Abstract

The fatigue life of polymer materials like epoxy can be improved by using stiffeners such as carbon fiber and/or adding multiwall carbon nanotubes (MWCNTs). This article studies the effect of adding MWCNTs with different ratios (0.5, 1, and 2 wt%) to epoxy and composite (epoxy + 30% carbon fibers). The experimental results of the fatigue test with fully reversed bending stress (with R = −1) showed a maximum increase of 788% in fatigue life when adding 1 wt% MWCNTs to epoxy, while the maximum improvement ratio reaches 2,500% when adding 1 wt% MWCNTs to composite. The best results of fatigue life improvement were observed for samples with MWCNTs of 1 wt%. The material will be transferred from low cycle fatigue (less than 105 cycles) to high cycle fatigue (more than 105 cycles) by adding 1 wt% of MWCNTs. At the same time, the ratio of MWCNTs of more than 1 wt% (such as 2 wt%) will decrease the fatigue life due to the agglomeration of nanotubes inside the resin and reduce the positive effect of it. These agglomeration points work as a barrier to load transfer and stress concentration points. The numerical model was built to simulate the fatigue test and compare the results with the experimental with a discrepancy value of 7.5%.

1 Introduction

Composites are utilized in various structures, including automotive, airplanes, and space crafts, because of their excellent characteristics of hardness-to-density and strength-to-density ratios [1]. Owing to its light weight, high tensile strength, and superior corrosion and fatigue resistance, carbon fiber reinforced polymer has been widely used in the fields of aircraft, ships, and automobiles [2]. In this case, the used materials are subjected to cyclic loadings, triggering questions concerning their fatigue behavior [3]. In lightweight applications, a composite made of epoxy and carbon fibers has higher/better properties than usual materials such as aluminum, copper, and steel. Still, it is inferior to other materials for high-load applications. The chassis of a vehicle will experience various loading, including fatigue, lateral bending, and longitudinal torsion loading [4]. A fundamental problem in the composite material is fatigue load, which is a major concern. Since composite materials are anisotropic and heterogeneous, the fatigue behavior is more complicated, particularly in applications of structures with high loads. The composite materials exhibit a highly complex failure mechanism under fatigue loading. Fatigue failure in composite materials occurs for the following reasons: matrix cracking, fiber breakage, casting defects, and their interaction [5]. Tang et al. [6] studied the effect of multiwall carbon nanotubes (MWCNTs) on the thermal conductivity and mechanical properties of epoxy resin, like tensile strength, Young modulus, and impact toughness. The results showed increases in the thermal conductivity by about 61%, and mechanical properties improved with a range of 30–45% when adding about 0.5 wt% of MWCNTs to the pure epoxy resin. Wang et al. [7] presented the effect of adding carbon nanotubes (CNTs) to the composite of (epoxy + glass fibers) on the strength and toughness of the composite. The results showed improvement in the interlaminar shear strength and toughness with a 28 and 189% ratio when adding CNTs to epoxy glass fiber composite. Jen and Ni [8] experimentally studied the effect of adding CNT and graphene nanoplates on the fatigue properties of carbon fiber-reinforced epoxy materials. The results showed that the samples with a 9:1 MWCNT-to-graphene nanoparticle (GNP) ratio improved fatigue strength and life. Turaka et al. [9] concluded the effect of adding MWCNT and GNPs in the range of 0.1–0.3 wt% to the glass fiber/epoxy composite on the fatigue life of the composite. The results showed that the fatigue life increased by 56% when using MWCNT/GNPs of 0.2 wt%. Genedy et al. [10] presented the effect of adding the MWCN with a ratio of 0.5 and 1 wt% to the glass fiber-reinforced plastics (GFRPs). The results showed a maximum improvement of 1,143% in fatigue life of GFRP when using MWCNT of 0.5 wt%. Böger et al. [11] concluded the influence of adding CNTS to the glass fiber/epoxy hybrid composite. The results presented the positive effect of adding CNTs in increasing the fatigue life of the composite material to more than 50%. The properties of composites are greatly affected by the nature of bonding at the interface, the strength of the interface, and the mechanical load transfer from the surrounding matrix to nanotubes. Shokrieh et al. [12] presented the effect of experimentally adding nanographene platelets to the nanocomposite of the epoxy matrix with ratios of 0.1, 0.25, and 0.5 wt%. These results showed that the fatigue life on nanocomposite would increase about 27 times compared with neat epoxy. Mahdi and Alithari [13] investigated the effect of adding nanoparticle additives on the mechanical properties of epoxy/Kevlar fiber composite. The nanographene platelets were added in three different percentages of 0.5, 1, and 2 wt%. The results showed improvement in material stiffness reaching 134 and 90% for flexure strength. Islam et al. [14] presented a review of the effects of adding CNTs to composite and the agglomeration effects of CNTs inside the resin on reducing the properties of the composite. The present work studies the effects of adding MWCNTs to the epoxy and composite on the fatigue life and how that will enhance the composite’s working life subjected to fully reversed loads and how to transfer the material from low fatigue life to high fatigue life.

2 Materials and methods

2.1 Materials

The materials used in preparing the composite samples for fatigue tests from resin and reinforcement materials (carbon fibers and/or MWCNTs) are summarized as follows:

2.1.1 Epoxy resin

Renksan-Renfloor HT 2000 is the epoxy resin used in this study, and it is used as a matrix for the composite material; it has properties such as low viscosity, low creep, good mechanical resistance, transparent color, and mixing ratio with its hardener at 2 epoxy/1 hardener. The epoxy was used as the matrix system to develop a composite material. Table 1 shows the properties of this type of epoxy [13].

Properties of epoxy [13]

| Property | Density (kg/m3) | Viscosity (Poise) at 35°C | Compression strength (MPa) | Fracture toughness (MPa-m½) | Tensile strength (MPa) | Bending strength (MPa) | Modulus of elasticity (GPa) |

|---|---|---|---|---|---|---|---|

| Epoxy | 1,050 | 1 | 70 | 0.6 | 27 | 63 | 2.8 |

2.1.2 Fibers

Properties of carbon fiber used as reinforcement with trade name (SikaWrap®-300 C/60) made by Sika from Italy are shown in Table 2 [15].

Carbon fiber properties [15]

| Type | Density (kg/m3) | Tensile strength (MPa) | Young’s modulus (GPa) | Poisson’s ratio | Color |

|---|---|---|---|---|---|

| Carbon fiber | 1,800 | 4,000 | 230 | 0.2 | Black |

2.1.3 MWCNTs

MWCNTs (shown in Figure 1) are used as nanoadditives to epoxy to improve its properties. The MWCNTs were made by combustion chemical vapor deposition and purified using concentrated acid chemistry with a purity of 90%, an outer diameter of 20–40 nm, and a length of 10–30 µm. Table 3 shows the properties of MWCNTs [16,17].

![Figure 1

MWCNTs [17].](/document/doi/10.1515/eng-2022-0490/asset/graphic/j_eng-2022-0490_fig_001.jpg)

MWCNTs [17].

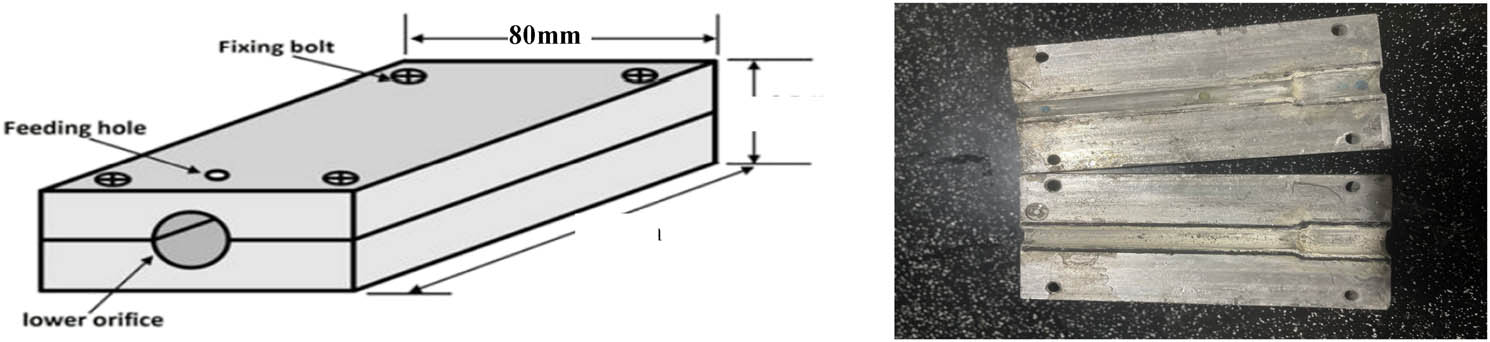

2.2 Mold preparation

The hand layout method was used to manufacture the composite samples from epoxy and composite with and without MWCNTs with different ratios of 0.5, 1, and 2 wt%.

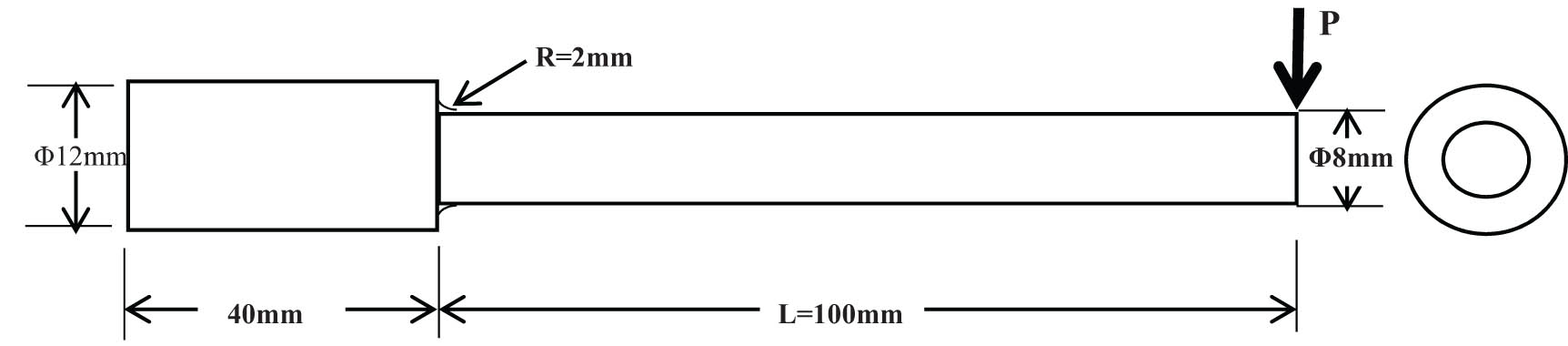

Figure 2 shows that the open metallic mold was used to produce a fatigue test of rotating bending composite samples with dimensions shown in Figure 3.

Metalic mold.

Dimensions of composite sample for fatigue test.

2.2.1 Mixing process of MWCNTs with epoxy resin [18,19]

The MWCNTs are mixed with epoxy resin at three ratios, i.e., 0.5, 1, and 2 wt%.

The epoxy was mixed with MWCNTs mechanically by a shear mixer with the speed of 2,000 rpm for 30 min and then sonicated with a high-power (250 W) sonic dismembrator type MTI for 30 min with a probe diameter of 20 mm. The sonication power increased gradually until it reached 250 W, maintaining the mixture’s temperature at 30°C using the ice jacket that worked as a heat sink to avoid overheating inside the sonication vessel. Then the mixture was placed inside a vacuum oven at 40°C for 30 min to remove the bubbles that may be found in the mixture and then poured into the mixture hardener with a ratio of 1:2 and mixed mechanically for 30 min. Before curing, the mixture was degassed under vacuum at 25 ± 5°C for 30 min, and then the mixture was poured into a metallic mold using the technique of slow injection by a feeding tube to completely produce fatigue test samples with a volume fraction of fibers of 30%, as shown in Figure 4.

Fatigue tests samples: (a) without MWCNTs and (b) with MWCNTs.

The Halpin-Tsai mathematical model was used to determine the modulus of elasticity for nanocomposite samples depending on the geometry and orientation of reinforcement and the values of elastic modulus of matrix E m and for nanomaterial E n [20].

where

2.3 Samples test

2.3.1 Fatigue Test

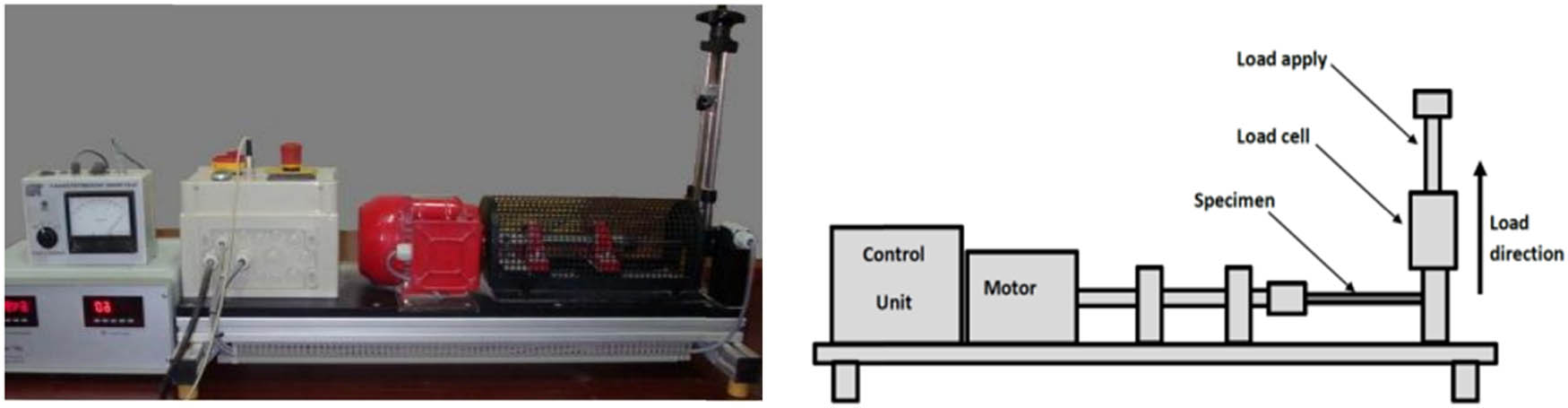

The fatigue test (rotating bending) for composite specimens was done according to the standard specification of ASTM E467-21 [21], using a fatigue tester machine of GUNT from Germany, as shown in Figure 5, with applying different load values on the rotating samples to produce fully reversed bending stress of 15, 20, 25, and 30 MPa (chosen according to past researches) on cantilever rotating shaft with a stress ratio of R = −1, and to calculate the average value of a number of cycles for five testing samples for each test [22,23].

Parts of test machine.

The bending stress can be calculated as follows [22,23]:

where

where F is the applied bending load (N), L is the active length of the sample (m), y is the maximum distance of the surface from the center of cross-section (m), and I moment of inertia of sample (m4).

where d is the diameter of the sample (m).

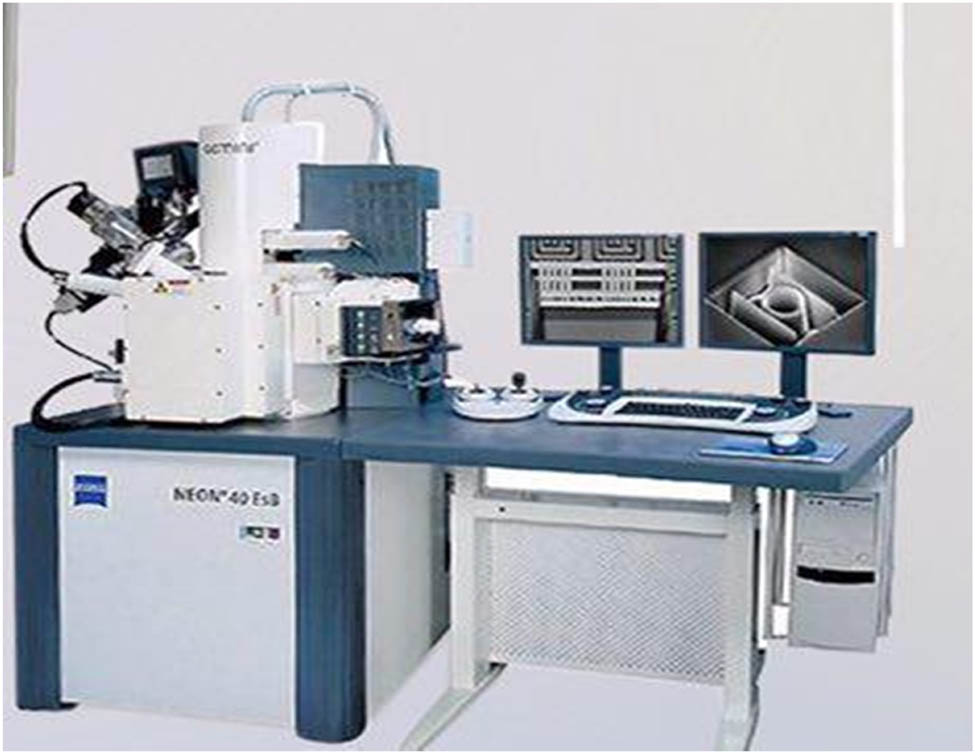

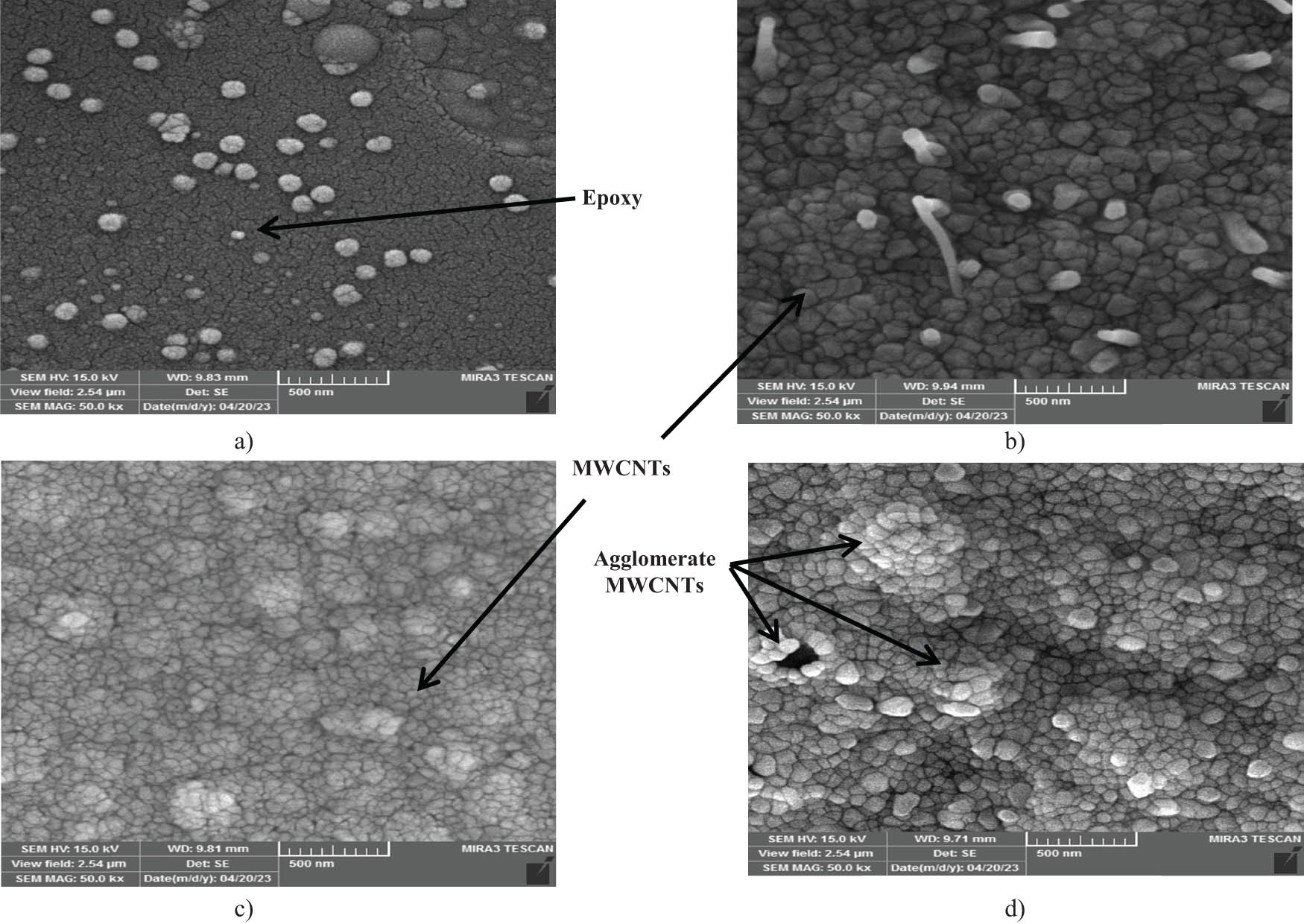

2.3.2 Scanning electron microscope (SEM) test

The test composite samples were observed under SEM to obtain high-resolution images of MWCNTs distribution inside the resin and to know how that affects the properties of the composite especially fatigue life. Figure 6 show the SEM.

Scanning electron microscopy.

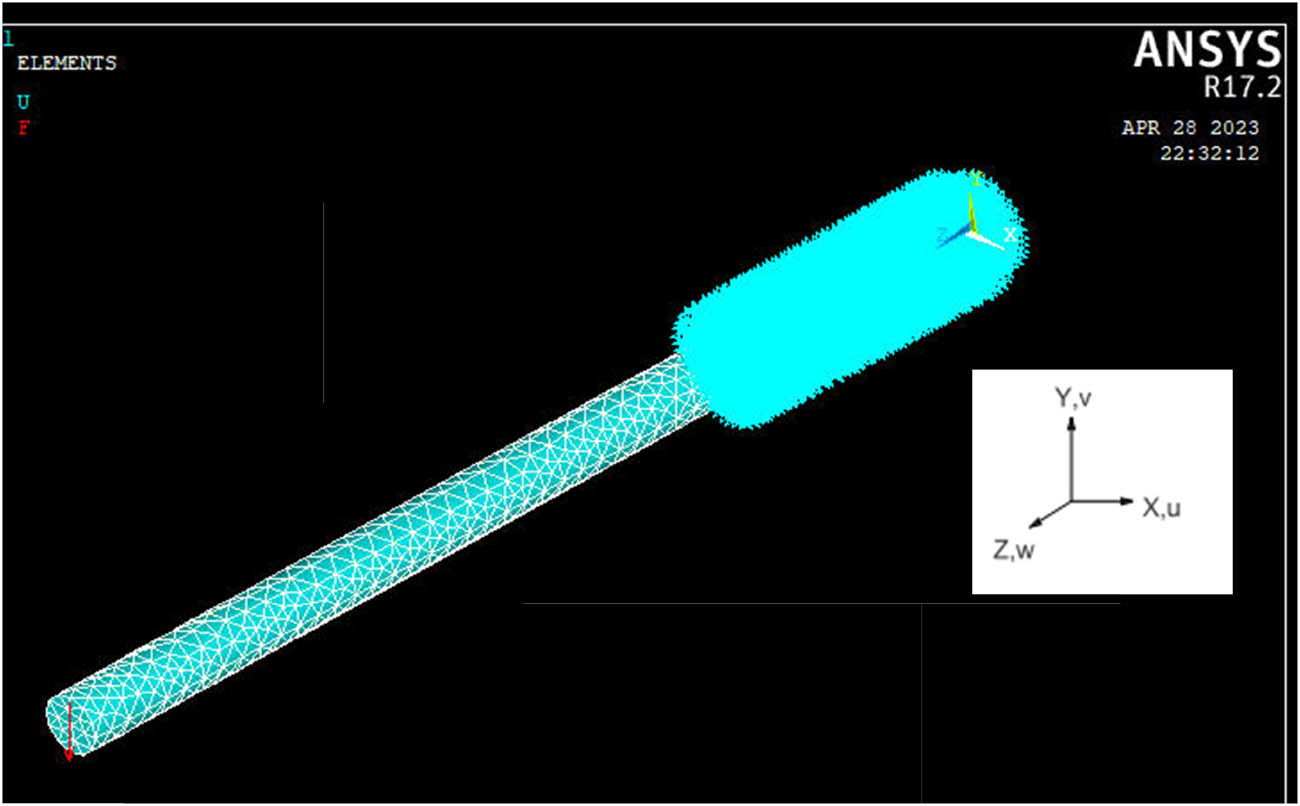

2.4 Numerical models

The numerical model for fatigue analysis was done using the finite element method using ANSYS Workbench R17.2 to simulate the fatigue test with 10860 elements of element type solid 187 (3D 10-node tetrahedral), as shown in Figure 7 [13].

![Figure 7

Tetrahedral element of 3D solid187 [13].](/document/doi/10.1515/eng-2022-0490/asset/graphic/j_eng-2022-0490_fig_007.jpg)

Tetrahedral element of 3D solid187 [13].

Figure 8 shows the finite element meshed model for fatigue test for epoxy resin only, epoxy + MWCNTs with different weight ratios 0.5, 1, and 2 wt%, and composite (epoxy with carbon fiber of 30% volume fraction with and without MWCNTs). The sample is fixed in X, Y, and Z directions at the fixed end and freely rotates about the Z-axis with a bending load at the free end to produce fully reversed bending fatigue stress with R = −1 to set the same boundary conditions of experimental work. The numerical results are compared with experimental results.

Numerical model of fatigue test sample.

3 Results and discussion

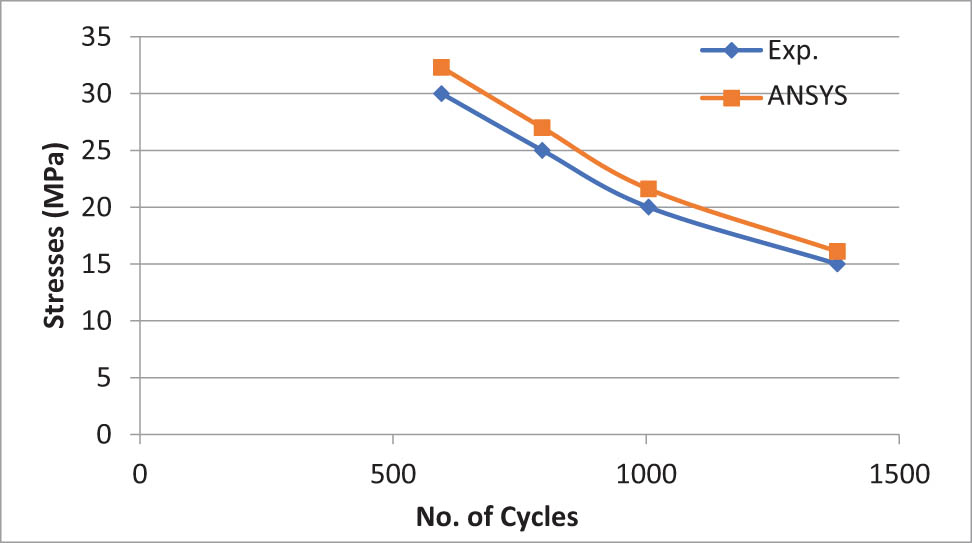

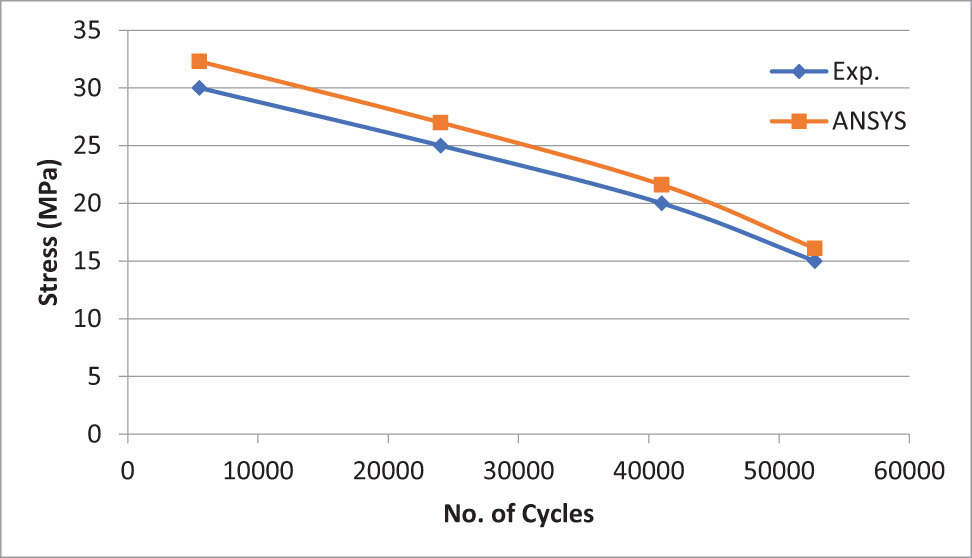

Figure 9 shows the S–N curve of the epoxy sample for different values of bending stresses for experimental and numerical analyses. This figure shows the experimental low values of fatigue life for the epoxy resin that ranged between 1,378 cycles at bending stress of 15 MPa and 596 cycles at 30 MPa due to the high possibility of crack initiation and propagation in the epoxy resin with low toughness property that leads to increasing ability of fatigue failure with very low life cycles. The divergence between the experimental and numerical results was 7.5%.

S–N curve for epoxy resin.

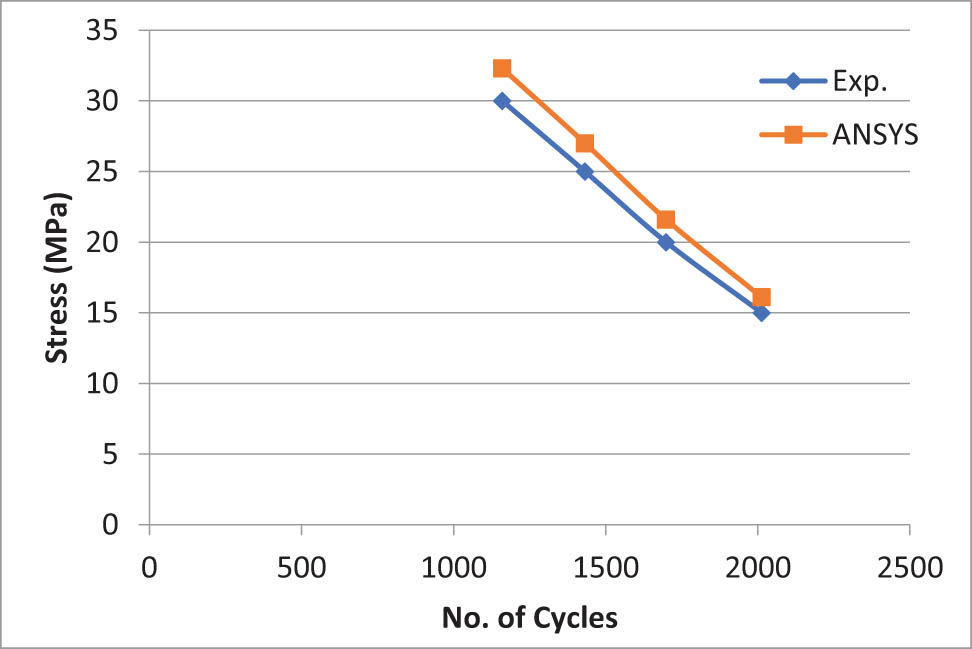

Figure 10 shows the S–N curve for the composite sample of epoxy + 30% carbon fiber experimentally and numerically. This figure shows that fatigue life ranged between 2,013 cycles at a bending stress of 15 MPa and 1,160 cycles at a bending stress of 30 MPa, with an increasing ratio in fatigue life of 46% compared with epoxy only due to the positive effect of adding the carbon fiber that had high mechanical properties such as high strength and high Young modulus that improve the fatigue life of the composite.

S–N curve for composite (epoxy + 30% carbon fiber).

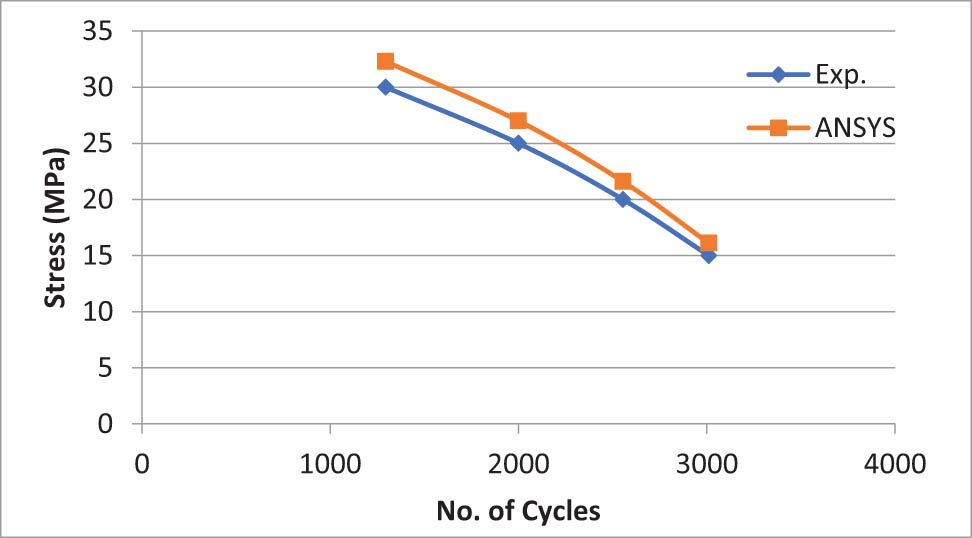

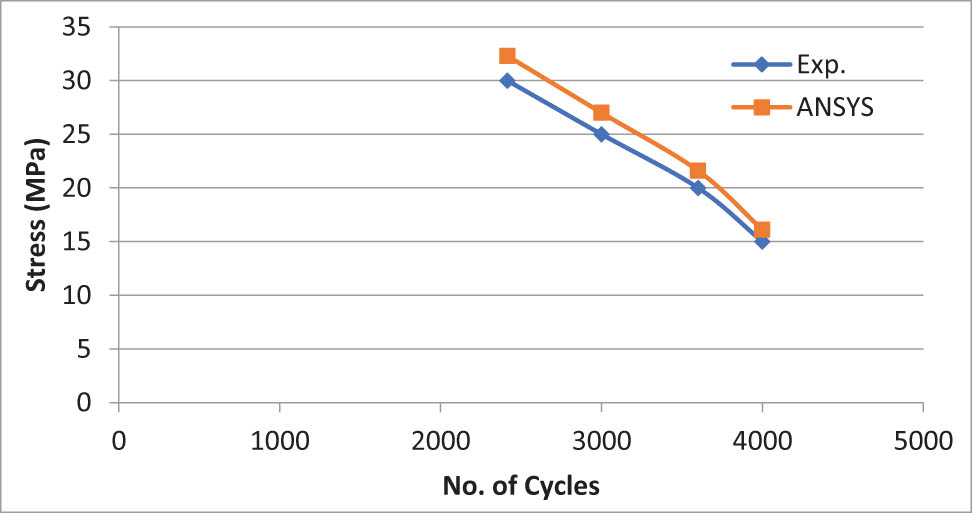

Figure 11 shows the S–N curve for samples of (epoxy + 0.5 wt% MWCNTs) experimentally and numerically. This figure shows the effect of adding MWCNTs to the epoxy and how that affected fatigue life. The fatigue ranged between 3,011 cycles at bending stress of 15 MPa and 1,295 cycles at bending stress of 30 MPa, with an increasing ratio for fatigue life of 118% due to the positive effect of adding MWCNTs that had a high interface with epoxy and work as micro stiffeners that gave extra strength and stiffness to the composite, helped in stress transfer between nanomaterials, and reduced the ability to initiate the micro-cracks inside epoxy that may lead to starting of fatigue failure.

S–N curve for nanocomposite (epoxy + 0.5 wt% MWCNTs).

Figure 12 shows the S–N curve for composite samples of (epoxy + 30% carbon fiber + 0.5 wt% MWCNTs) experimentally and numerically. This figure shows the dual effect of adding carbon fiber and MWCNTs on the fatigue life of epoxy. The fatigue life ranged from 4,000 cycles at the stress of 15 MPa to 2,415 cycles at 30 MPa, thus increasing fatigue life by about 99% compared with composite samples. This improves fatigue life due to the effect of MWCNTs that have a good interface with epoxy and increase composite strength, stress transfer between nanomaterials, reduce the crack initiation ability, and increase fatigue life.

S–N curve for hybrid composite (epoxy + 30% carbon fiber + 0.5 wt% MWCNTs).

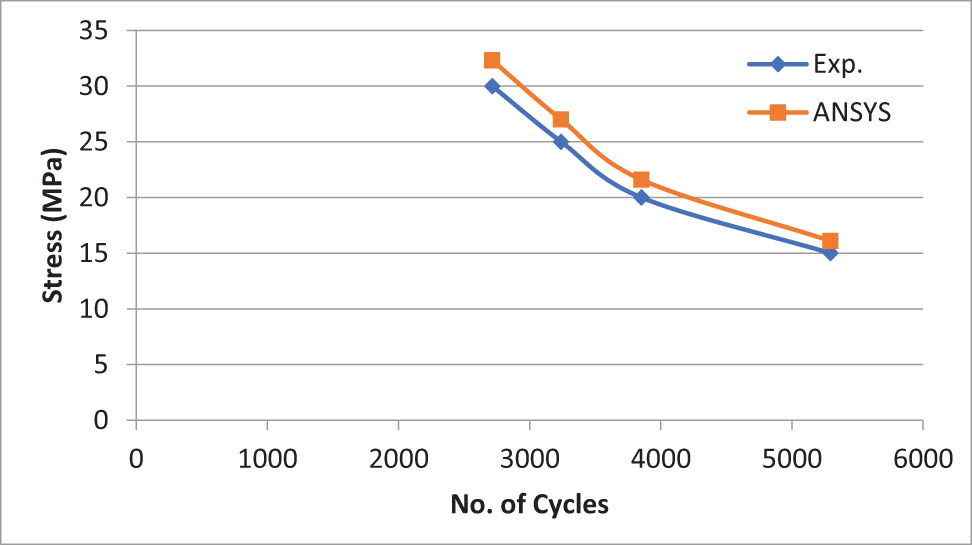

Figure 13 shows the S–N curve for samples of epoxy + 1 wt% MWCNTs experimentally and numerically. This figure shows the effect of adding 1 wt% of MWCNTs to the epoxy and how that will improve the fatigue life. The fatigue life ranged from 5,295 cycles at the stress of 15 MPa to 2,715 cycles at 30 MPa, with the increasing ratio in fatigue life by 788% due to MWCNTs increase in the strength and stiffness of epoxy, stress transfer between nanomaterials, and decrease in the ability of crack initiation and propagation that causes fatigue failure.

S–N curve for nanocomposite (epoxy + 1 wt% MWCNTs).

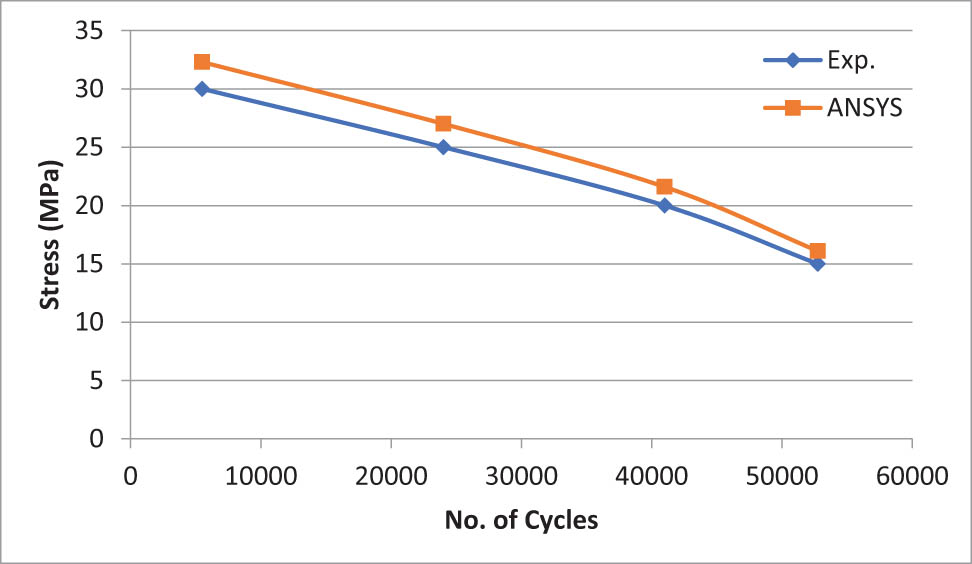

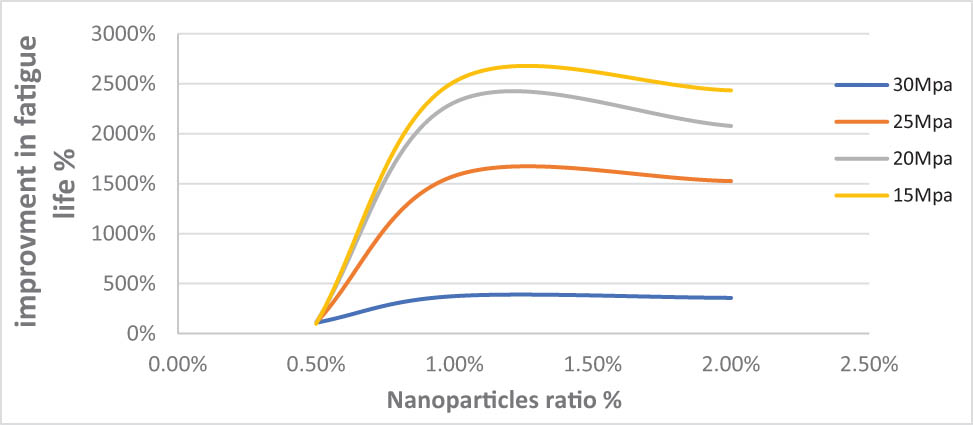

Figure 14 shows the S–N curve for composite samples of (epoxy + 30% carbon fiber + 1 wt% MWCNTs) experimentally and numerically. This figure shows the dual effect of adding carbon fiber and MWCNTs on the fatigue life of epoxy. The fatigue life ranged from 52,756 cycles at the stress of 15 MPa to 5,500 cycles at 30 MPa, thus increasing the fatigue life by about 2,500% compared with composite without nanomaterials. The material will be transferred from low cycle fatigue (LCF; less than 105 cycles) to high cycle fatigue (HCF; more than 105 cycles) by adding 1 wt% of MWCNTs. The improvement in fatigue life is due to the effect of MWCNTs that increase the strength and stiffness, help in stress transfer between nanomaterials, and reduce the ability of crack initiation and growth, leading to increasing fatigue life.

S–N curve for hybrid composite (epoxy + 30% carbon fiber 1 wt% MWCNTs).

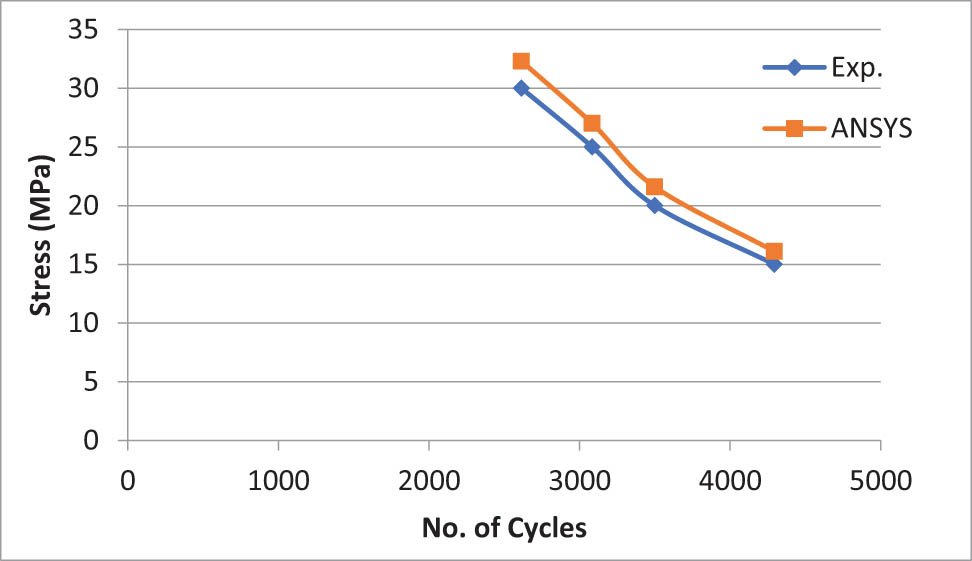

Figure 15 shows the S–N curve for samples of epoxy + 2 wt% MWCNTs experimentally and numerically. This figure shows the effect of adding 2 wt% of MWCNTs to the epoxy and how that will improve the fatigue life. The fatigue life ranged from 4,294 cycles at the stress of 15 MPa to 2,615 cycles at the stress of 30 MPa with an improving ratio in fatigue life of 620% due to the effect of MWCNTs that work as microstiffeners with epoxy to increase the strength, help in stress transfer between nanomaterials, and reduce the ability of crack initiation crack growth.

S–N curve for nanocomposite (epoxy + 2 wt% MWCNTs).

Figure 16 shows the S–N curve for composite samples of epoxy + 30% carbon fiber + 2 wt% MWCNTs experimentally and numerically. This figure shows the dual effect of adding carbon fiber and MWCNTs on the fatigue life of epoxy. The fatigue life ranged from 51,000 cycles at the stress of 15 MPa to 5,299 cycles at 30 MPa, increasing fatigue life by about 2,430% compared with composite without nanomaterials. The improvement in fatigue life is due to the effect of MWCNTs that reduces the crack initiation and growth ability, increasing the fatigue life.

S–N curve for hybrid composite (epoxy + 30% carbon fiber 0.5 wt% MWCNTs).

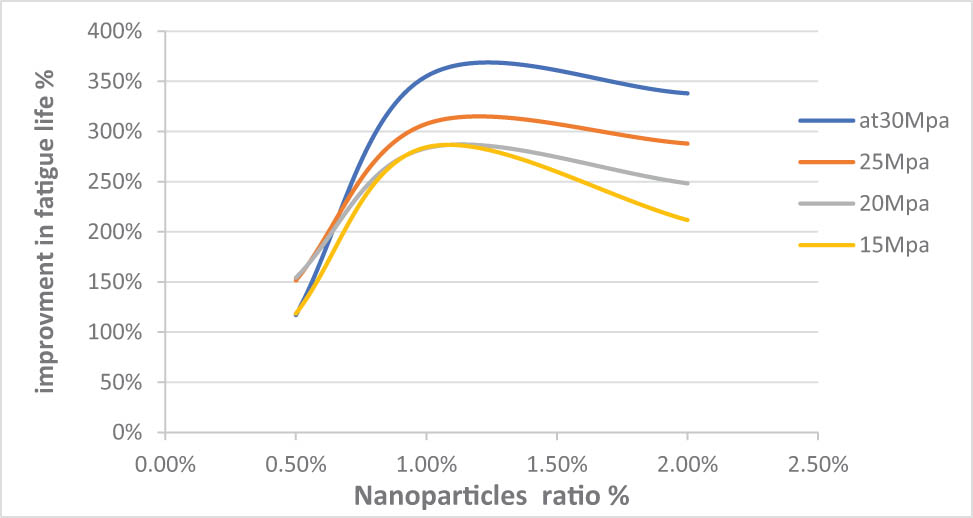

Figure 17 shows the ratio of improvement in fatigue life for the epoxy when adding MWCNTs with different ratios of 0.5, 1, and 2 wt% experimentally. This figure shows the positive effect of adding MWCNTs and how they work as stiffeners for epoxy. It increases the strength and stiffness of the composite, reduces the ability of crack initiation and growth inside the epoxy, and enhances its fatigue life. The best-adding ratio was 1 wt%, giving the best fatigue life for epoxy.

The improvement ratio of fatigue life of nanocomposite (epoxy + % MWCNTs).

Figure 18 shows the ratio of improvement in fatigue life for the composite (epoxy + 30% carbon fiber) when adding MWCNTs with different ratios (0.5, 1, and 2 wt%) experimentally. This figure shows the positive effect of adding MWCNTs and how they work as stiffeners for composite and reduce the ability of crack initiation and crack growths inside the epoxy that enhance epoxy’s fatigue life. The best-adding ratio was 1 wt%, giving the best fatigue life for epoxy.

The improvement ratio of fatigue life of hybrid composite (epoxy + 30% carbon fiber + MWCNTs).

Figure 19 shows the SEM images for surfaces of epoxy without and with different amounts of MWCNTs. The properties of composites are greatly affected by the nature of bonding at the interface, the strength of the interface, and the mechanical load transfer from the surrounding matrix to nanotubes. The best homogenization and distribution of MWCNTs in epoxy are shown for sample of 1 wt%. The figure shows also the agglomeration of nanomaterials when added 2 wt% of MWCNTs to the epoxy. The agglomeration points will work as stress concentration points and be as a barrier to stress transfer between nanomaterials inside the resin that decreases the strength of material.

SEM images of epoxy and composite samples: (a) epoxy only, (b) epoxy + 0.5 wt% MWCNTs, (c) epoxy + 1 wt% MWCNTs, and (d) epoxy + 2 wt% MWCNTs.

4 Conclusions

The fatigue properties of epoxy and composite material can be improved by adding superior properties of MWCNTs that work as extra stiffeners to the materials and make a strong interface with matrix that increases the ability of stress transfer between nanotubes inside the resin. The properties of composites are greatly affected by the nature of bonding at the interface, the strength of the interface, and the mechanical load transfer from the surrounding matrix to nanotubes. The fatigue life of epoxy increased with a maximum ratio of 788% for 1 wt% of MWCNTs, while the improving ratio reached 2,500% for composite (epoxy + 30% carbon fiber) due to the presence of carbon fiber that works as stiffeners, and MWCNTs will work as extra stiffeners. The MWCNTs will decrease the cracks’ ability to initiate and grow inside the composite due to the super strength property of MWCNTs, especially when using the ratio of 1 wt% and its very good improvement when compared with Turaka et al. [9], Genedy et al. [10], and Shokrieh et al. [12]. The unique findings of this work are transferring the material from LCF to HCF. The improvement ratio in fatigue life will start decrease to 2,430% when using 2 wt% of MWCNTs as nanomaterials start to agglomerate inside the resin. This agglomerated point works as stress concentration points and a barrier for stress transfer between nanotubes and that will reduce the positive effect of adding the MWCNTs. The numerical model simulates the experimental tests done with a divergence of 7.5% due to the effect of using numerical solution hypotheses that tried to approach the experimental conditions.

Acknowledgment

The authors would like to acknowledge the assistance offered by the Nanotechnology and Advanced Materials Research Unit/University of Kufa, Laboratories of Mechanical Engineering Department/the University of Kufa.

-

Funding information: The authors state no funding involved.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: Most datasets generated and analyzed in this study are in this submitted manuscript. The other datasets are available on reasonable request from the corresponding author with the attached information.

References

[1] Mahajan G. Composite material: A review over current development and automotive application. Int J Sci Res Publ. 2012;2(11):1–5.Suche in Google Scholar

[2] Guo R, Li C, Niu Y, Xian G. The fatigue performance of carbon fiber reinforced polymer composite-A review. J Mater Res Technol. 2022;21(47):4773–89. 10.1016/j.jmrt.2022.11.053.Suche in Google Scholar

[3] Kahtan YY. Investigation of biaxial fatigue behavior of fiber reinforced plastic using experimental and numerical techniques. Ph.D.Thesis, University of Technology, Department of Machines and, Equipment Engineering, Iraq; 2014.Suche in Google Scholar

[4] Vasudevan DK. Mechanical and fatigue charactrization of carbon fiber rienforced composite containing rubber microparticles ans silica nanoparticles. Ph.D. Thesis, Texas State University, Iraq; 2016.Suche in Google Scholar

[5] Uki Y. High-speed bending-fatigue testing of composite materials. IOP Conf Ser: Mater Sci Eng. 2018;388:1–14. 10.1088/1757-899X/388/1/012008.Suche in Google Scholar

[6] Tang P, Zhang Z, Guo C, Zeng S, Chen P, Xu Y, et al. Layered montmorillonite/3D carbon nanotube networks for epoxy composites with enhanced mechanical strength and thermal properties. ACS Appl Nano Mater. 2022;5(6):8343–52. 10.29354/diag/140001.Suche in Google Scholar

[7] Wang Q, Chen S, Zeng S, Chen P, Xu Y, Nie W, et al. Tunable mechanical properties of glass fiber/epoxy composites by incorporating bioinspired montmorillonite–carbon nanotube/epoxy interface layer around the fiber. Compos B Eng. 2022;242:222–34. 10.1016/j.compositesb.2022.110092.Suche in Google Scholar

[8] Jen Y, Ni W. Effect of dispersing multiwalled carbon nanotubes and graphene nano platelets hybrids in matrix on the flexural fatigue properties of carbon/epoxy composites. Polymers. 2022;44(14):1–24. 10.3390/polym14050918.Suche in Google Scholar PubMed PubMed Central

[9] Turaka S, Reddy K, Sahu R, Katiyar J. Mechanical properties of MWCNTs and graphene nanoparticles modified glass fibre-reinforced polymer nanocomposite. Bull Mater Sci. 2021;44(1):194–207. 10.1007/s12034-021-02444-z.Suche in Google Scholar

[10] Genedy M, Daghash S, Soliman E, Taha M. Improving fatigue performance of GFRP composite using carbon nanotubes. Fibers. 2015;3:13–29. 10.3390/fib3010013.Suche in Google Scholar

[11] Böger L, Wichmann M, Hedemann H, Schulte K. Influence of Cnt modification on the fatigue life of glass fibre reinforced epoxy composites; 2011.Suche in Google Scholar

[12] Shokrieh M, Esmkhani M, Haghighatkhah A. Mechanical properties of graphene/epoxy nanocomposites under static and flexural fatigue loadings. Mech Adv Compos Struct. 2014;1:1–7.Suche in Google Scholar

[13] Mahdi L, Alithari A. Improvement of tensile and flexural properties of fiber pre-stressing composite by using nano graphene. Mater Sci Forum. 2022;1077:117–27.10.4028/p-80asutSuche in Google Scholar

[14] Islam R, Ali M, Jafor M, Alam M. Carbon nanotubes agglomeration in reinforced composites: A review. AIMS Mater Sci. 2019;6(5):756–80. 10.3934/matersci.2019.5.756.Suche in Google Scholar

[15] Carbon Fiber Product Data, SikaWrap®-300 C; 2017.Suche in Google Scholar

[16] Cheap Nanotube, Industrial Carbon Nanotubes Data Sheet; 2021.Suche in Google Scholar

[17] Al-Gebory L, Al‐Zubaidi A, Al‐Tabbakh A. Production of self-cleaning SiO2/CNT nanoparticles substituted cement mortar. Eng Tech J. 2020;38(3):335–42. 10.30684/etj.v38i3A.349.Suche in Google Scholar

[18] Fadhi B, Ahmedv P. Improving mechanical properties of epoxy by adding multi-wall carbon nanotube. J Theor Appl. 2016;54(2):5541–60. 10.15632/jtam-pl.54.2.551.Suche in Google Scholar

[19] Gupta M, Sydlik S, Schnorr J, Raghavan D. The effect of mixing methods on dispersion of carbon nanotubes during the solvent-free processing of MWCNTs/epoxy Composites. J Polym Sci. 2013;51:410–20.10.1002/polb.23225Suche in Google Scholar

[20] Shokrieh M, Esmkhani M. Fatigue life prediction of nanoparticle/fibrous polymeric composites based on the micromechanical and normalized stiffness degradation approaches. J Mater Sci. 2013;48:1027–34. 10.1007/s10853-012-6833.Suche in Google Scholar

[21] ASTM E467-21. Standard practice for verification of constant amplitude dynamic forces in fatigue testing system.Suche in Google Scholar

[22] Lukačević I, Androić B, Dujmović D. Assessment of reliable fatigue life of orthotropic steel deck. Open Eng. 2011;1(3):306–15. 10.2478/s13531-011-0028-3.Suche in Google Scholar

[23] Ryabov A, Romano V, Rechkin V, Kudryavtsev A, Strelets D. Computer technology of the thermal stress state and fatigue life analysis of turbine engine exhaust support frames. Open Eng. 2019;9(1):530–5. 10.1515/eng-2019-0057.Suche in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq

Artikel in diesem Heft

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq