Abstract

This study investigates the development of novel reinforcing rods produced from waste polyester, polypropylene, and cotton ropes treated with epoxy resin, as a sustainable alternative to conventional steel reinforcement. Compared with steel bars, the treated ropes (TR) provide several advantages, including light weight, low cost, corrosion resistance, ease of application, and alignment with sustainable development goals. Experimental testing was carried out to evaluate their physical, mechanical, and durability properties. The results showed that the bond strengths of polyester, polypropylene, and cotton ropes were lower than those of steel rods by 63.3, 69.0, and 76.1%, respectively; however, the ropes exhibited comparable elongation capacity, zero water absorption after epoxy treatment (except cotton), and superior resistance to corrosion and alkali attack. The performance mechanisms were analyzed, revealing that rope failure was governed primarily by tensile rupture rather than debonding, indicating higher rope strength relative to bond capacity with concrete. Furthermore, empirical models were proposed to predict the stress–strain and bond behavior of the TR. These findings confirm that although the tensile and bonding capacities of the ropes remain lower than steel, their environmental benefits, corrosion resistance, and cost-effectiveness make them promising candidates for eco-friendly reinforcement solutions in certain structural applications.

1 Introduction

Changes in usage and load requirements necessitate reinforcing existing concrete structures [1,2]. Various strategies for strengthening a specific structure or a portion of it have been successfully developed to date, depending on the type of construction and the situation [3,4]. In recent years, the employment of cement mortar, concrete, and steel confinement has received much attention [5,6]. Synthetic fiber-reinforced polymer (FRP) composites have emerged as a viable alternative to steel bars, plagued by issues such as the cumbersome handling of heavy steel bars, welding challenges, and corrosion. Over the past few decades, an alternative to steel has gained popularity as it offers improved strength, flexibility, and durability to reinforced concrete structures [7,8]. Polyester is very strong and has excellent abrasion resistance. It stretches much less than nylon but does not absorb shock like nylon; this makes polyester very popular for marine or industrial applications, where stretch is not desired. It is resistant to ultraviolet (UV) rays, rot, petroleum products, and most chemicals [9,10]. Ropes are distinguished by high axial strength and stiffness in proportion to their weight and low flexural stiffness [11,12,13]. A rope can be a critical load-carrying member in many engineering applications, including cranes, lifts, mine hoisting, bridges, cableways, electrical conductors, offshore mooring systems, and so on [14,15]. Synthetic fiber ropes have been proven to be the most acceptable substitute for steel wire ropes or chains in deep-water mooring applications over the past two decades due to their perceived cost, ease of handling, and ability to lower peak loadings compared to steel wire ropes or chains [16,17]. Polypropylene ropes have properties such as cohesiveness, freeze–thaw resistance, fire resistance, impact resistance, abrasion resistance, structural strength, and ductility. However, the effectiveness of polypropylene ropes is dependent on several factors, including fiber length, diameter, and the number of fibers [18,19]. Polypropylene ropes, textile fibers, marine ropes, and battery separators are used for molded items and films and have properties such as lightweight, hydrophobicity, and chemical resistance [20,21]. Cotton rope is a naturally occurring fiber that is usually white. Cotton cordage is soft and enjoyable to work with. It also knots well. A lightweight, cotton 3-strand rope is frequently used as a decorative item. It may be cultured and flame-proofed with ease. Cotton rope is slightly elastic due to its soft weave and is not usually used for lifting. It is, nevertheless, extremely easy to handle, making it a favorite among aerialists. Cotton ropes are still used on traditional small boats [22]. Cotton rope has a soft feel and was one of the first fibers used in horse rope goods despite its lower strength than other fibers [23,24]. Previous studies have explored the potential of using sprayed FRP to rehabilitate and strengthen concrete structures. The results indicated that the use of sprayed FRP composites is highly effective in enhancing the load capacity of members. Moreover, the use of the sprayed FRP method could serve as a promising alternative to conventional FRP strengthening methods [25,26,27]. Ropes possess several key characteristics, such as their easy availability, simple application, low cost, and environmentally friendly nature. It has been previously observed that dry vinylon and polypropylene fiber ropes are highly efficient for modifying the ultimate stress and strain of concrete [28,29]. Both studies [30,31] demonstrated that carbon fiber reinforced polymer (CFRP) ropes can effectively alter the load-carrying capacity and ultimate failure of strengthened concrete beams. This led to significant improvements in beam flexural and shear capacities, leading to enhanced structural performance and durability of reinforced concrete elements. Using epoxy-bonded synthetic CFRP ropes offers a simple and cost-effective way of strengthening the existing concrete structures, which can be used instead of traditional strengthening methods [32,33,34].

To better understand the role of FRP composites in structural strengthening, it is important to summarize their performance based on the type of fiber and resin system [35]. Different fibers, such as carbon, glass, aramid, and basalt, provide distinct balances of strength, stiffness, fatigue resistance, durability, and cost [36]. Likewise, the selection of resin (epoxy, polyester, or vinyl ester) influences the bonding efficiency, environmental resistance, and overall performance of the composite. A concise overview of their comparative characteristics is presented in Tables 1 and 2, which highlight the advantages and limitations of each combination in relation to structural applications.

Summary of fiber- and resin-based FRP composite properties and advantages

| FRP type | Mechanical properties | Fatigue and durability | Key advantages | Ref. |

|---|---|---|---|---|

| CFRP (carbon fiber) | Very high tensile strength and stiffness; excellent strength-to-weight ratio | Excellent fatigue resistance; durable in aggressive environments | Superior structural performance; ideal for flexural and shear strengthening | [37] |

| GFRP (glass fiber) | Moderate tensile strength and stiffness; lightweight | Good corrosion resistance, but moderate fatigue performance | Cost-effective; easy handling; non-magnetic; widely used in infrastructure | [38] |

| AFRP (Aramid fiber) | High tensile strength; good impact resistance | Excellent fatigue durability but sensitive to UV/moisture | Good toughness; suitable for dynamic/impact-prone structures | [39] |

| BFRP (Basalt fiber) | Strength higher than GFRP but lower than CFRP; good stiffness | Excellent chemical resistance; stable at high temperatures | Eco-friendly, cost-efficient, and sustainable alternative | [40] |

Common resin systems in FRP composites

| Resin type | Properties | Cost | Advantages | Ref. |

|---|---|---|---|---|

| Epoxy | Excellent adhesion, mechanical strength, and moisture resistance | High | Best performance for structural strengthening | [41] |

| Polyester | Adequate strength; lower chemical resistance | Low | Economical and widely available | [42] |

| Vinyl ester | Good chemical resistance; balance of strength and cost | Moderate | Resistant to alkaline and acidic environments; good compromise option | [43] |

In addition to conventional FRP composites, waste-derived fiber ropes such as polyester, polypropylene, and cotton have attracted attention for their potential in sustainable reinforcement applications. Their effectiveness depends largely on their mechanical, physical, and durability properties. Polyester ropes exhibit high tensile strength, chemical resistance, and long-term durability under marine or industrial environments [44]. Polypropylene ropes, while lightweight and hydrophobic with good freeze–thaw resistance, are more sensitive to UV exposure and elevated temperatures [45]. Cotton ropes, though weaker and less durable than synthetic alternatives, offer good bonding behavior with cementitious matrices due to their hydrophilic and rough surface texture [46,47]. These findings from existing studies provide an important reference for assessing the feasibility of using these ropes, treated with epoxy resin, as novel reinforcing rods in concrete.

The current study evaluated whether polyester, polypropylene, or cotton ropes would replace steel bars since they possess high tensile strength but low weight, are easy to establish, do not rust or erode, and provide full reinforcement. This study mainly examines how polyester, polypropylene, and cotton ropes behave when cured with epoxy materials compared to steel bars.

2 Research novelty and significance

The novelty of this research lies in the development of epoxy-treated reinforcing rods produced from waste polyester, polypropylene, and cotton ropes as an innovative alternative to conventional steel reinforcement. Unlike previous studies that mainly focused on FRP composites or synthetic fibers, this work introduces recycled textile and polymer ropes into structural applications, directly addressing sustainability and circular economy principles. The study provides a comprehensive evaluation of the physical, mechanical, and durability properties of the treated ropes compared with steel rods, while also proposing new empirical models to predict their stress–strain behavior and bond performance. By combining experimental validation with the use of recycled materials, this research contributes to advancing eco-friendly construction solutions that align with the sustainable development goals of the United Nations, offering both engineering feasibility and significant environmental benefits.

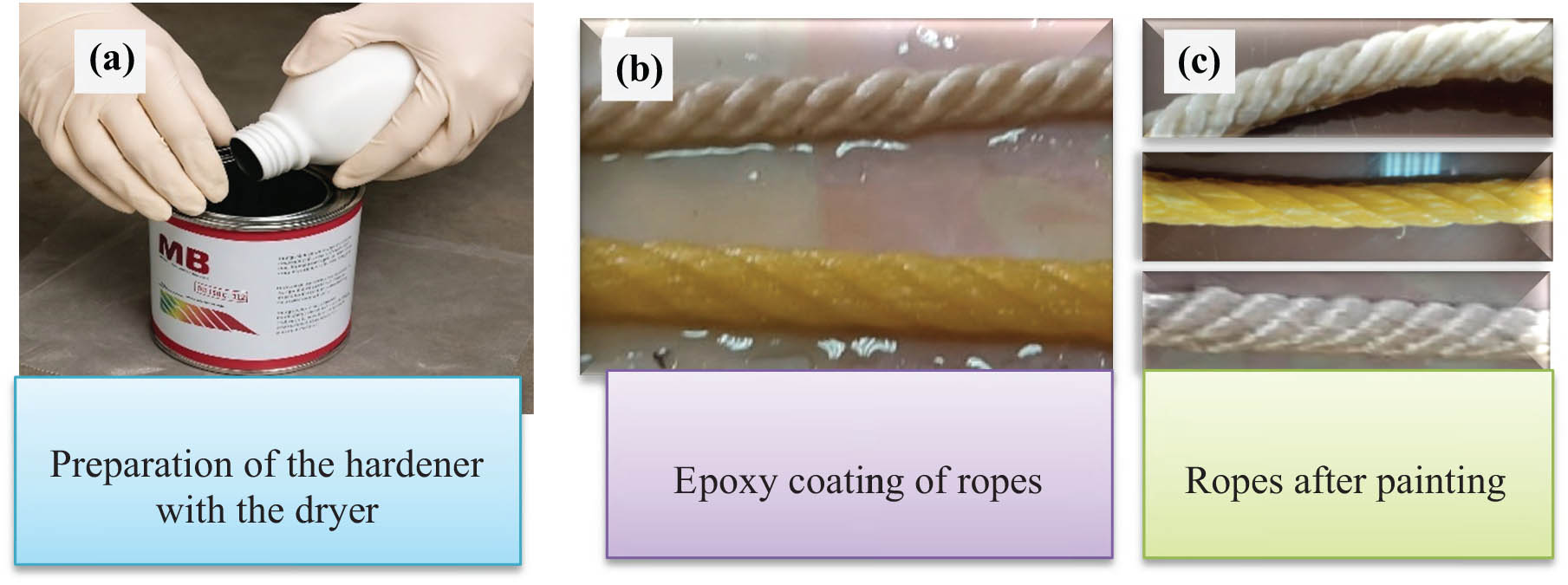

This study presents experimental findings on the use of ropes as a potential alternative to conventional construction steel bars. The study examines the ropes’ physical, mechanical, and durability properties; see Figure 1. It aims to produce novel bars that match the strength and other properties of traditional steel bars while also being cost-effective. Additionally, in this study, the results are compared with those of previous research conducted by different researchers.

(a) Mix preparation, (b) processing, and (c) ropes after processing (layer of protection and strength).

3 Experimental work

A group of destructive tests was carried out on ropes to show the performance of these novel bars, and the tests were compared with control bars (Steel Bars).

3.1 Polyester, polypropylene, and cotton fiber

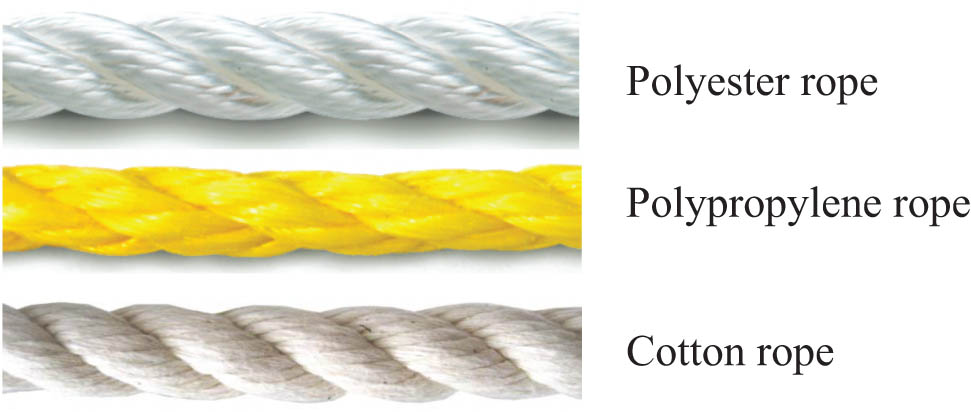

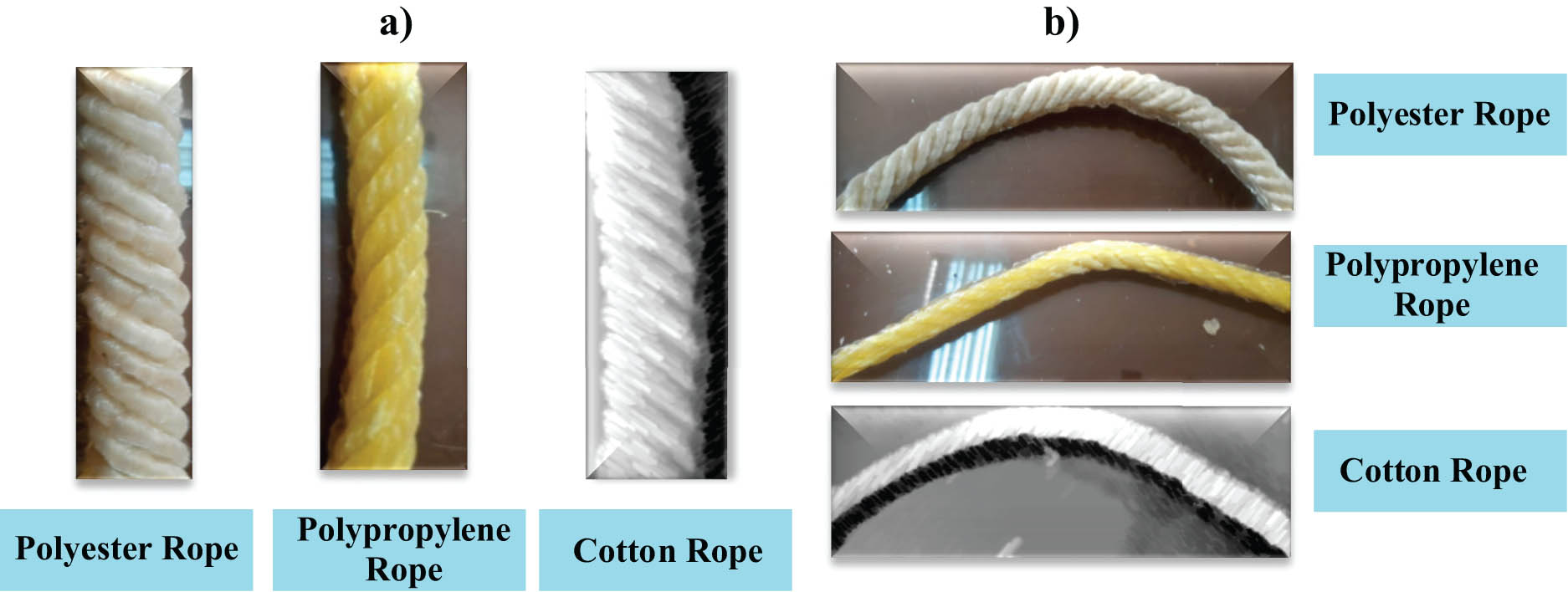

Polyester, polypropylene, and cotton ropes are lightweight and have high tensile bearing capacity, in addition to their low cost compared to other substitutes. This experimental study demonstrates the properties of ropes; see Figure 2. Polyester, polypropylene, and cotton ropes brought locally were used. In the textile consolidation fund (Alexandria), they had these necessary tests: First, the humidity content of the instrument is illustrated in Figure 3 and Table 3. Second, the Pressley tester measures fiber tensile strength, as shown in Figure 4.

Polyester, polypropylene, and cotton ropes.

(Libeccio) semiautomatic regains cabinet code 245B.

Humidity content, breaking strength, elongation, and structures of polyester, polypropylene, and cotton fibers

| No. | Test | Standard specifications | Sample | Note | ||

|---|---|---|---|---|---|---|

| Polyester | Polypropylene | Cotton | ||||

| 1 | Humidity content% | ASTM-D 2495 | 0 | 0 | 7.8 | Temperature, 20°C; relative humidity, 65% |

| 2 | Elongation% (Pressley Tester) | ASTM-D 1445 | 12:18% | 13–17% | 10% | Temperature. 20°C; relative humidity, 65% |

| 3 | Rope structure | BS EN ISO 1181:2004 | 3 strand laid (twisted) | — | ||

| 4 | Number of ends/strand | 18 | — | |||

| 5 | Level of twist | 50 turns/m | — | |||

Pressley tester – code 231 A.

3.2 Characterization of bars after processing

Ropes of polyester, polypropylene, and cotton, with a diameter of 16 mm, are the most available in the market; fibers in the form of ropes were processed by good tightness and then rubbed with kemapoxy 150 to ensure the bar’s intransigence. It is easy to handle fibers such as steel bars. This type of rope was compared with indented steel (highly resistant), as there is the indentation on the ropes. It is normally used in reinforcing elements of concrete. The structures of polyester, polypropylene, and cotton ropes are shown in Table 4.

Technical data for kemapoxy 150f

| No. | Characteristics | Value |

|---|---|---|

| 1 | Density (at 25°C) | 1.32 ± 0.02 kg/1 |

| 2 | Mixing ratio (a:b) by weight | 2:1 |

| 3 | Pot life (at 25°C) | 2 h |

| 4 | Initial setting time (at 25°C) | 3–4 h |

| 5 | Final setting time (at 25°C) | 24 h |

| 6 | Full hardness (at 25°C) | 7 days |

| 7 | Min application temperature | 15°C |

| 8 | Compressive strength | ≥400 kg·cm−2 |

| 9 | Heat resistance | Up to 250°C |

3.3 Processing of ropes

A substance that makes fiber ropes strong and intransigent was used in processing fibers. The ropes were first cleaned and dried to remove any surface impurities. The epoxy resin was then applied using a controlled brushing and impregnation method, ensuring that the resin penetrated uniformly into the interstices of the rope strands. To enhance uniformity, the impregnated ropes were gently rotated and passed through rollers to remove excess resin and achieve even distribution along the fibers. Finally, the ropes were cured under controlled temperature and humidity conditions to facilitate complete resin polymerization and strong bonding with the fibers. This stepwise process ensures that the epoxy resin is evenly processed across the rope fibers, improving mechanical performance and durability. The ropes were rubbed with kimapoxy 150f. After rubbing, fibers were tied from both sides to dry and to avoid bending or deflection. Then, the ropes became stubborn, hard, and strong. Table 4 shows the features of the rubbing substance, the processing stage, and the epoxy resin matrix (kemapoxy 150). Ropes were dried and primarily intransigent after 24 h, but final intransigence occurred after 7 days, when ropes were extremely strong and stubborn.

3.4 Experimental tests

The testing procedures for the novel reinforcing rods are discussed in the following sections.

3.4.1 Physical tests

Standard ASTM-D 1445 was used to perform the physical tests on the reinforcing rods. This would test properties like high temperature, working limit, electrical conductivity, etc.

3.4.2 Mechanical tests

Bond and tensile strengths were tested according to standard ESS 4756-1/2007. This measures how well the rebar bonds to the concrete and determines the maximum stress the rebar can withstand before failure. Water absorption testing was performed to determine the amount of water the rebar can absorb, which can impact corrosion resistance. Elongation percentage was measured to evaluate ductility according to the standard ASTM-D 1445.

3.4.3 Durability tests

Durability properties, including absorption of shock loads, acid exposure, alkali exposure, abrasion resistance, and aging resistance, were evaluated. Specifically, for acid and alkali resistance tests, the rope specimens were immersed in 5% H2SO4 and 5% NaOH solutions, respectively, for a period of 30 days at room temperature (25 ± 2°C). For abrasion resistance, a standard abrasion wheel method was adopted, and the test was conducted under ambient laboratory conditions. For aging resistance, the specimens were exposed to continuous UV radiation and elevated temperature (60 ± 2°C) for 15 days in an accelerated weathering chamber. Shock load absorption tests were performed under repeated impact loading using a drop-weight setup, and the response was recorded until failure.

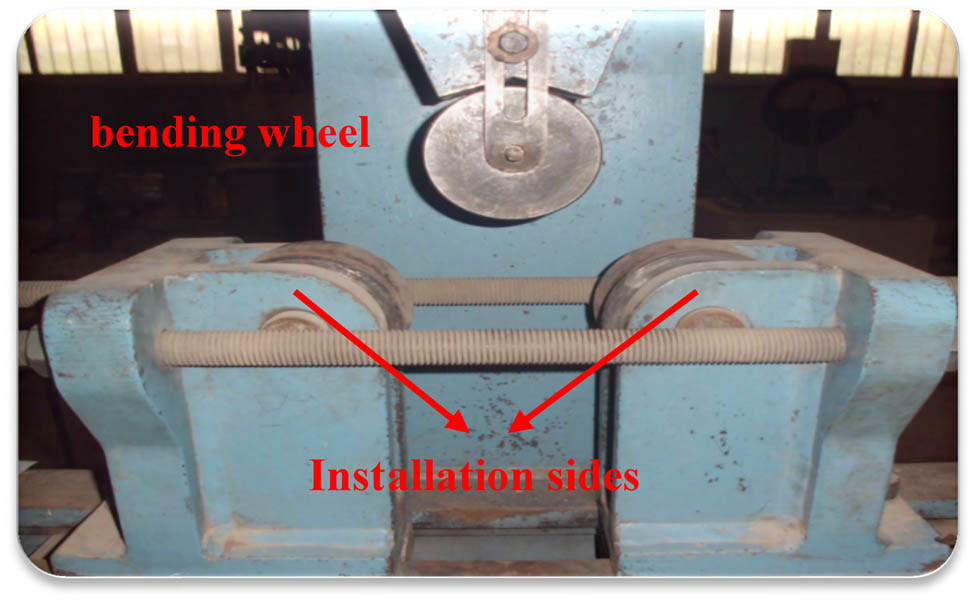

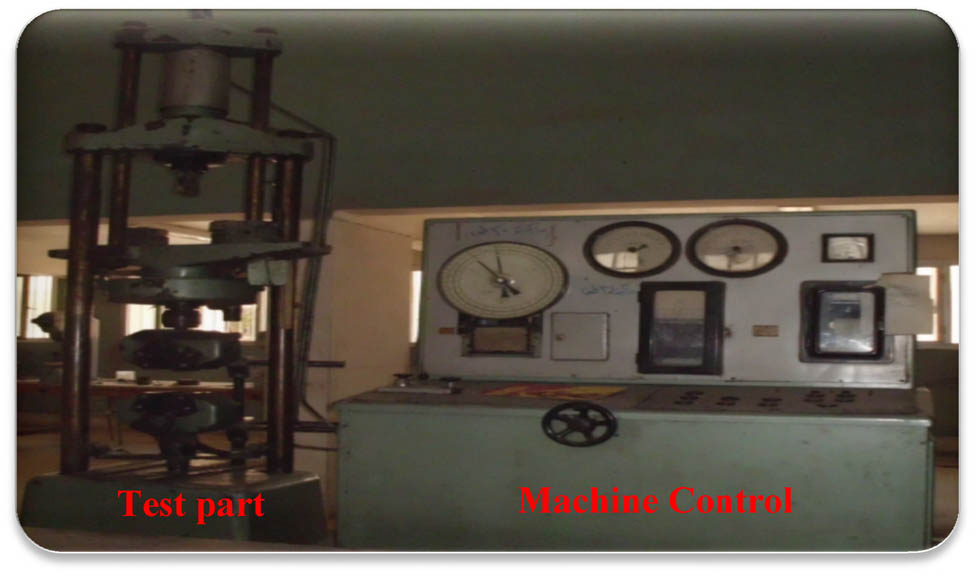

In summary, comprehensive testing was performed using relevant standards to evaluate the novel reinforcing rods’ physical, mechanical, and durability properties. This is essential to determine their suitability and performance for structural use; see Eq. (1) and Figures 5 and 6:

where Ƭ b is the bond stress (MPa), F is the pullout force (N), L is the embedded length (mm), and d is the bar diameter (mm).

Machine bending on the cold.

Tensile strength machine.

4 Results and discussion

The results of the polyester, polypropylene, and cotton ropes in terms of physical, mechanical, and durability properties were studied. The high- and low-temperature working limits of the polyester, polypropylene, and cotton ropes were determined based on data provided in Material Property Handbooks and relevant manufacturer’s specifications, which define the safe service temperature range where the ropes retain their mechanical integrity without significant loss of strength or brittleness. Tables 5–7 present the results obtained from the experiments.

Physical properties of reinforcement steel rods (RSR), polyester rope, polypropylene rope, and cotton rope

| No. | Properties | RSR | Polyester | Polypropylene | Cotton |

|---|---|---|---|---|---|

| 1 | High-temperature working limit | 1,500°C | 150°C | 65°C | 150°C |

| 2 | Low-temperature working limit | 250°C | −22°C | −71°C | −38.8°C |

| 3 | Melting point | 1,538°C | 262°C | 172°C | NA |

| 4 | Electrical conductivity resistance | Good | Good | Good | Poor |

| 5 | Storage requirements | Dry only | Wet or dry | Wet or dry | Dry only |

Mechanical properties of RSR, polyester rope, polypropylene rope, and cotton rope

| No. | Properties | RSR | Polyester | Polypro-pylene | Cotton | |

|---|---|---|---|---|---|---|

| 1 | Bond strength | Stresses (MPa) | 7.1 | 2.6 | 2.2 | 1.7 |

| 2 | Mode of failure | Splitting | Cut | Cut | Cut | |

| 3 | Cold bending | Excellent | Very good | Very good | Good | |

| 4 | Tensile strength | Yield stresses (MPa) | 43.7 | — | — | — |

| 5 | Maximum stresses | 59.0 | 15.03 | 13.23 | 12.74 | |

| 6 | ||||||

| 7 | Water absorption | Zero | Zero | Zero | Zero | |

| 8 | Elongation (%) | 20 (high tensile steel) | 18 | 16 | 11 | |

Durability properties for RSR, polyester rope, polypropylene rope, and cotton rope

| No. | Properties | RSR | Polyester | Polypropylene | Cotton |

|---|---|---|---|---|---|

| 1 | Absorption of shock loads | Excellent | Good | Very good | Very poor |

| 2 | Acid exposure | Affected | Most mineral acids resist it, but it is decomposed by 95% percent sulfuric acid. | Very resistant | In hot dilute and cold concentrates, it disintegrates |

| 3 | Alkali exposure | Affected | Cold has little impact; powerful alkalis slowly destroy it at boiling point | Very resistant | When exposed, it weakens |

| 4 | Abrasion resistance | Good | Very good | Good | Good |

| 5 | Aging resistance | Excellent | Excellent | Moderate | Good |

4.1 Physical properties

The physical properties of RSR, polyester ropes, polypropylene rope, and cotton rope are shown in Table 7. First, the high-temperature working limit of the RSR and ropes was studied, which were 200, 150, 65, and 150°C for RSR, polyester ropes, polypropylene rope, and cotton, respectively. It is shown that polyester and cotton had the same results, and RSR recorded the highest temperature, while polypropylene recorded the lowest temperature. This indicates that the properties of cotton and polyester are as close as possible to those of RSR. Second, the study of the low-temperature working limit were 45, −22, −71, and −38.8°C for RSR, polyester ropes, polypropylene rope, and cotton, respectively. From this, it was clear that the RSR were the highest, while the ropes were below zero. On the other hand, RSR recorded the highest melting point because it is a metal, followed by polyester and polypropylene. As cotton is a fiber, they have no melting point [9,22,48].

Electrical conductivity resistance was good for all rods and ropes, but cotton recorded poor resistance. Finally, storage requirements were wet or dry for polyester and polypropylene; in contrast, RSR and cotton were dry only. This is because polyester and polypropylene can withstand drought and moisture, which are good properties. As for the reinforcement steel, it must be dried to prevent rust, and the cotton must be dried to avoid rotting [49,50,51,52].

4.2 Mechanical properties

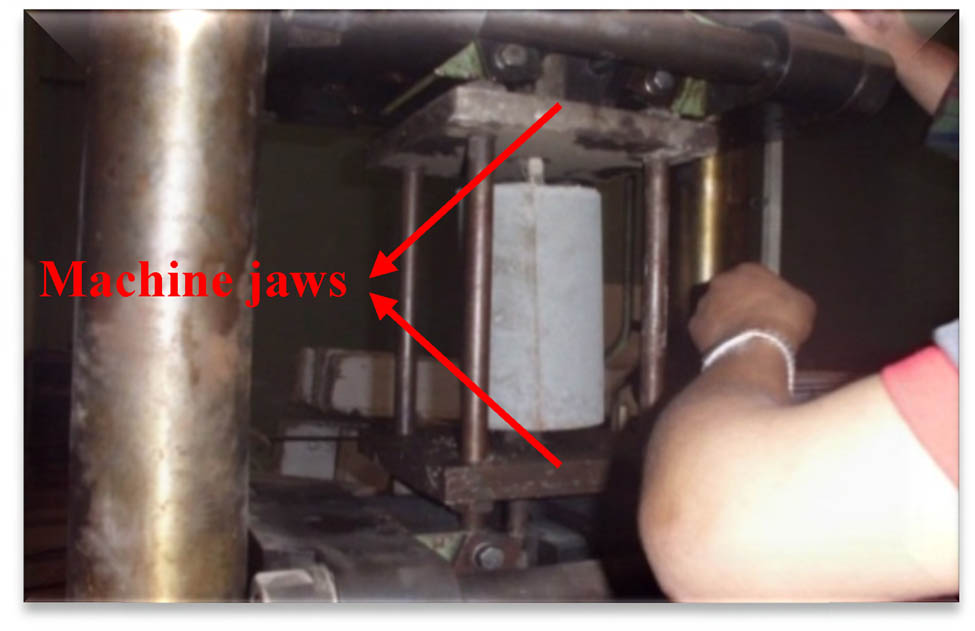

A bond strength test was conducted on cylinder samples (15 × 30 cm) after 28 days to ensure cohesiveness and bond strength between ropes and concrete; see Figure 7. When the tests were conducted, the ropes (polyester, polypropylene, and cotton) did not split during the test; however, they were cut, which displays these samples loaded on the machine after 28 days.

Bond strength test.

Table 8 shows the bond strength of RSR, which is higher than that of polyester, polypropylene, and cotton ropes. The bond strengths for RSR, polyester, polypropylene, and cotton were 7.1, 2.6, 2.2, and 1.7 MPa, respectively. The bond strengths of polyester, polypropylene, and cotton ropes were lower than those of RSR by 63.3, 69.0, and 76.1%, respectively; this behavior is consistent with that observed in the literature [53,54,55,56].

Costs of RSR, polyester rope, polypropylene rope, and cotton rope

| e | Shape | Diameterᴓ (mm) | Length of bars (m) | Number of bars for 1 ton | Weight of bars (kg) | Weight of bar of 12 m (kg) | Cost of tone (USD) | |

|---|---|---|---|---|---|---|---|---|

| RSR (Control) |

|

16 | 12 | 53 | 1.579 | 18.95 | 806 | |

| Polyester | Before processing |

|

16 | 12 | 14,286 | 0.070 | 8.4 | 59 |

| After processing |

|

16 | 12 | 8,334 | 0.120 | 14.40 | 84 | |

| Polypropylene | Before processing |

|

16 | 12 | 15,385 | 0.065 | 7.80 | 55 |

| After processing |

|

16 | 12 | 7,143 | 0.140 | 16.80 | 80 | |

| Cotton | Before processing |

|

16 | 12 | 13,334 | 0.075 | 9.0 | 63 |

| After processing |

|

16 | 12 | 6,452 | 0.155 | 18.6 | 88 | |

The fact that the ropes were cut rather than rebounded from the concrete indicates that the ropes’ strength is greater than the bond strength between the ropes and the concrete. Therefore, this test method was unsuitable for determining the actual bond strength. To effectively improve the rope–concrete bonding performance in future applications, several approaches can be considered: (i) applying surface treatments such as epoxy impregnation, resin coating, or roughening to increase adhesion; (ii) chemical modification of rope fibers to improve compatibility with cementitious matrices; and (iii) using alternative test methods (e.g., pull-out tests with end anchorage or embedded length adjustment) that prevent premature rope failure and allow for a more reliable assessment of interfacial bonding.

The following key factors have to be considered:

The ropes (polyester, polypropylene, and cotton) are likely considerably stronger than the bond between the ropes and concrete. These ropes can withstand high tensile loads before failure.

Cutting the ropes in the test never exceeded the actual bond strength between the ropes and concrete. The ropes failed in tension before any debonding could occur.

Other test methods are needed to determine the bond strength.

The test of bending in cold was conducted on RSR, polyester rope, polypropylene rope, and cotton rope, as shown in Figure 8. The results of this test do not yield a value but provide in terms of the bending shapes of the samples. After the test, it was noted that the cohesive samples were together and not unassembled in the test area after exposure to bending in cold, as shown in Figure 8. This test was conducted on the three samples of the bars, and the length of the sample was 1,000 mm; the bending on the cold test was carried out according to the American Code ACI 318M-2019 [57,58].

(a) Before and (b) after bending.

Samples were tightened on the steel tension machine, as shown in Figure 8, and the results are shown in Table 8. A problem encountered was that the samples were not stable or held firmly on the machine. The ropes can be used at a higher tension capacity, but the machine test could not show this force. Because of the ductility of ropes and the large elongation during the test process, rope breaking load can be calculated from the following equation:

where σ t is the tensile strength of the ropes (MPa), ρ l is the linear density of the rope (kg·m−1), T f is the fiber tenacity (N/tex), and η is the strength conversion efficiency (dimensionless fraction).

Table 8 shows the results for RSR, polyester rope, polypropylene rope, and cotton rope, which were 43.7, 15.03, 13.23, and 12.74, respectively. From the results, the RSR sample had a higher value, followed by the polyester sample, and the polypropylene and cotton samples converged. The tensile strength was measured according to American Code ACI 318M-2019 [58,59].

Water absorption was zero for all samples because the processing material protects against water for liquids [60,61]. The elongation values were convergent to all samples; the RSR sample exhibited the highest value by 20% and the cotton sample the lowest value by 11% [16,62].

4.3 Durability properties

4.3.1 Absorption of shock loads

Table 7 suggests that the mechanical energy absorption capacity of reinforcement materials is closely related to their fiber morphology, tensile strength, and deformation behavior under impact or shock loading. In our study, the observed ranking for shock load absorption was steel rods > polypropylene ropes > cotton ropes > polyester ropes, which aligns with expectations based on their intrinsic material properties. Steel reinforcement is specifically designed for concrete reinforcement, offering high tensile strength and durability. It is an excellent choice for resisting shock loads in concrete [63,64].

Steel reinforcement rods exhibit the highest energy absorption due to their high tensile strength, ductility, and ability to undergo plastic deformation before failure. This enables them to dissipate large amounts of energy under sudden loads, making them highly suitable for structural reinforcement in concrete. Polypropylene is a tough, durable plastic that can withstand some impact and shock loading, though not at the same level as steel. A “good” rating seems appropriate.

Cotton ropes, being natural fibers, demonstrate moderate energy absorption. Although cotton fibers have relatively lower tensile strength than synthetic fibers, their hierarchical fiber structure provides some capacity to deform and dissipate energy under shock loading [65]. A “very good” rating indicates they provide decent durability while still being lower than steel or polypropylene.

Polyester ropes showed the lowest shock absorption in our tests. Despite having high tensile strength, polyester fibers are relatively stiff and exhibit lower elongation at break than polypropylene, which limits their ability to absorb mechanical energy during impact. The compact, less deformable fiber morphology reduces inter-fiber load redistribution, resulting in early localized damage under repeated shock loads.

In summary, the relative ratings in Table 7 match expectations for the durability and resistance to shock loads of these common reinforcement materials, with steel reinforcement providing the highest durability, followed by polypropylene, cotton, and polyester ropes. The test results confirm steel reinforcement is the best choice when high durability and resistance to impact loads are required in concrete reinforcement applications.

4.3.2 Alkali exposure

Steel reinforcement is likely more susceptible to corrosion from acids and alkalis than rope samples. Steel does not have inherent chemical resistance and relies on concrete to provide a protective environment. However, acids and alkalis can permeate the concrete and corrode the steel over time [60,66]. Polypropylene and polyester ropes, being synthetic polymers, possess excellent inherent chemical resistance to alkaline environments [67]. Their molecular chains are stable under high-pH conditions and they do not react chemically with hydroxide ions present in concrete. As a result, these ropes maintain their structural integrity, tensile strength, and flexibility over extended periods, making them suitable for use in alkaline concrete matrices.

Cotton ropes, as natural cellulose-based fibers, are significantly more vulnerable to alkaline attack. The hydroxide ions in the concrete can hydrolyze the glycosidic bonds in cellulose, leading to fiber swelling, weakening, and gradual loss of tensile capacity [68]. Prolonged exposure to high-pH environments accelerates this degradation, which can compromise the mechanical performance of cotton ropes in concrete reinforcement applications.

In summary, the differences in alkali resistance among steel, synthetic, and natural fiber ropes highlight the critical role of chemical stability in durability. While steel requires sufficient concrete cover for protection, cotton is prone to degradation. In contrast, synthetic ropes such as polypropylene and polyester provide superior performance in alkaline environments, combining chemical resistance with mechanical durability.

4.3.3 Abrasion resistance

All the reinforcement materials appear to provide acceptable abrasion resistance for use in concrete, although this may vary to some degree. The properties of the individual materials will influence their abrasion resistance [69,70,71]. The abrasion resistance of reinforcement materials is strongly influenced by fiber composition, surface roughness, and inter-fiber bonding within the rope structure. Steel reinforcement rods exhibit excellent abrasion resistance due to their high hardness, continuous metallic surface, and resistance to wear under frictional contact with concrete aggregates. They maintain structural integrity even under repeated mechanical action.

Polypropylene ropes demonstrate moderate abrasion resistance. Their synthetic polymer filaments are relatively tough and flexible, allowing them to withstand surface wear without immediate failure. The braided structure of the rope helps distribute localized frictional forces among multiple filaments, reducing the rate of fiber degradation. However, prolonged exposure to rough concrete surfaces may lead to surface fibrillation or fiber fraying over time.

Cotton ropes, composed of natural cellulose fibers, show intermediate abrasion resistance. While cotton fibers can absorb energy and deform under friction, their softer surface and weaker inter-fiber bonding make them more prone to wear and gradual thinning of individual strands under repeated contact with rough surfaces. On the other hand, polyester ropes exhibit higher initial tensile strength but relatively lower abrasion resistance compared to polypropylene. The stiffer, less deformable fiber structure of polyester limits its ability to redistribute frictional stress among filaments, which can lead to localized fiber wear. Surface roughness and compact fiber packing in polyester ropes can accelerate micro-abrasion under repeated mechanical loading.

4.3.4 Aging resistance

Steel reinforcement generally provides the longest service life and best-aging resistance due to its high strength and durability. However, adequate concrete cover is required to protect it from corrosion. Polyester ropes may offer aging resistance comparable to that of steel reinforcement, due to the high strength and durability of modern polyester fibers. However, polyester will still degrade faster over time in a concrete environment.

The aging resistance of reinforcement materials is influenced by their chemical composition, environmental exposure, and fiber morphology. Steel reinforcement rods generally provide the longest service life due to their high strength and toughness; however, they rely on adequate concrete cover to prevent corrosion. Exposure to moisture, chlorides, or carbonation can gradually compromise steel, leading to a reduction in mechanical performance over time.

Polyester ropes demonstrate relatively superior aging resistance among the rope materials tested. This is due to the high chemical stability of polyester polymers, which exhibit strong resistance to hydrolytic degradation, thermal stress, and UV radiation. The tightly packed filament structure and inherent hydrophobicity of polyester fibers reduce moisture uptake and prevent significant loss of tensile strength over prolonged exposure to environmental stressors.

Polypropylene ropes show moderate aging resistance. Although polypropylene is chemically stable and hydrophobic, it is more sensitive to UV radiation and high temperatures compared to polyester. Prolonged exposure can lead to surface embrittlement, micro-cracking, or a gradual reduction in tensile performance, limiting its long-term durability in outdoor or exposed concrete applications.

Cotton ropes, being natural cellulose fibers, are most vulnerable to aging. They are susceptible to hydrolysis, thermal degradation, and microbial attack, especially under conditions of high moisture and temperature. UV exposure accelerates cellulose breakdown, resulting in decreased fiber strength and flexibility over time.

In summary, RSR has some disadvantages related to chemical resistance but provides the best overall durability and aging resistance due to its high strength and toughness. Polyester ropes offer better-aging resistance than the cotton and polypropylene samples, though still not at the level of steel reinforcement [9,72,73].

5 Comparison of the cost between RSR, polyester rope, polypropylene rope, and cotton rope

As shown in Table 8, before processing, the polyester ropes were reduced in cost by 99.93%, the polypropylene rope by 99.92%, and the cotton rope by 92.7% of the control (RSR). On the other hand, after processing, the cost of the cotton ropes was reduced by 99.9%, the polyester rope by 99.01%, and finally, the polypropylene rope by 90.06% of the control (RSR).

When comparing the cost with other characteristics, it was found that polyester ropes are the best type, followed by polypropylene ropes and cotton ropes [56,74,75].

6 Conclusion

Polyester ropes exhibited physical properties comparable to steel reinforcement, with the exception of electrical conductivity. However, the bond strengths of polyester, polypropylene, and cotton ropes were lower than those of steel reinforcement rods by 63.3, 69.0, and 76.1%, respectively.

Samples remained cohesive and intact during cold bending tests. Steel reinforcement rods (RSR) demonstrated the highest tensile strength, followed by polyester ropes, with polypropylene and cotton ropes showing similar but lower performance.

All treated samples displayed zero water absorption, except for cotton ropes, which exhibited 100% liquid absorbency due to their inherent material characteristics.

The elongation values across all samples were comparable, with steel reinforcement rods showing the highest elongation at 20%, while cotton ropes had the lowest at 11%. Polyester and polypropylene ropes exhibited intermediate elongation values.

Steel reinforcement rods showed greater susceptibility to acids and alkalis compared to the ropes. However, all tested materials exhibited acceptable abrasion resistance.

Steel reinforcement rods demonstrated the longest service life and superior aging resistance compared to the alternative materials, while polyester ropes showed moderate durability over time.

Acknowledgments

The authors extend their appreciation to Prince Sattam bin Abdulaziz University for funding this research ( project number PSAU/2025/01/33470).

-

Funding information: This study was supported by a research fund from Prince Sattam bin Abdulaziz University, 2025.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Triantafillou, T. C. Shear strengthening of reinforced concrete beams using epoxy-bonded FRP composites. ACI Structural Journal, Vol. 95, 1998, pp. 107–115.10.14359/531Suche in Google Scholar

[2] Hussain, Q., W. Rattanapitikon, and A. Pimanmas. Axial load behavior of circular and square concrete columns confined with sprayed fiber‐reinforced polymer composites. Polymer Composites, Vol. 37, No. 8, 2016, pp. 2557–2567.10.1002/pc.23450Suche in Google Scholar

[3] Torabian, A., B. Isufi, D. Mostofinejad, and A. P. Ramos. Flexural strengthening of flat slabs with FRP composites using EBR and EBROG methods. Engineering Structures, Vol. 211, 2020, id. 110483.10.1016/j.engstruct.2020.110483Suche in Google Scholar

[4] Adam, M. A., M. Said, A. A. Mahmoud, and A. S. Shanour. Analytical and experimental flexural behavior of concrete beams reinforced with glass fiber reinforced polymers bars. Construction and Building Materials, Vol. 84, 2015, pp. 354–366.10.1016/j.conbuildmat.2015.03.057Suche in Google Scholar

[5] Thermou, G. E., S. J. Pantazopoulou, and A. S. Elnashai. Flexural behavior of brittle RC members rehabilitated with concrete jacketing. Journal of Structural Engineering, Vol. 133, No. 10, 2007, pp. 1373–1384.10.1061/(ASCE)0733-9445(2007)133:10(1373)Suche in Google Scholar

[6] Adam, J. M., E. Gimenez, P. A. Calderón, F. J. Pallares, and S. Ivorra. Experimental study of beam-column joints in axially loaded RC columns strengthened by steel angles and strips. Steel and Composite Structures, Vol. 8, No. 4, 2004, pp. 329–342.10.12989/scs.2008.8.4.329Suche in Google Scholar

[7] Hussain, Q., A. Ruangrassamee, S. Tangtermsirikul, and P. Joyklad. Behavior of concrete confined with epoxy bonded fiber ropes under axial load. Construction and Building Materials, Vol. 263, 2020, id. 120093.Suche in Google Scholar

[8] Naser, M., R. Hawileh, and J. Abdalla. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A critical review. Engineering Structures, Vol. 198, 2019, id. 109542.10.1016/j.engstruct.2019.109542Suche in Google Scholar

[9] Selection guide to help you decide which kind of rope is right for your application, Continental Western Corporation, 2020. www.cwcglobal.com.Suche in Google Scholar

[10] Masuelli, M. A. Introduction of fibre-reinforced polymers − polymers and composites: concepts, properties and processes. In Fiber reinforced polymers-the technology applied for concrete repair, IntechOpen, London, UK, 2013.10.5772/3162Suche in Google Scholar

[11] Beltrán, J. F. and E. B. Williamson. Numerical procedure for the analysis of damaged polyester ropes. Engineering Structures, Vol. 33, 2011, pp. 1698–1709.10.1016/j.engstruct.2011.02.007Suche in Google Scholar

[12] Rajak, D. K., D. D. Pagar, P. L. Menezes, and E. Linul. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers, Vol. 11, No. 10, 2019, id. 1667.10.3390/polym11101667Suche in Google Scholar PubMed PubMed Central

[13] Saba, N., M. Paridah, and M. Jawaid. Mechanical properties of kenaf fibre reinforced polymer composite: A review. Construction and Building materials, Vol. 76, 2015, pp. 87–96.10.1016/j.conbuildmat.2014.11.043Suche in Google Scholar

[14] Foster, G. P. Advantages of fiber rope over wire rope. Journal of Industrial Textiles, Vol. 32, 2002, pp. 67–75.10.1106/152808302031656Suche in Google Scholar

[15] GangaRao, H. V., N. Taly, and P. Vijay. Reinforced concrete design with FRP composites, CRC Press, Boca Raton, 2006.10.1201/9781420020199Suche in Google Scholar

[16] Lian, Y., H. Liu, L. Li, and Y. Zhang. An experimental investigation on the bedding-in behavior of synthetic fiber ropes. Ocean Engineering, Vol. 160, 2018, pp. 368–381.10.1016/j.oceaneng.2018.04.071Suche in Google Scholar

[17] Banfield, S. J. and N. F. Casey. Evaluation of fiber rope properties for offshore mooring. Ocean Engineering, Vol. 25, No. 10, 2008, pp. 861–879.10.1016/S0029-8018(97)10017-8Suche in Google Scholar

[18] Andrew, J. J., S. M. Srinivasan, A. Arockiarajan, and H. N. Dhakal. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials A critical review. Composite Structures, Vol. 244, 2019, id. 111007.10.1016/j.compstruct.2019.111007Suche in Google Scholar

[19] Kheyroddin, A., H. Arshadi, M. R. Ahadi, G. Taban, and M. Kioumarsi. The impact resistance of Fiber-Reinforced concrete with polypropylene fibers and GFRP wrapping. Materials Today: Proceedings, Vol. 45, 2021, pp. 5433–5438.10.1016/j.matpr.2021.02.116Suche in Google Scholar

[20] Kunimitsu, T., K. Toyoda, T. Ikaga, K. Kim, Y. Ohkoshi, and K. Koike. High strength fiber obtained from a high stereoregularity metallocene catalyst-synthesized polypropylene. Polymer, Vol. 202, 2020, id. 122654.10.1016/j.polymer.2020.122654Suche in Google Scholar

[21] Monaldo, E., F. Nerilli, and G. Vairo. Basalt-based fiber-reinforced materials and structural applications in civil engineering. Composite Structures, Vol. 214, 2019, pp. 246–263.10.1016/j.compstruct.2019.02.002Suche in Google Scholar

[22] Unit 9 Deptford Trading Estate, Blackhorse Road, London, SE8 5HY www.flints.co.uk.Suche in Google Scholar

[23] Company, C. B. K. Samson and New England Ropes carried by CBKnot, https://cbknot.com/content/Equestrian creating quality rope products in the USA., 2021.Suche in Google Scholar

[24] Hollaway, L. C. Advanced polymer composites and polymers in the civil infrastructure, Elsevier, Amsterdam, Netherlands, 2001.10.1016/B978-008043661-6/50011-5Suche in Google Scholar

[25] Yinh, S., Q. Hussain, P. Joyklad, P. Chaimahawan, W. Rattanapitikon, S. Limkatanyu, et al. Strengthening effect of natural fiber reinforced polymer composites (NFRP) on concrete. Case Studies in Construction Materials, Vol. 15, 2021, id. e00653.10.1016/j.cscm.2021.e00653Suche in Google Scholar

[26] Rodsin, K. Confinement effects of glass FRP on circular concrete columns made with crushed fired clay bricks as coarse aggregates. Case Studies in Construction Materials, Vol. 15, 2021, id. e00609.10.1016/j.cscm.2021.e00609Suche in Google Scholar

[27] Firouzsalari, S. E. Flexural response of short flax fabric-reinforced epoxy tubes: An experimental study. Composites Part C: Open Access, Vol. 5, 2021, id. 100160.10.1016/j.jcomc.2021.100160Suche in Google Scholar

[28] Saidi, M. and A. Gabor. Iterative analytical modelling of the global behaviour of textile-reinforced cementitious matrix composites subjected to tensile loading. Construction and Building Materials, Vol. 263, 2020, id. 120130.10.1016/j.conbuildmat.2020.120130Suche in Google Scholar

[29] Juntanalikit, P., T. Jirawattanasomkul, and A. Pimanmas. Experimental and numerical study of strengthening non-ductile RC columns with and without lap splice by carbon fiber reinforced polymer (CFRP) jacketing. Engineering Structures, Vol. 125, 2016, pp. 400–418.10.1016/j.engstruct.2016.07.019Suche in Google Scholar

[30] Obaidat, Y. T., W. S. Barham, and A. H. Aljarah. New anchorage technique for NSM-CFRP flexural strengthened RC beam using steel clamped end plate. Construction and Building Materials, Vol. 263, 2020, id. 120246.10.1016/j.conbuildmat.2020.120246Suche in Google Scholar

[31] Yan, B., L. Huang, L. Yan, C. Gao, and B. Kasal. Behavior of flax FRP tube encased recycled aggregate concrete with clay brick aggregate. Construction and Building Materials, Vol. 136, 2017, pp. 265–276.10.1016/j.conbuildmat.2017.01.046Suche in Google Scholar

[32] Jiang, N., H. Zhang, Z. Chang, E. Schlangen, Z. Ge, and B. Šavija. Discrete lattice fracture modelling of hydrated cement paste under uniaxial compression at micro-scale. Construction and Building Materials, Vol. 263, 2020, id. 120153.10.1016/j.conbuildmat.2020.120153Suche in Google Scholar

[33] Chen, J. and N. Chouw. Compressive behaviour of flax FRP double tube confined coconut fibre reinforced concrete. Construction and Building Materials, Vol. 112, 2016, pp. 666–673.10.1016/j.conbuildmat.2016.02.120Suche in Google Scholar

[34] Chen, J. and N. Chouw. Flexural behaviour of flax FRP double tube confined coconut fibre reinforced concrete beams with interlocking interface. Composite Structures, Vol. 192, 2018, pp. 217–224.10.1016/j.compstruct.2018.02.050Suche in Google Scholar

[35] Du, H., G. Xian, J. Tian, Z. Ma, C. Li, M. Xin, et al. Effect of fiber surface treatment with silane coupling agents and carbon nanotubes on mechanical properties of carbon fiber reinforced polyamide 6 composites. Polymer Composites, Vol. 46, No. 2, 2025, pp. 1267–1283.10.1002/pc.29035Suche in Google Scholar

[36] Zhang, Z., Q. Ji, Z. Guo, C. Li, R. Guo, J. Tian, et al. Design, preparation, and mechanical properties of glass fiber reinforced thermoplastic self-anchor plate cable exposed in alkaline solution environment. Polymer Composites, Vol. 45, No. 13, 2024, pp. 11687–11700.10.1002/pc.28591Suche in Google Scholar

[37] Hegde, S., B. Satish Shenoy, and K. N. Chethan. Review on carbon fiber reinforced polymer (CFRP) and their mechanical performance. Materials Today: Proceedings, Vol. 19, 2019, pp. 658–662.10.1016/j.matpr.2019.07.749Suche in Google Scholar

[38] Yu, Y., S. Liu, Y. Pan, X. Miu, and J. Liu. Durability of glass fiber-reinforced polymer bars in water and simulated concrete pore solution. Construction and Building Materials, Vol. 299, 2021, id. 123995.10.1016/j.conbuildmat.2021.123995Suche in Google Scholar

[39] Zhang, X., D. Zhu, Y. Yao, H. Zhang, B. Mobasher, and L. Huang. Experimental study of tensile behaviour of AFRP under different strain rates and temperatures. Journal of Structural Integrity and Maintenance, Vol. 1, No. 1, 2016, pp. 22–34.10.1080/24705314.2016.1153327Suche in Google Scholar

[40] Chen, D., G. Sun, M. Meng, X. Jin, and Q. Li. Flexural performance and cost efficiency of carbon/basalt/glass hybrid FRP composite laminates. Thin-Walled Structures, Vol. 142, 2019, pp. 516–531.10.1016/j.tws.2019.03.056Suche in Google Scholar

[41] Sadowski, Ł., Ł. Kampa, A. Chowaniec, A. Królicka, A. Żak, H. Abdoulpour, et al. Enhanced adhesive performance of epoxy resin coating by a novel bonding agent. Construction and Building Materials, Vol. 301, 2021, id. 124078.10.1016/j.conbuildmat.2021.124078Suche in Google Scholar

[42] Ezeh, E. M. Advances in the development of polyester resin composites: a review. World Journal of Engineering, 2024.10.1108/WJE-12-2023-0517Suche in Google Scholar

[43] Nodehi, M. Epoxy, polyester and vinyl ester based polymer concrete: a review. Innovative Infrastructure Solutions, Vol. 7, No. 1, 2021, id. 64.10.1007/s41062-021-00661-3Suche in Google Scholar

[44] Abdulridha, S. Q., M. S. Nasr, B. H. Al-Abbas, and Z. A. Hasan. Mechanical and structural properties of waste rope fibers-based concrete: An experimental study. Case Studies in Construction Materials, Vol. 16, 2022, id. e00964.10.1016/j.cscm.2022.e00964Suche in Google Scholar

[45] Hossain, M. T., M. A. Shahid, N. Mahmud, A. Habib, M. M. Rana, S. A. Khan, et al. Research and application of polypropylene: a review. Discover Nano, Vol. 19, No. 1, 2024, id. 2.10.1186/s11671-023-03952-zSuche in Google Scholar PubMed PubMed Central

[46] Mukhopadhyay, S. and S. Khatana. A review on the use of fibers in reinforced cementitious concrete. Journal of Industrial Textiles, Vol. 45, No. 2, 2014, pp. 239–264.10.1177/1528083714529806Suche in Google Scholar

[47] Hossain, M. A., S. D. Datta, A. S. Akid, M. H. Sobuz, and M. S. Islam. Exploring the synergistic effect of fly ash and jute fiber on the fresh, mechanical and non-destructive characteristics of sustainable concrete. Heliyon, Vol. 9, No. 11, 2023, e21708.10.1016/j.heliyon.2023.e21708Suche in Google Scholar PubMed PubMed Central

[48] Leramo, R. O., L. O. Adekoya, and C. A. Loto. Evaluation of surface geometries and physical properties of concrete reinforcement steel rods rolled in Nigeria. Case Studies in Construction Materials, Vol. 8, 2018, pp. 150–159.10.1016/j.cscm.2017.12.003Suche in Google Scholar

[49] Sun, B., R. C. Xiao, W. D. Ruan, and P. B. Wang. Corrosion-induced cracking fragility of RC bridge with improved concrete carbonation and steel reinforcement corrosion models. Engineering Structures, Vol. 208, 2020, id. 110313.10.1016/j.engstruct.2020.110313Suche in Google Scholar

[50] Zhang, Q., M. Song, Y. Xu, W. Wang, Z. Wang, and L. Zhang. Bio-based polyesters: Recent progress and future prospects. Construction and Building Materials, Vol. 216, 2016, pp. 40–57.Suche in Google Scholar

[51] Akid, A. S., S. Hossain, M. I. Munshi, M. M. Elahi, M. H. Sobuz, V. W. Tam, et al. Assessing the influence of fly ash and polypropylene fiber on fresh, mechanical and durability properties of concrete. Journal of King Saud University - Engineering Sciences, Vol. 35, No. 7, 2023, pp. 474–484.10.1016/j.jksues.2021.06.005Suche in Google Scholar

[52] Li, X., Y. Lei, Y. Han, Z. Wang, G. Wang, L. Feng, et al. The relative impacts of changes in plant density and weather on cotton yield variability. Field Crops Research, Vol. 270, 2021, id. 108202.10.1016/j.fcr.2021.108202Suche in Google Scholar

[53] Song, X., Y. Li, and C. Li. Bond behavior between steel bars and carbon nanotube modified concrete. Construction and Building Materials, Vol. 255, 2020, id. 119339.10.1016/j.conbuildmat.2020.119339Suche in Google Scholar

[54] Lee, H., S. Jeong, S. Cho, and W. Chung. Enhanced bonding behavior of multi-walled carbon nanotube cement composites and reinforcing bars. Composite Structures, Vol. 243, 2020, id. 112201.10.1016/j.compstruct.2020.112201Suche in Google Scholar

[55] Hawreen, A. and J. A. Bogas. Influence of carbon nanotubes on steel–concrete bond strength. Materials and Structures, Vol. 51, 2018, id. 155.10.1617/s11527-018-1279-8Suche in Google Scholar

[56] Hussain, Q., A. Ruangrassamee, S. Tangtermsirikul, and P. Joyklad. Behavior of concrete confined with epoxy bonded fiber ropes under axial load. Construction and Building Materials, Vol. 263, 2020, id. 120093.10.1016/j.conbuildmat.2020.120093Suche in Google Scholar

[57] Wan, Y., W. Jiang, and H. Li. Cold bending effect on residual stress, microstructure and mechanical properties of Type 316L stainless steel welded joint. Engineering Failure Analysis, Vol. 117, 2020, id. 104825.10.1016/j.engfailanal.2020.104825Suche in Google Scholar

[58] 318, A.C. Building code requirements for structural concrete (ACI 318m-14) and commentary (ACI 318 14), American Concrete Institute, 2019.Suche in Google Scholar

[59] Abdu, M. F. A. N. Shear behavior of reinforced geopolymer concrete beams, Doctoral thesis, Helwan University, 2023.Suche in Google Scholar

[60] Bachchan, A. A., P. P. Das, and V. Chaudhary. Effect of moisture absorption on the properties of natural fiber reinforced polymer composites: A review. Materials Today: Proceedings, Vol. 49, 2022, pp. 3403–3408.10.1016/j.matpr.2021.02.812Suche in Google Scholar

[61] Spierings, A. B., O. Henkel, and M. Schmid. Water absorption and the effects of moisture on the dynamic properties of synthetic mountaineering ropes. International Journal of Impact Engineering, Vol. 34, 2007, pp. 205–215.10.1016/j.ijimpeng.2005.08.008Suche in Google Scholar

[62] Xu, S., S. Wang, H. Liu, Y. Zhang, L. Li, and C. G. Soares. Experimental evaluation of the dynamic stiffness of synthetic fibre mooring ropes. Applied Ocean Research, Vol. 112, 2021, id. 102709.10.1016/j.apor.2021.102709Suche in Google Scholar

[63] Rousakis, T. Natural fibre rebar cementitious composites, in Advanced high strength natural fibre composites in construction, Elsevier, Amsterdam, Netherlands, 2017, pp. 215–234.10.1016/B978-0-08-100411-1.00009-1Suche in Google Scholar

[64] Balla, V. K., K. H. Kate, J. Satyavolu, P. Singh, and J. G. Tadimeti. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Composites Part B: Engineering, Vol. 174, 2019, id. 106956.10.1016/j.compositesb.2019.106956Suche in Google Scholar

[65] Bajpai, S. K., G. Mary, and N. Chand. The use of cotton fibers as reinforcements in composites. In Biofiber reinforcements in composite materials, Faruk, O. and M. Sain, Eds., Woodhead Publishing, Cambridge, United Kingdom, 2015, pp. 320–341.10.1533/9781782421276.3.320Suche in Google Scholar

[66] Kerni, L., S. Singh, A. Patnaik, and N. Kumar. A review on natural fiber reinforced composites. Materials Today: Proceedings, Vol. 28, 2020, pp. 1616–1621.10.1016/j.matpr.2020.04.851Suche in Google Scholar

[67] Sharath, B. N., T. G. Yashas Gowda, and M. Puttegowda. Prospects of synthetic fiber-reinforced polymer composites in engineering and commercial applications. In Applications of composite materials in engineering, Puttegowda, M. et al., Eds., Elsevier Science Ltd, Amsterdam, Netherlands, 2025, pp. 365–395.10.1016/B978-0-443-13989-5.00015-2Suche in Google Scholar

[68] Lv, C. and J. Liu. Alkaline degradation of plant fiber reinforcements in geopolymer: a review. Molecules, Vol. 28, 2023, id. 1868.10.3390/molecules28041868Suche in Google Scholar PubMed PubMed Central

[69] Xu, S., N. Girouard, G. Schueneman, M. L. Shofner, and J. C. Meredith. Mechanical and thermal properties of waterborne epoxy composites containing cellulose nanocrystals. Polymer, Vol. 54, No. 24, 2013, pp. 6589–6598.10.1016/j.polymer.2013.10.011Suche in Google Scholar

[70] Effiong, J. U. and A. N. Ede. Experimental investigation on the strengthening of reinforced concrete beams using externally bonded and near-surface mounted natural fibre reinforced polymer composites – a review. Materials, Vol. 15, No. 17, 2022, id. 5848.10.3390/ma15175848Suche in Google Scholar PubMed PubMed Central

[71] Chawla, K. K. Composite materials: science and engineering, Springer Science & Business Media, 2012.Suche in Google Scholar

[72] Spagnuolo, S., Z. Rinaldi, J. Donnini, and A. Nanni. Physical, mechanical and durability properties of GFRP bars with modified acrylic resin (modar) matrix. Composite Structures, Vol. 262, 2021, id. 113557.10.1016/j.compstruct.2021.113557Suche in Google Scholar

[73] Ding, L., M. Lei, X. Wang, Y. Shi, Z. Zhu, P. Yu, et al. Durability of concrete members reinforced with steel-FRP composite bars under dry-wet cycles of seawater. Structures, Vol. 33, 2021, pp. 2273–2283.10.1016/j.istruc.2021.05.073Suche in Google Scholar

[74] Hearle, J. W. S. Developments in rope structures and technology, Specialist Yarn and Fabric Structures, 2011. Book chapter.10.1533/9780857093936.56Suche in Google Scholar

[75] Sabia, F. T. C. Smart reinforcement steel bars with low-cost MEMS sensors for the structural health monitoring of RC structures. Construction and Building Materials, Vol. 173, 2018, pp. 740–753.10.1016/j.conbuildmat.2018.04.045Suche in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters

- Fe-containing nominal wollastonite (CaSiO3)–Na2O glass-ceramic: Characterization and biocompatibility

- Relevance of pore network connectivity in tannin-derived carbons for rapid detection of BTEX traces in indoor air

- A life cycle and environmental impact analysis of sustainable concrete incorporating date palm ash and eggshell powder as supplementary cementitious materials

- Eco-friendly utilisation of agricultural waste: Assessing mixture performance and physical properties of asphalt modified with peanut husk ash using response surface methodology

- Benefits and limitations of N2 addition with Ar as shielding gas on microstructure change and their effect on hardness and corrosion resistance of duplex stainless steel weldments

- Effect of selective laser sintering processing parameters on the mechanical properties of peanut shell powder/polyether sulfone composite

- Impact and mechanism of improving the UV aging resistance performance of modified asphalt binder

- AI-based prediction for the strength, cost, and sustainability of eggshell and date palm ash-blended concrete

- Investigating the sulfonated ZnO–PVA membrane for improved MFC performance

- Strontium coupling with sulphur in mouse bone apatites

- Transforming waste into value: Advancing sustainable construction materials with treated plastic waste and foundry sand in lightweight foamed concrete for a greener future

- Evaluating the use of recycled sawdust in porous foam mortar for improved performance

- Improvement and predictive modeling of the mechanical performance of waste fire clay blended concrete

- Polyvinyl alcohol/alginate/gelatin hydrogel-based CaSiO3 designed for accelerating wound healing

- Research on assembly stress and deformation of thin-walled composite material power cabin fairings

- Effect of volcanic pumice powder on the properties of fiber-reinforced cement mortars in aggressive environments

- Analyzing the compressive performance of lightweight foamcrete and parameter interdependencies using machine intelligence strategies

- Selected materials techniques for evaluation of attributes of sourdough bread with Kombucha SCOBY

- Establishing strength prediction models for low-carbon rubberized cementitious mortar using advanced AI tools

- Investigating the strength performance of 3D printed fiber-reinforced concrete using applicable predictive models

- An eco-friendly synthesis of ZnO nanoparticles with jamun seed extract and their multi-applications

- The application of convolutional neural networks, LF-NMR, and texture for microparticle analysis in assessing the quality of fruit powders: Case study – blackcurrant powders

- Study of feasibility of using copper mining tailings in mortar production

- Shear and flexural performance of reinforced concrete beams with recycled concrete aggregates

- Advancing GGBS geopolymer concrete with nano-alumina: A study on strength and durability in aggressive environments

- Leveraging waste-based additives and machine learning for sustainable mortar development in construction

- Study on the modification effects and mechanisms of organic–inorganic composite anti-aging agents on asphalt across multiple scales

- Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs

- Structural, physical, and luminescence properties of sodium–aluminum–zinc borophosphate glass embedded with Nd3+ ions for optical applications

- Eco-friendly waste plastic-based mortar incorporating industrial waste powders: Interpretable models for flexural strength

- Bioactive potential of marine Aspergillus niger AMG31: Metabolite profiling and green synthesis of copper/zinc oxide nanocomposites – An insight into biomedical applications

- Preparation of geopolymer cementitious materials by combining industrial waste and municipal dewatering sludge: Stabilization, microscopic analysis and water seepage

- Seismic behavior and shear capacity calculation of a new type of self-centering steel-concrete composite joint

- Sustainable utilization of aluminum waste in geopolymer concrete: Influence of alkaline activation on microstructure and mechanical properties

- Optimization of oil palm boiler ash waste and zinc oxide as antibacterial fabric coating

- Tailoring ZX30 alloy’s microstructural evolution, electrochemical and mechanical behavior via ECAP processing parameters

- Comparative study on the effect of natural and synthetic fibers on the production of sustainable concrete

- Microemulsion synthesis of zinc-containing mesoporous bioactive silicate glass nanoparticles: In vitro bioactivity and drug release studies

- On the interaction of shear bands with nanoparticles in ZrCu-based metallic glass: In situ TEM investigation

- Developing low carbon molybdenum tailing self-consolidating concrete: Workability, shrinkage, strength, and pore structure

- Experimental and computational analyses of eco-friendly concrete using recycled crushed brick

- High-performance WC–Co coatings via HVOF: Mechanical properties of steel surfaces

- Mechanical properties and fatigue analysis of rubber concrete under uniaxial compression modified by a combination of mineral admixture

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part II

- Investigating the effect of locally available volcanic ash on mechanical and microstructure properties of concrete

- Flexural performance evaluation using computational tools for plastic-derived mortar modified with blends of industrial waste powders

- Foamed geopolymers as low carbon materials for fire-resistant and lightweight applications in construction: A review

- Autogenous shrinkage of cementitious composites incorporating red mud

- Special Issue on AI-Driven Advances for Nano-Enhanced Sustainable Construction Materials

- Advanced explainable models for strength evaluation of self-compacting concrete modified with supplementary glass and marble powders

- Analyzing the viability of agro-waste for sustainable concrete: Expression-based formulation and validation of predictive models for strength performance

- Special Issue on Advanced Materials for Energy Storage and Conversion

- Innovative optimization of seashell ash-based lightweight foamed concrete: Enhancing physicomechanical properties through ANN-GA hybrid approach

- Production of novel reinforcing rods of waste polyester, polypropylene, and cotton as alternatives to reinforcement steel rods

Artikel in diesem Heft

- Review Articles

- Utilization of steel slag in concrete: A review on durability and microstructure analysis

- Technical development of modified emulsion asphalt: A review on the preparation, performance, and applications

- Recent developments in ultrasonic welding of similar and dissimilar joints of carbon fiber reinforcement thermoplastics with and without interlayer: A state-of-the-art review

- Unveiling the crucial factors and coating mitigation of solid particle erosion in steam turbine blade failures: A review

- From magnesium oxide, magnesium oxide concrete to magnesium oxide concrete dams

- Properties and potential applications of polymer composites containing secondary fillers

- A scientometric review on the utilization of copper slag as a substitute constituent of ordinary Portland cement concrete

- Advancement of additive manufacturing technology in the development of personalized in vivo and in vitro prosthetic implants

- Recent advance of MOFs in Fenton-like reaction

- A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites

- Non-conventional approaches to producing biochars for environmental and energy applications

- Review of the development and application of aluminum alloys in the nuclear industry

- Advances in the development and characterization of combustible cartridge cases and propellants: Preparation, performance, and future prospects

- Recent trends in rubberized and non-rubberized ultra-high performance geopolymer concrete for sustainable construction: A review

- Cement-based materials for radiative cooling: Potential, material and structural design, and future prospects

- A comprehensive review: The impact of recycling polypropylene fiber on lightweight concrete performance

- A comprehensive review of preheating temperature effects on reclaimed asphalt pavement in the hot center plant recycling

- Exploring the potential applications of semi-flexible pavement: A comprehensive review

- A critical review of alkali-activated metakaolin/blast furnace slag-based cementitious materials: Reaction evolution and mechanism

- Dispersibility of graphene-family materials and their impact on the properties of cement-based materials: Application challenges and prospects

- Research progress on rubidium and cesium separation and extraction

- A step towards sustainable concrete with the utilization of M-sand in concrete production: A review

- Studying the effect of nanofillers in civil applications: A review

- Studies on the anticorrosive effect of phytochemicals on mild steel, carbon steel, and stainless-steel surfaces in acid and alkali medium: A review

- Research Articles

- Investigation of the corrosion performance of HVOF-sprayed WC-CoCr coatings applied on offshore hydraulic equipment

- A systematic review of metakaolin-based alkali-activated and geopolymer concrete: A step toward green concrete

- Evaluation of color matching of three single-shade composites employing simulated 3D printed cavities with different thicknesses using CIELAB and CIEDE2000 color difference formulae

- Novel approaches in prediction of tensile strain capacity of engineered cementitious composites using interpretable approaches

- Effect of TiB2 particles on the compressive, hardness, and water absorption responses of Kulkual fiber-reinforced epoxy composites

- Analyzing the compressive strength, eco-strength, and cost–strength ratio of agro-waste-derived concrete using advanced machine learning methods

- Tensile behavior evaluation of two-stage concrete using an innovative model optimization approach

- Tailoring the mechanical and degradation properties of 3DP PLA/PCL scaffolds for biomedical applications

- Optimizing compressive strength prediction in glass powder-modified concrete: A comprehensive study on silicon dioxide and calcium oxide influence across varied sample dimensions and strength ranges

- Experimental study on solid particle erosion of protective aircraft coatings at different impact angles

- Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters

- Fe-containing nominal wollastonite (CaSiO3)–Na2O glass-ceramic: Characterization and biocompatibility

- Relevance of pore network connectivity in tannin-derived carbons for rapid detection of BTEX traces in indoor air

- A life cycle and environmental impact analysis of sustainable concrete incorporating date palm ash and eggshell powder as supplementary cementitious materials

- Eco-friendly utilisation of agricultural waste: Assessing mixture performance and physical properties of asphalt modified with peanut husk ash using response surface methodology

- Benefits and limitations of N2 addition with Ar as shielding gas on microstructure change and their effect on hardness and corrosion resistance of duplex stainless steel weldments

- Effect of selective laser sintering processing parameters on the mechanical properties of peanut shell powder/polyether sulfone composite

- Impact and mechanism of improving the UV aging resistance performance of modified asphalt binder

- AI-based prediction for the strength, cost, and sustainability of eggshell and date palm ash-blended concrete

- Investigating the sulfonated ZnO–PVA membrane for improved MFC performance

- Strontium coupling with sulphur in mouse bone apatites

- Transforming waste into value: Advancing sustainable construction materials with treated plastic waste and foundry sand in lightweight foamed concrete for a greener future

- Evaluating the use of recycled sawdust in porous foam mortar for improved performance

- Improvement and predictive modeling of the mechanical performance of waste fire clay blended concrete

- Polyvinyl alcohol/alginate/gelatin hydrogel-based CaSiO3 designed for accelerating wound healing

- Research on assembly stress and deformation of thin-walled composite material power cabin fairings

- Effect of volcanic pumice powder on the properties of fiber-reinforced cement mortars in aggressive environments

- Analyzing the compressive performance of lightweight foamcrete and parameter interdependencies using machine intelligence strategies

- Selected materials techniques for evaluation of attributes of sourdough bread with Kombucha SCOBY

- Establishing strength prediction models for low-carbon rubberized cementitious mortar using advanced AI tools

- Investigating the strength performance of 3D printed fiber-reinforced concrete using applicable predictive models

- An eco-friendly synthesis of ZnO nanoparticles with jamun seed extract and their multi-applications

- The application of convolutional neural networks, LF-NMR, and texture for microparticle analysis in assessing the quality of fruit powders: Case study – blackcurrant powders

- Study of feasibility of using copper mining tailings in mortar production

- Shear and flexural performance of reinforced concrete beams with recycled concrete aggregates

- Advancing GGBS geopolymer concrete with nano-alumina: A study on strength and durability in aggressive environments

- Leveraging waste-based additives and machine learning for sustainable mortar development in construction

- Study on the modification effects and mechanisms of organic–inorganic composite anti-aging agents on asphalt across multiple scales

- Morphological and microstructural analysis of sustainable concrete with crumb rubber and SCMs

- Structural, physical, and luminescence properties of sodium–aluminum–zinc borophosphate glass embedded with Nd3+ ions for optical applications

- Eco-friendly waste plastic-based mortar incorporating industrial waste powders: Interpretable models for flexural strength

- Bioactive potential of marine Aspergillus niger AMG31: Metabolite profiling and green synthesis of copper/zinc oxide nanocomposites – An insight into biomedical applications

- Preparation of geopolymer cementitious materials by combining industrial waste and municipal dewatering sludge: Stabilization, microscopic analysis and water seepage

- Seismic behavior and shear capacity calculation of a new type of self-centering steel-concrete composite joint

- Sustainable utilization of aluminum waste in geopolymer concrete: Influence of alkaline activation on microstructure and mechanical properties

- Optimization of oil palm boiler ash waste and zinc oxide as antibacterial fabric coating

- Tailoring ZX30 alloy’s microstructural evolution, electrochemical and mechanical behavior via ECAP processing parameters

- Comparative study on the effect of natural and synthetic fibers on the production of sustainable concrete

- Microemulsion synthesis of zinc-containing mesoporous bioactive silicate glass nanoparticles: In vitro bioactivity and drug release studies

- On the interaction of shear bands with nanoparticles in ZrCu-based metallic glass: In situ TEM investigation

- Developing low carbon molybdenum tailing self-consolidating concrete: Workability, shrinkage, strength, and pore structure

- Experimental and computational analyses of eco-friendly concrete using recycled crushed brick

- High-performance WC–Co coatings via HVOF: Mechanical properties of steel surfaces

- Mechanical properties and fatigue analysis of rubber concrete under uniaxial compression modified by a combination of mineral admixture

- Special Issue on Recent Advancement in Low-carbon Cement-based Materials - Part II

- Investigating the effect of locally available volcanic ash on mechanical and microstructure properties of concrete

- Flexural performance evaluation using computational tools for plastic-derived mortar modified with blends of industrial waste powders

- Foamed geopolymers as low carbon materials for fire-resistant and lightweight applications in construction: A review

- Autogenous shrinkage of cementitious composites incorporating red mud

- Special Issue on AI-Driven Advances for Nano-Enhanced Sustainable Construction Materials

- Advanced explainable models for strength evaluation of self-compacting concrete modified with supplementary glass and marble powders

- Analyzing the viability of agro-waste for sustainable concrete: Expression-based formulation and validation of predictive models for strength performance

- Special Issue on Advanced Materials for Energy Storage and Conversion

- Innovative optimization of seashell ash-based lightweight foamed concrete: Enhancing physicomechanical properties through ANN-GA hybrid approach

- Production of novel reinforcing rods of waste polyester, polypropylene, and cotton as alternatives to reinforcement steel rods