Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

-

Alaa Kharbat Shadhar

Abstract

The cement industry is considered one of the strategic industries, because it is directly related to construction work and cement is used as a hydraulic binder. However, it is a simple industry compared to major industries and depends on the availability of the necessary raw materials. This study focuses on optimizing and coordinating the location of raw materials needed for the cement manufacturing in Wasit Governorate in Iraq. Field works include detailed reconnaissance, topographic work, and description and sampling of 24 lithological sections that represent the carbonate deposits, which crop out in the area. The investigated area has the following specifications: The weighted averages of chemical components in the industrial bed are as follows: CaO = 47.83%, MgO = 1.12%, SiO2 = 7.28%, SO3 = 0.34%, Fe2O3 = 1.85%, Al2O3 = 1.85%, L.O.I = 39.26%, Na2O = 0.29%, and K2O = 0.38%. The average thickness of the investigated raw materials is 15.68 m. The average bulk density of the investigated raw materials is 2.32 g/cm3. The compressive strength of the investigated raw materials ranges from 6.182 to 55.21 MN/m2. The positive area is 922,552 m2. The volume of the industrial bed is 14,466,242 m3. The economic reserve of the industrial bed is 33,561,682 tons.

1 Introduction

Since ancient times, the use of mortars was documented extremely. Clay was likely the first binder, because of its wide availability and applications that required low technology. Since at least 6000 B.C., mortars were used in the primal form as several archaeological sites were testified, including Iraq, Egypt, Turkey, and Syria. At the later centuries, several civilizations adopted mortars, such as the Mesopotamia, Minoans, Romans, Egyptians, and Greeks. The calcination technologies, raw materials, and the building techniques were developed rapidly from one locality to another in different ways. Many studies dealt with geomaterials, stones, and raw material provenance of cement, with all of their related aspects, as well as the physical, mineralogical, and chemical properties. This study will focus on exploring and identifying the areas of raw materials needed for the cement industry in Wasit Governorate in Iraq.

2 Literature review

The complexity of the projects was accompanied by the great development in the construction industry, so over the past 150 years, concrete, especially cement, dominated this industry and the increase in demand for cement products prompted an increase in the manufacturing rate in 2012 to more than 3 billion tons when the quantities produced were 1,500 million tons in 2000 [1].

The evolution of developing economies and the rapid growth of their infrastructure led to an increase in the global production of ordinary Portland cement (OPC) to reach 4 billion tons annually [2], which made OPC as a strategic commodity and vital material for those economies [3]. It is estimated that making concrete consumes 50% of the world’s annual OPC to produce approximately 11 billion tons of concrete, while the remainder is used for coatings, screeds, stucco, mortars, and other applications [4]. In the near future, especially with the increasing requirements of buildings and infrastructure, sustainable, durable, and economical concrete is increasingly desirable [5]. It is expected by 2050 that the demand will increase to produce more than 18 billion tons of concrete of all kinds annually [6]. In recent years, emerging economies have experienced significant growth, especially developing countries such as India, China, and North Africa and the Middle East. Today, the cement market is dominated by China with a total production of 58.13% of global consumption [2].

Portland cement is one of the most produced materials in the world because it is the first essential material that supports global development [7]. Globally, when cement is compared to other building materials, there is an abundance of raw materials required for the manufacture of cement due to the good durability and low cost of cement [8].

The two largest cement producers in the world are China and India. In 2017, they produced nearly 64% as part of the world’s production, roughly equivalent to 2.61 million ton (MT) of cement as part of a global production of 4.05 M.T. In 2018, these two countries produced 65% of the whole world production, or 2.66 million tons as part of a total world production of 4.10 million tons. By comparison, the United States directly produced 0.86 and 0.88 M.T. of cement in 2017 and 2018, respectively. In the Middle East, the main producer of cement in the region is Saudi Arabia, which produced in the same years 0.47 and 0.45 million tons. In the region of Middle East and North Africa region, the rate of growing in cement demand at a of 5.5% compound annual growth rate [9].

The increasing demand for cement has become inevitable, especially with the increasing growth of cities and the resulting steady urban expansion. The growing investments in the construction sector have been the main driving force for the development of infrastructure in North Africa and the Middle East region. As rail and road networks, infrastructure development and the construction of more major cities are likely to expand as part of the development of the regional market; therefore, the need to cement in North Africa and the Middle East region will continue to rise [10]. In Iraq, the healthy increase in demand for cement, especially for the increase in construction activity, requires an increase in its production.

3 Study area

The investigated area is located in Zurbatiyah region, bounded by the following coordinates (Table 1).

Coordinates of study area

| Longitude | Latitude |

|---|---|

| 46°5′42.00″ | 33°16′54.00″ |

| 46°7′0.37″ | 33°15′56.75″ |

Within Wasit Governorate, Badra district, it is about 18 km northeast of Zurbatiyah city (Figure 1).

Location map of the studied area.

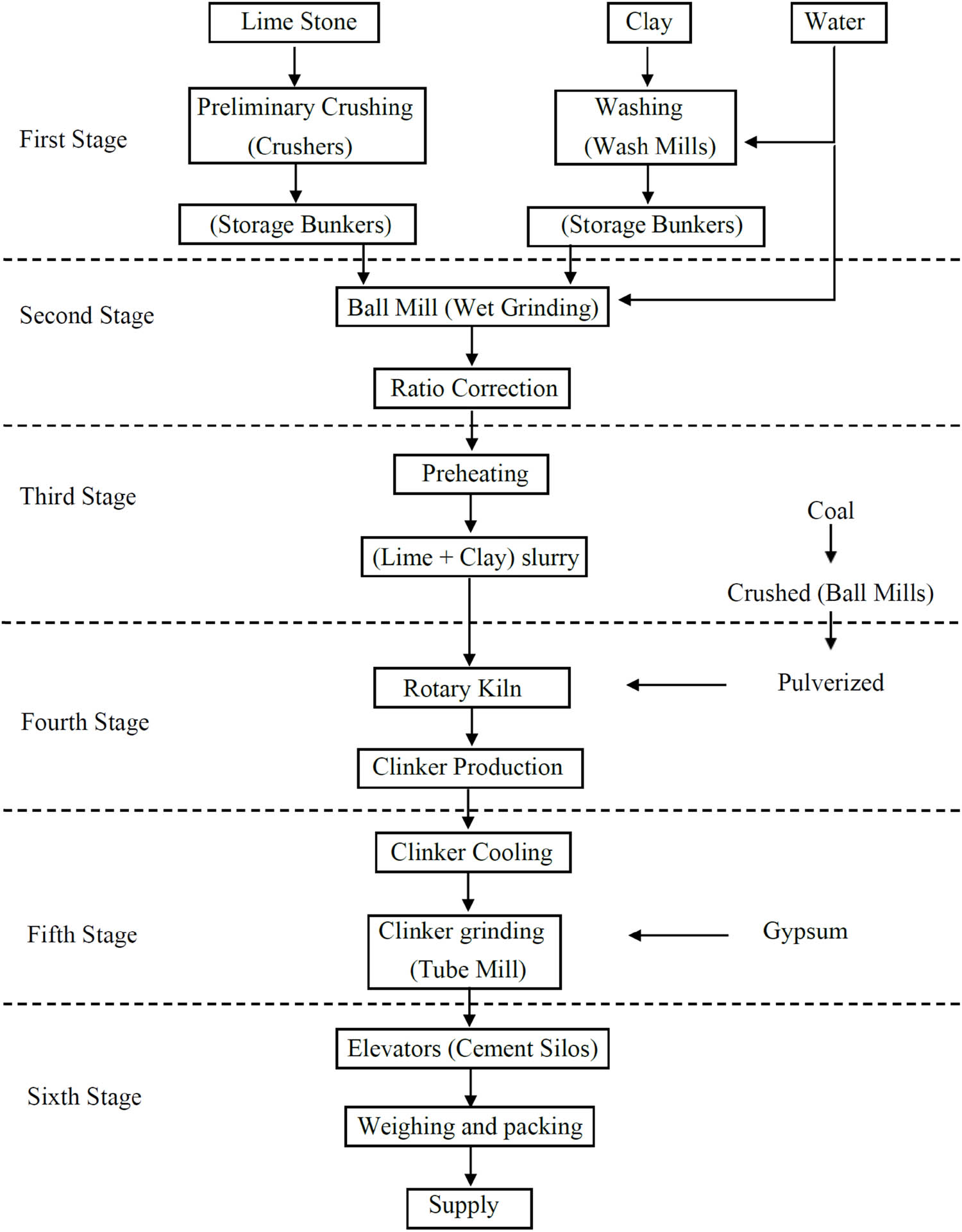

4 Cement production process

Suitable raw materials for cement production are selected and then produced using a six-stage process: mining of raw materials (limestone); mixing, homogenizing, and grinding of various raw ingredients in the form of a mixture; heat treatment stage by preheating in an oven; production of the final material clinker grinding; and finally, the packaging and transportation of the product [11].

In the first stage, the main raw materials are prospected and mined, such as bauxite, clay, limestone, iron ore, kaolin, laterite, and sandstone. The main source of calcium is limestone, while aluminum is obtained from kaolin and bauxite ores. Iron ore and red ocher meet the requirements for iron, and, to some extent, the main sources of silica are phyllite sandstone and quartzite. Since the need for other components is significantly lower than that for limestone, stone supplies are usually located near cement kilns, with the plant relying on the transportation of other raw materials. The second stage involves designing appropriate mixing ratios for raw materials and characterizing these different materials. The raw mixture is then transferred to common grinding mills known as vertical roller mills/ball mills, to grind the raw material, achieve the target fineness of the powder, and thus store it in special silos [12].

In the third stage, or the heating stage to remove carbon from the raw materials, the raw mixture is passed through vertical spiral cyclones with a number ranging between 5 and 6 inside a chamber prepared for this purpose [13]. In the fourth stage, raw mix is fed to the preheated rotary kiln to make clinker, noting that the raw material is decarbonized in the previous stage. The kiln feed retention time also varies from one factory to another. The production capacity and reaction speed of the raw mix are among the most important considerations for determining the timing of kiln feeding. Normally, 900°C is the inlet temperature of the oven, while 1,450°C is the final temperature [7,14]. During the heating phase, many chemical reactions occur between iron, aluminum, silicon, calcium, etc., to reach clinker. In the fifth stage, forced air is used to quickly cool the clinker as it leaves the kiln. The energy requirement is decreased by recirculating the heated air back into the preheater or kiln [7]. A suitable grinding mill is then used to grind the cooled clinker along with calcium sulfate source or 5% gypsum, as well as additional trace elements such as limestone and stannous or ferrous sulfate. The ground cement is finally transported via an appropriate transport system to storage silos. For instance, the silos must guard against contamination and dehydration. Following storage, cement is either carried in bulk or packaged in 20–50 kg waterproof bags. Figure 2 illustrates the six-stage process of cement manufacturing.

Six-stage process of cement manufacturing.

5 Field survey and laboratory works

The field survey started by detailed reconnaissance to determine the best locations suitable for selecting the lithological sections that represent the carbonate sediments in the area. In this part of the work, the limits of the project area were determined and the appropriate ways of team work were also identified.

5.1 Lithological sections

According to the work program of the project, 24 lithological sections were described; they represent the best geographical and vertical extensions of the carbonate beds cropped out in the project area. The intra-distances between these sections range from 125 to 500 m, and the total thickness of all sections is 481 m.

5.2 Description and sampling

The characteristic properties of field rocks are studied, depending on the visual inspection of the field and the rock changes; the distance between samples ranges from 0.5 to 3.5 m.

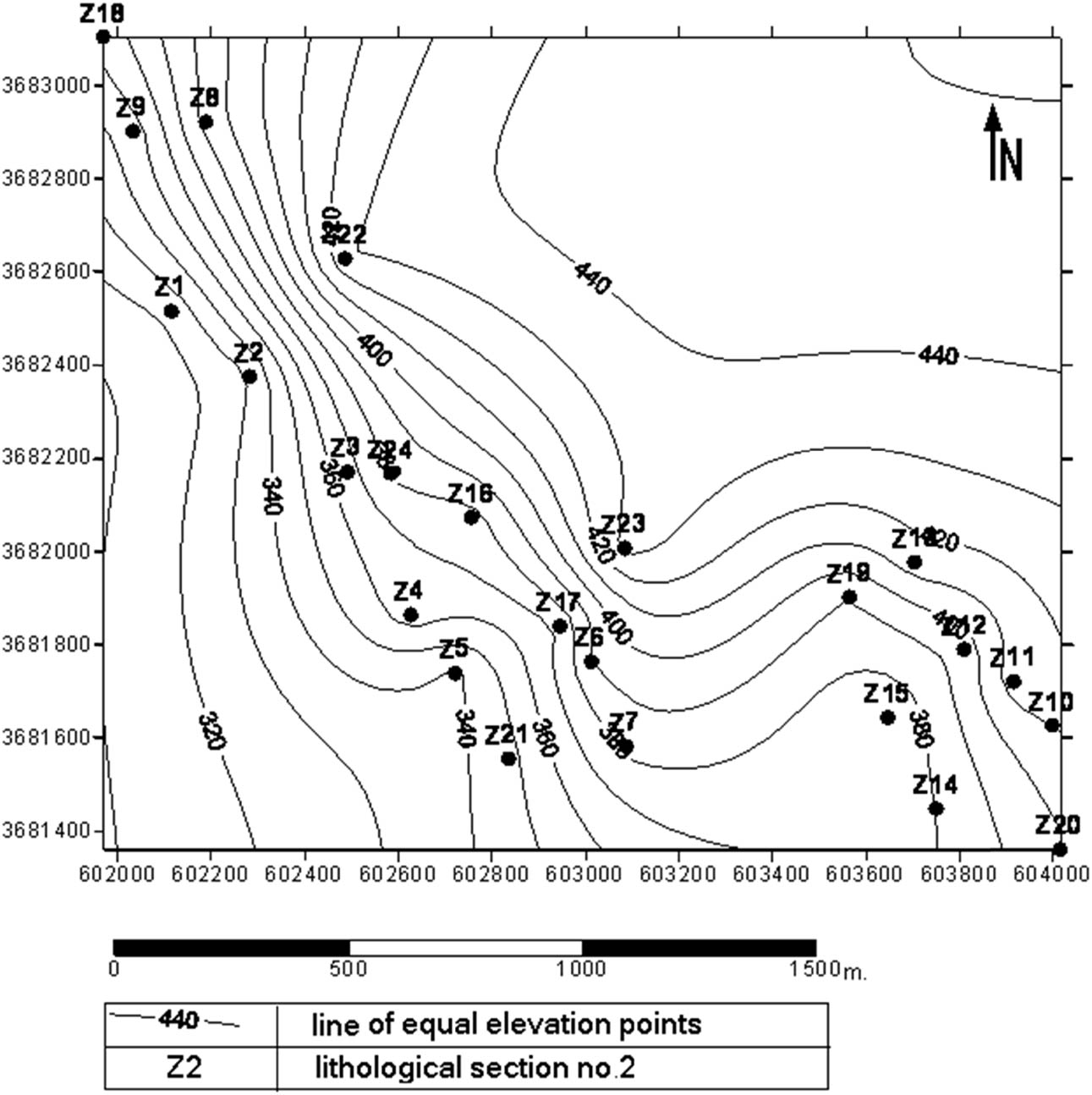

5.3 Topographic work

The topographic work included the determination of the coordinates and elevations of the lithological sections. A simple contour map of the investigated area obtained using the mentioned information is shown in Figure 3.

Contour map of the studied area.

5.4 Laboratory works

The laboratory work carried out in this work includes the following analysis and tests.

5.5 Chemical analysis

Three hundred and thirty-eight rock samples were collected from 481 m. in 24 lithological sections and analyzed to determine the following chemical components: CaO, MgO, SiO2, SO3, L.O.I, Na2O, K2O, Fe2O3, and Al2O3.

5.6 Petrophysical and rock mechanics tests

5.6.1 Bulk density

This test includes 12 samples collected from different levels within the sections to cover most rocks in the area.

5.6.2 Compressive strength

This test includes eight samples collected from different levels within the sections to cover most rocks in the area.

6 Office work

The results analysis is an important stage that includes gathering information and previous studies before entering field work, such as studies on the region in addition to access to the aerial photographs, satellite images, show the area, the creation of services, and equipment necessary for field work. During the field work, in the daily meetings of the working group, the completed work was discussed, all the acquired data were documented, maps and drawings were prepared, besides sample preparation, and sent them to the laboratory. The results analysis includes data collected from the field, and laboratory tests, to interpret the results set out and recommended of the final conclusion.

6.1 Qualitative evaluation

Specifications of chemical and physical characteristics of the industrial bed are discussed in the following to make a qualitative evaluation of the carbonate rocks.

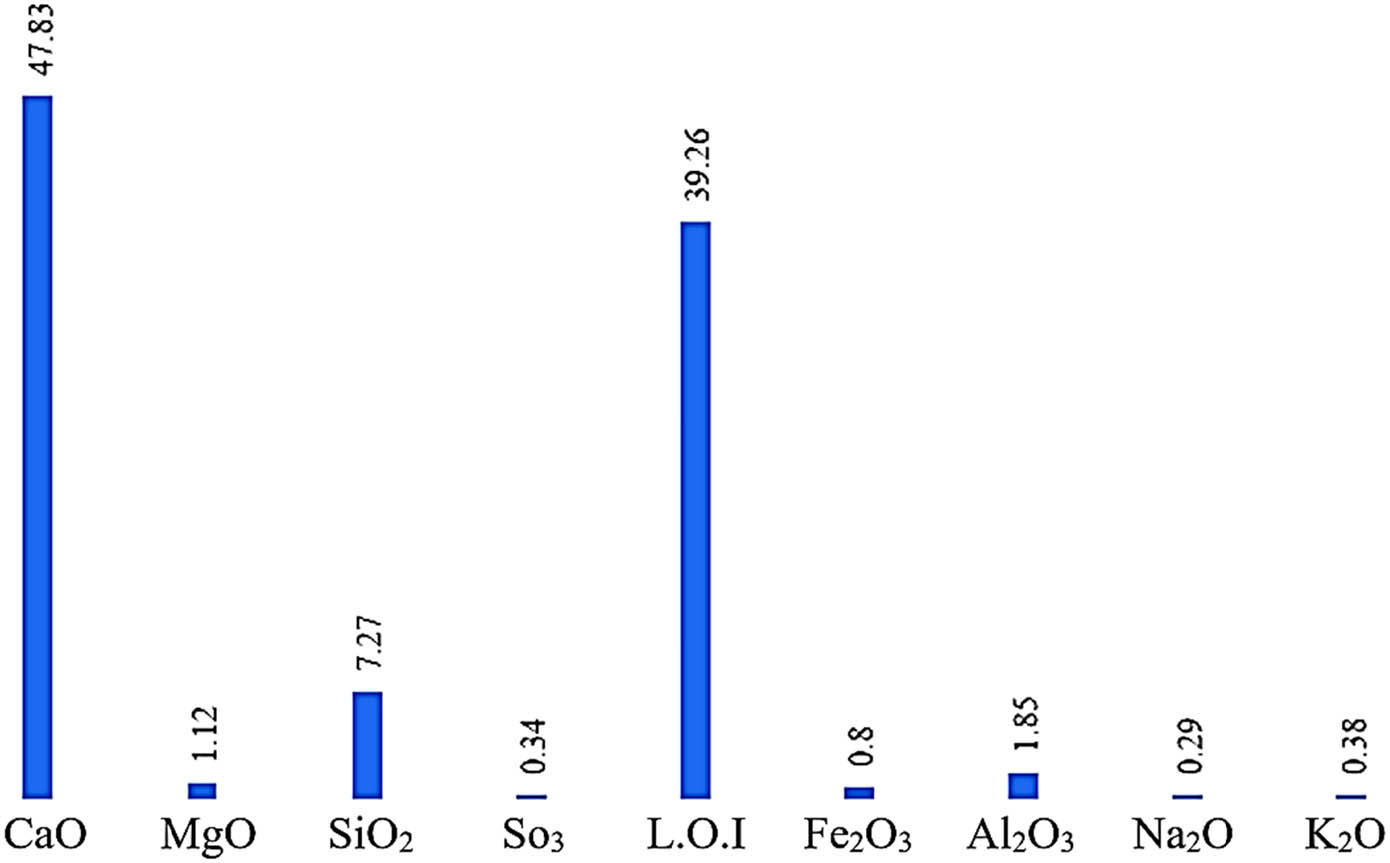

6.1.1 Chemical specifications

The most important specification in the qualitative evaluation of the carbonate rocks suitable for cement manufacturing is the concentration of the defined investigated area; chemical components and the distribution of these components are discussed in the next paragraphs. Chemical component ratio of the investigated raw material in the studied area was calculated depending on the chemical analysis of several hundreds of samples gained from 24 sections. The illustration charts of these sections are attached in Appendix 1; they include all available information about the studied lithosections. Figure 4 shows the chemical component ratio of the investigated raw material in the studied area.

Chemical component ratio.

The values of the averages and limits of the chemical components in the industrial bed are listed in Table 2.

Chemical component ratio limits in the industrial bed

| Chemical component | Minimum value | Maximum value | Average value |

|---|---|---|---|

| CaO | 45.16 | 51.86 | 47.83 |

| MgO | 0.46 | 1.7 | 1.12 |

| SiO2 | 3.98 | 8.92 | 7.27 |

| SO3 | 0.07 | 0.7 | 0.34 |

| L.O.I | 37.34 | 41.53 | 39.26 |

| Fe2O3 | 0.46 | 1.14 | 0.8 |

| Al2O3 | 0.89 | 2.7 | 1.85 |

| Na2O | 0.15 | 0.57 | 0.29 |

| K2O | 0.21 | 0.81 | 0.38 |

6.1.2 Bulk density

It is defined as the mass of many particles of the material divided by the total volume they occupy. The total volume includes particle volume, inter-particle void volume, and internal pore volume. Table 3 shows the bulk density average of the investigated raw material in the industrial bed.

Bulk density average of the investigated raw material

| Sample No. | Thickness (m) | Bulk density (g/cm3) | Sample No. | Thickness (m) | Bulk density (g/cm3) |

|---|---|---|---|---|---|

| Z9/11 | 2.0 | 2.168 | Z19/5 | 2.0 | 2.451 |

| Z10/13 | 0.5 | 2.389 | Z21/3 | 1.0 | 2.472 |

| Z13/2 | 2.0 | 2.290 | Z22/9 | 2.0 | 2.219 |

| Z14/3 | 1.0 | 2.386 | Z22/24 | 2.0 | 2.262 |

| Z16/17 | 2.0 | 2.405 | Z23/7 | 2.0 | 2.408 |

| Z17/3 | 2.0 | 2.270 | Z24/8 | 1.0 | 2.362 |

| Average | 2.32 | ||||

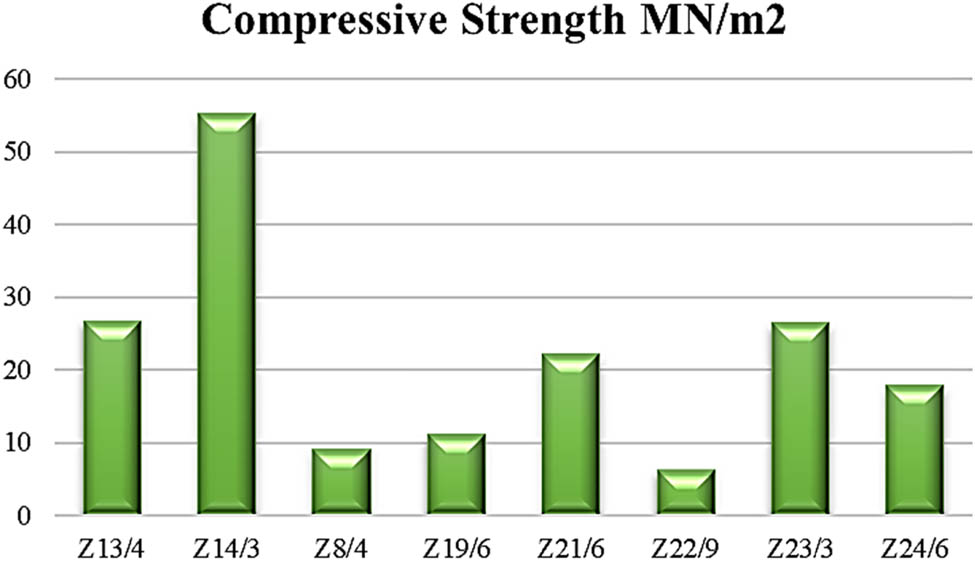

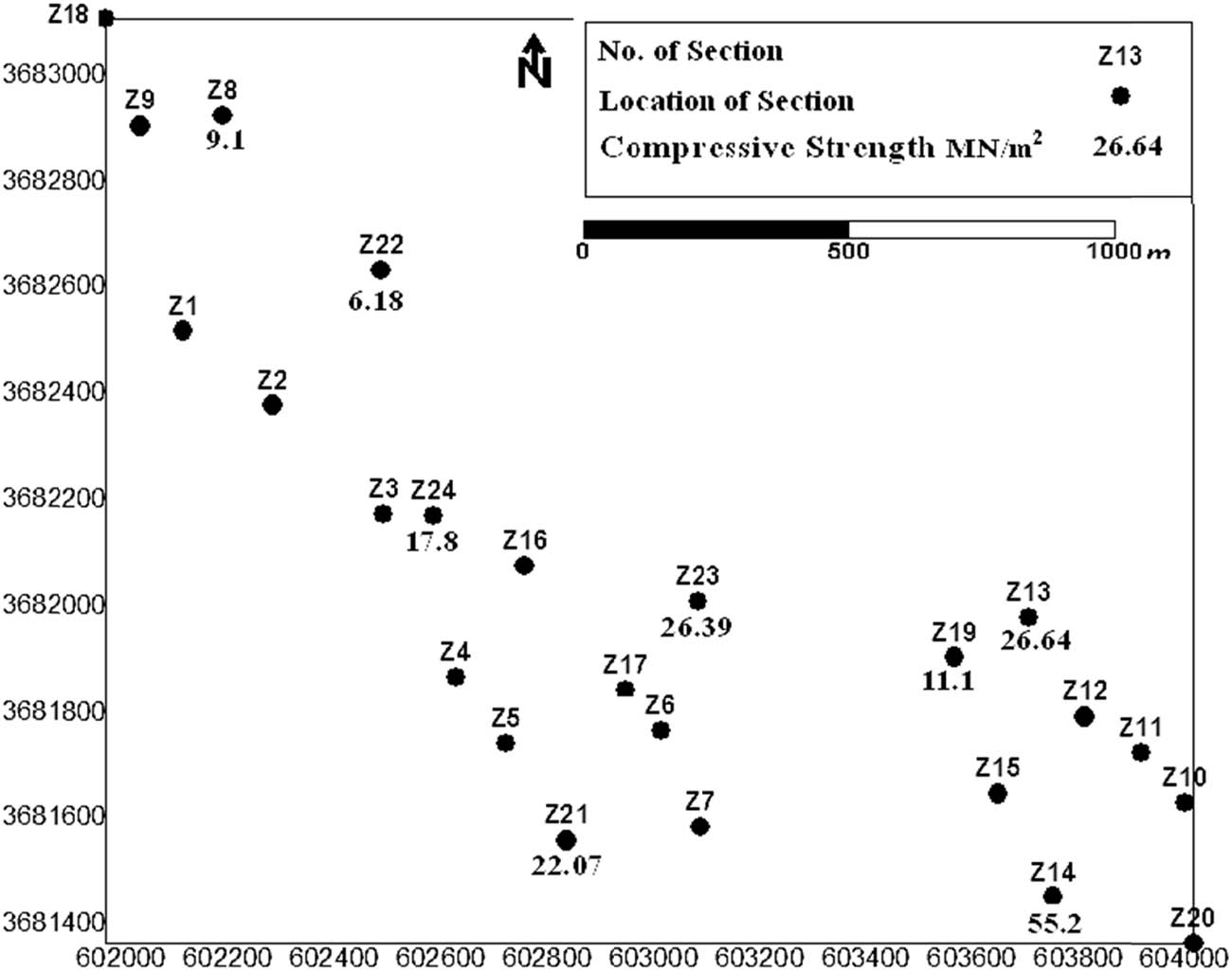

6.1.3 Compressive strength

The compressive strength of a material is the value of uniaxial compressive stress reached when the material fails completely. Compressive strength has the unit of stress, i.e., force per unit area (MN/m2) (Figures 5 and 6). The compressive strength and average of the investigated raw material in the industrial bed are presented in Table 4.

Compressive strength of the bed area.

Distribution map of compressive strength in the area.

Results of compressive strength tests

| Sample no. | Thickness (m) | Compressive strength (MN/m2) |

|---|---|---|

| Z13/4 | 2.0 | 26.643 |

| Z14/3 | 1.0 | 55.2104 |

| Z8/4 | 1.0 | 9.101 |

| Z19/6 | 1.0 | 11.114 |

| Z21/6 | 2.0 | 22.0779 |

| Z22/9 | 2.0 | 6.182 |

| Z23/3 | 1.0 | 26.395 |

| Z24/6 | 2.0 | 17.825 |

| Average | 16.16 | |

6.2 Quantitative evaluation

To evaluate the rocks of the industrial bed quantitatively, it is important to know the following parameters for reserve estimation:

6.2.1 Thickness

The average thickness of the industrial bed in the positive area is 15.68 m.

6.2.2 Area

The positive area is computed by using the coordinate method. It is 922,592 m2.

6.2.3 Bulk density

The average bulk density of the industrial bed in the area is 2.32 g/cm3.

6.2.4 Cut-off limits

The cut-off limits used in this study are dependent on the common limits considered by the most of cement factories in Iraq; they are as follows:

6.3 Results of data analysis

Three parameters are considered the main factors when calculating reserve: the investigated area (922,592 m2), the average thickness of the raw material bed in investigated area (15.68 m), and the average of bulk density of the bed (2.32 g/cm3).

The equation for reserve is as follows:

The total volume of industrial bed is 14,466,242 m3, and the reserve is 33,561,682 tons.

7 Conclusions

The study reached the following conclusions:

More investigation to the rounding area was needed to locate the suitable raw material for cement industry.

The investigated area contains an industrial bed of limestone rocks suitable for the cement industry due to its chemical specifications.

The industrial bed lies within Fat’ha Formation (Middle Miocene), and this study dealt with the exposed parts of the formation only.

The category of exploration in this study, which is based on prevailing conditions, is C 1.

The weighted averages of chemical components in industrial bed are as follows:

CaO = 47.83%, MgO = 1.12%, SiO2 = 7.28%, SO3 = 0.34%, Fe2O3 = 1.85%, Al2O3 = 1.85%, L.O.I = 39.26%, Na2O = 0.29%, K2O = 0.38%.

The average thickness of the industrial bed is 15.68 m.

The average bulk density of the industrial bed is 2.32 g/cm3.

The compressive strength of the industrial bed ranges from 6.182 to 55.21 MN/m2.

The positive area is 922,552 m2.

The volume of the industrial bed is 14,466,242 m3.

The economic reserve of the industrial bed is 33,561,682 tons.

8 Recommendations

It is important to upgrade the exploration in order to use the rocks in investment projects. It is not recommended to use this study for direct investment. The upgrading work requires a more detailed fieldwork, including the high technique of drilling and topography because of the structural and geomorphologic conditions that control the extension of the industrial bed in the area, laterally and vertically.

Other investigation work could be achieved in the area to evaluate clay sediments that could be used in the cement industry. It is important to execute a detailed survey in the Zurbatiya area to take it as a database for future works.

More field work and investigations must be conducted in order to reach the best ratios of compounds involved in the cement industry and to greater reserve, because the current study was limited in thickness because of funding limitation. An additional study will also be conducted to indicate the suitability of the existing compounds and their proportions for the plaster industry. It is also possible to verify the suitability of these raw materials for the manufacture of some types of concrete admixtures.

Acknowledgments

The University of Wasit supported this project. I am grateful to my classmates and cohort members, especially my office mates, for their editing help. Thanks should also go to the librarians, research assistants, and study participants from the different Iraqi projects.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Imbabi MS, Carrigan C, McKenna S. Trends and developments in green cement and concrete technology. Int J Sustain Built Environ. 2012;1:194–216.10.1016/j.ijsbe.2013.05.001Suche in Google Scholar

[2] U.S. Geological Survey. Mineral commodity summaries 2018. Reston, VA, USA: U.S. Geological Survey; 2018.Suche in Google Scholar

[3] Phair JW. Green chemistry for sustainable cement production and use. Green Chem. 2006;8:763–80.10.1039/b603997aSuche in Google Scholar

[4] Smith RA, Kersey JR, Griffiths PJ. The construction industry mass balance: Resource use, wastes and emissions. Construction. 2002;4:680.Suche in Google Scholar

[5] Schneider M. Process technology for efficient and sustainable cement production. Cem Concr Res. 2015;78:14–23.10.1016/j.cemconres.2015.05.014Suche in Google Scholar

[6] Mehta PK, Monteiro PJM. Concrete microstructure, properties, and materials. 3rd edn. New York, NY, USA: McGraw-Hill; 2006.Suche in Google Scholar

[7] Deolalkar SP. Designing green cement plants. UK: Butterworth-Heinemann; 1st edition, 2015.10.1016/B978-0-12-803420-0.00001-9Suche in Google Scholar

[8] Herfort D, Moir GK, Johansen V, Sorrentino F, Bolio Arceo H. The chemistry of Portland cement clinker. Adv Cem Res. 2010;22(4):187–94.10.1680/adcr.2010.22.4.187Suche in Google Scholar

[9] Uwasu M, Hara K, Yabar H. World cement production and environmental implications. Environ Dev. 2014;10(1):36–47.10.1016/j.envdev.2014.02.005Suche in Google Scholar

[10] Abbass RA, Kumar P, El-Gendy A. An overview of monitoring and reduction strategies for health and climate change related emissions in the Middle East and North Africa region. Atmos Environ. 2018;175:33–43.10.1016/j.atmosenv.2017.11.061Suche in Google Scholar

[11] Van Oss HG, Padovani AC. Cement manufacture and the environment - Part I: Chemistry and technology. J Ind Ecol. 2002;6(1):89–106.10.1162/108819802320971650Suche in Google Scholar

[12] Aitcin PC, Flatt RJ. Science and technology of concrete admixtures. Amsterdam, The Netherlands: Woodhead Publishing; 2016.Suche in Google Scholar

[13] Wasilewski M, Duda J. Influence construction of suspension preheater on energy consumption process during burning in rotary kiln. XIVth International Symposium on Heat Transfer and Renewable Sources of Energy. Poland; 2012.Suche in Google Scholar

[14] Boateng AA. Rotary kiln minerals process applications. Transport Phenomena and Transport Processes. UK: Butterworth-Heinemann; 2016. p. 231–64.10.1016/B978-0-12-803780-5.00010-1Suche in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq

Artikel in diesem Heft

- Regular Articles

- Design optimization of a 4-bar exoskeleton with natural trajectories using unique gait-based synthesis approach

- Technical review of supervised machine learning studies and potential implementation to identify herbal plant dataset

- Effect of ECAP die angle and route type on the experimental evolution, crystallographic texture, and mechanical properties of pure magnesium

- Design and characteristics of two-dimensional piezoelectric nanogenerators

- Hybrid and cognitive digital twins for the process industry

- Discharge predicted in compound channels using adaptive neuro-fuzzy inference system (ANFIS)

- Human factors in aviation: Fatigue management in ramp workers

- LLDPE matrix with LDPE and UV stabilizer additive to evaluate the interface adhesion impact on the thermal and mechanical degradation

- Dislocated time sequences – deep neural network for broken bearing diagnosis

- Estimation method of corrosion current density of RC elements

- A computational iterative design method for bend-twist deformation in composite ship propeller blades for thrusters

- Compressive forces influence on the vibrations of double beams

- Research on dynamical properties of a three-wheeled electric vehicle from the point of view of driving safety

- Risk management based on the best value approach and its application in conditions of the Czech Republic

- Effect of openings on simply supported reinforced concrete skew slabs using finite element method

- Experimental and simulation study on a rooftop vertical-axis wind turbine

- Rehabilitation of overload-damaged reinforced concrete columns using ultra-high-performance fiber-reinforced concrete

- Performance of a horizontal well in a bounded anisotropic reservoir: Part II: Performance analysis of well length and reservoir geometry

- Effect of chloride concentration on the corrosion resistance of pure Zn metal in a 0.0626 M H2SO4 solution

- Numerical and experimental analysis of the heat transfer process in a railway disc brake tested on a dynamometer stand

- Design parameters and mechanical efficiency of jet wind turbine under high wind speed conditions

- Architectural modeling of data warehouse and analytic business intelligence for Bedstead manufacturers

- Influence of nano chromium addition on the corrosion and erosion–corrosion behavior of cupronickel 70/30 alloy in seawater

- Evaluating hydraulic parameters in clays based on in situ tests

- Optimization of railway entry and exit transition curves

- Daily load curve prediction for Jordan based on statistical techniques

- Review Articles

- A review of rutting in asphalt concrete pavement

- Powered education based on Metaverse: Pre- and post-COVID comprehensive review

- A review of safety test methods for new car assessment program in Southeast Asian countries

- Communication

- StarCrete: A starch-based biocomposite for off-world construction

- Special Issue: Transport 2022 - Part I

- Analysis and assessment of the human factor as a cause of occurrence of selected railway accidents and incidents

- Testing the way of driving a vehicle in real road conditions

- Research of dynamic phenomena in a model engine stand

- Testing the relationship between the technical condition of motorcycle shock absorbers determined on the diagnostic line and their characteristics

- Retrospective analysis of the data concerning inspections of vehicles with adaptive devices

- Analysis of the operating parameters of electric, hybrid, and conventional vehicles on different types of roads

- Special Issue: 49th KKBN - Part II

- Influence of a thin dielectric layer on resonance frequencies of square SRR metasurface operating in THz band

- Influence of the presence of a nitrided layer on changes in the ultrasonic wave parameters

- Special Issue: ICRTEEC - 2021 - Part III

- Reverse droop control strategy with virtual resistance for low-voltage microgrid with multiple distributed generation sources

- Special Issue: AESMT-2 - Part II

- Waste ceramic as partial replacement for sand in integral waterproof concrete: The durability against sulfate attack of certain properties

- Assessment of Manning coefficient for Dujila Canal, Wasit/-Iraq

- Special Issue: AESMT-3 - Part I

- Modulation and performance of synchronous demodulation for speech signal detection and dialect intelligibility

- Seismic evaluation cylindrical concrete shells

- Investigating the role of different stabilizers of PVCs by using a torque rheometer

- Investigation of high-turbidity tap water problem in Najaf governorate/middle of Iraq

- Experimental and numerical evaluation of tire rubber powder effectiveness for reducing seepage rate in earth dams

- Enhancement of air conditioning system using direct evaporative cooling: Experimental and theoretical investigation

- Assessment for behavior of axially loaded reinforced concrete columns strengthened by different patterns of steel-framed jacket

- Novel graph for an appropriate cross section and length for cantilever RC beams

- Discharge coefficient and energy dissipation on stepped weir

- Numerical study of the fluid flow and heat transfer in a finned heat sink using Ansys Icepak

- Integration of numerical models to simulate 2D hydrodynamic/water quality model of contaminant concentration in Shatt Al-Arab River with WRDB calibration tools

- Study of the behavior of reactive powder concrete RC deep beams by strengthening shear using near-surface mounted CFRP bars

- The nonlinear analysis of reactive powder concrete effectiveness in shear for reinforced concrete deep beams

- Activated carbon from sugarcane as an efficient adsorbent for phenol from petroleum refinery wastewater: Equilibrium, kinetic, and thermodynamic study

- Structural behavior of concrete filled double-skin PVC tubular columns confined by plain PVC sockets

- Probabilistic derivation of droplet velocity using quadrature method of moments

- A study of characteristics of man-made lightweight aggregate and lightweight concrete made from expanded polystyrene (eps) and cement mortar

- Effect of waste materials on soil properties

- Experimental investigation of electrode wear assessment in the EDM process using image processing technique

- Punching shear of reinforced concrete slabs bonded with reactive powder after exposure to fire

- Deep learning model for intrusion detection system utilizing convolution neural network

- Improvement of CBR of gypsum subgrade soil by cement kiln dust and granulated blast-furnace slag

- Investigation of effect lengths and angles of the control devices below the hydraulic structure

- Finite element analysis for built-up steel beam with extended plate connected by bolts

- Finite element analysis and retrofit of the existing reinforced concrete columns in Iraqi schools by using CFRP as confining technique

- Performing laboratory study of the behavior of reactive powder concrete on the shear of RC deep beams by the drilling core test

- Special Issue: AESMT-4 - Part I

- Depletion zones of groundwater resources in the Southwest Desert of Iraq

- A case study of T-beams with hybrid section shear characteristics of reactive powder concrete

- Feasibility studies and their effects on the success or failure of investment projects. “Najaf governorate as a model”

- Optimizing and coordinating the location of raw material suitable for cement manufacturing in Wasit Governorate, Iraq

- Effect of the 40-PPI copper foam layer height on the solar cooker performance

- Identification and investigation of corrosion behavior of electroless composite coating on steel substrate

- Improvement in the California bearing ratio of subbase soil by recycled asphalt pavement and cement

- Some properties of thermal insulating cement mortar using Ponza aggregate

- Assessment of the impacts of land use/land cover change on water resources in the Diyala River, Iraq

- Effect of varied waste concrete ratios on the mechanical properties of polymer concrete

- Effect of adverse slope on performance of USBR II stilling basin

- Shear capacity of reinforced concrete beams with recycled steel fibers

- Extracting oil from oil shale using internal distillation (in situ retorting)

- Influence of recycling waste hardened mortar and ceramic rubbish on the properties of flowable fill material

- Rehabilitation of reinforced concrete deep beams by near-surface-mounted steel reinforcement

- Impact of waste materials (glass powder and silica fume) on features of high-strength concrete

- Studying pandemic effects and mitigation measures on management of construction projects: Najaf City as a case study

- Design and implementation of a frequency reconfigurable antenna using PIN switch for sub-6 GHz applications

- Average monthly recharge, surface runoff, and actual evapotranspiration estimation using WetSpass-M model in Low Folded Zone, Iraq

- Simple function to find base pressure under triangular and trapezoidal footing with two eccentric loads

- Assessment of ALINEA method performance at different loop detector locations using field data and micro-simulation modeling via AIMSUN

- Special Issue: AESMT-5 - Part I

- Experimental and theoretical investigation of the structural behavior of reinforced glulam wooden members by NSM steel bars and shear reinforcement CFRP sheet

- Improving the fatigue life of composite by using multiwall carbon nanotubes

- A comparative study to solve fractional initial value problems in discrete domain

- Assessing strength properties of stabilized soils using dynamic cone penetrometer test

- Investigating traffic characteristics for merging sections in Iraq

- Enhancement of flexural behavior of hybrid flat slab by using SIFCON

- The main impacts of a managed aquifer recharge using AHP-weighted overlay analysis based on GIS in the eastern Wasit province, Iraq