mechanical, barrier, and optical properties

- ARGET ATRP of styrene with low catalyst usage in bio-based solvent γ-valerolactone

- New PMMA-InP/ZnS nanohybrid coatings for improving the performance of c-Si photovoltaic cells

- Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites

- Preparation of cardanol-based curing agent for underwater drainage pipeline repairs

- Preparation of lightweight PBS foams with high ductility and impact toughness by foam injection molding

- Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study

- Experimental study on impact and flexural behaviors of CFRP/aluminum-honeycomb sandwich panel

- Normal-hexane treatment on PET-based waste fiber depolymerization process

- Effect of tannic acid chelating treatment on thermo-oxidative aging property of natural rubber

- Design, synthesis, and characterization of novel copolymer gel particles for water-plugging applications

- Influence of 1,1′-Azobis(cyclohexanezonitrile) on the thermo-oxidative aging performance of diolefin elastomers

- Characteristics of cellulose nanofibril films prepared by liquid- and gas-phase esterification processes

- Investigation on the biaxial stretching deformation mechanism of PA6 film based on finite element method

- Simultaneous effects of temperature and backbone length on static and dynamic properties of high-density polyethylene-1-butene copolymer melt: Equilibrium molecular dynamics approach

- Research on microscopic structure–activity relationship of AP particle–matrix interface in HTPB propellant

- Three-layered films enable efficient passive radiation cooling of buildings

- Electrospun nanofibers membranes of La(OH)3/PAN as a versatile adsorbent for fluoride remediation: Performance and mechanisms

- Preparation and characterization of biodegradable polyester fibers enhanced with antibacterial and antiviral organic composites

- Preparation of hydrophobic silicone rubber composite insulators and the research of anti-aging performance

- Surface modification of sepiolite and its application in one-component silicone potting adhesive

- Study on hydrophobicity and aging characteristics of epoxy resin modified with nano-MgO

- Optimization of baffle’s height in an asymmetric twin-screw extruder using the response surface model

- Effect of surface treatment of nickel-coated graphite on conductive rubber

- Experimental investigation on low-velocity impact and compression after impact behaviors of GFRP laminates with steel mesh reinforced

- Development and characterization of acetylated and acetylated surface-modified tapioca starches as a carrier material for linalool

- Investigation of the compaction density of electromagnetic moulding of poly(ether-ketone-ketone) polymer powder

- Experimental investigation on low-velocity-impact and post-impact-tension behaviors of GFRP T-joints after hydrothermal aging

- The repeated low-velocity impact response and damage accumulation of shape memory alloy hybrid composite laminates

- Exploring a new method for high-performance TPSiV preparation through innovative Si–H/Pt curing system in VSR/TPU blends

- Large-scale production of highly responsive, stretchable, and conductive wrapped yarns for wearable strain sensors

- Preparation of natural raw rubber and silica/NR composites with low generation heat through aqueous silane flocculation

- Molecular dynamics simulation of the interaction between polybutylene terephthalate and A3 during thermal-oxidative aging

- Crashworthiness of GFRP/aluminum hybrid square tubes under quasi-static compression and single/repeated impact

- Review Articles

- Recent advancements in multinuclear early transition metal catalysts for olefin polymerization through cooperative effects

- Impact of ionic liquids on the thermal properties of polymer composites

- Recent progress in properties and application of antibacterial food packaging materials based on polyvinyl alcohol

- Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters

- Rapid Communication

- Design, synthesis, characterization, and adsorption capacities of novel superabsorbent polymers derived from poly (potato starch xanthate-graft-acrylamide)

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Development of smart core–shell nanoparticles-based sensors for diagnostics of salivary alpha-amylase in biomedical and forensics

- Thermoplastic-polymer matrix composite of banana/betel nut husk fiber reinforcement: Physico-mechanical properties evaluation

- Special Issue: Electrospun Functional Materials

- Electrospun polyacrylonitrile/regenerated cellulose/citral nanofibers as active food packagings

Articles in the same Issue

- Research Articles

- Flame-retardant thermoelectric responsive coating based on poly(3,4-ethylenedioxythiphene) modified metal–organic frameworks

- Highly stretchable, durable, and reversibly thermochromic wrapped yarns induced by Joule heating: With an emphasis on parametric study of elastane drafts

- Molecular dynamics simulation and experimental study on the mechanical properties of PET nanocomposites filled with CaCO3, SiO2, and POE-g-GMA

- Multifunctional hydrogel based on silk fibroin/thermosensitive polymers supporting implant biomaterials in osteomyelitis

- Marine antifouling coating based on fluorescent-modified poly(ethylene-co-tetrafluoroethylene) resin

- Preparation and application of profiled luminescent polyester fiber with reversible photochromism materials

- Determination of pesticide residue in soil samples by molecularly imprinted solid-phase extraction method

- The die swell eliminating mechanism of hot air assisted 3D printing of GF/PP and its influence on the product performance

- Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes

- The effects of property variation on the dripping behaviour of polymers during UL94 test simulated by particle finite element method

- Experimental evaluation on compression-after-impact behavior of perforated sandwich panel comprised of foam core and glass fiber reinforced epoxy hybrid facesheets

- Synthesis, characterization and evaluation of a pH-responsive molecular imprinted polymer for Matrine as an intelligent drug delivery system

- Twist-related parametric optimization of Joule heating-triggered highly stretchable thermochromic wrapped yarns using technique for order preference by similarity to ideal solution

- Comparative analysis of flow factors and crystallinity in conventional extrusion and gas-assisted extrusion

- Simulation approach to study kinetic heterogeneity of gadolinium catalytic system in the 1,4-cis-polyisoprene production

- Properties of kenaf fiber-reinforced polyamide 6 composites

- Cellulose acetate filter rods tuned by surface engineering modification for typical smoke components adsorption

- A blue fluorescent waterborne polyurethane-based Zn(ii) complex with antibacterial activity

- Experimental investigation on damage mechanism of GFRP laminates embedded with/without steel wire mesh under low-velocity-impact and post-impact tensile loading

- Preparation and application research of composites with low vacuum outgassing and excellent electromagnetic sealing performance

- Assessing the recycling potential of thermosetting polymer waste in high-density polyethylene composites for safety helmet applications

- Mesoscale mechanics investigation of multi-component solid propellant systems

- Preparation of HTV silicone rubber with hydrophobic–uvioresistant composite coating and the aging research

- Experimental investigation on tensile behavior of CFRP bolted joints subjected to hydrothermal aging

- Structure and transition behavior of crosslinked poly(2-(2-methoxyethoxy) ethylmethacrylate-co-(ethyleneglycol) methacrylate) gel film on cellulosic-based flat substrate

- Mechanical properties and thermal stability of high-temperature (cooking temperature)-resistant PP/HDPE/POE composites

- Preparation of itaconic acid-modified epoxy resins and comparative study on the properties of it and epoxy acrylates

- Synthesis and properties of novel degradable polyglycolide-based polyurethanes

- Fatigue life prediction method of carbon fiber-reinforced composites

- Thermal, morphological, and structural characterization of starch-based bio-polymers for melt spinnability

- Robust biaxially stretchable polylactic acid films based on the highly oriented chain network and “nano-walls” containing zinc phenylphosphonate and calcium sulfate whisker: Superior mechanical, barrier, and optical properties

- ARGET ATRP of styrene with low catalyst usage in bio-based solvent γ-valerolactone

- New PMMA-InP/ZnS nanohybrid coatings for improving the performance of c-Si photovoltaic cells

- Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites

- Preparation of cardanol-based curing agent for underwater drainage pipeline repairs

- Preparation of lightweight PBS foams with high ductility and impact toughness by foam injection molding

- Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study

- Experimental study on impact and flexural behaviors of CFRP/aluminum-honeycomb sandwich panel

- Normal-hexane treatment on PET-based waste fiber depolymerization process

- Effect of tannic acid chelating treatment on thermo-oxidative aging property of natural rubber

- Design, synthesis, and characterization of novel copolymer gel particles for water-plugging applications

- Influence of 1,1′-Azobis(cyclohexanezonitrile) on the thermo-oxidative aging performance of diolefin elastomers

- Characteristics of cellulose nanofibril films prepared by liquid- and gas-phase esterification processes

- Investigation on the biaxial stretching deformation mechanism of PA6 film based on finite element method

- Simultaneous effects of temperature and backbone length on static and dynamic properties of high-density polyethylene-1-butene copolymer melt: Equilibrium molecular dynamics approach

- Research on microscopic structure–activity relationship of AP particle–matrix interface in HTPB propellant

- Three-layered films enable efficient passive radiation cooling of buildings

- Electrospun nanofibers membranes of La(OH)3/PAN as a versatile adsorbent for fluoride remediation: Performance and mechanisms

- Preparation and characterization of biodegradable polyester fibers enhanced with antibacterial and antiviral organic composites

- Preparation of hydrophobic silicone rubber composite insulators and the research of anti-aging performance

- Surface modification of sepiolite and its application in one-component silicone potting adhesive

- Study on hydrophobicity and aging characteristics of epoxy resin modified with nano-MgO

- Optimization of baffle’s height in an asymmetric twin-screw extruder using the response surface model

- Effect of surface treatment of nickel-coated graphite on conductive rubber

- Experimental investigation on low-velocity impact and compression after impact behaviors of GFRP laminates with steel mesh reinforced

- Development and characterization of acetylated and acetylated surface-modified tapioca starches as a carrier material for linalool

- Investigation of the compaction density of electromagnetic moulding of poly(ether-ketone-ketone) polymer powder

- Experimental investigation on low-velocity-impact and post-impact-tension behaviors of GFRP T-joints after hydrothermal aging

- The repeated low-velocity impact response and damage accumulation of shape memory alloy hybrid composite laminates

- Exploring a new method for high-performance TPSiV preparation through innovative Si–H/Pt curing system in VSR/TPU blends

- Large-scale production of highly responsive, stretchable, and conductive wrapped yarns for wearable strain sensors

- Preparation of natural raw rubber and silica/NR composites with low generation heat through aqueous silane flocculation

- Molecular dynamics simulation of the interaction between polybutylene terephthalate and A3 during thermal-oxidative aging

- Crashworthiness of GFRP/aluminum hybrid square tubes under quasi-static compression and single/repeated impact

- Review Articles

- Recent advancements in multinuclear early transition metal catalysts for olefin polymerization through cooperative effects

- Impact of ionic liquids on the thermal properties of polymer composites

- Recent progress in properties and application of antibacterial food packaging materials based on polyvinyl alcohol

- Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters

- Rapid Communication

- Design, synthesis, characterization, and adsorption capacities of novel superabsorbent polymers derived from poly (potato starch xanthate-graft-acrylamide)

- Special Issue: Biodegradable and bio-based polymers: Green approaches (Guest Editors: Kumaran Subramanian, A. Wilson Santhosh Kumar, and Venkatajothi Ramarao)

- Development of smart core–shell nanoparticles-based sensors for diagnostics of salivary alpha-amylase in biomedical and forensics

- Thermoplastic-polymer matrix composite of banana/betel nut husk fiber reinforcement: Physico-mechanical properties evaluation

- Special Issue: Electrospun Functional Materials

- Electrospun polyacrylonitrile/regenerated cellulose/citral nanofibers as active food packagings