Preparation of geopolymer cementitious materials by combining industrial waste and municipal dewatering sludge: Stabilization, microscopic analysis and water seepage

Abstract

To develop durable landfill capping materials using solid waste, this study investigated freeze–thaw (F-T) resistance of novel composites synthesized from ground granulated blast-furnace slag, flue gas desulfurization residue, fly ash (FA), construction waste, and municipal sludge). The solidified municipal sludge (SMS) exhibited 1.80–2.06% volumetric shrinkage, 6.00–10.83 MPa compressive strength, and permeability coefficients of 9.67 × 10−8–4.14 × 10−7 cm·s−1 after 20 F-T cycles. Advanced characterization (XRD, FTIR, SEM-EDS, and NMR) revealed that F-T cycling induced structural reorganization, with rod/columnar formations and amorphous phases increasing pore volume while maintaining integrity. A multi-layered cover system was designed, comprising vegetative, capillary barrier, drainage, and impermeable layers (0.3 m SMS). Field monitoring over 1 year demonstrated stable moisture content in the SMS layer despite rainfall–evaporation cycles, confirming effective hydraulic isolation. The material’s performance met landfill closure requirements while utilizing 72.3–81.4% industrial by-products and sludge. This work provides both a technical framework for sustainable capping systems and an innovative pathway for valorizing solid wastes, achieving dual environmental benefits in waste management and infrastructure protection.

Graphical abstract

1 Introduction

China’s solid-waste stockpile reached ∼60 billion tons by 2018 (≈2 million ha), comprising 20 billion tons construction and 30 billion tons industrial residues; annual generation now exceeds 4 and 3 billion tons, respectively. About 11,000 wastewater treatment plants further yield >60 million tons per·year of municipal sludge (MS) [1], which produced over 60 million tons of MS in 2021. Projections indicate that China’s annual production of MS will exceed 80 million tons by 2025 [2]. Solid wastes contain significant amounts of nutrients, organic matter, heavy metals, and viruses, posing a serious threat to human health and ecological balance [3–5]. The National Soil Pollution Survey Bulletin identifies 188 solid waste disposal sites, noting that up to 21.3% exceed pollutant thresholds. However, the utilization rate of solid waste resources in China remains notably low, with the comprehensive utilization rate of general industrial solid waste at approximately 60% and that of construction and demolition waste merely 10%. Despite the increasing use of industrial waste and MS as landfill covers [6], there are still key gaps. The freeze-thaw (F-T) durability data of multi-source solid waste geopolymers are limited [7,8]; lack of field-verified hydraulic performance under natural rain–evaporation cycles [9,10]; and there is insufficient understanding of the microstructure of damage evolution during F-T processes [11,12]. Therefore, exploring novel approaches to multi-source solid waste co-disposal and resource utilization is crucial for achieving solid waste elimination and mitigating ecological harm.

Conventional compacted clay cover materials used in landfills are susceptible to cracking or fracturing due to significant volume shrinkage, which can result in potential engineering issues, including accelerated water seepage from the cover system [13–15]. In response, researchers have endeavored to develop barrier materials suitable for landfill applications by solidifying MS with various ingredients, including cement, lime, clay, and industrial sludge [16,17]. These efforts included testing and analyzing the unconfined compressive strength, permeability coefficient, and leaching toxicity of the solidified municipal sludge (SMS) under various conditions, such as natural states and dry–wet cycling [18–20]. Test results provided preliminary validation of the engineering performance of SMS as a landfill cover material [21,22]. Considering that the landfill cover system directly interfaces with the atmospheric environment, its effectiveness is influenced by temperature fluctuations, rainfall, and evaporation cycles [23]. Hence, the engineering performance of SMS under repeated F-T cycles deserves investigation. Moo-Young et al. [24,25] investigated the impact of F-T cycles on the permeability coefficient of sludge cover material utilizing paper mill sludge. He et al. [26] employed soda residue-SMS to prepare landfill cover material and systematically analyzed its unconfined compressive strength, water content, and pore structure under dry–wet and F-T cycles. Notably, a key engineering parameter, the permeability coefficient, was not tested. During F-T cycling, the unconfined compressive strength of SMS decreased, accompanied by reduced cohesion and an increased angle of internal friction [27]. Furthermore, an increase in pore volume and diameter led to a higher permeability coefficient [28]. Factors, including curing agent type, admixture, initial moisture content, and age of maintenance, significantly influence the engineering performance of SMS [29,30]. Notably, existing studies have primarily focused on F-T cycle tests for SMS units and analyzed their permeability or mechanical characteristics under F-T conditions. However, the scarcity of physical modeling studies on cover systems under natural climate conditions restricts the effectiveness of these studies in evaluating the field service performance of solid waste-based cover systems. Moreover, few studies have explored the macroscopic mechanical characteristics, microstructural evolution processes, and damage mechanisms of industrial waste combined with construction waste (CW) SMS under F-T cycles. Collectively, the literature reveals two critical shortcomings. First, most laboratory investigations [31,32] track strength or pore structure under ≤10 F-T cycles, yet landfill covers in cold regions may experience 50–100 cycles over their service life; corresponding long-term permeability data are scarce. Second, physical-model studies that couple F-T cycling with natural rainfall–evapotranspiration on multi-layer cover systems (vegetative, capillary-barrier, drainage, impermeable layers) are essentially absent [33,34]. Consequently, the field-scale hydraulic performance of solid-waste-based covers after repeated F-T remains unverified. The present study addresses these gaps by measuring permeability up to 20 F-T cycles and providing 1-year field-monitoring data from a four-layer prototype cover.

This study utilized ground granulated blast-furnace slag (GGBS), flue gas desulfurization (FGD), fly ash (FA), and CW to jointly solidify MS for the development of a novel landfill closure cover material. The material’s volumetric shrinkage, unconfined compressive strength, and permeability coefficient were evaluated through unconfined compression and permeability tests conducted over 20 F-T cycles. Furthermore, the mineral phase composition, surface microstructures, elemental composition, and pore structures of the cover material under F-T conditions were analyzed using X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), and nuclear magnetic resonance (NMR). The study proposed a solid waste-based landfill closure cover system, with SMS serving as the impermeable layer (IL), and monitored the water barrier performance of this system for 1 year through outdoor modeling tests. The findings of this study provide a theoretical basis and data support for the utilization of SMS as a landfill closure cover material and for the design of effective cover systems.

2 Materials and test methods

2.1 Materials

The MS originated from a sewage treatment plant in Wuhan City, Hubei Province, characterized by its black-brown hue, pungent odor, and water content ranging from 75 to 85%. CW was sourced from a CW plant in Wuhan City, Hubei Province, and underwent screening to isolate CW with particle sizes of less than 0.15 mm (FCW), 4.75–10 mm (MCW), and 20–40 mm (CCW) for further processing. FGD, a secondary FGD gypsum, is presented as a yellowish powder. FA, graded as V1500-I, manifested as a gray powder with a density of 2.39 g·cm−3 and a strength activity index of 72. GGBS, graded as V500-I, appeared as an off-white powder, boasting a density of 2.90 g·cm−3, a specific surface area of 428 m2·kg−1, and a 28-day activity index of 96%. For the alkaline activator, quicklime was selected as the activator, in which the content of CaO was 72.56%. Prior to utilization, FCW, FGD, FA, and GGBS underwent drying in a 105°C constant temperature-drying oven (DHG-9071A, Shanghai Yiheng Science and Technology Instrument Co., Ltd, China) for 24 h. The chemical compositions and contents of the test materials are depicted in Table 1.

Chemical composition and content of raw materials

| Raw materials | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | P2O5 | Others |

|---|---|---|---|---|---|---|---|---|

| MS | 37.19 | 17.19 | 10.87 | 6.62 | 3.25 | 4.19 | 14.65 | 6.14 |

| GGBS | 26.75 | 19.66 | 0.32 | 36.82 | 11.10 | 2.65 | 0.36 | 2.34 |

| FGD | 2.38 | 0.90 | 0.48 | 45.36 | 0.62 | 49.16 | 0.02 | 1.08 |

| CW | 39.87 | 8.93 | 6.03 | 35.07 | 2.01 | 3.09 | 0.17 | 4.83 |

| FA | 47.70 | 37.53 | 4.55 | 3.70 | 0.94 | 1.04 | 0.36 | 4.18 |

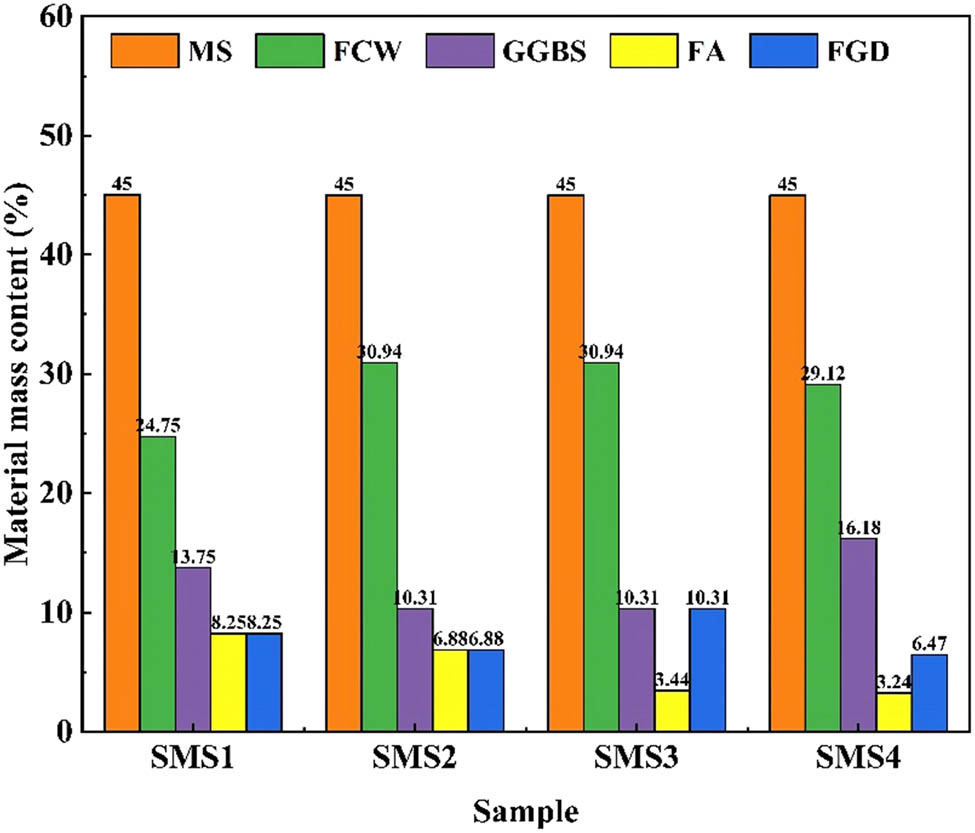

The MS was introduced into a cement mortar mixer (JJ-5, Hebei High-Speed Railway Construction Experimental Instrument Co., Ltd, China) and stirred at a low speed of 60 rpm for 10 min until a viscous consistency was achieved. Subsequently, an alkaline activator was added, followed by an additional low-speed stirring for 5 min. Then, GGBS, FA, FGD, and FCW were sequentially added, initially stirred at low speed for 10 min, followed by a high-speed stirring at 120 rpm for 5 min. After thorough mixing of industrial solid waste and MS, the mixture was uniformly pressed into customized steel cylindrical molds with a diameter of 50 mm and a height of 100 mm to form solidified sludge samples SMS1, SMS2, SMS3, and SMS4. The material ratios of the samples are depicted in Figure 1. The dosage of the alkaline activator was 2% of the mixture materials. The alkaline activator dosage (2% CaO by dry mass) was selected based on the optimization results of Zhang et al. [32] and Changjutturas et al. [35] for similar precursor blends, which identified 2% CaO as the level that maximized strength and minimized permeability without exceeding environmental limits.

Proportioning of SMS samples.

2.2 Test methods

After 28 days of maintenance, the SMS underwent a series of F-T cycles. Initially, they were placed in a cryogenic test chamber (Model: Zhejiang Jiesheng Cryogenic Equipment Co., Ltd, China) and subjected to freezing at a controlled temperature of −20°C for 24 h. Subsequently, the frozen samples were transferred to a drying oven and dried for 24 h at a controlled temperature of 50°C. Temperature was ramped at 1°C·min−1 between −20°C and +50°C; the chamber reached the target temperatures in ≈70 min, followed by the specified 24 h dwell periods. This freezing and thawing procedure was repeated for a total of 20 cycles.

A pressure tester (TAW-2000, Jinan Zhonglu Chang Testing Machine Manufacturing Co., Ltd, China) was used to test the unconfined compressive strength of the samples with an axial strain of 3% per minute. Referring to ASTM D5084 and ASTM D7100 test methods, a flexible wall permeameter (PN3230M, Geoequip, USA) was used to test the hydraulic conductivity of the samples. The permeation medium was deionized water, and the perimeter pressure and permeation counterpressure were set to 300 and 30 kPa.

An XRD (Smart Lab SE, Rigaku, Japan), an FTIR spectrometer (Nicolet 6700, Thermo Scientific, America), an SEM (Gemini SEM 300, Zeiss, Germany), an NMR analyzer (PQ-001, Suzhou Newmax Electronic Technology Co., Ltd, China) were employed to analyze the mineral phase composition, surface microforms, elemental composition, and pore structures of SMS subjected to F-T cycles.

The model test of the outdoor landfill cover system is illustrated in Figure 2(a). The model box dimensions were 1.0 m × 0.5 m × 1.0 m (length × width × height) with a tilt angle of 5°. The cover system comprised four layers: a 0.1 m thick vegetative layer (VL) composed of engineering waste soil (EWS) at the surface; followed by a 0.5 m thick capillary barrier layer (CBL) consisting of MS, MCW, and calcium bentonite (CB); a 0.1 m thick drainage layer (DL) comprising CCW in the middle; and finally, a 0.3 m thick IL comprising SMS4 at the bottom. The soil parameters for each layer are shown in Table 2. To monitor the environmental conditions, three rows (noted from left to right as the first, second, and third columns) of soil temperature and humidity sensors (CR-SL01TH, Shandong Weihai Qitong Technology Development Co., Ltd, China) were installed at intervals of 0.1, 0.3, 0.5, 0.7, and 0.9 m from the top of the model box, totaling 15 sensors. A data collector (485-USB, Shandong Jiandarenke Electronic Technology Co., Ltd, China) was utilized to record the volumetric water content at various spatial locations from November 2022 to October 2023. Additionally, rainfall data were collected during this period.

Material testing model: (a) longitudinal section of landfill cover system and (b) sample preparation flowchart.

Basic parameters of soil layers

| Type of cover | Layer thickness (cm) | Material composition | Material proportion (%) | Density (g·cm−3) | Initial water content (%) | Permeability coefficient (cm·s−1) |

|---|---|---|---|---|---|---|

| VL | 10 | EWS | 100 | 1.45 | 22.6 | 2.66 × 10−4 |

| CBL | 50 | MS/MCW/CB | 20/75/5 | 0.72 | 21.3 | 3.15 × 10−5 |

| DL | 10 | CCW | 100 | 1.57 | / | 0.17 |

| IL | 30 | SMS4 | 100 | 1.64 | 52.4 | 1.65 × 10−8 |

3 Results and discussion

3.1 Volume shrinkage and unconfined compressive strength

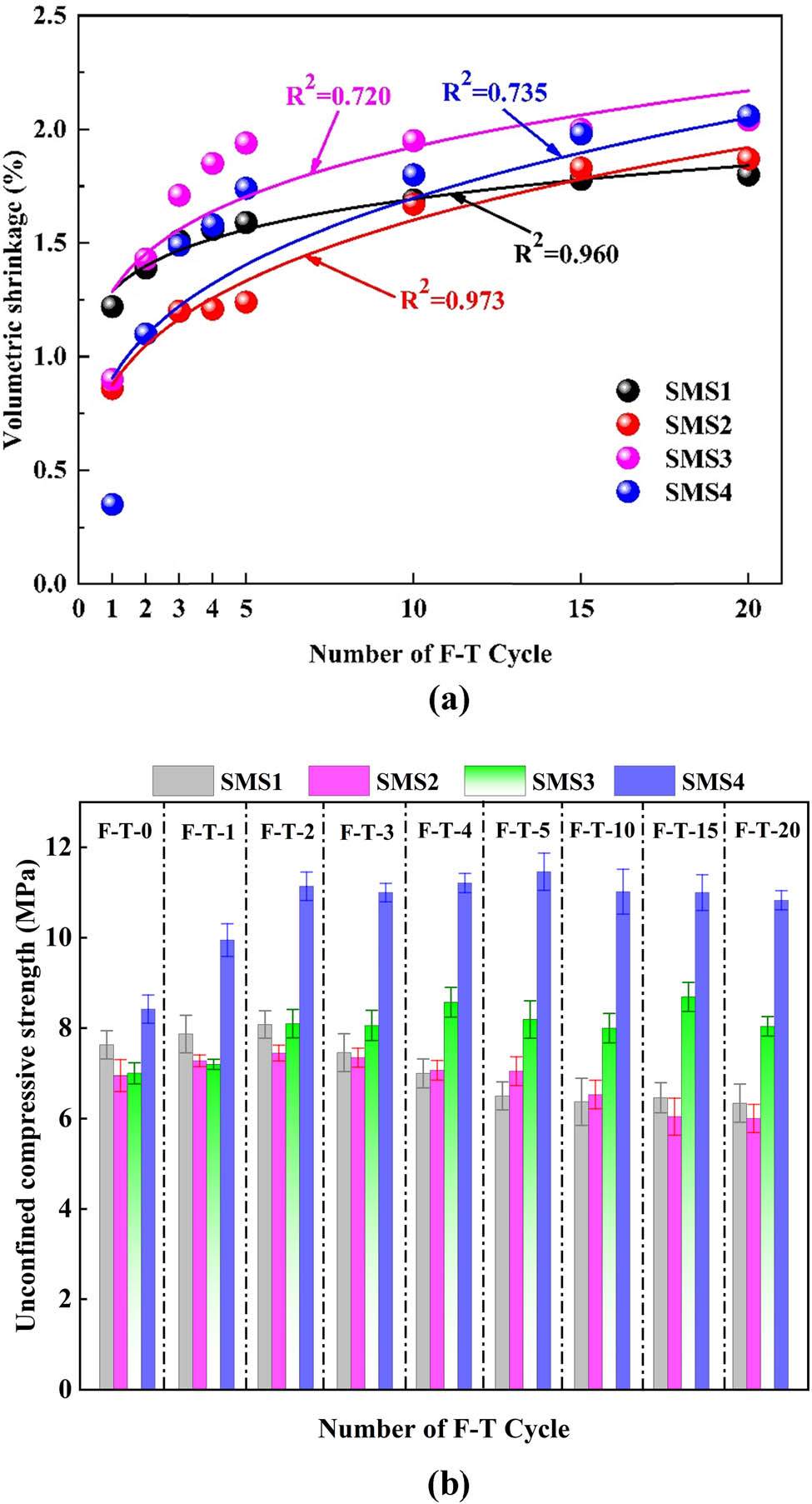

Figure 3(a) illustrates the volumetric shrinkage of SMS1–SMS4 samples. Under the influence of F-T cycles, the SMS exhibited an increasing trend in volumetric shrinkage. Initially, the volumetric shrinkage of SMS1, SMS2, SMS3, and SMS4 samples rose from 1.22, 0.86, 0.90, and 0.35% to 1.59, 1.24, 1.94, and 1.74%, respectively, after five cycles. However, this upward trend notably weakened during cycles 10–20, eventually stabilizing at a constant value. Following 20 F-T cycles, the volumetric shrinkage of SMS1–SMS4 samples reached 1.80, 1.87, 2.04, and 2.06%, respectively, without any observed cracks in the samples. These results indicate the solidified sludge’s robust structural stability. Utilizing this material as a landfill cover can substantially enhance the cover system’s longevity and address the engineering shortcomings associated with the poor durability of traditional compacted clay cover materials, such as bulk shrinkage and cracking.

(a) Volume shrinkage and (b) unconfined compression strength of SMS.

Figure 3(b) depicts the unconfined compressive strengths of SMS1–SMS4 samples. Following the initial two F-T cycles, the unconfined compressive strength of SMS1–SMS4 samples exhibited an increasing trend, rising from 7.63, 6.95, 7.00, and 8.42 MPa to 8.08, 7.45, 8.10, and 11.14 MPa, respectively. Notably, the SMS4 sample demonstrated the most significant strength increase, reaching 32%. Subsequently, the compressive strength of SMS1–SMS4 samples gradually declined to 6.34, 6.00, 8.04, and 10.83 MPa during cycles 3–20. After 20 F-T cycles, the compressive strength of SMS4 slid slightly from 11.14 to 10.83 MPa (Figure 3(b)). This minor decline is mirrored at the microscale: NMR T2 distributions shift rightward as pores ≥0.1 µm proliferate, while SEM images disclose a looser fabric enriched in amorphous phases. Together, these structural defects eclipse any late-stage hydration benefit, yielding the observed 2.8% loss in strength. These findings affirm that SMS exhibits robust resistance to damage from F-T cycles. In regions akin to Northwest and Northeast China, the SMS cover material can maintain high compressive strength over an extended period under repeated high and low temperatures, thereby enhancing the overall stability of the cover system.

At low freezing temperatures, the liquid water within the SMS undergoes a phase change to ice crystals, leading to volume expansion that disrupts the association and arrangement between the material particles. Upon melting at higher temperatures, the ice transitions back to water, causing the pores to shrink. Simultaneously, unreacted FA and GGBS undergo a secondary hydration reaction, generating hydrated calcium silicate, which enhances structural linkage within the sample, consuming water in the process. In the initial F-T cycles, the structural damage inflicted by freezing and thawing is outweighed by the cementing effect of hydration products, increasing the unconfined compressive strength of the SMS. However, in the later stages of the F-T cycle, with reduced water content in the sample, the effect of ice crystal freezing and swelling diminishes, and the hydration reaction nearly ceases. Consequently, some portions of the sample may experience fracturing, leading to a decrease in unconfined compressive strength, while the volumetric shrinkage remains relatively stable.

3.2 Hydraulic conductivity

Figure 4(a) presents the hydraulic conductivity coefficients of SMS1–SMS4 samples. The hydraulic conductivity of SMS demonstrates a positive correlation with the number of F-T cycles. After 20 F-T cycles, the hydraulic conductivity of SMS1 and SMS2 samples increased from 4.51 × 10−8 and 6.53 × 10−8 to 1.90 × 10−7 and 4.13 × 10−7 cm·s−1, respectively. These values exceeded the engineering requirement stipulating that the hydraulic conductivity of the landfill closure capping layer should be less than 1.0 × 10−7 cm·s−1. Nonetheless, the hydraulic conductivity coefficients of SMS3 and SMS4 samples after F-T cycles were 9.67 × 10−8 and 8.87 × 10−8 cm·s−1, respectively, which still met the impermeability performance criteria of the cover material.

(a) Hydraulic conductivity and (b) T2 distribution curve of SMS.

The hydraulic conductivity is primarily influenced by the degree of pore development within the sample. The NMR T2 distribution curve serves as a reflection of the pore characteristics of the sample. Examining the T2 distribution curve of the SMS4 sample (Figure 4(b)), it is evident that the peaks of the T2 spectra gradually enlarged during the initial ten F-T cycles, while the distribution intervals remained relatively constant. This observation suggests that the pore volume of the SMS increased, yet the pore diameter remained largely unchanged. However, after 20 F-T cycles, a significant rightward skewing of the distribution area of the T2 spectral peaks was observed. This phenomenon indicates that the pore size of the internal pores within the SMS expanded, with small pores evolving into medium or large pores. Throughout the F-T cycle, the pore water within the sample undergoes repeated solid–liquid transformations. Frost expansion or contraction occurs at the interface between pore water and sludge particles or cementation products, leading to decreased particle contact interface, particle dispersion, and ultimately an increase in pore size or enlargement. Consequently, this leads to an elevation in the hydraulic conductivity of the sample.

3.3 Water-resistant performance

The volumetric water content in this solid waste-based landfill closure cover system for the period November 2022 through October 2023 is shown in Figure 5. Volumetric water content in CBL and IL responds to rainfall and evapotranspiration cycle recharge processes. There was a delay in the response of volumetric water content as the depth of cover extended. The volumetric water content response curve in CBL fluctuates at a fast frequency. However, the fluctuation amplitude changes are small and basically consistent with the initial water content. The frequency of volumetric water content fluctuations in IL relative to CBL is significantly slower and the amplitude of fluctuations is larger. The volumetric water content showed an overall increasing trend. However, this layer is still in a non-saturated state, and no water leakage occurs at the bottom. The main reason for the difference in volumetric water content fluctuations in CBL and IL is the pore characteristics of the materials. CBL with large pores has weak capillary action and poor water-blocking capacity, and rainfall rapidly infiltrates into DL through this layer. However, IL is composed of SMS with small pores and low permeability. The strong capillary action of IL caused the IL–DL contact interface region to be in a water-saturated state. The increase in volumetric water content in the IL layer was caused by long-term percolation. The overburden system was set at a 5° slope, which caused water in the overburden layer to seep toward the foot of the slope. So much so that the volumetric water content increases near the foot of the slope relative to the top of the slope in the CBL and IL, which is more pronounced in the IL layer. At the end of monitoring, the water content of CR10, CR11, and CR12 near the upper part of IL was 28.19, 48.00, and 44.52%, respectively, and that of CR13, CR14, and CR15 in the lower part of IL was 23.05, 38.73, and 43.88%, respectively, as shown in Figure 5(a)–(c). The 1-year volumetric water content monitoring data of the cover layer showed that the 0.3 m thick SMS IL still exerted good water-blocking service performance under the complex environmental conditions of low temperature, high temperature, rainfall, and evaporation. The results of the outdoor modeling test can provide data support for the promotion of this solid waste-based cover system.

Volumetric water content of landfill cover systems: (a) first column, (b) second column, and (c) third column.

3.4 Microscopic mechanism

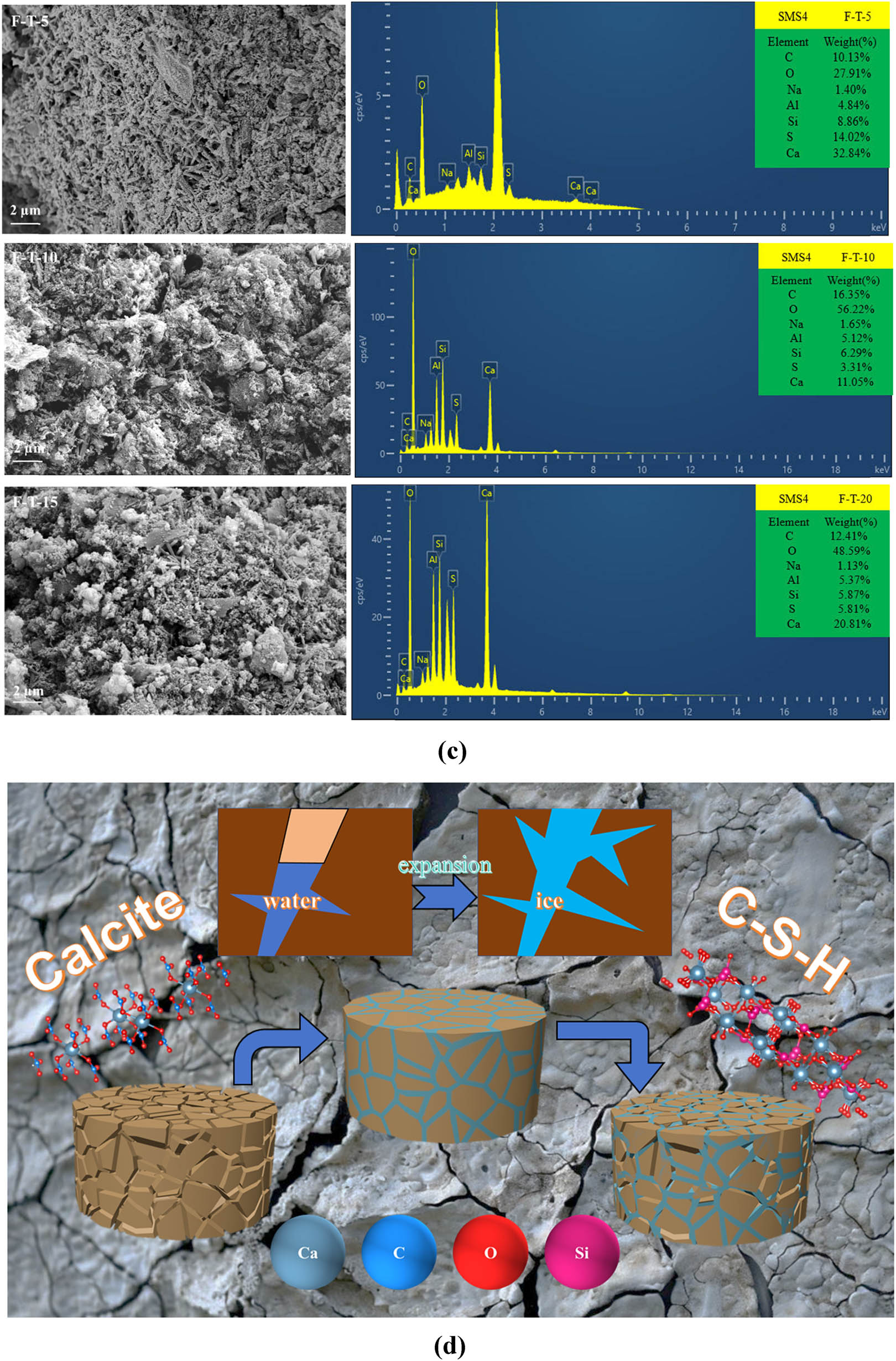

SMS4 samples still have relatively good mechanical properties after F-T cycling. Therefore, the changes in mineral composition, microstructure and elemental composition of SMS4 after different F-T cycles were explored (Figure 6). As can be seen from Figure 6(a), there are obvious diffraction peaks in the XRD patterns of SMS4 samples with different numbers of F-T cycles. The mineral structures contained in the SMS4 samples without F-T cycling are mainly silicon oxide (SiO2), calcite (CaCO3), tamarugite, gypsum, ettringite, C–S–H, and analcime. The front of CaCO3 increased for 1, 5, and 10 F-T cycles compared to the samples that did not experience F-T cycles. The reason for this may be that the SMS itself contains enough calcium-containing compounds within the sludge to allow Ca2+ to react with the CO2 in the air to produce a certain amount of CaCO3. In addition, the other peaks in the graph do not change much, which also indicates that the F-T cycle has less effect on the hydration products generated inside the SMS [32].

Mineral, microstructure, and F-T failure mechanism analysis of SMS4 sample: (a) XRD atlas, (b) FTIR atlas, and (c) SEM micromorphology and EDS distribution map total spectrum. (d) Model of F-T failure mechanism.

From Figure 6(b), it can be seen that the wave number of the absorption peak of –OH stretching and bending vibration is shifted from 3420.87 cm−1 to the absorption peak with a larger wave number of 3441.02 cm−1, and the wave number of the absorption peak of C–O is shifted from 1423.54 cm−1 to the absorption peak with a larger wave number of 1477.21 cm−1, as compared to the FTIR of the sample which did not undergo the effect of F-T cycling for 20 F-T cycles in the SMS4 sample. This suggests that after 20 F-T cycles of the SMS4 sample, substances containing

There are a large number of rods, columns, and agglomerates in the samples during the first five F-T cycles. These materials are stacked on top of each other, forming a spatial skeleton with a compact and regular structure and small and uniform pores. After ten F-T cycles, these rods, columns, and agglomerates were intricately arranged with slightly enlarged pores, but with better integrity. After 20 F-T cycles, the amorphous material increased and the internal structure was loosened (Figure 6(c)). The above phenomenon also further illustrates the pattern of change in the permeability coefficient of SMS. In addition, Al and Na changed less with the increase of F-T cycles. This indicates that the F-T cycles do not damage the C–A–S–H and N–A–S–H gelation products much. However, the changes in the elements Ca, Si, O, C, and S are more prominent. After five F-T cycles, the content of Ca and Si elements increased. This suggests that some of the substances have once again undergone hydration reactions to produce amorphous polymers such as silicates. This may be the reason for the increase in mechanical strength of the samples at the early stage of the F-T cycle. With the increase of the number of F-T cycles, the content of Ca and Si elements decreased slightly [37]. This caused a decrease in the mechanical strength of the samples at the later stage of the F-T cycle.

The F-T failure mechanism of the specimen is shown in Figure 6(d). When the number of F-T cycles is small, the formation of ice crystals in the pore water enlarges some of the pores, resulting in a larger contact area between the melted pore water and the material, which promotes the hydration reaction. As the number of F-T cycles increases, the excess water in the system forms ice crystals after the materials are fully hydrated, leading to volume expansion and damage to the internal structure of the specimen. Due to the repeated phase transition of water, the small pores inside the specimen begin to increase and gradually develop into large pores, thereby releasing the internal pore water pressure. The CaCO3 and amorphous C–S–H generated by the original hydration reaction also suffered varying degrees of damage during this process [38], resulting in a decrease in the mechanical strength of the samples in the later stage of F-T cycles.

4 Conclusions

In this study, an innovative approach is proposed to fabricate landfill cover materials by utilizing industrial waste residues (GGBS, FA, FGD, and CW) cured MS, which not only improves the F-T resistance of the materials, but also provides a new way of resourceful utilization of industrial waste residues and MS. The resulting SMS impermeable material demonstrates remarkable resistance to F-T cycles. Following 20 F-T cycles, the SMS exhibits no cracks, with permeability coefficients ranging from 8.87 × 10−8 to 4.135 × 10−7 cm·s−1. Notably, the permeability coefficients of SMS3 and SMS4 samples satisfy impermeable engineering requirements for landfill cover barrier systems. During the initial F-T cycles, unactivated GGBS and FA undergo hydration reactions, leading to the formation of new cementitious products. However, as the F-T cycles progress, significant damage from frost heaving occurs, resulting in fractures in the cementitious products, increased amorphous substances, and the development of medium to large pores. Consequently, the structure transitions from dense to loose.

A four-layer solid waste landfill cover barrier system, comprising a VL, CBL, DL, and IL was constructed utilizing SMS as the impermeable material. Throughout the yearlong outdoor model test, the solid waste landfill cover barrier system exhibits satisfactory performance. Particularly noteworthy is the IL composed of a 0.3 m thick SMS, which demonstrates stable waterproofing properties, thereby providing initial validation of the efficacy of this cover system. This study contributes fundamental data for the preparation of SMS impermeable materials and the design of solid waste landfill cover systems. Moreover, it introduces a novel approach for the collaborative disposal of industrial waste and MS, thereby offering a promising avenue for waste management practices.

Limitations and future work: (1) the F-T test was limited to 20 cycles, extrapolation to the 50–100 cycles expected in cold-region service requires further verification. (2) Field monitoring covered only one hydrological year, multi-year datasets are needed to capture extreme climatic events. (3) Leaching behavior of heavy metals under long-term F-T was not assessed. These aspects will be addressed in our ongoing full-scale trial.

-

Funding information: This study was financially supported by the Natural Science Foundation of Hubei Province of China (2023AFD214), Science and Technology Project of Natural Resources Department of Hubei Province of China (ZRZY2025KJ41, ZRZY2025KJ42), and Open Foundation of Science and Technology Innovation Center of Hubei Institute of Urban Geological Engineering (KCJJ202404).

-

Author contributions: Jun Xu: conceptualization, formal analysis, data curation, writing – original draft, funding acquisition, resources; Wencheng Meng: conceptualization, formal analysis, data curation, writing – original draft; Dongli Zuo: formal analysis, data curation; Zhenhua Wang: formal analysis, data curation, investigation; Guolun Hou: formal analysis, data curation; Hongyan Shuai: formal analysis, data curation; Yajun Liu: conceptualization, validation, writing – review and editing. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Ministry of Ecology and Environment of the People’s Republic of China. Annual Report on China’s Ecological and Environmental Statistics in 2021, Ministry of Ecology and Environment of the People’s Republic of China, Beijing, 2023.Suche in Google Scholar

[2] Dai, X., A. Li, L. Zhang, and D. Yang. Safe disposal and resource recovery of urban sewage sludge in China. Strategic Study of Chinese Academy of Engineering, Vol. 24, 2022, pp. 145–153.10.15302/J-SSCAE-2022.05.017Suche in Google Scholar

[3] Zhang, C., G. Zhao, Y. Jiao, B. Quan, W. Lu, P. Su, et al. Critical analysis on the transformation and upgrading strategy of Chinese municipal wastewater treatment plants: towards sustainable water remediation and zero carbon emissions. Science of the total Environment, Vol. 902, 2023, id. 165201.10.1016/j.scitotenv.2023.165201Suche in Google Scholar PubMed

[4] Fu, K., M. Liao, J. Wang, Z. Yang, H. Li, and F. Chou. Present situation on low concentration domestic wastewater in villages and towns and its treatment technology analysis. Environmental Engineering, Vol. 37, 2019, pp. 48–51 + 111.Suche in Google Scholar

[5] Moraci, N., S. Busana, G. Cortellazzo, M. Favaretti, M. C. Mandaglio, M. Schepis, et al. Design and construction of a compacted clay liner in cover system of a municipal solid waste landfill using nonstandard procedures. Canadian Geotechnical Journal, Vol. 55, 2018, pp. 1182–1192.10.1139/cgj-2017-0371Suche in Google Scholar

[6] Cortellazzo, G., L. E. Russo, S. Busana, L. Carbone, M. Favaretti, and H. Hangen. Field trial of a reinforced landfill cover system: performance and failure. Geotext Geomembranes, Vol. 50, 2022, pp. 655–667.10.1016/j.geotexmem.2022.03.007Suche in Google Scholar

[7] Feng, D., F. Ye, D. Chen, and S. Liang. Research progress on solidification/stabilization of sludge with alkali-activated cementitious materials: a review. Sustainable Chemistry and Pharmacy, Vol. 43, 2025, id. 101904.10.1016/j.scp.2025.101904Suche in Google Scholar

[8] Jiang, X., Y. Zhang, R. Xiao, P. Polaczyk, M. Zhang, W. Hu, et al. A comparative study on geopolymers synthesized by different classes of fly ash after exposure to elevated temperatures. Journal of Cleaner Production, Vol. 270, 2020, id. 122500.10.1016/j.jclepro.2020.122500Suche in Google Scholar

[9] Wang, M., Y. Zhu, W. Mao, M. Ye, and J. Yang. Chemical characteristics and reactive transport of soil salt ions in frozen soil during the freeze and thaw period. Journal of Hydrology, Vol. 621, 2023, id. 129580.10.1016/j.jhydrol.2023.129580Suche in Google Scholar

[10] Dabrowska, D. and W. Rykala. A review of lysimeter experiments carried out on municipal landfill waste. Toxics, Vol. 9, 2021, id. 26.10.3390/toxics9020026Suche in Google Scholar PubMed PubMed Central

[11] Meng, F., Y. Zhai, Y. Li, R. Zhao, Y. Li, and H. Gao. Research on the effect of pore characteristics on the compressive properties of sandstone after freezing and thawing. Engineering Geology, Vol. 286, 2021, id. 106088.10.1016/j.enggeo.2021.106088Suche in Google Scholar

[12] Jia, W., H. Zhou, S. Xie, Y. Wang, Z. Liu, and H. Deng. Real-time monitoring of pore-fracture structure evolution during coal creep based on NMR. Energy & Fuels, Vol. 37, 2023, pp. 1057–1069.10.1021/acs.energyfuels.2c03759Suche in Google Scholar

[13] Tan, X., Y. Chen, Q. Xue, Y. Wan, and L. Liu. Conditioning of resuspension excess sludge with chemical oxidation technology: the respective performance of filtration and expression stage in compression dewatering. Separation and Purification Technology, Vol. 237, 2020, id. 116317.10.1016/j.seppur.2019.116317Suche in Google Scholar

[14] Rowe, R. K., J. Reinert, Y. Li, and R. Awad. The need to consider the service life of all components of a modern MSW landfill liner system. Waste Management (New York, N.Y.), Vol. 161, 2023, pp. 43–51.10.1016/j.wasman.2023.02.004Suche in Google Scholar PubMed

[15] He, J., J. Wan, and Y. Wang. Desiccation cracks on hydraulic performance of compacted clay liner via laboratory wet–dry cycling tests. Chinese Journal of Engineering Geology, Vol. 20, 2012, pp. 397–402.Suche in Google Scholar

[16] Liang, S. and D. Feng. Experimental study on strength and water stability of concentrated solution sludge solidified with sulfoaluminate cement collaborating waste incineration by-products. Rock and Soil Mechanics, Vol. 43, 2021, pp. 1453–1468.Suche in Google Scholar

[17] Liu, M., H. Lu, Q. Deng, S. Ji, L. Qin, Y. Wan, et al. Shear strength, water permeability and microstructure of modified municipal sludge based on industrial solid waste containing calcium used as landfill cover materials. Waste Management (New York, N.Y.), Vol. 145, 2022, pp. 20–28.10.1016/j.wasman.2022.04.031Suche in Google Scholar PubMed

[18] Liu, Y., H. Lu, C. Wang, Y. Liu, J. Ma, and M. Liu. Mechanical strength, water seepage and microstructure of a novel landfill solidified sludge liner material. Processes, Vol. 10, 2022, id. 1641.10.3390/pr10081641Suche in Google Scholar

[19] Yang, Y., S. Hu, and S. Yang. New solidification technology and mechanical properties of municipal sludge. Rock and Soil Mechanics, Vol. 40, 2019, pp. 4439–4449.Suche in Google Scholar

[20] Chen, P., L. Zhan, and W. Wilson. Experimental investigation on shear strength and permeability of a deeply dewatered sewage sludge for use in landfill covers. Environmental Earth Sciences, Vol. 71, 2014, pp. 4593–4602.10.1007/s12665-013-2851-8Suche in Google Scholar

[21] Changjutturas, K., M. Hoy, A. Rashid, S. Horpibulsuk, and A. Arulrajah. Solidification and stabilisation of metal plating sludge with fly ash geopolymers. Environmental Geotechnics, Vol. 10, 2019, pp. 66–75.Suche in Google Scholar

[22] Taki, K., S. Choudhary, S. Gupta, and M. Kumar. Enhancement of geotechnical properties of municipal sewage sludge for sustainable utilization as engineering construction material. Journal of Cleaner Production, Vol. 251, 2020, id. 119723.10.1016/j.jclepro.2019.119723Suche in Google Scholar

[23] Rosli, N., H. Aziz, M. Selamat, and L. Lim. A mixture of sewage sludge and red gypsum as an alternative material for temporary landfill cover. Journal of Environmental Management, Vol. 263, 2020, id. 110420.10.1016/j.jenvman.2020.110420Suche in Google Scholar PubMed

[24] Moo-Young, H. Jr. and T. Zimmie. Effects of freezing and thawing on the hydraulic conductivity of paper mill sludges used as landfill covers. Canadian Geotechnical Journal, Vol. 33, 1996, pp. 783–792.10.1139/t96-103Suche in Google Scholar

[25] Heineck, K. S., N. C. Consoli, and L. S. Ibeiro. Engineering properties of fibrous paper mill sludge from Southern Brazil. Journal of Materials in Civil Engineering, Vol. 23, 2011, pp. 1346–1352.10.1061/(ASCE)MT.1943-5533.0000306Suche in Google Scholar

[26] He, J., L. Zhang, and C. Zhang. Durability analysis of sludge solidified with soda residue subjected to dry–wet and freeze–thaw cycles. Advances in Civil Engineering, Vol. 2021, 2021, id. 9960416.10.1155/2021/9960416Suche in Google Scholar

[27] Hu, X., B. Liang, Y. Chen, Q. Xue, and Y. Wang. Study of the influence of freezing and thawing on strength and deformation properties of solidified sewage sludge. Journal of Experimental Mechanics, Vol. 31, 2016, pp. 557–563.Suche in Google Scholar

[28] Hu, X., B. Liang, Y. Chen, Q. Xue, and Y. Wang. Mechanical and microstructural properties changes of solidified sewage sludge due to cyclic freezing and thawing. Rock and Soil Mechanics, Vol. 37, 2016, pp. 1317–1323.Suche in Google Scholar

[29] Zhang, X., X. Fang, F. Hu, C. Chen, and C. Shen. Freeze–thaw cycle characteristics of solidified sludge with composite rapid soil stabilizer. Journal of Materials in Civil Engineering, Vol. 35, 2023, id. 04023345.10.1061/JMCEE7.MTENG-16198Suche in Google Scholar

[30] Peng, C., Z. Tian, H. Long, and Y. Tan. Experiment on the effect of freezing–thawing cyclic on mechanical properties of solidified sludge. Geotechnical and Geological Engineering, Vol. 39, 2021, pp. 4195–4204.10.1007/s10706-021-01748-5Suche in Google Scholar

[31] Liu, Y., Y. Zhuge, C. W. K. Chow, A. Keegan, D. Li, P. N. Pham, et al. Utilization of drinking water treatment sludge in concrete paving blocks: microstructural analysis, durability and leaching properties. Journal of Environmental Management, Vol. 262, 2020, id. 110352.10.1016/j.jenvman.2020.110352Suche in Google Scholar PubMed

[32] Zhang, X., P. Ye, Y. Wu, M. Fujii, A. Takahashi, and Y. Wang. Insights into conditioning landfill sludge with freeze–thaw method: effects on the physical–mechanical properties and micro characteristics. Journal of Cleaner Production, Vol. 377, 2022, id. 134390.10.1016/j.jclepro.2022.134390Suche in Google Scholar

[33] Mbonimpa, M., M. Bouda, I. Demers, M. Benzaazoua, D. Bois, and M. Gagnon. Preliminary geotechnical assessment of the potential use of mixtures of soil and acid mine drainage neutralization sludge as materials for the moisture retention layer of covers with capillary barrier effects. Canadian Geotechnical Journal, Vol. 53, 2016, pp. 828–838.10.1139/cgj-2014-0319Suche in Google Scholar

[34] Devapriya, A. S. and T. Thyagaraj. Evaluation of red soil–bentonite mixtures for compacted clay liners. Journal of Rock Mechanics and Geotechnical Engineering, Vol. 16, 2024, pp. 697–710.10.1016/j.jrmge.2023.04.006Suche in Google Scholar

[35] Changjutturas, K., M. Hoy, A. S. A. Rashid, S. Horpibulsuk, and A. Arulrajah. Solidification and stabilisation of metal plating sludge with fly ash geopolymers. Environmental Geotechnics, Vol. 10, 2023, pp. 66–75.10.1680/jenge.19.00050Suche in Google Scholar

[36] Xu, Y., Y. Wu, X. Zhang, and G. Chen. Effects of freeze–thaw and chemical preconditioning on the consolidation properties and microstructure of landfill sludge. Water Research, Vol. 200, 2021, id. 117249.10.1016/j.watres.2021.117249Suche in Google Scholar PubMed

[37] Chen, X., W. Wolfe, and M. Hargraves. The influence of freeze–thaw cycles on the compressive strength of stabilized FGD sludge. Fuel, Vol. 76, 1997, pp. 755–759.10.1016/S0016-2361(96)00214-1Suche in Google Scholar

[38] Li, Y. Study on landfill and durability of sewage sludge solidified with skeleton builders. Ph.D. thesis. Huazhong University of Science and Technology, Wuhan, 2013.Suche in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters

- Fe-containing nominal wollastonite (CaSiO3)–Na2O glass-ceramic: Characterization and biocompatibility

- Relevance of pore network connectivity in tannin-derived carbons for rapid detection of BTEX traces in indoor air

- A life cycle and environmental impact analysis of sustainable concrete incorporating date palm ash and eggshell powder as supplementary cementitious materials

- Eco-friendly utilisation of agricultural waste: Assessing mixture performance and physical properties of asphalt modified with peanut husk ash using response surface methodology

- Benefits and limitations of N2 addition with Ar as shielding gas on microstructure change and their effect on hardness and corrosion resistance of duplex stainless steel weldments

- Effect of selective laser sintering processing parameters on the mechanical properties of peanut shell powder/polyether sulfone composite

- Impact and mechanism of improving the UV aging resistance performance of modified asphalt binder

- AI-based prediction for the strength, cost, and sustainability of eggshell and date palm ash-blended concrete

- Investigating the sulfonated ZnO–PVA membrane for improved MFC performance

- Strontium coupling with sulphur in mouse bone apatites

- Transforming waste into value: Advancing sustainable construction materials with treated plastic waste and foundry sand in lightweight foamed concrete for a greener future

- Evaluating the use of recycled sawdust in porous foam mortar for improved performance

- Improvement and predictive modeling of the mechanical performance of waste fire clay blended concrete

- Polyvinyl alcohol/alginate/gelatin hydrogel-based CaSiO3 designed for accelerating wound healing

- Research on assembly stress and deformation of thin-walled composite material power cabin fairings

- Effect of volcanic pumice powder on the properties of fiber-reinforced cement mortars in aggressive environments

- Analyzing the compressive performance of lightweight foamcrete and parameter interdependencies using machine intelligence strategies

- Selected materials techniques for evaluation of attributes of sourdough bread with Kombucha SCOBY

- Establishing strength prediction models for low-carbon rubberized cementitious mortar using advanced AI tools

- Investigating the strength performance of 3D printed fiber-reinforced concrete using applicable predictive models

- An eco-friendly synthesis of ZnO nanoparticles with jamun seed extract and their multi-applications

- The application of convolutional neural networks, LF-NMR, and texture for microparticle analysis in assessing the quality of fruit powders: Case study – blackcurrant powders

- Study of feasibility of using copper mining tailings in mortar production

- Shear and flexural performance of reinforced concrete beams with recycled concrete aggregates

- Advancing GGBS geopolymer concrete with nano-alumina: A study on strength and durability in aggressive environments

- Leveraging waste-based additives and machine learning for sustainable mortar development in construction

- Study on the modification effects and mechanisms of organic–inorganic composite anti-aging agents on asphalt across multiple scales

- Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs

- Structural, physical, and luminescence properties of sodium–aluminum–zinc borophosphate glass embedded with Nd3+ ions for optical applications

- Eco-friendly waste plastic-based mortar incorporating industrial waste powders: Interpretable models for flexural strength

- Bioactive potential of marine Aspergillus niger AMG31: Metabolite profiling and green synthesis of copper/zinc oxide nanocomposites – An insight into biomedical applications

- Preparation of geopolymer cementitious materials by combining industrial waste and municipal dewatering sludge: Stabilization, microscopic analysis and water seepage

- Seismic behavior and shear capacity calculation of a new type of self-centering steel-concrete composite joint

- Sustainable utilization of aluminum waste in geopolymer concrete: Influence of alkaline activation on microstructure and mechanical properties

- Optimization of oil palm boiler ash waste and zinc oxide as antibacterial fabric coating

- Tailoring ZX30 alloy’s microstructural evolution, electrochemical and mechanical behavior via ECAP processing parameters

- Comparative study on the effect of natural and synthetic fibers on the production of sustainable concrete

- Microemulsion synthesis of zinc-containing mesoporous bioactive silicate glass nanoparticles: In vitro bioactivity and drug release studies

- On the interaction of shear bands with nanoparticles in ZrCu-based metallic glass: In situ TEM investigation

- Developing low carbon molybdenum tailing self-consolidating concrete: Workability, shrinkage, strength, and pore structure

- Experimental and computational analyses of eco-friendly concrete using recycled crushed brick

- High-performance WC–Co coatings via HVOF: Mechanical properties of steel surfaces

- Mechanical properties and fatigue analysis of rubber concrete under uniaxial compression modified by a combination of mineral admixture

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part II

- Investigating the effect of locally available volcanic ash on mechanical and microstructure properties of concrete

- Flexural performance evaluation using computational tools for plastic-derived mortar modified with blends of industrial waste powders

- Foamed geopolymers as low carbon materials for fire-resistant and lightweight applications in construction: A review

- Autogenous shrinkage of cementitious composites incorporating red mud

- Special Issue on AI-Driven Advances for Nano-Enhanced Sustainable Construction Materials

- Advanced explainable models for strength evaluation of self-compacting concrete modified with supplementary glass and marble powders

- Analyzing the viability of agro-waste for sustainable concrete: Expression-based formulation and validation of predictive models for strength performance

- Special Issue on Advanced Materials for Energy Storage and Conversion

- Innovative optimization of seashell ash-based lightweight foamed concrete: Enhancing physicomechanical properties through ANN-GA hybrid approach

- Production of novel reinforcing rods of waste polyester, polypropylene, and cotton as alternatives to reinforcement steel rods

Artikel in diesem Heft

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters

- Fe-containing nominal wollastonite (CaSiO3)–Na2O glass-ceramic: Characterization and biocompatibility

- Relevance of pore network connectivity in tannin-derived carbons for rapid detection of BTEX traces in indoor air

- A life cycle and environmental impact analysis of sustainable concrete incorporating date palm ash and eggshell powder as supplementary cementitious materials

- Eco-friendly utilisation of agricultural waste: Assessing mixture performance and physical properties of asphalt modified with peanut husk ash using response surface methodology

- Benefits and limitations of N2 addition with Ar as shielding gas on microstructure change and their effect on hardness and corrosion resistance of duplex stainless steel weldments

- Effect of selective laser sintering processing parameters on the mechanical properties of peanut shell powder/polyether sulfone composite

- Impact and mechanism of improving the UV aging resistance performance of modified asphalt binder

- AI-based prediction for the strength, cost, and sustainability of eggshell and date palm ash-blended concrete

- Investigating the sulfonated ZnO–PVA membrane for improved MFC performance

- Strontium coupling with sulphur in mouse bone apatites

- Transforming waste into value: Advancing sustainable construction materials with treated plastic waste and foundry sand in lightweight foamed concrete for a greener future

- Evaluating the use of recycled sawdust in porous foam mortar for improved performance

- Improvement and predictive modeling of the mechanical performance of waste fire clay blended concrete

- Polyvinyl alcohol/alginate/gelatin hydrogel-based CaSiO3 designed for accelerating wound healing

- Research on assembly stress and deformation of thin-walled composite material power cabin fairings

- Effect of volcanic pumice powder on the properties of fiber-reinforced cement mortars in aggressive environments

- Analyzing the compressive performance of lightweight foamcrete and parameter interdependencies using machine intelligence strategies

- Selected materials techniques for evaluation of attributes of sourdough bread with Kombucha SCOBY

- Establishing strength prediction models for low-carbon rubberized cementitious mortar using advanced AI tools

- Investigating the strength performance of 3D printed fiber-reinforced concrete using applicable predictive models

- An eco-friendly synthesis of ZnO nanoparticles with jamun seed extract and their multi-applications

- The application of convolutional neural networks, LF-NMR, and texture for microparticle analysis in assessing the quality of fruit powders: Case study – blackcurrant powders

- Study of feasibility of using copper mining tailings in mortar production

- Shear and flexural performance of reinforced concrete beams with recycled concrete aggregates

- Advancing GGBS geopolymer concrete with nano-alumina: A study on strength and durability in aggressive environments

- Leveraging waste-based additives and machine learning for sustainable mortar development in construction

- Study on the modification effects and mechanisms of organic–inorganic composite anti-aging agents on asphalt across multiple scales

- Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs

- Structural, physical, and luminescence properties of sodium–aluminum–zinc borophosphate glass embedded with Nd3+ ions for optical applications

- Eco-friendly waste plastic-based mortar incorporating industrial waste powders: Interpretable models for flexural strength

- Bioactive potential of marine Aspergillus niger AMG31: Metabolite profiling and green synthesis of copper/zinc oxide nanocomposites – An insight into biomedical applications

- Preparation of geopolymer cementitious materials by combining industrial waste and municipal dewatering sludge: Stabilization, microscopic analysis and water seepage

- Seismic behavior and shear capacity calculation of a new type of self-centering steel-concrete composite joint

- Sustainable utilization of aluminum waste in geopolymer concrete: Influence of alkaline activation on microstructure and mechanical properties

- Optimization of oil palm boiler ash waste and zinc oxide as antibacterial fabric coating

- Tailoring ZX30 alloy’s microstructural evolution, electrochemical and mechanical behavior via ECAP processing parameters

- Comparative study on the effect of natural and synthetic fibers on the production of sustainable concrete

- Microemulsion synthesis of zinc-containing mesoporous bioactive silicate glass nanoparticles: In vitro bioactivity and drug release studies

- On the interaction of shear bands with nanoparticles in ZrCu-based metallic glass: In situ TEM investigation

- Developing low carbon molybdenum tailing self-consolidating concrete: Workability, shrinkage, strength, and pore structure

- Experimental and computational analyses of eco-friendly concrete using recycled crushed brick

- High-performance WC–Co coatings via HVOF: Mechanical properties of steel surfaces

- Mechanical properties and fatigue analysis of rubber concrete under uniaxial compression modified by a combination of mineral admixture

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part II

- Investigating the effect of locally available volcanic ash on mechanical and microstructure properties of concrete

- Flexural performance evaluation using computational tools for plastic-derived mortar modified with blends of industrial waste powders

- Foamed geopolymers as low carbon materials for fire-resistant and lightweight applications in construction: A review

- Autogenous shrinkage of cementitious composites incorporating red mud

- Special Issue on AI-Driven Advances for Nano-Enhanced Sustainable Construction Materials

- Advanced explainable models for strength evaluation of self-compacting concrete modified with supplementary glass and marble powders

- Analyzing the viability of agro-waste for sustainable concrete: Expression-based formulation and validation of predictive models for strength performance

- Special Issue on Advanced Materials for Energy Storage and Conversion

- Innovative optimization of seashell ash-based lightweight foamed concrete: Enhancing physicomechanical properties through ANN-GA hybrid approach

- Production of novel reinforcing rods of waste polyester, polypropylene, and cotton as alternatives to reinforcement steel rods