Abstract

The disposal of sawdust, a major byproduct of the timber and woodworking industries, presents a growing environmental concern due to its large volume and limited reuse options. Finding sustainable and rational approaches to repurpose this lignocellulosic waste is essential to reduce its environmental footprint. In this study, recycled sawdust was investigated as a partial replacement for fine sand in the production of porous foam mortar (FM), aiming to develop lightweight, eco-friendly construction materials. The experimental tests were focused on the physical (slump flow, setting time, density), mechanical (compression, flexural, splitting tensile, modulus of elasticity), durability (water absorption, porosity, permeability), and microstructural characteristics of the mortars. The FM mixes were produced using sawdust substitutes ranging from 0 to 25% by weight of fine sand. With a 25% substitution, the compressive strength dropped by 33.7%, from 9.8 MPa for the control mix (0% sawdust) to 6.5 MPa. Durability tests indicated a linear increase in water absorption and porosity with higher sawdust content. Despite these reductions, mixes with up to 15% sawdust substitution maintained acceptable mechanical and durability performance, demonstrating potential for non-structural applications. Further optimization of mix designs is suggested to improve performance characteristics, and this study emphasizes the dual benefits of reusing sawdust waste and encouraging sustainable construction methods.

1 Introduction

The construction industry plays a pivotal role in global economic development but is also one of the most resource-intensive and environmentally impactful sectors. Conventional building materials such as sand, gravel, and cement are obtained by methods that deplete natural resources, worsen the environment, and produce greenhouse gas emissions [1,2]. The urgent need for sustainable construction practices is underscored by these challenges, especially the incorporation of recycled or waste byproducts for material development.

Out of several types of industrial waste, sawdust is one of those with associated significant environmental concerns. Large quantities of sawdust are generated annually by the world’s wood processing businesses; a large portion of the material is burned or dumped in landfills, polluting the air and environment [3,4]. In Malaysia, sawdust waste is particularly abundant, given the country’s reliance on timber exports and wood-based manufacturing [5]. The recycling of sawdust as a building material has two advantages, which include reduction in dependency on virgin raw materials and controlling potential environmental issues.

The use of sawdust in concrete has been thoroughly investigated for its capacity to mitigate environmental effects and enhance material attributes, including thermal insulation and reduced weight. Numerous studies have emphasized the capability of sawdust to substitute fine aggregates in concrete, especially for non-structural purposes. Abdulhameed et al. [6] revealed that substitution of up to 15% sawdust in concrete results in a notable decrease in density while preserving adequate compressive strength for non-load-bearing uses. Priya et al. [7] investigated the durability of sawdust concrete and determined that although moisture absorption and biodegradation provide considerable obstacles, appropriate curing methods and the incorporation of chemical admixtures can improve the material’s resilience to environmental deterioration.

Over the last 5 years, research has increasingly concentrated on the utilization of sawdust as a sustainable option in the production of lightweight concrete and foam concrete. Olaiya et al. [8] and Özkan et al. [9] investigated the mechanical characteristics and thermal conductivity of foam concrete derived from sawdust. Their research revealed that the ideal proportion of sawdust (often between 10 and 20%) not only diminishes weight but also offers effective thermal insulation and sound absorption characteristics, rendering it appropriate for construction materials that necessitate low density yet high thermal efficiency.

The integration of sawdust in foam mortars (FMs) has attracted interest for use in lightweight partitions, insulating layers, and non-structural components. Batool et al. [10] examined the incorporation of sawdust to produce medium- to low-strength concrete and determined that sawdust improves workability and decreases the density of concrete; however, excessive sawdust concentration may compromise compressive strength due to its organic composition. Cheng et al. [11] corroborate these findings, indicating that the organic characteristics of sawdust impede its adhesion to cement paste, thus compromising the interfacial transition zone (ITZ), a vital region in FMs that influences strength and durability.

The interplay between sawdust and the cement matrix constitutes a significant challenge in foam solutions. High sawdust content result in inadequate bonding in the ITZ [10], hence diminishing [8] examined the microstructural properties of FMs incorporating sawdust and discovered that increased sawdust content dramatically elevates porosity, hence compromising the material’s integrity. The enhanced porosity, although advantageous for weight reduction, may render the material more vulnerable to moisture absorption and microbial deterioration, particularly in humid or biologically active settings.

One proposed strategy is to incorporate sawdust into FM. Because of its lower density, thermal insulating qualities, and capacity to lessen structural loads, FM is a popular building material [12]. In the traditional FMs, river sand is used as the main aggregate; however, over-reliance on this natural aggregate has led to the increasing scarcity and environmental issues that are associated with its exploration. Sawdust’s low density and organic composition make it a suitable candidate, especially for non-structural applications where high strength is less critical [3].

Using sawdust as an aggregate substitute in FM could result in financial savings and greater sustainability. However, sawdust incorporation also presents challenges, such as its hygroscopic nature, which could affect workability, durability, and strength [13]. Several studies have explored the use of agricultural and industrial byproducts like rice husk ash, fly ash, and slag in concrete. Yet, limited research focuses on the specific implications of sawdust in FM, particularly its impact on mechanical, durability, and microstructural properties.

The effects of using sawdust in place of fine sand in FM at different percentages (0–25%) are examined in this study. The current research aims to provide insights into the performance of FM modified by sawdust by conducting comprehensive tests on fresh, hardened, durability, and microscale properties of the materials. In addition, findings from this study will help in the pursuit of environmentally friendly building practices since they offer a different way to recycle sawdust and lessen the impact of building materials on the environment.

Although much research has investigated sustainable alternatives to conventional concrete components, the incorporation of recycled materials like sawdust in mortar is still inadequately examined, especially regarding porous FM. Current research has predominantly concentrated on sawdust as a filler or aggregate substitute in traditional concrete or lightweight mortar, frequently neglecting its capacity to improve the efficacy of porous systems. Furthermore, insufficient emphasis has been directed into the thorough assessment of physical, mechanical, durability, and microstructural characteristics when sawdust is integrated into porous FM. This results in a deficiency in comprehending the material’s properties and its potential as a sustainable, performance-enhancing additive in eco-friendly construction materials.

The study also provides a significant information gap about the microscopic interactions between sawdust particles and the cement matrix. The tests help to know how the sawdust affects the composite properties, particularly the interfacial bonding, pore structure, and material homogeneity that are provided by scanning electron microscopy (SEM) investigation. The results aim to establish guidelines for incorporating sawdust into FM mixes for specific applications, balancing sustainability and performance. Finally, this study integrates economic and environmental concerns with experimental data to support the green construction movement. It backs international efforts to transition to circular economies, which use waste as a resource to produce durable and creative building materials.

2 Materials and mix proportion

2.1 Materials

The materials utilized in this experimental program were carefully selected to ensure they fit the application in FM. As the principal binder, Ordinary Portland Cement (OPC CEM1) complied with BS EN 197-1 [14] requirements. Tables 1 and 2 show that it was compatible with lightweight and structural applications because of its high calcium oxide content (62.76%), specific gravity (3.13), particle size (68 μm), and 28-day compressive strength (32 MPa). In order to ensure balanced grading and enhanced workability, natural river sand was utilized as the control aggregate. Its specific gravity was 2.58, and its fineness modulus was 2.31 (Table 3). When evaluating mortars amended with sawdust, this baseline mix served as a reference (Figure 1).

OPC chemical compositions

| Components | Percentage |

|---|---|

| Calcium oxide | 62.76 |

| Silicon dioxide | 20.35 |

| Aluminum oxide | 4.72 |

| Iron oxide | 3.62 |

| Sulfur trioxide | 2.88 |

| Magnesium oxide | 1.48 |

| Potassium oxide | 0.6 |

| Sodium oxide | 0.25 |

| Loss of ignition | 3.34 |

OPC physical characteristics

| Properties | Value |

|---|---|

| Density (kg·m−3) | 3,160 |

| Soundness | 0.5 |

| Specific surface area (cm2·g−1) | 3,350 |

| Specific gravity | 3.13 |

| 28-day compressive strength (MPa) | 32 |

| Average particle size (µm) | 68 |

| Initial and final setting time (min) | 170/250 |

Sawdust and fine sand physical properties

| Properties | Sawdust | Fine sand |

|---|---|---|

| Bulk density (kg·m−3) | 1,260 | 1,690 |

| Specific gravity | 2.51 | 2.58 |

| Voids (%) | 59 | 38 |

| Fineness modulus | 1.79 | 2.31 |

| Water absorption (%) | 0.60 | 0.50 |

| Moisture content (%) | 0.67 | 2.45 |

Process of turning raw sawdust into fine sawdust: (a) raw sawdust, (b) crushed sawdust, and (c) sieved sawdust.

The protein-based foaming agent, Noraite PA-1, generated stable, uniform foam with an expansion ratio of 25×, a specific gravity of 1.13, and a pH of 5.58. It enabled the target mortar density of 1,000 kg·m−3, a standard for lightweight applications. In order to balance workability and strength, a consistent water-to-cement ratio of 0.47 was used in all mixes, using water that met BS 3148 requirements.

Locally produced sawdust was used as the experimental sand substitute. It was cleaned, dried, crushed, and sieved to provide a consistent particle distribution with a fineness modulus of 1.79 (Figure 2). Its modest levels of calcium and magnesium oxides (Table 4) and high silicon dioxide concentration (69.05%) indicated possible pozzolanic qualities.

Physical appearance of fine sawdust and its sieve analysis in comparison to fine river sand.

Sawdust chemical composition

| Elements | Percentage |

|---|---|

| Silicon dioxide | 69.05 |

| Calcium oxide | 10.78 |

| Magnesium oxide | 6.56 |

| Aluminium oxide | 5.21 |

| Iron oxide | 3.45 |

| Phosphorus pentoxide | 0.42 |

| Sulfur dioxide | 0.39 |

| Potassium oxide | 0.09 |

| Sodium oxide | 0.08 |

| Manganese oxide | 0.02 |

| Loss on ignition | 3.95 |

Figure 3 shows the X-ray diffraction (XRD) pattern of sawdust employed in this study. Identification and characterization of cellulose using XRD were based on methods proposed by Park et al. [15] and French [16]. Sawdust principally comprises amorphous particles; nonetheless, the cellulose portion has some crystalline characteristics, as indicated by the XRD results. Three crystalline peaks can be seen in Figure 3 at 2-θ of 16°, 22.5°, and 34.5°. The initial peak at 16° gives a sign of its crystallized state. Nonetheless, it is commonly less intense and more expansive than the second peak, ascribed to the semi-crystalline characteristics of cellulose in wood. The second peak at 22.5° is the most significant, signifying the crystalline parts of cellulose. It is frequently extensive and scattered due to the incomplete crystallinity of cellulose in sawdust. The third peak at 34.5° implies a further crystallography sign for cellulose. The level of intensity is generally moderate, as the cellulose crystals in sawdust may lack precise order; yet it remains detectable.

XRD pattern of sawdust.

The XRD examination generally confirmed the existence of crystalline cellulose structures characteristic of lignocellulosic biomass. The peaks suggest that the sawdust maintains its fibrous, organic characteristics and does not exhibit pozzolanic reactivity in the conventional manner. Sawdust, in contrast to materials like fly ash or silica fume, does not possess the amorphous silica or alumina necessary for a productive pozzolanic reaction with calcium hydroxide during cement hydration. Minor interactions between organic components and hydration products are more likely to affect setting time and microstructure than to contribute to additional cementitious reactions. The article has been revised to clarify in the XRD and discussion sections that sawdust serves primarily as a lightweight, inert filler exerting physical effects on the mortar matrix, rather than functioning as a chemically reactive addition.

Sawdust replaced sand in increments of 0–25%, with its density (1,260 kg·m−3) and water absorption (0.6%) accounted for in the mix designs (Table 5). This methodical material preparation and characterization created a solid basis for assessing the advantages of adding sawdust to FM in terms of performance requirements, durability, and mechanical properties.

FM mix design

| Mix code | Density (kg·m−3) | Sawdust (%) | Sawdust (kg·m−3) | Fine sand (kg·m−3) | OPC (kg·m−3) | Foam (kg·m−3) | Water (kg·m−3) |

|---|---|---|---|---|---|---|---|

| F0 | 1,000 | 0 | 0.00 | 558.00 | 372.16 | 30.66 | 174.91 |

| F5 | 1,000 | 5 | 27.90 | 530.10 | 372.16 | 30.66 | 174.91 |

| F10 | 1,000 | 10 | 55.80 | 502.20 | 372.16 | 30.66 | 174.91 |

| F15 | 1,000 | 15 | 83.70 | 474.30 | 372.16 | 30.66 | 174.91 |

| F20 | 1,000 | 20 | 111.60 | 446.40 | 372.16 | 30.66 | 174.91 |

| F25 | 1,000 | 25 | 139.50 | 418.50 | 372.16 | 30.66 | 174.91 |

2.2 FM mix design

The FM mix design sought to evaluate the impact of using sawdust in different ratios in place of fine sand. A protein-based foaming agent and precise material proportions were used to produce air gaps, achieving the desired density of 1,000 kg·m−3. This makes it suitable for lightweight building applications, such as partitioning and insulation. Workability, strength, and durability were balanced in the design by using a set water-to-cement ratio of 0.47 and a cement-to-sand ratio of 1:1.5. Sawdust was used in six different blends, substituting fine sand at weight percentages of 0, 5, 10, 15, 20, and 25%. The control mix (F0) contained only fine sand, while subsequent mixes incrementally incorporated sawdust (Table 5).

In order to maintain mix consistency and desired density, sawdust has to be adjusted due to its lower density (1,260 kg·m−3) and higher water absorption (0.6%) in comparison to fine sand (1,690 kg·m−3, 0.5%). A 25× expansion ratio was used for the foaming agent so as to ensure the stability of the mixture and the uniform distribution of air gaps. The preparation involved a dry mixing of cement, sand, and sawdust. Water and a foaming agent were then added to produce a stable, constant foam. The mixtures were poured into molds and allowed to be cured in line with accepted procedures. Figure 4 shows the FM specimens in steel molds after casting. Moreover, the workability, mechanical properties, durability, and microstructure of each mix were evaluated to determine the optimal quantity of sawdust substitution that balances functional performance and environmental benefits. Thus, this approach provided useful data regarding sawdust’s sustainable application in lightweight construction.

FM specimens in steel molds after casting.

3 Experimental setup

The experimental setup was designed to comprehensively evaluate the properties of FM mixes incorporating varying proportions of sawdust. This required applying standardized testing techniques to evaluate the microstructural, mechanical, fresh, and durability qualities. Every test sought to measure the effect of replacing sawdust on FM’s overall performance and appropriateness for use in construction.

3.1 Fresh properties

The fresh properties of the FM mixes were determined just after mixing to measure the workability and setting times. The density was also determined. The slump flow test was used to determine workability according to ASTM C230 [17], and the mortar’s spread diameter was also noted. The target slump flow diameter, which is typical for FM applications, was chosen between 210 and 250 mm. The projected effect of sawdust’s water-absorbing capacity on flow behavior led to the recording and correlation of any deviations from this range with its composition.

The fresh density of the FM mixtures was measured using BS EN 12350-6 [18]. An accurate density measurement was ensured in the mixes considering the fact that the materials’ composition was altered by the addition of sawdust. To record the start and final setting times, setting time was measured using a Vicat device in accordance with BS EN 196-3 [19]. The results of these experiments provided crucial information regarding the mixtures’ initial performance, which influences application and handling.

3.2 Mechanical properties

The tests for modulus of elasticity (MOE), splitting tensile strength, flexural strength, and compressive strength were used to evaluate mechanical performance. 100 mm3 cubes were subjected to compressive strength tests in accordance with BS EN 12390-3 [20]. The average of three specimens per mix was used to reflect the findings of the tests conducted on the samples after 28 days of curing.

Flexural strength was measured using 100 × 100 × 500 mm prisms in accordance with BS EN 12390-5 [21], while splitting tensile strength tests were conducted on cylindrical specimens measuring 100 × 200 mm, following BS EN 12390-6 [22]. Static loading tests, in accordance with ASTM C469 [23], were used to measure the MOE using cylindrical specimens under uniaxial compression. A thorough understanding of the structural performance of FM with different sawdust contents was made possible by these mechanical tests.

3.3 Durability properties

Tests on gas permeability, porosity, and water absorption were used to evaluate the mixes’ durability. Water absorption tests were performed on cylindrical specimens measuring 50 mm in diameter and 100 mm in height in accordance with BS EN 1881-122 [24]. The samples were immersed in water for 24 h, and the percentage increase in mass was recorded.

The vacuum immersion method outlined in RILEM TC-14 CPC11 [25] was used to measure porosity. To determine the material’s pore volume, cylindrical specimens with dimensions of 50 mm in diameter and 50 mm in height were vacuum-saturated. Gas permeability tests were carried out on similar-sized specimens using the method developed by Cabrera and Lynsdale [26], which involved measuring the rate of gas flow through the material under controlled pressure conditions. These tests collectively evaluated the impact of sawdust on the resistance of FM to moisture ingress and gas diffusion.

3.4 Microstructural analysis

After 28 days of curing, representative fragments of the FM samples were selected and oven-dried at 60°C for 24 h to remove residual moisture without damaging the microstructure. The dried samples were then carefully fractured to expose a fresh surface and subsequently mounted on aluminum stubs using carbon adhesive tape. To ensure proper conductivity and minimize charging effects during SEM observation, the mounted samples were sputter-coated with a thin layer of gold (Au) using a vacuum sputter coater. SEM imaging was then conducted at an accelerating voltage of 15–20 kV to examine the morphology and pore structure of the FM matrix.

Using SEM for microstructural examination, the internal structure of the mortar and the interfacial zones between sawdust particles and the cement matrix were detected. The SEM analysis was performed in accordance with ISO 16700 [27] guidelines, using a Quanta FEG 650 electron microscope. Samples measuring 15 × 15 × 15 mm were prepared from each mix, coated with a conductive layer, and examined at a magnification of 150×. The SEM images provided qualitative insights into the dispersion of sawdust particles, pore distribution, and the effects of sawdust on matrix homogeneity.

This experimental program ensured that all critical aspects of FM performance were systematically evaluated. Moreover, the experiments were intended to give a thorough understanding of the material’s behavior in real-world scenarios, in addition to measuring the impact of sawdust as sand replacement.

4 Results and discussion

This part presents and analyses the experimental program’s results, with an emphasis on the FM new qualities, mechanical strengths, durability performance, and microstructural features with different sawdust substitution amounts. Trends are covered in depth, and the interpretation of the findings is backed up by quantitative data.

4.1 Fresh properties

Figures 5 and 6 show the slump flow and setting times for the mortar mixes. The fresh properties of FM mixes were significantly influenced by the inclusion of sawdust. There was a gradual reduction in workability with increasing sawdust content, as shown in the slump flow test results. The control mix (F0) achieved a slump flow diameter of 250 mm, consistent with typical FM specifications [28]. However, mixes with 25% sawdust (F25) recorded a reduced slump flow of 210 mm, indicating a 16% decrease in workability. The reason for this decline is that sawdust’s hygroscopic qualities allowed it to absorb water from the mixture and reduce flowability, which aligns with findings in related studies [29].

Slump flow of mixes.

Setting time of mixes.

Recent density studies demonstrated a steady decrease with the rise in sawdust content. The control mix (0% sawdust) exhibited a fresh density of around 1,000 kg·m−3, whereas the mix with 25% sawdust substitution (F25) demonstrated a decreased density of 925 kg·m−3. This trend is ascribed to the markedly reduced specific gravity of sawdust in relation to natural fine sand, resulting in a lighter overall mixture. The reduction in fresh density indicates possible advantages for lightweight building applications where a diminished dead load is advantageous.

The initial and final setting times were prolonged with the increase in sawdust content. The delay, averaging approximately 10 min for elevated sawdust levels, is presumably attributable to the presence of lignocellulosic elements in the sawdust. These organic compounds can disrupt cement hydration events by adsorbing water and partially interacting with calcium ions, leading to reduced hydration kinetics. The minor retardation suggests that sawdust may function similarly to other plant-derived additives that affect setting time by chemical interaction with the binder matrix. These results align with prior research indicating delayed setting when cellulose-based materials are present [15,16]. The observed alterations in fresh properties indicate that sawdust significantly affects the density and hydration characteristics of FM. These impacts must be considered while optimizing mix design for certain performance criteria.

4.2 Mechanical properties

The mechanical performance of the FM mixes was systematically evaluated to understand the impact of sawdust substitution on compressive strength, flexural strength, splitting tensile strength, and MOE. The findings clearly indicate that strength decreases as sawdust concentration rises, which can be attributed to variations in density, matrix porosity, and interfacial bonding. Moderate substitution levels, however, continued to provide satisfactory results, especially for non-structural applications.

4.2.1 Compressive strength

A crucial factor in assessing mortar’s structural performance is its compressive strength. In Figure 7, the compressive strength is shown, and in Figure 8, the percent change in the compressive strength is shown. The control mix (F0), which is typical for FM, has a 28-day compressive strength of 9.8 MPa. When the maximum substitution level of 25% (F25) was attained, the compressive strength decreased by 33.7% to 6.5 MPa. The sawdust particles have a lesser density and stiffness compared to fine sand, and this eventually led to a decrease in the compressive strength [6]. Moreover, the matrix was also weakened because of the microstructure’s increased porosity, especially at higher sawdust substitution levels. This is consistent with earlier studies that reported similar declines in mechanical performance when incorporating cellulose-rich biomass into cement-based materials [9]. Despite the strength reduction, the values achieved at moderate replacement levels remain within acceptable ranges for non-structural and lightweight construction applications. These results emphasize the trade-off between mechanical properties and sustainability when incorporating recycled organic materials into cementitious composites.

Compressive strength of mixes.

Percentage of change in compressive strength.

ASTM C796/C796M and analogous standards indicate that FMs and cellular concretes designed for non-structural or lightweight construction applications generally necessitate compressive strengths between 2 and 7 MPa, contingent upon their specific application (e.g., insulating material layers, wall partitions, void filling). With a 15% replacement of sawdust, the FM attained a compressive strength of around 2.82 MPa at 28 days, satisfying or surpassing the established criteria, while simultaneously reducing density and encouraging the utilization of sustainable materials. Consequently, the 15% threshold is recognized as a performance-sustainability trade-off juncture, in which mechanical properties are maintained within acceptable parameters for non-load-bearing applications.

4.2.2 Flexural strength

The flexural strength results and rate of variation in the values are shown in Figures 9 and 10, respectively. Generally, flexural strength measures a material’s capacity to tolerate bending pressures, and it is essential in applications where the mortar is subjected to flexural stresses. The control mix’s (F0) flexural strength at 28 days was 3.5 MPa. As the sawdust concentration increased, this value gradually dropped, reaching 3.2 MPa for F5 and 2.8 MPa for F15. The observed flexural strength for F25 was 2.75 MPa, which is 21.5% less than the control mix. This decrease is related to sawdust particles disrupting cohesiveness within the mortar matrix, which acts as a weak spot. A similar assertion was made in a related study [11]. However, considering the very slight reduction in flexural strength, the material might still have sufficient ductility for various uses [30].

Flexural strength of mixes.

Percentage of change in flexural strength.

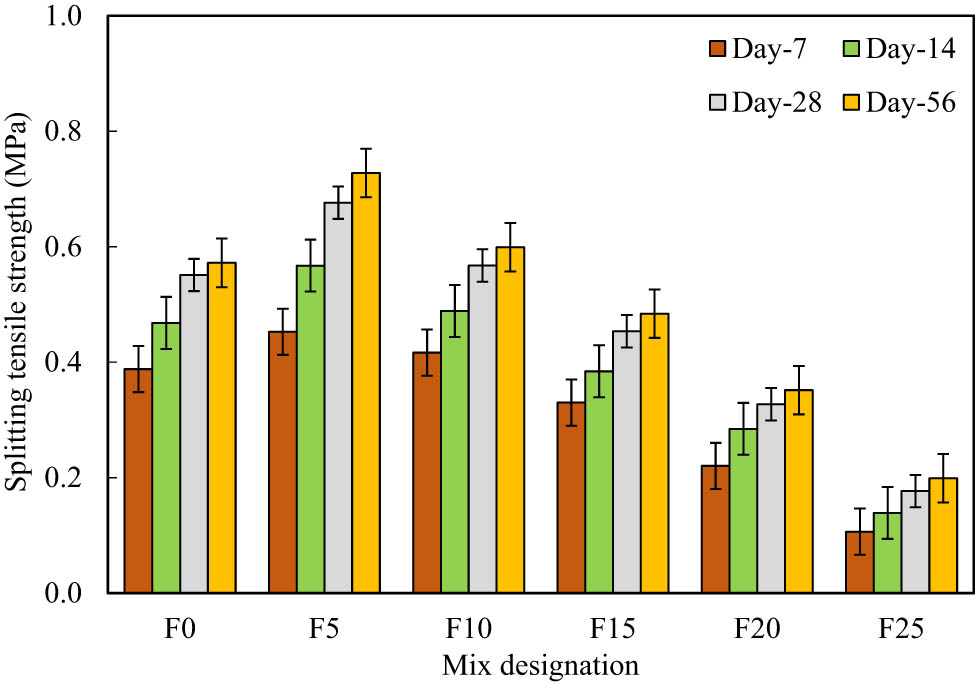

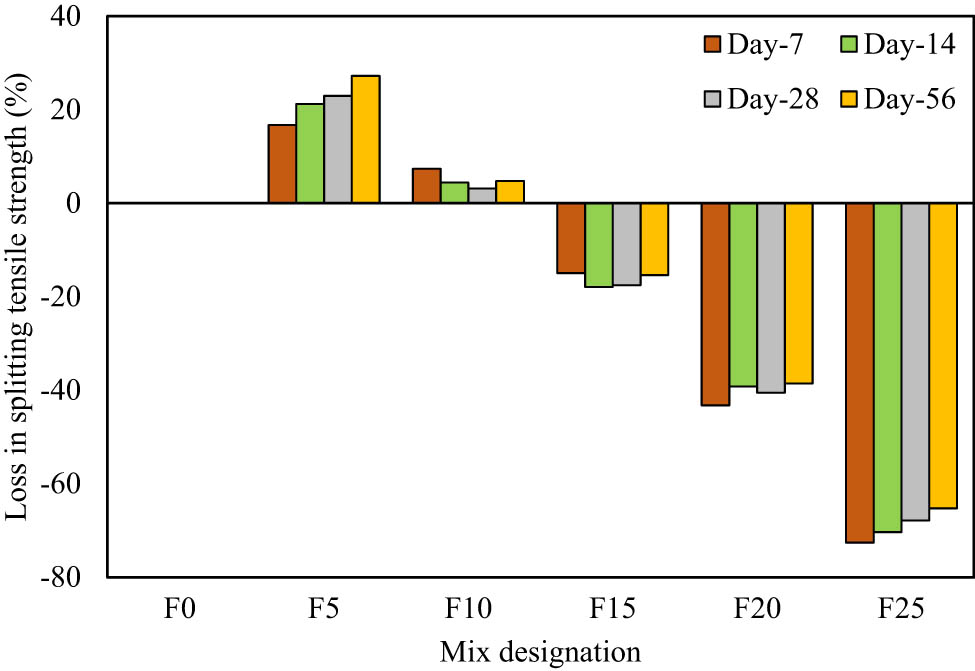

4.2.3 Splitting tensile strength

The splitting tensile strength of the FM mixes and the percentage change in the values are shown in Figures 11 and 12, respectively. This is a crucial factor in comprehending how cracks spread in the matrix. For the control mix, the splitting tensile strength was 2.2 MPa. As the quantity of sawdust increased, the splitting tensile strength decreased in the same trend as the flexural and compressive strength values. Mix F25 indicated a tensile strength of 1.8 MPa, the lowest and 18.2% lower than the control. The corresponding tensile strengths of mixes F5 and F15 were 2.0 and 1.85 MPa. Compared to the relatively little decline in tensile strength, the reductions in compressive and flexural strengths are more pronounced. This pattern suggests that the dispersion of tensile stresses across the matrix is less affected by sawdust substitution since the particles are uniformly distributed at moderate substitution levels [11].

Splitting tensile strength of mixes.

Percentage of change in splitting tensile strength.

4.2.4 Modulus of elasticity

The stiffness and the ability of the mortar to deform elastically under load have been measured using the MOE tests (Figure 13). The MOE for the control mix was measured at 15 GPa. As the sawdust content increased, this value progressively decreased, dropping to 13 GPa for F10 and 11 GPa for F25. There was a decrease in the MOE values, and this was attributed to the higher number of voids and reduced rigidity. Moreover, the results were supported by SEM analysis, which showed discontinuities in the matrix, and this could be attributed to higher sawdust content added. Despite this decline, the mortar’s elastic behavior remained suitable for lightweight applications where flexibility and reduced density are prioritized [31].

MOE of mixes.

4.3 Durability properties

Durability is a crucial aspect when assessing the performance of FM for long-term applications, especially in environments exposed to moisture, temperature fluctuations, and other harsh conditions. In this study, water absorption, porosity, and gas permeability were examined to assess the durability of the FM mixes with different sawdust substitution amounts. These characteristics are crucial markers of a material’s resistance to environmental pressures since high porosity and water absorption can cause deterioration and shorten the material’s lifespan.

4.3.1 Water absorption

The water absorption is shown in Figure 14. The results showed that the control mix’s (F0) water absorption was 4.8%. The rate of water absorption rose in tandem with the sawdust concentration. Water absorption rose to 5.3% and 5.9% for F5 and F10, respectively. The mixes F15, F20, and F25 showed similar trends at 6.5, 7.3, and 8.2%, respectively. From F0 to F25, there was a 70.8% increase in water absorption. Moreover, the hygroscopic nature of sawdust particles and their tendency to retain moisture contributed to the increase in water absorption as the sawdust concentration increased [6]. Water may also enter the material through the increased number of voids in the mortar matrix caused by sawdust’s porosity [29]. Although this enhanced absorption may make sawdust-modified mortar less efficient in wet situations, it can still be used in dry or non-exposed conditions where water absorption is less of an issue [32].

Water absorption of mixes.

4.3.2 Porosity

Porosity is another vital durability parameter, influencing both the strength and the water absorption capacity of a material. Figure 15 shows the porosity results. The control mix (F0) exhibited a porosity of 15%, which is typical for FM mixes. As sawdust content increased, the porosity of the mixes also rose. F5 had a porosity of 16.3%, and by the time 25% sawdust was incorporated (F25), the porosity reached 20%, a 33% increase compared to the control mix. The presence of sawdust, which creates voids and air pockets in the mortar, is directly related to the increased porosity. This finding was also supported by SEM images, which revealed that the mix had more big voids at higher sawdust percentages. Although these spaces help the mortar be lightweight, they also weaken the internal structure of the substance. More porosity increases the mortar’s vulnerability to water absorption and may compromise its mechanical strength. The material’s capacity to withstand heat transfer may be enhanced by the increased voids, which also offers a possible advantage in terms of thermal insulation qualities [33].

Porosity of mixes.

4.3.3 Gas permeability

Gas permeability is an essential durability test that evaluates the ease with which gases, such as air or carbon dioxide, can penetrate the mortar. Figure 16 shows the gas permeability values. This property is particularly important for assessing the material’s performance in structures where air and moisture resistance are necessary. The controlled procedure described by Cabrera and Lynsdale [18] was used to examine the gas permeability of the FM mixes. Permeability clearly increased with increasing sawdust content, according to the data. Permeability was 0.32 × 10−12 m2 for the control mix (F0) and 0.40 × 10−12 m2 for the 25% sawdust mix (F25), a 25% increase. In mixes with more sawdust, the improved gas permeability is directly caused by the increased porosity and void spaces within the mortar matrix. Gases can more readily diffuse through the material through the voids [34]. While this may not be a significant issue in non-structural applications, it could potentially affect the performance of FM in conditions where airtightness or low permeability is required, such as in energy-efficient building designs.

Gas permeability of mixes.

4.4 Microstructural analysis

Figure 17 presents the SEM analysis of FM. The results revealed that sawdust addition affected the microstructure of the matrix. There was a uniform matrix with a solid cement paste-sand bond in the control mix (F0), thus showing evidence of good stability and strength. Moreover, lower sawdust levels (5–10%) showed dispersed voids and partial bonding with the cement paste with little impact on strength[35]. Nevertheless, substantial segregation, bigger voids, and poor bonding between sawdust particles and the matrix were seen at higher substitution levels (15–25%), which resulted in decreased strength and increased porosity. While sawdust’s silica content suggests potential pozzolanic activity at low levels, the weak interfacial bonding at higher contents undermined mechanical performance.

SEM images of different LFC mixtures: (a) F0, (b) F1, (c) F2, (d) F3, (e) F4, and (f) F5.

The incorporation of sawdust in the FM mixture substantially affects the hydration process, resulting in a modified microstructure. Sawdust particles, owing to their low density and fibrous composition, generate supplementary voids within the mortar matrix, so augmenting the total porosity. This subsequently influences the formation of the toughened structure. The air spaces produced by the foam, along with the inclusion of sawdust, create a less dense matrix characterized by interconnecting pores. The SEM investigation indicated that increased sawdust content results in more irregular and bigger holes, potentially leading to diminished mechanical strength while improving thermal insulation qualities. The creation of the foam structure can be elucidated by the gas entrapment mechanism during mixing and the stabilization of air spaces by surfactants or admixtures, as articulated in the theories of [36] and [37]. The interaction between cement hydration products (calcium silicate hydrate, or C–S–H) and sawdust particles results in localized regions of reduced density, influencing the overall microstructure. This phenomenon has been examined within the framework of the gel-space ratio theory [38], which elucidates the equilibrium between hydration products and porosity in the cementitious matrix.

The ITZ, where sawdust particles mix with cement paste, is critical in influencing the overall mechanical properties and durability of FM. The SEM pictures reveal that the ITZ is more pronounced with increased sawdust content, as the sawdust particles serve as vulnerabilities within the matrix. The existence of these organic particles results in limited regions of diminished strength due to the weaker bonding between the cement hydration products (such as C–S–H) and the sawdust fibers. The feeble link within the ITZ is likely to contribute to the diminished compressive strength reported in the sawdust-modified mortars.

Additionally, the possible breakdown pathways of sawdust under various curing settings. Sawdust, as an organic substance, is subject to biodegradation, especially in situations with elevated moisture levels. Under humid curing circumstances, the cellulose and lignin in sawdust may undergo partial breakdown over time, potentially resulting in a decrease in the filler’s structural integrity. This deterioration can influence the stability and long-term resilience of the FM, especially in settings subjected to elevated humidity or cyclic wet-dry conditions. To address this, we have cited works such as [39], which investigate the impact of environmental exposure on organic fillers in cementitious materials. These findings highlight the need to optimize sawdust content and enhance bonding to maintain structural integrity in FM.

4.5 Sawdust long-term behavior in humid or biological environments

Although this study focused on the short- and medium-term performance of sawdust-based FM (up to 56 days), it is important to consider the potential long-term behavior of sawdust within cementitious systems, particularly in humid or biologically active environments. Sawdust, being an organic, lignocellulosic material, is inherently susceptible to biodegradation over time, especially when exposed to moisture, oxygen, and microbial activity. In humid conditions, water absorption by sawdust may not only lead to dimensional instability and increased porosity but could also accelerate microbial degradation, weakening the interfacial bond between the organic filler and the cement matrix.

Furthermore, under favorable biological conditions such as consistent moisture and moderate temperatures, sawdust may serve as a substrate for fungi or bacteria, potentially resulting in the slow breakdown of cellulose and hemicellulose components. This degradation could progressively compromise the mechanical integrity and durability of the mortar, especially in structural or load-bearing applications [40].

However, the alkaline nature of the cement matrix may offer some degree of protection against microbial activity by creating an inhospitable environment for many decaying organisms. Additionally, the encapsulation of sawdust within the dense matrix may limit oxygen access, thereby slowing down biological degradation. Previous studies [23,24] have reported that while initial mechanical strength may be reduced due to the inclusion of organic fillers, the long-term degradation is highly dependent on environmental exposure conditions and mixed design parameters [41].

5 Conclusion

The performance of sawdust-fabricated lightweight mortar was investigated in this study, with an emphasis on the impact on the material’s mechanical, durability, and microstructural qualities. The results demonstrate that sawdust can be effectively used in FM mixes, thereby contributing to sustainability. Moreover, the findings also point to a number of important considerations that must be made when adding sawdust to building supplies. The study’s findings were as follows:

Addition of sawdust to the mortar mixture significantly reduced its mechanical strength. Both compressive and flexural strength declined with increasing sawdust content; the largest reductions were observed at substitution levels above 15%. The reduction in mechanical performance is caused by the sawdust particles’ increased porosity and voids, as well as the cement paste’s poor bonding with the sawdust particles. Also, this was backed by the SEM results, showing a weak interfacial bonding and more empty spaces, particularly in mixes having a higher sawdust content.

It was discovered that higher water absorption and porosity was because of the increased sawdust content. Furthermore, there was an increase in gas permeability, underscoring the possible drawbacks of sawdust-modified FM for uses requiring air permeability and moisture resistance. Notwithstanding these disadvantages, the material’s voids might lessen heat transfer; therefore, the higher porosity may be advantageous in applications where thermal insulation is a top concern.

With microstructural analysis, the study revealed how sawdust affected the cement matrix. Higher levels of sawdust substitution resulted in a considerable separation between the sawdust and cement particles, weakening the interfacial connections and making the matrix more unstable overall, whereas low levels revealed little structural disturbance. In essence, this has shown how crucial it is to maximize the sawdust content to strike a balance between the advantages of sustainability and the required material qualities for certain applications.

Finally, despite the limitations, the results suggested that sawdust could be utilized in non-structural and lightweight applications. The environmental benefits, including waste reduction and reduced reliance on natural resources, make sawdust-modified FM a promising alternative for sustainable construction. Further research into the treatment of sawdust, the incorporation of chemical admixtures, or the use of other supplementary materials could enhance the material’s performance and expand its range of applications. Additionally, future studies should include long-term exposure tests (e.g., under wet–dry cycles, microbial environments, and chemical attacks) to assess the hypothetical degradation of lignocellulosic components within the cement matrix and their impact on structural integrity over time.

Acknowledgments

The authors thank the Ministry of Higher Education for providing financial support to this research work through the Fundamental Research Grant Scheme (FRGS/1/2022/TK01/USM/02/3).

-

Funding information: This research work was funded by the Ministry of Higher Education through the Fundamental Research Grant Scheme (FRGS/1/2022/TK01/USM/02/3).

-

Author contributions: Md Azree Othuman Mydin: writing – review and editing, writing – original draft, visualization, validation, resources, methodology. Paul O. Awoyera – review and editing, writing – original draft, data curation, conceptualization. Mohd Mustafa Al Bakri Abdullah: writing – review and editing, writing – original draft, visualization, validation, resources. Kennedy Onyelowe: writing – review and editing, writing – original draft, visualization. Yasin Onuralp Özkılıç: writing – review & editing, writing – original draft, visualization. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Miller, S. A., G. Habert, R. J. Myers, and J. T. Harvey. Achieving net zero greenhouse gas emissions in the cement industry via value chain mitigation strategies. One Earth, Vol. 4, 2021, pp. 1398–1411.10.1016/j.oneear.2021.09.011Search in Google Scholar

[2] Kuoribo, E., H. Shokry, and H. Mahmoud. Attaining material circularity in recycled construction waste to produce sustainable concrete blocks for residential building applications. Journal of Building Engineering, Vol. 96, 2024, id. 110503.10.1016/j.jobe.2024.110503Search in Google Scholar

[3] Adegoke, K. A., O. O. Adesina, O. A. Okon-Akan, O. R. Adegoke, A. B. Olabintan, O. A. Ajala, et al. Sawdust-biomass based materials for sequestration of organic and inorganic pollutants and potential for engineering applications. Current Research in Green and Sustainable Chemistry, Vol. 5, 2022, id. 100274.10.1016/j.crgsc.2022.100274Search in Google Scholar

[4] Szczurek, A., M. Maciejewska, Ż. Zajiczek, and K. Mościcki. Detection of emissions from the combustion of wood-based materials being furniture industry waste. Atmospheric Pollution Research, Vol. 12, 2021, pp. 375–385.10.1016/j.apr.2020.11.018Search in Google Scholar

[5] Osman, N., R. A. Karim, H. T. Othman, and M. A. Firdaus Mazlan. Biomass in Malaysia: Forestry-based residues. International Journal of Biomass and Renewables, Vol. 3, 2014, id. 7.10.61762/ijbrvol3iss1art13872Search in Google Scholar

[6] Abdulhameed, A. A., M. M. Hason, A. A. K. Sharba, A. N. Hanoon, M. Amran, H. M. Magbool, et al. Experimental and environmental investigations of the impacts of wood sawdust on the performance of reinforced concrete composite beams. Case Studies in Construction Materials, Vol. 19, 2023, id. e02550.10.1016/j.cscm.2023.e02550Search in Google Scholar

[7] Priya, E., P. Vasanthi, B. Prabhu, and P. Murugesan. Sawdust as a sustainable additive: Comparative insights into its role in concrete and brick applications. Cleaner Waste Systems, Vol. 11, 2025, id. 100286.10.1016/j.clwas.2025.100286Search in Google Scholar

[8] Olaiya, B. C., M. M. Lawan, and K. A. Olonad. Utilization of sawdust composites in construction – A review. SN Applied Sciences, Vol. 5, 2023, id. 140.10.1007/s42452-023-05361-4Search in Google Scholar

[9] Özkan, İ. G. M., K. Aldemir, O. Alhasan, A. Benli, O. Y. Bayraktar, M. U. Yılmazoğlu, et al. Investigation on the sustainable use of different sizes of sawdust aggregates in eco-friendly foam concretes: Physico-mechanical, thermal insulation and durability characteristics. Construction and Building Materials, Vol. 438, 2024, id. 137100.10.1016/j.conbuildmat.2024.137100Search in Google Scholar

[10] Batool, F., K. Islam, C. Cakiroglu, and A. Shahriar. Effectiveness of wood waste sawdust to produce medium- to low-strength concrete materials. Journal of Building Engineering, Vol. 44, 2021, id. 103237.10.1016/j.jobe.2021.103237Search in Google Scholar

[11] Cheng, Y., J. Liu, W. Wang, L. Jin, and S. Yan. Preparation and property study of sawdust-modified cement mortar. Frontiers in Materials, Vol. 11, 2024, id. 1457167.10.3389/fmats.2024.1457167Search in Google Scholar

[12] Liu, Y., Z. Zhao, M. N. Amin, B. Ahmed, K. Khan, S. U. Arifeen, et al. Foam concrete for lightweight construction applications: A comprehensive review of the research development and material characteristics. Reviews on Advanced Materials Science, Vol. 63, No. 1, 2024, id. 20240022.10.1515/rams-2024-0022Search in Google Scholar

[13] Majeed, S. S. Formulating eco-friendly foamed mortar by incorporating sawdust ash as a partial cement replacement. Sustainability, Vol. 16, 2024, id. 2612.10.3390/su16072612Search in Google Scholar

[14] BS EN 197. Cement composition, specifications and conformity criteria for common cements, British Standards Institute, London, UK, 2011.Search in Google Scholar

[15] Park, S., J. O. Baker, M. E. Himmel, P. A. Parilla, and D. K. Johnson. Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnology for Biofuels, Vol. 3, 2010, id. 10.10.1186/1754-6834-3-10Search in Google Scholar PubMed PubMed Central

[16] French, A. D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose, Vol. 21, 2014, pp. 885–896.10.1007/s10570-013-0030-4Search in Google Scholar

[17] ASTM C230/C230M. Standard specification for flow table for use in tests of hydraulic cement; 2020.Search in Google Scholar

[18] BS EN 12350-6. Testing fresh concrete density; 2016.Search in Google Scholar

[19] BS EN 196 - Part 3. Methods of testing cement determination of setting times and soundness; 2016.Search in Google Scholar

[20] BS EN 12390-3. Testing hardened concrete. Compressive strength of test specimens, 2011.Search in Google Scholar

[21] BS EN 12390-5. Testing hardened concrete. Flexural strength of test specimens; 2019.Search in Google Scholar

[22] 12390-6 BS EN. Testing hardened concrete – part 6: Tensile splitting strength of test specimens; 2006.Search in Google Scholar

[23] ASTM C469. Standard test method for static modulus of elasticity and Poisson’s ratio of concrete in compression; 2002.Search in Google Scholar

[24] BS EN 1881-122. Testing concrete method for determination of water absorption; 2020.Search in Google Scholar

[25] RILEM TC-14 CPC 11. Absorption of water by concrete by immersion under vacuum; 1984.Search in Google Scholar

[26] Cabrera, J. G. and C. J. Lynsdale. A new gas permeameter for measuring the permeability of mortar and concrete. Magazine of Concrete Research, Vol. 40, 1988, pp. 177–182.10.1680/macr.1988.40.144.177Search in Google Scholar

[27] ISO 16700. Microbeam analysis — Scanning electron microscopy — Guidelines for calibrating image magnification; 2016.Search in Google Scholar

[28] Gupta, S., A. Kashani, and A. H. Mahmood. Carbon sequestration in engineered lightweight foamed mortar – Effect on rheology, mechanical and durability properties. Construction and Building Materials, Vol. 322, 2022, id. 126383.10.1016/j.conbuildmat.2022.126383Search in Google Scholar

[29] Ferede, E. Evaluation of mechanical and water absorption properties of alkaline-treated sawdust-reinforced polypropylene composite. Journal of Engineering, Vol. 2020, 2020, pp. 1–8.10.1155/2020/3706176Search in Google Scholar

[30] Aaron, G. H., M. A. O. Mydin, D. E. Tobbala, P. Jagadesh, Y. O. Özkılıç, S. D. Datta, et al. Experimental and machine learning approaches to investigate the properties of foamed concrete made with surkhi and dolomitic limestone as cement replacements. Multiscale and Multidisciplinary Modeling Experiments and Design, Vol. 8, No. 2, 2025, id. 151.10.1007/s41939-025-00730-5Search in Google Scholar

[31] Waqar, A., M. B. Khan, T. Najeh, H. R. Almujibah, and O. Benjeddou. Performance-based engineering: formulating sustainable concrete with sawdust and steel fiber for superior mechanical properties. Frontiers in Materials, Vol. 11, 2024, id. 1428700.10.3389/fmats.2024.1428700Search in Google Scholar

[32] Maglad, A. M., M. A. O. Mydin, S. D. Datta, B. A., and Tayeh. Assessing the mechanical, durability, thermal and microstructural properties of sea shell ash based lightweight foamed concrete. Construction and Building Materials, Vol. 402, 2023, id. 133018.10.1016/j.conbuildmat.2023.133018Search in Google Scholar

[33] He, Y.-L. and T. Xie. Advances of thermal conductivity models of nanoscale silica aerogel insulation material. Applied Thermal Engineering, Vol. 81, 2015, pp. 28–50.10.1016/j.applthermaleng.2015.02.013Search in Google Scholar

[34] Senadheera, S. S., S. Gupta, H. W. Kua, D. Hou, S. Kim, D. C. W. Tsang, et al. Application of biochar in concrete – A review. Cement and Concrete Composites, Vol. 143, 2023, id. 105204.10.1016/j.cemconcomp.2023.105204Search in Google Scholar

[35] Tiegoum Wembe, J., L. L. Mambou Ngueyep, E. Elat, C. D. Fotseu Miyo, A. Hamadou, J.-M. B. Ndjaka, et al. Impact of the partial substitution of cement and sand by ash from several types of wood species in cementitious materials manufacture: valorization in the industrial field. Discover Civil Engineering, Vol. 1, 2024, id. 36.10.1007/s44290-024-00035-5Search in Google Scholar

[36] Golewski, G. L. The role of pozzolanic activity of siliceous fly ash in the formation of the structure of sustainable cementitious composites. Sustainable Chemistry, Vol. 3, 2022, pp. 520–534.10.3390/suschem3040032Search in Google Scholar

[37] Agarwal, S. K. Pozzolanic activity of various siliceous materials. Cement and Concrete Research, Vol. 36, 2006, pp. 1735–1739.10.1016/j.cemconres.2004.06.025Search in Google Scholar

[38] Taylor, H. F. W. Cement chemistry, Thomas Telford Publishing, London, UK, 1997.10.1680/cc.25929Search in Google Scholar

[39] Chowdhury, S., A. Maniar, and O. M. Suganya. Strength development in concrete with wood ash blended cement and use of soft computing models to predict strength parameters. Journal of Advanced Research, Vol. 6, 2015, pp. 907–913.10.1016/j.jare.2014.08.006Search in Google Scholar PubMed PubMed Central

[40] Bodur, B., A. Benli, O. Y. Bayraktar, H. G. Alcan, G. Kaplan, and A. C. Aydın. Impact of attapulgite and basalt fiber additions on the performance of pumice-based foam concrete: Mechanical, thermal, and durability properties. Archives of Civil and Mechanical Engineering, Vol. 25, 2025, id. 74.10.1007/s43452-025-01128-3Search in Google Scholar

[41] Gencel, O., O. Y. Bayraktar, G. Kaplan, O. Arslan, M. Nodehi, A. Benli, et al. Lightweight foam concrete containing expanded perlite and glass sand: Physico-mechanical, durability, and insulation properties. Construction and Building Materials, Vol. 320, 2022, id. 126187.10.1016/j.conbuildmat.2021.126187Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Nanotechnology for calcium aluminate cement: thematic analysis

- Towards sustainable concrete pavements: a critical review on fly ash as a supplementary cementitious material

- Optimizing rice husk ash for ultra-high-performance concrete: a comprehensive review of mechanical properties, durability, and environmental benefits

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters

- Fe-containing nominal wollastonite (CaSiO3)–Na2O glass-ceramic: Characterization and biocompatibility

- Relevance of pore network connectivity in tannin-derived carbons for rapid detection of BTEX traces in indoor air

- A life cycle and environmental impact analysis of sustainable concrete incorporating date palm ash and eggshell powder as supplementary cementitious materials

- Eco-friendly utilisation of agricultural waste: Assessing mixture performance and physical properties of asphalt modified with peanut husk ash using response surface methodology

- Benefits and limitations of N2 addition with Ar as shielding gas on microstructure change and their effect on hardness and corrosion resistance of duplex stainless steel weldments

- Effect of selective laser sintering processing parameters on the mechanical properties of peanut shell powder/polyether sulfone composite

- Impact and mechanism of improving the UV aging resistance performance of modified asphalt binder

- AI-based prediction for the strength, cost, and sustainability of eggshell and date palm ash-blended concrete

- Investigating the sulfonated ZnO–PVA membrane for improved MFC performance

- Strontium coupling with sulphur in mouse bone apatites

- Transforming waste into value: Advancing sustainable construction materials with treated plastic waste and foundry sand in lightweight foamed concrete for a greener future

- Evaluating the use of recycled sawdust in porous foam mortar for improved performance

- Improvement and predictive modeling of the mechanical performance of waste fire clay blended concrete

- Polyvinyl alcohol/alginate/gelatin hydrogel-based CaSiO3 designed for accelerating wound healing

- Research on assembly stress and deformation of thin-walled composite material power cabin fairings

- Effect of volcanic pumice powder on the properties of fiber-reinforced cement mortars in aggressive environments

- Analyzing the compressive performance of lightweight foamcrete and parameter interdependencies using machine intelligence strategies

- Selected materials techniques for evaluation of attributes of sourdough bread with Kombucha SCOBY

- Establishing strength prediction models for low-carbon rubberized cementitious mortar using advanced AI tools

- Investigating the strength performance of 3D printed fiber-reinforced concrete using applicable predictive models

- An eco-friendly synthesis of ZnO nanoparticles with jamun seed extract and their multi-applications

- The application of convolutional neural networks, LF-NMR, and texture for microparticle analysis in assessing the quality of fruit powders: Case study – blackcurrant powders

- Study of feasibility of using copper mining tailings in mortar production

- Shear and flexural performance of reinforced concrete beams with recycled concrete aggregates

- Advancing GGBS geopolymer concrete with nano-alumina: A study on strength and durability in aggressive environments

- Leveraging waste-based additives and machine learning for sustainable mortar development in construction

- Study on the modification effects and mechanisms of organic–inorganic composite anti-aging agents on asphalt across multiple scales

- Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs

- Structural, physical, and luminescence properties of sodium–aluminum–zinc borophosphate glass embedded with Nd3+ ions for optical applications

- Eco-friendly waste plastic-based mortar incorporating industrial waste powders: Interpretable models for flexural strength

- Bioactive potential of marine Aspergillus niger AMG31: Metabolite profiling and green synthesis of copper/zinc oxide nanocomposites – An insight into biomedical applications

- Preparation of geopolymer cementitious materials by combining industrial waste and municipal dewatering sludge: Stabilization, microscopic analysis and water seepage

- Seismic behavior and shear capacity calculation of a new type of self-centering steel-concrete composite joint

- Sustainable utilization of aluminum waste in geopolymer concrete: Influence of alkaline activation on microstructure and mechanical properties

- Optimization of oil palm boiler ash waste and zinc oxide as antibacterial fabric coating

- Tailoring ZX30 alloy’s microstructural evolution, electrochemical and mechanical behavior via ECAP processing parameters

- Comparative study on the effect of natural and synthetic fibers on the production of sustainable concrete

- Microemulsion synthesis of zinc-containing mesoporous bioactive silicate glass nanoparticles: In vitro bioactivity and drug release studies

- On the interaction of shear bands with nanoparticles in ZrCu-based metallic glass: In situ TEM investigation

- Developing low carbon molybdenum tailing self-consolidating concrete: Workability, shrinkage, strength, and pore structure

- Experimental and computational analyses of eco-friendly concrete using recycled crushed brick

- High-performance WC–Co coatings via HVOF: Mechanical properties of steel surfaces

- Mechanical properties and fatigue analysis of rubber concrete under uniaxial compression modified by a combination of mineral admixture

- Experimental study of flexural performance of solid wood beams strengthened with CFRP fibers

- Eco-friendly green synthesis of silver nanoparticles with Syzygium aromaticum extract: characterization and evaluation against Schistosoma haematobium

- Predictive modeling assessment of advanced concrete materials incorporating plastic waste as sand replacement

- Self-compacting mortar overlays using expanded polystyrene beads for thermal performance and energy efficiency in buildings

- Enhancing frost resistance of alkali-activated slag concrete using surfactants: sodium dodecyl sulfate, sodium abietate, and triterpenoid saponins

- Equation-driven strength prediction of GGBS concrete: a symbolic machine learning approach for sustainable development

- Empowering 3D printed concrete: discovering the impact of steel fiber reinforcement on mechanical performance

- Advanced hybrid machine learning models for estimating chloride penetration resistance of concrete structures for durability assessment: optimization and hyperparameter tuning

- Influence of diamine structure on the properties of colorless and transparent polyimides

- Post-heating strength prediction in concrete with Wadi Gyada Alkharj fine aggregate using thermal conductivity and ultrasonic pulse velocity

- Experimental and RSM-based optimization of sustainable concrete properties using glass powder and rubber fine aggregates as partial replacements

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part II

- Investigating the effect of locally available volcanic ash on mechanical and microstructure properties of concrete

- Flexural performance evaluation using computational tools for plastic-derived mortar modified with blends of industrial waste powders

- Foamed geopolymers as low carbon materials for fire-resistant and lightweight applications in construction: A review

- Autogenous shrinkage of cementitious composites incorporating red mud

- Mechanical, durability, and microstructure analysis of concrete made with metakaolin and copper slag for sustainable construction

- Special Issue on AI-Driven Advances for Nano-Enhanced Sustainable Construction Materials

- Advanced explainable models for strength evaluation of self-compacting concrete modified with supplementary glass and marble powders

- Analyzing the viability of agro-waste for sustainable concrete: Expression-based formulation and validation of predictive models for strength performance

- Special Issue on Advanced Materials for Energy Storage and Conversion

- Innovative optimization of seashell ash-based lightweight foamed concrete: Enhancing physicomechanical properties through ANN-GA hybrid approach

- Production of novel reinforcing rods of waste polyester, polypropylene, and cotton as alternatives to reinforcement steel rods

Articles in the same Issue

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Nanotechnology for calcium aluminate cement: thematic analysis

- Towards sustainable concrete pavements: a critical review on fly ash as a supplementary cementitious material

- Optimizing rice husk ash for ultra-high-performance concrete: a comprehensive review of mechanical properties, durability, and environmental benefits

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters

- Fe-containing nominal wollastonite (CaSiO3)–Na2O glass-ceramic: Characterization and biocompatibility

- Relevance of pore network connectivity in tannin-derived carbons for rapid detection of BTEX traces in indoor air

- A life cycle and environmental impact analysis of sustainable concrete incorporating date palm ash and eggshell powder as supplementary cementitious materials

- Eco-friendly utilisation of agricultural waste: Assessing mixture performance and physical properties of asphalt modified with peanut husk ash using response surface methodology

- Benefits and limitations of N2 addition with Ar as shielding gas on microstructure change and their effect on hardness and corrosion resistance of duplex stainless steel weldments

- Effect of selective laser sintering processing parameters on the mechanical properties of peanut shell powder/polyether sulfone composite

- Impact and mechanism of improving the UV aging resistance performance of modified asphalt binder

- AI-based prediction for the strength, cost, and sustainability of eggshell and date palm ash-blended concrete

- Investigating the sulfonated ZnO–PVA membrane for improved MFC performance

- Strontium coupling with sulphur in mouse bone apatites

- Transforming waste into value: Advancing sustainable construction materials with treated plastic waste and foundry sand in lightweight foamed concrete for a greener future

- Evaluating the use of recycled sawdust in porous foam mortar for improved performance

- Improvement and predictive modeling of the mechanical performance of waste fire clay blended concrete

- Polyvinyl alcohol/alginate/gelatin hydrogel-based CaSiO3 designed for accelerating wound healing

- Research on assembly stress and deformation of thin-walled composite material power cabin fairings

- Effect of volcanic pumice powder on the properties of fiber-reinforced cement mortars in aggressive environments

- Analyzing the compressive performance of lightweight foamcrete and parameter interdependencies using machine intelligence strategies

- Selected materials techniques for evaluation of attributes of sourdough bread with Kombucha SCOBY

- Establishing strength prediction models for low-carbon rubberized cementitious mortar using advanced AI tools

- Investigating the strength performance of 3D printed fiber-reinforced concrete using applicable predictive models

- An eco-friendly synthesis of ZnO nanoparticles with jamun seed extract and their multi-applications

- The application of convolutional neural networks, LF-NMR, and texture for microparticle analysis in assessing the quality of fruit powders: Case study – blackcurrant powders

- Study of feasibility of using copper mining tailings in mortar production

- Shear and flexural performance of reinforced concrete beams with recycled concrete aggregates

- Advancing GGBS geopolymer concrete with nano-alumina: A study on strength and durability in aggressive environments

- Leveraging waste-based additives and machine learning for sustainable mortar development in construction

- Study on the modification effects and mechanisms of organic–inorganic composite anti-aging agents on asphalt across multiple scales

- Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs

- Structural, physical, and luminescence properties of sodium–aluminum–zinc borophosphate glass embedded with Nd3+ ions for optical applications

- Eco-friendly waste plastic-based mortar incorporating industrial waste powders: Interpretable models for flexural strength

- Bioactive potential of marine Aspergillus niger AMG31: Metabolite profiling and green synthesis of copper/zinc oxide nanocomposites – An insight into biomedical applications

- Preparation of geopolymer cementitious materials by combining industrial waste and municipal dewatering sludge: Stabilization, microscopic analysis and water seepage

- Seismic behavior and shear capacity calculation of a new type of self-centering steel-concrete composite joint

- Sustainable utilization of aluminum waste in geopolymer concrete: Influence of alkaline activation on microstructure and mechanical properties

- Optimization of oil palm boiler ash waste and zinc oxide as antibacterial fabric coating

- Tailoring ZX30 alloy’s microstructural evolution, electrochemical and mechanical behavior via ECAP processing parameters

- Comparative study on the effect of natural and synthetic fibers on the production of sustainable concrete

- Microemulsion synthesis of zinc-containing mesoporous bioactive silicate glass nanoparticles: In vitro bioactivity and drug release studies

- On the interaction of shear bands with nanoparticles in ZrCu-based metallic glass: In situ TEM investigation

- Developing low carbon molybdenum tailing self-consolidating concrete: Workability, shrinkage, strength, and pore structure

- Experimental and computational analyses of eco-friendly concrete using recycled crushed brick

- High-performance WC–Co coatings via HVOF: Mechanical properties of steel surfaces

- Mechanical properties and fatigue analysis of rubber concrete under uniaxial compression modified by a combination of mineral admixture

- Experimental study of flexural performance of solid wood beams strengthened with CFRP fibers

- Eco-friendly green synthesis of silver nanoparticles with Syzygium aromaticum extract: characterization and evaluation against Schistosoma haematobium

- Predictive modeling assessment of advanced concrete materials incorporating plastic waste as sand replacement

- Self-compacting mortar overlays using expanded polystyrene beads for thermal performance and energy efficiency in buildings

- Enhancing frost resistance of alkali-activated slag concrete using surfactants: sodium dodecyl sulfate, sodium abietate, and triterpenoid saponins

- Equation-driven strength prediction of GGBS concrete: a symbolic machine learning approach for sustainable development

- Empowering 3D printed concrete: discovering the impact of steel fiber reinforcement on mechanical performance

- Advanced hybrid machine learning models for estimating chloride penetration resistance of concrete structures for durability assessment: optimization and hyperparameter tuning

- Influence of diamine structure on the properties of colorless and transparent polyimides

- Post-heating strength prediction in concrete with Wadi Gyada Alkharj fine aggregate using thermal conductivity and ultrasonic pulse velocity

- Experimental and RSM-based optimization of sustainable concrete properties using glass powder and rubber fine aggregates as partial replacements

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part II

- Investigating the effect of locally available volcanic ash on mechanical and microstructure properties of concrete

- Flexural performance evaluation using computational tools for plastic-derived mortar modified with blends of industrial waste powders

- Foamed geopolymers as low carbon materials for fire-resistant and lightweight applications in construction: A review

- Autogenous shrinkage of cementitious composites incorporating red mud

- Mechanical, durability, and microstructure analysis of concrete made with metakaolin and copper slag for sustainable construction

- Special Issue on AI-Driven Advances for Nano-Enhanced Sustainable Construction Materials

- Advanced explainable models for strength evaluation of self-compacting concrete modified with supplementary glass and marble powders

- Analyzing the viability of agro-waste for sustainable concrete: Expression-based formulation and validation of predictive models for strength performance