Abstract

Numerical simulation of laser welding dissimilar joint was presented. Results of butt joint for low carbon and austenitic steels are studied. Numerical calculations based on thermo-mechanical method and phase transformation were used for estimating weld dimensions and joint properties. Unconventional welding method where focused photons beam are used as a heat source were presented. Problems with welding of dissimilar joints, where different composition and thermo physical material properties affect on this phenomena complexity are solved using numerical methods and laser welding technology. Simulation of low carbon and stainless steel joints using SimufactWelding software are presented. Model of heat source within geometry and parameters was programmed. Laser beam welding simulation was performed for estimating parameters for complete joints penetration. Programming welding boundary condition and heat source geometry welding parameters with output power and welding speed rate was estimated. Materials used in simulation process and experimental welding was low carbon construction S235JR and stainless 316L steels in sheets form. Joint properties such as fusion zone and heat affected zones dimensions and stress-strain distribution were calculated. Estimation of complete joint characteristics was obtained using thermo-mechanical simulation method and Marc solver engine.. Experimental trial butt joint welding were performed based on estimated parameters. Welding process was performed using 6kW CO2 laser system. Based on numerical simulation, microstructure analysis, hardness distribution and chemical distribution of fusion zone, properties of obtained joint was studied. Model for simulation of dissimilar laser welding joint was obtained, and properties of obtained joint based on simulation and experiment was studied.

1 Introduction

Article present laser welding results of austenitic and low carbon steels joint, where numerical simulation is used for estimating welding parameters and performing joint properties analysis. Properties of obtained butt weld joint are studied based on simulation stress-strain analysis, experimental validation, performed destructive test and metal-lographic analysis. Therefore possibility of using software dedicated for welding simulation in order to predict parameters of laser dissimilar joint welding was presented, moreover joint properties analysis based on simulation results was presented. Welding of dissimilar material is complex problem, and require consider weldability of two materials with different chemical compositions and thermo physical material properties [1, 2]. Conventional welding methods use filler material and electric arc as a heat source. Nevertheless additional material usually have some differences in chemical compositions compare to welded materials, and may caused some difficulties and extend complexity of joining process. Therefore welding of dissimilar materials using concentrated photons beam, where welding process is performed by melting edges of joined materials and crystallization process can be performed without filler material. Laser beam welding (LBW) with keyhole phenomena, where high surface energy density of focused photons beam, exceeding 2·106W/cm2 allow to obtain deep welding penetration with high speed rate [3, 4]. Nowadays, many researcher studied modern technology, where plasma, laser or electron beams are used as a heat sources for welding of metallic materials [5, 6, 7].Among conducting research, advanced joints of titanium with aluminum alloys [8, 9, 10], and similar joints of high alloy materials are analyses. Weldability of low carbon with stainless steels are studied widely, however usually steel in grade 304, as well as research over simulation of this joints type. However lots of them are based on conventional welding methods and even consider electron or laser welding, process parameters were selected experimentally or for pulse welding mode [11]. Moreover aided methods based on simulations are carried out with solving complex heat-mass flow equations (ANSYS-Fluent) [12, 13, 14].However some software use simplifying some physics phenomena, where programming are based on macros implementing (SYSWELD) or software dedicated for stress-strain analysis with additional welding module (Abaqus) [15, 16, 17]. Nevertheless software base on simple solving engine give less accurate results, and advanced numerical programs require high programming capability. Performing numerical simulation in SimufactWelding software, dedicated for welding applications, where multiphase nonlinear problem using Marc solver was simulated with good time to accuracy factor [18]. Alternative to time consumable numerical simulations are analytical methods, where solving heat transfer in solid material problem fusion zone can be estimated. This methods give quick, however only approximate solution. Numerical methods give simplifying or override some physics phenomena, nevertheless solving nonlinear finite element solution accurate results can be obtained [19]. Therefore in dissimilar joint where materials with different thermo physical material properties are welded numerical methods can be used [20, 21]. Programming welding simulation heat source geometry and properties is crucial, therefore for obtaining accurate results of fusion zone (FZ) and heat affected zone (HAZ) geometries, stress-strain distribution and thermal gradients HS calibration is required [22, 23].

Validation of simulation results are performed based on trial joint, were welding parameters estimated in numerical simulation was used. Laser welding machine used for experimental welding was Trumpf TruFlow 6000 laser source mounted on 6-axies TLC1005 laser machine. Due to reduce heat accumulation in material, laser power for numerical simulation was set as maximum output power of laser system equal to 6kW. Heat source speed rate for obtained complete joint penetration was calculated.Welding trajectory was set on edges of attached S235JR and 316L steels sheet plates meshed using solid finite elements [24, 25].

Thermo physical material properties as absorption of laser beam in metal surface and material conductivity affect on results of dissimilar welding joint properties. Results of welding numerical simulation with properly defined boundary conditions give accurate estimation of weld dimension. Performing complex calculations using library of variable material properties thermo-mechanical analysis with phase transformation can be performed [26].

Paper presents study of numerical simulation of dissimilar laser welded butt joint with experimental verification, moreover according to performed simulation, properties of joint was estimated. Therefore further analysis of obtained trial joint was performed, where hardness test, microstructure and electron dispersive spectroscopy analysis was carried out.

2 Numerical simulation

In boundary conditions rigid restraint using fixing geometry was used, and specimen in form of two sheet plate 30x20mm and thickness 6mm simulated welded elements was established. Geometry was meshed using hexahedral type of elements, where general size was programmed as 1mm, however in area near welding trajectory, FE was refine and size was equal to 0.25mm (Figure 1). Simulation process of laser welding uses volumetric heat source based on double cylindrical model. Therefore conical HS (simulated kayhole effect) with upper radius 0.4mm, down radius 0.2mm and depth geometry equal to 12mm, and disc HS (simulated laser absorption effect) with radius 0.5mm and depth 0.2mm was programmed. For programmed geometry materials libraries with variable thermo-mechanical properties of low carbon and stainless steels was assigned. Materials selected for simulation was low carbon ferritic-pearlitic construction steel in grade S235JR and austenitic stainless steel in grade 316L.

Numerical model of laser welding dissimilar butt joint: a) welding configuration, b) finite element model

SimufactWelding software based on Marc solver for laser welding simulation was used. Laser welding of butt joint use single pass process where heat source moving along attached edges was simulated. Calculation of heat distribution during welding process was performed in order to estimate weld and HAZ dimension. Stress and strain analysis of obtained dissimilar joint was studied.

Numerical simulation of welding process was performed in 7 steps, with constant maximum output power equal to 6kW and speed rate between 800 - 2000 mm/min with step 200 mm/min. Laser welding simulation process was performed according to established boundary conditions (Figure 2).

Overview of laser welding process of dissimilar butt joint

Welded materials properties affect on heat expansions, therefore some differences in weld pool and HAZ geometries can be shown. Estimation of welding properties was performed based on performed simulations. For first step simulation with maximum output power and 2mm/min speed was carried out, and with every next step was reduced until complete weld penetration were obtained (Figure 3). No preheat or post weld heat treatment was programmed. Laser welding simulation of dissimilar butt joints was performed for constant output power, changed welding speed rate, and HS parameters, where efficiency of 0.9 and Gaussian parameter of conical heat source equal to 3 was programmed. Results of simulation shown that output power equal to 6kW for 6mm S235JR and 316L steel sheets with speed of 1000 mm/min give complete joint penetration.

Dimensions of simulated dissimilar laser welded joint in cross section

Results of simulation for speed rate of 1200 mm/min give erratic penetration. Thermo-mechanical simulation give realistic results of welding process with convex face of weld and material deformation. Parameters given from numerical simulation were used in experimental welding process to verifying numerical model. Differences in dimension of weld sides result from used material, chemical composition (Table 1) and thermo physical properties such as thermal conductivity and diffusivity, which affect on melting and solidification process (Table 2).

Chemical composition of used materials (in wt-%)

| Material | Cmax | Mnmax | Momax | Smax | Cumax |

|---|---|---|---|---|---|

| S235JR | 0.17 | 1.4 | 0.045 | 0.04 | 0.55 |

| Material | Cmax | Mnmax | Momax | Nimax | Crmax |

| 316L | 0.03 | 2.0 | 3.0 | 14.0 | 18.0 |

Basic thermo physical properties of welded materials

| Material | Thermal conductivity | Specific heat | Thermal expansion | Laten heat |

|---|---|---|---|---|

| S235JR | 47 | 470 | 12 | 250 |

| 316L | 15 | 480 | 16 | 300 |

Obtained joint simulation results was used for stress-strain analysis, therefore effective stress and yield stress distributions was studied (Figure 4, 5).

Effective stress distribution of simulated laser welded joint in cross section

Yield stress distribution of simulated laser welded joint in cross section

Figure 4 shown effective stress distribution for complete penetration of dissimilar butt joint of low carbon and stainless steel. Greater stress distribution occur in stainless steel. Laser welding process was performed with speed 1m/min and output power equal to 6kW. High temperature gradient combining with differences in thermo physical material properties affect on welding results. Significantly higher value of low carbon steel thermal conductivity result in narrower fusion zone and differences in phase transformation. Solidification of molten metal, chemical composition and thermal gradient define crystallographic structure of welded materials, and affect on stress-strain distributions.

Material using in welding simulation are characterized as good weldable, chemical composition and thermo physical material properties affect on differences in stress and displacement in welded materials. Calculated results of full penetration welding process was achieved. Greater value of effective stress (562MPa) and yield stress (557MPa) occur in stainless steel.

3 Experimental laser welding of trial joint

Estimating parameters based on numerical simulation was used to perform trial joint. Using CO2 Trumpf TruFlow 6000 laser system with maximum output power equal to 6kW was used. Welding process with speed of 1m/min and output power 6kW was conducted (Figure 6). Numerical simulation do not assume shielding gas effect, therefore to reduce surface tension and ionization effect helium with flow rate 15l/min was used. Two steel sheets with thickness of 6mm was welded using laser beam. Process welding head with focal length of 270mm, and coaxial shielding gas delivery system was used.

Experimental laser welding stand

Trial joint with complete weld penetration and good weld build was obtained. Moreover no defects in form of incompletely filled groove, root concavity, cracks or porosity in visual test (VT) was detected, therefore restrict B quality level was assumed.

Results of experimental trial joint are similar to numerical simulations data. Some differences in fusion zone geometry can be shown, therefore are converged with simulation analysis. Wider fusion zone of stainless steel are related to lowest thermal conductivity and heat capacity of material [27]. Differences are greater than in simulation, however surface tension and shielding gas convection effect in simulation algorithms was omitted. Therefore obtained fusion zone geometry are not uniform (Figure 7).

Trial laser welded but joint in cross section

Structure of base material for 316L was austenitic and for S235JR was ferritic- pearlitic. Microstructure of obtained weld was assumed as a dendritic and are related to crystallization direction. Heat affected zone shown differences in structure over base materials. In austenitic steel grain refining (Figure 8) and in low carbon steel grain growth (Figure 9) was observed [28].

Structure of weld and HAZ of 316L steel

Structure of HAZ and weld of S235JR steel

Structure of obtained weld is uniform, no differences in grain size and dendrite growth direction was observed. HAZ size for both material are slightly different, in low carbon steel grain gradually growth, in austenitic steel refining of grain are more abruptly, chemical compounds in stainless steel increase hardenability and have great affect on welded material crystallographic structure. Chemical composition of obtained weld, especially equivalent of chromium, nickel and molybdenum affect on joint properties [29]. In order to define but weld joint strength characteristic destructive tests need to be performed.

4 Properties of obtained trial joint

Melting and solidification process changes the crystallographic structure affecting on strength characteristics. Due to welding of dissimilar joint important is that obtained weld and HAZ of both welded materials have similar properties. Due to investigate quality of obtained joint micro hardness testing in cross-section was carried out, without additional post weld heat treatment. Hardness test was carried out according to PN-EN ISO 6507-1 using Innovatest Nexus 4303 machine. Figure 10 shown distribution of test points, Figure 11 shown results of hardness.

Point distribution of measured hardness test in laser welded dissimilar joint

Hardness value in measured test points

Value of obtained hardness in fusion zone exceed 420HV10, and are considerably great, small increase of hardness in HAZ (188 to 219HV10) towards BM. However high value of weld hardness (419 to 429HV10) proves of material hardening. Mixture of low carbon and stainless steels chemical elements affect on increase equivalent value of carbon and hardenablility elements such as chromium in fusion zone. Therefore high temperature gradient affect on solidification and crystallization process. During mixing of molten materials, chemical composition of fusion zone change and hardening process occur.

5 Chemical composition of obtained dissimilar joint

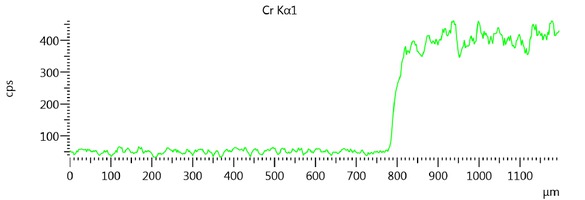

Hardening in weld are effect of crystallographic change in fusion zone. Mixing of chemical compounds during melting and solidification process affect on weld properties. Properties of weld can be assume as uniform when high mixing factor can be obtained, therefore in order to define uniform weld structure, quality and quantity energy-dispersive X-ray spectroscopy analysis (EDS) using scanning electron microscope was performed (Figure 12-17). Chemical composition of obtained dissimilar but joint shown uniform mixture of fusion zone, and negligible diffusion in edgewise of weld.

Measure line of HAZ and weld of S235JR steel for chemical analyze

Ferrite amount alongside measurement line

Chromium amount alongside measurement line

Measure line of HAZ and weld of 316L steel for chemical analyze

Ferrite amount alongside measurement line

Chromium amount alongside measurement line

Results of energy-dispersive X-ray spectroscopy analysis shown uniform mixture of fusion zone, and differences between base materials and weld. Chemical composition of obtained weld affect on mechanical properties of joint. Diffusion of chromium and nickel from 316L to weld improve hardenability. Obtained weld structure of dissimilar joint was assume as a dendritic. Moreover some diffusion in overheat zone can be observed. Greater differences alongside fusion line in low carbon steel of ferrite and chromium distribution can be observed.

6 Discussion

The paper presents possibility of using numerical simulation for estimating welding parameters of the dissimilar low carbon S235JR and stainless 316L steels joint. According to established boundary conditions with HS geometry and parameters, parameters for full welding penetrations was obtained. Therefore based on estimated parameters with trial joint using CO2 laser with speed rate of 1m/min and output power equal to 6kW was carried out. Obtained weld is similar to simulation results, both in simulation and experiment weld width are greater over stainless steel side, however bigger differences are shown in trial joint. This results can be related to phenomena override in numerical simulation like surface tension and shielding gas flow creating forced convection effect results in greater heat removal. Properties of dissimilar but joint based on stress-strain analysis and hardness test was investigated. Therefore maximum effective stress equal to 562MPa occur in stainless steel, however in low carbon steel not exceed 340MPa. Moreover yield stress analysis shown maximum value equal to 557MPa in stainless steel, with 270MPa in low carbon steel. Stress concentration is not uniform, and occur across fusion line in overheat zone. Properties of joint are related to chemical composition of welded materials and process parameters, therefore hardness test using Vickers method with load force equal to 10kgF was performed. Hardness distribution is relative uniform, slightly hardening in S235JR steel HAZ (not exceed 200HV10 with 138HV10 of BM), and uniform value of BM and HAZ in 316L steel (202 to 228HV10). However in fusion zone occur typical hardening effect, where maximum hardness number are 429HV10. Measured value exceed maximum allowable value (350HV10), therefore for industrial application additional post weld heat treatment is required.

Microstructure of obtained weld is with dendritic with dendrites growth related to crystallization direction. Structure of HAZ are characteristic for welded material, and in austenitic steel grain refining is observed, nevertheless in low carbon steel occur grain growth phenomena. In S235JR steel typical overheated, normalization and partial recrystallization zone can be observed. Weld mixture factor was studied using EDS quantity method, where ferrite and chromium distribution in cross section of weld was tested. Distribution of chromium and ferrite have characteristic similar to linear, therefore decrease of chromium and increasing of ferrite in weld comparing to BM of 316L steel, and opposite situation for BM of S235JR can be observed. Nevertheless uniform ferrite and chromium distribution in fusion zone prove high mixing factor of obtained joint.

7 Conclusion

Based on the obtained results, it can be stated that:

establishing accurate boundary conditions and HS properties laser welding parameters for dissimilar joint can be estimated.

laser welding technology without additional material can be used for carried out joining of low carbon with stainless steel

based on thermo-mechanical analysis stress-strain study of joint properties can be performed

obtained hardness exceed 350HV10, and for industrial applications additional heat treatment are required

obtained weld have uniform chemical composition with high welded materials mixture factor

developed laser welding technology can be used for welding of low carbon and stainless steel in industrial applications, however obtained joint require additional post weld heat treatment

further analysis of mechanical properties such as tensile strength test and corrosion test are planned in future in order to obtained complete weld characteristics [30].

Acknowledgement

Research carried out in the NCBiR project nr LIDER/31/0173/L-8/16/NCBR/2017 “Technology of manufacturing sealed weld joints for gas installation by using concentrated energy source”

References

[1] Iordachescu D, Scutelnicu E, Iordachescu M, Valiente A, Ruiz-Hervias J, Ocaña JL. Specific properties of ferritic/austenitic Dissimilar Metals Welded Joints. Weld World. 2011, 55, 2–11, DOI: 10.1007/BF0332128010.1007/BF03321280Search in Google Scholar

[2] Pouranavari M, Marashi SPH. Similar and dissimilar RSW of low carbon and austenitic stainless steels: effect of weld microstructure and hardness profile on failure mode. Mater Sci Tech-lond. 2009, 25, 1411-1416, DOI: https://doi.org/10.1179/026708309X12459430509292https://doi.org/10.1179/026708309X12459430509292Search in Google Scholar

[3] Steen WM, Mazumder J. Laser Material Processing. Springer. 2010, DOI: 10.1007/978-1-84996-062-510.1007/978-1-84996-062-5Search in Google Scholar

[4] Khan MMA, Romoli L, Fiaschi M, Dini G, Sarri F. Laser beam welding of dissimilar stainless steels in a fillet joint configuration. J Mater Res Technol. 2012, 212, 856-867, DOI:10.1016/j.jmatprotec.2011.11.01110.1016/j.jmatprotec.2011.11.011Search in Google Scholar

[5] Weglowski M, Błacha S, Phillips A. Electron beam welding – Techniques and trends – Review. Vacuum. 2016, 130, 72-92, DOI: 10.1016/j.vacuum.2016.05.00410.1016/j.vacuum.2016.05.004Search in Google Scholar

[6] Danielewski H, Skrzypczyk A. Properties and Microstructure of Laser Welded VM12-SHC Steel Pipes Joints. Arch Metall Mater. 2016, 61, 1143-1149, DOI: 10.1515/amm-2016-019110.1515/amm-2016-0191Search in Google Scholar

[7] Elaragi GA. Design and Operation of First Egyptian IEC Fusion Plasma Device. Emerg Sci J. 2019, 3, 241-248, DOI: 10.28991/esj-2019-0118610.28991/esj-2019-01186Search in Google Scholar

[8] Sun Z, Ion JC. Laser welding of dissimilar metal combinations. J Mater Sci. 1995, 30, 4205–4214, DOI: https://doi.org/10.1007/BF00361499https://doi.org/10.1007/BF00361499Search in Google Scholar

[9] Behúlová M, Babalová E, Sahul M. Design of Laser Welding Parameters for Joining Ti Grade 2 and AW 5754 Aluminium Alloys Using Numerical Simulation. Adv Mater Sci Eng. 2017, 1-15, DOI: https://doi.org/10.1155/2017/3451289https://doi.org/10.1155/2017/3451289Search in Google Scholar

[10] Kuryntsev SV, Morushkin AE, Gilmutdinov AKh. Fiber laser welding of austenitic steel and commercially pure copper butt joint. Opt Lasers Eng. 2017, 90, 101-109, DOI: 10.1016/j.optlaseng.2016.10.00810.1016/j.optlaseng.2016.10.008Search in Google Scholar

[11] Kumar KS. Numerical Modeling and Simulation of a Butt Joint Welding Of AISI 316L Stainless Steels Using a Pulsed Laser Beam. Mater Today Proc. 2015, 2, 2256-2266, DOI: https://doi.org/10.1016/j.matpr.2015.07.246https://doi.org/10.1016/j.matpr.2015.07.246Search in Google Scholar

[12] Turňa M, Taraba B, Ambrož P, Sahul M. Contribution to Numerical Simulation of Laser Welding. Phys Procedia. 2011, 12, 638–645, DOI: 10.1016/j.phpro.2011.03.08010.1016/j.phpro.2011.03.080Search in Google Scholar

[13] Esfahani R, Coupland J, Marimuthu S. Numerical simulation and experimental investigation of laser dissimilar welding of carbon steel and austenitic stainless steel. Proc SPIE. 2015, 9567, DOI: 10.1117/12.217602610.1117/12.2176026Search in Google Scholar

[14] Laftah A, Mohammed AH, Abdul-Razzaq KS. Finite Element Analysis and Optimization of Steel Girders with External Prestressing. Civil Eng J. 2018, 4, 1490-1450, DOI: 10.28991/cej-030918910.28991/cej-0309189Search in Google Scholar

[15] Koňár R, Mičian M, Zrak A. Lap weld joint modelling and simulation of welding in programme SYSWELD. MATEC Web Conf. 2018, 157, DOI: 10.1051/matecconf/20181570201810.1051/matecconf/201815702018Search in Google Scholar

[16] Deng D, Murakawa H. Numerical simulation of temperature field and residual stress in multi-pass welds in stainless steel pipe and comparison with experimental measurements. Comput Mater Sci. 2006, 37, 269-277, DOI: 10.1016/j.commatsci.2005.07.00710.1016/j.commatsci.2005.07.007Search in Google Scholar

[17] Zhang GD, Zhou CY. Numerical Simulation of Welding Residual Stress and Post-Weld Heat Treatment for Dissimilar Steel Welded Joint. Mater Sci Forum. 2008, 575–578, 747–752, DOI: https://doi.org/10.4028/www.scientific.net/msf.575-578.747https://doi.org/10.4028/www.scientific.net/msf.575-578.747Search in Google Scholar

[18] Danielewski H. Laser welding of pipe stubs made from super 304 steel. Numerical simulation and weld properties. Techn Trans. 2019, 1, 167–176, DOI: 10.4467/2353737XCT.19.011.1005110.4467/2353737XCT.19.011.10051Search in Google Scholar

[19] Kumar P, Sinha AN. Studies of temperature distribution for laser welding of dissimilar thin sheets through finite element method. J Braz Soc Mech Sci. 2018, 40, 455, DOI: https://doi.org/10.1007/s40430-018-1380-5https://doi.org/10.1007/s40430-018-1380-5Search in Google Scholar

[20] Koo BS, Thasanaraphan P, Nied HF. Numerical simulation of the formation of hourglass welds during laser welding. J Mater Process Tech. 2019, 263, 176-185, DOI: 10.1016/j.jmatprotec.2017.12.01510.1016/j.jmatprotec.2017.12.015Search in Google Scholar

[21] D’Ostuni S, Leo P, Casalino G. FEM Simulation of Dissimilar Aluminum Titanium Fiber Laser Welding Using 2D and 3D Gaussian Heat Sources. Metals-Basel. 2017, 7, 1-15, DOI: https://doi.org/10.3390/met7080307https://doi.org/10.3390/met7080307Search in Google Scholar

[22] Esfahani R, Coupland J, Marimuthu S. Numerical simulation of alloy composition in dissimilar laser welding, JMater Process Tech. 2015, 224, 135-142, DOI: https://doi.org/10.1016/j.jmatprotec.2015.05.005https://doi.org/10.1016/j.jmatprotec.2015.05.005Search in Google Scholar

[23] Sundqvist J, Kim KH, Bang H-Se, Bang H-Su, Kaplan AFH. Numerical simulation of laser preheating of friction stir welding of dissimilar metals. Sci Technol Weld Joi. 2018, 23, 351-356, DOI: 10.1080/13621718.2017.139193610.1080/13621718.2017.1391936Search in Google Scholar

[24] Prabakarana MP, Kannan GR. Optimization of laser welding process parameters in dissimilar joint of stainless steel AISI316/AISI1018 low carbon steel to attain the maximum level of mechanical properties through PWHT. Opt Laser Technol. 2019, 112, 314-322, DOI: 10.1016/j.optlastec.2018.11.03510.1016/j.optlastec.2018.11.035Search in Google Scholar

[25] Radek N, Pietraszek J, Goroshko A. The Impact of Laser Welding Parameters on the Mechanical Properties of the Weld. AIP Conf Proc 2017. 2018, 1, 020025, DOI: https://doi.org/10.1063/1.5056288https://doi.org/10.1063/1.5056288Search in Google Scholar

[26] Hamdan AI. Stress Concentration Factors (SCFs) in Circular Hollow Section CHS-to-H-shaped Section Welded T-Joints under Axial Compression. Civil Eng J. 2019, 5, 33-47, DOI: 10.28991/cej-2019-0309122310.28991/cej-2019-03091223Search in Google Scholar

[27] Pankaj P, Tiwari A, Bhadra R, Biswas P. Experimental investigation on CO2 laser butt welding of AISI 304 stainless steel and mild steel thin sheets. Opt Laser Technol. 2019, 119, 105633, DOI: https://doi.org/10.1016/j.optlastec.2019.105633https://doi.org/10.1016/j.optlastec.2019.105633Search in Google Scholar

[28] Ramkumar DK, Dev S, Prabhakar KVP, Rajendran R, Mugundan KG, Narayanan S. Microstructure and properties of Inconel 718 and AISI 416 laser welded joints. JMater Process Tech. 2019, 266, 52-62, DOI: https://doi.org/10.1016/j.jmatprotec.2018.10.039https://doi.org/10.1016/j.jmatprotec.2018.10.039Search in Google Scholar

[29] Yao Ch, Xu B, Zhang X, Huang J, Fu J, Wu Y. Interface microstructure and mechanical properties of laser welding copper–steel dissimilar joint. Opt Laser Eng. 2009, 47, 807-814, DOI: https://doi.org/10.1016/j.optlaseng.2009.02.004https://doi.org/10.1016/j.optlaseng.2009.02.004Search in Google Scholar

[30] Scendo M, Trela J, Radek N. Influence of laser power on the corrosive resistance of WC-Cu coating. Surf Coat Tech. 2014, 259, 401-407, DOI: https://doi.org/10.1016/j.surfcoat.2014.10.062https://doi.org/10.1016/j.surfcoat.2014.10.062Search in Google Scholar

© 2020 H. Danielewski et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor

Articles in the same Issue

- Regular Articles

- Fabrication of aluminium covetic casts under different voltages and amperages of direct current

- Inhibition effect of the synergistic properties of 4-methyl-norvalin and 2-methoxy-4-formylphenol on the electrochemical deterioration of P4 low carbon mold steel

- Logistic regression in modeling and assessment of transport services

- Design and development of ultra-light front and rear axle of experimental vehicle

- Enhancement of cured cement using environmental waste: particleboards incorporating nano slag

- Evaluating ERP System Merging Success In Chemical Companies: System Quality, Information Quality, And Service Quality

- Accuracy of boundary layer treatments at different Reynolds scales

- Evaluation of stabiliser material using a waste additive mixture

- Optimisation of stress distribution in a highly loaded radial-axial gas microturbine using FEM

- Analysis of modern approaches for the prediction of electric energy consumption

- Surface Hardening of Aluminium Alloy with Addition of Zinc Particles by Friction Stir Processing

- Development and refinement of the Variational Method based on Polynomial Solutions of Schrödinger Equation

- Comparison of two methods for determining Q95 reference flow in the mouth of the surface catchment basin of the Meia Ponte river, state of Goiás, Brazil

- Applying Intelligent Portfolio Management to the Evaluation of Stalled Construction Projects

- Disjoint Sum of Products by Orthogonalizing Difference-Building ⴱ

- The Development of Information System with Strategic Planning for Integrated System in the Indonesian Pharmaceutical Company

- Simulation for Design and Material Selection of a Deep Placement Fertilizer Applicator for Soybean Cultivation

- Modeling transportation routes of the pick-up system using location problem: a case study

- Pinless friction stir spot welding of aluminium alloy with copper interlayer

- Roof Geometry in Building Design

- Review Articles

- Silicon-Germanium Dioxide and Aluminum Indium Gallium Arsenide-Based Acoustic Optic Modulators

- RZ Line Coding Scheme With Direct Laser Modulation for Upgrading Optical Transmission Systems

- LOGI Conference 2019

- Autonomous vans - the planning process of transport tasks

- Drivers ’reaction time research in the conditions in the real traffic

- Design and evaluation of a new intersection model to minimize congestions using VISSIM software

- Mathematical approaches for improving the efficiency of railway transport

- An experimental analysis of the driver’s attention during train driving

- Risks associated with Logistics 4.0 and their minimization using Blockchain

- Service quality of the urban public transport companies and sustainable city logistics

- Charging electric cars as a way to increase the use of energy produced from RES

- The impact of the truck loads on the braking efficiency assessment

- Application of virtual and augmented reality in automotive

- Dispatching policy evaluation for transport of ready mixed concrete

- Use of mathematical models and computer software for analysis of traffic noise

- New developments on EDR (Event Data Recorder) for automated vehicles

- General Application of Multiple Criteria Decision Making Methods for Finding the Optimal Solution in City Logistics

- The influence of the cargo weight and its position on the braking characteristics of light commercial vehicles

- Modeling the Delivery Routes Carried out by Automated Guided Vehicles when Using the Specific Mathematical Optimization Method

- Modelling of the system “driver - automation - autonomous vehicle - road”

- Limitations of the effectiveness of Weigh in Motion systems

- Long-term urban traffic monitoring based on wireless multi-sensor network

- The issue of addressing the lack of parking spaces for road freight transport in cities - a case study

- Simulation of the Use of the Material Handling Equipment in the Operation Process

- The use of simulation modelling for determining the capacity of railway lines in the Czech conditions

- Proposals for Using the NFC Technology in Regional Passenger Transport in the Slovak Republic

- Optimisation of Transport Capacity of a Railway Siding Through Construction-Reconstruction Measures

- Proposal of Methodology to Calculate Necessary Number of Autonomous Trucks for Trolleys and Efficiency Evaluation

- Special Issue: Automation in Finland

- 5G Based Machine Remote Operation Development Utilizing Digital Twin

- On-line moisture content estimation of saw dust via machine vision

- Data analysis of a paste thickener

- Programming and control for skill-based robots

- Using Digital Twin Technology in Engineering Education – Course Concept to Explore Benefits and Barriers

- Intelligent methods for root cause analysis behind the center line deviation of the steel strip

- Engaging Building Automation Data Visualisation Using Building Information Modelling and Progressive Web Application

- Real-time measurement system for determining metal concentrations in water-intensive processes

- A tool for finding inclusion clusters in steel SEM specimens

- An overview of current safety requirements for autonomous machines – review of standards

- Expertise and Uncertainty Processing with Nonlinear Scaling and Fuzzy Systems for Automation

- Towards online adaptation of digital twins

- Special Issue: ICE-SEAM 2019

- Fatigue Strength Analysis of S34MnV Steel by Accelerated Staircase Test

- The Effect of Discharge Current and Pulse-On Time on Biocompatible Zr-based BMG Sinking-EDM

- Dynamic characteristic of partially debonded sandwich of ferry ro-ro’s car deck: a numerical modeling

- Vibration-based damage identification for ship sandwich plate using finite element method

- Investigation of post-weld heat treatment (T6) and welding orientation on the strength of TIG-welded AL6061

- The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material

- Investigation of Meshing Strategy on Mechanical Behaviour of Hip Stem Implant Design Using FEA

- The effect of multi-stage modification on the performance of Savonius water turbines under the horizontal axis condition

- Special Issue: Recent Advances in Civil Engineering

- The effects of various parameters on the strengths of adhesives layer in a lightweight floor system

- Analysis of reliability of compressed masonry structures

- Estimation of Sport Facilities by Means of Technical-Economic Indicator

- Integral bridge and culvert design, Designer’s experience

- A FEM analysis of the settlement of a tall building situated on loess subsoil

- Behaviour of steel sheeting connections with self-drilling screws under variable loading

- Resistance of plug & play N type RHS truss connections

- Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles

- Bearing capacity of floating geosynthetic encased columns (GEC) determined on the basis of CPTU penetration tests

- The effect of the stress distribution of anchorage and stress in the textured layer on the durability of new anchorages

- Analysis of tender procedure phases parameters for railroad construction works

- Special Issue: Terotechnology 2019

- The Use of Statistical Functions for the Selection of Laser Texturing Parameters

- Properties of Laser Additive Deposited Metallic Powder of Inconel 625

- Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint

- Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy

- Characteristics of selected measures of stress triaxiality near the crack tip for 145Cr6 steel - 3D issues for stationary cracks

- Assessment of technical risk in maintenance and improvement of a manufacturing process

- Experimental studies on the possibility of using a pulsed laser for spot welding of thin metallic foils

- Angular position control system of pneumatic artificial muscles

- The properties of lubricated friction pairs with diamond-like carbon coatings

- Effect of laser beam trajectory on pocket geometry in laser micromachining

- Special Issue: Annual Engineering and Vocational Education Conference

- The Employability Skills Needed To Face the Demands of Work in the Future: Systematic Literature Reviews

- Enhancing Higher-Order Thinking Skills in Vocational Education through Scaffolding-Problem Based Learning

- Technology-Integrated Project-Based Learning for Pre-Service Teacher Education: A Systematic Literature Review

- A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures

- Enhancing Students’ Ability in Learning Process of Programming Language using Adaptive Learning Systems: A Literature Review

- Topical Issue on Mathematical Modelling in Applied Sciences, III

- An innovative learning approach for solar power forecasting using genetic algorithm and artificial neural network

- Hands-on Learning In STEM: Revisiting Educational Robotics as a Learning Style Precursor