Abstract

Most construction projects face the problem of a high percentage of gypsum in the soil. To get rid of the unwanted effects of gypsum, which lead to the dissolution of gypsum in the presence of water and the settlement of the foundations of buildings and subsoil of roads, the researchers used several materials that can be added to the soil to improve its properties in resisting loads. This research presents a study of the effect of adding cement kiln dust (CKD) and ground-granulated blast-furnace slag (GGBS) on the California Bearing ratio (CBR) of gypsum sandy soil. The percentages of 2.5, 5, 7.5, and 10% of additives by the weight of the soil sample were collected, and CBR tests were performed on dry and soaked samples. The main results showed that the ideal CKD ratio, which improves the CBR soil in a dry state, is 5% and in a soaked condition is 7.5%. Also, CBR in dry and soaked states increases slightly when the GGBS percentage increases reaching 10%. The use of GGBS gives an increment in CBR, which is around 1.6 times in a dry condition and 4 times in a soaked state.

1 Introduction

The gypsum soil covers nearly 32% of Iraq [1]. Many structures are constructed on this soil subjected to the total or differential settlement, mainly when the water attacks these sites. This article studies the effect of adding cement kiln dust (CKD) and ground-granulated blast slag (GGBS) separately and investigates if these additives can improve the California Bearing ratio (CBR) to increase the strength of this soil. Before delving into the stages of this research, it is necessary to review previous research and studies dealing with this topic.

Khattab [2] reported that sulfate-resisting cement improved the unconfined compression strength of granular gypsum soil but showed a substantial amount of reduction in power and stiffness upon immersion in water.

Muthumari et al. [3] presented an experimental study investigating the effects of CKD and ceramic dust (CD) on soil expansivity. The results showed that the liquid limit, plasticity index, optimum moisture content, and free swell index were decreased with an increase in CKD and percent of CD.

Choobbasti et al. [4] studied the effect of adding nano-silica and cement on sandy soil’s unconfined compressive strength and compaction. About 5, 9, and 14% cement by the dry weight were mixed with 0, 5, 10, and 15% by weight of cement. The results showed that the maximum dry density increases when the cement percent increases and the optimal percentages of nano-silica can improve the properties of cement sand.

Mosa et al. [5] used CKD with percentages of 5, 10, 15, 20, 25, and 30% by dry weight of soil to improve the CBR of poor subgrade soil properties. The results showed that the use of 20% of CKD with curing for 2 weeks increases the CBR from 3.4% for untreated soil to 48% for treated soil, and there is a significant increase in CBR if the curing period varies from 2 to 4 weeks. Also, the saving in the cost of pavements reached 25.8 $/m2 due to the subgrade treatment by CKD.

Aziz et al. [6] evaluated the effective use of a mixture of asphalt powder and the waste oil of vehicles on the shear strength of sandy clay gypsum soil – 3, 5, and 7% percentages by dry weight of the soil sample. The main results are that the mixture of waste materials improves the shear strength, and there is a sound reduction in the permeability, which reduces the collapse.

Eisa et al. [7] presented an experimental study to stabilize weak soil layers using lime, CKD, fiberglass, and Addicrete 11 in ratios of 2, 4, and 6% of the clayey and sandy soil sample weight. The results showed that the maximum dry density increased from 1.65 to 1.86 g/cm3, and the swelling in the earth decreased with a significant value of shear strength with 6% CKD.

2 Materials and testing

2.1 Used soil

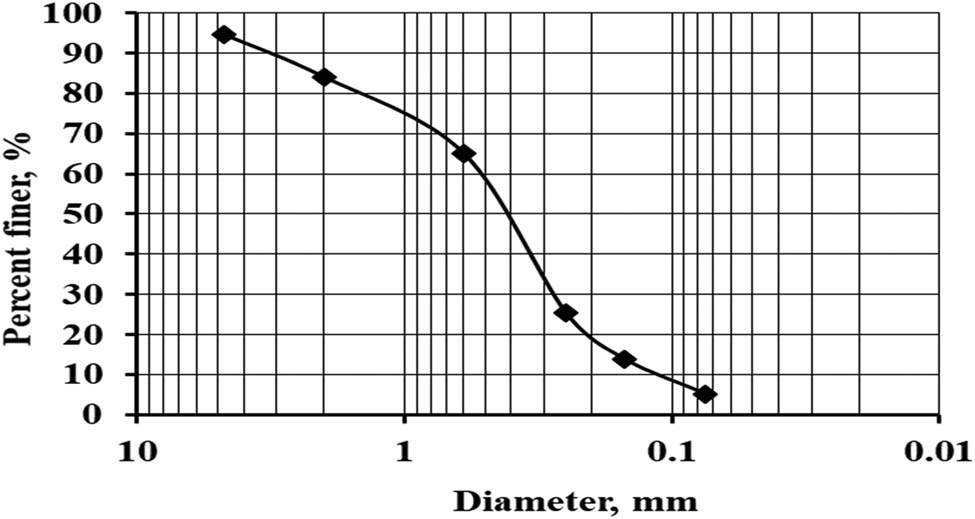

The soil used in the laboratory tests was brought from an area in northwest of Al-Najaf governorate in Iraq. Most of the physical and chemical properties of this soil are drawn in Table 1. The grain size distribution is illustrated in Figure 1. The sample was classified as SP (poorly graded sands) according to the Unified Soil Classification. The used soil can be classified as highly gypsum soil, according to Al-Barazanji [8], as in Table 2.

Physical and chemical properties of used soil

| No. | Physical properties | Values | Specification |

|---|---|---|---|

| 1 | Specific gravity | 2.68 | ASTM D792-20 [9] |

| 2 | Optimum water content | 16% | ASTM D698-12 [10] |

| 3 | Maximum dry density (kN/m3) | 17.22 | ASTM D698-12 [10] |

| 4 | C u | 4.17 | ASTM C136-06 [11] |

| 5 | C c | 1.4 | ASTM C136-06 [11] |

| 6 | Soil type | SP | ASTM D2487-17 [12] |

| No. | Chemical properties | Values | Specification |

|---|---|---|---|

| 1 | Organic material | 2.4% | ASTM D2974-20 [13] |

| 2 | CaSO4·2H2O (gypsum content) | 26.1% | ASTM C471M-20 [13] |

| 3 | SO4 (sulfate content) | 10.7% | ASTM C1580-05 [14] |

Grain size distribution of used soil.

Classification of gypsum soil [8]

| Gypsum content (%) | Classification |

|---|---|

| 0–0.3 | Non-gypsum |

| 0.3–3 | Very slightly gypsum |

| 3–10 | Slightly gypsum |

| 10–25 | Moderately gypsum |

| 25–50 | Highly gypsum |

| >50 | Sandy gypsum |

2.2 CKD

CKD is known as a heterogeneous powder. In this research, CKD was collected from Al-Kufa Cement Plant, which lies in Kufa, Al-Najaf governorate, Iraq. The chemical properties of CKD are shown in Table 3.

Chemical analysis of CKD [15]

| Constituents | Percent by weight |

|---|---|

| SiO3 | 15.4 |

| Al2O3 | 3.5 |

| Fe2O3 | 3.2 |

| CaO | 42.88 |

| MgO | 2.9 |

| SO3 | 6.3 |

| K2O | 2.5 |

| Na2O | 1.48 |

| Loss of ignition | 27.7 |

| Chlorides | 0.89 |

2.3 GGBS

GGBS is a material used mainly in concrete and is a by-product of iron industry. Blast furnaces at 1,500°C use a carefully controlled mixture of limestone, coke, and iron ore. The iron ore is demoted into iron, and the remaining materials form a slag that floats over the iron. If it is to produce GGBS, the slag is periodically tapped off as a molten liquid and has to be quickly quenched in a large quantity of water. The quenching operation improves the characteristics and makes granules similar to coarse sand. The final granular slag is then dried and formulated into a fine powder. In the UK it is usually named as “GGBS.” It is also called as “GGBFS” or “slag cement.” The properties of GGBS are shown in Table 4 [16].

Properties of GGBS

| Chemical properties | Value (%) |

|---|---|

| Calcium oxide | 40 |

| Silica | 35 |

| Alumina | 13 |

| Magnesia | 8 |

| Physical properties | Value |

|---|---|

| Color | Off-white |

| Specific gravity | 2.9 |

| Bulk density | 1,000–1,100 |

| Fineness | >350 m2/kg |

2.4 CBR test

The investigation of CBR was divided into three main stages: the first stage investigated the performance of the reference soil sample and carried out the CBR test for dry and soaked conditions. The second stage contained a CBR test using CKD with 2.5, 5, 7.5, and 10% as an additive to soil mass for dry and soaked conditions. In the third stage CBR test was performed using GGBS for the exact percentages of CKD to compare the two added materials. The CBR test was carried out according to the ASTM D1883-21 [17]. This test calculates the sub-base, base materials, and sub-base to use its value in pavement design. In the laboratory, a circular piston penetrates a compacted material in a mold at a constant penetration rate. The CBR represents the ratio of the unit load on the sample required to punch 2.5 mm (1 in) and 5.1 mm (2 in) into the unit load needed to punch a standard material of well-graded crushed stone. The CBR test machine is shown in Figure 2.

CBR test machine.

3 Results

3.1 CBR testing for reference sample

CBR test was conducted according to the ASTM D1883-21 [17] on the reference sample in dry and soaked conditions. For soaked state testing, the samples were soaked in water for 7 days. The results of the CBR test are shown in Figure 3. From this figure, CBR values were found to be 9.5 and 7.1% for dry and soaked samples, respectively.

Relationships between load and displacement for the dry and soaked reference samples.

3.2 CBR testing for CKD/soil mixture

Many previous researchers adopted 2.5, 5, 7.5, and 10% of CKD/soil percentages, significantly improving this range. These percentages were collected to investigate the effect of adding CKD as a percentage by the weight of the soil. The CBR tests for dry and soaked conditions were carried out. Load–displacement relationships are shown in Figures 4 and 5, respectively. From these relationships, the CBR values for the dry state were calculated as 12.2, 14, 12.5, and 5.9%. For soaked conditions, CBR values were 10.5, 19.7, 23.4, and 9.2%.

Relationships between load and displacement for CKD/soil mixture in the dry condition.

Relationships between load and displacement for CKD/soil mixture in the soaked condition.

3.3 CBR testing for GGBS/soil mixture

The effect of adding GGBS material to the soil as a percentage of the weight of soil on CBR is studied for the exact percentages of CKD. The dry and soaked conditions are also adopted. Load–displacement relationships are shown in Figures 6 and 7, respectively. The CBR values were calculated as 12.6, 17, 18, and 24.8% for dry conditions and 7.4, 13.3, 22.8, and 36.4% for soaked conditions.

Relationships between load and displacement for GGBS/soil mixture in the dry condition.

Relationships between load and displacement for GGBS/soil mixture in the soaked condition.

The final results of all cases are summarized in Table 5.

Summary of results

| Percent | CBR for CKD | CBR for GGBS |

|---|---|---|

| Dry condition | ||

| 0 | 9.5 | 9.5 |

| 2.5 | 12.2 | 12.6 |

| 5 | 14 | 17 |

| 7.5 | 12.5 | 18 |

| 10 | 5.9 | 24.8 |

| Soaked condition | ||

| 0 | 7.1 | 7.1 |

| 2.5 | 10.5 | 7.4 |

| 5 | 19.7 | 13.3 |

| 7.5 | 23.4 | 22.8 |

| 10 | 9.2 | 36.4 |

4 Discussion of the results

4.1 Dry condition

The final results of CBR for the dry condition are shown in Figure 8, and it can be seen that the use of GGBS increases the CBR within the range of collected percentages while the use of CKD increases the CBR up to 5% and thereafter decreases. From these results, it can be concluded that the use of GGBS up to 10% (in the present study) is more effective in increasing the CBR of gypsum soil. The use of GGBS higher than 10% can be studied in future works.

Percent of additive and CBR values relationship in the dry condition.

4.2 Soaked condition

For the soaked condition, Figure 9 shows the final results of CBR. It can be seen that the use of GGBS, same as in dry conditions, increases the CBR but with higher values than in dry after 7.5%. The use of CKD increases CBR up to 5% and for higher than this percentage decreases but with a little value of CBR, then it can be concluded that the use of GGBS with GGBS higher than 7.5% in the soaked state gives a higher CBR than the dry state, while using CKD, the CBR decreases for 2.5% and then increases for 5, 7.5, and 10%, respectively, with the comparison of dry state.

Percent of additive and CBR values relationship in the soaked condition.

4.3 Comparison between dry and soaked

To study the effect of soaking of the additives separately, Figures 10 and 11 show the effect of soaking on CKD and GGBS, respectively. The use of CKD in the soaked condition decreases CBR by up to 2.5% after which the CBR increases as compared to the dry state, as shown in Figure 10. The use of GGBS in the soaked condition decreases CBR by up to 5% after which CBR increases in comparison with the dry state as shown in Figure 11. It is worth mentioning here that the soaking process has great importance on the results, and therefore must keep the samples soaked in water throughout the week, as water is added to the samples whenever they dry.

Percent of additive and CBR values relationship for CKD in dry and soaked conditions.

Percent of additive and CBR values relationship for GGBS in dry and soaked conditions.

5 Conclusions

In this study, a series of laboratory tests were carried out to investigate the effect of adding CKD and GGBS on CBR of gypsum sandy soil in dry and soaked conditions. The following conclusions are drawn:

The ideal CKD ratio, which improves the CBR of gypsum sandy soil in a dry state is 5%.

In a soaked state, the CBR of gypsum sandy soil improves optimally when it is mixed with a CKD at a percentage of 7.5%.

The CBR of gypsum sandy soil in dry and soaked states increases slightly when the GGBS percentage increases reaching the maximum collected value in this study (10%).

In dry conditions, the CBR of gypsum sandy soil increases using CKD higher than using GGBS by up to 5%, after which the CBR decreases with CKD and continues to rise with GGBS.

In soaked conditions, the CBR of gypsum sandy soil increases using CKD higher than using GGBS by up to 7.5%, after which the CBR decreases with CKD and continues to rise with GGBS.

The use of GGBS gives an increment in CBR, which reaches 1.6 times in a dry state.

The use of GGBS gives an increment in CBR, which reaches 4 times in a soaked state.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: Most datasets generated and analyzed in this study are comprised in this submitted manuscript. The other datasets are available on reasonable request from the corresponding author with the attached information.

References

[1] Ismail HN. The use of gypseous soils. Symposium on gypsiferous soils and their effect on structures. Baghdad, Iraq: NCCL; 1994.Search in Google Scholar

[2] Khattab SA. Effect of gypsum on strength of cement treated granular soil and untreated soil. MSc thesis. Iraq: University of Mosul; 1986.Search in Google Scholar

[3] Muthumari G, Nasar Ali R, Dhaveethu Raja J. Comparative study on stabilization of expansive soil using cement kiln dust and ceramic dust. J Geotech Eng. 2014;1(3):1–7.Search in Google Scholar

[4] Choobbasti AJ, Vafaei A, Kutanaei SS. Mechanical properties of sandy soil improved with cement and nanosilica. Open Eng. 2015;5:111–6.10.1515/eng-2015-0011Search in Google Scholar

[5] Mosa AM, Taher AH, Al-Jaberi LA. Improvement of poor subgrade soils using cement kiln dust. Case Study Constr Mater. 2017;7:138–43.10.1016/j.cscm.2017.06.005Search in Google Scholar

[6] Aziz HY, Maula BH, Abbas BJ. Evaluation of stabilizer material using a waste additive mixture. Open Eng. 2020;10:311–7.10.1515/eng-2020-0034Search in Google Scholar

[7] Eisa MS, Basiouny ME, Mohamady A, Mira M. Improving weak subgrade soil using different additives. Materials. 2022;15:4462.10.3390/ma15134462Search in Google Scholar PubMed PubMed Central

[8] Al-Barazanji AF. Gypsiferous soils of Iraq. PhD thesis, University of Ghent Belgium; 1973.Search in Google Scholar

[9] ASTM D792-20. Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM; 2020.Search in Google Scholar

[10] ASTM D698-12. Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12 400 ft-lbf/ft3 (600 kN-m/m3)). ASTM; 2020.Search in Google Scholar

[11] ASTM C136-06. Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM; 2015.Search in Google Scholar

[12] ASTM D2487-17. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM; 2020.Search in Google Scholar

[13] ASTM D2974-20. Standard Test Methods for Determining the Water (Moisture) Content, Ash Content, and Organic Material of Peat and Other Organic Soils. ASTM; 2020.Search in Google Scholar

[14] ASTM C1580-05. Standard Test Method for Water-Soluble Sulfate in Soil. ASTM; 2010.Search in Google Scholar

[15] Kufa cement plant report. Physical and Chemical Properties of Cement Kiln Dust. Najaf, Iraq; 2022.Search in Google Scholar

[16] https://ukcsma.co.uk/what-is-ggb/.Search in Google Scholar

[17] ASTM D 1883-21. Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM; 2020.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq

Articles in the same Issue

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq