Abstract

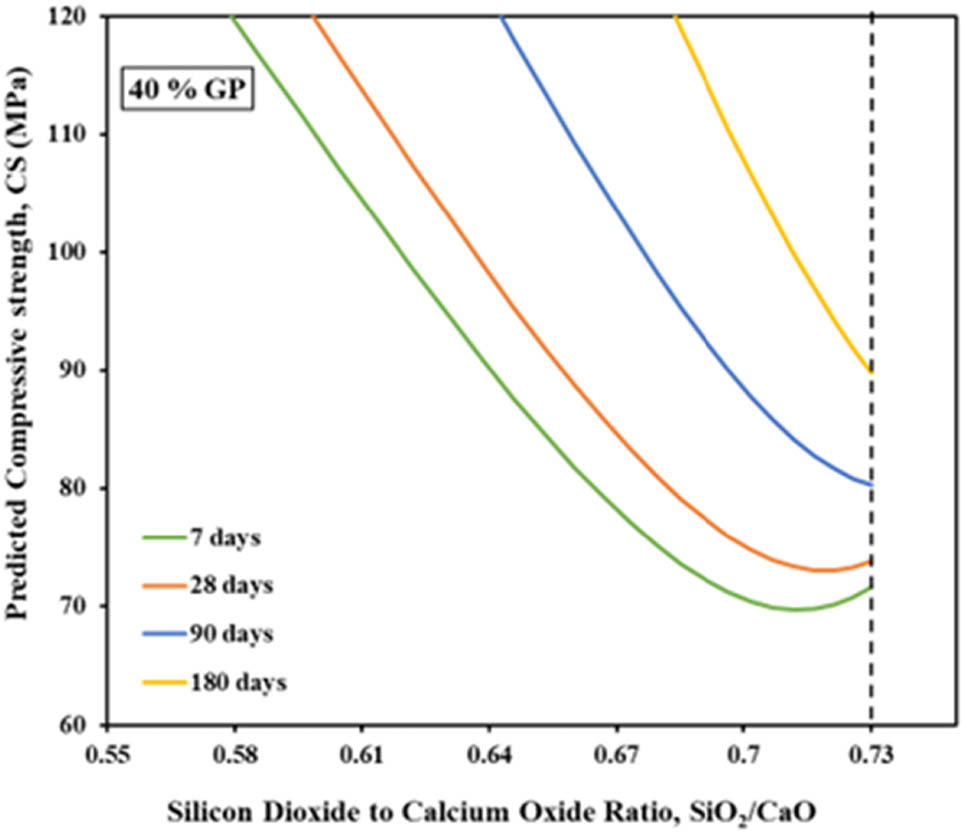

The cement industry contributes significantly to greenhouse gas emissions, accounting for an estimated 5–8% of global carbon output. Waste material substitution has been employed to mitigate this impact, aiming to reduce carbon footprint, preserve resources, and minimize landfill use. This study explores using waste glass powder in concrete, focusing on its effects on compressive strength. The analysis considers variables such as water-to-binder ratio (0.25–0.57), cement (189–494 kg·m−3), aggregates, glass powder content (0–50%), and curing duration (7–300 days). Chemical composition variables include silicon dioxide (SiO₂) and calcium oxide (CaO) content in cement and glass powder. Four predictive models were evaluated: linear (LR), nonlinear (NLR), pure quadratic, and interaction (INT). Model accuracy was assessed using R 2, root mean squared error (RMSE), mean absolute error, and scatter index, with the INT model showing the best performance (RMSE = 5.27 MPa). This study found that increasing the SiO₂/CaO ratio from 0.63 to 0.73, with higher glass powder replacement levels, decreased predicted compressive strength. Beyond certain replacement levels, compressive strength increased, except at 40–50% replacement. Sensitivity analysis indicated that curing time significantly affected the compressive strength, while the water-to-binder ratio had minimal influence. The study highlights the potential of optimizing waste glass powder usage to enhance concrete sustainability.

1 Introduction

The utilization of waste materials in buildings and the construction industry has grown considerably in the past few years due to the absence of adverse impacts on the qualities of concrete, providing a practical mechanism for the permanent disposal of waste materials within concrete structures [1]. Waste glass disposal is currently a severe environmental concern due to the rising need for land space and natural environmental resources, in addition to focusing on minimizing the greenhouse gas emissions of structural construction industries [2,3]. Manufacturing Portland cement is energy-intensive, producing approximately 5–8% of the global CO2 emissions. On average, generating one metric ton of cement clinker emits around 0.9–1.0 tons of CO2, depending on the fuel source. Substituting glass waste powder for cement offers an opportunity to minimize carbon footprints while preserving energy. The decision is essential for promoting the creation of sustainable concrete [4]. Supplementary cementitious materials (SCMs) supply an exceptional potential for minimizing the environmental effect of concrete production. Materials such as silica fume, ground granulated blast furnace slag, and fly ash have been employed as SCMs, improving the strength and characteristics of fresh and cured concrete while reducing cost. In spite of its potential as an SCM, waste glass is unable to achieve economic viability [5]. According to previous studies, glass has a chemical composition and condition identical to commonly utilized additional cementitious materials. It characterizes the pozzolanic reaction of waste glass powder extremely depending on the particle size distribution [6,7]. However, cement replacement by glass powder lowers strength at early ages and has a contrast effect at a later age [8,9]. Based on the fact that the chemical composition of waste glass and the high amount of silica in an amorphous state can create a pozzolanic reaction to produce the hydration product calcium silicate hydrate gel (C-S-H), it is obvious that pozzolanic reactivity depends on the fineness of the glass powder particles and the percentage of replacement by cement. According to previous studies [10,11], particles with 300 μm size of glass powder revealed minimal alkali–silica reaction. Another observation by Schwarz and Neithalath [12] illustrated that the pozzolanic reactivity of a glass powder is higher in 90 days compared to fly ash for particles smaller than 100 μm at low proportion replacement. In addition, Rahman and Uddin [13] indicated that using glass powder ground to obtain a particle size of less than 75 μm for curing age up to 28 days could improve the performance of mechanical properties for percentage replacement up to 30%. Furthermore, glass powder utilization as a cement replacement in different ranges up until 20% for particles passing through sieve No. 100 (150 μm), cured for 7, 28, 60, and 90 days, shows increasing compressive strength until 15% due to a filler effect, and waste glass particles tend to fill the porous increase packing density [4]. Olutoge [14] concluded glass powder as a cement replacement up to 30%, as the replacement proportion increases, resulting in a lowering in workability; the optimum replacement level for enhancing mechanical properties is 10% of particle size less than 300 μm. The mechanical properties of concrete can be evaluated by crushing concrete specimens with standard sizes of cube and cylinder [15]. Employing laboratory testing devices is costly and time-consuming. However, the development of theoretical learning models revolutionized concrete science through their capacity to evaluate and predict desirable properties. This progress promotes the creation of new materials and designs. As data availability expands and modeling techniques develop, functioning experimental and computational approaches will continue to improve, speeding up scientific breakthroughs well into the twenty-first century and beyond [16]; soft computing approaches are highly effective at resolving civil engineering complexities. These methods utilize flexible algorithms, achieving exceptional reliability [17]. This study is organized to systematically explore the role of waste glass powder in concrete production and its implications for sustainability and mechanical performance. The introduction establishes the motivation for reducing the environmental impact of cement through waste material substitution. It provides a comprehensive literature review on the pozzolanic potential of glass powder and its effects on concrete properties, emphasizing particle size and replacement levels. Section 2 details the dataset, variables, and predictive models, including their statistical evaluation metrics. Section 3 analyzes the impact of silicon dioxide and calcium oxide in glass powder on compressive and tensile strength, addressing low, normal, and high-strength concrete categories. The study concludes with key findings on optimal replacement levels, curing durations, and predictive model performance, offering actionable insights for sustainable concrete practices. This work examines the application of machine learning algorithms to forecast the shear strength and compressive strength of concrete beams and cement-based mortars, emphasizing the role of externally bonded fiber-reinforced polymer composites. The study employs a constrained monotonic neural network model trained on a dataset of 273 beam tests. It exhibits enhanced precision in forecasting shear strength, with an R 2 value of 0.9 and a minimal mean absolute error (MAE). Furthermore, several machine learning methodologies, including support vector machines, random forests, and decision trees, are examined to forecast compressive strength in mortars. AdaBoost and random forest are identified as the most dependable models. The research emphasizes the creation of six hybrid ensemble models for forecasting the deflection of reinforced concrete beams, with the SVM-ANFIS model demonstrating the most incredible accuracy. Finally, the study demonstrates the use of extreme learning machine models for forecasting the compressibility of clay in soil enhancement, surpassing regression and neural network models in predictive accuracy. These machine-learning techniques signify substantial progress in structural design and optimization [18,19,20,21,22]. The intent of this study was a prediction of compression of concrete modified with glass powder using computational models and statistical methods to indicate the influence of the chemical composition of waste glass powder, specifically silicon dioxide (SiO2) and calcium dioxide (CaO), on the mechanical properties of concrete. These properties included compressive strength and splitting tensile strength, which were tested in various replacement proportions and curing periods up to 300 days. Data (321 data sets) collected from different research studies, cement substitution by glass powder ranged from 5 to 50%, with SiO2 and CaO contents ranging from 59.7 to 74.03% and 8.04 to 18.2%. In comparison, the SiO2 level in cement ranged from 19.58 to 21.57%, and the percentage amount of CaO% is from 61.9 to 65.5%. The compressive strength values varied from 18 to 86 MPa and were divided into three categories. The first group includes values less than 28 MPa, classified as low-strength concrete (LSC). The second range, with values ranging from 28 to 55 MPa, was defined as normal strength concrete (NSC), and compression values beyond 55 MPa were categorized as high strength concrete (HSC). The dataset is separated into training data 215 and 53, and testing and validating the dataset examines and assesses the integrity and dependability of the calculated model obtained from the training dataset. Progressed models on training data utilized linear regression (LR) [23], nonlinear regression (NLR) [24], interaction (INT), and pure quadratic (PQ). Moreover, statistical parameters were evaluated to assess the accuracy and reliability of the estimated models, such as root mean squared error (RMSE), correlation coefficient (R 2), MAE, scatter index (SI), and objective (OBJ). The four models (LR, NLR, INT, and PQ) differentiated their performance to predict the compressive strength of the concrete with glass powder incorporation by comparing the obtained statistical parameters.

1.1 Objectives

Investigate the effect of SiO2 and CaO content in the glass powder replacement on the compressive strength predicted for different ranges.

Quantify parameters for the correlation model to predict the splitting tensile strength from observed compressive strength values.

Identify the optimum ratios of SiO2 and CaO for incorporation of different glass powder replacement percentages in concrete.

Four models were utilized to estimate the compressive strength of concrete modified with glass powder in various replacement percentages. Model evaluation criteria were used to indicate the finest model performance.

2 Methodology

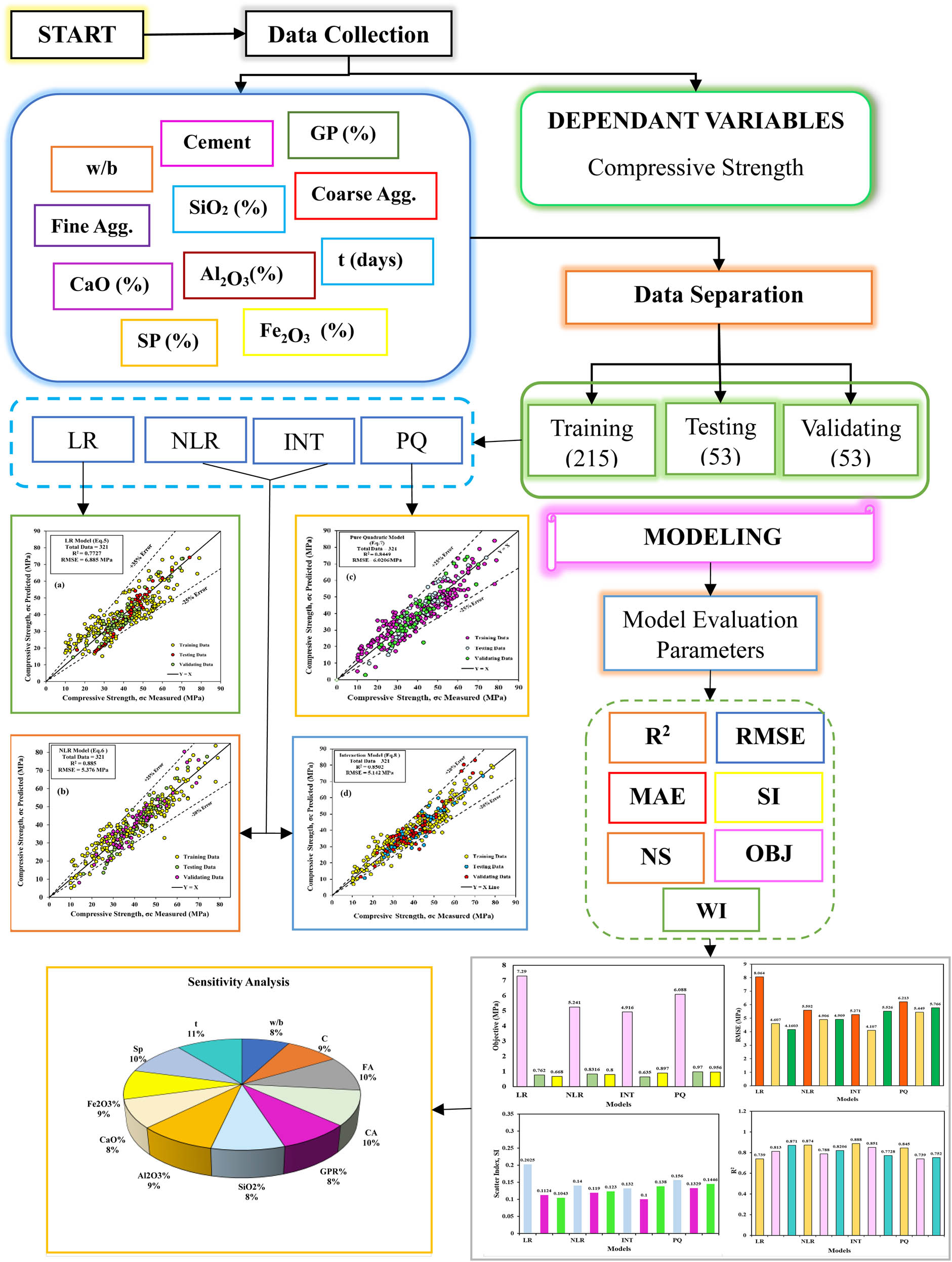

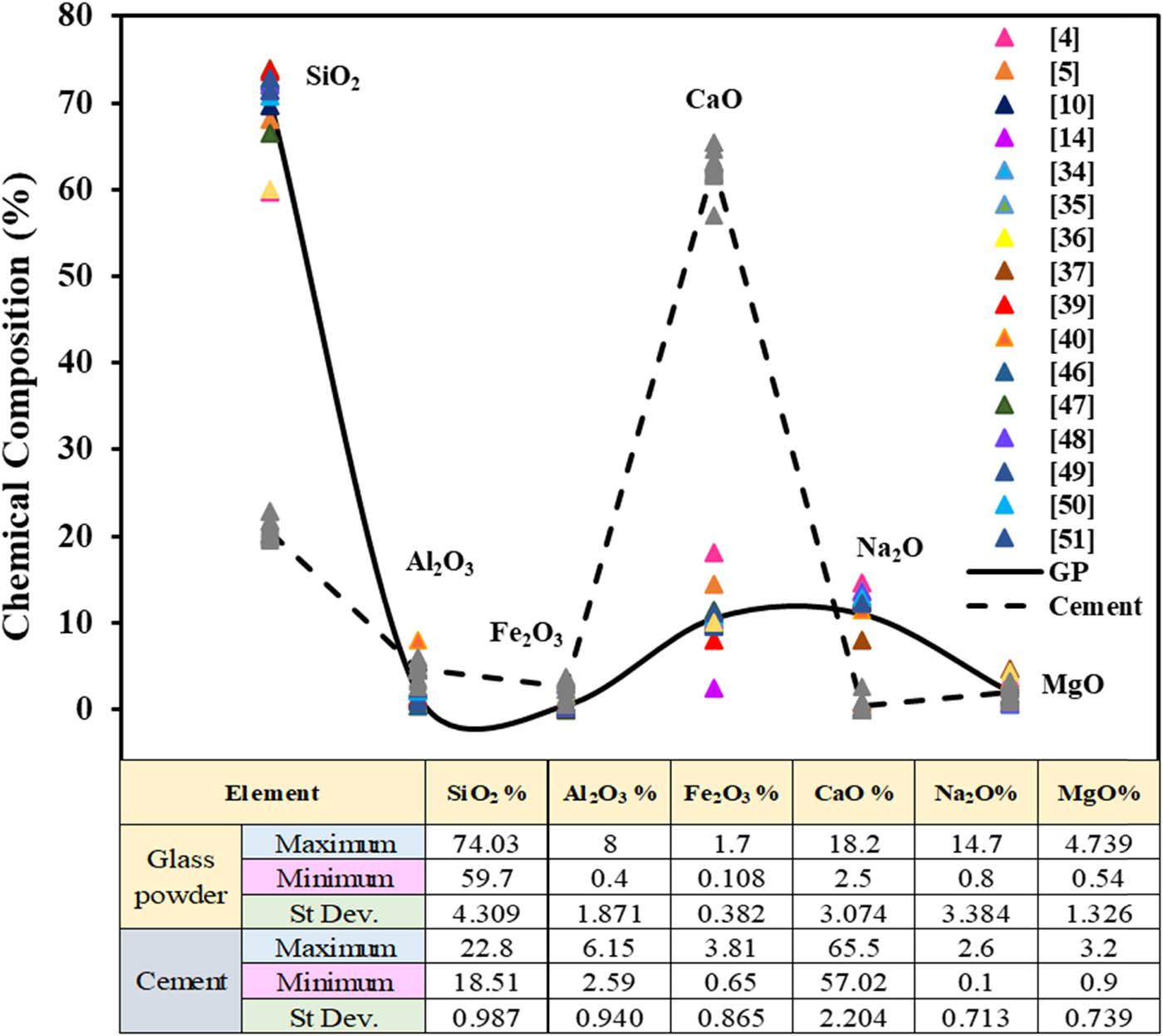

The approach utilized in this study is demonstrated in Figure 1. From the earlier research, data were collected and are as shown in Table 1. An overview of the collected 321 dataset includes conventional concrete and concrete incorporated glass powder as cement partial replacement. Data were separated into three sections: training, testing, and validating randomly distributed previously utilized RAND functions. The training data was selected as 70% of totaling 215 samples from the collected dataset of 321. The remaining 30% (53 samples each) was allocated for both testing and validation. Therefore, testing and validating were established to assess and evaluate model accuracy. The independent variables for the data collected include the water-to-cement ratio, fine and coarse aggregate (CA), percentage of glass powder replacement as a partial replacement of cement, the chemical composition of glass powder and cement, including SiO2 and CaO proportions (Figure 2), superplasticizer (SP) and curing time, according to the steps demonstrated in the flow chart to evaluate the predicted compressive strength utilizing four different models (LR, NLR, INT, and PQ).

Flow chart diagram of key steps perfomed in this study.

Summary of the collected dataset from the literature review used for modeling

| Var. | References | Remark | |||||||

|---|---|---|---|---|---|---|---|---|---|

| [4] | [25] | [26] | [27] | [28] | [29] | [30] | [31] | ||

| w/b | 0.48 | 0.45 | 0.4–0.57 | 0.39 | 0.41–0.54 | 0.41 | 0.25–0.45 | 0.38–0.46 | Varied between 0.25 and 0.57 |

| C (kg·m−3) | 372–465 | 360–426 | 280–400 | 189–380 | 297–331 | 340–400 | 442–494 | 354–444 | Ranged between 189 and 494 |

| FA (kg·m−3) | 715 | 545 | 690 | 793 | 949–957 | 750 | 665 | 580 | Varied between 545 and 957 |

| CA (kg·m−3) | 1,030 | 1,186 | 1,070 | 1,119 | 848, 776 | 1,035 | 1,144 | 875 | Varied between 848 – 1,186 |

| GP (%) | 0–15 | 0–15 | 0–30 | 0–50 | 0–15 | 0–20 | 5–15 | 0–20 | Ranged between 0 and 50 |

| SP (%) | 0 | 0.7 | 0.39 | 0.2 | 0 | 1.2–1.4 | 0.1–1.8 | 0.6 | Varied between 0 and 1.4 |

| t (days) | Up to 90 | 7, 28 | Up to 365 | 7, 28 | 28, 180 | Up to 240 | 7, 28 | Up to 300 | Ranged between 7 and 300 |

| CS (MPa) | 26–65 | 23–37 | 44–78 | 35–50 | 41–68 | 40–79 | 44–86 | 18–63 | Varied between 18 and 86 |

| Shape and size (mm) | Cube 100 × 100 × 100 & Cylinder 100 × 200 | Cube 100 × 100 × 100 | Cylinder 100 × 200 | Cube 100 × 100 × 100 | Cylinder 100 × 200 & 150 × 300 | Cube 100 × 100 × 100 | Cube 100 × 100 × 100 | Cylinder 150 × 300 | |

Comparison between chemical composition of cement and glass powder.

2.1 Statistical analysis

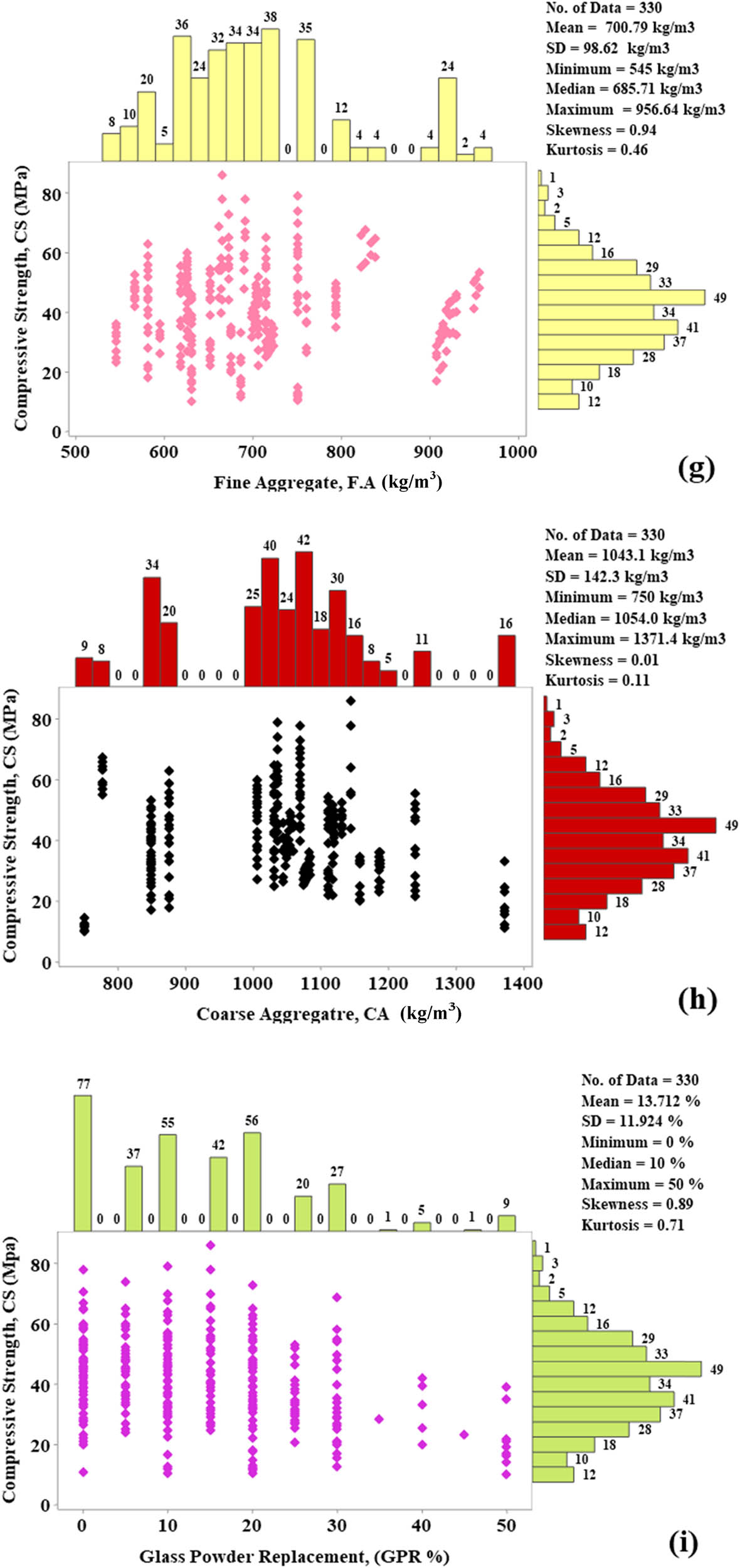

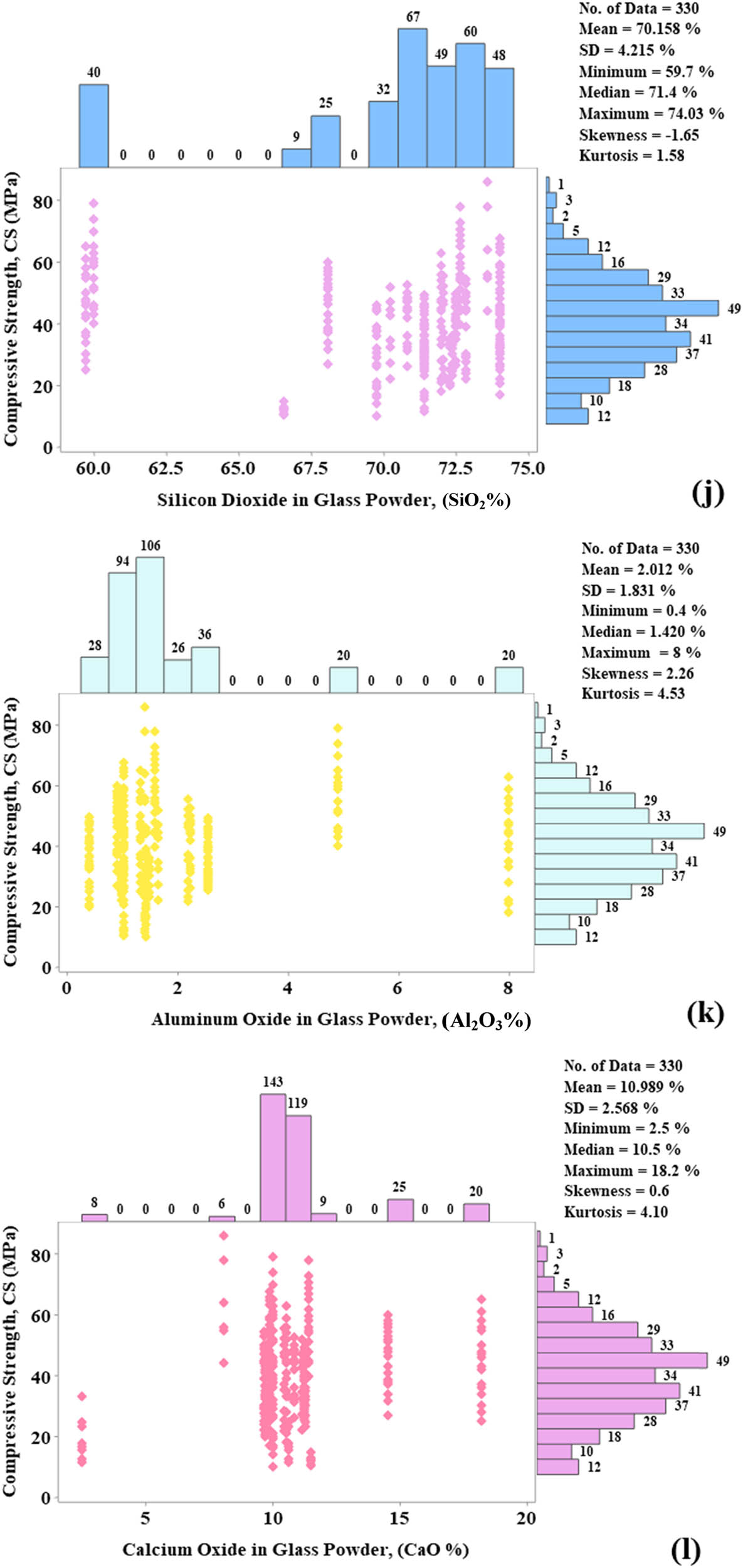

The data were collected and analyzed using statistical parameters to evaluate the relation existing among the input variables, which includes water-to-binder ratio (w/b), cement (C), fine aggregate (FA), CA, SP, curing time (t), chemical composition for both cement and glass powder, silicon dioxide (SiO2%), aluminum oxide (Al2O3%), calcium oxide (CaO%), iron oxide (Fe2O3%), and the proportion of glass replacement (GP%). Independent variables (output) that have been plotted are shown in Figure 3, and the data obtained from previous studies are normally distributed based on the normality curve conducted from the histogram, as shown in Figure 4. For model evaluation, the data of chemical composition for glass powder and cement were calculated as combined proportions [32] according to Eqs. (1)–(4):

Marginal plot of compressive strength of concrete mixtures contains various percentages of glass powder: (a) w/b ratio (b) C (kg·m−3), (c) SiO2 (%), (d) Al2O3 (%), (e) CaO(%), (f) Fe2O3 (%), (g) FA (kg·m−3), (h) CA (kg·m−3), (i) GP(%), (j) SiO2 (%), (k) Al2O3 (%), (l) CaO(%), (m) Fe2O3 (%), (n) t (days), and (o) SP(%).

A histogram for the normality distribution of the data collected for compressive strength (MPa) of a concrete incorporated with glass powder.

Statistical analysis was evaluated for every variable by measuring the median, mean, standard deviation, variance, skewness, and kurtosis, as illustrated in Table 2.

Statistical analysis of the concrete mixes

| Input parameters | Statistical parameters | |||||||

|---|---|---|---|---|---|---|---|---|

| Mean | StDev. | Variance | Minimum | Median | Maximum | Skewness | Kurtosis | |

| w/b | 0.44763 | 0.0787 | 0.00619 | 0.25 | 0.41 | 0.615 | 0.6 | −0.63 |

| C (kg·m−3) | 354.64 | 78.92 | 6227.9 | 189.74 | 350 | 600 | 0.53 | 0.36 |

| FA (kg·m−3) | 701.39 | 99.77 | 9953.21 | 545 | 685.71 | 956.64 | 0.92 | 0.38 |

| CA (kg·m−3) | 1040.4 | 142.7 | 20,365 | 750 | 1,052 | 1371.4 | 0.02 | 0.06 |

| GP (%) | 13.894 | 11.987 | 143.695 | 0 | 10 | 50 | 0.87 | 0.66 |

| *SiO2 (%) | 27.665 | 6.26 | 39.19 | 18.51 | 26.697 | 46.44 | 0.77 | 0.32 |

| *Al2O3 (%) | 4.3268 | 0.9199 | 0.8462 | 2.276 | 4.276 | 6.52 | 0.33 | −0.05 |

| *CaO (%) | 55.346 | 6.409 | 41.081 | 35.8 | 55.868 | 65.5 | −0.75 | 0.46 |

| *Fe2O3 (%) | 2.4197 | 0.7869 | 0.6192 | 0.52 | 2.44 | 4.83 | −0.21 | −0.42 |

| SP (%) | 0.6426 | 0.7823 | 0.612 | 0 | 0 | 2.67 | 0.96 | −0.09 |

| t (day) | 58.88 | 77.81 | 6053.98 | 7 | 28 | 365 | 2.54 | 6.5 |

| CS (MPa) | 40.042 | 14.465 | 209.242 | 10 | 40 | 79 | 0.12 | −0.36 |

w/b, water-to-binder ratio; C, cement content; FA, fine aggregate; CA, coarse aggregate; GPR %, percentage replacement of glass powder; *SiO2, silicon dioxide as calculated in Eq. (1); *Al2O3, aluminum oxide as calculated in Eq. (2); *CaO, calcium oxide as measured in Eq. (3); *Fe2O3, iron oxide as estimated in Eq. (4); SP, superplasticizer; t, curing time, CS,compressive strength.

2.2 Specimen shape and size

As previously stated [33], the shape and size of concrete specimens considerably impact their compressive strength and splitting tensile strength. In the present study, multiple models were developed utilizing a dataset gathered from research studies, considering the shape and size of the concrete sample while measuring the predicted compressive strength. The dataset from several research investigations was utilized in four different models to measure compressive strength predicted for standard cube sizes of 150 mm × 150 mm × 150 mm and 100 mm × 100 mm × 100 mm and cylindrical specimens of 100 mm × 200 mm and 100 mm × 300 mm, as shown in Table 3. It was concluded that 14% of the data were cubes with 150 mm3, while 23% were cubes with standard size with 100 mm3; the same evaluation was done for the cylindrical specimens, and the results were 25 and 10% for cylinders with 100 mm × 200 mm and 100 mm × 300 mm, respectively.

RMSE for developed models using various specimen sizes

| Dataset | Sample | No. of samples | Models | Finest model performance | ||||

|---|---|---|---|---|---|---|---|---|

| Shape | Size (mm) | LR | NLR | IN | PQ | |||

| Training data | Cube | 150 × 150 × 150 | 31 | 2.79 | 4.11 | 3.52 | 3.05 | LR |

| Cube | 100 × 100 × 100 | 51 | 6.17 | 3.72 | 3.78 | 3.34 | PQ | |

| Cylinder | 100 × 200 | 56 | 3.45 | 2.08 | 2.59 | 3.71 | NLR | |

| Cylinder | 150 × 300 | 22 | 5.62 | 1.15 | 5.32 | 4.8 | NLR | |

| Testing data | Cube | 150 × 150 × 150 | 13 | 5.67 | 6.6 | 4.48 | 4.62 | INT |

| Cube | 100 × 100 × 100 | 21 | 7.88 | 4.54 | 6.45 | 6.27 | NLR | |

| Cylinder | 100 × 200 | 23 | 3.7 | 2.48 | 4.9 | 3.17 | NLR | |

| Cylinder | 150 × 300 | 9 | 4.82 | 3.8 | 5.94 | 5.9 | NLR | |

2.3 Glass powder

The byproduct, economical waste, was potentially a pozzolanic process when the particle size was less than 75 μm due to high silica content in the amorphous state [34]. The chemical composition of glass powder consists of silicon dioxide (SiO2), aluminum oxide (Al2O3), calcium oxide (CaO), iron oxide (Fe2O3), alkalis (K2O and Na2O), and magnesium oxide (MgO) in various quantities, as illustrated in Table 4. Figure 1 presents the chemical composition of glass powder and cement. The chemical components found in the glass powder, especially the quantity of silica, were shown to have significant effects on the pozzolanic process. In addition, the particle size distribution of the glass particles is essential to determine the role of glass powder, which can be a pozzolanic material, a filler, or both. The relationship is shown in Figure 5. Previous studies showed a smooth distribution curve for particle size identical to that of cement. Therefore, in this study, light will be shed on the effect of the chemical composition and the various amounts of cement replaced by glass powder on the predicted compressive strength using four different types of statistical models: the four chemical compounds in cement and glass powder were selected due to their sufficient effect on the characteristics of the material used because cement can affect in several forms such as any variation of these four compounds can change its type and properties. Similar to glass powder, chemical characteristics can be highly influenced by the four compounds SiO2, Al2O3, CaO, and Fe2O3.

Chemical composition of cement and glass powder used in the concrete mixture

| Ref. | Cement | Glass powder | ||||||

|---|---|---|---|---|---|---|---|---|

| *SiO2 (%) | Al2O3 (%) | CaO (%) | Fe2O3 (%) | SiO2 (%) | Al2O3 (%) | CaO (%) | Fe2O3 (%) | |

| [4] | 19.58 | 4.59 | 63.19 | 3.67 | 59.7 | 1.31 | 18.2 | 0.77 |

| [25] | 21.56 | 5.39 | 65.5 | 3.39 | 72.39 | 1.47 | 11.25 | 0.29 |

| [26] | 20.43 | 4.7 | 62.39 | 2.92 | 72.66 | 1.57 | 11.41 | 0.39 |

| [27] | 20.2 | 4.7 | 61.9 | 3 | 72.5 | 0.4 | 9.7 | 0.2 |

| [28] | 19.83 | 4.48 | 61.66 | 2.32 | 74.03 | 1.023 | 9.868 | 0.108 |

| [29] | 20.41 | 4.91 | 62.73 | 3.21 | 59.98 | 4.9 | 10 | 1.7 |

| [30] | 20.39 | 4.55 | 62.2 | 3.81 | 73.6 | 1.4 | 8.04 | 1.4 |

| [31] | 20.25 | 6.15 | 64.5 | 2.55 | 72 | 8 | 10.5 | 0.6 |

| Remark | Varied between 19.58 and 21.57 | Ranged between 4.55 and 6.15 | Varied between 61.9 and 65.5 | Ranged between 2.32 and 3.81 | Varied between 59.7 and 74.03 | Ranged between 0.4 and 8 | Varied between 8.04 and 18.2 | Ranged between 0.108 and 1.7 |

*Chemicals selected in cement and glass powder are silicon dioxide (SiO2), aluminum oxide (Al2O3), calcium oxide (CaO), and iron oxide (Fe2O3) due to their sufficient effect on cement characteristics.

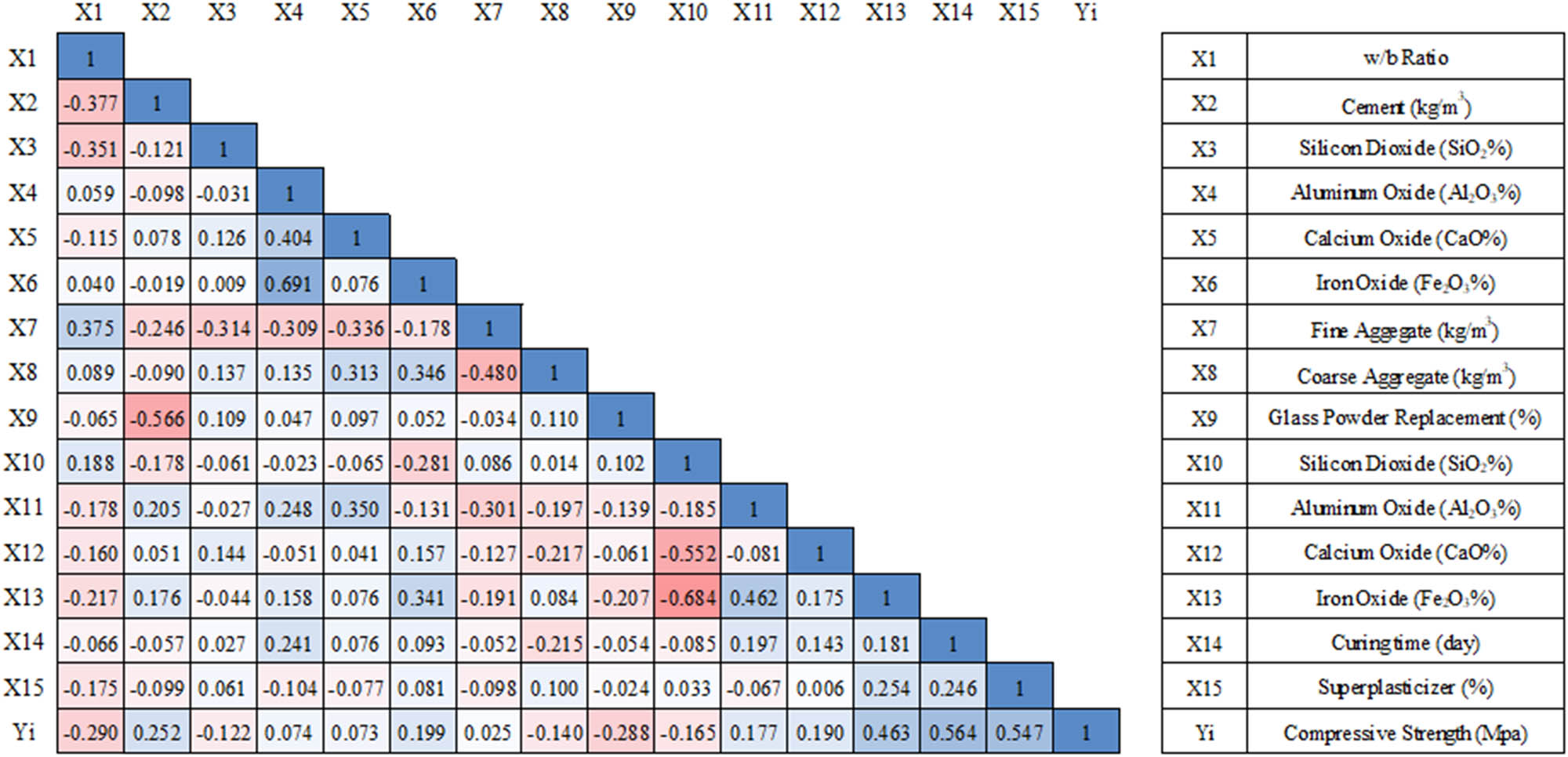

2.4 Modeling

In this study, soft computing learning machines (models) are utilized to evaluate the relationships between input and output variables: LR, NLR, PQ, and INT models for three groups of datasets that (training) are used to construct the models, test and validate, and to investigate the reliability and dependability of the calculated models. Additionally, evaluation criteria such as the correlation coefficient (R 2), RMSE, MAE, and SI are used to evaluate the model performance and accuracy. Based on the correlation matrix, the results are shown in Figure 6. A high correlation value greater than 0.5 was indicated between the compressive strength and curing time and SP 0.56 and 0.55, respectively, while a poor correlation was observed between the compressive strength and other dependent variables: −0.29, 0.25, −0.12, 0.074, 0.19, 0.025, −0.14, −0.29, −0.17, 0.18, 0.19, and 0.46 for w/b, cement, the chemical composition of cement, silicon dioxide, aluminum oxide, calcium oxide, iron oxide, FA, CA, glass powder replacement, chemical compounds of glass powder: silicon dioxide, aluminum oxide, calcium oxide, and iron oxide, respectively. Additionally, Figure 3 represents the scatter plot of the data collected with statistical parameters for each variable, such as mean, median, range, skewness, and kurtosis. The same are presented in Table 2. Moreover, Figure 4 illustrates the histogram of the output investigated from data gathered from previous studies, showing the normality and distribution curve of the output (compressive strength).

Correlation matrix for the coefficient of correlation between input and output data.

2.4.1 Linear model

The Linear model is a basic statistical analysis model that depends on a large number of datasets and is considered the least accurate model [47]; the coefficient of LR gives an obvious explanation of the relationships between inputs and output; it is known for its simplicity and the predicted output is obtained quickly. However, it is of low quality due to its sensitivity to outliers and will not perform well for complex datasets. As calculated in Eq. (5), the compressive strength is predicted using the following LR equation:

The CS (MPa), w/b, C (kg·m−3), FA (kg·m−3), CA (kg·m−3), GP (%), SiO2 (%), Al2O3 (%), CaO (%), Fe2O3 (%), SP (%), and t (day) are the predicted compressive strength, water to binder ratio, FA, CA, glass powder replacement, silicon dioxide, aluminum oxide, calcium oxide, iron oxide, SP, curing time, respectively, and β 0, β 1 to β 11 are constants.

2.4.2 Nonlinear model

A notable characteristic is the nonlinear dependency of the prediction equation on one or more unidentified variables. Nonlinear models are common when there are physical justifications for an issue. In contrast, LR is frequently utilized to develop a purely empirical model, assuming a certain functional structure to the connection between the outcome and the predictors [24]. This model is flexible and conducts complex relationships between variables that are considered challenging for the LR equation; more reliable and accurate, it is more complicated and susceptible to overfitting. Eq. (6) shows the nonlinear relation between the predicted compressive strength and the independent variables:

Here, the CS (MPa), w/b, C (kg·m−3), FA (kg·m−3), CA (kg·m−3), GP (%), SiO2 (%), Al2O3 (%), CaO (%), Fe2O3 (%), SP (%), and t (day) are the predicted compressive strength, water to binder ratio, FA, CA, glass powder replacement, silicon dioxide, aluminum oxide, calcium oxide, iron oxide, SP, and curing time, which were calculated in Eqs. (1)–(4), and β 0, β 1 to β 11 are constants.

2.4.3 PQ model

To calculate the predicted value of the compressive strength of concrete incorporated waste glass powder as a cement replacement and determine the relationships between the input and output variables in the collected dataset, the PQ model is utilized to convey the nonlinear relation between variables, allowing for more flexibility and provide a better fit to the dataset. However, it requires a large sample size. In this investigation, as shown in Eq. (7), the PQ equation for the collected dataset is separated for all the other three models in training, testing, and validating data:

2.4.4 INT model

The statistical model is utilized to investigate a complicated relationship between the variables and provide an understanding of the difference between the interacted variables to affect the output results, as illustrated in Eq. (8):

Here, the CS (MPa), w/b, C (kg·m−3), FA (kg·m−3), CA (kg·m−3), GP (%), SiO2 (%), Al2O3 (%), CaO (%), Fe2O3 (%), SP (%), and t (day) are the predicted compressive strength, water to binder ratio, FA, CA, glass powder replacement, silicon dioxide, aluminum oxide, calcium oxide, iron oxide, SP, and curing time, and β 0, β 1 to β 69 are constants.

2.5 Statistical parameters for model evaluation

To evaluate the model’s reliability and performance, there are evaluation criteria that assess the model’s dependability, RMSE, correlation coefficient (R 2), MAE, SI, and objective (OBJ), as demonstrated in Eqs. (9)–(13):

where

2.6 Correlation equations between the compressive strength and splitting tensile strength

Various parameters can be calculated to find the relationship between the compressive strength of concrete and the splitting tensile strength utilizing the correlation equations Eqs. (14)–(18) collected from the literature. The Vipulanandan hyperbolic model was employed to predict the relationship between compressive and tensile strength in various studies [49–51]. Moreover, Eq. (19) is used to develop a Vipulanandan model for predicting the correlation between the measured compression and predicted tensile strength of concrete modified with glass powder as a cement replacement:

where CS (MPa) is the compressive strength measured, STS (MPa) is the splitting tensile strength predicted in Eqs. (14)–(18), and

3 Results and discussion

3.1 Evaluation criteria and model performance

3.1.1 Linear model (LR)

This study uses a linear model to predict the compression values of modified concrete with glass in powder using data collected from previous studies, as shown in Table 1. Eq. (5) can be used for testing and validating the dataset by using the training dataset for checking model performance; the linear model quantifies a simple linear relationship between the variables, as shown in Figure 7(a), of all the data collected (321) and has been used to form a linear model, obtaining R 2 0.7727 and RMSE 6.885 MPa; the dataset between the error line is −25 to 35%.

Plots of measured and predicted compressive strength (MPa) using LR, NLR, PQ, and INT models for the training, testing, and validating datasets.

For training data (215), RMSE and R 2 values are 8.064 MPa and 0.74.

3.1.2 Nonlinear model (NLR)

For more complexity of the relationship between dependent and independent variables, nonlinear is to be modeled; this statistical model is used to evaluate the predicted compressive strength incorporated with glass powder as a cement replacement. As shown in Figure 7(b), the nonlinear model for the dataset with error lines −20 to 25%, the values of R 2 and RMSE are 0.886, 5.376 MPa, and the nonlinear equation utilized on the training dataset (Eq. 20)

3.1.3 PQ

This model represents a quadratic relation between variables, and it is functional when the relationship between inputs and outputs exhibits a curved pattern and cannot be represented in a straight line as in the LR model; in this investigation, it is used to calculate the predicted compressive strength of concrete enhanced with glass powder as a cement partial replacement and Eq. (21) is applied on the training dataset and some model evaluation parameters were obtained such as R 2 and RMSE to ensure model efficiency. Figure 7(c) shows the PQ model performance for the three groups of data with RMSE and R 2 being 6.0206 MPa and 0.845.

For training data number 215, RMSE and R 2 are 6.213 MPa and 0.845.

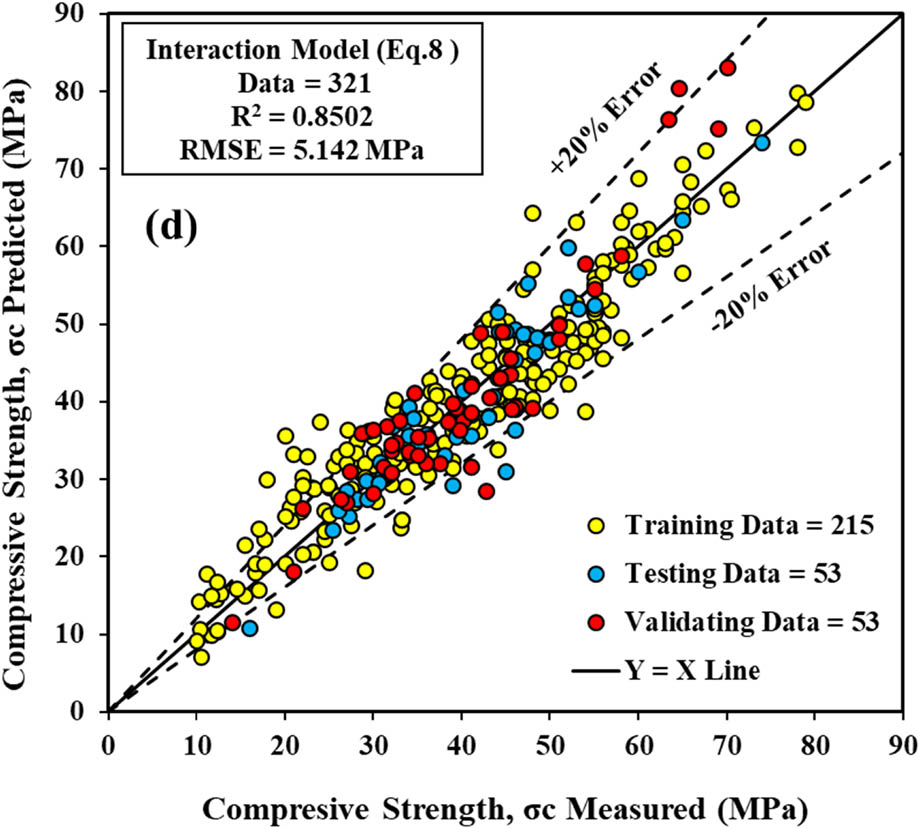

3.1.4 INT model

This model stands for the INT between independent and dependent variables used to predict the compressive strength of concrete containing glass powder; due to its advanced mathematical expression, high model efficiency obtained for compression prediction, a model derived from mathematical parameters constant, linear equation, INT variables, Eq. (22) applied on training dataset to calculate predicted compression, model evaluation parameters for all the three groups of data as is shown in Figure 7(d) with a coefficient correlation (R 2) 0.85 and an RMSE value of 5.14 MPa.

For the training dataset number 215, RMSE = 5.271 MPa and R 2 = 0.888.

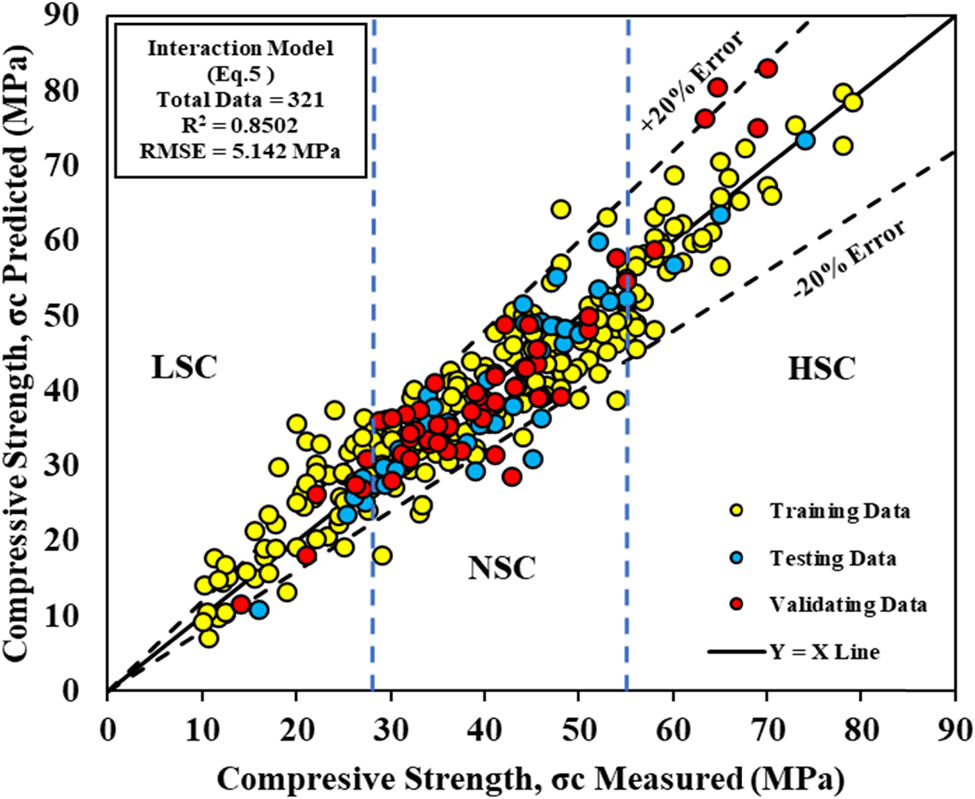

3.2 Model evaluation for various compressive strength-modified concrete ranges

In the current investigation and according to the dataset collected from previous studies and four different types of models constructed on 321 datasets, paying attention to the compressive strength values, a variety of types are observed, as shown in Table 5. RMSE and MAE measure evaluation criteria for the predicted compression strength of the modified concrete less than 28 MPa, which is considered as LSC for 71 data, which is almost 22% of the dataset. It was concluded that the highest model performance is the INT model due to its lowest RMSE and MAE values obtained; a similar observation was made for the NSC, and the compressive strength value is between 28 and 55 MPa when the results of the RMSE and MAE of all the created models were compared for the 197 number of data, which is almost 61%. INT model conducted a satisfied evaluation parameter, while for the predicted compression value that is greater than 55 MPa of 55 data, which is almost 17%. PQ model gives the finest functioning according to the least quantity of RMSE and MAE. As illustrated in Figure 8, the relationship between the measured compressive strength and the predicted shows that most of the data fall within the NSC region, exhibiting a strong correlation compared to the other two regions. Additionally, the INT model demonstrates the best performance, as it maintains a high correlation between the measured and predicted values across all three data groups. Furthermore, the INT model is the most satisfying performance due to the high relationship between the measured and predicted values for all three grouped data.

Overview of the criteria employed to evaluate the performance of the generated models

| Dataset | Model evaluation parameters | Model | |||

|---|---|---|---|---|---|

| LR | NLR | INT | PQ | ||

| Training | R 2 | 0.739 | 0.874 | 0.888 | 0.845 |

| RMSE (MPa) | 8.064 | 5.592 | 5.271 | 6.213 | |

| MAE (MPa) | 7.007 | 4.469 | 4.232 | 5.19 | |

| Testing | R 2 | 0.8134 | 0.788 | 0.851 | 0.739 |

| RMSE (MPa) | 4.607 | 4.906 | 4.107 | 5.449 | |

| MAE (MPa) | 3.713 | 4.033 | 2.984 | 4.678 | |

| Validating | R 2 | 0.871 | 0.8206 | 0.772 | 0.752 |

| RMSE (MPa) | 4.16 | 4.909 | 5.526 | 5.766 | |

| MAE (MPa) | 3.380 | 3.859 | 4.029 | 4.295 | |

| Figure No. | 5 | 5 | 5 | 5 | |

| Eq. No. | 5 | 6 | 8 | 7 | |

| Ranking | 4 | 2 | 1 | 3 | |

INT model for dataset collected for various ranges of compressive strength of concrete.

3.3 Correlation between the compressive strength of modified concrete and its splitting tensile strength

For the compressive strength values collected for various types of mixtures of concrete modified utilizing glass powder as a cement replacement, and splitting tensile strength was measured. It was concluded that a predicted splitting tensile strength can be calculated utilizing correlation equations corresponding to Figure 9(a) and demonstrates the data plotted of measured compression and tensile strength of concrete mixes containing a different percentage of glass powder as a cement replacement 0–50% followed by applying the correlation equation for normal concrete. It was observed that Eqs. (15)–(19) overlap with all the existing data plotted except Eq. (14) [55], which passes under the data accumulation; the selected equation by Code [52] is applicable for compression value less than 83 MPa while Eq. (17) is suitable for compressive strength values less than 117 MPa; for further procedure applications, it estimates a parameter of the correlation models specialized for concrete modified with glass powder, as shown in Figure 9(b). The results were calculated using Eq. (24):

where CS is the compressive strength, and STS is the predicted splitting tensile strength.

Correlation between measured compressive strength and predicted splitting tensile strength of (a) concrete without glass powder and (b) concrete modified with glass powder.

The results obtained for the Eq. [52] are as follows.

where STS is the predicted splitting tensile strength and CS is the measured compressive strength.

The parameters calculated in Eq. (15) [53] for the modified concrete with glass powder are the same as in Eq. (26):

where STS and CS are the predicted splitting tensile strength and measured compressive strength, respectively.

While the [54] correlation model is shown in Eq. (27):

Another equation has been selected to form the correlation relation between the measured compression value and predicted splitting tensile, as demonstrated in Eq. (28) [55]:

Eq. (24) is considered the most accurate and satisfied correlation model to measure the predicted splitting tensile strength from the observed value of the compressive strength for both plain and modified concrete mixtures with glass powder as a partial replacement of cement, as shown in Figure 10 (Vipulanandan model), measured for both concrete containing 0% glass powder and concrete mixtures with various percentages of glass powder incorporated corresponding to evaluation parameters 0.8, 0.43 MPa, 0.133 and 0.371 MPa for R 2, RMSE, SI, and MAE, respectively. High reliability and accuracy were found; a comparison of the correlation equations between normal concrete and concrete incorporated with glass powder as a partial cement replacement is illustrated in Table 6.

Vipulanandan model for dataset correlation between compression and splitting tensile strength for normal concrete and modified concrete with glass powder.

Comparison between normal concrete and concrete modified with glass powder using different correlation models

| Splitting tensile strength | ||

|---|---|---|

| Reference | Normal concrete | Concrete modified with glass powder |

| Developed equation |

|

|

| [52] | STS = 0.3 CS2/3 | STS = 0.4 CS0.62 |

| [53] | STS = 0.56 CS0.5 | STS = 0.61 CS0.5 |

| [54] | STS = 0.46 CS0.55 | STS = 0.51 CS0.55 |

| [55] | STS = 0.39 CS0.63 | STS = 0.38 CS0.63 |

| [56] | STS = 0.36 CS0.5 | STS = 0.39 CS0.657 |

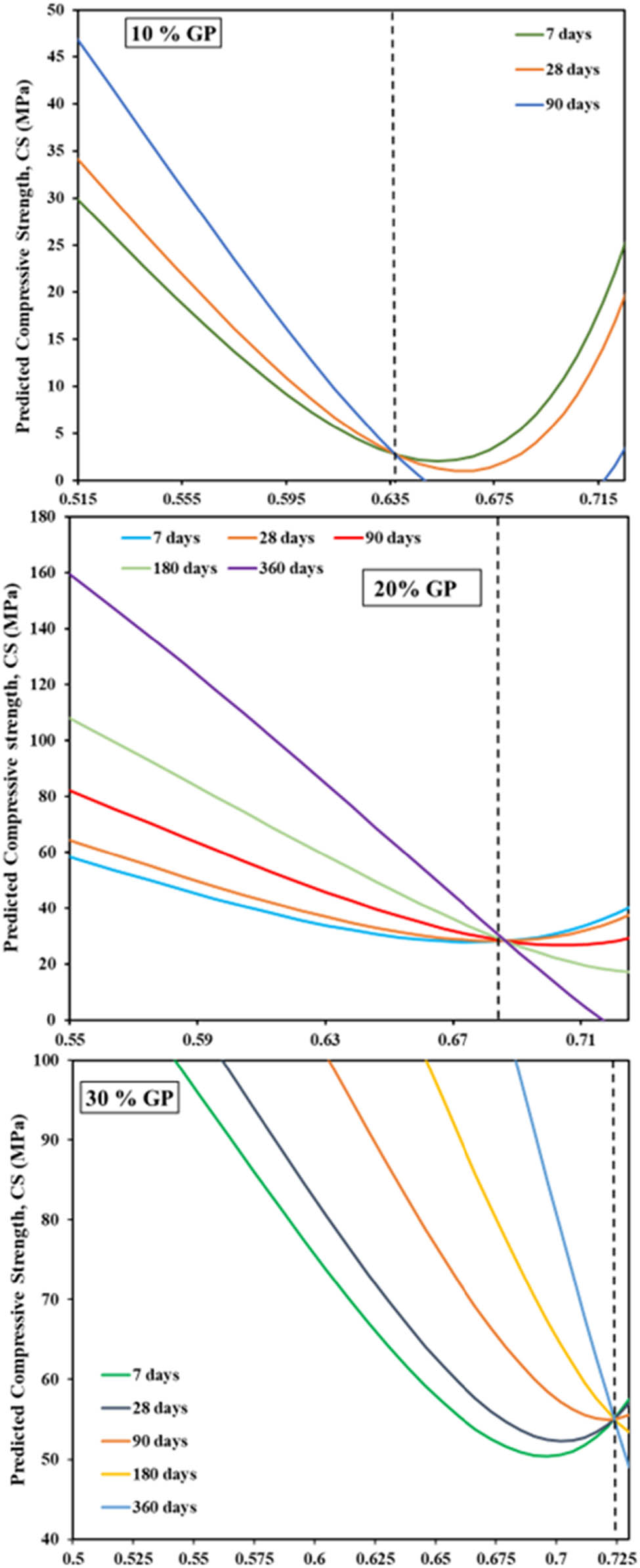

3.4 Impact of SiO2/CaO ratio on the compressive strength prediction

Corresponding to the evaluation criteria, the high accuracy satisfied model performance is the INT model, which has been utilized to estimate the change occurring in the predicted compressive strength due to the effect of the SiO2/CaO ratio. As illustrated in Figure 11, for the 10% replacement initially, there is a gradual decrease in the predicted compressive strength value until 0.63 for various curing times 7, 28, and 90 days, indicating an increasing amount of predicted output as the curing times increase. All intersect at point 0.63; then, an obvious increase is observed. A similar scenario occurs when the percentage replacement increases to 20%; however, the curing time curves take an upper position while the inflection point of SiO2/CaO generated from the intersection of predicted compression at different times of curing 7, 28, 90, 180, and 360 days will have a higher value of 0.68. When the continuous glass powder replacement reaches 30%, a higher value for SiO2/CaO is obtained at 0.73. For 40% replacement, the curves for compression prediction for curing time up to 180 days will gradually decrease and reach 0.73. Beyond this point, there is no indication of any increment in the predicted output. For 50% replacement, the same point of 0.73 was indicated; however, the prediction lines of different curing times will tend to have a steeper reduction.

Impact of SiO2/CaO ratio on the compression prediction as glass powder percentage replacement increases.

3.5 Particle size distribution for cement and glass powder

According to the values obtained from calculating the coefficient of uniformity (Cu) and coefficient of curvature (Cc), as demonstrated in Figure 5, the particle size distribution of cement and glass powder collected from different research studies, typically range (Cc), is between 2 and 100. Meanwhile, Cu varied between 4 and 14.3 for glass powder. However, for cement, the values range from 2.5 to 36 for the coefficient of curvature, and 4.9–12.1 is the range of coefficient of uniformity; both parameters, coefficient of curvature and coefficient of uniformity, used to describe the particle size distribution curve shape and variation of the particle size distribution that can be measured by D 10, D 30, and D 60 for every curve obtained and collected from different studies.

D 10 refers to the 10% diameter of the sample passing through a specific sieve, D 30 refers to 30% of the sample diameter passing through a specific sieve, and D 60 refers to 60% passing on the grain size distribution curve.

The typical range of D 10, D 30, and D 60 for glass powder is from 2 to 10, 4.3 to 20, and 14 to 40, respectively. Meanwhile, it was 1.4 to 4 for cement, from 4.8 to 15, and between 14 and 25 for D 10, D 30, and D 60, respectively.

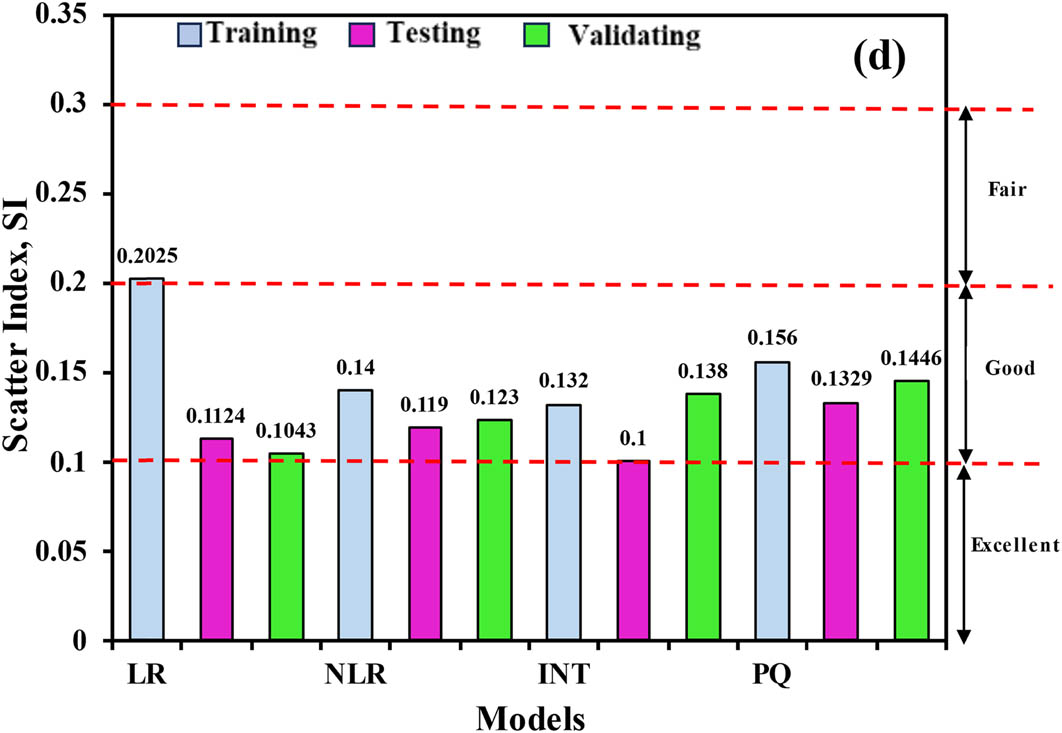

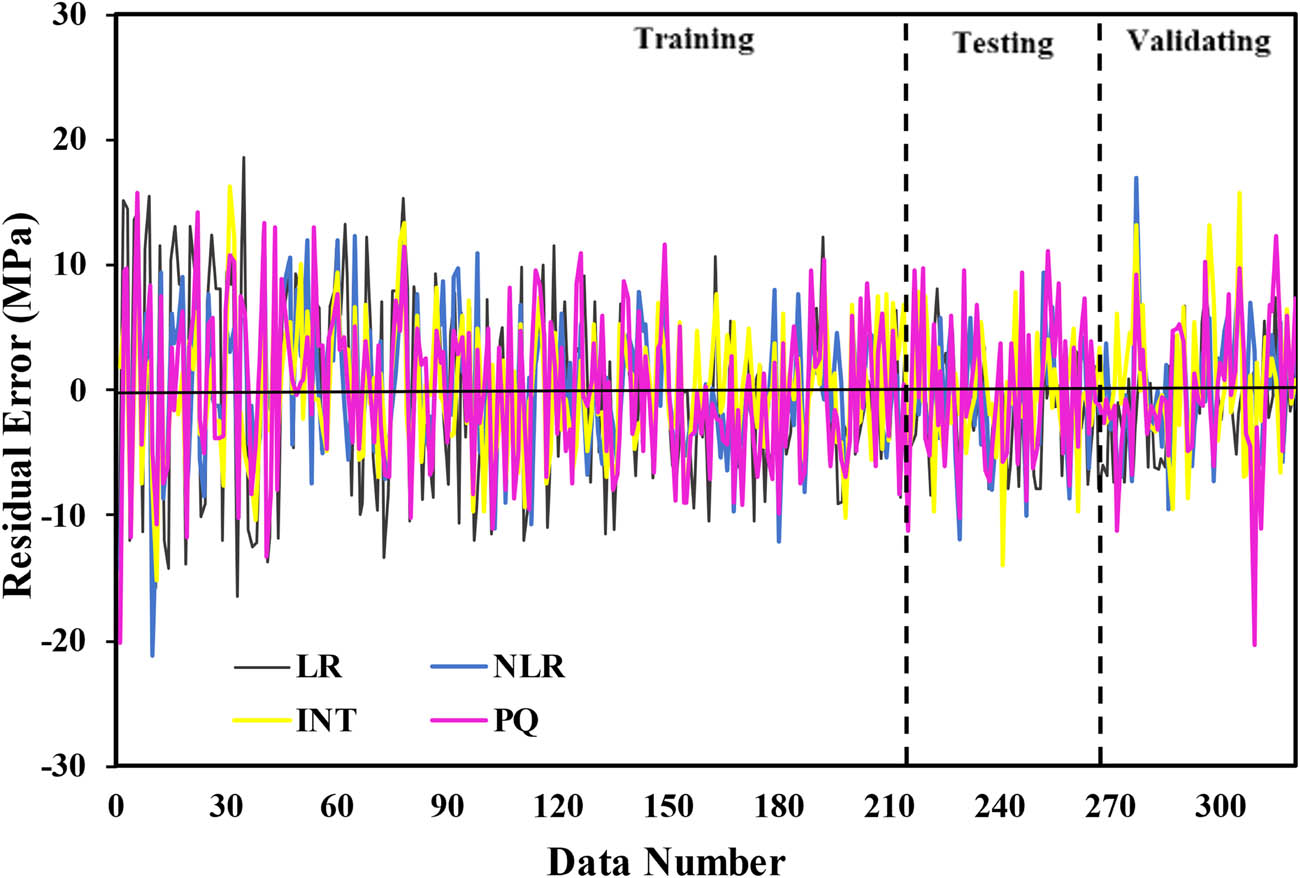

4 Model performance

The aim of this investigation is to calculate the predicted compressive strength of the concrete containing glass powder as a partial replacement and the effect of SiO2 and CaO content utilizing different models for the collected data set, which are divided into training data, testing, and validating dataset. Different evaluation parameters were used to assess the model performance R 2, RMSE, and MAE, as shown in Table 5. The most satisfied model performance ranked as the finest functioning model is the INT model due to the lowest values resulting from 5.3 and 4.2 MPa for RMSE and MAE, while 0.888 was obtained for R 2. However, the LR model was the most effective model for validating datasets 0.871, 4.16, and 3.8 MPa for R 2, RMSE, and MAE, respectively, as illustrated in Figure 12. The comparison between the measured compressive strength and the predicted compressive strength of the trained dataset (216) showed the accumulation and clustering of the majority of the data close to the straight-line Y = X line. The correlation coefficients (R 2) were 0.74, 0.87, 0.845, and 0.888 for LR, NLR, PQ, and INT, respectively. Meanwhile, the SI values were 0.2, 0.14, 0.16, and 0.13 for LR, NLR, PQ, and INT, respectively. According to Figure 13, the error line for the training dataset in all four model assessments is between −30 and +35%.

Evaluating the (a) Obj., (b) RMSE, (c) R 2, and (d) SI performance characteristics of the generated models LR, NLR, INT, and PQ for the training, testing, and validating dataset.

Comparison among models LR, NLR, INT, and PQ utilizing training dataset.

Furthermore, the four models were utilized to predict the compressive strength for training and testing data of different shapes and sizes of the concrete sample, as demonstrated in Table 3. For the standard cube size of 150 mm × 150 mm × 150 mm, the training data RMSE for the finest model performance (LR) was 2.79 MPa, while for the cubes with 100 mm × 100 mm × 100 mm, the PQ results satisfied with the RMSE value equals to 3.34 MPa; for cylindrical specimens with 100 mm × 200 mm, NLR exhibited the best performance with RMSE value equal to 2.08 MPa. Similarly, for the cylinder samples with 150 mm × 300 mm that has the highest quality performance was the NLR model with RMSE of 1.15 MPa. Moreover, the finest model performance for the testing dataset was NLR for a cylinder with 100 mm × 200 mm size, 150 mm × 300 mm size, and 100 mm × 100 mm × 100 mm cube with RMSE values of 2.48, 3.8, and 4.54 MPa, respectively. The 150 mm × 150 mm × 150 mm size cube of the INT model has the least RMSE value of 4.48 MPa. Additionally, as shown in Figure 14, the amount of residual error calculated by the difference between the predicted and observed compression of modified concrete for LR varied between −16.5 and 18.6 MP, NLR ranged between −21.3 and 17 MPa and PQ residual error values ranged from −20.3 to 15.8 MPa and INT varied from −15.2 to 16.4 MPa (Table 7 and Figure 11).

Comparison between the generated models for concrete incorporated glass powder depending on residual error LR, NLR, INT, and PQ.

Model evaluation parameters RMSE and MAE for LR, NLR, INT, and PQ model

| Type | Range | Data no. | Evaluation parameters | Model | Best model | |||

|---|---|---|---|---|---|---|---|---|

| LR | NLR | INT | PQ | |||||

| Low-strength concrete | CS < (28 MPa) | 71 | RMSE (MPa) | 4.1 | 2.230 | 1.421 | 2.755 | INT |

| MAE (MPa) | 3.414 | 1.712 | 1.085 | 2.296 | INT | |||

| NSC | CS (28–55 MPa) | 197 | RMSE (MPa) | 4.942 | 4.169 | 3.843 | 4.386 | INT |

| MAE (MPa) | 3.852 | 3.138 | 2.888 | 3.419 | INT | |||

| HSC | CS (55–90 MPa) | 55 | RMSE (MPa) | 3.243 | 3.235 | 2.602 | 2.566 | PQ |

| MAE (MPa) | 2.471 | 2.475 | 2.081 | 2.027 | PQ | |||

5 Sensitivity analysis

Since the INT model has the finest performance due to satisfied values obtained for model evaluations, sensitivity analysis is measured utilizing training data to assess and evaluate the effect of individual input parameters on the output, which is the predicted compressive strength shown in Figure 15. The percentage effect of each independent variable on the predicted compressive strength, curing time (t) was ranked as the most effective factor that influenced the predicted outcome; this assessment can be calculated by removing one variable every time to compute the resulting output and then observing the assessment criteria. Curing time is the number one factor that affects the predicted output values 0.75, 8, and 6.3 MPa for R 2, RMSE, and MAE, respectively. However, the least factor influencing the output is the water-to-binder ratio (w/b) R 2, RMSE, and MAE, which are 0.867, 5.748, and 4.583 MPa for the INT model after removing the w/b ratio.

The percentage influence of the independent variables for speculating concrete output using the INT model.

6 Limitations and future work

Despite the promising results of the machine learning models used in this study for predicting the compressive strength of concrete modified with glass powder as a partial replacement of cement, several limitations remain. The dataset utilized in training the models may not fully capture the diversity of real-world conditions, particularly regarding variations in the material properties and environmental factors. Future work could expand the dataset to include a broader range of experimental conditions and structural configurations to improve model robustness and generalizability. Additionally, while the models show great potential for predicting concrete behavior, they still require further validation with real-world data to ensure their accuracy in practical applications. Another avenue for future research includes exploring other machine learning techniques, such as deep learning or hybrid models, to refine predictions and address the challenges of overfitting and interpretability. Furthermore, future studies could investigate the integration of these models into design software for more efficient and optimized structural design. Finally, ongoing research should focus on advancing the sustainability of materials used in concrete construction by integrating eco-friendly alternatives and reducing the environmental impact of conventional practices.

7 Conclusions

The following conclusions are arrived at to create a dependable and accurate model for compressive strength prediction of a dataset collected from different studies (321) for concrete modified with glass powder as a cement replacement at various percentages for different curing periods of 7, 28, 90, and 360 days corresponding to the results:

The INT model used to predict compressive strength obtained satisfactory results for low and normal strength concrete; meanwhile, the PQ is considered the optimal model for high-strength concrete.

Compared to the other models, the INT model performed the best due to the lowest values obtained for RMSE and MAE for the training, testing, and validating datasets.

The shape and size of the concrete specimen are highly influential factors in predicting compressive strength using various models.

Among the correlation models utilized for the data collected from different research studies, the Vipulanandan model satisfies the equation for predicting the correlation between the measured compressive strength and predicted splitting tensile strength.

Adding glass powder to the concrete mixture will enhance its mechanical properties for up to 360 days; however, it is not convenient for more than 30% replacement.

The chemical composition of glass powder plays a decisive role in the strength enhancement approach for the various percentage replacements; no further strength is observed for the ratio of SiO2/CaO increase beyond 0.73.

The glass powder particle size distribution of the cement replacement process demonstrates a smooth curve similar to that of cement. This illustration concludes that the particle size of glass powder utilized in previous research corresponds with that of cement particles.

-

Funding information: The authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Khan, F. A., M. Fahad, K. H. A. N. Shahzada, H. A. R. I. S. Alam, and N. Ali. Utilization of waste glass powder as a partial replacement of cement in concrete. Magnesium, Vol. 2, No. 5, 2015.Search in Google Scholar

[2] Mohajerani, A., J. Vajna, T. H. H. Cheung, H. Kurmus, A. Arulrajah, and S. Horpibulsuk. Practical recycling applications of crushed waste glass in construction materials: A review. Construction and Building Materials, Vol. 156, 2017, pp. 443–467.10.1016/j.conbuildmat.2017.09.005Search in Google Scholar

[3] Sudan, S. and S. Dhiman. Impact of glass waste and rubber waste over the environment and their applications in concrete. In IOP Conference Series: Earth and Environmental Science, Vol. 1110, No. 1, IOP Publishing, 2023, p. 012051.10.1088/1755-1315/1110/1/012051Search in Google Scholar

[4] Muhedin, D. A. and R. K. Ibrahim. Effect of waste glass powder as partial replacement of cement & sand in concrete. Case Studies in Construction Materials, Vol. 19, 2023, id. e02512.10.1016/j.cscm.2023.e02512Search in Google Scholar

[5] Islam, G. S., M. Rahman, and N. Kazi. Waste glass powder as partial replacement of cement for sustainable concrete practice. International Journal of Sustainable Built Environment, Vol. 6, No. 1, 2017, pp. 37–44.10.1016/j.ijsbe.2016.10.005Search in Google Scholar

[6] Ryou, J., S. P. Shah, and M. S. Konsta-Gdoutos. Recycling of cement industry wastes by grinding process. Advances in Applied Ceramics, Vol. 105, No. 6, 2006, pp. 274–279.10.1179/174367606X128766Search in Google Scholar

[7] Soroushian, P. Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Construction and Building Materials, Vol. 29, 2012, pp. 368–377.10.1016/j.conbuildmat.2011.10.061Search in Google Scholar

[8] Du, H. and K. H. Tan. Waste glass powder as cement replacement in concrete. Journal of Advanced Concrete Technology, Vol. 12, No. 11, 2014, pp. 468–477.10.3151/jact.12.468Search in Google Scholar

[9] Kamali, M. and A. Ghahremaninezhad. Effect of glass powders on the mechanical and durability properties of cementitious materials. Construction and Building Materials, Vol. 98, 2015, pp. 407–416.10.1016/j.conbuildmat.2015.06.010Search in Google Scholar

[10] Kalakada, Z., and J. H. Doh. Studies on recycled waste glass powder as binder in concrete. In ACMSM25. Lecture Notes in Civil Engineering, Vol. 37, Wang, C., J. Ho, and S. Kitipornchai, eds., Springer, Singapore, 2020, pp. 61–70. 10.1007/978-981-13-7603-0_7.Search in Google Scholar

[11] Shayan, A. and A. Xu. Value-added utilisation of waste glass in concrete. Cement and Concrete Research, Vol. 34, No. 1, 2004, pp. 81–89.10.1016/S0008-8846(03)00251-5Search in Google Scholar

[12] Schwarz, N. and N. Neithalath. Influence of a fine glass powder on cement hydration: Comparison to fly ash and modeling the degree of hydration. Cement and Concrete Research, Vol. 38, No. 4, 2008, pp. 429–436.10.1016/j.cemconres.2007.12.001Search in Google Scholar

[13] Rahman, S. and M. N. Uddin. Experimental investigation of concrete with glass powder as partial replacement of cement. Civil Engineering and Architecture, Vol. 6, No. 3, 2018, pp. 149–154.10.13189/cea.2018.060304Search in Google Scholar

[14] Olutoge, F. A. Effect of waste glass powder (WGP) on the mechanical properties of concrete. American Journal of Engineering Research, Vol. 5, No. 11, 2016, pp. 213–220.Search in Google Scholar

[15] Li, M., H. Hao, Y. Shi, and Y. Hao. Specimen shape and size effects on the concrete compressive strength under static and dynamic tests. Construction and Building Materials, Vol. 161, 2018, pp. 84–93.10.1016/j.conbuildmat.2017.11.069Search in Google Scholar

[16] Li, Z., J. Yoon, R. Zhang, F. Rajabipour, W. V. Srubar III, I. Dabo, et al. Machine learning in concrete science: applications, challenges, and best practices. npj Computational Materials, Vol. 8, No. 1, 2022, id. 127.10.1038/s41524-022-00810-xSearch in Google Scholar

[17] Mirrashid, M. and H. Naderpour. Recent trends in prediction of concrete elements behavior using soft computing (2010–2020). Archives of Computational Methods in Engineering, Vol. 28, 2021, pp. 3307–3327.10.1007/s11831-020-09500-7Search in Google Scholar

[18] Benzaamia, A., M. Ghrici, R. Rebouh, N. Zygouris, and P. G. Asteris. Predicting the shear strength of rectangular RC beams strengthened with externally-bonded FRP composites using constrained monotonic neural networks. Engineering Structures, Vol. 313, 2024, id. 118192.10.1016/j.engstruct.2024.118192Search in Google Scholar

[19] Asteris, P. G., M. Koopialipoor, D. J. Armaghani, E. A. Kotsonis, and P. B. Lourenço. Prediction of cement-based mortars compressive strength using machine learning techniques. Neural Computing and Applications, Vol. 33, No. 19, 2021, pp. 13089–13121.10.1007/s00521-021-06004-8Search in Google Scholar

[20] Asteris, P. G., A. Mamou, M. Ferentinou, T. T. Tran, and J. Zhou. Predicting clay compressibility using a novel Manta ray foraging optimization-based extreme learning machine model. Transportation Geotechnics, Vol. 37, 2022, id. 100861.10.1016/j.trgeo.2022.100861Search in Google Scholar

[21] Bai, C., H. Nguyen, P. G. Asteris, T. Nguyen-Thoi, and J. Zhou. A refreshing view of soft computing models for predicting the deflection of reinforced concrete beams. Applied Soft Computing, Vol. 97, 2020, id. 106831.10.1016/j.asoc.2020.106831Search in Google Scholar

[22] Asteris, P. G., A. Ashrafian, and M. Rezaie-Balf. Prediction of the compressive strength of self-compacting concrete using surrogate models. Computers and Concrete, Vol. 24, No. 2, 2019, pp. 137–150.Search in Google Scholar

[23] James, G., D. Witten, T. Hastie, R. Tibshirani, and J. Taylor. Linear regression. In An introduction to statistical learning: With applications in python, Springer International Publishing, Cham, 2023, pp. 69–134.10.1007/978-3-031-38747-0_3Search in Google Scholar

[24] Smyth, G. K. Nonlinear regression. Encyclopedia of Environmetrics, Vol. 3, 2002, pp. 1405–1411.Search in Google Scholar

[25] Vandhiyan, R., K. Ramkumar, and R. Ramya. Experimental study on replacement of cement by glass powder. International Journal of Engineering Research & Technology, Vol. 2, No. 5, 2013, pp. 234–238.Search in Google Scholar

[26] Zidol, A., M. T. Tognonvi, and A. Tagnit-Hamou. Effect of glass powder on concrete sustainability. New Journal of Glass and Ceramics, Vol. 7, No. 2, 2017, id. 34.10.4236/njgc.2017.72004Search in Google Scholar

[27] Khadeer, M. and U. K. Singh. An experimental study for optimal usage of powdered glass in concrete as a cement replacement material. In IOP Conference Series: Materials Science and Engineering, IOP Publishing, 2021, p. 012036.10.1088/1757-899X/1197/1/012036Search in Google Scholar

[28] Omer, B. and J. A. Saeed. Characterizations and modeling the influence of particle size distributions (PSD) of glass powder on the mechanical behavior of normal strength concrete. Civil Engineering and Architecture, Vol. 8, 2020, pp. 993–1005.10.13189/cea.2020.080526Search in Google Scholar

[29] Alwared, A. I., S. K. Al-Hubboubi, and R. A. Rasen. Effect of waste glass powder as a supplementary cementitious material on the concrete mix properties. Association of Arab Universities Journal of Engineering Sciences, Vol. 25, No. 4, 2018, pp. 43–54.Search in Google Scholar

[30] Saify, S., M. S. Radhi, S. A. Al-Mashhadi, B. Mareai, S. F. Jabr, Z. A. Mohammed, et al. Impact of waste materials (glass powder and silica fume) on features of high-strength concrete. Open Engineering, Vol. 13, No. 1, 2023, id. 20220479.10.1515/eng-2022-0479Search in Google Scholar

[31] Soroushian, P. and M. Sufyan-Ud-Din. Long-term field performance of concrete produced with powder waste glass as partial replacement of cement. Case Studies in Construction Materials, Vol. 15, 2021, id. e00745.10.1016/j.cscm.2021.e00745Search in Google Scholar

[32] Abdalla, A. A. and A. Salih Mohammed. Theoretical models to evaluate the effect of SiO2 and CaO contents on the long-term compressive strength of cement mortar modified with cement kiln dust (CKD). Archives of Civil and Mechanical Engineering, Vol. 22, No. 3, 2022, id. 105.10.1007/s43452-022-00418-4Search in Google Scholar

[33] Zabihi, N. Effect of specimen size and shape on strength of concrete. Doctoral dissertation, Eastern Mediterranean University (EMU), 2012.Search in Google Scholar

[34] Raju, S. and P. R. Kumar. Effect of using glass powder in concrete. International Journal of Innovative Research in Science, Engineering and Technology, Vol. 31, 2014, pp. 21–427.Search in Google Scholar

[35] Hussain, G. and G. Verma. Experimental investigation on glass powder as partial replacement of cement for M-30 concrete. International Journal of Scientific Research in Science, Engineering and Technology, Vol. 2, 2016, pp. 846–853.Search in Google Scholar

[36] Talsania, S., J. Pitroda, and C. Vyas. Experimental investigation for partial replacement of cement with waste glass powder on pervious concrete. In International Conference on: Engineering: Issues, opportunities and Challenges for Development, 2015.Search in Google Scholar

[37] Anwar, A. The influence of waste glass powder as a pozzolanic material in concrete. International Journal of Civil Engineering and Technology, Vol. 7, No. 6, 2016, pp. 131–148.Search in Google Scholar

[38] Belouadah, M., Z. E. Rahmouni, and N. Tebbal. Experimental characterization of ordinary concretes obtained by adding construction waste (glass, marble). Procedia Computer Science, Vol. 158, 2019, pp. 153–162.10.1016/j.procs.2019.09.038Search in Google Scholar

[39] Ibrahim, K. I. M. Recycled waste glass powder as a partial replacement of cement in concrete containing silica fume and fly ash. Case Studies in Construction Materials, Vol. 15, 2021, id. e00630.10.1016/j.cscm.2021.e00630Search in Google Scholar

[40] Aliabdo, A. A., M. Abd Elmoaty, and A. Y. Aboshama. Utilization of waste glass powder in the production of cement and concrete. Construction and Building Materials, Vol. 124, 2016, pp. 866–877.10.1016/j.conbuildmat.2016.08.016Search in Google Scholar

[41] Schwarz, N., H. Cam, and N. Neithalath. Influence of a fine glass powder on the durability characteristics of concrete and its comparison to fly ash. Cement and Concrete Composites, Vol. 30, No. 6, 2008, pp. 486–496.10.1016/j.cemconcomp.2008.02.001Search in Google Scholar

[42] Matos, A. M. and J. Sousa-Coutinho. Durability of mortar using waste glass powder as cement replacement. Construction and Building Materials, Vol. 36, 2012, pp. 205–215.10.1016/j.conbuildmat.2012.04.027Search in Google Scholar

[43] Elaqra, H. and R. Rustom. Effect of using glass powder as cement replacement on rheological and mechanical properties of cement paste. Construction and Building Materials, Vol. 179, 2018, pp. 326–335.10.1016/j.conbuildmat.2018.05.263Search in Google Scholar

[44] Shi, C., Y. Wu, C. Riefler, and H. Wang. Characteristics and pozzolanic reactivity of glass powders. Cement and Concrete Research, Vol. 35, No. 5, 2005, pp. 987–993.10.1016/j.cemconres.2004.05.015Search in Google Scholar

[45] Du, H. and K. H. Tan. Properties of high volume glass powder concrete. Cement and Concrete Composites, Vol. 75, 2017, pp. 22–29.10.1016/j.cemconcomp.2016.10.010Search in Google Scholar

[46] Elaqra, H. A., M. A. Abou Haloub, and R. N. Rustom. Effect of new mixing method of glass powder as cement replacement on mechanical behavior of concrete. Construction and Building Materials, Vol. 203, 2019, pp. 75–82.10.1016/j.conbuildmat.2019.01.077Search in Google Scholar

[47] Complexity. Retracted: Application of Linear Regression Mathematical Model in the Evaluation of Teachers’ Informatization Quality, 2023.10.1155/2023/9784010Search in Google Scholar

[48] Willmott, C. J. Some comments on the evaluation of model performance. Bulletin of the American Meteorological Society, Vol. 63, No. 11, 1982, pp. 1309–1313.10.1175/1520-0477(1982)063<1309:SCOTEO>2.0.CO;2Search in Google Scholar

[49] Mohammed, A. S. Vipulanandan models to predict the mechanical properties, fracture toughness, pulse velocity and ultimate shear strength of shale rocks. Geotechnical and Geological Engineering, Vol. 37, No. 2, 2019, pp. 625–638.10.1007/s10706-018-0633-5Search in Google Scholar

[50] Vipulanandan, C. and A. Mohammed. New Vipulanandan failure model and property correlations for sandstone, shale and limestone rocks. In IFCEE 2018, 2018, pp. 365–376.10.1061/9780784481585.036Search in Google Scholar

[51] Mohammed, A. and W. Mahmood. Statistical variations and new correlation models to predict the mechanical behavior and ultimate shear strength of gypsum rock. Open Engineering, Vol. 8, No. 1, 2018, pp. 213–226.10.1515/eng-2018-0026Search in Google Scholar

[52] Code, C. F. M. CEB-FIP model code for concrete structures, euro-international committe for concrete. Bulletin (213/214), 1990.Search in Google Scholar

[53] ACI Committee. Building code requirements for structural concrete (ACI 318-08) and commentary, American Concrete Institute, United States, 2008.Search in Google Scholar

[54] Ahmad, S. H. and S. P. Shah. Structural properties of high strength concrete and its implications for precast prestressed concrete. PCI Journal, Vol. 30, No. 6, 1985, pp. 92–119.10.15554/pcij.11011985.92.119Search in Google Scholar

[55] Arιoglu, N., Z. C. Girgin, and E. Arιoglu. Evaluation of ratio between splitting tensile strength and compressive strength for concretes up to 120 MPa and its application in strength criterion. ACI Materials Journal, Vol. 103, No. 1, 2006, pp. 18–24.10.14359/15123Search in Google Scholar

[56] Gilbert, R. I., N. C. Mickleborough, and G. Ranzi. Design of prestressed concrete to AS3600-2009, CRC Press, 2016.10.1201/b19123Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Nanotechnology for calcium aluminate cement: thematic analysis

- Towards sustainable concrete pavements: a critical review on fly ash as a supplementary cementitious material

- Optimizing rice husk ash for ultra-high-performance concrete: a comprehensive review of mechanical properties, durability, and environmental benefits

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters

- Fe-containing nominal wollastonite (CaSiO3)–Na2O glass-ceramic: Characterization and biocompatibility

- Relevance of pore network connectivity in tannin-derived carbons for rapid detection of BTEX traces in indoor air

- A life cycle and environmental impact analysis of sustainable concrete incorporating date palm ash and eggshell powder as supplementary cementitious materials

- Eco-friendly utilisation of agricultural waste: Assessing mixture performance and physical properties of asphalt modified with peanut husk ash using response surface methodology

- Benefits and limitations of N2 addition with Ar as shielding gas on microstructure change and their effect on hardness and corrosion resistance of duplex stainless steel weldments

- Effect of selective laser sintering processing parameters on the mechanical properties of peanut shell powder/polyether sulfone composite

- Impact and mechanism of improving the UV aging resistance performance of modified asphalt binder

- AI-based prediction for the strength, cost, and sustainability of eggshell and date palm ash-blended concrete

- Investigating the sulfonated ZnO–PVA membrane for improved MFC performance

- Strontium coupling with sulphur in mouse bone apatites

- Transforming waste into value: Advancing sustainable construction materials with treated plastic waste and foundry sand in lightweight foamed concrete for a greener future

- Evaluating the use of recycled sawdust in porous foam mortar for improved performance

- Improvement and predictive modeling of the mechanical performance of waste fire clay blended concrete

- Polyvinyl alcohol/alginate/gelatin hydrogel-based CaSiO3 designed for accelerating wound healing

- Research on assembly stress and deformation of thin-walled composite material power cabin fairings

- Effect of volcanic pumice powder on the properties of fiber-reinforced cement mortars in aggressive environments

- Analyzing the compressive performance of lightweight foamcrete and parameter interdependencies using machine intelligence strategies

- Selected materials techniques for evaluation of attributes of sourdough bread with Kombucha SCOBY

- Establishing strength prediction models for low-carbon rubberized cementitious mortar using advanced AI tools

- Investigating the strength performance of 3D printed fiber-reinforced concrete using applicable predictive models

- An eco-friendly synthesis of ZnO nanoparticles with jamun seed extract and their multi-applications

- The application of convolutional neural networks, LF-NMR, and texture for microparticle analysis in assessing the quality of fruit powders: Case study – blackcurrant powders

- Study of feasibility of using copper mining tailings in mortar production

- Shear and flexural performance of reinforced concrete beams with recycled concrete aggregates

- Advancing GGBS geopolymer concrete with nano-alumina: A study on strength and durability in aggressive environments

- Leveraging waste-based additives and machine learning for sustainable mortar development in construction

- Study on the modification effects and mechanisms of organic–inorganic composite anti-aging agents on asphalt across multiple scales

- Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs

- Structural, physical, and luminescence properties of sodium–aluminum–zinc borophosphate glass embedded with Nd3+ ions for optical applications

- Eco-friendly waste plastic-based mortar incorporating industrial waste powders: Interpretable models for flexural strength

- Bioactive potential of marine Aspergillus niger AMG31: Metabolite profiling and green synthesis of copper/zinc oxide nanocomposites – An insight into biomedical applications

- Preparation of geopolymer cementitious materials by combining industrial waste and municipal dewatering sludge: Stabilization, microscopic analysis and water seepage

- Seismic behavior and shear capacity calculation of a new type of self-centering steel-concrete composite joint

- Sustainable utilization of aluminum waste in geopolymer concrete: Influence of alkaline activation on microstructure and mechanical properties

- Optimization of oil palm boiler ash waste and zinc oxide as antibacterial fabric coating

- Tailoring ZX30 alloy’s microstructural evolution, electrochemical and mechanical behavior via ECAP processing parameters

- Comparative study on the effect of natural and synthetic fibers on the production of sustainable concrete

- Microemulsion synthesis of zinc-containing mesoporous bioactive silicate glass nanoparticles: In vitro bioactivity and drug release studies

- On the interaction of shear bands with nanoparticles in ZrCu-based metallic glass: In situ TEM investigation

- Developing low carbon molybdenum tailing self-consolidating concrete: Workability, shrinkage, strength, and pore structure

- Experimental and computational analyses of eco-friendly concrete using recycled crushed brick

- High-performance WC–Co coatings via HVOF: Mechanical properties of steel surfaces

- Mechanical properties and fatigue analysis of rubber concrete under uniaxial compression modified by a combination of mineral admixture

- Experimental study of flexural performance of solid wood beams strengthened with CFRP fibers

- Eco-friendly green synthesis of silver nanoparticles with Syzygium aromaticum extract: characterization and evaluation against Schistosoma haematobium

- Predictive modeling assessment of advanced concrete materials incorporating plastic waste as sand replacement

- Self-compacting mortar overlays using expanded polystyrene beads for thermal performance and energy efficiency in buildings

- Enhancing frost resistance of alkali-activated slag concrete using surfactants: sodium dodecyl sulfate, sodium abietate, and triterpenoid saponins

- Equation-driven strength prediction of GGBS concrete: a symbolic machine learning approach for sustainable development

- Empowering 3D printed concrete: discovering the impact of steel fiber reinforcement on mechanical performance

- Advanced hybrid machine learning models for estimating chloride penetration resistance of concrete structures for durability assessment: optimization and hyperparameter tuning

- Influence of diamine structure on the properties of colorless and transparent polyimides

- Post-heating strength prediction in concrete with Wadi Gyada Alkharj fine aggregate using thermal conductivity and ultrasonic pulse velocity

- Experimental and RSM-based optimization of sustainable concrete properties using glass powder and rubber fine aggregates as partial replacements

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part II

- Investigating the effect of locally available volcanic ash on mechanical and microstructure properties of concrete

- Flexural performance evaluation using computational tools for plastic-derived mortar modified with blends of industrial waste powders

- Foamed geopolymers as low carbon materials for fire-resistant and lightweight applications in construction: A review

- Autogenous shrinkage of cementitious composites incorporating red mud

- Mechanical, durability, and microstructure analysis of concrete made with metakaolin and copper slag for sustainable construction

- Special Issue on AI-Driven Advances for Nano-Enhanced Sustainable Construction Materials

- Advanced explainable models for strength evaluation of self-compacting concrete modified with supplementary glass and marble powders

- Analyzing the viability of agro-waste for sustainable concrete: Expression-based formulation and validation of predictive models for strength performance

- Special Issue on Advanced Materials for Energy Storage and Conversion

- Innovative optimization of seashell ash-based lightweight foamed concrete: Enhancing physicomechanical properties through ANN-GA hybrid approach

- Production of novel reinforcing rods of waste polyester, polypropylene, and cotton as alternatives to reinforcement steel rods

Articles in the same Issue

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Nanotechnology for calcium aluminate cement: thematic analysis

- Towards sustainable concrete pavements: a critical review on fly ash as a supplementary cementitious material

- Optimizing rice husk ash for ultra-high-performance concrete: a comprehensive review of mechanical properties, durability, and environmental benefits

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters