Flexural performance evaluation using computational tools for plastic-derived mortar modified with blends of industrial waste powders

-

Ahmed A. Alawi Al-Naghi

, Suleman Ayub Khan

, Nawaf Alnawmasi

, Omar Algassem

Abstract

Cementitious composites, which include waste plastic, have limited uses in the construction sector due to a decline in strength. Substituting industrial waste for cement in plastic-based mortar mixes (PBMs) is an environmentally preferable and long-term sustainable alternative. Machine learning (ML) models including bagging regressors (BGR), AdaBoost regressors (ADB), and random forest regressors (RFR) were used to assess the flexural strength (FS) of PBMs. An extensive dataset of 408 samples was employed that included six inputs such as cement, fine aggregate, plastic, silica fume, marble powder, and glass powder. Analysis was performed to determine the importance of contributing variables using the Shapley additive explanations (SHAP) approach. When it came to predicting PBM’s FS, RFR outperformed BGR and ADB. The RFR model had an R 2-value of 0.98, which was much higher than 0.88 and 0.92 reported by the BGR and ADB models, respectively. The statistical results indicated that BGR had an MAPE of 4.00%, an ADB of 2.90%, and an RFR of 1.80%, adding further weight to the claims made about the deployed ML models. Sand, cement, and silica fume were identified as the three most critical components in terms of strength according to the SHAP study. The created models can assist in identifying the feasible solutions of PBMs for diverse input parameter values, hence minimizing the necessity for expensive and time-intensive laboratory testing.

1 Introduction

Solid garbage is generated at a substantial pace worldwide. Infectious, flammable, corrosive, and chemically reactive materials are prevalent in this refuse. Regularly landfilling these items is detrimental to ecosystems and public health [1,2,3]. Plastic remnants, which are non-biodegradable, represent a significant fraction of solid waste and provide a grave threat to the ecosystem. The primary contributors to the growing plastic waste problem are disposable containers and excess materials from construction projects. Burial, incineration, and recycling are the prevailing methods for managing this waste; however, none are especially sustainable. Recycling remains the most prevalent method due to numerous environmentally beneficial advantages, as illustrated in Figure 1 [4]. Inadequate waste management at landfills intensifies environmental problems such as contamination and pollution, resulting in health consequences [5,6,7]. Recycled plastic trash has been investigated as a possible component of composite materials. Investigators have assessed the viability of utilizing plastic trash as aggregates in construction materials to produce eco-friendly goods, following an evaluation of several properties of plastic, such as its flexibility, lightweight composition, and chemical inertness [8,9,10,11,12]. Nonetheless, the inconsistent behavior of strength qualities in plastic-based mortar (PBM) or concrete under diverse situations restricts their applicability. This requires an in-depth investigation to fully understand and improve their effectiveness across various applications.

![Figure 1

Advantages of plastic waste recycling [4].](/document/doi/10.1515/rams-2025-0092/asset/graphic/j_rams-2025-0092_fig_001.jpg)

Advantages of plastic waste recycling [4].

In recent decades, supplementary cementitious materials (SCMs) such as marble powder (M-P), silica fume (SiF), glass powder (GlP), bagasse ash, slags, and rice husk ash have been extensively researched as alternatives to cement [13,14,15,16,17]. Cement can experience hydraulic and pozzolanic hydration in a pore solution in the presence of SCMs [18,19]. A proficient approach to advocate for sustainable construction is to integrate industrial byproducts as SCMs in construction composites [20,21,22,23]. This technique may decrease dependence on cement, alleviate carbon monoxide emissions, and improve the economic efficiency of waste management [24,25]. Moreover, research indicates that using SCMs sourced from industrial waste can improve the strength of cementitious composites [26,27,28].

GlP, SiF, and M-P are common industrial byproducts that can be converted into SCMs. Due to its small particle size, SiF is able to penetrate the crevices between cement grains, which increases matrix compaction when used as a filler material [29,30]. Due to its high reactivity with Ca(OH)2, a byproduct of cement hydration, Si-F presents a viable option for partial cement replacement [31,32]. Incorporating SiF oxides into cementitious composites may reduce bleeding, porosity, and permeability by interacting with and utilizing Ca(OH)2 produced during the hydration of cement [33]. The excess of glass debris in landfills is mainly due to the yearly disposal of glass bottles [34]. Glass, due to its chemical composition, demonstrates superior durability compared to other materials such as wood and plastic. Glass retains its structural integrity despite extended entombment [35]. The conversion of waste glass into construction materials is viable. Cementitious composites can make use of crushed glass waste as a partial replacement for sand and cement [36,37]. Powdered glass, according to the research, can greatly increase the strength of cementitious composites [27]. Research on recycling M-P has demonstrated potential in enhancing the structural integrity of materials and creating more sustainable alternatives to cement and fine aggregate (FA) [38]. The impacts of SiF, M-P, and GlP on cement mortar including waste plastic as a partial sand substitute, referred to as plastic mortar, have not been examined in prior research.

The significance of the mechanical properties of cement-based materials (CBMs) has prompted extensive research on these substances [39]. Information about the CBM’s properties can be derived from its compressive strength (CS) and flexural strength (FS). Various mechanical and durability properties are intrinsically linked to the mortar’s CS and FS [40,41]. In an effort to reduce unnecessary testing, analysts are working on analytical models to ascertain the strength of materials. Several common models, including best-fit curves, are used to reproduce the observable qualities acquired by regression analysis. The non-linear characteristics of CBMs pose a threat to conventional regression techniques, which may incorrectly assume their intrinsic behavior [42]. The rising use of AI methodologies, particularly supervised machine learning (ML), is resulting in models within this domain being progressively intricate [12,43]. For these models to yield dependable predictions based on input features, they must undergo experimental testing to verify their accuracy. The utilization of ML methods to forecast the features of coalbed methane is increasing [44].

Advancements in soft computing have facilitated more accurate simulations of the technical characteristics of various materials. Accurate predictions necessitate ML models driven by data. Producing trustworthy quality estimations is challenging due to the varied morphology and intrinsic unpredictability of building materials. A notable use of ML techniques is the estimation of technical characteristics for construction materials. ML algorithms have assessed several modern and traditional varieties of mortar and concrete, including lightweight concrete, fiber-reinforced concrete, recycled aggregate concrete, self-compacting concrete, concrete incorporating phase change materials, among numerous others [45,46,47,48,49]. Multiple academic research have shown that advanced ML models surpass conventional physical and empirical techniques in precisely predicting certain engineering features of concrete. Precise forecasting of concrete properties necessitates the resolution of computational obstacles. This study investigates the complex mechanisms of cement hydration and morphology formation, as well as the non-linear temporal and temperature-dependent characteristics of cement paste [50,51,52]. Utilizing input data on mixture ratios and curing circumstances, ML models can be developed to precisely forecast desired characteristics. The utilization of ML models offers several benefits, such as their capacity for precise and flexible predictions, minimal computing demands, and reproducibility.

The use of properly trained ML algorithms could help build a trustworthy computational framework for FS prediction of PBMs, as shown in the research. This study uses a number of robust ML models to investigate the FS of PBMs. A dataset consisting of 408 points has been compiled from academic journals that are open to the public. Bagging regressor (BGR), the AdaBoost regressor (ADB), and the random forest regressor (RFR) were utilized to build regression models that could predict the FS of PBMs. Mathematical tests using K-fold and statistical checks verify the models, and Shapley additive explanations (SHAP) analysis was used to look at how the variables affected the forecast. Innovative methodologies for the controlled examination of material properties with minimal human involvement may impact the construction sector.

2 Study approach

2.1 Dataset assortment and evaluation

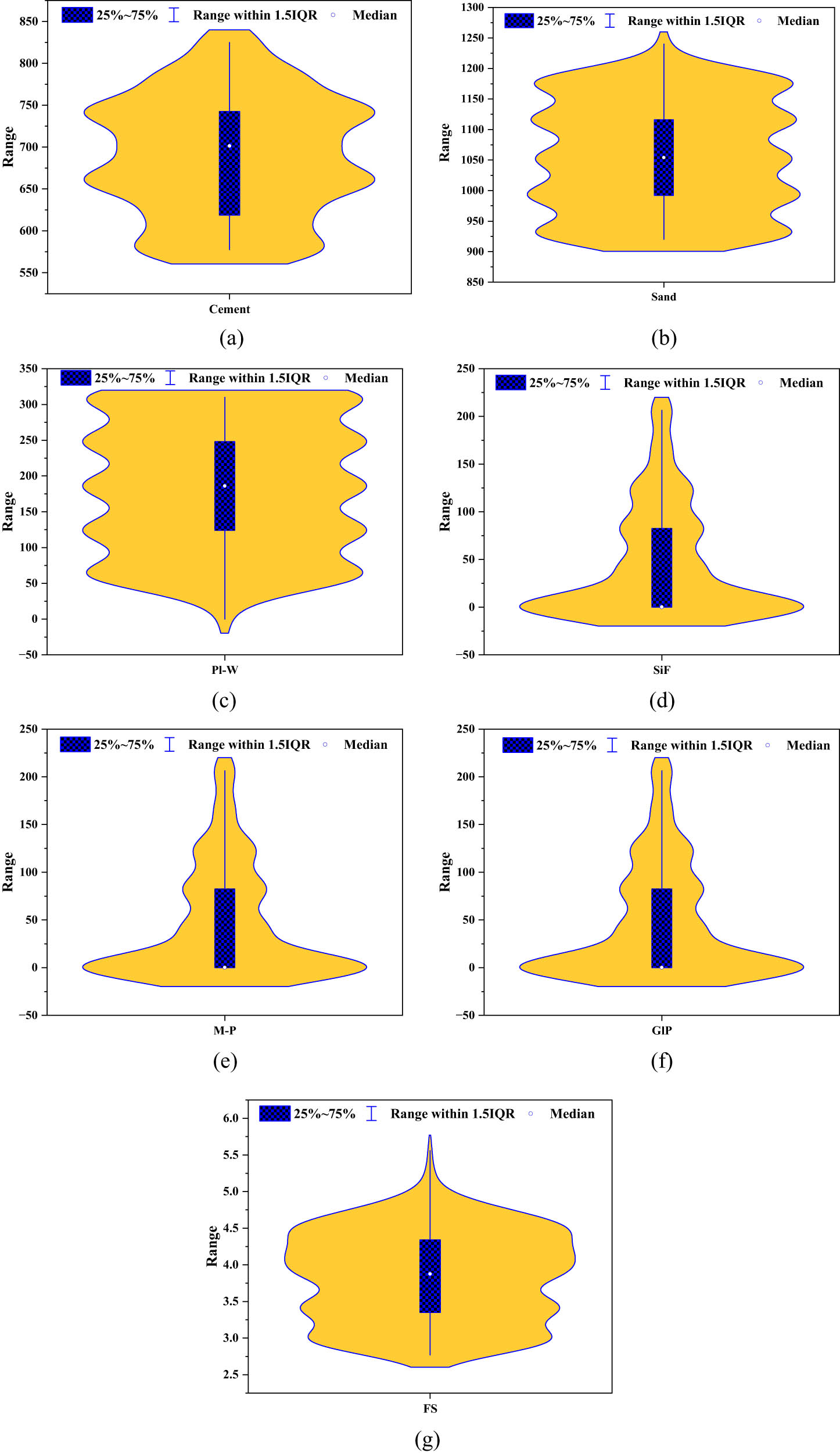

This work drew on a dataset of 408 data points for FS of PBM that had been compiled for model development in earlier research [53]. Included in the dataset are cement (CM), FA, plastic (Pl-W), silica fume (Si-F), marble powder (M-P), and glass powder (GlP) as inputs, whereas FS was set as output variable. Experts across various fields have emphasized that the ratio of data points to inputs is crucial for a model’s effectiveness. A ratio greater than 5 is considered ideal, as it enables sufficient data points for testing and uncovering relationships between the specified variables [54]. In this study, six inputs are used to predict the FS of PBMs, achieving a data point-to-input ratio of 68.0, which meets the criteria established by researchers. Table 1 provides an overview of the FS database that has been set up. Including these statistics enhances the dataset’s understandability. The FS data, with 408 samples, has a mean of 3.83 MPa and a standard deviation of 0.61 MPa, indicating moderate variability. The range spans from 2.77 to 5.56 MPa, showing a broad spread of values, and the distribution is slightly platykurtic with a kurtosis of −1.03. The data is nearly symmetric with a skewness value of 0, indicating no significant skew. Similarly, for plastic (Pl-W), the dataset consists of 408 samples with a mean value of 184.63 kg·m−³ and a standard deviation of 88.9 kg·m−³, indicating significant variability. The levels of plastic in the concrete mix are shown by the values, which vary from 0 to 310 kg·m−³ [55,56,57]. It is shown in Table 1 that these measurements are within the allowed range. Figure 2(a)–(g) show violin plots with a box representation of the FS database variables that are being considered. Important statistical parameters, such as the interquartile range, are shown in the box plot. A median line indicates the middle tendency, while a box indicates the range between the 25th and 75th percentiles. A visual representation of the data’s density and shape is provided by the violin-shaped plot. More data density is represented by wider parts of the violin plot, which gives a detailed picture of the dataset’s distribution. Both the statistical measures and the distribution of the qualities (inputs) are successfully shown by using a dual-plot approach. The models’ performance is impacted by the inputs’ distribution; data is distributed randomly across their whole range.

A statistical summary of the FS database [53]

| Statistical metrics | Cement (kg·m−3) | Sand (kg·m−3) | Pl-W (kg·m−3) | SiF (kg·m−3) | M-P (kg·m−3) | GlP (kg·m−3) | FS (MPa) |

|---|---|---|---|---|---|---|---|

| Mean | 688.51 | 1054.78 | 184.63 | 45.5 | 45.5 | 45.5 | 3.83 |

| Standard error | 3.51 | 4.42 | 4.4 | 2.91 | 2.91 | 2.91 | 0.03 |

| Median | 701.25 | 1,054 | 186 | 0 | 0 | 0 | 3.88 |

| Mode | 742.5 | 1,178 | 62 | 0 | 0 | 0 | 3.4 |

| Standard deviation | 70.92 | 89.2 | 88.9 | 58.68 | 58.68 | 58.68 | 0.61 |

| Sample variance | 5029.8 | 7955.92 | 7903.35 | 3443.58 | 3443.58 | 3443.58 | 0.37 |

| Range | 247.5 | 320 | 310 | 206.25 | 206.25 | 206.25 | 2.79 |

| Minimum | 577.5 | 920 | 0 | 0 | 0 | 0 | 2.77 |

| Maximum | 825 | 1,240 | 310 | 206.25 | 206.25 | 206.25 | 5.56 |

| Sum | 280912.5 | 430,350 | 75,330 | 18562.5 | 18562.5 | 18562.5 | 1562.89 |

| Count | 408 | 408 | 408 | 408 | 408 | 408 | 408 |

FS database data dispersion violin plots: (a) Cement; (b) Sand; (c) Pl-W; (d) SiF; (e) M-P; (f) GlP; (g) FS.

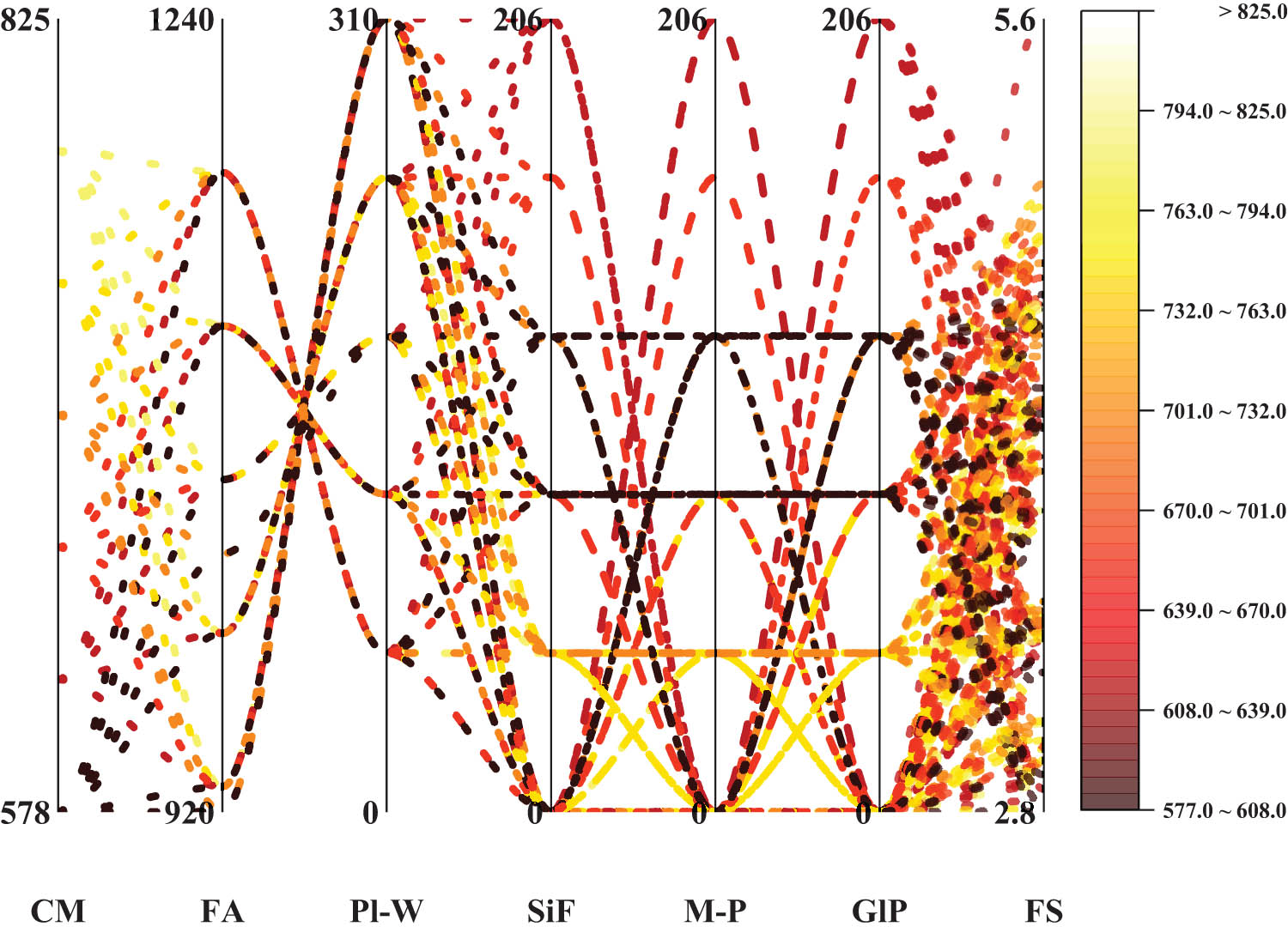

Furthermore, multicollinearity and dependency pose difficulties for ML models. It becomes difficult to isolate and assess the unique impacts of each variable when there are multiple highly correlated independent variables in an analysis, a phenomenon known as multicollinearity. Coefficient estimations and interpretations can become unreliable as a result of this. Beyond basic correlation, complex interconnections between variables impede the model’s ability to detect causal relationships; this is known as interdependency [58,59,60]. Figure 3 shows the results of plotting parallel correlations for the FS database, which were used to examine these concerns in this work. Several axes run parallel to one another, and a vertical axis represents each parameter. Consistent with the prevailing pattern observed in most data sets, it is evident that all inputs substantially influence the outcome. Of the total data points, 70% (286 points) were allocated for training, whereas 30% (122 points) were designated for model evaluation (testing). To assess the efficacy of ML models, data must be divided into training and testing subsets. This procedure verifies the model’s applicability to fresh data, prevents overfitting, aids in hyperparameter adjustment, investigates variance and bias, evaluates robustness, and enhances model transparency. Improving the reliability and effectiveness of models in real-world situations requires this strategy. Data tuning and hyperparameter optimization are critical for improving the performance of ML models. They involve adjusting parameters like learning rate, number of estimators, and regularization to balance bias and variance. Techniques such as grid search, random search, and Bayesian optimization are commonly used to find the optimal combination of hyperparameters for better accuracy and generalization.

Parallel correlation plots for FS database.

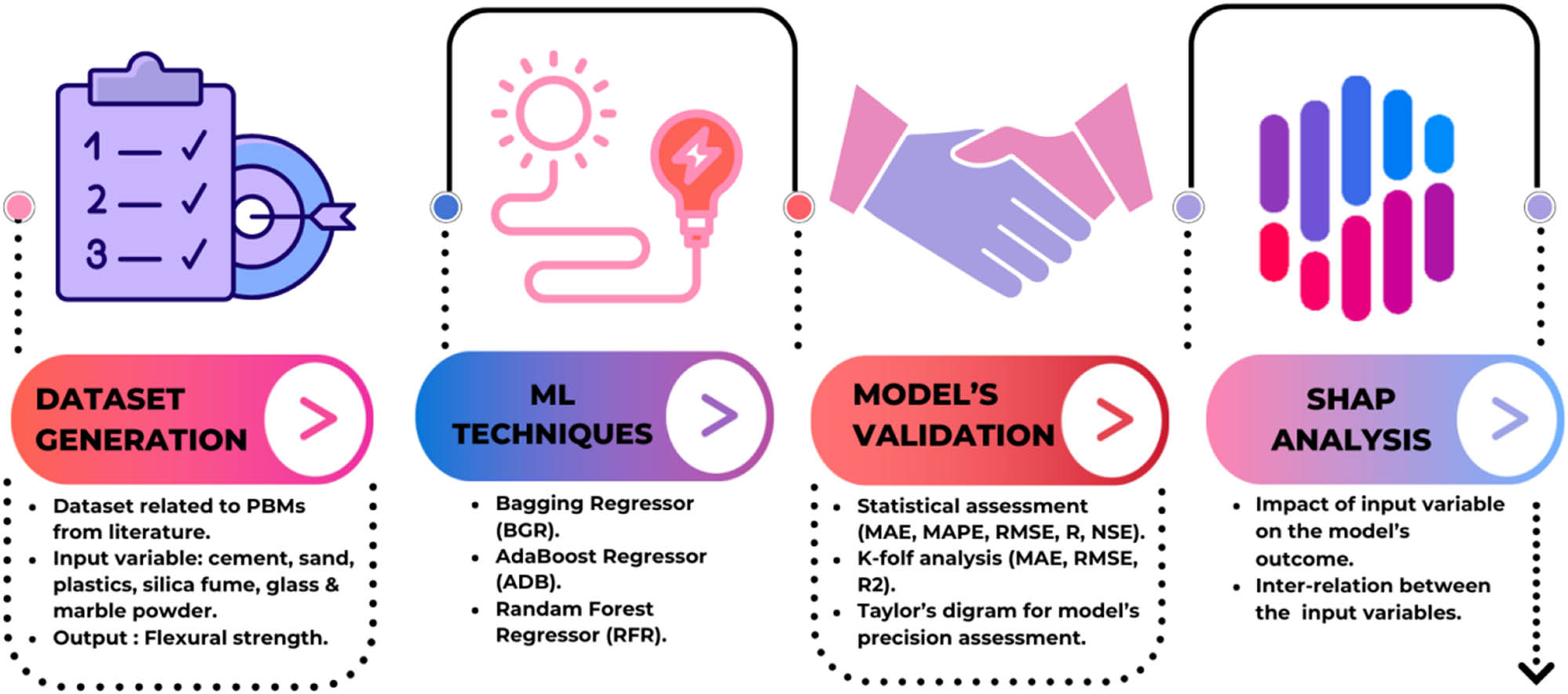

2.2 ML modeling

The six-variable experiment mainly focused on PBM’s FS. Contemporary ML techniques, including BGR, ADB, and RFR, were employed to predict the FS of PBMs. Ensemble models like BGR, ADB, and RFR are highly precise because they combine predictions from multiple individual models, reducing overfitting and improving generalization. These techniques reduce the influence of errors from individual models and effectively capture complex patterns in the data, leading to improved accuracy. Evaluation of results following analysis of input data using ML techniques was considerably less complicated. The dataset was divided into two parts: one for testing purposes and one for training the ML algorithms. Models were assessed by calculating the R 2 score of the predicted outcomes; a low value suggests a substantial discrepancy, whereas a high value shows that the predicted and actual outcomes are quite congruent [61]. To ensure the model was accurate, it was subjected to a battery of tests, including statistical analyses and evaluations of errors. Figure 4 shows a simplified image of an event model.

Sequence of the research process.

2.2.1 BGR

A comparable ensemble method essentially denotes the integration of further training data into the predictive model. The original set’s statistics by the implementation of an asymmetrical sampling methodology are substituted. Subsequent training data batches may include identical observations if replacement sampling is utilized. Post-bagging, each component possesses an equal probability of being integrated into the new dataset. An augmented training dataset does not intrinsically produce enhanced predictions. Improving the precision of the intended output may significantly reduce the divergence. This ensemble utilizes the simulation-wide average forecast. Regression utilizes a mean prediction obtained from multiple simulations [62]. The bagging method with MLPNN is optimized with the aid of 20 distinct sub-models to achieve the most efficient output value.

2.2.2 ADB

ML professionals develop several models with one algorithm using ensemble learning [63]. Combining the efforts of multiple algorithms, an ensemble can finish a single categorization. In order to discover an answer, a huge number of students – hundreds or perhaps thousands strong – join forces. The ABR technique makes use of ensemble learning, a controlled ML approach. Another name for it is adaptive boosting, which is derived from the fact that the weights are reorganized after each instance is processed in order to give more weight to the examples with inaccurate labels. When it comes to supervised ML, boosting techniques are heavily utilized for data smoothing and noise elimination. Students who are struggling are helped by using the strategies indicated above. Decision trees (DTs) are used in an indefinite number during the training process with new input data. Fixing the original model’s inaccurate categorizations is a primary goal during development. To another mathematical model, these are the sole inputs. The prior procedure will be reiterated once a sufficient number of primary learners have been generated. Using the ABR, DTs perform much better on binary classification tasks. In addition, helping other ML methods work better is its secondary goal. If your student is nervous, this tactic will help them relax again. The prediction of concrete’s mechanical properties is a common civil engineering use of ensemble methods.

2.2.3 RFR

Utilizing bagged DTs and a method known as random split selection are two methods that can be utilized to successfully complete the RFR [64]. Both the input parameters that are used to generate each branch split and the training data that are employed by each tree in the forest are chosen at random [65]. This particular characteristic contributes to the enhancement of the tree’s natural diversity. Only binary trees that have reached their full maturity can be found in the forest. Since its inception, the RFR approach has shown to be an efficient universal regression methodology. When there are more variables than there are different interpretations that are valid, it is considered to be more accurate to aggregate the findings of numerous DTs that were chosen at random. As a result of the fact that its indications change over the course of time, it can be utilized for both planned and spontaneous learning [64]. RF is often more accurate because it creates multiple DTs using bootstrapped data samples and averages their predictions, reducing overfitting. It handles variance better than AdaBoost and is less sensitive to outliers compared to both AdaBoost and BGRs. This balance between bias and variance makes it robust and reliable for diverse datasets [66].

2.3 SHAP analysis

Lundberg and Lee [67] presented SHAP as a way to characterize the supplementary feature attribute method of ML. The input variables to the process are represented by their linear sum in the input model. Assuming x is the input variable to the model, the clarification model

When there are no features, the value of

![Figure 5

Diagram of the SHAP schematic [67].](/document/doi/10.1515/rams-2025-0092/asset/graphic/j_rams-2025-0092_fig_005.jpg)

Diagram of the SHAP schematic [67].

2.4 Generated models validation

The entire ML methods were double-checked for correctness using quantitative analysis and K-fold testing. Researchers frequently employ these methods to ensure that ML models are accurate [69,70]. A frequently employed method for evaluating the efficacy of a study is K-fold validation, which involves partitioning a random dataset into ten separate segments [71]. Enhancing accuracy in the ML approach is achieved by minimizing errors and augmenting the R 2 value. Moreover, it is essential to execute this task ten times before any benefits become evident. A significant portion of the model’s remarkable accuracy is ascribed to this effort. A rigorous error assessment was performed to quantitatively evaluate the accuracy of each ML technique. The evaluation criteria included mean absolute percentage error, root mean squared error, and mean absolute error (MAE). A statistical assessment of the predictive capabilities of the ML systems was conducted using regression Eqs. (2)–(6)

Among the equations mentioned earlier,

Utilizing a Taylor diagram is yet another strategy that can be utilized in order to evaluate the predictive capabilities of a model. Statistical validation is a comprehensive method that may be utilized. The correctness and dependability of the models that were generated from the data may be evaluated with the help of this image by comparing the models’ deviations from the truth or point of reference [78,79]. The radial lines on the graph represent the correlation coefficient, while the x- and y-axes of the graph display the variance of the data. A representation of the RMSE can be seen in the circular lines that are located at the real value point. We can evaluate the best spot for a made-up model using these three factors. In terms of the accuracy of predictions, the most trustworthy model is the one that performs the best [78].

3 Results and analysis of the models

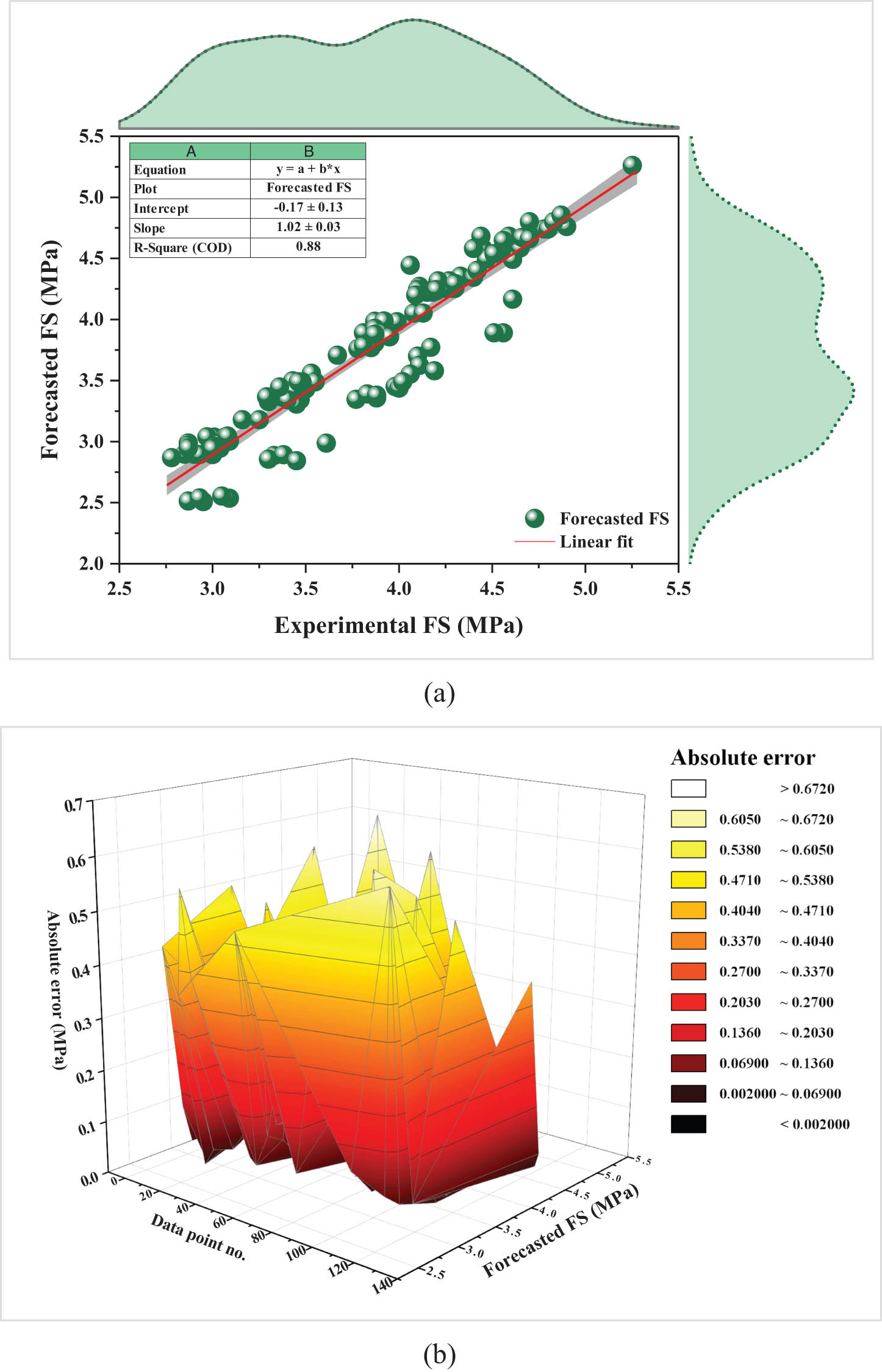

3.1 FS-based BGR model

A BGR model was built using six independent variables and FS as the output. Bagging, an ensemble method, combines predictions from multiple DTs to improve accuracy. Its significance lies in reducing overfitting and increasing model stability by averaging the predictions of the ensemble. Figure 6(a) presents a scatter plot of forecast vs experimental FS, with a best-fit line demonstrating the model’s performance. The strong agreement between the forecasted and experimental values, with points clustering near the line, indicates good predictive accuracy. The best-fit line’s slope is 1.02, close to 1, suggesting that the model accurately captures the relationship between the experimental and predicted values of FS. The intercept of −0.17, being close to zero, further confirms minimal bias in the model. An R 2 of 0.88 is also included in the picture, which means that the model accounts for 88% of the variation in experimental FS. The uncertainty in the slope (±0.03) and intercept (±0.13) is low, reinforcing the model’s precision. Overall, the model demonstrates high predictive capability and reliability in estimating the FS of PBMs. As shown in Figure 6(b), the experimental, projected, and divergent values (errors) for the BGR model that was used to predict FS of PBMs are distributed. It shows how the model handles the deviations between predicted and experimental values, with most points closely aligned, indicating a good fit. Figure 7 presents the frequency distribution of errors (MPa) in the BGR model. The error values range from a minimum of 0.00372 MPa to a maximum of 0.67025 MPa, with an average error of 0.1503 MPa. The majority of errors are small, with 82 instances below 0.1 MPa, 29 between 0.1 and 0.5 MPa, and only 12 exceeding 0.5 MPa. This distribution shows that the model consistently performs well, with most predictions having minimal deviation from the actual values. Given this error distribution, it can be concluded that the BGR model effectively predicts the FS of PBMs, with a significant proportion of errors being relatively small, confirming its accuracy and robustness in handling the dataset.

(a) FS-BGR predicted vs test strength correlation and (b) scatter of model predictions, true values, and error margins.

Frequency distribution for FS-BGR model’s errors.

3.2 FS-based ADB model

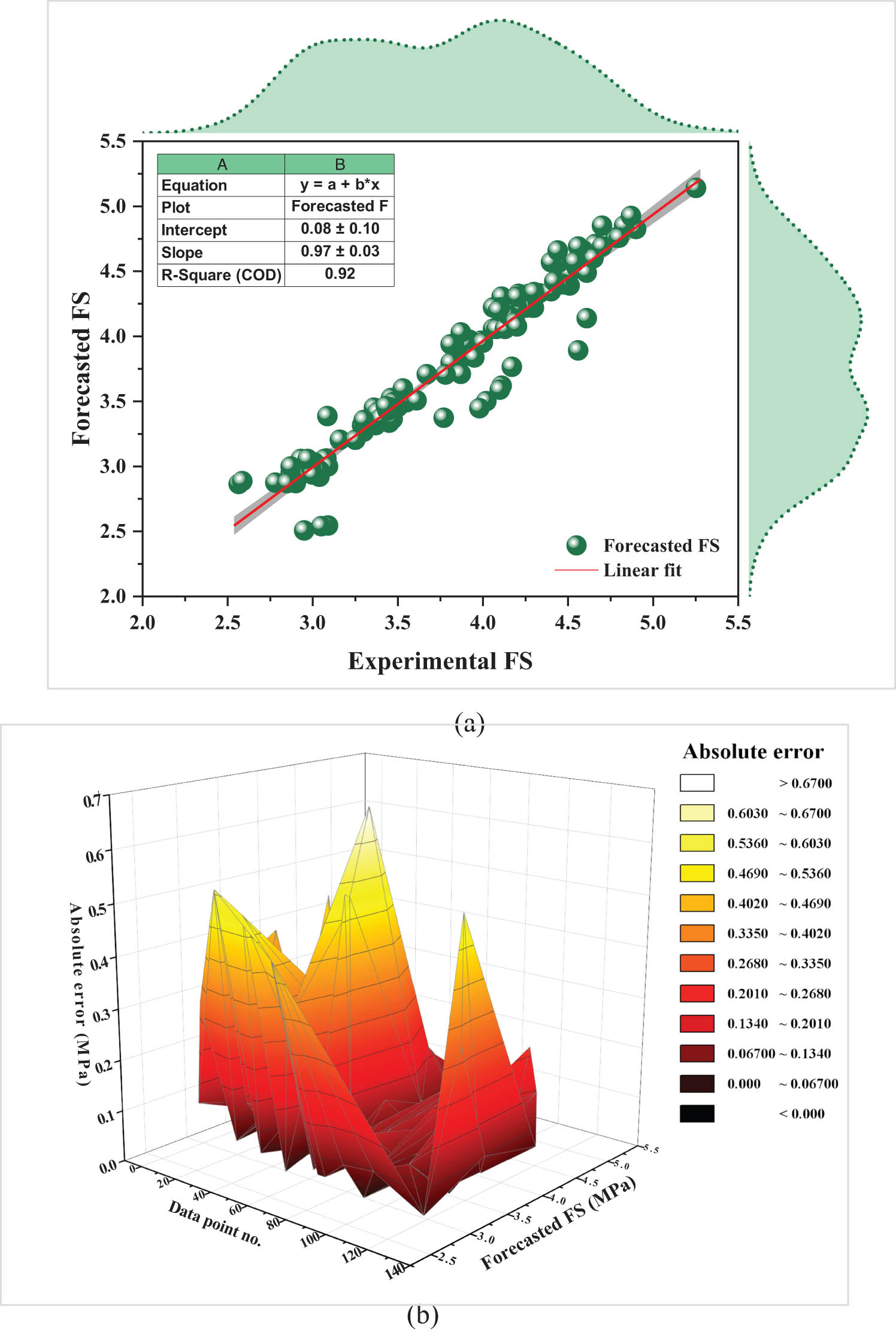

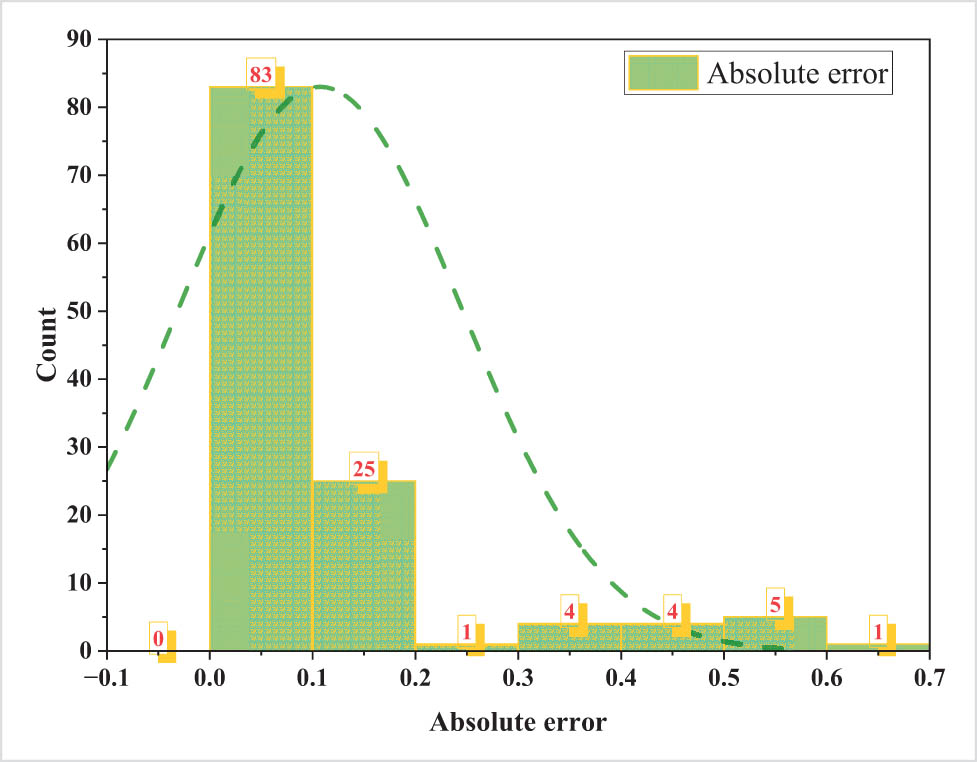

An ADB model was created using six independent variables with FS as the output. AdaBoost works by sequentially improving weak learners (DTs), focusing on difficult-to-predict data points. Its key feature is adaptive weighting, where misclassified samples are emphasized, leading to improved accuracy. Figure 8(a) illustrates a scatter plot of forecasted vs experimental FS, with a best-fit line showing the model’s performance. The slope of 0.97 and intercept of 0.08 indicate that the forecasted FS closely follows the experimental values with minimal bias. The R 2 (COD) value of 0.92 reflects that 92% of the variance in experimental FS is explained by the AdaBoost model, which is a strong indication of its accuracy. When comparing the AdaBoost model to the Bagging model, the ADB shows a slightly higher R 2 value (0.92 vs 0.88), indicating better predictive accuracy. The slope of 0.97 is closer to 1, compared to 1.02 in the Bagging model, suggesting that AdaBoost might provide a slightly more precise fit. Overall, based on the provided data, the AdaBoost model demonstrates greater accuracy and a more refined fit in predicting FS. To estimate the FS of PBMs, the ADB model was used, and Figure 8(b) depicts the distribution of actual, projected, and error values. The plot shows close alignment between forecasted and experimental values, reflecting the model’s good performance. Figure 9 illustrates the error frequency distribution of the AdaBoost model, indicating that error values span from 0.00028 to 0.66881 MPa, with a mean error of 0.1075 MPa. The majority of predictions were accurate, with 83 cases below 0.1 MPa, 34 cases between 0.1 and 0.5 MPa, and only 6 cases beyond 0.5 MPa. When comparing the AdaBoost model to the BGR, the AdaBoost model shows a slightly smaller average error (0.1075 MPa vs 0.1503 MPa) and fewer large errors. Based on the error distribution, the AdaBoost model performs better in predicting FS for PBMs, with more accurate and consistent results than the BGR.

(a) FS-ADB predicted vs test strength correlation and (b) scatter of model predictions, true values, and error margins.

Frequency distribution for FS-ADB model’s errors.

3.3 FS-based RFR model

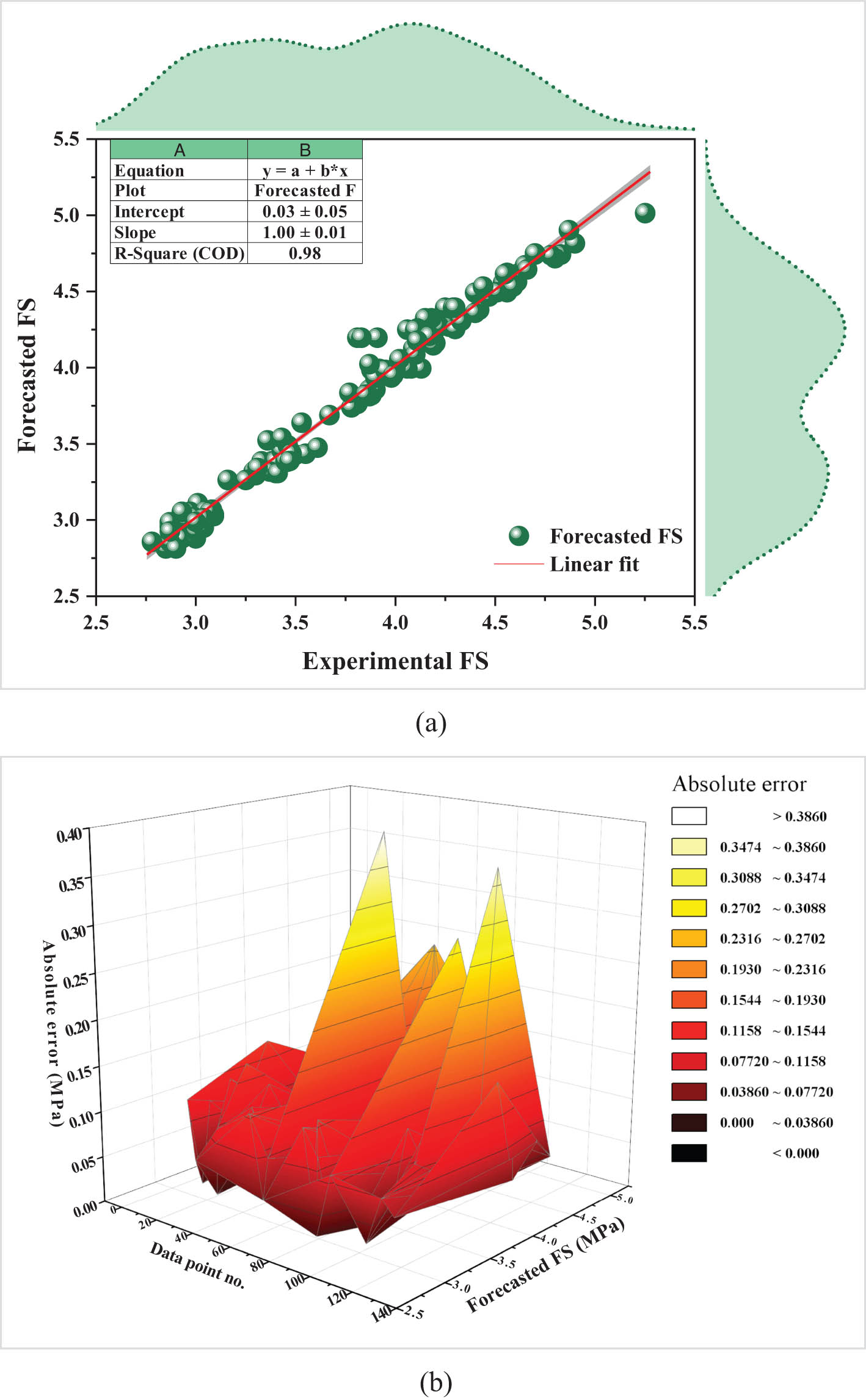

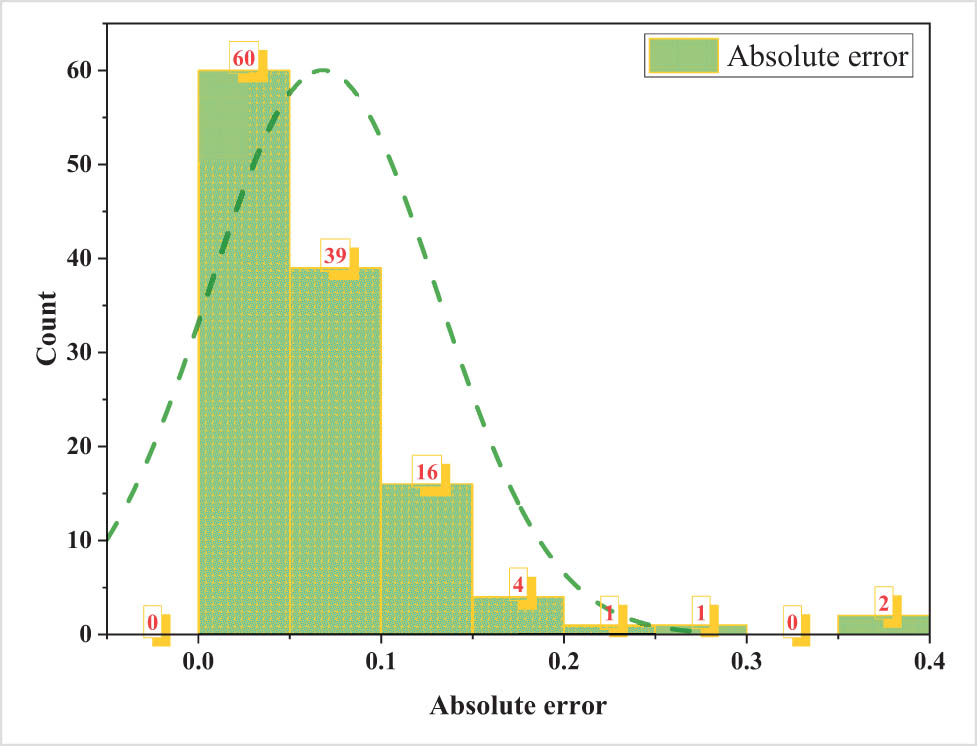

A RFR model was developed using six independent variables and one output, FS. The goal of this ensemble approach is to increase accuracy while decreasing overfitting by constructing numerous DTs and averaging their predictions. Key features include robustness to noise, handling of multicollinearity, and high prediction accuracy. Its significance lies in capturing complex relationships between variables, making it effective for reliable FS prediction in PBMs. Figure 10(a) presents a scatter plot of forecasted vs experimental FS with a best-fit line for the RFR model. The slope of 1.00 and intercept of 0.03 show that the forecasted FS values almost perfectly align with the experimental data, indicating minimal bias. The R 2 (COD) value of 0.98 reveals that the model explains 98% of the variance in FS, demonstrating exceptional accuracy. When comparing the Random Forest model with the Bagging and AdaBoost models, the Random Forest outperforms both. The Bagging model has an R 2 of 0.88, while AdaBoost has 0.92, making Random Forest significantly more accurate. Its near-perfect slope (1.00) and highest R 2 value suggest it provides the best fit and the most reliable predictions for FS among the three models. Figure 10(b) shows the distribution of experimental, expected, and divergent values (errors) generated by the RFR for the FS of PBMs. The plot reflects how closely the forecasted FS values match the experimental results. Figure 11 presents the frequency distribution of errors in MPa, indicating how frequently specific error magnitudes occurred during the model’s predictions. The error analysis reveals a minimum error of 0.00175 MPa and a maximum error of 0.386 MPa, with an average error of 0.0681 MPa. Most of the errors (99 instances) are below 0.1 MPa, while 24 instances fall between 0.1 and 0.5 MPa, and there are no errors above 0.5 MPa. This tight clustering of errors indicates the model’s strong predictive performance. In comparison to the Bagging and AdaBoost models, the RFR demonstrates superior accuracy. It has lower average errors (0.0681 MPa) and a more favorable error distribution, with fewer large errors. Therefore, based on these error metrics, the RFR outperforms the Bagging and AdaBoost models in predicting the FS of PBMs.

(a) FS-RFR predicted vs test strength correlation and (b) scatter of model predictions, true values, and error margins.

Frequency distribution for FS-RFR model’s errors.

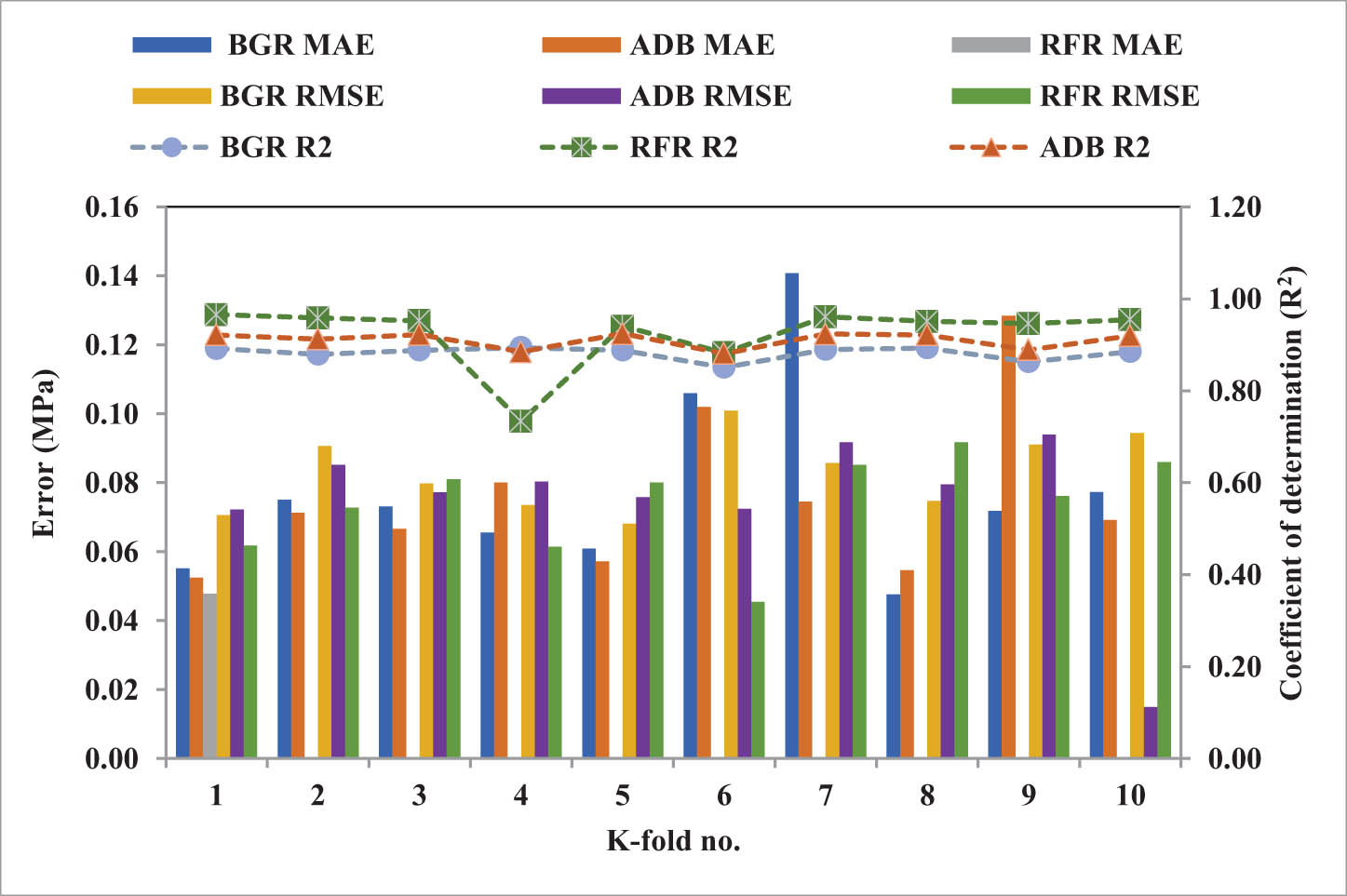

3.4 Statistics and K-fold analysis based model validation

Table 2 displays the results of the efficacy and error calculations generated from Eqs. (2)–(6) for MPE, NSE, RMSE, R, and MAE. Based on BGR FS predictions, the MAE was 0.15 MPa, the ADB was 0.11 MPa, and the RFR was 0.0.07 MPa. The results indicated that BGR had an MAPE of 4.00%, an ADB of 2.90%, and an RFR of 1.80%. Additionally, BGR has an NSE of 0.837, an ADB of 0.920, and an RFR of 0.976. Due to its significantly reduced effective and error rates, the RFR technique surpasses the BGR and ADB models in terms of performance. Table 3 displays the results of the validation tests conducted on the K-fold approach. These tests include R 2, RMSE, and MAE. Figure 12 shows the results of K-fold tests performed on several FS prediction ML methods. Based on MAE values between 0.05 and 0.14 MPa, the BGR method produced an average FS estimate of 0.08 MPa. From 0.05 to 0.13 MPa, the typical MAE for the ADB is around 0.07 MPa. An MAE of 0.07 MPa was recorded for RFR, with a range of 0.04–0.09 MPa. On average, the RMSE when conducting the analysis with BGR was 0.08 MPa, ADB was 0.07 MPa, and RFR was also 0.07 MPa. At 0.92 and 0.97, respectively, ADB and RFR had worse R 2 values than BGR’s 0.89. For PBM’s FS prediction, an improved RFR model would be shown by a reduced error rate and a higher R 2. Combining these errors with R 2 values obtained using the K-fold approach further demonstrated the improved accuracy of the RFR model. The BGR and ADM models do very well in terms of accuracy, which should be noted. More accurate FS estimations for PBMs might be generated via BGR, ADB, and RFR models.

Statistical metric results

| ML model | MAE (MPa) | R | RMSE (MPa) | MAPE (%) | NSE |

|---|---|---|---|---|---|

| BGR | 0.15 | 0.939 | 0.240 | 4.00 | 0.837 |

| ADB | 0.11 | 0.961 | 0.174 | 2.90 | 0.920 |

| RFR | 0.07 | 0.988 | 0.092 | 1.80 | 0.976 |

K-fold model study utilizing MAE, RMSE, R 2

| K-fold no. | FS (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| BGR | ADB | RFR | |||||||

| MAE | RMSE | R 2 | MAE | RMSE | R 2 | MAE | RMSE | R 2 | |

| 1 | 0.06 | 0.07 | 0.89 | 0.05 | 0.07 | 0.92 | 0.04 | 0.06 | 0.97 |

| 2 | 0.08 | 0.09 | 0.88 | 0.07 | 0.09 | 0.91 | 0.07 | 0.07 | 0.96 |

| 3 | 0.07 | 0.08 | 0.89 | 0.07 | 0.08 | 0.92 | 0.07 | 0.08 | 0.95 |

| 4 | 0.07 | 0.07 | 0.89 | 0.08 | 0.08 | 0.88 | 0.04 | 0.06 | 0.73 |

| 5 | 0.06 | 0.07 | 0.89 | 0.06 | 0.08 | 0.92 | 0.04 | 0.08 | 0.94 |

| 6 | 0.11 | 0.10 | 0.85 | 0.10 | 0.07 | 0.88 | 0.09 | 0.05 | 0.88 |

| 7 | 0.14 | 0.09 | 0.89 | 0.07 | 0.09 | 0.92 | 0.07 | 0.09 | 0.96 |

| 8 | 0.05 | 0.07 | 0.89 | 0.05 | 0.08 | 0.92 | 0.05 | 0.09 | 0.95 |

| 9 | 0.07 | 0.09 | 0.86 | 0.13 | 0.09 | 0.89 | 0.06 | 0.08 | 0.95 |

| 10 | 0.08 | 0.09 | 0.89 | 0.07 | 0.01 | 0.92 | 0.05 | 0.09 | 0.95 |

K-fold scrutiny results.

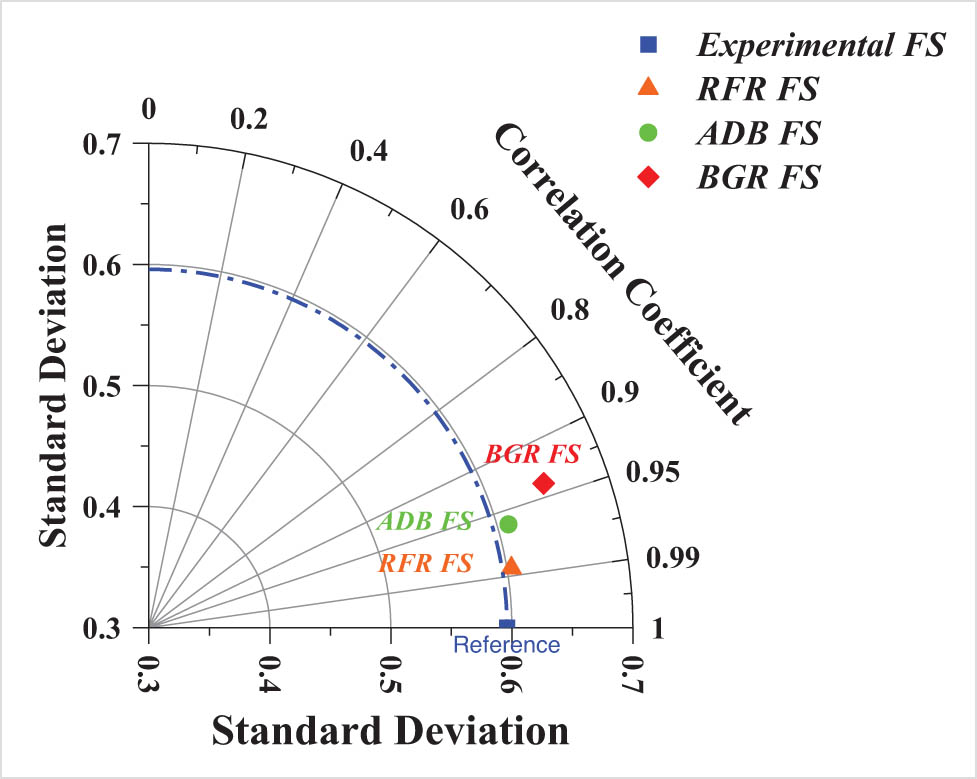

Taylor diagrams offer an interesting alternative to error-based analysis for assessing how well different models predict the given outcome. When comparing many ML models, a Taylor diagram that takes standard deviation and R 2 into account is a useful tool. Finding the algorithm’s dispersion from the reference value is one way to verify its precision. The location of an accurate algorithm should be near the actual data point, and the opposite is also true. A Taylor plot comparing the methods used in this investigation is shown in Figure 13. The closest point to the reference point is RFR, which gives it the highest accuracy. Based on the fact that the ADB point is in a closer relationship with the standard deviation line of the actual data compared to the BGR point, it can be deduced that the ADB values are less off from the actual values. The Taylor plot shows that RFR is more accurate than ADB and BGR is the most accurate overall.

Evaluation of created models using the Taylor graph.

3.5 SHAP analysis

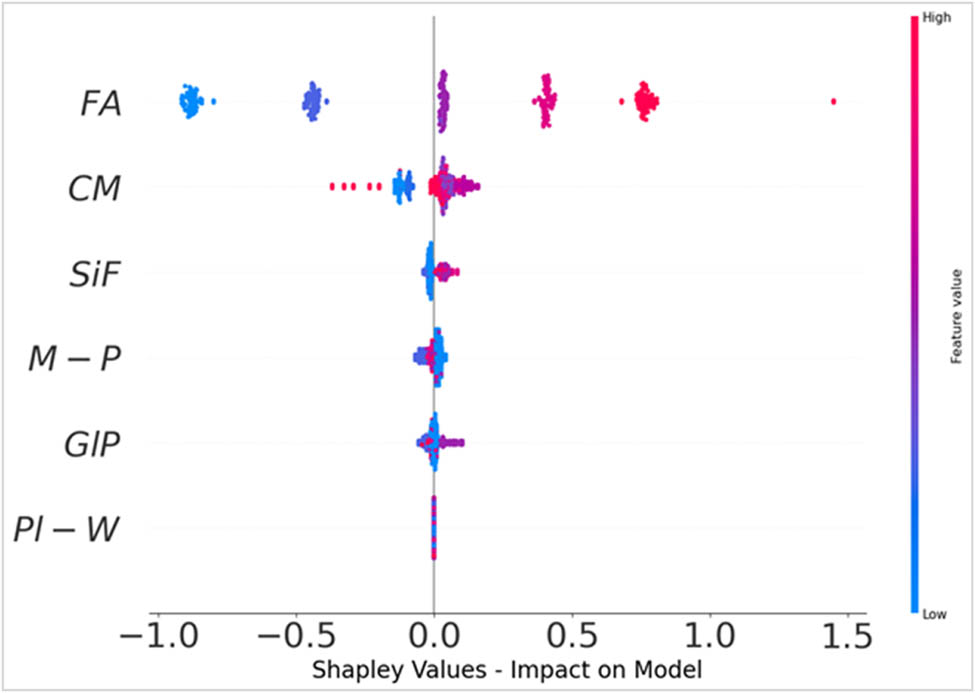

Experiments were carried out to ascertain the impact of various raw materials on the FS of PBMs. More comprehensive awareness of the full effects of features and the particular implications of local SHAP was produced by applying the SHAP network decoder to the full database. Each raw material’s effect on PBM’s FS is shown in Figure 14’s violin SHAP plots, with the x-axis SHAP value reflecting the relative contribution of each material and color gradients indicating variable values. According to SHAP, there was a favorable relationship between FA and PBM’s FS. On the positive axis, there are many red dots with a high intensity, which indicates a strong positive influence on strength. On the negative axis, there are fewer blue spots with a lower intensity. Therefore, raising the FA content should increase strength up to some extent as evident from the experimental results [80]. The SHAP plot in Figure 14 shows that there was a less negative and more positive association between CM and the FS of PBMs. According to the graph, the strength increases when the content of this variable is first increased but then decreases when the content is increased further. This relation of CM with the FS of mortar is evident from the experimental findings in existing literature [81,82]. Figure 14 shows that the cluster of red and blue dots on the zero line indicates that the connection of Si-F, M-P, and M-P is more balanced. This suggests that the pattern of strength improvement changes as the content of these variables increases. Limited data variability was the main reason for the inconclusive results about the impacts of Pl-W. Stronger and more conclusive results could be obtained using a bigger dataset that is more diverse and includes more input factors. Increasing the size of the dataset would allow us to see more effects, which would make the results more solid.

Important and influential input factor SHAP plot.

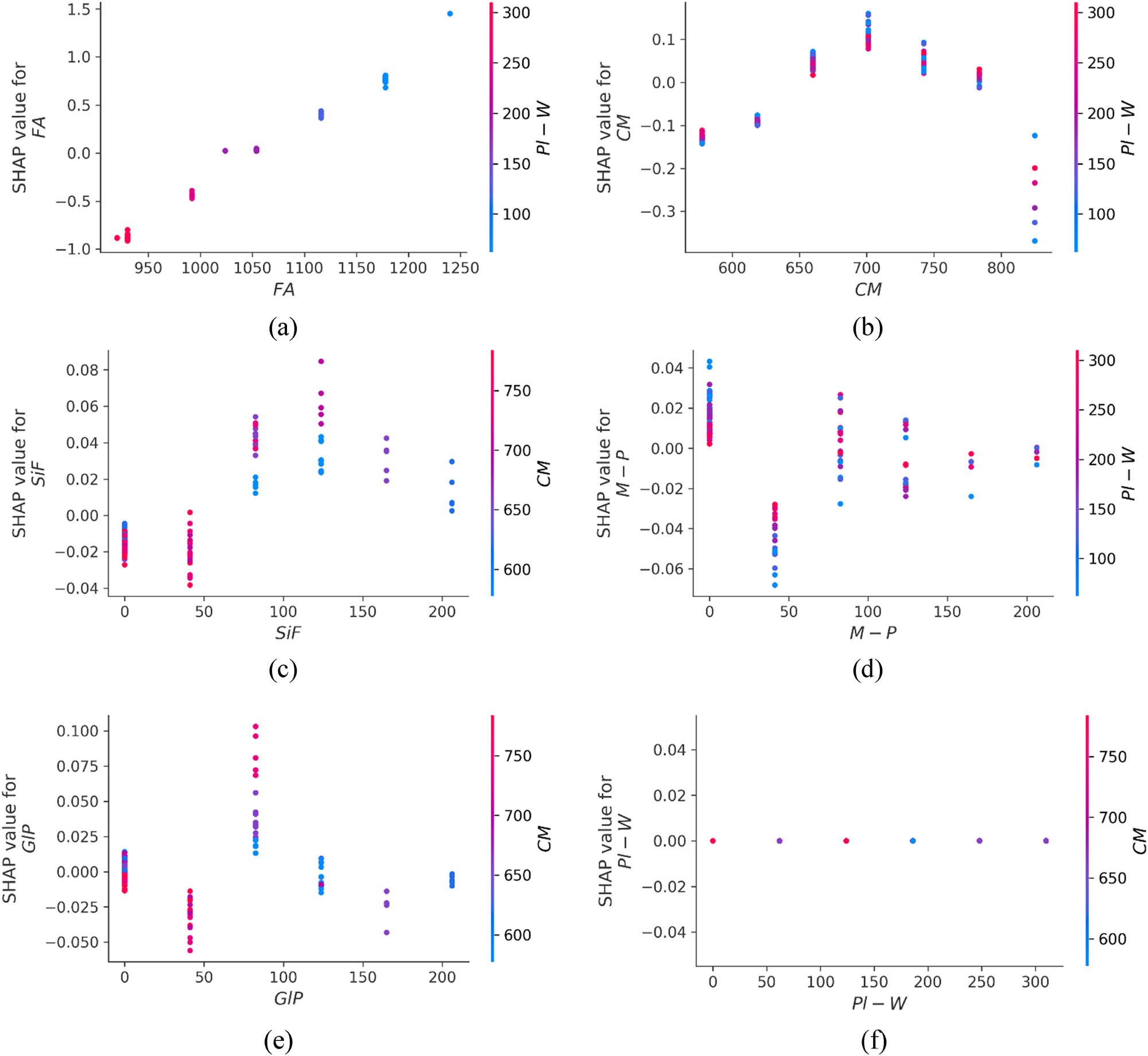

The effect of raw ingredients on PBM’s strength is graphically shown in Figure 15 (see Figure 15(a) for an illustration of FA’s effect and interaction). Increasing the FA concentration regularly improves the FS of PBMs, as shown in the graph. As shown in Figure 15(b) and (c), the strength of PBMs increases significantly when the CM content increases up to 700 and 120 kg·m−3, respectively. The power of PBMs drastically drops below these values. Figures 15(d) and (e) further show how M-P and GlP affect PBM’s FS. As the concentration of these variables increases up to 40 kg·m−3, the strength decreases somewhat at first, but then it increases steadily thereafter. As shown in Figure 15(f), the effect of the variable Pl-W on the FS of PBMs is small. This is because there is very little variation among these variables. In order for the SHAP statistical analysis to yield meaningful results, two key variables must be considered: the size of the data sample and the particular raw materials used. Modifying the input parameters or increasing or decreasing the sample size could produce different outcomes.

Interaction of PBMs FS input parameters: (a) FA; (b) CM; (c) SiF; (d) M-P; (e) GlP; and (f) Pl-W.

4 Discussions

The main binding component, ordinary Portland cement (OPC), is extremely harmful to the environment since it contributes to the loss of biodiversity and the increase in carbon emissions caused by humans [83,84]. Consequently, the OPC sector needs to provide more sustainable alternatives to OPC if it wants to cut down on carbon dioxide emissions. By incorporating plastic and other waste materials into mortar and concrete, there is a significant opportunity to enhance the material’s properties. This technology not only improves the performance of mortar and concrete, but also contributes to environmental cleanliness by strategically reusing materials. Researchers in this study used ML and SHAP techniques in an effort to help people better grasp the many uses of PBMs. This enhancement was its intended outcome. BGR, ADB, and RFR ML approaches were employed to estimate PBM’s FS. By comparing their accuracy levels, the best predictor can be identified among the strategies. Results from using the XGB approach were more accurate than those from using the BGR and ADB methods (R 2 = 0.98). The BGR and ADB methods had noticeably different R 2 values: 0.88 and 0.92, respectively. Inconsistency between expected and actual results (errors) is another evidence of the RFR method’s higher accuracy. The RFR models outperformed the BGR and ADB models in terms of the degree of agreement between the experimental and anticipated results, as shown by the error analysis. The RFR methodology has shown in previous research to be as accurate as other ML methods in estimating the strength of construction materials [69,85].

Mathematical and K-fold approaches were used to verify that ML procedures were accurate. Reduced values of R 2, R, NSE, RMSE, MAPE, and MAE indicate a more accurate model. The method’s sensitivity to inputs and data samples makes it difficult to determine the optimal machine-learning strategy for domain-agnostic attribute prediction [69]. By utilizing the dataset to train and refine sub-models with the less effective learner, ensemble ML techniques can sometimes surpass individual ML models. Based on these statistics, the RFR model is more accurate than the BGR and ADB models. Additionally, different raw materials’ effects on the FS of PBMs were investigated using the SHAP analysis. There is a positive correlation between the input parameters of the material (FA, CM, and Si-F) and the FS of PBMs. With an increase in the contents of the aforementioned variables, the FS of PBMs grows. However, for the input variables GlP and M-P, the SHAP analysis demonstrated that the FS of PBMs is balanced. SHAP analysis is widely used to interpret ML models by providing insights into the importance of different features. In the context of construction materials and PBM, SHAP helps identify the key factors influencing material properties such as strength, durability, and sustainability. This analysis aids in optimizing the composition of PBMs and understanding the interactions between various ingredients, ultimately leading to more efficient and sustainable material designs. Therefore, in theory, PBMs will produce superior building materials with the same strength-wise performance when used in place of OPC-based materials. Also, it will help with the environmental issues related to OPC production, namely waste and managing the diminishing raw materials used to make OPC.

ML models offer a wide range of applications in the construction industry, including enhancing energy efficiency, predicting material strength, ensuring quality control, assessing risks, and enabling predictive maintenance. Despite their potential, these models face challenges, such as dependence on human intervention, reliance on imperfect data, and the risk of inaccuracies in predictions. To address these limitations, future research could focus on improving ML solutions by leveraging advancements on the Internet of Things, developing hybrid modeling techniques, incorporating Explainable AI (XAI) methods, and integrating sustainability goals. Additionally, optimizing data collection and dissemination strategies to meet industry-specific demands could be key. By embracing these advancements, construction projects could experience shorter completion times, improved worker safety, and enhanced environmental health. The insights from this study could encourage the adoption of PBMs in construction, supporting more eco-friendly practices. Moreover, emerging fields like nanotechnology-infused geopolymer and 3D printing with geopolymer could be explored using ML, opening up new frontiers in sustainable building materials [86,87,88,89,90,91].

5 Conclusions

This work aims to analyze and forecast the FS of PBMs using ML approaches such as BGR, ADB, and RFR. The research used 408 sets of FS data from PBM’s laboratory investigations to train, test, and validate the model. The key findings are as follows:

The RFR method had a higher R 2 value of 0.98 when estimating the FS of PBMs compared to the BGR and ADB approaches, which had R 2 values of 0.88 and 0.92, respectively.

With respect to the BGR, ADB, and RFR approaches, the mean difference between the actual and anticipated FS (errors) was 0.068, 0.107, and 0.150 MPa, respectively. Although the RFR method demonstrated superior accuracy in predicting the intensity of PBMs, the error levels demonstrated that the BGR and ADB models were correct.

Statistical and K-fold tests validated the effectiveness of the created models. There is evidence that ML models are accurate, including improved R 2, fewer mistakes, and more efficiency. In terms of FS prediction, the RMSE for the BGR, ADB, and RFR models was 0.240, 0.174, and 0.92 MPa, respectively. The RMSE showed that the RFR model was superior at FS prediction for PBMs.

There was a positive correlation between the FS of the PBM and the three main raw materials and variables (FA, CM, and Si-F) identified in the SHAP study. Unlike Pl-W, which remained inactive throughout, M-P and GlP initially improved PBM’s FS but subsequently had the opposite effect as their concentration rose.

By means of sophisticated prediction frameworks, this research sheds light on the design of PBMs. In order to evaluate, optimize, and rationalize the amounts of PBMs in mixes, scientists and engineers use these methodologies. Greener building practices and lessening the environmental effect of conventional concrete production are both promoted by ML models that increase chemical combination efficiency.

Acknowledgments

This research has been funded by the Scientific Research Deanship at the University of Ha’il, Saudi Arabia, through project number RG-24 047.

-

Funding information: This research was funded by the Scientific Research Deanship at the University of Ha’il, Saudi Arabia, through project number RG-24 047.

-

Author contributions: A.A.A.-N.: conceptualization, funding acquisition, visualization, methodology, data acquisition, writing – original draft. S.A.K.: software, supervision, validation, formal analysis, writing – original draft, reviewing, and editing. N.A.: funding acquisition, validation, project administration, writing, reviewing, and editing. M.N.A.: funding acquisition, investigation, supervision, project administration, writing, reviewing, and editing. O.A.: validation, writing, reviewing, and editing. M.F.J.: methodology, formal analysis, writing, reviewing, and editing. E.R.L.: investigation, resources, writing, reviewing, and editing. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The data generated and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

[1] Kang, S., Y. Zhao, W. Wang, T. Zhang, T. Chen, H. Yi, et al. Removal of methylene blue from water with montmorillonite nanosheets/chitosan hydrogels as adsorbent. Applied Surface Science, Vol. 448, 2018, pp. 203–211.10.1016/j.apsusc.2018.04.037Search in Google Scholar

[2] Wang, W., Y. Zhao, H. Bai, T. Zhang, V. Ibarra-Galvan, and S. Song. Methylene blue removal from water using the hydrogel beads of poly (vinyl alcohol)-sodium alginate-chitosan-montmorillonite. Carbohydrate Polymers, Vol. 198, 2018, pp. 518–528.10.1016/j.carbpol.2018.06.124Search in Google Scholar PubMed

[3] Asif, U., M. F. Javed, D. M. Alsekait, D. S. AbdElminaam, and H. Alabduljabbar. Toward sustainability: Integrating experimental study and data-driven modeling for eco-friendly paver blocks containing plastic waste. Reviews on Advanced Materials Science, Vol. 63, 2024, id. 20240051.10.1515/rams-2024-0051Search in Google Scholar

[4] Alyousef, R., W. Ahmad, A. Ahmad, F. Aslam, P. Joyklad, and H. Alabduljabbar. Potential use of recycled plastic and rubber aggregate in cementitious materials for sustainable construction: A review. Journal of Cleaner Production, Vol. 329, 2021, id. 129736.10.1016/j.jclepro.2021.129736Search in Google Scholar

[5] Li, X., T.-C. Ling, and K. H. Mo. Functions and impacts of plastic/rubber wastes as eco-friendly aggregate in concrete–A review. Construction and Building Materials, Vol. 240, 2020, id. 117869.10.1016/j.conbuildmat.2019.117869Search in Google Scholar

[6] Li, X., D. Qin, Y. Hu, W. Ahmad, A. Ahmad, F. Aslam, et al. A systematic review of waste materials in cement-based composites for construction applications. Journal of Building Engineering, Vol. 45, 2022, id. 103447.10.1016/j.jobe.2021.103447Search in Google Scholar

[7] Asif, U., M. F. Javed, F. Aslam, and D. S. Abd Elminaam. Data-driven evolutionary programming for evaluating the mechanical properties of concrete containing plastic waste. Case Studies in Construction Materials, Vol. 21, 2024, id. e03763.10.1016/j.cscm.2024.e03763Search in Google Scholar

[8] Ismail, Z. Z. and E. A. Al-Hashmi. Use of waste plastic in concrete mixture as aggregate replacement. Waste Management, Vol. 28, 2008, pp. 2041–2047.10.1016/j.wasman.2007.08.023Search in Google Scholar PubMed

[9] Tafheem, Z., R. I. Rakib, M. D. Esharuhullah, S. M. R. Alam, and M. M. Islam. Experimental investigation on the properties of concrete containing post-consumer plastic waste as coarse aggregate replacement. Journal of Materials and Engineering Structures «JMES», Vol. 5, 2018, pp. 23–31.Search in Google Scholar

[10] Thorneycroft, J., J. Orr, P. Savoikar, and R. J. Ball. Performance of structural concrete with recycled plastic waste as a partial replacement for sand. Construction and Building Materials, Vol. 161, 2018, pp. 63–69.10.1016/j.conbuildmat.2017.11.127Search in Google Scholar

[11] Saxena, R., S. Siddique, T. Gupta, R. K. Sharma, and S. Chaudhary. Impact resistance and energy absorption capacity of concrete containing plastic waste. Construction and Building Materials, Vol. 176, 2018, pp. 415–421.10.1016/j.conbuildmat.2018.05.019Search in Google Scholar

[12] Asif, U., M. F. Javed, M. Alyami, and A. W. A. Hammad. Performance evaluation of concrete made with plastic waste using multi-expression programming. Materials Today Communications, Vol. 39, 2024, id. 108789.10.1016/j.mtcomm.2024.108789Search in Google Scholar

[13] Mehta, A. and D. K. Ashish. Silica fume and waste glass in cement concrete production: A review. Journal of Building Engineering, Vol. 29, 2020, id. 100888.10.1016/j.jobe.2019.100888Search in Google Scholar

[14] Khodabakhshian, A., M. Ghalehnovi, J. De Brito, and E. A. Shamsabadi. Durability performance of structural concrete containing silica fume and marble industry waste powder. Journal of Cleaner Production, Vol. 170, 2018, pp. 42–60.10.1016/j.jclepro.2017.09.116Search in Google Scholar

[15] Barham, W. S., B. Albiss, and O. Latayfeh. Influence of magnetic field treated water on the compressive strength and bond strength of concrete containing silica fume. Journal of Building Engineering, Vol. 33, 2021, id. 101544.10.1016/j.jobe.2020.101544Search in Google Scholar

[16] Ashish, D. K. Concrete made with waste marble powder and supplementary cementitious material for sustainable development. Journal of Cleaner Production, Vol. 211, 2019, pp. 716–729.10.1016/j.jclepro.2018.11.245Search in Google Scholar

[17] Khan, M. and C. McNally. A holistic review on the contribution of civil engineers for driving sustainable concrete construction in the built environment. Developments in the Built Environment, Vol. 16, 2023, id. 100273.10.1016/j.dibe.2023.100273Search in Google Scholar

[18] Shanmugasundaram, N. and S. Praveenkumar. Influence of supplementary cementitious materials, curing conditions and mixing ratios on fresh and mechanical properties of engineered cementitious composites–A review. Construction and Building Materials, Vol. 309, 2021, id. 125038.10.1016/j.conbuildmat.2021.125038Search in Google Scholar

[19] Gupta, S. and S. Chaudhary. State of the art review on supplementary cementitious materials in India–I: An overview of legal perspective, governing organizations, and development patterns. Journal of Cleaner Production, Vol. 261, 2020, id. 121203.10.1016/j.jclepro.2020.121203Search in Google Scholar

[20] Sandanayake, M., Y. Bouras, R. Haigh, and Z. Vrcelj. Current sustainable trends of using waste materials in concrete – a decade review. Sustainability, Vol. 12, 2020, id. 9622.10.3390/su12229622Search in Google Scholar

[21] Singh, G. V. P. B. and K. V. L. Subramaniam. Production and characterization of low-energy Portland composite cement from post-industrial waste. Journal of Cleaner Production, Vol. 239, 2019, id. 118024.10.1016/j.jclepro.2019.118024Search in Google Scholar

[22] Khan, M., A. Rehman, and M. Ali. Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Construction and Building Materials, Vol. 244, 2020, id. 118382.10.1016/j.conbuildmat.2020.118382Search in Google Scholar

[23] Khan, M., M. Cao, A. Hussain, and S. H. Chu. Effect of silica-fume content on performance of CaCO3 whisker and basalt fiber at matrix interface in cement-based composites. Construction and Building Materials, Vol. 300, 2021, id. 124046.10.1016/j.conbuildmat.2021.124046Search in Google Scholar

[24] Khan, K., W. Ahmad, M. N. Amin, A. Ahmad, S. Nazar, A. A. Alabdullah, et al. Exploring the use of waste marble powder in concrete and predicting its strength with different advanced algorithms. Materials, Vol. 15, 2022, id. 4108.10.3390/ma15124108Search in Google Scholar PubMed PubMed Central

[25] Li, G., C. Zhou, W. Ahmad, K. I. Usanova, M. Karelina, A. M. Mohamed, et al. Fly ash application as supplementary cementitious material: a review. Materials, Vol. 15, 2022, id. 2664.10.3390/ma15072664Search in Google Scholar PubMed PubMed Central

[26] Lou, Y., K. Khan, M. N. Amin, W. Ahmad, A. F. Deifalla, and A. Ahmad. Performance characteristics of cementitious composites modified with silica fume: A systematic review. Case Studies in Construction Materials, Vol. 18, 2023, id. e01753.10.1016/j.cscm.2022.e01753Search in Google Scholar

[27] Khan, K., W. Ahmad, M. N. Amin, M. I. Rafiq, A. M. A. Arab, I. A. Alabdullah, et al. Evaluating the effectiveness of waste glass powder for the compressive strength improvement of cement mortar using experimental and machine learning methods. Heliyon, Vol. 9, 2023, id. e16288.10.1016/j.heliyon.2023.e16288Search in Google Scholar PubMed PubMed Central

[28] Ashish, D. K. Feasibility of waste marble powder in concrete as partial substitution of cement and sand amalgam for sustainable growth. Journal of Building Engineering, Vol. 15, 2018, pp. 236–242.10.1016/j.jobe.2017.11.024Search in Google Scholar

[29] Siddique, R. Utilization of silica fume in concrete: Review of hardened properties. Resources, Conservation and Recycling, Vol. 55, 2011, pp. 923–932.10.1016/j.resconrec.2011.06.012Search in Google Scholar

[30] Sun, M., T. Bennett, and P. Visintin. Plastic and early-age shrinkage of ultra-high performance concrete (UHPC): Experimental study of the effect of water to binder ratios, silica fume dosages under controlled curing conditions. Case Studies in Construction Materials, Vol. 16, 2022, id. e00948.10.1016/j.cscm.2022.e00948Search in Google Scholar

[31] Nochaiya, T., T. Suriwong, and P. Julphunthong. Acidic corrosion-abrasion resistance of concrete containing fly ash and silica fume for use as concrete floors in pig farm. Case Studies in Construction Materials, Vol. 16, 2022, id. e01010.10.1016/j.cscm.2022.e01010Search in Google Scholar

[32] Mokhtari, S. and M. Madhkhan. The performance effect of PEG-silica fume as shape-stabilized phase change materials on mechanical and thermal properties of lightweight concrete panels. Case Studies in Construction Materials, Vol. 17, 2022, id. e01298.10.1016/j.cscm.2022.e01298Search in Google Scholar

[33] Sarıdemir, M. Effect of silica fume and ground pumice on compressive strength and modulus of elasticity of high strength concrete. Construction and Building Materials, Vol. 49, 2013, pp. 484–489.10.1016/j.conbuildmat.2013.08.091Search in Google Scholar

[34] Qin, D., Y. Hu, and X. Li. Waste glass utilization in cement-based materials for sustainable construction: a review. Crystals, Vol. 11, 2021, id. 710.10.3390/cryst11060710Search in Google Scholar

[35] Meena, A. and R. Singh. Comparative study of waste glass powder as pozzolanic material in concrete, Doctoral dissertation, 2012.Search in Google Scholar

[36] Mohajerani, A., J. Vajna, T. H. H. Cheung, H. Kurmus, A. Arulrajah, and S. Horpibulsuk. Practical recycling applications of crushed waste glass in construction materials: A review. Construction and Building Materials, Vol. 156, 2017, pp. 443–467.10.1016/j.conbuildmat.2017.09.005Search in Google Scholar

[37] Aliabdo, A. A., M. Abd Elmoaty, and A. Y. Aboshama. Utilization of waste glass powder in the production of cement and concrete. Construction and Building Materials, Vol. 124, 2016, pp. 866–877.10.1016/j.conbuildmat.2016.08.016Search in Google Scholar

[38] Prakash, B., T. J. Saravanan, K. I. S. A. Kabeer, and K. Bisht. Exploring the potential of waste marble powder as a sustainable substitute to cement in cement-based composites: A review. Construction and Building Materials, Vol. 401, 2023, id. 132887.10.1016/j.conbuildmat.2023.132887Search in Google Scholar

[39] Yuan, X., Y. Tian, W. Ahmad, A. Ahmad, K. I. Usanova, A. M. Mohamed, et al. Machine learning prediction models to evaluate the strength of recycled aggregate concrete. Materials, Vol. 15, 2022, id. 2823.10.3390/ma15082823Search in Google Scholar PubMed PubMed Central

[40] Singh, N., P. Kumar, and P. Goyal. Reviewing the behaviour of high volume fly ash based self compacting concrete. Journal of Building Engineering, Vol. 26, 2019, id. 100882.10.1016/j.jobe.2019.100882Search in Google Scholar

[41] Althoey, F. Compressive strength reduction of cement pastes exposed to sodium chloride solutions: Secondary ettringite formation. Construction and Building Materials, Vol. 299, 2021, id. 123965.10.1016/j.conbuildmat.2021.123965Search in Google Scholar

[42] Awoyera, P. O. Nonlinear finite element analysis of steel fibre-reinforced concrete beam under static loading. Journal of Engineering Science and Technology, Vol. 11, 2016, pp. 1669–1677.Search in Google Scholar

[43] Amin, M. N., W. Ahmad, K. Khan, M. N. Al-Hashem, A. F. Deifalla, and A. Ahmad. Testing and modeling methods to experiment the flexural performance of cement mortar modified with eggshell powder. Case Studies in Construction Materials, Vol. 18, 2023, id. e01759.10.1016/j.cscm.2022.e01759Search in Google Scholar

[44] Javed, M. F., M. N. Amin, M. I. Shah, K. Khan, B. Iftikhar, F. Farooq, et al. Applications of gene expression programming and regression techniques for estimating compressive strength of bagasse ash based concrete. Crystals, Vol. 10, 2020, id. 737.10.3390/cryst10090737Search in Google Scholar

[45] Marani, A., A. Jamali, and M. L. Nehdi. Predicting ultra-high-performance concrete compressive strength using tabular generative adversarial networks. Materials, Vol. 13, 2020, id. 4757.10.3390/ma13214757Search in Google Scholar PubMed PubMed Central

[46] Marani, A. and M. L. Nehdi. Machine learning prediction of compressive strength for phase change materials integrated cementitious composites. Construction and Building Materials, Vol. 265, 2020, id. 120286.10.1016/j.conbuildmat.2020.120286Search in Google Scholar

[47] Nunez, I., A. Marani, and M. L. Nehdi. Mixture optimization of recycled aggregate concrete using hybrid machine learning model. Materials, Vol. 13, 2020, id. 4331.10.3390/ma13194331Search in Google Scholar PubMed PubMed Central

[48] Zhang, J., Y. Huang, F. Aslani, G. Ma, and B. Nener. A hybrid intelligent system for designing optimal proportions of recycled aggregate concrete. Journal of Cleaner Production, Vol. 273, 2020, id. 122922.10.1016/j.jclepro.2020.122922Search in Google Scholar

[49] Zhang, J., D. Li, and Y. Wang. Toward intelligent construction: Prediction of mechanical properties of manufactured-sand concrete using tree-based models. Journal of Cleaner Production, Vol. 258, 2020, id. 120665.10.1016/j.jclepro.2020.120665Search in Google Scholar

[50] Rajasekar, A., K. Arunachalam, and M. Kottaisamy. Assessment of strength and durability characteristics of copper slag incorporated ultra high strength concrete. Journal of Cleaner Production, Vol. 208, 2019, pp. 402–414.10.1016/j.jclepro.2018.10.118Search in Google Scholar

[51] Naseri, H., H. Jahanbakhsh, P. Hosseini, and F. M. Nejad. Designing sustainable concrete mixture by developing a new machine learning technique. Journal of Cleaner Production, Vol. 258, 2020, id. 120578.10.1016/j.jclepro.2020.120578Search in Google Scholar

[52] Young, B. A., A. Hall, L. Pilon, P. Gupta, and G. Sant. Can the compressive strength of concrete be estimated from knowledge of the mixture proportions?: New insights from statistical analysis and machine learning methods. Cement and Concrete Research, Vol. 115, 2019, pp. 379–388.10.1016/j.cemconres.2018.09.006Search in Google Scholar

[53] Li, Y., G. Wang, M. N. Amin, A. Khan, M. T. Qadir, and S. U. Arifeen. Towards improved flexural behavior of plastic-based mortars: An experimental and modeling study on waste material incorporation. Materials Today Communications, Vol. 40, 2024, id. 109391.10.1016/j.mtcomm.2024.109391Search in Google Scholar

[54] Frank, I. E. and R. Todeschini. The data analysis handbook, Elsevier, The Netherlands, 1994.Search in Google Scholar

[55] Alabduljabbar, H., F. Farooq, M. Alyami, and A. W. A. Hammad. Assessment of the split tensile strength of fiber reinforced recycled aggregate concrete using interpretable approaches with graphical user interface. Materials Today Communications, Vol. 38, 2024, id. 108009.10.1016/j.mtcomm.2023.108009Search in Google Scholar

[56] Wang, X., L. Li, Y. Xiang, Y. Wu, and M. Wei. The influence of basalt fiber on the mechanical performance of concrete-filled steel tube short columns under axial compression. Frontiers in Materials, Vol. 10, 2024, id. 1332269.10.3389/fmats.2023.1332269Search in Google Scholar

[57] Huang, H., M. Guo, W. Zhang, and M. Huang. Seismic behavior of strengthened RC columns under combined loadings. Journal of Bridge Engineering, Vol. 27, 2022, id. 05022005.10.1061/(ASCE)BE.1943-5592.0001871Search in Google Scholar

[58] Nagaraju, T. V., S. Mantena, M. Azab, S. S. Alisha, C. El Hachem, M. Adamu, et al. Prediction of high strength ternary blended concrete containing different silica proportions using machine learning approaches. Results in Engineering, Vol. 17, 2023, id. 100973.10.1016/j.rineng.2023.100973Search in Google Scholar

[59] Alyami, M., M. Khan, M. Fawad, R. Nawaz, A. W. A. Hammad, T. Najeh, et al. Predictive modeling for compressive strength of 3D printed fiber-reinforced concrete using machine learning algorithms. Case Studies in Construction Materials, Vol. 20, 2024, id. e02728.10.1016/j.cscm.2023.e02728Search in Google Scholar

[60] Rauf, A., A. Tussupbekova, and S.-W. Moon. Effect of drying-wetting cycles on the mechanical behavior of cement-treated soil. 대한토목학회 학술대회, 2023, pp. 259–260.Search in Google Scholar

[61] Lee, B. C. and D. M. Brooks. Accurate and efficient regression modeling for microarchitectural performance and power prediction. ACM SIGOPS Operating Systems Review, Vol. 40, 2006, pp. 185–194.10.1145/1168917.1168881Search in Google Scholar

[62] Huang, J., Y. Sun, and J. Zhang. Reduction of computational error by optimizing SVR kernel coefficients to simulate concrete compressive strength through the use of a human learning optimization algorithm. Engineering with Computers, 2021, pp. 1–18.10.1007/s00366-021-01305-xSearch in Google Scholar

[63] Ribeiro, M. H. D. M. and L. dos Santos Coelho. Ensemble approach based on bagging, boosting and stacking for short-term prediction in agribusiness time series. Applied Soft Computing, Vol. 86, 2020, id. 105837.10.1016/j.asoc.2019.105837Search in Google Scholar

[64] Han, Q., C. Gui, J. Xu, and G. Lacidogna. A generalized method to predict the compressive strength of high-performance concrete by improved random forest algorithm. Construction and Building Materials, Vol. 226, 2019, pp. 734–742.10.1016/j.conbuildmat.2019.07.315Search in Google Scholar

[65] Grömping, U. Variable importance assessment in regression: linear regression versus random forest. The American Statistician, Vol. 63, 2009, pp. 308–319.10.1198/tast.2009.08199Search in Google Scholar

[66] Sheridan, R. P. Using random forest to model the domain applicability of another random forest model. Journal of Chemical Information and Modeling, Vol. 53, 2013, pp. 2837–2850.10.1021/ci400482eSearch in Google Scholar PubMed

[67] Lundberg, S. M. and S.-I. Lee. A unified approach to interpreting model predictions. Advances in Neural Information Processing Systems, Vol. 30, 2017, pp. 4765–4774.Search in Google Scholar

[68] Lundberg, S. M., G. G. Erion, and S.-I. Lee. Consistent individualized feature attribution for tree ensembles, Cornell University, New York, United States, arXiv preprint arXiv:1802.03888, 2018.Search in Google Scholar

[69] Farooq, F., W. Ahmed, A. Akbar, F. Aslam, and R. Alyousef. Predictive modeling for sustainable high-performance concrete from industrial wastes: A comparison and optimization of models using ensemble learners. Journal of Cleaner Production, Vol. 292, 2021, id. 126032.10.1016/j.jclepro.2021.126032Search in Google Scholar

[70] Asif, U., M. F. Javed, M. Abuhussain, M. Ali, W. A. Khan, and A. Mohamed. Predicting the mechanical properties of plastic concrete: An optimization method by using genetic programming and ensemble learners. Case Studies in Construction Materials, Vol. 20, 2024, id. e03135.10.1016/j.cscm.2024.e03135Search in Google Scholar

[71] Ahmad, A., K. Chaiyasarn, F. Farooq, W. Ahmad, S. Suparp, and F. Aslam. Compressive strength prediction via gene expression programming (GEP) and artificial neural network (ANN) for concrete containing RCA. Buildings, Vol. 11, 2021, id. 324.10.3390/buildings11080324Search in Google Scholar

[72] Alade, I. O., A. Bagudu, T. A. Oyehan, M. A. Abd Rahman, T. A. Saleh, and S. O. Olatunji. Estimating the refractive index of oxygenated and deoxygenated hemoglobin using genetic algorithm–support vector regression model. Computer Methods and Programs in Biomedicine, Vol. 163, 2018, pp. 135–142.10.1016/j.cmpb.2018.05.029Search in Google Scholar PubMed

[73] Zhang, W., R. Zhang, C. Wu, A. T. C. Goh, S. Lacasse, Z. Liu, et al. State-of-the-art review of soft computing applications in underground excavations. Geoscience Frontiers, Vol. 11, 2020, pp. 1095–1106.10.1016/j.gsf.2019.12.003Search in Google Scholar

[74] Alavi, A. H., A. H. Gandomi, H. C. Nejad, A. Mollahasani, and A. Rashed. Design equations for prediction of pressuremeter soil deformation moduli utilizing expression programming systems. Neural Computing and Applications, Vol. 23, 2013, pp. 1771–1786.10.1007/s00521-012-1144-6Search in Google Scholar

[75] Kisi, O., J. Shiri, and M. Tombul. Modeling rainfall-runoff process using soft computing techniques. Computers & Geosciences, Vol. 51, 2013, pp. 108–117.10.1016/j.cageo.2012.07.001Search in Google Scholar

[76] Alade, I. O., M. A. Abd Rahman, and T. A. Saleh. Modeling and prediction of the specific heat capacity of Al2 O3/water nanofluids using hybrid genetic algorithm/support vector regression model. Nano-Structures & Nano-Objects, Vol. 17, 2019, pp. 103–111.10.1016/j.nanoso.2018.12.001Search in Google Scholar

[77] Shahin, M. A. Use of evolutionary computing for modelling some complex problems in geotechnical engineering. Geomechanics and Geoengineering, Vol. 10, 2015, pp. 109–125.10.1080/17486025.2014.921333Search in Google Scholar

[78] Band, S. S., E. Heggy, S. M. Bateni, H. Karami, M. Rabiee, S. Samadianfard, et al. Groundwater level prediction in arid areas using wavelet analysis and Gaussian process regression. Engineering Applications of Computational Fluid Mechanics, Vol. 15, 2021, pp. 1147–1158.10.1080/19942060.2021.1944913Search in Google Scholar

[79] Taylor, K. E. Summarizing multiple aspects of model performance in a single diagram. Journal of Geophysical Research: Atmospheres, Vol. 106, 2001, pp. 7183–7192.10.1029/2000JD900719Search in Google Scholar

[80] Mehta, V. Machine learning approach for predicting concrete compressive, splitting tensile, and flexural strength with waste foundry sand. Journal of Building Engineering, Vol. 70, 2023, id. 106363.10.1016/j.jobe.2023.106363Search in Google Scholar

[81] Liang, R., Q. Liu, D. Hou, Z. Li, and G. Sun. Flexural strength enhancement of cement paste through monomer incorporation and in situ bond formation. Cement and Concrete Research, Vol. 152, 2022, id. 106675.10.1016/j.cemconres.2021.106675Search in Google Scholar

[82] Wu, F., X. You, M. Wang, T. Liu, B. Lu, G. Hou, et al. Increasing flexural strength of CO2 cured cement paste by CaCO3 polymorph control. Cement and Concrete Composites, Vol. 141, 2023, id. 105128.10.1016/j.cemconcomp.2023.105128Search in Google Scholar

[83] Naqi, A. and J. G. Jang. Recent progress in green cement technology utilizing low-carbon emission fuels and raw materials: A review. Sustainability, Vol. 11, 2019, id. 537.10.3390/su11020537Search in Google Scholar

[84] Valente, M., M. Sambucci, M. Chougan, and S. H. Ghaffar. Reducing the emission of climate-altering substances in cementitious materials: A comparison between alkali-activated materials and Portland cement-based composites incorporating recycled tire rubber. Journal of Cleaner Production, Vol. 333, 2022, id. 130013.10.1016/j.jclepro.2021.130013Search in Google Scholar

[85] Khan, K., W. Ahmad, M. N. Amin, A. Ahmad, S. Nazar, and M. A. Al-Faiad. Assessment of artificial intelligence strategies to estimate the strength of geopolymer composites and influence of input parameters. Polymers, Vol. 14, 2022, id. 2509.10.3390/polym14122509Search in Google Scholar PubMed PubMed Central

[86] Shilar, F. A., S. V. Ganachari, V. B. Patil, T. M. Y. Khan, N. M. Almakayeel, and S. Alghamdi. Review on the relationship between nano modifications of geopolymer concrete and their structural characteristics. Polymers, Vol. 14, 2022, id. 1421.10.3390/polym14071421Search in Google Scholar PubMed PubMed Central

[87] Shilar, F. A., S. V. Ganachari, and V. B. Patil. Advancement of nano-based construction materials-A review. Construction and Building Materials, Vol. 359, 2022, id. 129535.10.1016/j.conbuildmat.2022.129535Search in Google Scholar

[88] Shilar, F. A., S. V. Ganachari, V. B. Patil, B. E. Bhojaraja, T. M. Y. Khan, and N. Almakayeel. A review of 3D printing of geopolymer composites for structural and functional applications. Construction and Building Materials, Vol. 400, 2023, id. 132869.10.1016/j.conbuildmat.2023.132869Search in Google Scholar

[89] Chen, Y., K. Xia, Z. Jia, Y. Gao, Z. Zhang, and Y. Zhang. Extending applicability of 3D-printable geopolymer to large-scale printing scenario via combination of sodium carbonate and nano-silica. Cement and Concrete Composites, Vol. 145, 2024, id. 105322.10.1016/j.cemconcomp.2023.105322Search in Google Scholar

[90] Saadati, F. and E. N. Kani. Phosphorous slag-based geopolymer cement incorporate with mullite for 3D printing application. Construction and Building Materials, Vol. 406, 2023, id. 133444.10.1016/j.conbuildmat.2023.133444Search in Google Scholar

[91] Yao, X., X. Lyu, J. Sun, B. Wang, Y. Wang, M. Yang, et al. AI-based performance prediction for 3D-printed concrete considering anisotropy and steam curing condition. Construction and Building Materials, Vol. 375, 2023, id. 130898.10.1016/j.conbuildmat.2023.130898Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Nanotechnology for calcium aluminate cement: thematic analysis

- Towards sustainable concrete pavements: a critical review on fly ash as a supplementary cementitious material

- Optimizing rice husk ash for ultra-high-performance concrete: a comprehensive review of mechanical properties, durability, and environmental benefits

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters

- Fe-containing nominal wollastonite (CaSiO3)–Na2O glass-ceramic: Characterization and biocompatibility

- Relevance of pore network connectivity in tannin-derived carbons for rapid detection of BTEX traces in indoor air

- A life cycle and environmental impact analysis of sustainable concrete incorporating date palm ash and eggshell powder as supplementary cementitious materials

- Eco-friendly utilisation of agricultural waste: Assessing mixture performance and physical properties of asphalt modified with peanut husk ash using response surface methodology

- Benefits and limitations of N2 addition with Ar as shielding gas on microstructure change and their effect on hardness and corrosion resistance of duplex stainless steel weldments

- Effect of selective laser sintering processing parameters on the mechanical properties of peanut shell powder/polyether sulfone composite

- Impact and mechanism of improving the UV aging resistance performance of modified asphalt binder

- AI-based prediction for the strength, cost, and sustainability of eggshell and date palm ash-blended concrete

- Investigating the sulfonated ZnO–PVA membrane for improved MFC performance

- Strontium coupling with sulphur in mouse bone apatites

- Transforming waste into value: Advancing sustainable construction materials with treated plastic waste and foundry sand in lightweight foamed concrete for a greener future

- Evaluating the use of recycled sawdust in porous foam mortar for improved performance

- Improvement and predictive modeling of the mechanical performance of waste fire clay blended concrete

- Polyvinyl alcohol/alginate/gelatin hydrogel-based CaSiO3 designed for accelerating wound healing

- Research on assembly stress and deformation of thin-walled composite material power cabin fairings

- Effect of volcanic pumice powder on the properties of fiber-reinforced cement mortars in aggressive environments

- Analyzing the compressive performance of lightweight foamcrete and parameter interdependencies using machine intelligence strategies

- Selected materials techniques for evaluation of attributes of sourdough bread with Kombucha SCOBY

- Establishing strength prediction models for low-carbon rubberized cementitious mortar using advanced AI tools

- Investigating the strength performance of 3D printed fiber-reinforced concrete using applicable predictive models

- An eco-friendly synthesis of ZnO nanoparticles with jamun seed extract and their multi-applications

- The application of convolutional neural networks, LF-NMR, and texture for microparticle analysis in assessing the quality of fruit powders: Case study – blackcurrant powders

- Study of feasibility of using copper mining tailings in mortar production

- Shear and flexural performance of reinforced concrete beams with recycled concrete aggregates

- Advancing GGBS geopolymer concrete with nano-alumina: A study on strength and durability in aggressive environments

- Leveraging waste-based additives and machine learning for sustainable mortar development in construction

- Study on the modification effects and mechanisms of organic–inorganic composite anti-aging agents on asphalt across multiple scales

- Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs

- Structural, physical, and luminescence properties of sodium–aluminum–zinc borophosphate glass embedded with Nd3+ ions for optical applications

- Eco-friendly waste plastic-based mortar incorporating industrial waste powders: Interpretable models for flexural strength

- Bioactive potential of marine Aspergillus niger AMG31: Metabolite profiling and green synthesis of copper/zinc oxide nanocomposites – An insight into biomedical applications

- Preparation of geopolymer cementitious materials by combining industrial waste and municipal dewatering sludge: Stabilization, microscopic analysis and water seepage

- Seismic behavior and shear capacity calculation of a new type of self-centering steel-concrete composite joint

- Sustainable utilization of aluminum waste in geopolymer concrete: Influence of alkaline activation on microstructure and mechanical properties

- Optimization of oil palm boiler ash waste and zinc oxide as antibacterial fabric coating

- Tailoring ZX30 alloy’s microstructural evolution, electrochemical and mechanical behavior via ECAP processing parameters

- Comparative study on the effect of natural and synthetic fibers on the production of sustainable concrete

- Microemulsion synthesis of zinc-containing mesoporous bioactive silicate glass nanoparticles: In vitro bioactivity and drug release studies

- On the interaction of shear bands with nanoparticles in ZrCu-based metallic glass: In situ TEM investigation

- Developing low carbon molybdenum tailing self-consolidating concrete: Workability, shrinkage, strength, and pore structure

- Experimental and computational analyses of eco-friendly concrete using recycled crushed brick