Abstract

One of the problems experienced by reinforced concrete (RC) structures, whether a mistake at the design phase or a change in building use, is an overload. The goal of this study is to determine whether ultra-high-performance fiber-reinforced concrete (UHPFRC) is effective in repairing damaged concrete columns utilizing 30 mm thin concrete jacketing made of different steel fibers at various contents with varied aspect ratios (28, 37, and 45). Nine pieces of 500 mm long RC column specimens with a cross-sectional size of 150 mm × 150 mm were cast as part of the experimental program. By loading these columns with roughly 90% of their actual ultimate axial load capacities, damage was caused, and the columns were subsequently strengthened and rebuilt using UHPFRC jacketing materials. The results demonstrated that when steel fiber content increased, so did the mechanical qualities, such as compressive and tensile strengths. Rehab materials that contained 0.5% steel fiber recovered 138% of their maximum load-bearing capacities, while materials that contained 1.5% steel fiber recovered 164% of their original capacities, which were roughly 1.38–1.64 times that of the unjacketed reference column. Additionally, it was observed that employing steel fiber in UHPFRC contents in these approaches resulted in the ultimate displacement being improved from 2.91 to 5.53 mm at 1.5% of steel fiber content, which is an increase of almost double that of control specimens.

1 Introduction

Concrete is widely used worldwide and considered a common material in different sectors of the construction industry. Because of its properties such as durability and performance, it can reach up to several decades of building service life through fulfilling safety requirements of design either for concrete mix materials or structural design of the building. However, the concrete often suffers damage due to ignorance or non-compliance of building codes in the design phase, or unexpected environmental conditions that affect the safety of reinforced concrete (RC) [1]. For clarification, RC structures are damaged when exposed to severe environmental conditions, such as corrosion, fire, and natural disasters. Additionally, accidental mistakes in the design or changes in building usage which reach their intended design life causing overloading are considered as the main factors of damage that lead to failure to meet the functional requirements of the service life, thereby leading to loss in the bearing capacity of the principal components of structure building, such as beams, columns, and slabs [1,2]. If attention is not paid to these causes, then structures could fail to carry their design load and disasters could occur especially to the most important structural elements, i.e., columns, which are widely used in residential and high-rise buildings, leading to a partial or complete collapse of the structure because it is only the members that transmit the total vertical loads of buildings to the soil. Thus, if the damage occurs by overload, the columns lose their strength and stiffness by significantly degrading and causing the deformation of the steel bar and will appear as cracks in the surface. The cracks would then allow corrosive factors such as salt water and high humidity to penetrate and reach the steel reinforcement, and failure could occur [3]. Therefore, repair and rehabilitation are necessary in case of noticeably damaged cracks on the concrete surface to confirm that loads are further carried and transmitted to the soil [4]. Thus, rehabilitation for damaged structures is considered a challenging activity that experts could face during the repair process. According to Yaqub and Bailey [5], repairing and reusing the affected concrete structure is more economical than demolishing and constructing a new building, because the damaged RC columns have superficial damage in the concrete that appear as slight cracks without damage to the reinforcement and their tie [1]. Previous studies have suggested several solutions for the rehabilitation depending on the type of structure and loading. Strengthening method represents one of the most popular methods used in the rehabilitation of damaged columns [6]. Several techniques can be applied based on the degree of structural damage, such as injections, removal and replacement, or jacketing. To strengthen RC column damage by jacketing, which is commonly used, three principal techniques are used: concrete jacketing, steel jacketing, and composite jacketing [2,7]. Tayeh et al. [1] studied the repairing and strengthening of columns by jacketing with normal strength concrete (NSC) and ultrahigh-performance fiber-reinforced self-compacting concrete (UHPFRSCC) as jacketing materials. Results revealed that the ultimate load-carrying capacities and axial displacements had significantly increased in both materials with respect to the unjacketed reference column. Contrastingly, studies found that UHPFRSCC is more effective due to the use of steel fibers than using NSC as a jacketing material for repairing and strengthening RC columns. Elsamny et al. [8] investigated 37 specimens under various eccentricities from e/t = 0–25%, and they were split into three groups, 5 specimens were evaluated under various eccentricities as part of group 1 control columns, and 16 samples from group 2 were reinforced using varying numbers of steel wire mesh plies. Sixteen specimens from group 3 were strengthened with a sandwich of varied numbers of steel wire mesh plies and external vertical steel bars 3Ø8 in compression side and all groups were jacketed with cement mortar. The test findings demonstrated that employing the wire mesh jacketing approach increases the load carrying capacity by up to 23%, while adopting a sandwich wrapping system technology that consists of external vertical steel bars in compression side and steel wire mesh delivers a 54% improvement in load carrying capability. Composite jacketing is considered to be a modern technology that uses ultra-high-performance fiber-reinforced concrete (UHPFRC), which has been developed to increase the service life of a RC structure at a more effective cost. Furthermore, damage to the RC structure would improve the structural durability and load-bearing capacity of the structure by using UHPFRC, which was the most recent material used due to its capability to carry or sustain a higher load even with the presence of crack on the concrete. The UHPFRC consist of cement, sand, a high amount of silica fume, water, superplasticizer (SP), and steel fiber, which make these mixtures stronger and ductile [9]. Abbas et al. [9] indicated that UHPFRC is considered a new cementitious material because it contains fibers that are distributed in a homogeneous way and lead to an increase in the properties of concrete by improving the compressive strength, tensile strength, toughness, ductility, and durability of a concrete structure. Additionally, this technique has been developed to increase the service life of a RC structure that has been damaged and retained back in service. Brühwiler et al. [10] indicated that UHPFRC material is a favorable repair method due to its ease of placement on damaged areas. Plizzari et al. [11] conducted a study on the applications of a high-performance fiber-RC jacket with 170 MPa compressive strength to strengthen RC short columns. The result shows that improved durability marks an advancement in the concrete industry and leads to sustainable and economic buildings with resistance against all kinds of corrosion. Tayeh et al. [1] conducted an experimental study on the application of thin concrete jacketing by applying two jacketing materials, which were 25 and 35 mm thick, to repair and strengthen the damaged columns exposed to approximately 90% of their actual ultimate axial load capacities. Two groups were used in the experiment: group 1 with material consisting of NSC with a maximum aggregate size of 4.75 mm and steel reinforcement and group 2 containing ultra-high-performance fiber reinforced with steel reinforcement. The results showed that group 2 had a significant increase in ultimate load capacity by around three times than that of the unjacketed reference column and 1.86 times than that of group 1. Nowadays, the low cost and fast execution time of repairing techniques is desired, which should be identified and recognized. Hence, the current research studied UHPFRC for repairing and strengthening of damaged square RC columns that reach 90% of their actual axial capacity without failure by applying three contents of steel fiber (0, 0.5, and 1.5%) at fixed jacketing thickness with three different aspect ratios of steel fiber (28, 37, and 45). In addition, the impact of steel fiber content on axial displacement and maximum load carrying capability was investigated. The outcomes were contrasted with those of the reference columns.

2 Experimental program

The current experiment aims to investigate the UHPFRC using various contents of steel fiber at different aspect ratios (28, 37, and 45) as composite repair material for RC column damage caused by overload. By bonding this material to all four sides of a damaged column area at fixed jacketing thickness (30 mm), we can strengthen and restore damaged columns for further load-carrying capacity and axial displacement.

2.1 Column preparation

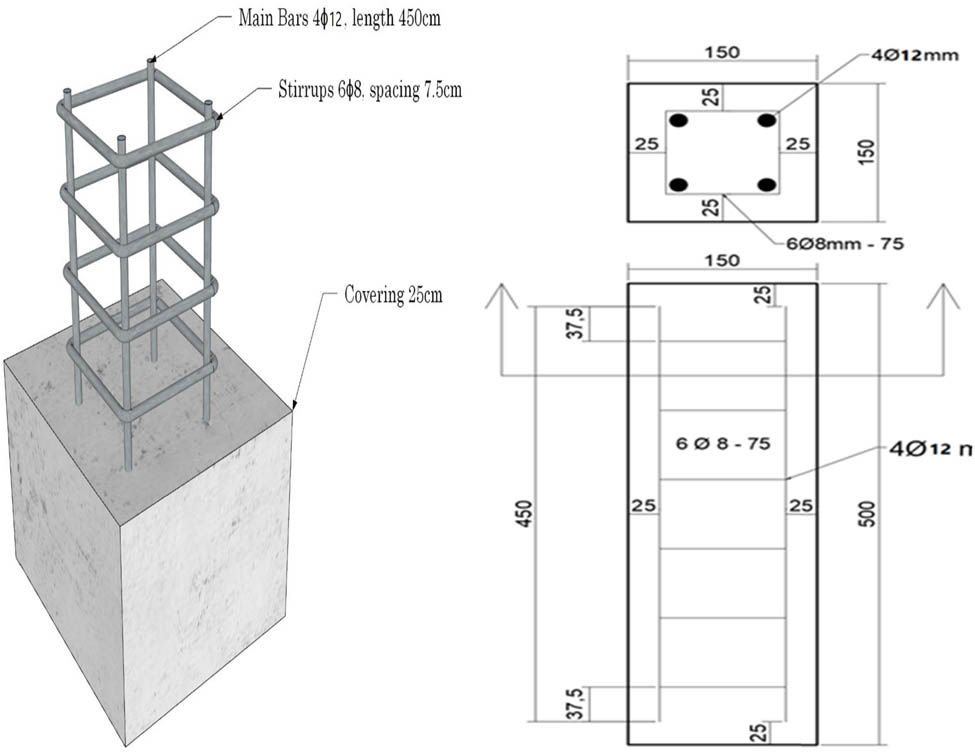

This research includes the fabrication of nine column specimens that are repaired and strengthened by applying jacketing using UHPFRC, which were damaged after being exposed to an overload. According to ACI 318 code requirements [12], all tested column specimens are designed with not less than 1% of longitudinal reinforcement ratio. Nine square column specimens are designed to act as normal columns and are exposed to an overload. Columns tested with cross-sectional square of 150 mm × 150 mm and a height of 500 mm with 4Ø12 mm longitudinal steel reinforcement and 6Ø8 mm use as link bars spaced at 75 mm center to center ties, as shown in Figure 1.

3D geometry columns and reinforcement details.

2.2 Mix design for columns

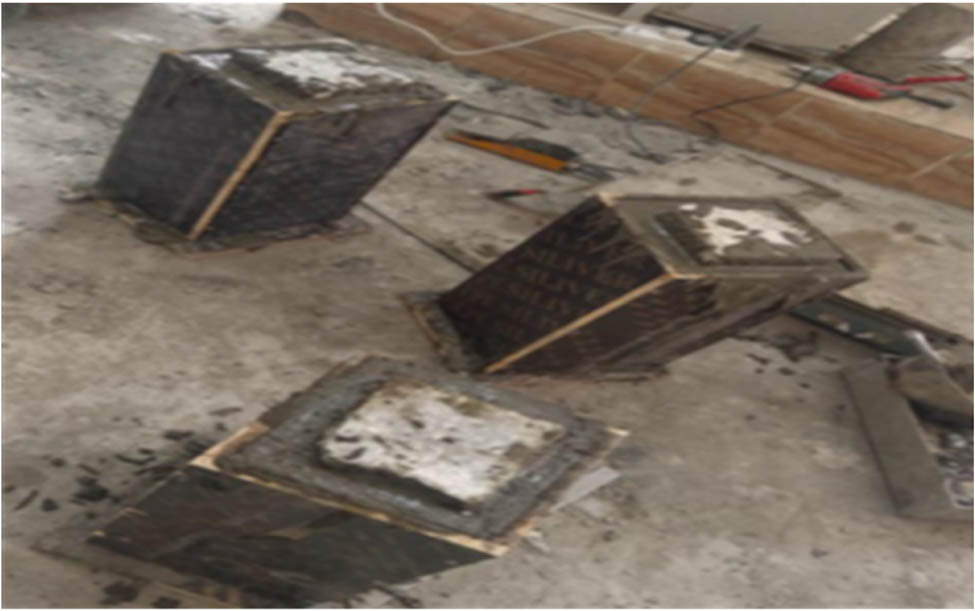

The concrete mix comprises sand with a relative density of 3.15, fineness modulus of 3.4, and absorption of 1%, natural crushed coarse aggregate (maximum size 14 mm), and ordinary Portland cement (Type 1). The mix proportion was designed to achieve a target compressive strength of 30 MPa at 28 days accordance to Building Research Establishment Method [13]. Concrete mix proportions as reported by Mohd Zahid et al. [14] were used for reinforcement, which consist of 550 kg/m3 cement, 250 kg/m3 water, 745 kg/m3 sand, and 805 kg/m3 coarse aggregate as shown in Table 1. The mix() were used to cast the columns and 100 mm cube edge were prepared, cured, and tested cubes. The cube-shaped columns were cured in water for 28 days and then kept at room temperature until testing as shown in Figure 2. These mixtures used for specimens act as normal columns until exposed to an overload test.

Mix proportion for 1 m3

| Mix ID | W/C | Coarse aggregate (kg) | Natural sand (kg) | Water (kg) | Cement (kg) | SP (kg/m3) |

|---|---|---|---|---|---|---|

| Mix0 | 0.39 | 805 | 745 | 215 | 550 | 0. 15 |

Casting of square columns.

2.3 Mix design for repair material (UHPFRC)

The mix proportion of UHPFRC for repair material consists of three mixtures depending on the percentage of fiber as shown in Table 2. Sodium naphthalene sulfonate (SNF) is included in this mixture to help concrete to be more workable and enhance the strength of the mixture by increasing the strength by around 20–60% and enhancing their durability in their service life [15]. Silica fume is one component in the UHPFRC mixture with its content limited to 6% due to its effect on the rheology property of UHPFRC, and the compressive strength of UHPFRC decreases when silica fume content exceeds a certain value (>10%) [16]. SP, conplast SP430, was used with a specific gravity of 1.06 for improving the workability of the concrete. Figure 3 shows that all the damaged columns were repaired by UHPFRC with 30 mm thickness jacket with different contents of micro copper-coated steel fibers (MSFs) of 0, 0.5, and 1.5% and at different aspect ratios of 28, 37, and 45, respectively, as shown in Table 3. Concrete cube was also cast from the reinforcement and repair mix to monitor concrete compressive strength at each mix.

Mixture proportion of UHPFRC for 1 m3

| Mix ID | Fiber (%) | W/C | SNF (kg) | Sand (kg) | SP430 (kg) | Silica fume (kg) | Fiber (kg) | Water (kg) | Cement (kg) |

|---|---|---|---|---|---|---|---|---|---|

| Mix1 | 0.0 | 0.25 | 5 | 887 | 55 | 53 | 0.0 | 250 | 1,000 |

| Mix2 | 0.5 | 0.25 | 10 | 887 | 65 | 53 | 39.5 | 250 | 1,000 |

| Mix3 | 1.5 | 0.25 | 10 | 887 | 65 | 53 | 118.5 | 250 | 1,000 |

Casting UHPFRC by jacketing for damaged columns.

Steel fiber properties

| No. | Fiber properties | MSFs | MSFs | MSFs |

|---|---|---|---|---|

| 1 | Shape | Straight | Straight | Straight |

| 2 | Length (mm) | 10 | 13 | 16 |

| 3 | Diameter (mm) | 0.35 | 0.35 | 0.35 |

| 4 | Aspect ratio | 28 | 37 | 45 |

| 5 | Tensile strength (MPa) | 2,800 | 2,800 | 2,800 |

| 6 | Young’s modulus (GPa) | 200 | 200 | 200 |

| 7 | Specific gravity | 7.9 | 7.9 | 7.9 |

2.4 Test set-up and instrumentation columns before and after repair

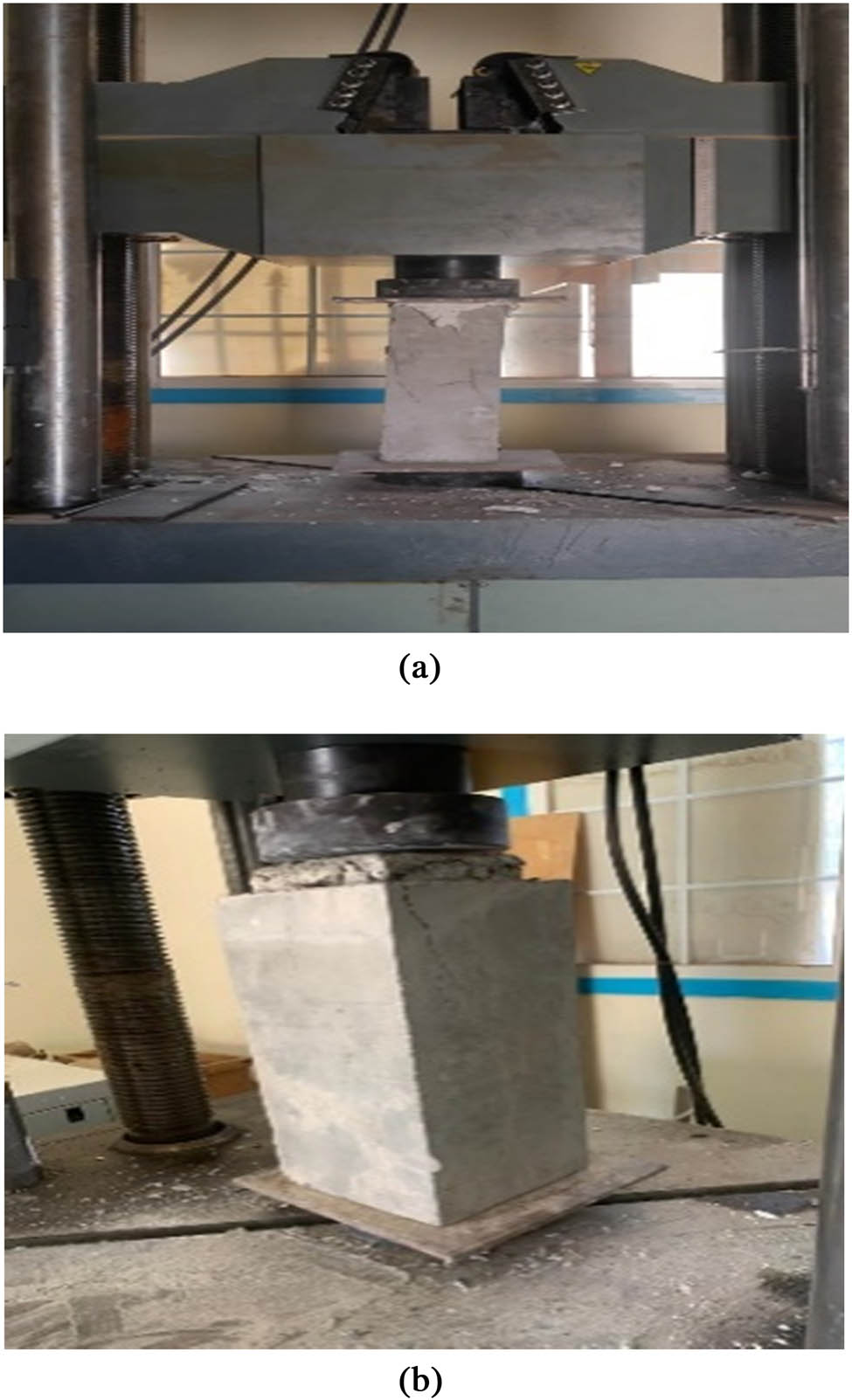

Column specimens were tested using a Universal Testing Machine with a load capacity of 200 tons before and after repair, as shown in Figure 4a and b. To prepare specimens for the test, the top surface of the column was smoothed using a Gipson layer before testing. To distribute the axial load into the column surfaces, two steel plates were placed on the upper and lower surfaces of the columns. Table 4 illustrates four groups of the columns that have been divided depending on the testing variables. The concrete type (normal), jacket strengthening (UHPFRC and MSFs 0%), jacket strengthening (MSFs 0.5% and MSFs with composite aspect ratio of 28, 37, and 45), and jacket strengthening (MSFs 1.5% and MSFs with composite aspect ratio of 28, 37, and 45). A total of nine RC columns were tested under concentric axial compression load with approximately 90% of their actual axial capacity at loading rate of 0.5 kN until the appearance of hairline cracks without reaching failure. Three best values out of nine non-repaired columns were chosen as a control sample depending on their strength and displacement and grouped into RC. All repaired specimens with UHPFRC were tested under axial compression with a displacement rate of 1 mm/min as recommended by Yaqub and Bailey [17], until crack appeared and failure occurred in the specimen. The average value of the three column specimens was considered. During the loading process, the axial load and vertical displacement data were recorded through a computerized system connected to the machine and then the vertical load–displacement curve was plotted which led to obtained three important mechanical properties of RC column i.e., ultimate load, displacement, and ductility.

(a) Experimental setup No. 1 before repair. (b) Experimental setup No. 2 after repair.

Column details and test variables

| Group ID | Column ID | Concrete mix | Strengthening layers | Test variables |

|---|---|---|---|---|

| RC | RC1 | Mix0 | Non | The best value in strengthening |

| RC2 | Non | |||

| RC3 | Non | |||

| H1 | H11 | Mix1 | 0% MSFs | Jacketing strengthening |

| H12 | 0% MSFs | |||

| H13 | 0% MSFs | |||

| H2 | H21 | Mix2 | 0.5% MSFs | Steel fiber content jacketing strengthening |

| H22 | 0.5% MSFs | |||

| H23 | 0.5% MSFs | |||

| H31 | 1.5% MSFs | |||

| 5H3 | H32 | Mix2 | 1.5% MSFs | Steel fiber content jacketing strengthening |

| H33 | 1.5% MSFs |

3 Results and discussion

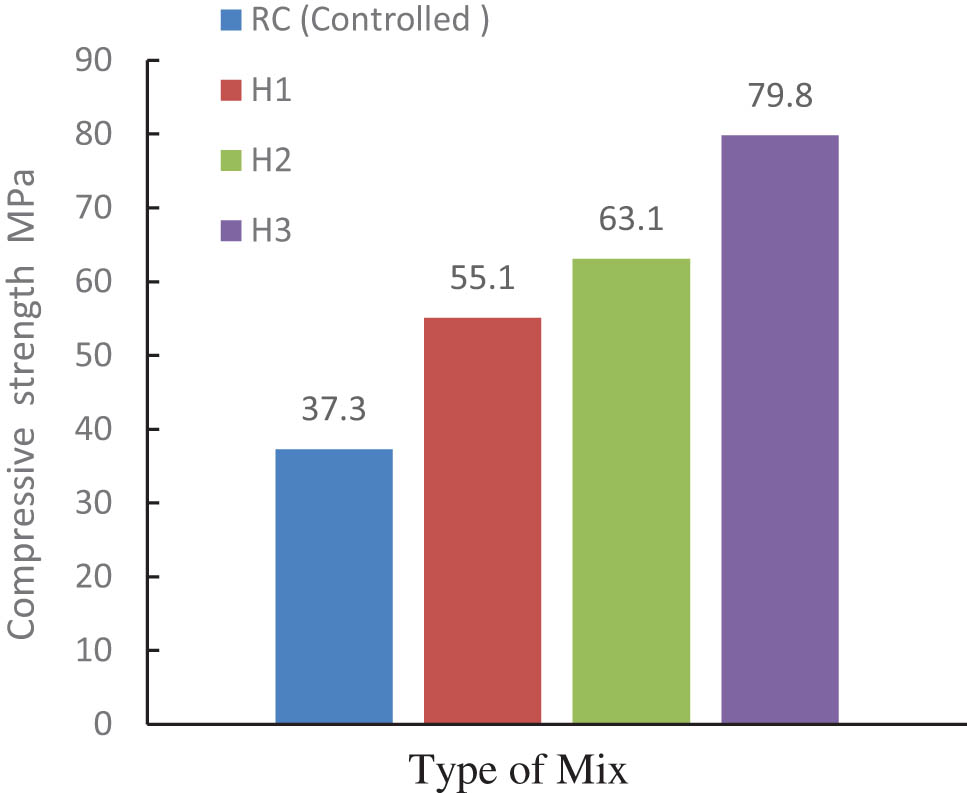

The properties of the normal concrete mixes and UHPFRC were investigated. Compressive strength of all specimens was obtained by testing three standard test cubes (100 mm × 100 mm × 100 mm) at 28 days. Figure 5 shows the average of compressive strength of normal and UHPFRC. On the testing date of the cubes of Mix0, the average compressive strength was 37.3 MPa which was lower when compared to all the mixtures of UHPFRC. As the MSFs increased in Mix2 and Mix3 by 0.5 and 1.5, the value of compressive strength increased by 14.51% for H2 (0.5%) fiber contents and 44.82% for H3 (1.5%), respectively, when compared to the batch of H1 with non-fiber (0%). Also, the compressive strength of UHPFRC in the Mix1 with non-fiber (0%) was increased by 47.72% compared to the normal concrete (Mix0). Previous studies reported that using steel fiber enhanced the concrete properties [18]. Moreover, according to Denarié [19], the addition of a large amount of steel fibers led to extremely high compressive strength.

Average compressive strength.

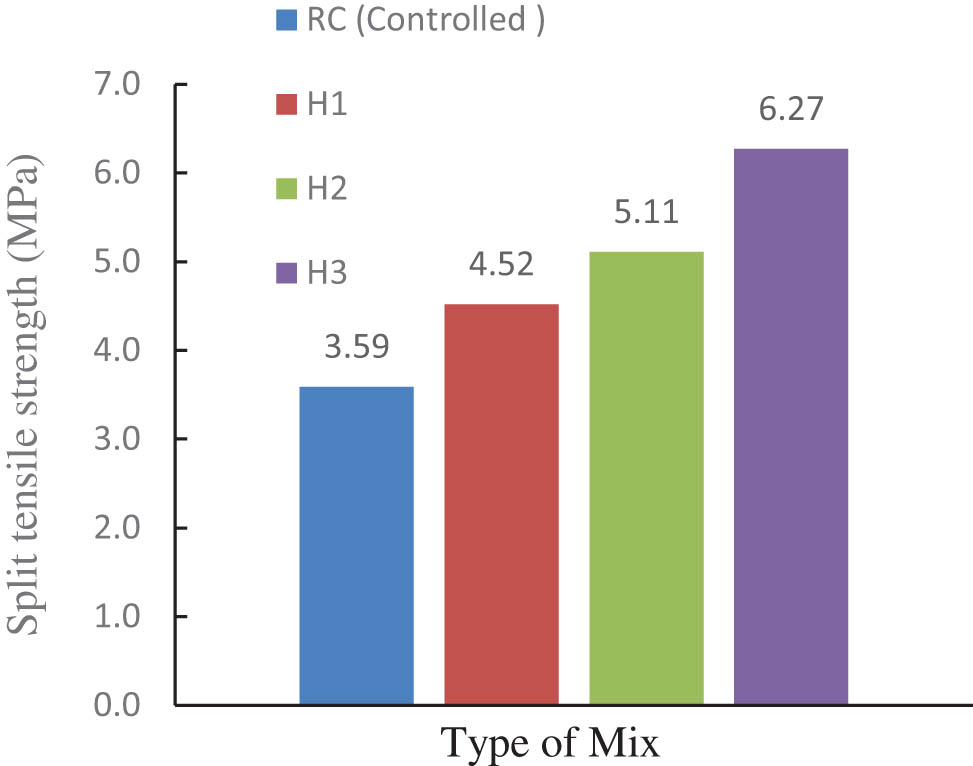

In contrast, compressive strength is not the main feature of UHPFRC for judging it as a good material for rehabilitation of the damaged columns. There are other features, for instance, tensile strength, which is considered the most important feature of UHPFRC because tensile strength in cementitious repair material avoids or reduces shrinkage deformations. In this study, dogbone-shaped specimens were used to obtain tensile strength by testing all mixtures at 28 days, as shown in Figure 6.

Experimental setup of the uniaxial tensile dogbone test.

The average tensile strength of the three UHPFRC ranged from 2.41 to 9.28 MPa, as shown in Figure 7. The tensile strength is crucial for cementitious repair material because the existing structure is restrained to more or less large shrinkage deformations, which means it needs high tensile strength [20,21]. In this study, as seen, the increase in steel fiber content led to an increase in the tensile strength, which is similar to the findings from previous studies [20]. UHPFRC (H3) with a 1.5% fiber content had the highest tensile strength.

Average tensile strength.

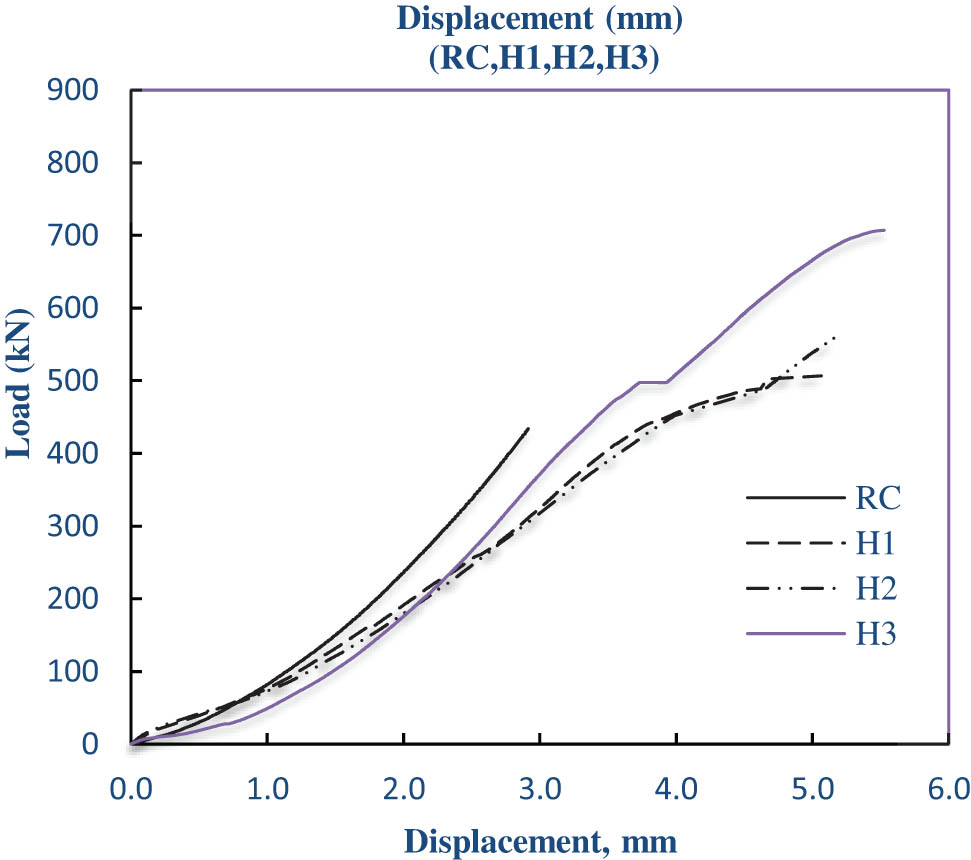

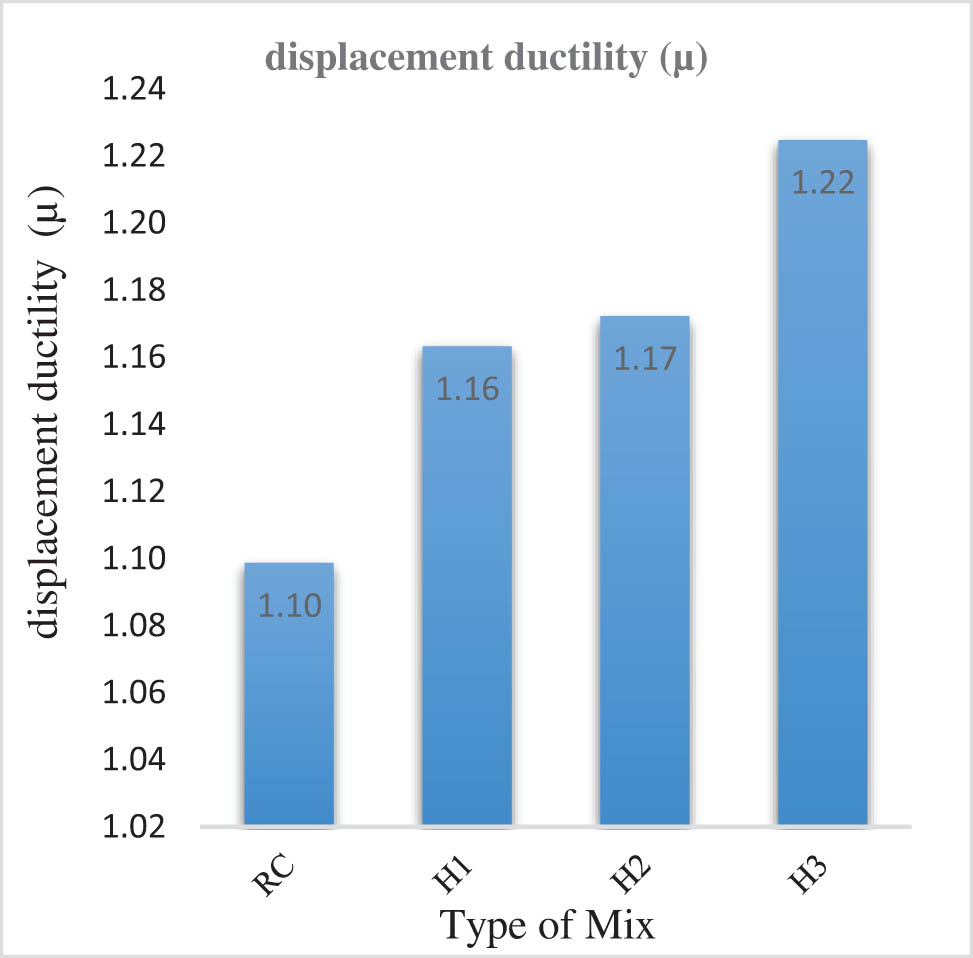

Table 5 indicates that the H1 and H2 jacketed column specimens show an increase in the average ultimate load-carrying capacity by 1.13 and 1.38 times than those of the RC-controlled columns, respectively. The average ultimate load-carrying capacity of H3 increased by 1.64 times than those of the RC-controlled columns. Under axial compression loading, the fiber orientation of the square cross-section column at the corner is in tension, whereas it behaves primarily in flexure conditions at the jacketing side due to the stresses produced from the column corner to the middle zone, which leads to an increased loading capacity [22]. Average load–displacement diagram, as shown in Figure 8, was plotted for all jacketed columns and control specimens. H3 jacketed column specimens gained almost a double increase at 90.03% in axial displacements at rupture with respect to the RC reference columns. As shown in Table 5, the axial displacements of the H1 and H2 jacketed column specimens increased by 73.88 and 78.35%, respectively, compared to the RC reference columns. Furthermore, the axial displacements of H3 give indications that 1.5% of steel fiber is appropriate for UHPFRC. Furthermore, the fibers in UHPFRC play a role in increasing the ductility of the columns, as shown in Figure 9, from 5.45 to 10.9%, compared with the control specimens, which affected the number of cracks and the crack width opening as observed. Hence, repairing with UHPFRC as a modern technique would restore the load-bearing capacity of the concrete, and these reflected on bearing capacity of rising up their figures [23].

Ultimate load of controlled columns and damaged square RC columns after repair with different UHPFRC jacketing thickness

| Types of mix | Specimen label | Specimen no. | Jacketing thickness (mm) | % MSFs | Ultimate load, Pult (kN) | Average ultimate load, Pult (kN) | Ultimate displacement, Δ ult (mm) | Average ultimate displacement, Δ ult (mm) |

|---|---|---|---|---|---|---|---|---|

| RC | Controlled | 1 | Null | 0.00 | 472 | 446.67 | 3.1 | 2.91 |

| 2 | 453 | 2.1 | ||||||

| 3 | 415 | 3.52 | ||||||

| H1 | UHPFRC | 1 | 30 | 0.00 | 490.4 | 506.53 | 5.26 | 5.06 |

| 2 | 498.6 | 3.431 | ||||||

| 3 | 530.6 | 6.48 | ||||||

| H2 | UHPFRC | 1 | 30 | 0.50 | 599 | 616.80 | 6 | 5.19 |

| 2 | 643.4 | 5.15 | ||||||

| 3 | 608 | 4.42 | ||||||

| H3 | UHPFRC | 1 | 30 | 1.50 | 761.4 | 732.53 | 6.25 | 5.53 |

| 2 | 737.4 | 5.96 | ||||||

| 3 | 698.8 | 4.37 |

Average load–displacement diagram of all specimens.

Average displacement ductility.

4 Conclusion

The outcomes of the experimental study using UHPFRC of jacketing materials for rehabilitation of damaged columns, which was observed, can be summarized as follows:

All the columns strengthened by UHPFRC showed higher maximum load capacities than the unstrengthened columns (RC), while increasing the MSFs content increased the load capacities.

The columns strengthened with UHPFRC jacket consisting of composite of different aspect ratios of steel fiber showed higher displacement than the unstrengthened columns and the corresponding columns with higher MSFs content, which then increased the column ductility afterward

There are substantial improvements in concrete compressive strength from H1 to H3 at 47.72–113.94% of its original value (RC), and the ultimate load-carrying capacities of the square columns were strengthened by 13–63% after applying UHPFRC jacketing procedures.

Acknowledgements

The author gratefully acknowledges Taif University for its financial support. Special thanks are due to the civil engineering students (Nawaf Alshlawi, Mohammed Alslimani, Abdulaziz Alotaibi, Mazen Alkhammash, Fahad Alroqi, and Khalid Althobaiti) for their help during the experimental labs.

-

Funding information: This work was supported by Taif University under the Saudi Ministry of Education.

-

Conflict of interest: There are no financial conflicts of interest to disclose.

References

[1] Tayeh BA, Naja MA, Shihada S, Arafa M. Repairing and strengthening of damaged RC columns using thin concrete jacketing. Adv Civil Eng. 2019;2019:1–16. 10.1155/2019/298741.Search in Google Scholar

[2] Calderón PA, Adam JM, Ivorra S, Pallarés FJ, Giménez E. Design strength of axially loaded RC columns strengthened by steel caging. Mater Des. 2009;30(10):4069–80. 10.1016/j.matdes.2009.05.014.Search in Google Scholar

[3] Sukontasukkul P, Nimityongskul P, Mindess S. Effect of loading rate on damage of concrete. Cem Concr Res. 2004;34(11):2127–34. 10.1016/j.cemconres.2004.03.022.Search in Google Scholar

[4] Fukuyama K, Higashibata Y, Miyauchi Y. Studies on repair and strengthening methods of damaged reinforced concrete columns. Cem Concr Compos. 2000;22(1):81–8. 10.1016/s0958-9465(99)00044-x.Search in Google Scholar

[5] Yaqub M, Bailey CG. Repair of fire damaged circular reinforced concrete columns with FRP composites. Constr Build Mater. 2011;25(1):359–70. 10.1016/j.conbuildmat.2010.06.017.Search in Google Scholar

[6] Rossi P. Ultra-high-performance fiber-reinforced concretes. Concr Int; 2001;23(12):46–52.Search in Google Scholar

[7] Campione G, Fossetti M, Giacchino C, Minafò G. RC columns externally strengthened with RC jackets. Mater Struct. 2013;47(10):1715–28. 10.1617/s11527-013-0146-x.Search in Google Scholar

[8] Elsamny MK, Abd-Elhamed MK, Ezz-Eldeen HA, Elmokrany AA. Strengthening of eccentrically loaded rectangular reinforced concrete columns using steel wire mesh. Civil Engineering Research Magazine (CERM). Civil Engineering Department, Faculty Of Engineering, Al-Azhar University, Cairo, Egypt; 2014. p. 226–47.Search in Google Scholar

[9] Abbas S, Nehdi ML, Saleem MA. Ultra-high performance concrete: mechanical performance, durability, sustainability and implementation challenges. Int J Concr Struct Mater. 2016;10(3):271–95. 10.1007/s40069-016-0157-4.Search in Google Scholar

[10] Brühwiler E, Denarié E. Rehabilitation and strengthening of concrete structures using ultra-high performance fibre reinforced concrete. Struct Eng Int. 2013;23(4):450–7. 10.2749/101686613x13627347100437.Search in Google Scholar

[11] Plizzari G, Rinaldi Z, Martinola G, Meda A. Strengthening of R/C existing columns with high performance fiber reinforced concrete jacket. Concrete Repair, Rehabilitation and Retrofitting II; 2008. p. 443–4. 10.1201/9781439828403.ch178.Search in Google Scholar

[12] ACI Committee. Building code requirements for structural concrete (ACI 318-08) and commentary. American Concrete Institute; 2008.Search in Google Scholar

[13] Building Research Establishment Method. https://www.designingbuildings.co.uk.Search in Google Scholar

[14] Mohd Zahid MZA, Abu Bakar BH, Nazri FM. Behaviour of post heated reinforced concrete columns. IOP Conf Ser Earth Environ Sci. 2019;244:012006. 10.1088/1755-1315/244/1/012006.Search in Google Scholar

[15] Kingsun Company. 2022. https://kingsunchemical.comSearch in Google Scholar

[16] Smith D, Jones EF. Load-cycling in cubic press in shock compression of condensed matter-2001. AIP Conference Proceedings 620. Vol. 2002. Melville, NY: AIP Publishing; 2002. p. 651–4.Search in Google Scholar

[17] Yaqub M, Bailey CG. Cross sectional shape effects on the performance of post-heated reinforced concrete columns wrapped with FRP composites. Compos Struct. 2011;93(3):1103–17. 10.1016/j.compstruct.2010.09.012.Search in Google Scholar

[18] Meda A, Mostosi S, Rinaldi Z, Riva P. Corroded RC columns repair and strengthening with high performance fiber reinforced concrete jacket. Mat Struct. 2015;49(5):1967–78. 10.1617/s11527-015-0627-1.Search in Google Scholar

[19] Denarié E. Recommendation for the tailoring of UHPFRC recipes for rehabilitation. ARCHES D06. 2009. http://arches.fehrl.org.Search in Google Scholar

[20] Vikan H, Justnes H. Rheology of cementitious paste with silica fume or limestone. Cem Concr Res. 2007;37(11):1512–7. 10.1016/j.cemconres.2007.08.012.Search in Google Scholar

[21] Wille K, El-Tawil S, Naaman AE. Properties of strain hardening ultra high performance fiber reinforced concrete (UHP-FRC) under direct tensile loading. Cem Concr Compos. 2014;48:53–66. 10.1016/j.cemconcomp.2013.12.015.Search in Google Scholar

[22] Eide MB, Hisdal JM. Ultra-high performance fibre reinforced conrete (UHPFRC) – State of Art. COIN Project Report 44. 2012. http://www.coinweb.no.Search in Google Scholar

[23] Khairunnisa M, Yew CY, Affandi AZMZ, Zaiha ZN, Fitriah IN, Norhaizura Y. Study on the potential of using HPFRC as a repair material for concrete damaged RC short columns. AIP Conference Proceedings; 2018. 10.1063/1.5066867.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq

Articles in the same Issue

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq