Abstract

Hot center plant recycling (HCPR) technology has been prioritized as a sustainable and cost-effective solution for asphalt pavement rehabilitation and maintenance due to its environmental and economic benefits. A critical component of HCPR is the preheating of reclaimed asphalt pavement (RAP), which aims at increasing RAP utilization rates and improving the performance of recycled asphalt mixtures. However, either insufficient or excessive preheating temperatures can negatively impact production efficiency and the mechanical properties of hot recycled mixtures containing RAP. This review systematically evaluates current RAP preheating strategies, analyzing their advantages, limitations, and practical implications. Furthermore, it reveals the influences of preheating temperature on the agglomeration and dispersion phenomena of RAP as well as the blending and fusion efficiency between aged and virgin asphalt binders, which are essential for achieving homogeneous recycled mixtures. Additionally, the study identifies relevant performance indicators for RAP and how to establish suitable preheating temperatures based on these indicators. By synthesizing existing research, this article highlights critical knowledge gaps and provides recommendations for future studies, particularly in refining the RAP preheating strategy and determining the optimal preheating temperature range.

1 Introduction

Asphalt pavement distresses, including cracking, rutting, and raveling, adversely impact ride comfort and potentially escalate maintenance costs during its service life. Simultaneously, the recycling and disposal of reclaimed asphalt pavement (RAP) pose significant environmental challenges worldwide [1]. In China, annual road reconstruction and rehabilitation activities generate over 180 million tons of RAP; however, the restricted RAP recycling rate results in substantial solid waste being disposed of in landfills or stockpiled at construction sites [2]. To address this concern, RAP can be combined with virgin aggregates and asphalt binders following pre-treatment processes such as crushing, screening, and preheating, to produce recycled mixtures with enhanced performance. This process, known as asphalt pavement recycling, promotes the utilization of solid waste, supports sustainable infrastructure development, and reduces carbon emissions in the transportation sector, aligning with global trends in environmental protection and energy conservation [3].

Current hot center plant recycling (HCPR) technology faces challenges due to the inherent variability of RAP, which includes key issues such as pseudo aggregate size distribution caused by RAP clustering, inconsistent RAP performance, and insufficient blending between aged and virgin binders [4]. RAP agglomeration not only disrupts aggregate gradation but also impedes the activation of the aged RAP binder trapped within the agglomerates. Furthermore, it has been demonstrated that the binder within RAP exhibits heterogeneous aging characteristics that differ significantly from the properties of virgin binders [4,5]. These factors collectively reduce the recycling efficiency of RAP and compromise the performance of hot-recycled asphalt mixtures. To mitigate the impact of the above-mentioned issues, RAP is typically pretreated through crushing and screening to reduce the gradation variability. In some cases, an asphalt rejuvenator is introduced and blended with the RAP before preheating treatment to restore the properties of the aged binder [6,7].

RAP preheating strategies vary according to the mixing equipment. In continuous mixing plants, RAP is directly mixed with superheated virgin aggregates. While in an intermittent mixing system, RAP is separately preheated before mixing with the virgin aggregates. The appropriate preheating temperature is selected based on various heating techniques and apparatus [8]. To prevent secondary aging of RAP due to excessively high preheating temperatures, the preheating temperature is generally limited to a low level. According to the Technical Specification for Highway Asphalt Pavement Recycling, the preheating temperature for RAP should not exceed 130°C [9]. The National Cooperative Highway Research Program (NCHRP) Report 452 recommends a maximum RAP preheating temperature of 110°C [10]. Additionally, the National Center for Asphalt Technology (NCAT) conducted laboratory tests with various RAP preheating methods, suggesting that RAP should be preheated for a minimum of 30 min and up to a maximum of 3 h at the same target mixing temperature as the virgin aggregate, depending on the amount of RAP incorporated [11]. Therefore, it is essential to select an appropriate preheating technique and temperature range that will not only facilitate the dispersion of RAP clusters but also promote the activation of the aged binder and enhance the blending between virgin and aged binders [12,13].

This review comprehensively examines the effects of preheating temperatures on RAP agglomeration and dispersion, aged binder properties, and the blending efficiency between virgin and aged binders. It also discusses the appropriate preheating temperature range using relevant performance indicators. The objectives of this review are as follows: (1) to summarize the commonly used RAP preheating strategies in HCPR, including indirect and direct heating methods; (2) to analyze the effect of preheating temperature on the clustering and dispersion characteristics of RAP; (3) to examine the impact of preheating temperature on the secondary aging and activation of the aged binder, as well as the evaluation methods; (4) to provide an overview of the optimal preheating temperature for achieving effective blending between virgin and aged binders, along with a summary of the widely used techniques for evaluating the degree of blending (DOB); and (5) to propose future research directions regarding the RAP preheating methods and temperatures. The logical framework of this review is illustrated in Figure 1.

Logical relationship.

2 Description of RAP preheating methods

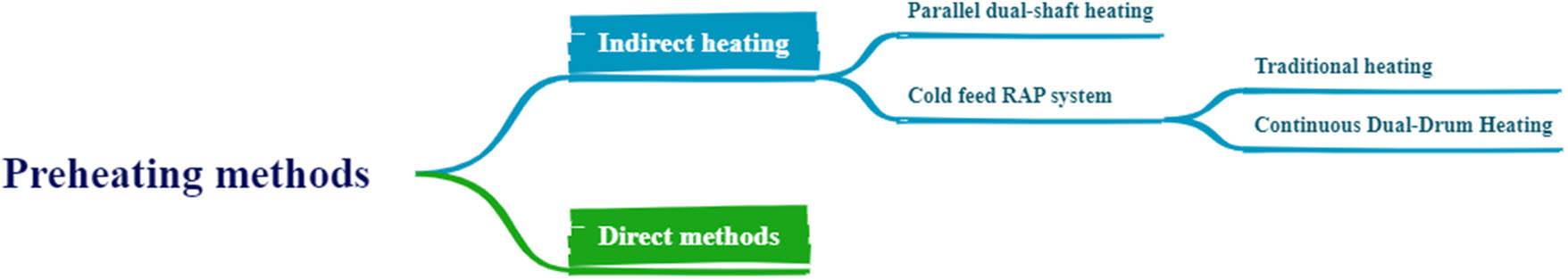

One of the primary challenges in binder thermal recycling technology is the preheating treatment of RAP. The main targets of RAP preheating are to (1) elevate the temperature of RAP to facilitate the dispersion of agglomerated RAP particles, (2) partially restore the rheological performance of aged binders, (3) promote fusion with the virgin binder, and (4) ultimately produce recycled asphalt mixtures with performance comparable to that of conventional asphalt mixtures [14]. The selection of heating equipment significantly influences the preheating temperature of RAP, as different systems exhibit distinct thermal efficiencies, heat transfer mechanisms, and risks of secondary aging. This study categorizes RAP heating methods into two distinct approaches: direct heating and indirect heating (Figure 2).

Preheating methods.

2.1 Direct heating

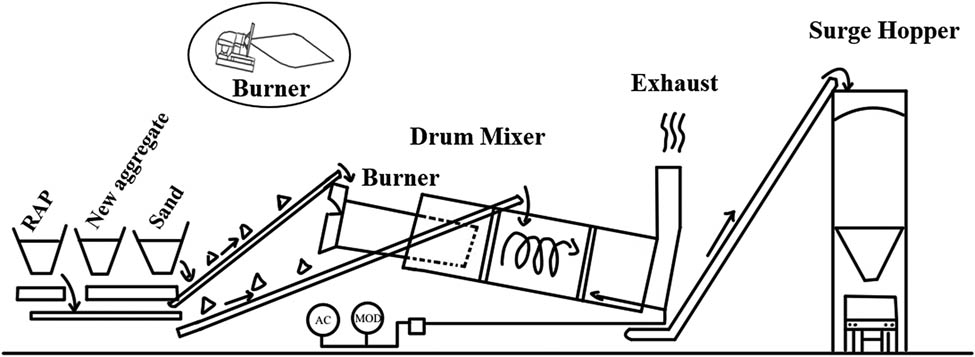

Direct heating is accomplished using a rotary drum mixer that contains a burner at one end. The aggregates are fed into the burner end of the drum mix plant, then move along the length of the rotating drum under gravity. When RAP is exposed to the open flame during the heating process, it enables rapid temperature elevation but may produce blue smoke due to localized overheating and binder degradation. As shown in Figure 3, a thermal screen and an extra cooling air unit are commonly mounted on the upper side of this equipment to mitigate its environmental impact [15]. In the United States, this technique was initially gained widespread application in Texas and Arizona [16].

Drum mixer with heat dispersion shield.

The drum-in-drum method is an advanced adaptation of the direct heating technique in asphalt production, featuring the installation of a smaller drum at the entrance of the rotary drum mixer. In this method, virgin aggregates are first preheated in the smaller drum, then the preheated virgin aggregates are transferred to the main mix drum, where the RAP is introduced through a feed chute. The two materials are mixed before undergoing further heating, as depicted in Figure 4. Despite the staged heating, the design of the main drum may still expose RAP to direct contact with the burner flame during secondary heating, leading to carbonization of the RAP binder [16].

Drum-within-a-drum plant.

2.2 Indirect heating

Indirect heating methods avoid direct flame contact with RAP during the thermal mixing process of RAP and virgin aggregates, which alleviates binder carbonization and gas emission. In this approach, heat is transferred through the drum walls to the material inside, allowing for uniform heating of the materials. Indirect heating mainly includes parallel dual-shaft heating and a cold feed RAP system.

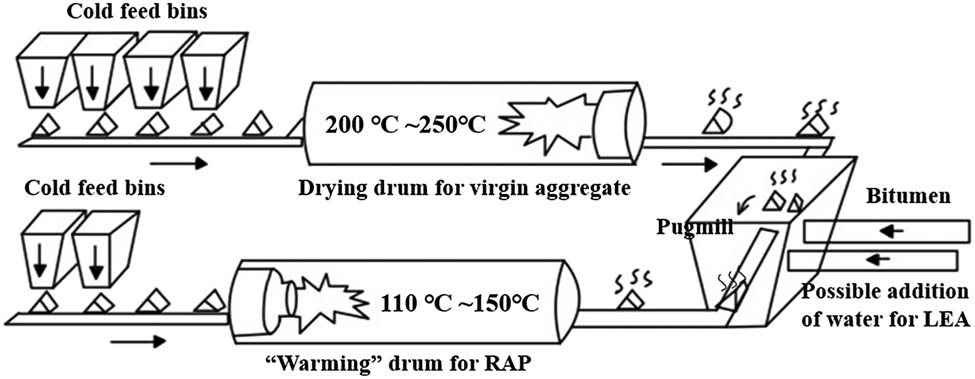

2.2.1 Parallel dual-shaft heating

In the parallel double-shaft heating process, virgin aggregates and RAP are heated in separate cylinders, ensuring optimal heating conditions for each material before mixing. The preheating temperature range of RAP is between 110 and 150°C, while the virgin aggregate is superheated to a temperature range of 200–250°C (Figure 5) [17]. Each cylinder has independent temperature regulation, allowing adjustments based on material properties and RAP content to meet specific heating requirements. Once both materials have reached their target temperatures, they are transported to the main mixing drum for blending. The dual-cartridge heating system design enables precise temperature control and separate processing of different components, which optimizes the thermal recycling process and enhances the quality and productivity of recycled asphalt mixtures. Currently, this type of heating apparatus is widely used in Germany and Northern Europe. This particular portable dual-shaft heating system supports both hot mix asphalt (HMA) and warm mix asphalt (WMA) production containing high RAP concentrations (>50%).

Parallel dual-shaft heater.

2.2.2 Cold feed RAP system

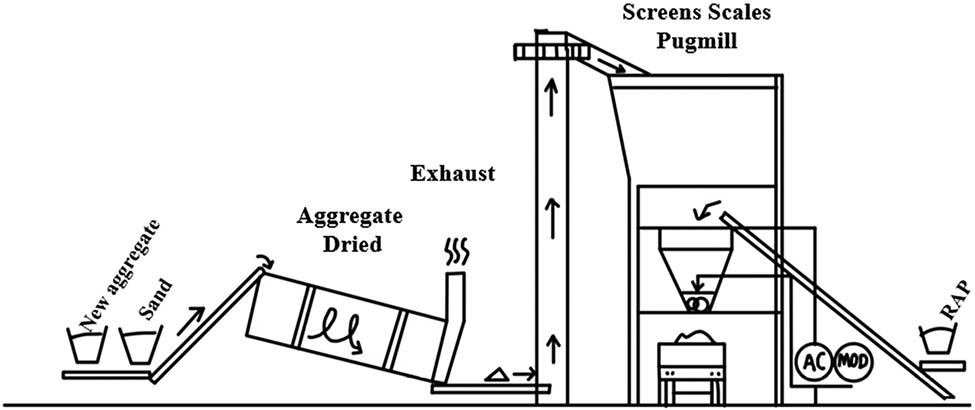

2.2.2.1 Traditional heating

The most common technique for cold RAP processing is moving the RAP batch to a hopper bin using a conveyor belt while heating the virgin aggregate to temperatures that are much higher than those utilized in conventional HMA, usually ranging from 150 to 260°C. A conveyor belt then transports the heated aggregates to the pugmill, where the heat transferred from virgin aggregates can be used for restoring the cohesion and fluidity of RAP binder (Figure 6). However, it is crucial to avoid excessively high heating temperatures for virgin aggregates because this might result in operational problems like the possibility of burning the baghouse in drum plants or producing too much steam and moisture in batch plants [18]. Furthermore, the rapid heating of RAP at high temperatures may cause carbonization of the aged binder, which impairs the performance of the recycled asphalt mixture [19]. Some research has indicated that the heating temperature of virgin aggregates should not be dropped by more than 30°C when the RAP content is increased by 5%. As a result, the proportion of RAP added in this heating method is often restricted [20,21].

Standard batch plant with old mix added to superheated aggregates at the pugmill.

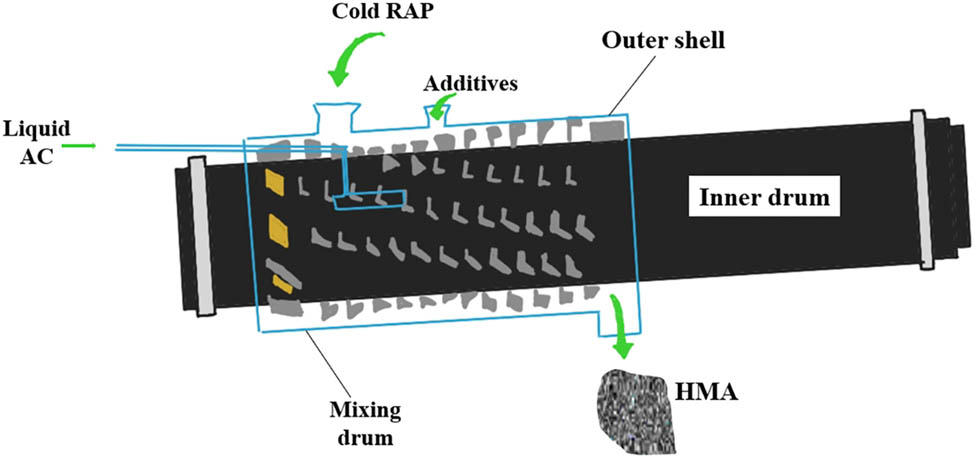

2.2.2.2 Continuous dual-drum heating

In the continuous double drum heating method, materials move continuously through the heating zone rather than being processed in batches. The drier drum is a highly sophisticated piece of equipment utilized for the production of hot mix recycled asphalt materials (HMRAM) containing RAP [22]. In this process, cold aggregates are first dried and heated inside the inner drum, and then discharged through an opening in the inner drum wall at the burner end. It then enters the mixing chamber, which is formed between the inner cavity of the outer drum and the outer diameter of the inner drum. In the mixing chamber, RAP and additives are introduced through the inlet of the fixed shell to blend with the heated aggregates. As illustrated in Figure 7, this type of double drum system has a stationary outer shell, whereas the inner cylinder is equipped with stirring paddles on its outer wall, which can rotate with the inner cylinder to continuously stir the mixture [23]. The dried virgin aggregate comes into contact with both the inner and outer walls of the RAP drum. The air temperature inside the inner drum can reach up to 760°C, while the temperature at the entrance of the exhaust filter is around 115°C [24]. The regenerative heating process is depicted in Figure 8. The primary mechanism of heat transfer is through the superheated aggregate, accounting for approximately 90% of the total heat transfer, with the remaining 10% resulting from heat conduction through the inner shell and mixing vanes [25,26]. The heat transmission helps break up larger RAP clusters [26], promotes the aggregation of fine RAP particles [27], and stimulates RAP binder activation [24,28,29]. The use of continuous dual-drum heating is highly efficient, as RAP is agitated within the cavity from the outer end of the burner, which prevents direct contact between RAP and the open flame, therefore, reducing the carbonization of the binder and enhancing the utilization rate of RAP.

Double drum.

Thermal conditioning process of RAP within a continuous dual-drum binder plant.

A comprehensive comparison of the aforementioned heating methods is presented in Table 1. Direct heating of RAP can lead to secondary aging of the binder and air pollution due to the presence of aged binder and its direct exposure to open flames. Additionally, the direct heating method is associated with low RAP utilization rates. Therefore, in many regions within the United States, superheated virgin aggregates combined with cold RAP remains a common practice [16]. It not only minimizes the over-aging of RAP binders but also contributes to energy conservation and environmental protection. In contrast, indirect heating techniques are now widely implemented in Europe, including France [17], the Netherlands [30], Belgium [31], etc. [32,33]. The utilization of indirect heating avoids the adverse effects of aged binder carbonization that are typically associated with direct heating of RAP. Under the same mixing conditions, this approach proves to produce recycled asphalt mixes with better performance compared to the direct heating method.

Comparison of different heating methods

| Preheating | Direct heating | Indirect heating | ||

|---|---|---|---|---|

| Parallel dual-cylinder heating | Cold feed RAP system | |||

| Traditional heating | Continuous dual-drum heating | |||

| Advantages |

|

|

|

|

| Disadvantages |

|

|

|

|

In summary, various preheating procedures have been reported, each associated with distinct heating equipment and specific preheating temperatures. The energy consumption of different preheating technologies varies based on practical production estimates. The two most commonly used heating systems are parallel dual-cylinder heating and continuous dual-drum heating. The parallel dual-cylinder heating method is capable of efficiently mixing RAP material and allows for the separated heating of aged and virgin materials. However, this approach is associated with high energy consumption and increased production costs. On the contrary, the continuous dual-drum heating system, featuring stirring blades attached to the outer wall in the inner cylinder, facilitates the heating of the aged material and the rolling motion of the surrounding RAP when the inner cylinder rotates. This process prevents RAP from clumping together and reduces its variability. Nevertheless, the excessively high heating temperature required for virgin aggregates by this equipment can negatively affect the performance of the aged binder, which in turn affects the overall mixture performance afterwards. Hence, future heating equipment should incorporate intelligent systems that are capable of dynamically adjusting the appropriate preheating temperatures based on specific material characteristics, RAP content, and minimal energy consumption requirements.

3 Effect of preheating temperature on the cluster and dispersion properties of RAP

Various preheating techniques are associated with specific heating apparatus and regulated preheating temperatures. These factors collectively influence the properties of RAP material, including phenomena such as particle clustering and the uniformity of dispersion. During the recycling process of old pavements, RAP tends to form substantial clusters, primarily due to the bonding effect of the aged binder [34]. Previous studies have indicated that when a rejuvenator is added directly into the RAP at a proportion ranging from 10 to 50% of the total mass of the aged binder, it requires 48–144 h for the rejuvenator to fully permeate into the RAP [35]. This finding suggests that if the RAP materials are not adequately dispersed during the plant-mixed hot recycling process, the binder within the clusters cannot be effectively reactivated, leading to insufficient bonding between the virgin and aged binders. Consequently, the recycled asphalt mixture is likely to exhibit poor performance. Therefore, the preheating treatment of RAP plays a significant role in efficiently addressing the issue of agglomeration in RAP and guarantees its complete integration with the virgin material.

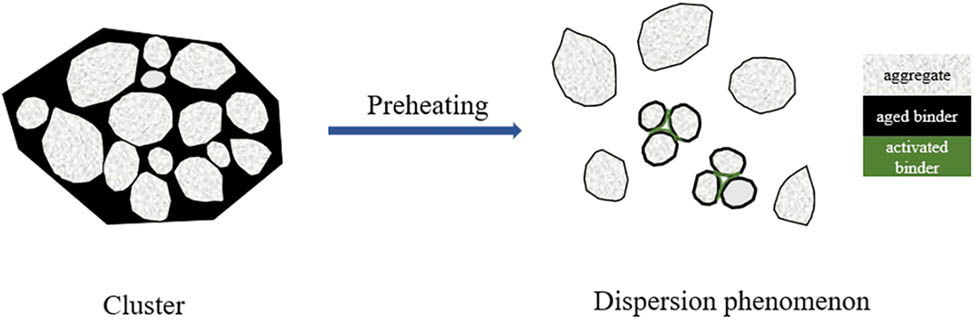

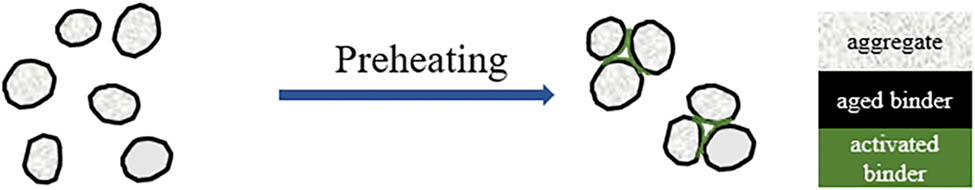

Effective preheating can prevent the formation of particle agglomerations in RAP since the aged binder is sensitive to temperature change. Ma et al. [36] investigated the effect of different preheating temperatures on dispersing the agglomerates in RAP through the evaluation of the cohesive force and internal friction angle using a triaxial shear test. The results revealed that adequate preheating treatment can effectively enhance the fluidity of the aged binder and aid its redistribution within the RAP, thus improving the dispersion of RAP material (Figure 9). Furthermore, the study identified that a minimum temperature of 130°C is required to achieve adequate dispersion of RAP.

Thermally induced dispersion of aggregate clusters in RAP.

In addition, other studies demonstrated that RAP preheating promotes the adhesion of small particles by activating the viscous properties of the aged binder. Bressi et al. [4] examined the agglomeration process of smaller aggregates forming larger clusters at a preheating temperature of 135°C. The results indicated that the aggregation of RAP is influenced by both temperature and RAP content; a higher RAP content leads to more pronounced agglomeration phenomena. These findings are consistent with those of Wan et al. [37], who found that increasing the preheating temperature is beneficial for the dispersion of RAP. However, excessively high preheating temperatures may induce bonding between the aged binders, resulting in the RAP particles agglomerating again, which hinders the dispersion of RAP (Figure 10).

Secondary cluster phenomenon of aggregates.

Furthermore, Roberto et al. [38] employed digital imaging technology to analyze the relationship between the concentration area of deformation and the positioning of aggregate and RAP clumps. This was achieved by integrating the outcomes of homogeneity image analysis (HIA) and digital image correlation (DIC) through overlap analysis [39,40]. Their study found that RAP has a greater abundance of smaller cross-sections after preheating, which promotes the dispersion of RAP clusters and improves the mix’s resilience to cracking. Therefore, it is essential to carefully regulate the preheating temperature to ensure the effective dispersion of RAP and to achieve the optimized performance of HMRAM. By precisely controlling the RAP preheating temperature, the occurrence of RAP clumping can be significantly reduced, thus decreasing the amount of “black rock” in HMRAM, which is crucial for enhancing the mechanical performance of the recycled asphalt mixture.

In summary, changing the RAP preheating temperature not only helps to break the large agglomerates but also can cause the small-size aggregates to bond together, forming a secondary RAP clumping phenomenon. The former effect is beneficial for reducing the variability of RAP materials, while the latter effect is detrimental to mixture uniformity. Based on the literature mentioned above, researchers have employed different RAP materials and conducted experiments to determine the optimal temperature range for achieving effective RAP dispersion. Nonetheless, it is worth considering both agglomeration and dispersion phenomena that occur simultaneously during the heating process. It is likely that a critical temperature threshold exists at which the dominance shifts from dispersion to secondary agglomeration. When the temperature reaches this specific value, RAP dispersion is optimized, but as the temperature continues to increase, the secondary agglomeration phenomenon may become more pronounced, potentially offsetting the benefits of preheating. Currently, there is limited research on the preheating temperature of RAP and its effects on agglomeration and dispersion characteristics. Future research should focus on a more comprehensive analysis of the relationship between preheating temperature and understanding the agglomeration behavior of RAP. Additionally, it is crucial to establish the correlations between preheating temperature and agglomeration characteristics, as well as to develop quantitative evaluation indices for identifying optimal preheating temperature ranges. These efforts would help reduce the variability of RAP and enable the production of recycled mixtures with more consistent and improved performance.

4 Effect of RAP preheating temperature on aging and activation of aged binder

4.1 Methods for evaluating aging and activation of binder

Over time, asphalt binder undergoes oxidation, volatilization, and other physicochemical changes due to environmental exposure. These changes result in significant alterations in its macroscale performance and microstructure. At the macro level, the aged binder exhibits properties of decreased ductility and penetration, increased softening point and viscosity, as well as physical hardening and brittleness. Under microscopic examination, the composition of aged binder changes, marked by a reduction in lighter components and an accumulation of carbonyl (C═O) and sulfoxide (S═O) in the chemical compounds [41]. The preheating temperature of RAP can directly affect the properties of aged asphalt during the thermal recycling process at the plant. Research has shown that preheating RAP can reactivate the aged binder, therefore improving the performance of recycled asphalt mixtures [24,28,29], However, most studies have solely focused on the effect of preheating temperature on activating the aged asphalt, without considering the potential secondary aging caused by excessive heating. Moreover, the combined impact of RAP aging and activation on recycled mixtures’ performance remains insufficiently explored [42].

The purpose of this section is to provide a concise overview of the existing methodologies applied for assessing the aging and activation of aged binders. According to the recycling specification (JTG/T 5521-2019), the evaluation of asphalt aging primarily relies on several key parameters, which are penetration (25°C, 100 g, 5 s), softening point, and ductility at 15°C [9]. These parameters reflect the macroscopic changes in the physical properties of asphalt binder. In addition, advanced microscale analytical techniques, such as gel permeation chromatography (GPC) coupled with Fourier-transform infrared spectroscopy (FTIR), can be used to investigate the changes in the functional groups of asphalt binders. The extent of binder aging can be quantified by measuring the carbonyl index (CI) and sulfoxide index (SI) derived from FTIR spectra [43].

Beyond aging evaluation, several methods have been proposed to characterize the activation of aged asphalt at different preheating temperatures. Menegusso Pires et al. [44] introduced a method to assess the level of aged asphalt activation under various preheating temperatures, which involves performing cohesion and indirect tensile tests on 100% RAP mixture samples. Furthermore, they proposed a formula to calculate the degree of activation (DOA) of the aged asphalt. Sreeram and Leng [45] conducted a comparative analysis of the carbonyl content in asphalt at different stages of aging. Based on the Attenuated total reflectance-Fourier transform infrared (ATR-FTIR) spectral analysis, they suggested that the carbonyl content could serve as an indicator of the activation level of aged asphalt.

More recent research has attempted to conduct quantitative analysis by integrating the aging process of asphalt binder and aged binder activation under various preheating temperatures. A new index, the activation-aging index (IAA), has been introduced to quantify the combined effects of activation and secondary aging [46]. This index provides a comprehensive understanding of how preheating temperatures affect the performance of aged asphalt, facilitating the determination of the optimal preheating temperature by considering both aging and activation effects. It also offers a novel perspective for further research in this field. Table 2 summarizes the current techniques and indicators used to evaluate the aging and activation of asphalt [38,43,46,48,50,51].

Methods for evaluating the aging and activation of asphalt

| Testing indicator | Testing methods | Evaluation indicator | Evaluation methods | Ref. |

|---|---|---|---|---|

| Aging | Fourier-transform infrared spectroscopy (FTIR) | CI |

|

Zhang et al. [43]1 |

| SI |

|

de Sá Araujo et al. [47] | ||

| Aging | Gel permeation chromatograph (GPC) | Large molecule size percentage (LMSP) | Assess the aging condition of asphalt based on the content of LMSP | Li et al. [48] |

| Zhao et al. [49] | ||||

| Aging | Nuclear magnetic resonance (NMR)/spectroscopy | Variation in the content of naphthenic aromatics | The aged asphalt shows a reduction in the quantity of naphthenic aromatics and an increase in asphaltenes | Siddiqui et al. [50] |

| X-ray diffraction (XRD) | ||||

| Aging | Atomic force microscopy (AFM) | AFM phase imaging (beelike structure); | The aging of asphalt leads to a reduction in the number of microcells and a decrease in surface roughness | Wang and Liu [51] |

| Surface roughness | Yu et al. [52] | |||

| Activation | Overlap image analysis (OIA) | Coverage of old and new asphalt | Combined with HIA and DIC technologies, OIA analyzed the initiation and propagation patterns of cracks, assessing the relationship with the degree of reactivation | Roberto et al. [38] |

| Activation | Cohesion test | DOA |

|

Menegusso Pires et al. [44]2 |

| Aging-activation | Gel permeation chromatograph (GPC) | Aging index (

|

|

Meng et al. [46] |

| Activation index (

|

|

|||

| Aging-activation index (

|

|

Note: 1

4.2 Estimation of the preheating temperature for RAP based on aging and activation of aged binder

The “preheating activation” phenomenon occurs during the preheating stage of RAP, wherein the incorporation of rejuvenators has been shown to effectively stimulate the activation of aged binders [53,54]. During this process, the aged asphalt becomes softer as its viscosity decreases and rheological properties are restored. These changes are directly associated with the physical and chemical transformations that happen when the aged asphalt is heated, which significantly affects the performance of HMRAM [55]. Roberto et al. [38] conducted a comparative study on the rejuvenation of aged asphalt under two different conditions: preheating at 150°C and no preheating (25°C). According to the digital image analysis, the preheated aged asphalt at 150°C exhibited more effective reactivation, leading to recycled mixtures with enhanced cracking resistance. This finding provides important empirical evidence for selecting the appropriate preheating temperature of RAP. Moreover, Meng and Liu [56] investigated the impact of varied preheating settings on 100% RAP mixtures and reported that higher preheating temperatures promoted the activation of aged asphalt binders, thereby reducing the void ratio within the specimens and improving the indirect tensile strength of the RAP mixtures.

However, existing research suggests that RAP may experience additional aging during the preheating process, which is directly correlated with the preheating temperature of RAP. Once the preheating temperature exceeds a specific threshold, the secondary aging of asphalt binders may occur in the preheated RAP, which negatively affects the performance of the recycled mixture [57]. This finding implies that when selecting the preheating temperature for RAP, it is crucial to consider not only the activation effect of the aged asphalt but also the prevention of additional aging caused by an excessively high-temperature environment.

Based on these experimental results, recommendations regarding optimal preheating temperatures for RAP have been proposed. Table 3 provides a summary of these findings and offers guidance on selecting the most appropriate preheating temperatures for RAP by considering both aging and activation indexes. However, the suggested optimal preheating temperature may vary between methods due to the differences in the properties of the raw materials used. Overall, most studies suggest that the suitable preheating temperature falls within a range from 120 to 160°C.

The impact of different preheating conditions on the aging or reactivation of aged asphalt

| Ref. | Testing indicators | Testing methodology | Preheating temperature (°C) | Preheating duration (h) | Results |

|---|---|---|---|---|---|

| Wu et al. [57] | Viscosity | Viscosity-temperature curve methodology | 110∼140 | N/A |

|

| Campher [53] | Air voids; indirect tensile strength | Cohesion test | 20/75/100 | N/A |

|

| Meng and Liu [56] | DOA | Fourier-transform infrared spectroscopy (FTIR); gel permeation chromatograph (GPC) | 120/150/180 | 2 |

|

| Roberto et al. [38] | Coverage of old and new asphalt | Overlap image analysis (OIA) | 25/150 | 2 |

|

| Menegusso Pires et al. [44] | DOA | Cohesion test | 70∼170 | N/A |

|

| Meng et al. [46] | Aging activation index (

|

Gel permeation chromatograph (GPC) | 110∼190 | 2 |

|

| Liu et al. [58] | DOA | Fourier-transform infrared spectroscopy (FTIR); bending beam rheometer (BBR) test | 90∼180 | 2 |

|

Currently, various technical methods are employed to assess the aging level and reactivation degree of asphalt. However, most studies have primarily focused on analyzing the impact of preheating temperature on either the aging process of fresh binder or the activation of RAP binder in isolation. In practice, both the abovementioned phenomena may occur during the RAP preheating process, especially when the temperature approaches or exceeds a certain threshold. Therefore, in future research, it is recommended to integrate the activation and aging indicators to quantitatively examine the combined effects of aging-activation characteristics of aged asphalt under different preheating temperatures. It is essential to determine the relationship between these indicators and the preheating temperature, as well as to verify the performance of recycled mixtures under various aging-activation situations. In essence, this approach aims at establishing an appropriate range of preheating temperatures to produce recycled mixtures with more stable and superior performance.

5 Effect of RAP preheating temperature on blending and fusion of virgin and aged binder

5.1 Methods for evaluating blending and fusion of virgin and aged binder

The aging and activation of RAP significantly impact the blending and fusion of the virgin and aged asphalt binder, which ultimately influences the overall performance of the recycled asphalt mixture. Analysis of RAP aging and activation primarily focuses on examining the effect of preheating temperature on RAP performance. Meanwhile, the DOB serves as an indicator that reflects the extent of diffusion and fusion between virgin and aged asphalt binders. A variety of methodologies have been developed to assess the DOB between virgin and aged asphalt binders.

In terms of the macroscale performance, Wu et al. [59] employed the dynamic shear rheometer (DSR) to measure the complex shear modulus of the asphalt binder sample, which was used to determine the DOB between virgin and aged asphalt using a defined formula. Additionally, to quantify the DOB in recycled mixtures, Zhang and Chen [60] conducted a study to establish a calibrated blending curve that elucidates the relationship between air void fraction and effective asphalt content (EAC). Then, they fabricated virgin mixes with different asphalt contents to simulate the different blending levels of recycled HMAs, after which the EAC of recycled HMAs could be back-calculated based on the measured air void fraction and the calibrated curve. The corresponding DOB values were then determined using the equation presented in Table 4. Moreover, the blending level between virgin and aged asphalt can be assessed by comparing the dynamic modulus of recycled mixtures with the dynamic modulus values that were anticipated by RAP properties [67,68]. Beyond quantitative indices, several studies have also performed qualitative evaluation on the DOB between virgin and aged asphalt, particularly with respect to the blending effectiveness achieved in plant-mixed hot-recycled mixtures [62,64,66]. A concise overview of these macroscopic methodologies is provided in Table 4.

Summary of macroscopic testing methods

| Testing methods | Evaluation indicator | Evaluation methods | Ref. |

|---|---|---|---|

| Dynamic shear rheometer (DSR) | The complex shear moduli (G *) |

|

Wu et al. [59]1 |

| Cai et al. [61] | |||

| Indirect tensile test/dynamic modulus test/creep compliance test | Dynamic modulus test/creep compliance test | Indirectly reflecting the DOB of virgin and aged asphalt through the performance of the mixture | Zhang and Muhunthan [62] |

| Lakshmi Roja et al. [63] | |||

| Semi-circular bending (SCB) | Fracture toughness (K)/fracture energy (G) | Indirectly reflecting the DOB of virgin and aged asphalt through the crack resistance performance of the mixture | Stimilli et al. [64] |

| Wen and Zhang [65] | |||

| Softening rate test (SRT) | Softening time | The measurement is the duration required for the aged asphalt sample to undergo softening and elongation towards the bottom due to the influence of the rejuvenator | Wang et al. [66] |

| A short duration suggests that the rejuvenator effectively mixes with the aged asphalt, indicating good blending capabilities | |||

| Calibrated blending curve | Air voids |

|

Zhang and Chen [60]2 |

Note: 1

Although macroscopic evaluation approaches may appear straightforward, their reliability can be compromised by various external factors, such as the accuracy of empirical equations or models, which are frequently used in the subsequent analysis process after collecting laboratory and field test results. Also, the variability in macroscopic results derives from the inherent inconsistency due to mixture inhomogeneity and inconsistent specimen preparation. Therefore, to address the limitations associated with macroscopic testing techniques, there has been a rapid development in microscopic characterization methods for assessing the blending mechanism between virgin and aged asphalt binders. Zhao et al. [69] pioneered a staged binder extraction approach where the blended asphalt was separated from the RAP aggregate surface layer-by-layer by controlling the time as well as the number of solution immersions, and it was possible to collect bitumen obtained from the same film thickness. The DOB was evaluated by analyzing the large macromolecule size percentage parameter of each layer using gel permeation chromatography (GPC). Vassaux et al. [70–72] employed ATR-FTIR to explore the impact of variables such as preheating temperature and RAP content on the DOB between virgin and aged asphalt. They proposed a method to quantitatively characterize DOB by measuring the area of the spectral curve peak corresponding to the C═O functional group in the blended region. Subsequently, numerous studies have been carried out to examine the extent of the blending between virgin and aged asphalt at a microscopic level, utilizing methods such as atomic force microscopy (AFM) and molecular dynamics simulations. Various techniques for assessing the microscopic blending of virgin and aged asphalt have been reported in multiple studies [28,35,73–78]. A summary of representative findings is displayed in Table 5.

Summary of microscopic testing methods

| Testing methods | Evaluation indicator | Evaluation methods | Ref. |

|---|---|---|---|

| Gel permeation chromatography (GPC) | Large molecular size (LMS%) |

|

Zhao et al. [69]1 |

| Ding et al. [79] | |||

| Atomic force microscopy (AFM) | AFM phase imaging (beelike structure) | Atomic force microscopy can differentiate between the fusion and transition regions of virgin and aged asphalt, hence providing insight into the extent and level of blending | Nazzal et al. [74] |

| Li et al. [80] | |||

| FTIR-ART | Diffusion coefficient | The detection of diffusion via a thin film involves quantifying the alteration in absorbance at certain wave numbers associated with the diffusing substances, hence determining the diffusion coefficient | Karlsson and Isacsson [35] |

| Scanning electron microscopy (SEM) | Index of diffusion degree (IOD) |

|

Li et al. [81]2 |

| Molecular dynamics (MD) | Inter-diffusion coefficient/fracture energy | Elevating the temperature leads to an augmentation in the interdiffusion coefficient of asphalt binder | Cui et al. [82] |

| An increase in molecular bond dissociation energy correlates with an enhanced degree of commingling within the asphalt mixture | Xu and Wang [83] |

Note: 1

When selecting a technique to assess the DOB between virgin and aged asphalt, each method possesses specific advantages and limitations. For example, DSR can accurately replicate the rheological characteristics of asphalt under service conditions, but requires sophisticated and expensive instrumentation. Conversely, microscopic techniques such as AFM and GPC can provide molecular-level insights into the blending region, allowing for a more comprehensive understanding of the fusion mechanism between virgin and aged asphalt. However, these methods usually involve more complex procedures and meticulous sample preparation. Therefore, in practical applications, researchers must carefully select appropriate methodologies and indicators by balancing the experimental objectives, experimental equipment availability, budget constraints, and desired resolution of results.

5.2 Estimation of preheating temperature of RAP based on blending of virgin and aged asphalt

During the design phase of plant-mixed hot recycled mixes, the aged asphalt is “activated” by either heating RAP or by adding a rejuvenator. This procedure enables the aged binder to be blended effectively with the virgin binder. However, the recycling process can lead to significant cluster formation, which can impede the complete binder fusion [84]. McDaniel and Anderson proposed three hypotheses regarding the fusion of virgin and aged asphalt [10,85]: (1) no blending, resembling the “block rock,” where RAP acts purely as an aggregate substitute in the recycled mixture and the aged binder remains inactive (Figure 11); (2) partial blending, in which the outer layer of the aged asphalt is activated and undergoes a process of fusion with the virgin asphalt, while the inner layer of aged asphalt remains unchanged; and (3) complete blending, where the aged asphalt is fully activated, exhibiting comparable fluidity to those of the virgin asphalt (Figure 12). The extent of fusion between the virgin and aged asphalt is influenced by several factors, including the addition of the rejuvenator, the preheating temperature of RAP, and the thickness of the binder layer on the surface of RAP aggregates [86,87].

Black rock model. (a) Type II, and (b) Type I.

Blending and diffusion phenomenon of aged and virgin asphalt. (a) No blending, (b) partial blending, and (c) complete blending.

Recent studies have demonstrated that the preheating temperature of RAP plays a crucial role in the fusion of virgin and aged asphalt. Meng et al. [46] found that variations in preheating temperatures affect the properties of RAP, which subsequently impacts the workability and fracture resistance of HMRAM. Their research also identified a positive correlation between preheating temperatures and the activation of aged binder within RAP across different RAP types. Moreover, optimal preheating temperatures enhance binder diffusion, resulting in a higher DOB between virgin and aged asphalt [88]. Hence, it is crucial to carefully control the preheating temperature of RAP.

Wu et al. [59] emphasized that the preheating temperature of RAP is a critical factor influencing the transfer of aged asphalt binder to the surface of virgin aggregates and ensuring more thorough mixing between virgin materials and RAP. Their experimental findings indicated that elevating the preheating temperature of RAP enhances the fusion level between the aged and virgin asphalt, which in turn improves the resistance to low-temperature cracking and the fatigue performance of HMRAM. Similarly, Zhang and Chen [60] observed that raising the RAP preheating temperature positively impacts the blending of virgin and aged binders, which directly contributes to improved performance in recycled mixtures. These studies suggest that the precise temperature during RAP preheating can maximize the performance of recycled mixtures and potentially extend the circular service life of asphalt pavements.

Chen and Zhi [89] discovered a positive correlation between both the preheating temperature and time of RAP and the DOB between virgin and aged asphalt. Their findings suggest that a higher preheating temperature and a longer preheating time promote fusion occur between the virgin and aged binder. Zhou et al. [90] demonstrated that an elevated preheating temperature promotes greater diffusion of the aged binder, leading to improved blending with virgin asphalt.

Wang et al. [91] proposed a series of ideal solutions based on an optimization analysis using an orthogonal test. These solutions focused on the ideal conditions for RAP preheating temperature, RAP dosage, and rejuvenator dosage, all of which are crucial factors for achieving a better blending between virgin and aged binders. This research provides practical guidance for the design and construction of recycled asphalt mixtures, facilitating efficient pavement waste utilization and promoting sustainable life-cycle asphalt pavement recycling.

Xu et al. [92] measured the complex modulus of binder samples using DSR under various blending conditions of virgin and aged asphalt binder. Their findings indicated a significant relationship between the DOB parameter and the cracking and fatigue characteristics of HMRAM. This relationship is also affected by the proportion of RAP incorporated into the mixture [93]. Stephens et al. [94] noted that a longer preheating time of RAP is necessary to enhance the DOB when at higher RAP contents, which resulted in increased unconfined compressive strength and splitting strength of the HMRAM.

Overall, these findings suggest that quantitative analysis of the activation-fusion behavior of virgin and aged binders in RAP mixtures is essential. Evaluating a fusion index or DOB indicator offers a systematic method to determine the optimal preheating temperature range for RAP. This approach enables a more precise specification of the required preheating temperature, thereby improving RAP utilization. This section provides a comprehensive analysis and overview of the behavior of virgin and aged asphalt fusion at various preheating temperatures, as summarized in Table 6. These findings indicate that an appropriate increase in preheating temperature can significantly enhance the blending effectiveness. However, it is important to avoid excessively high temperatures to prevent secondary aging of the asphalt binder and associated detrimental effects.

Blending conditions of aged and virgin asphalt at different preheating

| Ref. | Preheating temperature (°C) | Preheating duration (h) | Factors | Results |

|---|---|---|---|---|

| Wang et al. [95] | 100–140 | 2 | DOB; pavement performance of HMRAM |

|

| Ma et al. [36] | 100–120 | 2 | Compaction energy ratio (CER); pavement performance of HMRAM |

|

| He and Jia [96] | 135–165 | — | Air voids; DOB |

|

| Wu et al. [59] | 100–140 | 2 | DOB; fatigue performance of HMRAM |

|

| Wang et al. [91] | 100/120/140 | — | Pavement performance of HMRAM |

|

| Zhang and Chen [60] | 60/110/160 | 2 | DOB; pavement performance of HMRAM |

|

In conclusion, determining the optimal temperature range for RAP preheating based on the DOB between aged and virgin asphalt is a highly effective strategy. Most studies have quantified the DOB between aged and virgin asphalt and demonstrated that mixing temperature significantly affects the blending efficiency. Moreover, the DOB between aged and virgin asphalt is positively correlated with the performance of HMRAM. Nevertheless, there is a scarcity of studies linking the connection between the extent of blending and fusion directly to the preheating temperature of RAP materials. Therefore, further studies are needed to identify additional parameters that characterize the DOB between aged and virgin asphalt and to establish a clear correlation between the RAP preheating temperature and these parameters. Such research would enable more accurate detection of blending levels and facilitate the preliminary selection of an optimal preheating temperature range for RAP.

6 Conclusions

In recent decades, the extensive use of RAP in hot in-plant recycling has substantially contributed to the sustainable development of the pavement industry. A comprehensive investigation has been conducted to achieve improved pavement performance through the incorporation of RAP. However, the extent to which the preheating temperature of RAP affects the properties of recycled asphalt mixtures has not been fully addressed. This article aims to provide a summary of various RAP preheating methods, analyze the effects of different preheating temperatures on the dispersion of RAP clusters, the aging and reactivation of aged asphalt, and the blending and fusion between aged and virgin asphalt. Furthermore, relevant indicators, such as the DOB and DOA, are summarized for determining the optimal preheating temperature of RAP. The main findings are concluded as follows:

The study presents an overview and comparison of various preheating techniques for RAP; each method has its advantages and limitations. Future improvements on RAP heating equipment should consider the RAP content, the performance of HMRAM, and energy consumption.

During the RAP preheating process, the agglomeration and dispersion phenomena have significant impacts on the performance of the resulting mixture. The relationship between these phenomena and preheating temperature remains insufficiently understood. Therefore, further research is essential to comprehensively understand the inherent mechanism of RAP cluster dispersion and re-agglomeration under varying preheating temperatures.

Preheating RAP can result in either additional aging or reactivation of the aged asphalt, depending on the temperature range applied. Various technical methods have been employed to evaluate the aging and activation of asphalt; however, most studies have solely focused on one of the aging or activation indexes. Future research should intend to integrate both activation and aging indexes and establish their correlations with RAP preheating temperature. This approach enables a more precise understanding of the impact of preheating temperature on the performance of RAP. Based on this analysis, a recommended range of preheating temperatures can be determined.

The preheating temperature affects the DOB between aged and virgin asphalt. Currently, most research indirectly evaluates the DOB by examining the binder performance indicators. Further studies can measure additional parameters that define the DOB of aged and virgin asphalt, establish mathematical relationships between RAP preheating temperature and these parameters, and validate their predictive accuracy through HMRAM performance evaluation. This analysis allows for the determination of an optimal RAP preheating temperature range considering the blending effectiveness.

This article primarily focuses on the preheating process of RAP concerning the temperature impact. However, factors such as heating time and the type of heating equipment also significantly influence the performance of HMRAM. Therefore, future studies should include a multifactor analysis to establish comprehensive correlation models between the performance of HMRAM and these factors. Ultimately, the development of an integrated RAP heating strategy is recommended to maximize both recycling efficiency and pavement performance.

-

Funding information: This research was funded by the National Natural Science Foundation of China under Grant No. 52208431 and No. 52208429, and the Fundamental Research Funds for the Central Universities under Grant No. 2242024K30051 and No. 2242024K40036.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Zaumanis, M., R. B. Mallick, and R. Frank. 100% recycled hot mix asphalt: A review and analysis. Resources, Conservation and Recycling, Vol. 92, 2014 Nov, pp. 230–245.10.1016/j.resconrec.2014.07.007Search in Google Scholar

[2] Yu, X., W. Tang, N. Li, M. Jiang, J. Huang, and D. Wang. Refined decomposition: A new separation method for RAP materials and its effect on aggregate properties. Construction and Building Materials, Vol. 358, 2022 Dec, id. 129452.10.1016/j.conbuildmat.2022.129452Search in Google Scholar

[3] Mariyappan, R., J. S. Palammal, and S. Balu. Sustainable use of reclaimed asphalt pavement (RAP) in pavement applications—A review. Environmental Science and Pollution Research, Vol. 30, No. 16, 2023 Feb, pp. 45587–45606.10.1007/s11356-023-25847-3Search in Google Scholar PubMed

[4] Bressi, S., A. G. Dumont, and M. Pittet. Cluster phenomenon and partial differential aging in RAP mixtures. Construction and Building Materials, Vol. 99, 2015 Nov, pp. 288–297.10.1016/j.conbuildmat.2015.09.024Search in Google Scholar

[5] Ferreira, W. L. G., V. T. F. Castelo Branco, K. Vasconcelos, A. Bhasin, and A. Sreeram. The impact of aging heterogeneities within RAP binder on recycled asphalt mixture design. Construction and Building Materials, Vol. 300, 2021 Sep, id. 124260.10.1016/j.conbuildmat.2021.124260Search in Google Scholar

[6] Qu, L., Y. Wang, L. Wang, X. Li, and Y. Xiao. Experimental evaluation of fatigue performance of recycled asphalt mixture using refined separation recycled aggregates. Construction and Building Materials, Vol. 411, 2024 Jan, id. 134786.10.1016/j.conbuildmat.2023.134786Search in Google Scholar

[7] Sondag, M. S., B. A. Chadbourn, and A. Drescher. Investigation of recycled asphalt pavement (RAP) mixtures, Minnesota Department of Transportation, St. Paul, MN. Report No. MN/RC - 2002-15, 2002 Feb.Search in Google Scholar

[8] Qin, Y., S. Huang, X. Jian, and S. Wang. Research of blending performance of virgin and reclaimed asphalt in plant warm recycled asphalt mixture. Journal of Highway and Transportation Research and Development, Vol. 32, 2015 Jan, pp. 24–28.Search in Google Scholar

[9] MOT of PRC. Technical specifications for highway asphalt pavement recycling (JTG T5521-2019), China Communication Press, Beijing, 2019.Search in Google Scholar

[10] McDaniel, R. S. and R. M. Anderson. Recommended use of reclaimed asphalt pavement in the superpave mix design method: technician’s manual, Purdue University, North Central Superpave Center, Asphalt Institute, Transportation Research Board, Washington, D.C., 2001. Report No.: Project D9-12 FY'97. https://rosap.ntl.bts.gov/view/dot/15417.Search in Google Scholar

[11] Kvasnak, A. What to consider when designing a high RAP content mix. HMAT: Hot mix asphalt technology, National Asphalt Pavement Association, Greenbelt, MD, USA, 2010 Jul, 18-19.Search in Google Scholar

[12] Al-Qadi, I. L., S. H. Carpenter, G. Roberts, H. Ozer, Q. Aurangzeb, M. Elseifi, et al. Determination of usable residual asphalt binder in RAP, Illinois Department of Transportation, Springfield, IL., 2009. Report No.: FHWA-ICT-09-031.Search in Google Scholar

[13] Aurangzeb, Q., I. L. Al-Qadi, I. M. Abuawad, W. J. Pine, and J. S. Trepanier. Achieving desired volumetric and performance for high RAP mixtures. In Proceedings of the TRB Annual Meeting, Washington, DC, USA, 2012.10.3141/2294-04Search in Google Scholar

[14] Liu, S., A. Shukla, and T. Nandra. Technological, environmental and economic aspects of Asphalt recycling for road construction. Renewable and Sustainable Energy Reviews, Vol. 75, 2017 Aug, pp. 879–893.10.1016/j.rser.2016.10.080Search in Google Scholar

[15] Kennedy, T. W., J. A. Scherocman, and M. Tahmoressi. Drum mix plants: Equipment and operations, Texas State Department of Highway and Public Transportation, Transportation Planning Division, Austin, TX, 1986 Nov. Report No.: Research Report 440-1F.Search in Google Scholar

[16] National Cooperative Highway Research Program. Recycling materials for highways (NCHRP Synthesis 54), Transportation Research Board, National Research Council, Washington, D.C., 1978 Jun. Report No.: Project 20-5 FY'76.Search in Google Scholar

[17] Olard, F. and S. Pouget. Current status of RAP application in France. Transportation Research Circular, Number E-C188, Transportation Research Board, Washington, D.C., 2014 Jan 12, 42-50.Search in Google Scholar

[18] National Asphalt Pavement Association, American Public Works Association. Hot-mix asphalt plant operations. In Hot Mix Asphalt Paving Handbook: AC 150/5370-14A, Appendix 1 (FAA), U.S. Army Corps of Engineers, Washington, D.C., 2000, pp. 39–49.Search in Google Scholar

[19] Wan, L., Y. Xue, J. Fan, T. Ma, H. Zhao, and H. Yang. Morphological characteristics of low-asphalt RAP and influence of its reaction product during combustion heating on regenerated asphalt. Construction and Building Materials, Vol. 452, 2024 Nov, id. 138971.10.1016/j.conbuildmat.2024.138971Search in Google Scholar

[20] Nguyen, V. H. Effects of laboratory mixing methods and RAP materials on performance of hot recycled asphalt mixtures. Doctoral dissertation, University of Nottingham, Nottinghamshire, England, United Kingdom, 2009.Search in Google Scholar

[21] U.S. Environmental Protection Agency. Operation and maintenance manual for fabric filters, National Service Center for Environmental Publications (NSCEP), Washington, D.C., 2004. Report No.: EPA/625/1-86/020.Search in Google Scholar

[22] Moneron, P. Evolution of aggregate production plants of the dryer drum mixer type and their suitability for the use of recycled materials. Bulletin de liaison des laboratoires des ponts et chaussees, Vol. 1993, No. 184, 1993 Mar, pp. 3–17.Search in Google Scholar

[23] van de Ven, M., A. Molenaar, and G. Mengiste. Development of a lab production method with recycled asphalt pavement in a double barrel drum mixer. In Proceedings of the 11th International Conference on Asphalt Pavements, Nagoya, Japan, 2010, pp. 1–9.Search in Google Scholar

[24] Brock, J. D. Drum Dryer Mixer, Technical Paper T-119, Astec Industries, Chattanooga, TN, USA, 2006.Search in Google Scholar

[25] DeDene, C. D., V. R. Voller, M. O. Marasteanu, and E. V. Dave. Calculation of particle heating times of reclaimed asphalt pavement material. Road Materials and Pavement Design, Vol. 15, No. 3, 2014 May, pp. 721–732.10.1080/14680629.2014.909324Search in Google Scholar

[26] Heneash, U. Effect of the repeated recycling on hot mix asphalt properties. Doctoral dissertation, University of Nottingham, Nottinghamshire, England, United Kingdom, 2013.Search in Google Scholar

[27] Bressi, S., M. Pittet, A. G. Dumont, and M. N. Partl. A framework for characterizing RAP clustering in asphalt concrete mixtures. Construction and Building Materials, Vol. 106, 2016 Mar, pp. 564–574.10.1016/j.conbuildmat.2015.12.132Search in Google Scholar

[28] Huang, B., G. Li, D. Vukosavljevic, X. Shu, and B. K. Egan. Laboratory investigation of mixing hot-mix asphalt with reclaimed asphalt pavement. Transportation Research Record: Journal of the Transportation Research Board, Vol. 1929, No. 1, 2005 Jan, pp. 37–45.10.1177/0361198105192900105Search in Google Scholar

[29] Zhang, K., H. Wen, and A. Hobbs. Laboratory tests and numerical simulations of mixing superheated virgin aggregate with reclaimed asphalt pavement materials. Transportation Research Record: Journal of the Transportation Research Board, Vol. 2506, No. 1, 2019 Apr, pp. 62–71.10.3141/2506-07Search in Google Scholar

[30] Molenaar, A., M. Mohajeri, and M. van de Ven. Hot recycling in the Netherlands. In Application of reclaimed asphalt pavement and recycled asphalt shingles in hot-mix asphalt, transportation research circular, No. E-C188, Transportation Research Board, Washington, D.C., 2014 Jun, pp. 28–41.Search in Google Scholar

[31] Van den Kerkhof, E. Warm waste asphalt recycling in Belgium—30 years of experience and full confidence in the future. In Proceedings of the 5th Eurasphalt & Eurobitume Congress, Istanbul, Turkey, 2012, pp. 13–15.Search in Google Scholar

[32] Kubo, K. Recycling in Japan. In Application of reclaimed asphalt pavement and recycled asphalt shingles in hot-mix asphalt, transportation research circular, No. E-C188, Transportation Research Board, Washington, D.C., 2014 Jun, pp. 60–66.Search in Google Scholar

[33] Sonmez, I., S. A. Yildirim, and Z. Temren. Investigation of performance properties of laboratory and plant produced bituminous mixture containing high rates of reclaimed asphalt. In Proceedings of 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 2016 Jun, pp. 1–3.10.14311/EE.2016.309Search in Google Scholar

[34] Li, X., J. Mo, L. Zhao, H. Ma, L. Wang, B. Peng, et al. Analysis of the impact of reclaimed asphalt pavement agglomeration on the performance of hot-recycled asphalt pavement: A perspective on diffusion-fusion. Construction and Building Materials, Vol. 425, 2024 Apr, id. 135866.10.1016/j.conbuildmat.2024.135866Search in Google Scholar

[35] Karlsson, R. and U. Isacsson. Application of FTIR-ATR to characterization of bitumen rejuvenator diffusion. Journal of Materials in Civil Engineering, Vol. 15, No. 2, 2003 Mar, pp. 157–165.10.1061/(ASCE)0899-1561(2003)15:2(157)Search in Google Scholar

[36] Ma, X., Z. Leng, L. Wang, and P. Zhou. Effect of reclaimed asphalt pavement heating temperature on the compactability of recycled hot mix asphalt. Materials, Vol. 13, No. 16, 2020 Aug, id. 3621.10.3390/ma13163621Search in Google Scholar PubMed PubMed Central

[37] Wan, N., S. Zhang, and L. Hu. Study on the dispersion characteristics of hot in-plant recycled RAP. Highways & Automotive Applications, Vol. 6, 2022, pp. 82–87.Search in Google Scholar

[38] Roberto, A., J. B. Król, E. Romeo, A. Liphardt, G. Tebaldi, and A. Montepara. Evaluation of the role of reclaimed asphalt pavement preheating on cracking behavior of hot mix asphalt recycled mixtures by digital image analysis. Journal of Testing and Evaluation, Vol. 49, No. 6, 2021 Nov, pp. 4201–4213.10.1520/JTE20200465Search in Google Scholar

[39] Dall’Asta, E., V. Ghizzardi, R. Brighenti, E. Romeo, R. Roncella, and A. Spagnoli. New experimental techniques for fracture testing of highly deformable materials. Fracture and Structural Integrity, Vol. 10, No. 35, 2016, pp. 161–171.10.3221/IGF-ESIS.35.019Search in Google Scholar

[40] Birgisson, B., A. Montepara, E. Romeo, R. Roncella, J. A. L. Napier, and G. Tebaldi. Determination and prediction of crack patterns in hot mix asphalt (HMA) mixtures. Engineering Fracture Mechanics, Vol. 75, No. 3–4, 2008 Feb 1, pp. 664–673.10.1016/j.engfracmech.2007.02.003Search in Google Scholar

[41] Menapace, I. and E. Masad. Evolution of the microstructure of unmodified and polymer modified asphalt binders with aging in an accelerated weathering tester. Journal of Microscopy, Vol. 263, No. 3, 2016 Sep, pp. 341–356.10.1111/jmi.12405Search in Google Scholar PubMed

[42] Orešković, M., G. Menegusso Pires, S. Bressi, K. Vasconcelos, and D. Lo Presti. Quantitative assessment of the parameters linked to the blending between reclaimed asphalt binder and recycling agent: A literature review. Construction and Building Materials, Vol. 234, 2020 Feb, id. 117323.10.1016/j.conbuildmat.2019.117323Search in Google Scholar

[43] Zhang, S., Y. Cui, C. Du, L. Liu, and Q. Chen. Low-temperature performance and micro-structure of warm mix recycled composite aged asphalt. Construction and Building Materials, Vol. 440, 2024 Aug, id. 137443.10.1016/j.conbuildmat.2024.137443Search in Google Scholar

[44] Menegusso Pires, G., D. Lo Presti, and G. D. Airey. A practical approach to estimate the degree of binder activity of reclaimed asphalt materials. Road Materials and Pavement Design, Vol. 22, No. 5, 2021 May, pp. 1093–1116.10.1080/14680629.2019.1663244Search in Google Scholar

[45] Sreeram, A. and Z. Leng. Variability of rap binder mobilisation in hot mix asphalt mixtures. Construction and Building Materials, Vol. 201, 2019 Mar, pp. 502–509.10.1016/j.conbuildmat.2018.12.212Search in Google Scholar

[46] Meng, Y., L. Liu, W. Huang, and M. Li. Effect of increasing preheating temperature on the activation and aging of asphalt binder in reclaimed asphalt pavement (RAP). Journal of Cleaner Production, Vol. 402, 2023 May, id. 136780.10.1016/j.jclepro.2023.136780Search in Google Scholar

[47] de Sá Araujo, M.deF.A., V.deF.C. Lins, V. M. D. Pasa, and L. F. M. Leite. Weathering aging of modified asphalt binders. Fuel Processing Technology, Vol. 115, 2013 Nov, pp. 19–25.10.1016/j.fuproc.2013.03.029Search in Google Scholar

[48] Li, M., L. Liu, C. Xing, L. Liu, and H. Wang. Influence of rejuvenator preheating temperature and recycled mixture’s curing time on performance of hot recycled mixtures. Construction and Building Materials, Vol. 295, 2021 Aug, id. 123616.10.1016/j.conbuildmat.2021.123616Search in Google Scholar

[49] Zhao, X., S. Wang, Q. Wang, and H. Yao. Rheological and structural evolution of SBS modified asphalts under natural weathering. Fuel, Vol. 184, 2016 Nov, pp. 242–247.10.1016/j.fuel.2016.07.018Search in Google Scholar

[50] Siddiqui, M. N., M. F. Ali, and J. Shirokoff. Use of X-ray diffraction in assessing the aging pattern of asphalt fractions. Fuel, Vol. 81, No. 1, 2002 Jan, pp. 51–58.10.1016/S0016-2361(01)00116-8Search in Google Scholar

[51] Wang, M. and L. Liu. Investigation of microscale aging behavior of asphalt binders using atomic force microscopy. Construction and Building Materials, Vol. 135, 2017 Mar, pp. 411–419.10.1016/j.conbuildmat.2016.12.180Search in Google Scholar

[52] Yu, J., Z. Dai, J. Shen, H. Zhu, and P. Shi. Aging of asphalt binders from weathered asphalt mixtures compared with a SHRP process. Construction and Building Materials, Vol. 160, 2018 Jan, pp. 475–486.10.1016/j.conbuildmat.2017.11.060Search in Google Scholar

[53] Campher, L. Herwonne asfalt: Hoe effektief is verouderde bitumen in Bitumen Stabliliseerde Materiale, Bachelor Degree Project, Faculty of Engineering, University of Stellenbosch, Stellenbosch Central, Stellenbosch, South Africa, 2012.Search in Google Scholar

[54] Roberts, F. L., P. S. Kandhal, E. R. Brown, D. Y. Lee, and T. W. Kennedy. Hot mix asphalt materials, mixture design and construction, National Asphalt Pavement Association Research and Education Foundation, Lanham, MD, 1996.Search in Google Scholar

[55] Presti, D. L., K. Vasconcelos, M. Orešković, G. M. Pires, and S. Bressi. On the degree of binder activity of reclaimed asphalt and degree of blending with recycling agents. Road Materials and Pavement Design, Vol. 21, No. 8, 2020 Nov, pp. 2071–2090.10.1080/14680629.2019.1607537Search in Google Scholar

[56] Meng, Y. and L. Liu. Impact of preheating temperatures and RAP characteristics on the activation of RAP binder. Applied Sciences, Vol. 10, No. 23, 2020 Nov, id. 8378.10.3390/app10238378Search in Google Scholar

[57] Wu, S., J. Qiu, L. Mo, J. Yu, Y. Zhang, and B. Li. Investigation of temperature characteristics of recycled hot mix asphalt mixtures. Resources, Conservation and Recycling, Vol. 51, No. 3, 2007 Sep, pp. 610–620.10.1016/j.resconrec.2006.11.005Search in Google Scholar

[58] Liu, L., L. Sun, J. Xu, M. Li, C. Xing, and Y. Zhang. Effect of RAP’s preheating temperature on the secondary aging and performance of recycled asphalt mixtures containing high RAP content. Construction and Building Materials, Vol. 411, 2024 Jan, id. 134719.10.1016/j.conbuildmat.2023.134719Search in Google Scholar

[59] Wu, J., H. Sun, L. Wan, J. Yang, and S. Wang. Study on low-temperature and fatigue performance of high RAP content hot recycled asphalt mixture based on the degree of blending (DOB). Polymers, Vol. 14, No. 21, 2022 Oct, id. 4520.10.3390/polym14214520Search in Google Scholar PubMed PubMed Central

[60] Zhang, Y. and H. Chen. Evaluation of degree of blending and its effect on performance of recycled hot-mix asphalt under different preheating conditions. Canadian Journal of Civil Engineering, Vol. 51, No. 9, 2024 Sep, pp. 1013–1022.10.1139/cjce-2023-0389Search in Google Scholar

[61] Cai, X., Q. Zhang, H. Yu, W. Huang, K. Wu, G. Yang, et al. Study on performance of recycled asphalt mixture based on blending state analysis of virgin and aged asphalt. International Journal of Pavement Engineering, Vol. 24, No. 1, 2023 Feb, id. 2165658.10.1080/10298436.2023.2165658Search in Google Scholar

[62] Zhang, K. and B. Muhunthan. Effects of production stages on blending and mechanical properties of asphalt mixtures with reclaimed asphalt pavement. Construction and Building Materials, Vol. 149, 2017 Sep, pp. 679–689.10.1016/j.conbuildmat.2017.05.190Search in Google Scholar

[63] Lakshmi Roja, K., E. Masad, B. Vajipeyajula, W. Yiming, E. Khalid, and V. C. Shunmugasamy. Chemical and multi-scale material properties of recycled and blended asphalt binders. Construction and Building Materials, Vol. 261, 2020 Nov, id. 119689.10.1016/j.conbuildmat.2020.119689Search in Google Scholar

[64] Stimilli, A., A. Virgili, F. Giuliani, and F. Canestrari. Mix design validation through performance-related analysis of in plant asphalt mixtures containing high RAP content. International Journal of Pavement Research and Technology, Vol. 10, No. 1, 2017 Jan, pp. 23–37.10.1016/j.ijprt.2016.07.002Search in Google Scholar

[65] Wen, H. and K. Zhang. Investigation of blending mechanisms for reclaimed asphalt pavement binder and virgin binder in laboratory-produced reclaimed asphalt pavement mixtures. Transportation Research Record: Journal of the Transportation Research Board, Vol. 2575, No. 1, 2016 Jan, pp. 187–195.10.3141/2575-20Search in Google Scholar

[66] Wang, F., L. Zhang, B. Yan, D. Kong, Y. Li, and S. Wu. Diffusion mechanism of rejuvenator and its effects on the physical and rheological performance of aged asphalt binder. Materials, Vol. 12, No. 24, 2019 Dec, id. 4130.10.3390/ma12244130Search in Google Scholar PubMed PubMed Central

[67] Shah, A., R. McDaniel, G. Huber, and V. Gallivan. Investigation of properties of plant-produced reclaimed asphalt pavement mixtures. Transportation Research Record: Journal of the Transportation Research Board, Vol. 1998, No. 1, 2007 Jan, pp. 103–111.10.3141/1998-13Search in Google Scholar

[68] Bonaquist, R. Laboratory evaluation of hot mix asphalt (HMA) mixtures containing recycled or waste product materials using performance testing, Pennsylvania Department of Transportation, Harrisburg, PA, 2005. Report No.: FHWA-PA-2005-006 + 98-32(19).Search in Google Scholar

[69] Zhao, S., B. Huang, X. Shu, J. Moore, and B. Bowers. Effects of WMA technologies on asphalt binder blending. Journal of Materials in Civil Engineering, Vol. 28, No. 2, 2016 Feb, id. 04015106.10.1061/(ASCE)MT.1943-5533.0001381Search in Google Scholar

[70] Vassaux, S., V. Gaudefroy, L. Boulangé, A. Pévère, A. Michelet, V. Barragan-Montero, et al. Assessment of the binder blending in bituminous mixtures based on the development of an innovative sustainable infrared imaging methodology. Journal of Cleaner Production, Vol. 215, 2019 Apr, pp. 821–828.10.1016/j.jclepro.2019.01.105Search in Google Scholar

[71] Vassaux, S., V. Gaudefroy, L. Boulangé, A. Pévère, A. Michelet, V. Barragan-Montero, et al. Experimental investigation of blending phenomena in intergranular zones of recycled asphalt mixtures using customized infrared imaging and stage extraction methods. Construction and Building Materials, Vol. 213, 2019 Jul, pp. 234–245.10.1016/j.conbuildmat.2019.04.045Search in Google Scholar

[72] Vassaux, S., V. Gaudefroy, L. Boulangé, L. J. Soro, A. Pévère, A. Michelet, et al. Study of remobilization phenomena at reclaimed asphalt binder/virgin binder interphases for recycled asphalt mixtures using novel microscopic methodologies. Construction and Building Materials, Vol. 165, 2018 Mar, pp. 846–858.10.1016/j.conbuildmat.2018.01.055Search in Google Scholar

[73] Hettiarachchi, C., X. Hou, Q. Xiang, D. Yong, and F. Xiao. A blending efficiency model for virgin and aged binders in recycled asphalt mixtures based on blending temperature and duration. Resources, Conservation and Recycling, Vol. 161, 2020 Oct, id. 104957.10.1016/j.resconrec.2020.104957Search in Google Scholar

[74] Nazzal, M. D., W. Mogawer, S. Kaya, and T. Bennert. Multiscale evaluation of the composite asphalt binder in high–reclaimed asphalt pavement mixtures. Journal of Materials in Civil Engineering, Vol. 26, No. 7, 2014 Mar, id. 04014019.10.1061/(ASCE)MT.1943-5533.0000825Search in Google Scholar

[75] Shi, K., Z. Fu, J. Liu, R. Song, F. Ma, J. Dai, et al. Multiscale investigation of waste soybean oil rejuvenated asphalt binder utilising experimental methodologies and molecular dynamics simulations. International Journal of Pavement Engineering, Vol. 24, No. 1, 2023 Feb, id. 2181961.10.1080/10298436.2023.2181961Search in Google Scholar

[76] Bowers, B. F., B. Huang, Q. He, X. Shu, X. Jia, and B. C. Miller. Investigation of sequential dissolution of asphalt binder in common solvents by FTIR and binder fractionation. Journal of Materials in Civil Engineering, Vol. 27, No. 8, 2015 Aug, id. 04014233.10.1061/(ASCE)MT.1943-5533.0001198Search in Google Scholar

[77] Zhao, S., B. Huang, X. Shu, and M. E. Woods. Quantitative evaluation of blending and diffusion in high RAP and RAS mixtures. Materials & Design, Vol. 89, 2016 Jan, pp. 1161–1170.10.1016/j.matdes.2015.10.086Search in Google Scholar

[78] Sreeram, A., Z. Leng, Y. Zhang, and R. K. Padhan. Evaluation of RAP binder mobilisation and blending efficiency in bituminous mixtures: An approach using ATR-FTIR and artificial aggregate. Construction and Building Materials, Vol. 179, 2018 Aug, pp. 245–253.10.1016/j.conbuildmat.2018.05.154Search in Google Scholar

[79] Ding, Y., M. Deng, X. Cao, M. Yu, and B. Tang. Investigation of mixing effect and molecular aggregation between virgin and aged asphalt. Construction and Building Materials, Vol. 221, 2019 Oct, pp. 301–307.10.1016/j.conbuildmat.2019.06.093Search in Google Scholar

[80] Li, B., J. Yang, Z. Chen, and H. Li. Microstructure morphologies of asphalt binders using atomic force microscopy. Journal of Wuhan University of Technology-Mater Sci Ed, Vol. 31, No. 6, 2016 Dec, pp. 1261–1266.10.1007/s11595-016-1523-4Search in Google Scholar

[81] Li, N., W. Tang, X. Yu, H. Zhan, X. Wang, and Z. Wang. Laboratory investigation on blending process of reclaimed asphalt mixture. Construction and Building Materials, Vol. 325, 2022 Mar, id. 126793.10.1016/j.conbuildmat.2022.126793Search in Google Scholar

[82] Cui, B., H. Wang, X. Gu, and D. Hu. Study of the inter-diffusion characteristics and cracking resistance of virgin-aged asphalt binders using molecular dynamics simulation. Construction and Building Materials, Vol. 351, 2022 Oct, id. 128968.10.1016/j.conbuildmat.2022.128968Search in Google Scholar

[83] Xu, G. and H. Wang. Diffusion and interaction mechanism of rejuvenating agent with virgin and recycled asphalt binder: A molecular dynamics study. Molecular Simulation, Vol. 44, 2018 Nov, pp. 1433–1443.10.1080/08927022.2018.1515483Search in Google Scholar

[84] Kaseer, F., E. Arámbula-Mercado, and A. E. Martin. A method to quantify reclaimed asphalt pavement binder availability (effective RAP binder) in recycled asphalt mixes. Transportation Research Record: Journal of the Transportation Research Board, Vol. 2673, No. 1, 2019 Jan, pp. 205–216.10.1177/0361198118821366Search in Google Scholar

[85] Al-Qadi, I. L., M. Elseifi, and S. H. Carpenter. Reclaimed asphalt pavement — A literature review, Illinois Department of Transportation, Bureau of Materials and Physical Research, Springfield, IL, 2007 Mar. Report No.: FHWA-ICT-07-001.Search in Google Scholar

[86] Rad, F. Y., N. R. Sefidmazgi, and H. Bahia. Application of diffusion mechanism: Degree of blending between fresh and recycled asphalt pavement binder in dynamic shear rheometer. Transportation Research Record: Journal of the Transportation Research Board, Vol. 2444, No. 1, 2014 Jan, pp. 71–77.10.3141/2444-08Search in Google Scholar

[87] Kriz, P., D. L. Grant, B. A. Veloza, M. J. Gale, A. G. Blahey, J. H. Brownie, et al. Blending and diffusion of reclaimed asphalt pavement and virgin asphalt binders. Road Materials and Pavement Design, Vol. 15, No. supp 1, 2014 Jun, pp. 78–112.10.1080/14680629.2014.927411Search in Google Scholar

[88] Bowers, B. Investigation of asphalt pavement mixture blending utilizing analytical chemistry techniques. Doctoral dissertation, University of Tennessee - Knoxville, Knoxville, TN, USA, 2013.Search in Google Scholar

[89] Chen, L. and P. Zhi. Measurement and dissipative particle dynamics simulation of interface diffusion between virgin and aged asphalt. Journal of Shandong University (Engineering Science), Vol. 52, 2022, pp. 61–69.Search in Google Scholar

[90] Zhou, P., W. Wang, and Z. Yu. Analysis of interface fusion effect between old and new asphalt under plant mixing and cold recycling mode based on molecular dynamics simulation. Materials, Vol. 14, No. 16, 2021 Aug, id. 4637.10.3390/ma14164637Search in Google Scholar PubMed PubMed Central

[91] Wang, L., S. Zhuo, Z. Liang, and X. Chen. Optimization of parameters of large proportion hot central plant recycled mixture by response surface method. Science Technology and Engineering, Vol. 23, 2023, pp. 1691–1697.Search in Google Scholar

[92] Xu, Y., Z. Chou, Y. Li, J. Ji, and S. Xu. Effect of blending degree between virgin and aged binder on pavement performance of recycled asphalt mixture with high RAP content. Advances in Materials Science and Engineering, Vol. 2019, 2019 Sep, id. 5741642.10.1155/2019/5741642Search in Google Scholar

[93] McDaniel, R., H. Soleymani, R. Anderson, P. Turner, and R. Peterson. Recommended use of reclaimed asphalt pavement in the SuperPave mixture design method. NCHRP Final Report (9-12), Transportation Research Board;, Washington, D.C., 2000.Search in Google Scholar

[94] Stephens, J. E., J. Mahoney, and C. Dippold. Determination of the PG binder grade to use in a RAP mix, Connecticut Department of Transportation, Rockhill, CT, 2001 Apr. Report No.: JHR 00-278. https://rosap.ntl.bts.gov/view/dot/14366.Search in Google Scholar

[95] Wang, S., X. Huang, and L. Hu. Heating range analysis for hot in plant recycling of asphalt pavement. Modern Transportation Technology, Vol. 12, 2015, pp. 5–8.Search in Google Scholar

[96] He, H. and X. Jia. Research on the road performance and heating process of hot recycled asphalt mixtures with high RAP content. Journal of China & Foreign Highway, Vol. 41, 2021, pp. 286–290.Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry