Abstract

The aim of this study is to investigate the influence of natural pozzolana (NP) and silica fume (SF) as a partial replacement for ordinary Portland cement (OPC) to enhance the performance of fiber-cement mortar subjected to harsh environments. The samples were immersed in seawater mixed with sodium sulfate (Na2SO4) at a rate of 5 kg per 100 L to represent the harsh environment of surface groundwater in offshore soil. Mortar mixes were made by substituting the mass of OPC with NP and SF for 0, 5, 10, and 20%. The mortar samples underwent 90 cycles of drying and wetting, with 48 h allocated for each phase, for a duration of 360 days. Compressive strength (CS) and flexural strength (FS) tests were conducted on samples aged 7, 28, 90, 180, and 360 days, while cement samples after 28, 90, 180, and 360 curing days were examined for absorption and initial surface absorption capacity. The study indicates that the curing of control samples with seawater resulted in a slight decrease in CS and FS, up to 2.4 and 7.4%, respectively. Despite the application of seawater curing, the mortar samples containing NP and SF exhibited enhanced CS (up to 10.8% for SF), FS (up to 27.3% for NP and 30.7% for SF), and water resistance (up to 18.5% for NP and 24.9% for SF) compared to the OPC.

1 Introduction

Water plays a significant role in the curing process of concrete, impacting cement hydration, which is necessary for gaining strength, especially during the early days. During the hydration stage, water and cement react together to form calcium silicate hydrate (C–S–H) and calcium hydroxide, which are accountable for concrete hardening and strength. The reaction between water and cement lasts if water is available and the temperature is appropriate. The marine environment is one of the most challenging environments that significantly influence the long-term behavior of concrete. Conveying freshwater over extensive distances may lead to substantial costs and energy. One way to avoid the extra cost and energy due to long-distance delivery in some marine regions, such as islands where freshwater is limited, is to utilize seawater and ocean water to cure concrete and mortar. One issue with this way is that the presence of high levels of chloride ions, present in saltwater, causes corrosion of steel in reinforced concrete (RC), resulting in the deterioration of RC members. Besides chloride ions (Cl−), dissolved oxygen (O2) in water facilitates the electrochemical processes that cause corrosion. The presence of dissolved oxygen facilitates the oxidation of surfaces in metal, hence accelerating rust development in steel and iron. The elevated salt of seawater enhances its conductivity, facilitating electrochemical processes and expediting the rusting process. Due to all the factors mentioned previously, behaviors of concrete structures constructed in places with high seawater levels have been a concern. Mangi et al. [1] studied the effects of aggressive salts on concrete structures. They found that utilizing supplementary cementitious materials (SCMs) such as coal bottom ash (CBA) can mitigate the effects by decreasing the penetrability of concrete, hence increasing the durability of concrete structures. Adding two pozzolanic materials (volcanic pumice and zeolite) to make cement mortar in aggressive environments enhanced the corrosion resistance of steel rebar embedded in the mortars [2,3]. Moreover, incorporating natural pozzolan into mortars exposed to aggressive sulfate solutions increases corrosion resistance [4]. Hossain et al. [5] conducted a study on the behaviors of concrete cured in seawater in the presence of volcanic ash, a natural pozzolanic material. The findings revealed that concrete containing volcanic ash had enhanced performance in strength and durability in comparison to normal concrete. This enhancement was attributed to the pozzolanic properties of volcanic ash, which increases concrete resistance to saltwater ion diffusivity, a crucial factor for durability in marine environments. Performance evaluations of concrete blended with pozzolanic materials (blast furnace slag, fly ash, and silica fume [SF]) in marine environments were studied [6]. The findings indicated that including cement mixed with pozzolanic materials considerably enhanced the performance of concrete in marine environments. Besides improving durability, the utilization of these pozzolanic materials aids in conserving natural resources, decreasing pollution, and lowering energy usage, thus creating a more sustainable environment. Annual production of ordinary Portland cement (OPC) is over 4 billion tons, rendering it one of the most prevalent construction materials worldwide [7]. Martínez-Rosales et al. [2] studied the effects of incorporating volcanic pumice and zeolite, natural pozzolans, into mortars in sulfate environment. The results show that compressive strength (CS) of the mortars containing pozzolans is similar to the control mortar (without pozzolanic materials). This indicates that mechanical strength was not negatively affected by the replacement even when the substitution was up to 25%. Moreover, the inclusion of pozzolanic materials inhibited the development of ettringite, a chemical associated with durability issues in concrete. Also, incorporating pozzolanic materials can improve the lifetime and durability of RC structures in harsh environments. The manufacturing process of concrete production accounts for 5–8% of all global CO2 emissions [8]. This indicates a significant impact on global warming, highlighting the necessity for immediate action to reduce these emissions. The utilization of Beni-saf, natural pozzolan, was investigated to evaluate mortar mechanical properties in harsh environments having 5% of sodium sulfate solution (Na2SO4) [9]. The results exhibit that incorporating natural pozzolan may be an advantageous method for improving the performance and durability of construction materials. A study on the behaviors of natural pozzolan-based mortars exposed to 5% sodium chloride was carried out [10]. The replacement of Portland cement with natural pozzolan was up to 30%. The findings demonstrated that the inclusion of natural pozzolan considerably lowered the corrosion rate of the reinforcing bars embedded in the mortars. Furthermore, mortars containing pozzolan demonstrated superior mechanical properties and enhanced mortars’ resistance to chloride ion penetration. The diffusivity of chloride ions in concrete can be markedly decreased through the inclusion of pozzolanic materials such as SF, lowering the calcium-to-silicon (C/S) of calcium-silicate-hydrate (C–S–H), resulting in a more complicated porous surface structure that inhibits the diffusion of chloride ions [11]. The primary function of SF in concrete is as filler because of its fineness. It fills voids between particles [12]. SF was utilized to make up mortars to improve the penetration resistance by creating a surface protection material, mitigating the corrosion issue in concrete [13]. The results demonstrate that the surface created due to SF shows robust interfacial binding strength. Also, the diffusion coefficient of chloride is markedly decreased, signifying superior penetration resistance. Portland cement was partially replaced by SF for up to 10% of mass in harsh environments, and the results show enhancement in mechanical properties, mainly CS and flexural strengths (FSs), along with enhanced resistance to abrasion and weight loss in comparison to control concrete (without SF) [14]. Iqbal et al. [15] studied the impacts of the marine environment on SF-based concrete. The findings indicate that mixtures with SF had more strength and permeability than the control mixture without SF. These improvements in strength and permeability were attributed to denser microstructures resulting from the interaction between silica and unreacted portlandite, leading to the formation of C–S–H. The effect of using seawater in concrete curing was investigated in the presence of Bestmittel at 0.6% and SF at rates of 10, 20, and 25% [16]. The results show that specimens with 20% SF had the highest CS for those cured in tap water, while specimens with 25% SF had the highest CS for those cured in seawater. The findings indicate that the optimal dosage of SF could vary based on the curing methods. In seawater curing, the CS decreased, but a higher percentage of SF could mitigate this reduction. Incorporating SF in concrete exposed to the acids led to a reduction in mass and CS loss in comparison to concrete without pozzolanic ingredients [17]. Steel fiber (SFs) was added at 3% of total weight to improve mechanical properties in seawater environments, and the results showed that the inclusion of SF enhanced the overall performance, mainly strength and durability [18]. The CS values decreased as the duration of immersion in seawater increased. Notably, no carbonation was observed although there was a presence of steel fiber even after 120 days of exposure. Seawater was utilized for mixing instead of freshwater in the presence of steel fiber to observe its effect on the mechanical properties after 27 months [19]. Results showed that there was an enhancement in mechanical properties with time; however, FS and axial compressive toughness decreased when exposure time to carbonation exceeded 15 months. The alkalinity of concrete containing steel fiber decreased due to carbonation impact, speeding up steel fiber corrosion close to the concrete surface. At 27 months, the corrosion reached a thickness of 20–30 mm.

Further investigation into the incorporation of natural pozzolana (NP) and SF regarding its strength-enhancing properties and water-resistance features is necessary. The aim of this study is to investigate the influence of NP and SF as a partial replacement for OPC to enhance the performance of fiber-cement mortar subjected to harsh environments. Mortar mixes were made by substituting the mass of OP with NP and SF for 0, 5, 10, and 20%. The mortar samples underwent 90 cycles of drying and wetting, with 48 h allocated for each phase, for a duration of 360 days. CS and FS testing were conducted on samples aged 7, 28, 90, 180, and 360 days, while cement samples after 28, 90, 180, and 360 curing days were examined for absorption and initial surface absorption (ISA) capacity. In addition, the scanning electron microscopy (SEM) analysis was conducted at a testing age of 180 days.

2 Experimental study

2.1 Materials

This study’s OPC complies with ASTM C150 standards [20]. The Jazan state of Saudi Arabia, situated in the southeastern region of the Middle East, is awash in NP. In this study, the NP was collected from the byproducts of lightweight aggregate production from volcanic pumice, as shown in Figure 1(a). The specific surface area of the NP was increased to 3,640 cm2·g−1 by Blaine’s test as a result of the pulverization of the lightweight aggregate waste using a ball mill, as shown in Figure 1(b). The specific gravity was evaluated using a gas pycnometer according to ASTM C604 [21], while the surface area was determined by Blaine’s test (the air permeability test) following ASTM C204 [22]. Table 1 presents the physical properties of NP and OP. The chemical composition evaluation findings indicate that the OP and NP products comply with the standards set by ASTM C114 [23] and ASTM C618 [24], respectively. Table 2 presents the chemical composition of NP and OP. The fine aggregate (FA) utilized exhibits a specific gravity of 2.64 and a water absorption rate of 0.85%. The granular FA grading complies with ASTM C778 [25]. The specific weight of the polycarboxylate-based superplasticizer (PCE) that was employed in this study was 1.06 g·cm−3. Several laboratory procedures were used to assess PCE concentration, which was kept at 0.5% in all mixes. The fiber length and diameter were 20 and 0.25 mm, respectively, while the tensile strength was 1,100–1,300 MPa. The silica fume in this study containing 95.3% of SiO2 as shown in Figure 2. Table 1 presents the physical properties of SF, respectively.

Raw materials used in this study: (a) volcanic pumice waste and (b) NP refining process.

Physical properties of OP, NP, and SF

| Property | OP | NP | SF |

|---|---|---|---|

| Specific gravity | 3.10 | 2.56 | 2.26 |

| Surface area (cm2·g−1) | 3,410 | 3,640 | 16,200 |

Cement mortar proportion

| Mixture ID | Proportion (kg·m−3) | Fiber (%) | |||||

|---|---|---|---|---|---|---|---|

| Water | OP | NP | SF | Sand | Superplasticizer (SP) | ||

| OPC | 242.5 | 550 | 0 | 0 | 1,549 | 5.5 | 0 |

| NP5F0.1 | 242.5 | 522.5 | 27.5 | 0 | 1,544 | 5.5 | 0.1 |

| NP10F0.1 | 242.5 | 495 | 55 | 0 | 1,539 | 5.5 | 0.1 |

| NP20F0.1 | 242.5 | 440 | 110 | 0 | 1,530 | 5.5 | 0.1 |

| SF5F0.1 | 242.5 | 522.5 | 0 | 27.5 | 1,544 | 5.5 | 0.1 |

| SF10F0.1 | 242.5 | 495 | 0 | 55 | 1,539 | 5.5 | 0.1 |

| SF20F0.1 | 242.5 | 440 | 0 | 110 | 1,530 | 5.5 | 0.1 |

Chemical composition of OP, NP, and SF.

2.2 Mix proportion

The cement mortar mixing ratios were designed as per ASTM C305 [26]. The normal proportion for the cement mortar mix was 1:2.75 of OP to sand by weight. All mortar mixes used in this investigation had a water-to-cement ratio of 0.485. In this investigation, NP and SF partially replaced OP mass at rates of 5, 10, and 20%. Table 2 shows the cement mortar proportion used in this investigation. The control mix (i.e., OPC) was made without fiber, NP, and SF. The second to fourth mixes (i.e., NP5F0.1, NP10F0.1, and NP20F0.1) were made with NP of 5, 10, and 20%, respectively; and the fifth to seventh mixes (i.e., SF5F0.1, SF10F0.1, and SF20F0.1) were made with SF of 5, 10, and 20%, respectively.

2.3 Samples preparation

The mixing method utilized a mechanical mixer for a minimum duration of 8 min, ensuring that the mixes were completely homogenized. The OPC, NP, SF, and FA (i.e., dry constituents) were mixed together for 2 min. The SP was mixed with the required quantity of water and added to the dry mix in two stages (i.e., 70 and 30% of the required amount), and the mixing was continued for 3 min for both stages. Then, the fibers were added and continued mixing for 3 min until homogeneous. After that, the mix was compacted by using a mechanical vibrator, following the placement of the mix straight into the molds in two layers. The samples are covered with a moist cloth for 24 h to avoid moisture loss.

2.4 Curing method

Two different circumstances were employed for curing the mortar samples. Following a 24 h period of casting, the samples were placed in the immersion curing tank for 7 days. The two curing processes were performed at the same temperature, specifically the laboratory’s conditions of 20 ± 2°C. The laboratory’s immersion curing tank is partitioned into two parts for submerging the samples in drinking water and seawater until the testing date. In addition, the samples submerged in the seawater were exposed to wetting and drying cycles. Following a 48 h immersion in seawater, the mortar samples underwent daily 48 h drying outside. Mortar samples were taken for testing at the designated ages of 7, 28, 90, 180, and 360 days. Na2SO4 was incorporated at an amount of 5 kg per 100 L into Red Sea seawater and subsequently dissolved to represent the surface groundwater in offshore soil. Figure 3 shows the production of cement mortar samples.

Casting and curing of cement mortar samples: (a) mortar samples, (b) seawater consisting of Na2SO4, and (c) curing tanks.

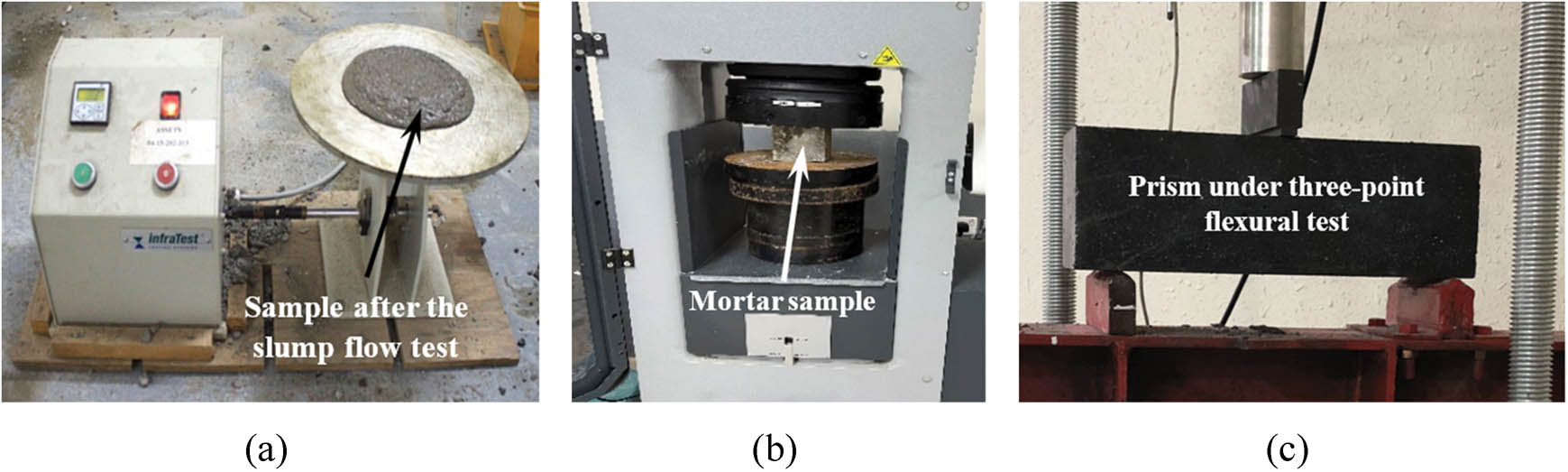

2.5 Testing procedure

In accordance with ASTM C1437 [27], a slump flow test was conducted to evaluate the fresh characteristics of cement mortar mix, as shown in Figure 4(a). A CS test was conducted to assess the efficacy of including fibers, NP, and SF in the preparation of cement mortar mix using cube samples of 70 mm, as shown in Figure 4(b). In accordance with ASTM C109 [28], the CS test was conducted at ages of 7, 28, 90, 180, and 360 curing days. Similar cube dimensions were employed to evaluate the performance of fiber-reinforced cement mortars in aggressive environments. In accordance with ASTM C348 [29], the FS test was conducted at ages of 7, 28, 90, 180, and 360 curing days. The prism dimensions used in the flexural tests were 100 mm × 100 mm × 400 mm, as shown in Figure 4(c). Each age group tested three samples, recording their averages for the compressive and flexural tests. The water saturation technique was used to analyze the water absorption of the cement mortar as described by Rilem [30]. The testing involved three cube samples measuring 70 mm each. The average was then calculated for all three samples in each mix. The water absorption was determined using Eq. (1)

where W 1 is the weight of samples in the air with saturated surface dry, g; W 2 is the weight of samples that were oven-dried in the air, g.

Cement mortar tests: (a) slump flow, (b) compressive tests, and (c) flexural test.

Following ASTM C1585 [31], the ISA of mortar samples was carried out in this study. Prior to the process of testing, the surface of the sample was cleansed with a brush and towel to eliminate any impurities. For 48 h, the samples were dried in an oven set at 105 ± 5°C. Weights of the oven-dried samples were recorded to the closest 0.01 g. The sample was immersed in a water pan at a temperature of 25 ± 2°C, putting it on steel plates with a depth of 20 mm to allow for water flow. At 60 min intervals following the beginning of the ISA test, the increase in sample mass was recorded to ascertain the water absorption value. A three-test ISA average was calculated. Eq. (2) was used to determine the ISA at each time interval

where

A microstructural investigation was performed to understand the influence of SF, fibers, NP, and seawater on the performance of cement mortar. SEM analysis was done on representative samples of the crushed sample 180 days after the CS test. Table 3 displays the test matrix’s details.

Test matrix’s details

| Mixture ID | Curing method | NP content | SF content |

|---|---|---|---|

| OPC | Drinking water | — | — |

| OPCH | Seawater | — | — |

| NP5F0.1 | 5% | — | |

| NP10F0.1 | 10% | — | |

| NP20F0.1 | 20% | — | |

| SF5F0.1 | — | 5% | |

| SF10F0.1 | — | 10% | |

| SF20F0.1 | — | 20% |

3 Results and discussion

3.1 Slump flow

Figure 5a illustrates the slump flow results for the cement mortar mix. Adding fibers significantly reduced the slump flow in mortar mixes, regardless of whether NP or SF materials replaced cement. The reduction in workability results from incorporating steel fibers, which create an interlocking structure within the mix that inhibits surface bleeding [32]. To address this issue, higher dosages of SP may be employed in future combination development; however, this work utilized a uniform dosage of SP across all mixes to investigate the impact of NP and SF. The inclusion of fibers negatively impacted the workability of the mix, a result that also corroborated prior findings [33,34]. Compared to the control mix (OPC), using NP with 5, 10, and 20% reduced the slump flow by 14.3, 10.7, and 7.1%, respectively. However, the slump values have increased due to increased NP replacement levels, with the NP20F0.1 (with 20%) exhibiting an increased ratio of 7.7% in comparison with the NP5F0.1 (with 5%). This can be attributed to that including NP that have greater fineness, resulting in wider distribution of particles, hence facilitating particle slide and diminishing frictional tensions among the angular particles [35]. According to Kwan and Fung [36], adding more SP increases the distance between particle surfaces, reduces the colloidal interactions among molecules, lowers the extent of flocculation, and decreases the attraction between molecules. These changes improve the fresh mixture’s rheological characteristics. Regarding the use of SF, the slump flow is reduced by 21.4, 28.6, and 28.6% for the SF5F0.1, SF10F0.1, and SF20F0.1, respectively, compared to the control mix (OPC). However, the slump values have decreased due to increased SF replacement levels, with the SF20F0.1 (with 20%) exhibiting a decreased ratio of 9.1% compared to the SF5F0.1 (with 5%) (Figure 5b). Furthermore, there was no discernible difference between the substitution levels of 5 and 10%. Ghafari et al. [37] reported that the incorporation of SF generally elevated the air content of the mix, irrespective of the quantity added. There was a significant correlation between the slump flow decrease rate and the SF dosage, with the slump flow decreasing as the SF dosage increased. Koksal et al. [38] reported that the presence of SF and fibers had a negative impact on the slump values. This outcome aligns with the results of the current investigation.

Slump flow results.

3.2 CS

Figure 6 illustrates the CS values for mortar mixes that incorporate NP and SF as partial replacements for OP at 0, 5, 10, and 20% at various curing ages and methods. Figure 6(a) presents the CS values of the NP mortar mixes after 7, 28, 90, 180, and 360 curing days. The curing of control samples using seawater (i.e., OPCH) resulted in a decrease in CS. The reduction ratios were 0.6, 0.6, 1.4, 2.4, and 1.2% at 7, 28, 90, 180, and 360 days, respectively, compared to the curing of control samples using drinking water (i.e., OPC). The findings indicate that, except for the 20% replacement ratio, the CS of samples with NP values of 5 and 10% has improved over time (Figure 6(a)). The CS of cement mortar with 5% NP (i.e., NP5F0.1) increased by 2.5 and 2.6% at 7 and 28 days, respectively, compared to the control mixture (OPC), and then decreased by 1.6, 2.4, and 8.5% at 90, 180, and 360 days, respectively. In the case of 10% NP (i.e., NP10F0.1), the increases were 4.3, 3.7, and 0.3% at 7, 28, and 90 days, respectively, while a reduction was noticed at 180 and 360 days by 0.5 and 5.4%, respectively. Conversely, employing a significant substitute rate of 20% (i.e., NP20F0.1) resulted in reductions at all test ages; the reductions were 7.9, 4.9, 3.4, 2.9, and 8.8% at test ages 7, 28, 90, 180, and 360 days, respectively.

CS results: (a) NP samples and (b) SF samples.

The CS values of the SF mortar mix after 7, 28, 90, 180, and 360 curing days are shown in Figure 6(b). The findings indicate that the CS of samples with SF values of 5, 10, and 20% has improved over time, as illustrated in Figure 6(b). The CS of cement mortar with 5% SF (i.e., SF5F0.1) increased by 7.2, 1.7, 1.1, 1.3, and 2.1% at 7, 28, 90, 180, and 360 days, respectively, compared to the control mixture (OPC). The same trend was noticed. In the case of 10 and 20% SF (i.e., SF10F0.1 and SF20F0.1), the increases for SF10F0.1 mix were 9.9, 4.2, 2.4, 2.7, and 2.6% at the same ages, while it was 10.8, 6.8, 3.9, 3.9, and 4.4% for SF20F0.1 mix.

The CS of all mixes was directly influenced by the use of NP as a partial substitute for OP and the curing procedures, as demonstrated in Figure 6. According to the results, the mixes with NP10F0.1 (10% NP) had the highest CS among the various replacement ratios at all curing ages. Moreover, the mixes with SF20F0.1 (20% SF) had the highest CS among the various replacement ratios at all curing ages. The results show that NP can be used as a 10% replacement for OP because of its pozzolanic characteristics and chemical composition. These properties allow it to react with OP’s products, Ca(OH)2, to generate an improved C–S–H gel. Furthermore, it functioned as a filler, reducing permeability and enhancing CS [39].

The efficacy of NP, particularly derived from volcanic pumice, is affected by OP level, surface area, and chemical composition. Seraj et al. [40] indicate that particle size is the primary factor affecting NP activity. The duration of the test positively influenced the results; mortar samples with extended curing periods had superior CSs relative to the samples tested at 7 days, as illustrated in Figure 6(a). This is due to NP materials necessitating a greater curing duration before the CH reaction. This perspective has already been corroborated by the results of several prior investigations [41,42,43]. Seawater significantly affects the long-term CS of cement mortar. When immersed in seawater, the CS of mortar exhibited a reduction at 360 days of 8.5, 5.4, and 8.8% for NP5F0.1, NP10F0.1, and NP20F0.1, respectively, in comparison to the OPC mix, as illustrated in Figure 6(a).

On the other hand, the SF sample’s CS persisted in its development for 360 days after being submerged in seawater (Figure 6(b)). Long-term curing seawater that contains chloride, sulfate, and sodium can initiate the SF pozzolanic process upon entering a combination, therefore reducing pore diameters and enhancing strength capacity. Seawater exposure can generate this type of reaction in mortar [44]. This illustrates how the inclusion of pozzolanic mitigates the effects of seawater on cement mortar. It has enhanced resistance to sulfates owing to a small increase in mineral admixtures. The benefits of pozzolanic cement mortar durability in seawater are evident over a longer period [45]. Although seawater contains elevated sulfate levels that facilitate ettringite formation, it was earlier reported that the pozzolanic reaction utilizes calcium hydroxide (CaO) and results in a denser composite [46]. Nonetheless, because of pozzolanic lower CaO content, it may contribute to a reduction in ettringite formation [47].

Saraç et al. [48] examined the CS of self-compacting mortars incorporating dunite powder and SF as substitutes for Portland cement, up to 30% replacement. The CS was reported to diminish with an increase in SF content over 15%. Nevertheless, the inclusion of fiber has mitigated this deficiency, as illustrated in Figure 6(b). Koksal et al. [38] reported that the use of 20% SF and fibers (0.75% of steel fibers and 3% of basalt fibers) had the highest CS compared with all mixes. Benli [49] reported that the CS of SF mixes shows a significant increase with aging development, although it also experiences a slight decrease as the SF content rises. In addition, the highest CS is demonstrated by a 5% addition of SF. Benli et al. [50] investigated the mechanical and rheological characteristics and freeze-thaw durability of self-compacting mortars containing SF and fly ash. They reported that the CS of SF mixes shows a significant increase with aging development. The CS of self-compacting mortars incorporating SF was typically observed to exceed that of self-compacting mortars with fly ash and the reference mix. Karataş et al. [51] investigated the mechanical and durability characteristics of self-compacting mortars containing ground pumice powder. They reported that the highest possible strength outcomes were achieved with samples incorporating 10–25% ground pumice powder in comparison to the control samples. Mangi et al. [45] investigated the effect of seawater on the behavior of concrete containing CBA with various fineness. The CBA-type-A (had 3,836 cm2·g−1) demonstrates superior strength performance at the later ages of 90 and 180 days. Therefore, using CBA-type-A as SCMs is recommended, considering its CS and durability in seawater and the perspective of energy consumption, as producing finer CBA particles necessitates greater energy input.

For the CS of cement mortar with a replacement level of 5%, the samples with SF show high strength compared with NP. The increased ratio was 5.0, 2.7, 3.7, and 10.8% at test ages 7, 90, 180, and 360 days, respectively, for the SF samples compared to NP samples. However, the NP samples at 7 days show a slight increase of 0.9% compared with SF samples at the same ages. The same trends were noticed at the OP replacement level of 10%. The increased ratio was 6.3, 0.6, 2.2, 3.4, and 8.2% at test ages 7, 28, 90, 180, and 360 days, respectively, for the SF samples compared to NP samples. In the case of the OP replacement level of 20%, the SF samples exhibited an increased ratio of 21.0, 12.7, 7.5, 7.1, and 13.8% at test ages of 7, 28, 90, 180, and 360 days, respectively, compared to NP samples, as illustrated in Figure 6.

3.3 FS

The FS results for all samples cured with drinking water and seawater at all curing ages are illustrated in Figure 7. The identical primary variables influencing the CS have also impacted the FS and its progression over time. These factors include curing methods and ages as well as OP replacement levels. The curing of control samples using seawater (i.e., OPCH) resulted in a decrease in FS. The reduction ratios were 4.7, 0.6, 1.4, 2.1, and 7.4% at 7, 28, 90, 180, and 360 days, respectively, compared to the curing of control samples using drinking water (i.e., OPC). The findings indicate that the FS at 5, 10, and 20% of NP has improved over time (Figure 7(a)). The FS of cement mortar with 5% NP (i.e., NP5F0.1) increased by 26.5, 26.7, 23.2, 22.0, and 16.5% at test ages of 7, 28, 90, 180, and 360 days, respectively, compared to the control mixture (OPC). In the case of 10% NP (i.e., NP10F0.1), the increases were 23.2, 23.7, 27.3, 26.0, and 20.9% at the same test ages. The same trend was noticed at 20% NP (i.e., NP20F0.1) with increased ratios of 19.7, 22.1, 18.6, 19.1, and 16.5% at the same test ages, as illustrated in Figure 7(a). During the early ages (i.e., 7 and 28 days), the NP5F0.1 demonstrated the highest FS compared to all other mortar samples. The ratios increased by 4.4 and 4.1% compared to NP10F0.1 and NP20F0.1 at 7 days, respectively, and by 9.3 and 6.3% compared to NP10F0.1 and NP20F0.1 at 28 days. During the late ages (i.e., 90, 180, and 360 days), the NP10F0.1 demonstrated the highest FS compared to all other mortar samples. The increase in ratios reached 10.7, 8.6, and 5.3% at 90, 180, and 360 days, respectively, compared to NP5F0.1 and NP20F0.1.

FS results: (a) NP samples and (b) SF samples.

Seawater has a substantial effect on the mortar’s long-term FS. The FS of the mortar samples with 5, 10, and 20% of NP content continued to notably increase to 90 days and then slightly increased in 180 days and then began to marginally decrease after 360 days of submersion in seawater with a decreased ratio up to 1.9%. In contrast, the NP20F0.1 sample persisted in its development until 360 days. When compared to its strength at 180 days, the increased ratio after 360 days was 1.9%. Additionally, the NP20F0.1 sample at 360 days exhibited a 19.7% increase in FS relative to the OPC sample at the same curing age. Consequently, employing NP as a partial substitute for OP during seawater curing significantly influences FS. Figure 7(a) shows that cement mortar samples immersed in drinking water exhibited the most significant enhancement in FS over ages, in contrast to all samples immersed in seawater, with an increased ratio of 31%.

The findings indicate that the FS at 5, 10, and 20% of SF has improved over time, as illustrated in Figure 7(b). The FS of cement mortar with 5% SF (i.e., SF5F0.1) increased by 23.2, 26.7, 23.2, 17.5, and 13.3% at test ages of 7, 28, 90, 180, and 360 days, respectively, compared to the OPC samples (control mixture). In the case of 10% SF (i.e., SF10F0.1), the increases were 28.0, 30.7, 27.3, 23.4, and 18.0% at the same test ages. The same trend was noticed at 20% SF (i.e., SF20F0.1) with increased ratios of 26.5, 28.1, 23.2, 22.0, and 14.9% at the same test ages, as illustrated in Figure 7(b). During all test ages (i.e., 7–360 days), the SF10F0.1 demonstrated the highest FS compared to all other mortar samples. FS increased significantly during the early ages and gradually decreased over time. For example, the FS of the SF10F0.1 sample was 28.0% higher than the control samples (OPC) at 7 days and increased by 18% at 360 days when compared to the control sample at the same age.

The long-term FS of the mortar is greatly influenced by seawater. The FS of the mortar samples containing 5, 10, and 20% SF content continued to notably increase up to 90 days, followed by a slight increase at 180 days. However, after 360 days of submersion in seawater, there was a marginal decrease, with a reduction ratio of up to 3.8%. In contrast, the SF5F0.1 sample did not show a reduction at 360 days compared to its strength at 180 days (Figure 7(b)). Additionally, the SF20F0.1 sample at 360 days exhibited a 17.5% increase in FS relative to the OPC sample at the same age. As a result, using SF as a partial replacement for OP in the curing of seawater has a notable impact on FS.

The cement mortar with steel fibers demonstrated an impressive ability to undergo significant deformation before reaching total failure. The enhanced FS of the cement mortar with steel fibers can be attributed to the bonding effect between the mortar matrix and steel fiber, which results in diminished crack propagation and formation, allowing for sustained load resistance at the cracks [52,53]. According to Benli [49], a 10% addition of SF demonstrates the highest FS. Benli et al. [54] investigated the effect of seawater on the mechanical and durability characteristics of self-compacting mortars containing fly ash/SF. They reported that the flexural tensile strength of ternary mixes of self-compacting mortars subjected to MgSO4 solution exhibited superior performance across all exposure conditions, with FA10SF6 (mortar with a combination of fly ash and SF) achieving the highest value at 90 days.

Figure 8 illustrates the correlation between FS and CS among all the samples. Linear relationships between FS and CS were established, exhibiting coefficients of correlation that reached up to 0.93.

The relationship between FS and CS.

For cement mortar with 5% replacement, the samples with NP had higher FS at 7, 180, and 360 days compared to SF, with increases of 4.4, 5.8, and 3.8%, respectively. However, the FS was the same for both SF and NP samples at 28 and 90 days. However, the FS was the same at test ages 28 and 90 days for the SF and NP samples. In the case of the OP replacement level of 10%, the SF samples exhibited an increased ratio of 6.3 and 9.3% at test ages 7 and 28 days (early curing ages), whereas, at late curing age, the NP samples showed a high strength with an increased ratio of 4.6 and 3.6% at test ages 7 and 28 days, respectively. Regarding the replacement level of 20%, the increased ratio was 8.5, 7.7, 5.7, and 3.6% at test ages 7, 28, 90, and 180 days, respectively, for the SF samples compared to NP samples. However, the NP samples at 360 days show a slight increase of 1.9% compared with SF samples at the same ages.

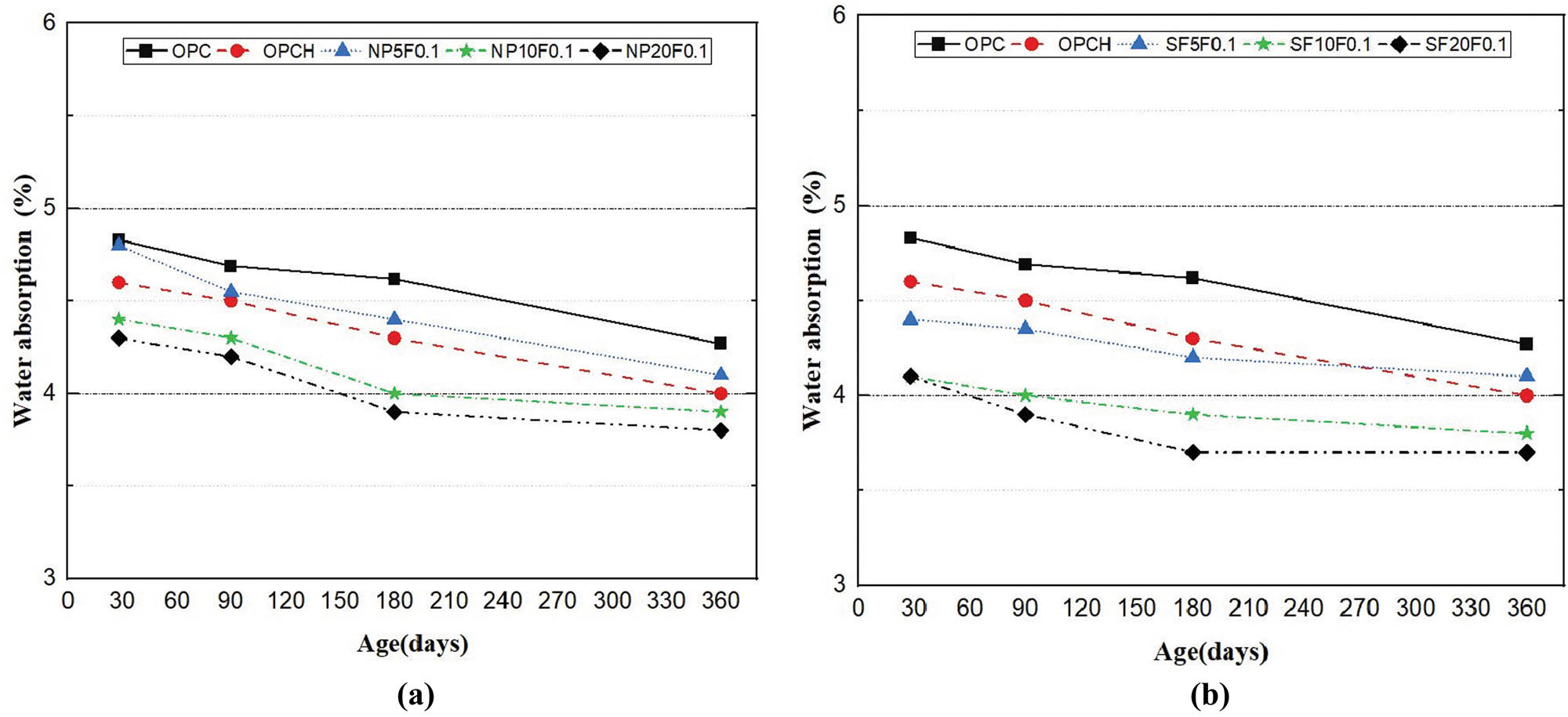

3.4 Water absorption

The evaluation of the mortar’s water absorption capability was conducted using standard sample cubes measuring 70 mm on each side. Figure 9 presents the results of water absorption for all mortar samples at 28, 90, 180, and 360 days. The trend lines of different samples demonstrated varying absorption rate performances across different ages, highlighting the considerable influence of curing methods. The OPC control sample demonstrated the highest water absorption across all ages, as illustrated in Figure 9. As the age of the mortar increases, the water absorption of the control sample decreases. For example, the water resistance of the OPC sample at 360 days was 13.1% higher than that at 7 days. The curing of control samples using seawater (i.e., OPCH) resulted in a decrease in water absorption. The reduction ratios were 5.0, 4.2, 7.4, and 6.7% at 28, 90, 180, and 360 days, respectively, compared to the curing of control samples using drinking water (i.e., OPC).

Water absorption results: (a) NP samples and (b) SF samples.

The findings indicate that the water absorption at 5, 10, and 20% of NP has improved over time, as illustrated in Figure 9(a). The water absorption of cement mortar with 5% NP (i.e., NP5F0.1) decreased by 0.6, 3.1, 5.0, and 4.1% at test ages 28, 90, 180, and 360 days, respectively, compared to the control mixture (OPC). In the case of 10% NP (i.e., NP10F0.1), the decreases were 9.8, 9.1, 15.5, and 9.5% at the same test ages. The same trend was noticed at 20% NP (i.e., NP20F0.1) with decreased ratios of 12.3, 11.7, 18.5, and 12.4% at the same test ages, as illustrated in Figure 9(a). The results show that water absorption at 5, 10, and 20% of SF has improved over time, as shown in Figure 9(b). The water absorption of cement mortar with 5% SF (i.e., SF5F0.1) decreased by 9.8, 7.8, 10.0, and 4.1% at test ages 28, 90, 180, and 360 days, respectively, when compared to the OPC samples (control mixture). At the same test ages, 10% SF (i.e., SF10F0.1) decreased by 17.8, 17.3, 18.5, and 12.4%, respectively. The same trend was observed at 20% SF (i.e., SF20F0.1), with reduced ratios of 17.8, 20.3, 24.9, and 15.4% at the same test ages, as shown in Figure 9(b).

Despite the application of seawater curing, the mortar samples containing NP exhibit enhanced water resistance relative to the control samples (i.e., those without NP). The results show that the rates of water absorption decreased as the NP level increased. The same trend was noticed for the mortar samples containing SF, where the water resistance enhanced as the SF level increased, as illustrated in Figure 9. The reduction in water absorption may be attributed to the presence of NP, which can occupy the mortar’s pores. This impedes the water transport through the mortar sample’s free voids. This outcome aligns with the findings of Tuoi Nguyen et al. [46] and Mangi et al. [45]. In comparison to samples that were immersed in drinking water, these samples demonstrated superior resistance to water absorption, despite being submerged in seawater. This could be attributed to the obstruction of water penetration by sediment accumulation on the mortar sample surfaces. Furthermore, Yiğiter et al. [55] reported that the corrosion protection of steel bars is crucially improved by blended cement, which is a combination of conventional Portland cement and slag cement. This combination may improve chloride-penetration resistance. Increasing the SF percentage reduces water absorption at all ages. Many studies have assessed the porosity of cement mortar and concrete through the incorporation of SF. They reported that the SF results in an impermeable and more discontinuous pore structure in concrete, thereby enhancing the water resistance capacity of cement [56,57]. This finding aligned with the results of this study.

Saraç et al. [48] reported that the concrete developed with SF exhibited greater density and reduced porosity compared to traditional concrete mixes. The cement matrix with SF yielded dense, amorphous C–S–H. Calcium hydroxide was generated during the hydration process of SF-containing cement paste. Karataş et al. [51] investigated the mechanical and durability characteristics of self-compacting mortars containing ground pumice powder. They reported that the substitution of cement with 10–20% ground pumice powder led to mortars that exhibited reduced water absorption, porosity, and sorptivity in comparison to the control mortar.

3.5 ISA

The ISA is significantly influenced by the size, distribution, and connection of the capillary and internal pores. The physical characteristics and pore size of SCMs (SF and NP), as well as their functionality and particle size, all influence the ongoing hydration procedure, the density of the cement paste, and the reduction in shrinkage. Figure 10 presents the ISA capacity values after applying different curing approaches (drinking water and seawater) at intervals of 28, 90, 180, and 360 days, which are measured 60 min from the test start. When NP and SF were used as partial replacements for OP at various rates (5–20%), along with seawater curing methods, the ISA results at 60 min showed similar trends. The ISA capacity results indicate that cement mortars containing NP generally demonstrated lower ISA capacity values than those without NP. With the rise in OP replacements with NP, there was a corresponding decline in the ISA rate. The same trend was noticed when SF was used as partial replacements for OP at various rates (5–20%). The curing of control samples using seawater (i.e., OPCH) resulted in a slight decrease in ISA capacity. The reduction ratios were 2.6, 1.1, 7.1, and 1.3% at 28, 90, 180, and 360 days, respectively, compared to the curing of control samples using drinking water (i.e., OPC).

ISA at time 60 min: (a) NP and (b) SF.

The findings indicate that the ISA capacity at 5, 10, and 20% of NP has improved over time. The ISA capacity of cement mortar with 5% NP (i.e., NP5F0.1) resulted in reductions at all test ages; the reductions were 5.6, 3.3, 2.1, and 9.9% at test ages 28, 90, 180, and 360 days, respectively, compared to the control mixture (OPC). In the case of 10% NP (i.e., NP10F0.1), the decreases were 8.8 and 2.2% at 28 and 90 days, respectively, while an increase was noticed at 180 and 360 days by 3.5 and 4.9%, respectively. Regarding 20% NP (i.e., NP20F0.1), the decreases were 9.9 and 8.0% at 28 and 90 days, respectively, while a slight increase was noticed at 180 days by 0.2%, while no change was observed at 360 days of age, as illustrated in Figure 10(a). All samples exhibited reduced ISA capacity values over time in comparison to the OPC sample, except for the NP10F0.1 and NP20F0.1 samples. During the late ages (i.e., 180 and 360 days), the NP10F0.1 and NP20F0.1 demonstrated the highest ISA capacity compared to OPC samples. The increases for the NP10F0.1 mix were 3.5 and 4.9% at the same ages, while a slight increase was noticed at 180 days by 0.2%, while no change was observed at 360 days of age for the NP20F0.1 mix relative to the OPC sample at the same age.

Figure 10(b) presents the ISA capacity values of the SF mortar mixes after 28, 90, 180, and 360 curing days. The findings indicate that the ISA capacity at 5, 10, and 20% of SF has improved over time. The ISA capacity of cement mortar with 5% SF (i.e., SF5F0.1) increased by 22.4, 18.6, 17.1, and 9.9% at 28, 90, 180, and 360 days, respectively, in comparison with the OPC samples (control mixture). The same trend was noticed. In the case of 10 and 20% SF (i.e., SF10F0.1 and SF20F0.1), the increases for the SF10F0.1 mix were 25.2, 26.4, 23.7, and 14.7% at the same ages, while it was 23.8, 29.8, 25.4, and 21.9% for the SF20F0.1 mix.

However, it was more noticeable that seawater, NP, and SF had an impact on the decrease in the samples’ ISA. The ISA capacity of mortars significantly diminished when seawater, NP, and SF were employed within 60 min of the beginning of the test. This phenomenon can be attributed to the saturation of the samples’ pores with water, resulting in a reduction in ISA rates [58]. The addition of NP and SF to the cement mortar further reduced the ISA capacity, aligning with the results of other investigations [59–61]. Liu et al. [62] illustrated that extending the curing procedure’s duration, along with curing at elevated relative humidity levels, resulted in a reduction in the ISA rate and capillary sorptivity. This serves as a fundamental base for enhancing the hydration process of cement and improving both the density and impermeability of concrete [63]. Numerous authors have observed that seawater, irrespective of the type of cementitious materials employed, diminishes the ISA and the water absorption of mixtures [64–66]. The results of this study indicate that the inclusion of steel fiber did not significantly affect water absorption. Moreover, Frazão [67] reported that the incorporation of steel fibers did not appreciably alter the capillary water absorption of self-compacting concrete, demonstrating that the capillary pore size remained mostly unchanged. This finding aligned with the results of this study.

Laoufi et al. [9] investigated the performance of mortar containing natural pozzolan under sulfate attack. The findings indicate that pozzolan enhances the resistance of mortars in sodium sulfate environments. Another study by Laoufi et al. [10] found that utilizing natural pozzolan led to a notable reduction in the corrosion rate of rebars, enhanced mechanical performance, and improved resistance to chloride ion penetration.

3.6 Visual analysis

Figure 11 shows the external morphology of concrete specimens exposed to an aggressive environment (wetting and drying cycles), as well as immersed in drinking water for 360 days. After wetting and drying cycles (360 days), the concrete samples were placed in laboratory conditions for 28 days. Figure 11(a) shows concrete samples treated with potable water for 360 days and free of fibers. The samples exposed to the wetting and drying cycles in the harsh environment and free of fibers, as shown in Figure 11(b), showed a change in color to yellowish white after the deposition of salts and sulfates layer dissolved in the curing water. While the samples exposed to the harsh environment and containing fibers showed a change in the color of the surface of the samples and the appearance of iron oxide resulting from the rust of the fibers. Figure 11(c) shows the concrete samples containing fibers and NP. The samples show the spread of rust on the surface of the sample, which confirms the damage of the fibers and the leakage of iron oxide outside the samples as a result of the drying and wetting cycles over a period of 360 days. Figure 11(d) shows the concrete samples containing fibers and SF. The samples show rust spread on the surface of the sample, which confirms the damage of the fibers and the leakage of iron oxide outside the samples as a result of the drying and wetting cycles over a period of 360 days. The samples containing fibers and SF show less rust spread than the samples containing fibers and NP. This may be attributed to the efficiency of filling and closing the pores that SF has compared to ash. This has led to limiting the penetration of liquids, salts, and dissolved sulfates into the samples. Figure 12 shows the condition of embedded fibers in concrete specimens exposed to harsh environment for 360 days.

Concrete samples after curing: (a) OPC, (b) OPCH, (c) NP10F0.1, and (d) SF10F0.1.

Fibers after curing in harsh environment.

The impact of seawater on the visual attributes of fiber-reinforced mortar samples is substantial, affecting both appearance and structural integrity. Numerous investigations have investigated the effects of seawater exposure on the physical properties and esthetics of fiber-reinforced mortars, providing essential insights into their performance in marine environments. Immersion in seawater causes an increase in porosity within the mortar samples, leading to a more saturated structure that may visually seem more deteriorated as time progresses [68]. The interaction between seawater and mortar can lead to the formation of micro-cracks, impacting both the visual integrity and the mechanical characteristics of the mortar. The occurrence of salts and minerals in seawater may result in efflorescence or discoloration on the surface of mortar samples, thereby changing their visual appeal [69]. Those findings align with the results for the OPCH sample in this study, as shown in Figure 11(a). Jute fiber composites demonstrate alterations in visual characteristics upon exposure to water, showcasing differences in crack formation and surface texture that are influenced by fiber content and water ratios [70]. In addition, the incorporation of basalt fibers has demonstrated an improvement in the CS of mortars subjected to seawater, which may help reduce certain visual degradation effects by preserving structural integrity [71]. These findings agree with the results for the NP10F0.1 and SF10F0.1 samples in the current investigation, as illustrated in Figure 11(c) and (d).

3.7 Sustainable analysis

Table 4 illustrates the overall cost, CO2 emissions, and energy consumption analysis associated with the OPC, NP, and SF. The values have been sourced from the existing literature. Thus, those values underscored the significance of incorporating NP and SF as a partial replacement for OP into cement mortars, leading to a decrease in CO2 emissions and improved rates of emission reduction. In addition, this method not only encourages sustainability but also converts waste and recycled materials into valuable building components, leading to a more environmentally friendly future in the building sector [72]. This study primarily conducts a cost analysis of the OP and SF materials utilized in cement mortar preparation, as the costs related to electricity and transportation usage can be negligible. The cost of NP is excluded from the cost analysis, given that it is a by-product derived from lightweight aggregate production from volcanic pumice and is used in the same manner as it is received after grinding using a ball mill (which holds no value). The waste materials acquired are typically available at no cost and contribute to the sustainability of concrete production. Consequently, NP is significantly more economical than OP. Nevertheless, the cost of SF exceeded that of OP, exhibiting an increased ratio of 83.8%. Although the cost of dust is greater than cement, this indicates that the main benefits of replacing OP with SF are predominantly in environmental improvements rather than cost savings, highlighting the importance of this material in fostering sustainability over mere financial advantages. The CO2 emissions significantly decreased with the alternative materials, as illustrated in Table 4. The NP and SF had CO2 emissions of 0.006 and 0.02 kg·kg−1, thus substituting OP with NP and SF led to a reduction of 15,400 and 4,550%, respectively, compared with CO2 emissions of OP. In addition, this study analyzed energy consumption by examining embodied energy, encompassing the energy needed for raw material extraction, transportation, processing, and usage in cement mortar production. The findings indicated that the energy required for producing the conventional cement mortar diminished with the use of NP and SF as replacements for OP. The NP and SF had embodied energy of 0.0045 and 0.1 MJ·kg−1, thus substituting OP with NP and SF led to a reduction of 122,122 and 5,400%, respectively, compared with embodied energy of OP, as illustrated in Table 4. The significant decrease in energy consumption due to OP replacement with NP and SF can be linked to the naturally lower energy demands of NP and SF in cement mortars, as NP, being a waste material, requires less energy for its use. Nevertheless, obstacles like landfill concerns and the ongoing depletion of environmental resources remain prevalent. The findings demonstrate the potential of NP and SF to serve as a substitute for OPC in cement mortars. This study highlights the necessity for cement mortar production to integrate materials like NP and SF, which can play a crucial role in reducing CO2 emissions and embodied energy. The significant expenditure, along with the lower CO2 emissions and reduced embodied energy of NP and SF, were essential considerations in evaluating the feasibility of these sustainable cement mortars. This approach minimizes the environmental footprint of the construction sector and plays a crucial role in tackling climate change, highlighting NP and SF materials as viable options for cement mortar applications. This study further bolsters worldwide initiatives aimed at conserving resources, minimizing carbon footprints, and tackling environmental pollution.

Cost, CO2 emissions, energy consumption analysis

| Materials | Cost* | CO2 | Embodied energy | |||

|---|---|---|---|---|---|---|

| $·kg−1 | Relative variation | kg·kg−1 | Relative variation | MJ·kg−1 | Relative variation | |

| OP | 0.11 | — | 0.93 [73] | — | 5.5 [73] | — |

| NP | 0 | — | 0.006 [74,75] | −15,400% | 0.0045 [74,75] | −122,122% |

| SF | 0.68 [76] | +83.8% | 0.02 [77] | −4,550% | 0.1 [78] | −5,400% |

*Cost may fluctuate based on current market dynamics.

4 Conclusion

The experimental findings of this investigation have yielded the following conclusions:

Fibers significantly reduced slump flow in mortar mixes by up to 14.3 and 28.6%, respectively, for the mortar containing NP and SF.

The curing of control samples with seawater (OPCH) resulted in a slight decrease in CS and FS, up to 2.4 and 7.4%, respectively.

Using 5 and 10% of NP increased CS at early ages, decreasing later. High NP (20%) reduced strength at all curing ages. Moreover, SF improved CS over time by up to 10.8%.

The study indicates that the FS of NP and SF samples has improved significantly over time, reaching up to 27.3 and 30.7%, respectively, compared to OPC samples.

The utilization of SF as a partial OP substitute showed superior performance in enhancing CS and FS over 360 days when compared to the use of NP as a partial cement substitute.

Despite the application of seawater curing, the mortar samples containing NP and SF exhibit enhanced water resistance and ISA capacity compared to the OPC. This may be due to sediment accumulation on the mortar sample surfaces, which obstructed the water’s penetration.

The study indicates that the water absorption of NP and SF samples has improved significantly over time, reaching up to 18.5 and 24.9%, respectively, compared to OPC samples.

The authors suggest that further research is essential for additional understanding of the effect of NP and SF on the properties of fiber-reinforced cement mortars in aggressive environments, which can include freeze–thaw cycles, mass loss due to corrosion, and high-temperature resistance. Additionally, SEM and XRD analysis, fiber corrosion analysis, chloride diffusion tests, and evaluation of steel fiber integrity over time using pull-out tests or tensile strength tests should be investigated.

-

Funding information: The authors gratefully acknowledge the funding of the Deanship of Graduate Studies and Scientific Research, Jazan University, Saudi Arabia, through project number: (RG24-S0160).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Mangi, S. A., M. H. W. Ibrahim, N. Jamaluddin, M. F. Arshad, and R. P. Jaya. Short-term effects of sulphate and chloride on the concrete containing coal bottom ash as supplementary cementitious material. Engineering Science and Technology, an International Journal, Vol. 22, No. 2, 2019, pp. 515–522.10.1016/j.jestch.2018.09.001Search in Google Scholar

[2] Martínez-Rosales, R. I., J. M. Miranda-Vidales, L. Narváez-Hernández, and J. M. L. de Poo. Strength and corrosion studies of mortars added with pozzolan in sulphate ions environment. KSCE Journal of Civil Engineering, Vol. 24, No. 12, 2020, pp. 3810–3819.10.1007/s12205-020-0183-2Search in Google Scholar

[3] Zeyad, A. M., A. H. Khan, and B. A. Tayeh. Durability and strength characteristics of high-strength concrete incorporated with volcanic pumice powder and polypropylene fibers. Journal of Materials Research and Technology, Vol. 9, No. 1, 2020, pp. 806–818.10.1016/j.jmrt.2019.11.021Search in Google Scholar

[4] Laoufi, L., Y. Senhadji, and A. Benosman. A study of natural pozzolan mortars exposed to sulfate as energy efficient building material. Key Engineering Materials, Vol. 678, 2016, pp. 109–122.10.4028/www.scientific.net/KEM.678.109Search in Google Scholar

[5] Hossain, K. M., M. S. Anwar, and K. M. Julkarnine. Strength and durability of concrete incorporating natural pozzolan in aggressive Solomon sea environment. Asian Journal of Engineering and Technology, Vol. 3, No. 1, 2015, pp. 24–32.Search in Google Scholar

[6] Khan, A. U. R. Performance of concrete blended with pozzolanic materials in marine environment. in MATEC Web of Conferences, Vol. 120, EDP Sciences, p. 03012.10.1051/matecconf/201712003012Search in Google Scholar

[7] He, Z., X. Zhu, J. Wang, M. Mu, and Y. Wang. Comparison of CO2 emissions from OPC and recycled cement production. Construction and Building Materials, Vol. 211, 2019, pp. 965–973.10.1016/j.conbuildmat.2019.03.289Search in Google Scholar

[8] Miller, S. A., M. Juenger, K. E. Kurtis, and J. Weiss. Cement and Alternatives in the Anthropocene. Annual Review of Environment and Resources, Vol. 49, 2024, pp. 309–335.10.1146/annurev-environ-112621-070104Search in Google Scholar

[9] Laoufi, L., Y. Senhadji, A. Benazzouk, T. Langlet, M. Mouli, and I. Laoufi. Durability of natural pozzolan-based mortar exposed to sulfate attack. Journal of Fundamental and Applied Sciences, Vol. 8, No. 2, 2016, pp. 268–279.10.4314/jfas.v8i2.7Search in Google Scholar

[10] Laoufi, L., M. Mouli, and Y. Senhadji. A study of natural pozzolan mortars exposed to chlorides as a sustainable building material. Key Engineering Materials, Vol. 650, 2015, pp. 105–113.10.4028/www.scientific.net/KEM.650.105Search in Google Scholar

[11] Saeki, T., K. Mashima, M. Kikuchi, and T. Saito. Chroride ion diffusivity in hardended cemetitious materials using various silica fume. Cement Science and Concrete Technology, Vol. 68, No. 1, 2014, pp. 352–359.10.14250/cement.68.352Search in Google Scholar

[12] Shawkat, A. and E. Dawood. Production of high-performance mortar containing metakaolin and silica fume. International Journal of Progressive Sciences and Technologies, Vol. 21, 2020, pp. 32–39.Search in Google Scholar

[13] Zhang, B., H. Tan, W. Shen, G. Xu, B. Ma, and X. Ji. Nano-silica and silica fume modified cement mortar used as surface protection material to enhance the impermeability. Cement and Concrete Composites, Vol. 92, 2018, pp. 7–17.10.1016/j.cemconcomp.2018.05.012Search in Google Scholar

[14] Sudarsono, I. Mechanical properties of silica fume concrete in marine environment. in IOP Conference Series: Earth and Environmental Science, Vol. 1321, No. 1, IOP Publishing, 2024, p. 012035.10.1088/1755-1315/1321/1/012035Search in Google Scholar

[15] Iqbal, M., D. Zhang, K. Khan, M. N. Amin, M. Ibrahim, B. A., and Salami. Evaluating mechanical, microstructural and durability performance of seawater sea sand concrete modified with silica fume. Journal of Building Engineering, Vol. 72, 2023, id. 106583.10.1016/j.jobe.2023.106583Search in Google Scholar

[16] Tandilino, F., L. E. Hutabarat, and R. M. Simanjuntak. Bestmittel and silica fume effect on concrete compressive strength with seawater curing. Jurnal PenSil, Vol. 13, No. 1, 2024, pp. 60–71.10.21009/jpensil.v13i1.39103Search in Google Scholar

[17] Catuzzo, H., G. P. Gava, and C. S. Malacarne. Study of pozzolanic admixtures effects in the concretes under chemical attack. New approaches to building pathology and durability, Springer Nature, Singapore, 2016, pp. 121–130.10.1007/978-981-10-0648-7_6Search in Google Scholar

[18] Yahya, Z., M. M. A. B. Abdullah, L. Y. Jing, L.-Y. Li, and R. Abd Razak. Seawater exposure effect on fly ash based geopolymer concrete with inclusion of steel fiber. in IOP Conference Series: Materials Science and Engineering, Vol. 743, No. 1, IOP Publishing, 2020, p. 012013.10.1088/1757-899X/743/1/012013Search in Google Scholar

[19] Xu, W., L. Yang, D. Gao, J. Tang, G. Sun, and Y. Zhang. Mechanical properties of seawater-mixed steel fiber reinforced concrete. Journal of Building Engineering, Vol. 73, 2023, id. 106823.10.1016/j.jobe.2023.106823Search in Google Scholar

[20] ASTM-C150. Standard test method for Portland cement, ed: West Conshohocken, PA, United States, 2016.Search in Google Scholar

[21] Standard test method for true specific gravity of refractory materials by gas-comparison pycnometer, ASTMC604, West Conshohocken, PA, USA, 2018.Search in Google Scholar

[22] ASTM-C204, Standard test methods for fineness of hydraulic cement by air-permeability apparatus, ASTM International, West Conshohocken, PA., 2011.Search in Google Scholar

[23] ASTM-C114, Standard test methods for chemical analysis of hydraulic cement, ed: ASTM C114-15, West Conshohocken, USA, 2015.Search in Google Scholar

[24] ASTM-C618, Specification for fly ash and raw or calcined natural puzzolan for use as a mineral admixture in Portland cement concrete, ed: Annual Book of ASTM, 2005.Search in Google Scholar

[25] ASTM-C778, Standard test method for standard sand, ed: West Conshohocken, PA, United States, 2017.Search in Google Scholar

[26] ASTM-C305, Standard test method for for mechanical mixing of hydraulic cement pastes and mortars of plastic consistency, ed: West Conshohocken, PA, United States, 2014.Search in Google Scholar

[27] ASTM-C1437, Standard test method for flow of hydraulic cement mortar, ed: West Conshohocken, PA, United States, 2007.Search in Google Scholar

[28] ASTM-C109, Standard test method for compressive strength of hydraulic cement mortars, ed: West Conshohocken, PA, United States, 2008.Search in Google Scholar

[29] ASTM-C348, Standard test method for flexural strength of hydraulic-cement mortars, ed: West Conshohocken, PA, United States, 2002.Search in Google Scholar

[30] Rilem, T. C. CPC 11.3 Absorption of water by concrete by immersion under vacuum, 1984. RILEM recommendation for the testing and use of constructions materials, E & FN SPON, London, 1994, pp. 36–37.Search in Google Scholar

[31] ASTM-C1585, Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-cement Concretes, ed: West Conshohocken, PA, United States., 2013.Search in Google Scholar

[32] Alwesabi, E. A. H., B. H. A. Bakar, I. M. H. Alshaikh, and H. M. Akil. Experimental investigation on mechanical properties of plain and rubberised concretes with steel–polypropylene hybrid fibre. Construction and Building Materials, Vol. 233, 2020, id. 117194.10.1016/j.conbuildmat.2019.117194Search in Google Scholar

[33] Magbool, H. M. and A. M. Zeyad. The effect of varied types of steel fibers on the performance of self-compacting concrete modified with volcanic pumice powder. Materials Science-Poland, Vol. 39, No. 2, 2021, pp. 172–187.10.2478/msp-2021-0016Search in Google Scholar

[34] Sharma, R., J. G. Jang, and P. P. Bansal. A comprehensive review on effects of mineral admixtures and fibers on engineering properties of ultra-high-performance concrete. Journal of Building Engineering, Vol. 45, 2022, id. 103314.10.1016/j.jobe.2021.103314Search in Google Scholar

[35] Shen, W., Z. Yang, L. Cao, L. Cao, Y. Liu, H. Yang, et al. Characterization of manufactured sand: Particle shape, surface texture and behavior in concrete. Construction and Building Materials, Vol. 114, 2016, pp. 595–601.10.1016/j.conbuildmat.2016.03.201Search in Google Scholar

[36] Kwan, A. and W. J. C. Fung. Effects of SP on flowability and cohesiveness of cement-sand mortar. Construction and Building Materials, Vol. 48, 2013, pp. 1050–1057.10.1016/j.conbuildmat.2013.07.065Search in Google Scholar

[37] Ghafari, E., S. A. Ghahari, H. Costa, E. Júlio, A. Portugal, and L. Durães. Effect of supplementary cementitious materials on autogenous shrinkage of ultra-high performance concrete. Construction and Building Materials, Vol. 127, 2016, pp. 43–48.10.1016/j.conbuildmat.2016.09.123Search in Google Scholar

[38] Koksal, F., M. S. Yıldırım, A. Benli, and O. Gencel. Hybrid effect of micro-steel and basalt fibers on physico-mechanical properties and durability of mortars with silica fume. Case Studies in Construction Materials, Vol. 15, 2021, id. e00649.10.1016/j.cscm.2021.e00649Search in Google Scholar

[39] Zeyad, A. M. and A. Almalki. Role of particle size of natural pozzolanic materials of volcanic pumice: flow properties, strength, and permeability. Arabian Journal of Geosciences, Vol. 14, No. 2, 2021, pp. 1–11.10.1007/s12517-020-06443-ySearch in Google Scholar

[40] Seraj, S., R. Cano, R. D. Ferron, and M. C. Juenger. The role of particle size on the performance of pumice as a supplementary cementitious material. Cement concrete Composites, Vol. 80, 2017, pp. 135–142.10.1016/j.cemconcomp.2017.03.009Search in Google Scholar

[41] Ramasamy, U., A. C. Bordelon, and P. J. Tikalsky. Properties of different pumice grades blended with cement. Journal of Materials in Civil Engineering, Vol. 29, No. 7, 2017, id. 04017040.10.1061/(ASCE)MT.1943-5533.0001891Search in Google Scholar

[42] Samimi, K., S. Kamali-Bernard, A. A. Maghsoudi, M. Maghsoudi, and H. Siad. Influence of pumice and zeolite on compressive strength, transport properties and resistance to chloride penetration of high strength self-compacting concretes. Construction Building Materials, Vol. 151, 2017, pp. 292–311.10.1016/j.conbuildmat.2017.06.071Search in Google Scholar

[43] Zeyad, A. M., M. A. M. Johari, B. A. Tayeh, and M. O. Yusuf. Pozzolanic reactivity of ultrafine palm oil fuel ash waste on strength and durability performances of high strength concrete. Journal of Cleaner Production, Vol. 144, 2017, pp. 511–522.10.1016/j.jclepro.2016.12.121Search in Google Scholar

[44] Lorenzo, M., S. Goni, and A. Guerrero. Role of aluminous component of fly ash on the durability of Portland cement-fly ash pastes in marine environment. Waste Management, Vol. 23, No. 8, 2003, pp. 785–792.10.1016/S0956-053X(03)00030-8Search in Google Scholar

[45] Mangi, S. A., M. H. W. Ibrahim, N. Jamaluddin, M. F. Arshad, S., and Shahidan. Performances of concrete containing coal bottom ash with different fineness as a supplementary cementitious material exposed to seawater. Engineering Science and Technology, an International Journal, Vol. 22, No. 3, 2019, pp. 929–938.10.1016/j.jestch.2019.01.011Search in Google Scholar

[46] Tuoi Nguyen, V., T. T. Tran, X. T. Nguyen, T. M. Tran, V., and Quyet Truong. Effect of natural pozzolanic additive on strength and durability of concrete immersed in seawater. Iranian Journal of Science Technology, Transactions of Civil Engineering, Vol. 47, No. 2, 2023, pp. 727–739.10.1007/s40996-022-00961-3Search in Google Scholar

[47] Barger, G. S., J. Bayles, B. Blair, D. Brown, H. Chen, T. Conway, et al. Ettringite formation and the performance of concrete, American Cement Association, United States, Vol. 2166, 2001, pp. 1–16.Search in Google Scholar

[48] Saraç, S., M. Karatas, and A. Benli. The effect of dunite powder and silica fume on the viscosity, physico-mechanical properties and sulphate resistance of self-compacting mortars. Construction and Building Materials, Vol. 375, 2023, id. 130970.10.1016/j.conbuildmat.2023.130970Search in Google Scholar

[49] Benli, A. Mechanical and durability properties of self‐compacting mortars containing binary and ternary mixes of fly ash and silica fume. Structural Concrete, Vol. 20, No. 3, 2019, pp. 1096–1108.10.1002/suco.201800302Search in Google Scholar

[50] Benli, A., K. Turk, and C. Kina. Influence of silica fume and class F fly ash on mechanical and rheological properties and freeze-thaw durability of self-compacting mortars. Journal of Cold Regions Engineering, Vol. 32, No. 3, 2018, id. 04018009.10.1061/(ASCE)CR.1943-5495.0000167Search in Google Scholar

[51] Karataş, M., A. Benli, and A. Ergin. Influence of ground pumice powder on the mechanical properties and durability of self-compacting mortars. Construction and Building Materials, Vol. 150, 2017, pp. 467–479.10.1016/j.conbuildmat.2017.05.220Search in Google Scholar

[52] Mo, K. H., K. K. Q. Yap, U. J. Alengaram, and M. Z. Jumaat. The effect of steel fibres on the enhancement of flexural and compressive toughness and fracture characteristics of oil palm shell concrete. Construction and Building Materials, Vol. 55, 2014, pp. 20–28.10.1016/j.conbuildmat.2013.12.103Search in Google Scholar

[53] Lin, C., T. Kanstad, S. Jacobsen, and G. Ji. Bonding property between fiber and cementitious matrix: A critical review. Construction and Building Materials, Vol. 378, 2023, id. 131169.10.1016/j.conbuildmat.2023.131169Search in Google Scholar

[54] Benli, A., M. Karataş, and E. Gurses. Effect of sea water and MgSO4 solution on the mechanical properties and durability of self-compacting mortars with fly ash/silica fume. Construction and Building Materials, Vol. 146, 2017, pp. 464–474.10.1016/j.conbuildmat.2017.04.108Search in Google Scholar

[55] Yiğiter, H., H. Yazıcı, and S. Aydın. Effects of cement type, water/cement ratio and cement content on sea water resistance of concrete. Building Environment, Vol. 42, No. 4, 2007, pp. 1770–1776.10.1016/j.buildenv.2006.01.008Search in Google Scholar

[56] Wen, C., P. Zhang, J. Wang, and S. Hu. Influence of fibers on the mechanical properties and durability of ultra-high-performance concrete: A review. Journal of Building Engineering, Vol. 52, 2022, id. 104370.10.1016/j.jobe.2022.104370Search in Google Scholar

[57] Benli, A., M. Karataş, and Y. Bakir. An experimental study of different curing regimes on the mechanical properties and sorptivity of self-compacting mortars with fly ash and silica fume. Construction and Building Materials, Vol. 144, 2017, pp. 552–562.10.1016/j.conbuildmat.2017.03.228Search in Google Scholar

[58] Zeyad, A. M., M. Shubaili, and A. Abutaleb. Using volcanic pumice dust to produce high-strength self-curing concrete in hot weather regions. Case Studies in Construction Materials, Vol. 18, 2023, id. e01927.10.1016/j.cscm.2023.e01927Search in Google Scholar

[59] Tsampali, E., E. C. Tsardaka, E. Pavlidou, K. M. Paraskevopoulos, and M. Stefanidou. Comparative study of the properties of cement pastes modified with nano-silica and nano-alumina. Solid State Phenomena, Vol. 286, 2019, pp. 133–144.10.4028/www.scientific.net/SSP.286.133Search in Google Scholar

[60] Du, H. J. P. and S. D. Pang. Effect of colloidal nano-silica on the mechanical and durability performances of mortar. Key Engineering Materials, Vol. 629, 2015, pp. 443–448.10.4028/www.scientific.net/KEM.629-630.443Search in Google Scholar

[61] Abd Elrahman, M., S.-Y. Chung, P. Sikora, T. Rucinska, and D. Stephan. Influence of nanosilica on mechanical properties, sorptivity, and microstructure of lightweight concrete. Materials, Vol. 12, No. 19, 2019, id. 3078.10.3390/ma12193078Search in Google Scholar PubMed PubMed Central

[62] Liu, B., G. Luo, and Y. Xie. Effect of curing conditions on the permeability of concrete with high volume mineral admixtures. Construction Building Materials, Vol. 167, 2018, pp. 359–371.10.1016/j.conbuildmat.2018.01.190Search in Google Scholar

[63] Zeyad, A. M., H. M. Magbool, M. Amran, M. Mijarsh, and A. Almalki. Performance of high-strength green concrete under the influence of curing methods, volcanic pumice dust, and hot weather. Archives of Civil Mechanical Engineering, Vol. 22, No. 3, 2022, pp. 1–26.10.1007/s43452-022-00445-1Search in Google Scholar

[64] Etxeberria, M., J. M. Fernandez, and J. Limeira. Secondary aggregates and seawater employment for sustainable concrete dyke blocks production: Case study. Construction Building Materials, Vol. 113, 2016, pp. 586–595.10.1016/j.conbuildmat.2016.03.097Search in Google Scholar

[65] Khatibmasjedi, M., S. Ramanthan, P. Suraneni, and A. Nanni. Shrinkage behavior of cementitious mortars mixed with seawater. Advances in Civil Engineering Materials, Vol. 8, No. 2, 2019, pp. 64–78.10.1520/ACEM20180110Search in Google Scholar

[66] Otsuki, N., H. Hamada, N. Takeda, K. I. Imamoto, T. Yamaji, T. Habuchi, et al. Technical Committee on the use of sea water in concrete. Technical Committee Reports, Vol. 22, 2014, pp. 1–22.Search in Google Scholar

[67] Frazão, C. M. V. Recycled steel fiber reinforced concrete for Structural elements subjected to chloride attack: mechanical and durability performance, Universidade do Minho, Portugal, 2019.Search in Google Scholar

[68] Wang, X., K. Ayuta, and S. Ono. Pore structure and degree of saturation of mortar affected by seawater and freeze-thaw action. in Cold Regions Engineering: Cold Regions Impacts on Transportation and Infrastructure, American Society of Civil Engineers, Reston, 2002, pp. 592–604.10.1061/40621(254)51Search in Google Scholar

[69] Zhao, J., Z. Jiang, Z. Lu, Y. Tan, S. Li, B. Zhang, et al. Coupling effects of seawater immersion and prestressing on the durability of BFRP bars embedded in seawater–sea sand geopolymer mortars. Journal of Materials in Civil Engineering, Vol. 36, No. 4, 2024, id. 04024049.10.1061/JMCEE7.MTENG-17106Search in Google Scholar

[70] Majumder, A., F. Stochino, A. Frattolillo, M. Valdes, E. Martinelli, and G. Gatto. Enhancing sustainability in construction: Water effect on jute fiber composite mortar. Periodica Polytechnica Civil Engineering, Vol. 68, No. 3, 2024, pp. 974–986.10.3311/PPci.23687Search in Google Scholar

[71] Jumahat, A., U. R. Hashim, N. F. A. M. Yosri, and A. H. Shamsuddin. Effect of Sea water exposure and basalt fibre reinforced polymer wrapping on compressive properties of granite dust mortar cubes, Springer, 2023, pp. 221–224.10.1007/978-981-97-0106-3_37Search in Google Scholar

[72] Zeyad, A. M., M. Shubaili, N. B. Frahat, A. H. Khan, and I. S. Agwa. Evaluation of sustainable lightweight concrete incorporating popcorn and pumice aggregates with sugarcane leaf ash. Sustainable Chemistry and Pharmacy, Vol. 45, 2025, id. 101975.10.1016/j.scp.2025.101975Search in Google Scholar

[73] Zhu, Q. CO2 abatement in the cement industry, IEA Clean Coal Centre, London, UK, 2011.Search in Google Scholar

[74] Letelier, V., J. M. Ortega, R. M. Tremiño, B. I. Henriquéz-Jara, I. Fustos, T. Real-Herraiz, et al. The use of volcanic powder as a cement replacement for the development of sustainable mortars. Applied Sciences, Vol. 10, No. 4, 2020, id. 1460.10.3390/app10041460Search in Google Scholar

[75] Letelier, V., J. M. Ortega, E. Tarela, P. Muñoz, B. I. Henríquez-Jara, and G. Moriconi. Mechanical performance of eco-friendly concretes with volcanic powder and recycled concrete aggregates. Sustainability, Vol. 10, No. 9, 2018, id. 3036.10.3390/su10093036Search in Google Scholar

[76] Wang, Y.-S., H.-K. Cho, and X.-Y. Wang. Mixture optimization of sustainable concrete with silica fume considering CO2 emissions and cost. Buildings, Vol. 12, No. 10, 2022, id. 1580.10.3390/buildings12101580Search in Google Scholar

[77] Meng, L.-Y., Y.-S. Wang, F. Sun, R. Lin, and X.-Y. Wang. An integrated strength-carbon emissions-total cost model for silica fume concrete. Case Studies in Construction Materials, Vol. 22, 2025, id. e04327.10.1016/j.cscm.2025.e04327Search in Google Scholar

[78] Thilakarathna, P. S. M., S. Seo, K. S. K. Baduge, H. Lee, P. Mendis, and G. Foliente. Embodied carbon analysis and benchmarking emissions of high and ultra-high strength concrete using machine learning algorithms. Journal of Cleaner Production, Vol. 262, 2020, id. 121281.10.1016/j.jclepro.2020.121281Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Nanotechnology for calcium aluminate cement: thematic analysis

- Towards sustainable concrete pavements: a critical review on fly ash as a supplementary cementitious material

- Optimizing rice husk ash for ultra-high-performance concrete: a comprehensive review of mechanical properties, durability, and environmental benefits

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites