Abstract

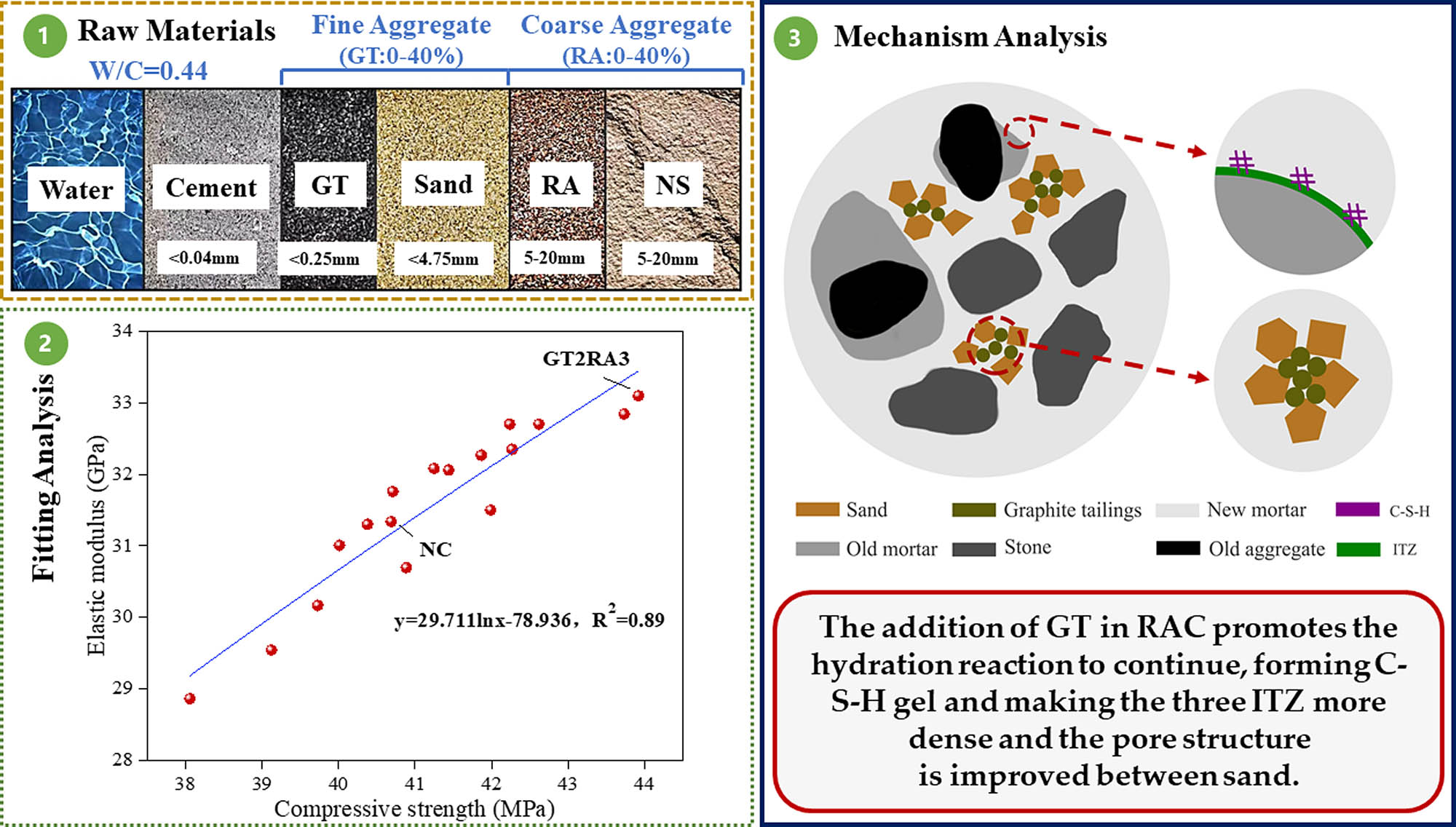

How to more effectively and comprehensively utilize recycled aggregate resources to prepare a richer new low-carbon concrete material system is the key path to achieve low-carbon development in China’s construction field. Based on the material properties of graphite tailings (GT), this article explores the organic combination of GT to replace sand and recycled aggregates (RA) to replace natural stones, in order to propose an efficient recycling path for multiple solid wastes and a new and cost-effective recycled aggregate concrete (RAC). This article focuses on investigating the influences of GT (0–40%) and RA (0–40%) on the workability, water absorption, and mechanical properties of GT reinforced recycled aggregate concrete (GTRAC). Simultaneously, the hydration products, microstructure morphology, key chemical bonds, and pore structure characteristics were analyzed by a combination of microscopic tests such as X-ray diffraction, scanning electron microscope, Fourier transform infrared and mercury intrusion porosimetry to propose the key factors affecting the macroscopic performance of GTRAC. The results show that incorporating 10–30% GT has significant positive effects on water absorption, surface water content, compressive strength, and elastic modulus of RAC. RAC’s micro-crack density, hydration, and pore structure distribution can be maximally improved by appropriate GT (20%). However, the high content of GT will lead to the degradation of its mechanical properties. Therefore, 20% GT and 30% recycled aggregate are the optimum combinations of the concrete material system. However, it might be changed when the ratio of water to binder varies. Finally, this article also comprehensively analyzes and evaluates the performance and price of different types of RACs, which provides theoretical support for evaluating and predicting the practical engineering application value of GTRAC. In summary, the research results in this study provide theoretical guidance for understanding the mechanism of GT on the enhancement of mechanical properties of RAC and exploring new ways of practical engineering application of it.

1 Introduction

With the development of industrialization and construction industry, the demand for concrete is extremely large. At present, the mining and consumption of natural aggregate materials are relatively large, intensifying the shortage of natural aggregate resources and the difficulty of sustainable development. According to the current estimate, the global demand for construction aggregates is more than 20 billion tons per annum [1]. At the same time, with the rapid development of urbanization in China, 1.5 billion tons of construction and demolition waste are generated every year [2], and the primary disposal method is landfill [3]. Academics believes that an effective way to address the shortage of natural aggregates and waste concrete stockpiles is to recycle concrete demolition waste as recycled aggregate (RA), partially or fully replacing natural aggregates for recycled aggregate concrete (RAC). It has also proven to provide significant environmental and economic benefits [4]. Although the reuse of RA to manufacture RAC has aroused more and more research interest in academia and has been extensively studied, due to the poor quality of RA compared with natural aggregates, the widespread use of RAC in construction projects is limited as before.

Compared to conventional natural aggregate concrete, RAC has been extensively researched for many properties, including compressive strength [5] and modulus of elasticity [6]. The replacement ratio between the weight of RA and the total weight of coarse aggregate in a concrete mix deems a vital influence on RAC properties [7]. In general, concrete made from RA configurations has a lower compressive strength and modulus of elasticity than conventional concrete. Compared to conventional concrete, the presence of new and old mortar causes the complexity of the interface transition zone (ITZ) of RAC [8], and its strength and compactness become one of the most critical factors affecting the structural and mechanical properties of concrete. Based on the nanoindentation technique, Xiao et al. [9] and Lee and Choi [10] found that the average indentation modulus of old ITZ was 70–80% of that of old paste matrix, while the average indentation modulus of new ITZ was 80–90% of that of new paste matrix. The more numerous and weaker ITZs lead to the poor performance of the RAC. Meanwhile, Xiao et al. [9] also found obvious voids and Ca(OH)2 (CH) exist in both old and new ITZs in RAC. It is found that the existence of coarse CH crystals has a certain negative effect on the strength of the ITZ. On the one hand, because of its layered overlapping arrangement, its specific surface area is reduced, and thus, the cohesive force is also reduced accordingly; on the other hand, the directional arrangement of CH makes it more prone to cracking [11]. Thus, researchers are studying how to improve the compressive strength of RAC by incorporating other materials. Existing studies have found that the addition of fly ash and silica fume can mitigate the adverse effects of RAs on the compressive strength of concrete. Kou et al. [12] found that 25% fly ash incorporation could maximize the compressive strength of recycled concrete by 17.43%. Abid et al. [13] have demonstrated that the use of silica fume can increase the compressive strength of RAC from 22.5 to 28 MPa, an increase of 24.4%. The spherical morphology of fly ash limits the amount of substitution, and silica fume’s weak volcanic ash activity limits its early strength. Meanwhile, nano-silica [14] and iron tailing sand [15] have been incorporated, but the cost of nano-silica and the low strength of iron tailing sand recycled concrete limit their widespread use.

At the same time, in 2020, China’s development strategy is of achieving “carbon peaking” by 2030 and “carbon neutral” by 2060. It puts forward higher and updated standards and requirements for the green treatment and comprehensive utilization of tailings solid waste in mining enterprises. With the rapid growth of graphite resource consumption, the basic reserves of graphite deposits in China have accounted for 43% of the world’s total. Graphite tailings (GT) is solid wastes produced in large quantities in the process of graphite mining [16], but it is also a resource to be developed. Statistics in recent years have found that the global graphite mine production was approximately 0.21 billion tons [16]. However, mining a 1-ton graphite mine produces 10–15 tons of GT. The large-scale storage of GT takes up a lot of land, pollutes the surrounding environment, and brings serious safety hazards [17]. Furthermore, the scarcity of river sand in the construction industry has become increasingly pronounced in recent years due to the prohibition of river sand exploitation for natural resource-saving and environmental protection [18]. Because the composition of GT is similar to that of river sand, it is possible to use GT as cement materials instead of river sand. The research and development of GT can reduce environmental pollution and effectively recycle resources. At the same time, it can also solve the shortage of building materials and bring significant economic benefits. Liu et al. [19] and Kathirvel et al. [20] found that GT concrete has good advantages in strength improvement, price, recovery process, etc. They used GT instead of river sand to prepare a new type of concrete and analyzed the material’s mechanical properties, durability, and electrical conductivity. The results show that the maximum compressive strength of concrete is 10% GT instead of sand, and the strength improved by 14.9%. Kathirvel et al. [21] and Peng et al. [22] studied the mechanical characteristics and electrochemical properties of GT-reinforced concrete and mortar with different incorporation amounts. The application of GT shows the feasibility of reusing waste as construction materials, and it also provides a reference to the possibilities for mixing GT into (RA) concrete.

However, research on the modification of RAC by tailings, particularly GT replacement sand, is at a nascent stage. At present, it is necessary to conduct systematic and in-depth research on its material system to support the actual effects of future engineering applications and the realization of double carbon emission reduction. This article uses GT with different dosages to replace sand, and RA was used to replace natural stone (single and mixed method) to prepare graphite tailings recycled coarse aggregate concrete (GTRAC). The compressive strength and elasticity modulus of GTRAC is investigated. The modification mechanism of GT on the mechanical strength of RAC was explained preliminarily through material science experiments such as mesoscopic morphology, compound component, and pore structure distribution. Finally, the optimal substitution rate of GT and RA in concrete was determined to improve the utilization rate of GT and RA and realize the utilization of solid waste.

2 Materials and experimental methods

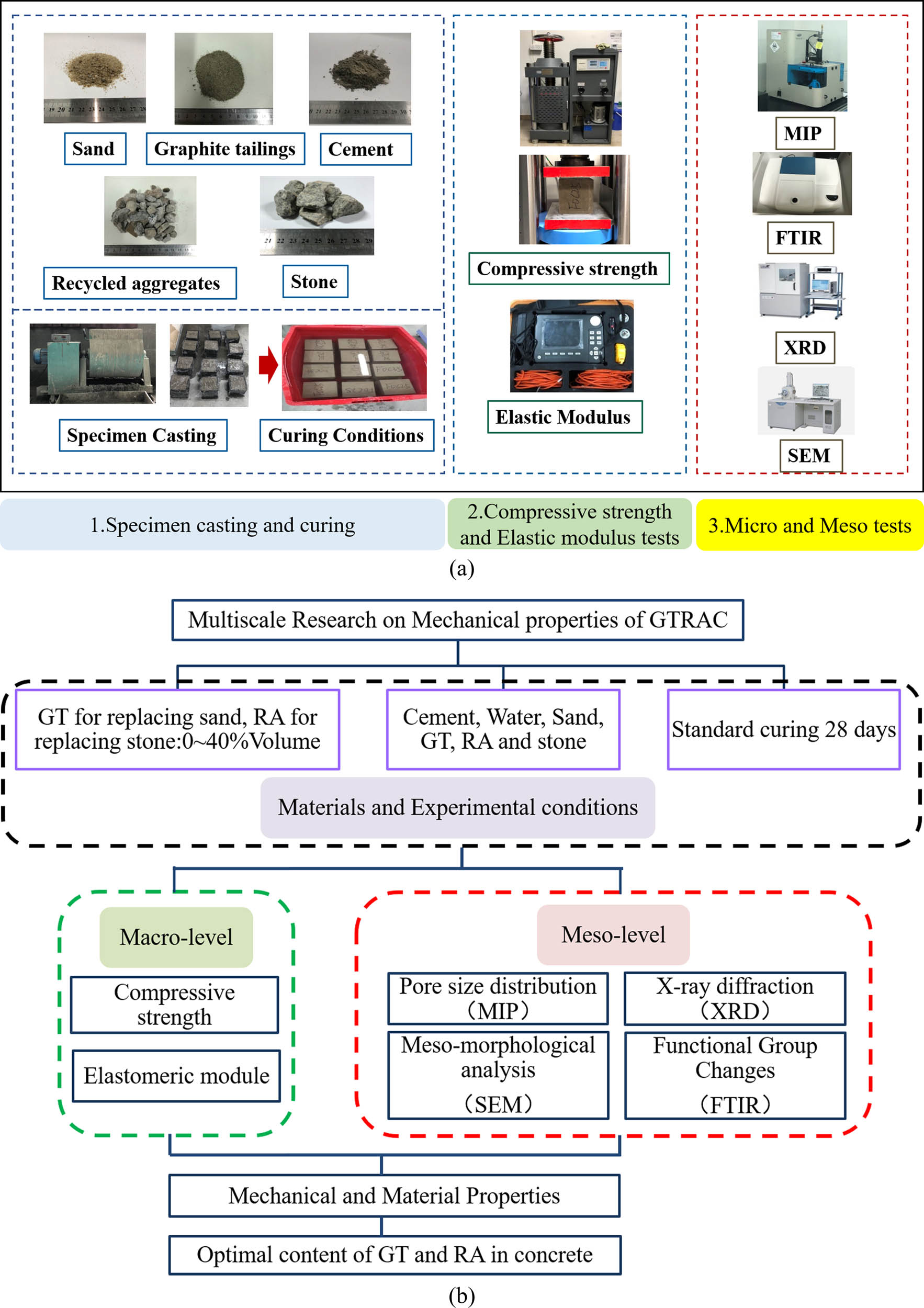

The experimental research flowchart of this article is shown in Figure 1. The practical details are as follows.

(a) Experimental flowchart; (b) research flowchart.

2.1 Materials

2.1.1 Raw materials and mixing proportions

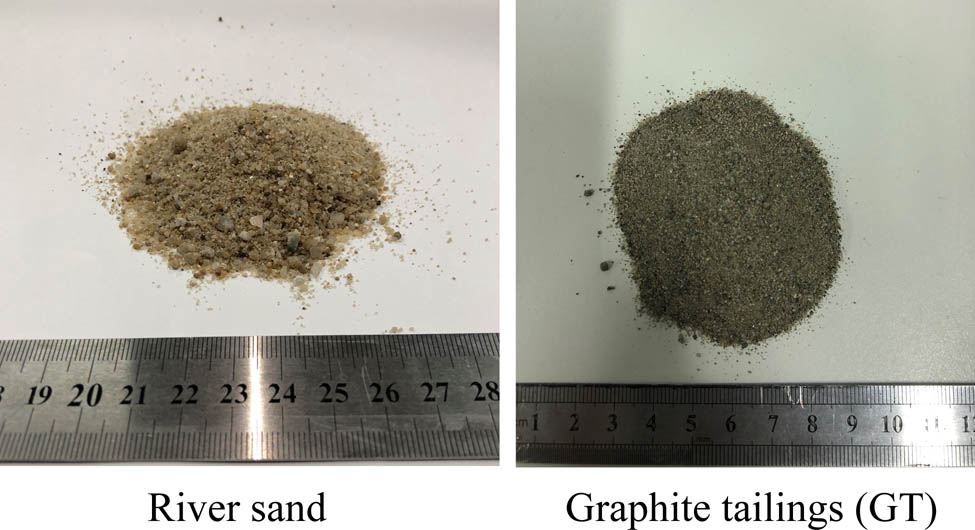

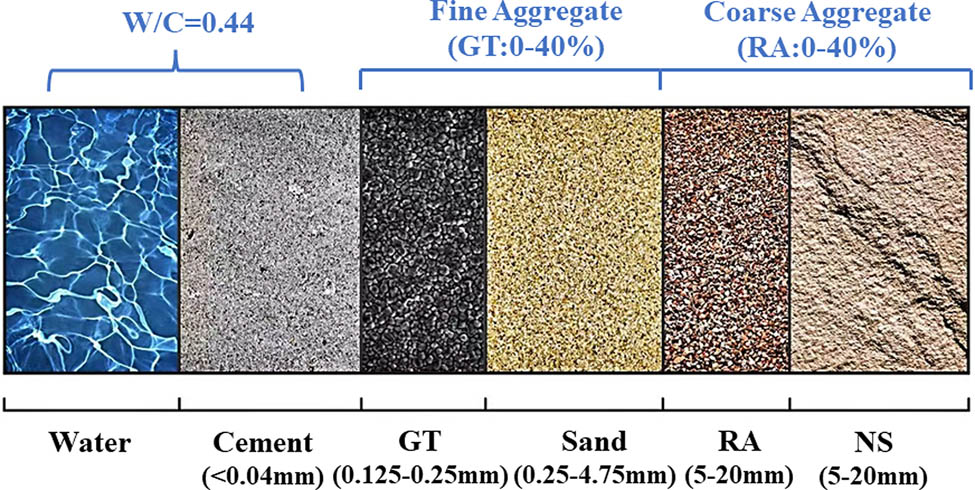

Ordinary Portland cement (P.O 42.5), local river sand (fineness modulus of 2.65), GT (fineness modulus of 0.9), and groundwater were used in the experiments. The mechanical properties and chemical composition of cement are shown in Tables 1 and 2. The apparent comparison of GT and river sand is shown in Figure 2. The physical properties and chemical composition of GT and river sand are shown in Tables 2 and 3. The apparent comparison and physical properties of natural stone (NS) and RA are shown in Figure 3 and Table 4. Depending on the size of the coarse and fine aggregates, the substitution methods of GT and RA are shown in Figure 4.

Mechanical properties of Portland cement (MPa)

| Flexural strength (MPa) | Compressive strength (MPa) | Fineness | Setting time (min) | |||

|---|---|---|---|---|---|---|

| 3 days | 28 days | 3 days | 28 days | Initial setting | Final setting | |

| 4.1 | 9.3 | 21.2 | 46.1 | 1.2 | 164 | 272 |

Chemical properties of Portland cement, sand, and graphite tailings (%)

| Materials | Chemical compositions | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cement | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | Loss | ||

| 59.64 | 21.47 | 5.80 | 4.04 | 1.40 | 2.98 | 4.67 | |||

| GT | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | K2O | TiO2 | Loss |

| 15.55 | 62.50 | 10.21 | 5.07 | 2.33 | 0.54 | 2.26 | 0.59 | 0.95 | |

| Sand | SiO2 | Loss | |||||||

| 99.80 | 0.20 | ||||||||

The apparent comparison of GT and sand.

Physical properties of fine aggregate

| Fine aggregate | Type | Apparent density (kg·m−3) | Bulk density (kg·m−3) | Fineness modulus | 24 h water absorption (%) |

|---|---|---|---|---|---|

| GT | Fine sand | 2,855 | 1,540 | 0.90 | 30.1 |

| Sand | Medium sand | 2,460 | 1,630 | 2.65 | 21.9 |

The apparent comparison of natural stone and RA.

Physical properties of coarse aggregate

| Coarse aggregate | Size (mm) | Apparent density (kg·m−3) | 24 h water absorption (%) | Crush indicators (%) |

|---|---|---|---|---|

| NS | 5–20 | 2,550 | 1.21 | 14 |

| RA | 5–20 | 2,360 | 8.02 | 27.6 |

The substitution methods for RA and GT.

In this article, according to Chinese standards JGJ55-2011 [23], the water–cement ratio of the concrete specimens used in the design experiment is 0.44, and the standard strength value is C30. Presoaking of the RA for 24 h to ensure that the high-water absorption of the RA itself does not have an impact on the slump. Afterward, the amount of water-reducing agent is 1.0% of the cementitious material, and after trial formulation, it meets the requirements for the slump. Scholars have made subsequent studies on selecting the optimal replacement rate of GT and RA. Thomas et al. [24] and De Brito et al. [25] pointed out that the replacement rate of RA does not exceed 25% and will not significantly change the compressive strength of concrete. Poon et al. [26] suggested that containing not more than 50% RA is optimum for producing normal strength RAC. Wang et al. [16] and Kathirvel et al. [20] found that 10–20% GT could significantly improve the compressive strength of conventional concrete. Therefore, in this article, the volume replacement rate of RA is 0–40% of natural coarse aggregate. The volume replacement rate of GT is 0–40% of river sand to ensure that GTRAC has favorable performance. The mixing proportion of concrete specimens is shown in Table 5.

Mix proportion design of RA concrete from graphite tailings

| W/C = 0.44 | Mix proportion design of concrete (kg·m−3) | Replacement rate of GT (%) | Replacement rate of RA (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Water | Cement | Sand | GT | NS | RA | Water reducing agent | |||

| NC | 2.19 | 4.97 | 6.51 | 0.00 | 15.18 | 0.00 | 0.0497 | 0 | 0 |

| GT1RA0 | 2.19 | 4.97 | 5.86 | 0.65 | 15.18 | 0.00 | 0.0497 | 10 | 0 |

| GT2RA0 | 2.19 | 4.97 | 5.20 | 1.30 | 15.18 | 0.00 | 0.0497 | 20 | 0 |

| GT3RA0 | 2.19 | 4.97 | 4.55 | 1.95 | 15.18 | 0.00 | 0.0497 | 30 | 0 |

| GT4RA0 | 2.19 | 4.97 | 3.90 | 2.32 | 15.18 | 0.00 | 0.0497 | 40 | 0 |

| GT0RA1 | 2.19 | 4.97 | 6.51 | 0.00 | 13.66 | 1.52 | 0.0497 | 0 | 10 |

| GT1RA1 | 2.19 | 4.97 | 5.86 | 0.65 | 13.66 | 1.52 | 0.0497 | 10 | 10 |

| GT2RA1 | 2.19 | 4.97 | 5.20 | 1.30 | 13.66 | 1.52 | 0.0497 | 20 | 10 |

| GT3RA1 | 2.19 | 4.97 | 4.55 | 1.95 | 13.66 | 1.52 | 0.0497 | 30 | 10 |

| GT4RA1 | 2.19 | 4.97 | 3.90 | 2.32 | 13.66 | 1.52 | 0.0497 | 40 | 10 |

| GT0RA2 | 2.19 | 4.97 | 6.51 | 0.00 | 12.14 | 3.04 | 0.0497 | 0 | 20 |

| GT1RA2 | 2.19 | 4.97 | 5.86 | 0.65 | 12.14 | 3.04 | 0.0497 | 10 | 20 |

| GT2RA2 | 2.19 | 4.97 | 5.20 | 1.30 | 12.14 | 3.04 | 0.0497 | 20 | 20 |

| GT3RA2 | 2.19 | 4.97 | 4.55 | 1.95 | 12.14 | 3.04 | 0.0497 | 30 | 20 |

| GT4RA2 | 2.19 | 4.97 | 3.90 | 2.32 | 12.14 | 3.04 | 0.0497 | 40 | 20 |

| GT0RA3 | 2.19 | 4.97 | 6.51 | 0.00 | 10.63 | 4.55 | 0.0497 | 0 | 30 |

| GT1RA3 | 2.19 | 4.97 | 5.86 | 0.65 | 10.63 | 4.55 | 0.0497 | 10 | 30 |

| GT2RA3 | 2.19 | 4.97 | 5.20 | 1.30 | 10.63 | 4.55 | 0.0497 | 20 | 30 |

| GT3RA3 | 2.19 | 4.97 | 4.55 | 1.95 | 10.63 | 4.55 | 0.0497 | 30 | 30 |

| GT4RA3 | 2.19 | 4.97 | 3.90 | 2.32 | 10.63 | 4.55 | 0.0497 | 40 | 30 |

| GT0RA4 | 2.19 | 4.97 | 6.51 | 0.00 | 9.11 | 6.07 | 0.0497 | 0 | 40 |

| GT1RA4 | 2.19 | 4.97 | 5.86 | 0.65 | 9.11 | 6.07 | 0.0497 | 10 | 40 |

| GT2RA4 | 2.19 | 4.97 | 5.20 | 1.30 | 9.11 | 6.07 | 0.0497 | 20 | 40 |

| GT3RA4 | 2.19 | 4.97 | 4.55 | 1.95 | 9.11 | 6.07 | 0.0497 | 30 | 40 |

| GT4RA4 | 2.19 | 4.97 | 3.90 | 2.32 | 9.11 | 6.07 | 0.0497 | 40 | 40 |

Notes: NC is the natural aggregate concrete as standard group. GT is the graphite tailings used to replace river sand and RA is used to replace natural aggregate. GT1RA1 is the graphite tailing – RA concrete in which 10% GT + 10% RA.

2.1.2 Specimen casting and curing conditions

The specimens were prepared regarding Chinese standards GB/T 50081-2002 [27] and JGJ/T70-2009 [28]. First, the coarse and fine aggregates were evenly stirred for 30 s. Then, the mixed liquid of water and water reducing agent is added and continued stirring for 2 min. Finally, it is poured into the preprepared molds and vibrated. The concrete specimens with dimensions of 100 mm × 100 mm × 100 mm (75 pieces), 150 mm × 150 mm × 150 mm (75 pieces) and 150 mm × 150 mm × 300 mm (75 pieces) were used to determine the water absorption characteristics, compressive strength, and elastic modulus performance at 28-day curing time, respectively. All experimental specimens were placed in the curing room with a temperature of 20 ± 2°C and relative humidity of 95% for curing for 28 days.

2.2 Experimental methods

After all the test pieces reach the 28-day curing age, the excess water on the surface of the test pieces was wiped off. It was placed at room temperature for 24 h, and the mechanical properties were tested after waiting for it to dry naturally.

2.2.1 Macro performance testing

2.2.1.1 Workability properties test

The slump bucket is used to measure the slump height of fresh concrete under specified conditions, and the workability is measured by slump according to the Chinese standard GB/T50080-2016 [29].

2.2.1.2 Water absorption and surface moisture content

According to the Chinese standard JGJ/T70-2009 [28], the GTRAC specimens are dried at 105 ± 5°C for 48 ± 0.5 h and weighed to obtain the mass m 0. The sample is immersed completely in water for 48 ± 0.5 h and removed; the free water on the surface of the specimens is wiped off with a rag to measure the mass m 1. The arithmetic average of the measured values of the three specimens is used as the water absorption of the concrete and is accurate to 1%. The water absorption of concrete is calculated using equation (1):

where W x is the water absorption of concrete (%), m 1 is the mass of a specimen after water absorption (g), and m 0 is the mass of a dried specimen (g).

In addition, the surface moisture content of GTRAC was measured in this article. GTRAC specimens were taken out of the curing room, and the surface was wiped dry. Subsequently, the PW-2 multifunctional surface material moisture meter is used to measure the moisture content of the three surfaces of each sample under the condition of ensuring that the test block test environment is similar, and the average value of the test is the measured value of the surface moisture content.

2.2.1.3 Mechanical properties test

This article tests and determines the compressive strength and elastic modulus according to GB/T 50081-2002 [27]. The compressive strength is tested on the RFP-03 intelligent force tester. The elastic modulus is tested on an electrohydraulic servo universal compression testing machine. The specific operation steps of the elastic modulus are as follows:

The micrometer was first fixed to the micro-deformation measuring frame at a distance of 150 mm and then placed on the testing machine for loading. At a reference stress of 0.5 MPa, the load is applied to the initial load value F 0 held for 60 s and the deformation ε 0 is recorded. Immediately, the load is applied continuously and uniformly for 60 s at one-third of the axial compressive strength to the load value F a , and the deformation ε a is recorded. Finally, the load is unloaded in the same manner as the loading rate. The value of the modulus of elasticity shall be calculated using equations (2) and (3):

where E c is the modulus of elasticity of concrete in static compression (MPa); F a is the load at a stress of one-third axial compressive strength (N); F 0 is the initial load at a stress of 0.5 MPa (N); A is the compressive area of the specimen (mm2); L is the measurement distance (mm); Δn is the average value of the deformation on both sides of the specimen at the last loading from F 0 to F a (mm); ε a is the average value of the deformation on both sides of the specimen at F a (mm); ε 0 is the average value of the deformation on both sides of the specimen at F 0 (mm).

The values for compressive strength and modulus of elasticity are the arithmetic mean of each set of three specimens.

2.2.2 Materials characterization tests

Several material experiments are conducted to further explore the effect of the GT and RA on the mechanical performance of concrete. Samples are subjected to mercury intrusion porosimetry (MIP), scanning electron microscopy (SEM), X-ray diffraction (XRD), and Fourier-transform infrared spectroscopy (FTIR) to analyze the changes in the pore structure distribution, mesomorphology, hydration products, and chemical bonding or molecules in the concrete specimens. The preparation and drying conditions of these samples are in accordance with Chinese regulations GB/T 21650-2011 [30], GB/T 16594-2008 [31], GB/T 30904-2014 [32], and ISO 19618-2017 [33].

3 Results and discussion

3.1 Macro-properties of GTRAC

3.1.1 Water phase change and workability of GTRAC

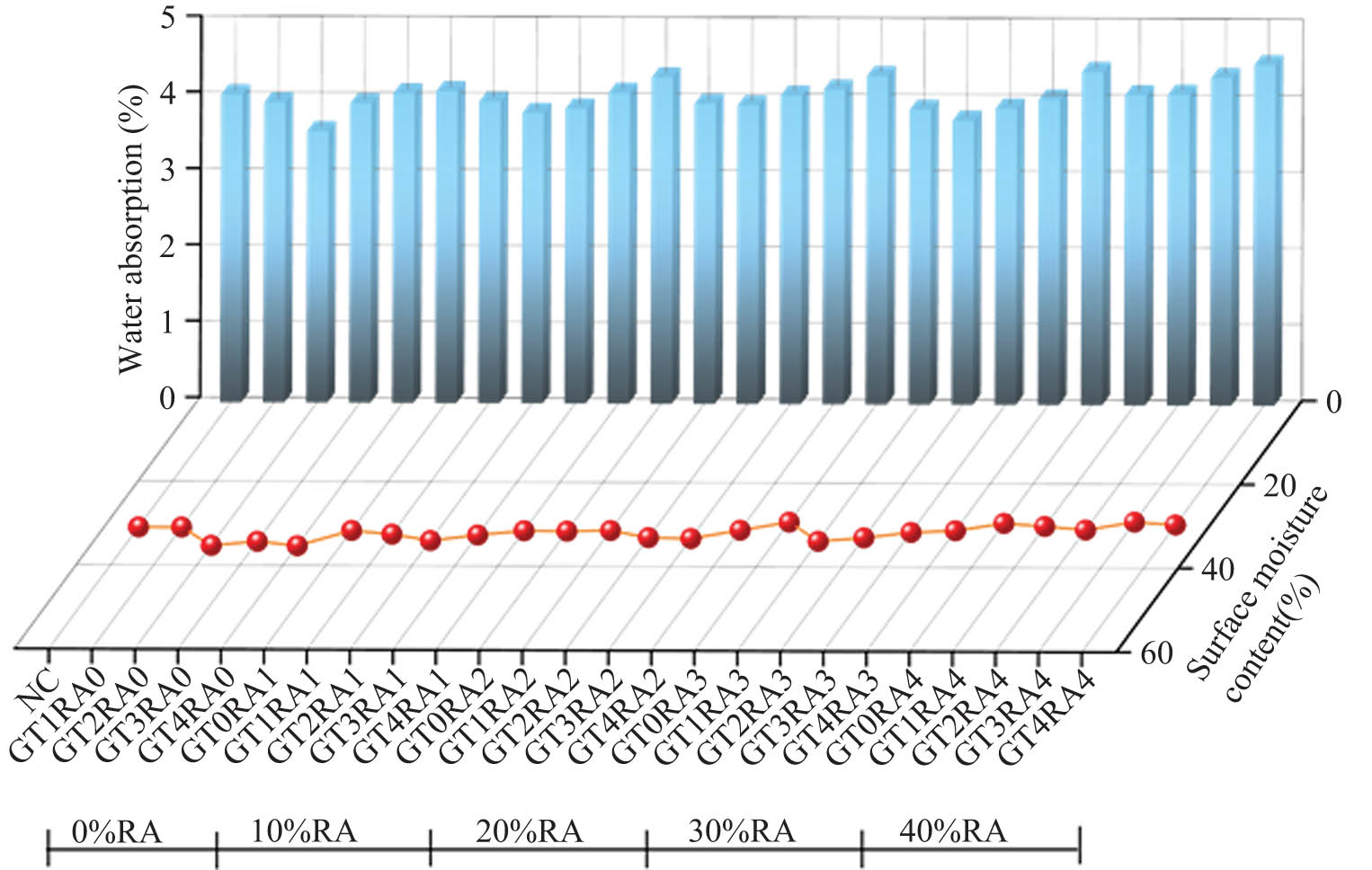

The water absorption and surface water content of cement-based materials such as concrete or cement mortar are closely related to hydration degree. They are one of the most significant influencing factors of concrete’s mechanical and durability performance. In this study, the water absorption and surface water content of GTRAC are shown in Figure 5. Due to RA’s water absorption characteristics, the water absorption rate of RAC is often larger than that of ordinary concrete. Studies have shown that RAC with a water absorption rate of less than 50% replacement rate has better performance when the water absorption rate is between 1.5 and 4.5% [34,35]. The water absorption rate of GTRAC is all within this range. GT has an inhibitory effect on the water absorption of GTRAC [20]. A certain amount of GT can reduce the water absorption of GTRAC by a maximum of 3.67%. In addition, a certain amount of GT can increase the surface water content of GTRAC (3.68% at greatest). Because GT contains higher active minerals than natural sand, it promotes the interface bonding between the aggregates in the concrete so that the old mortar attached to the surface of the RA and the mortar of the newly mixed concrete are better combined. A certain amount of GT class improves the compactness of the overall structure of concrete and reduces the water absorption rate. The internal moisture content affects the change of the surface moisture content. On the one hand, the denser the surface and the whole of the concrete (the lower the internal moisture content), the more difficult it is for water molecules to pass through the connected pores under the action of osmotic pressure and capillary surface tension. Most of the water molecules stay on and near the surface of the concrete test block causing an increase in surface water content. In addition, the more fully hydrated the concrete, the more the hydration products (decrease in internal moisture content), the increase in internal water demand, which promotes the diffusion of water molecules to the surface of the concrete through connected pores, increasing surface water content.

Surface moisture content and water absorption of GTRAC (GT1RA1 is the graphite tailing – RA concrete in which 10% GT + 10% RA).

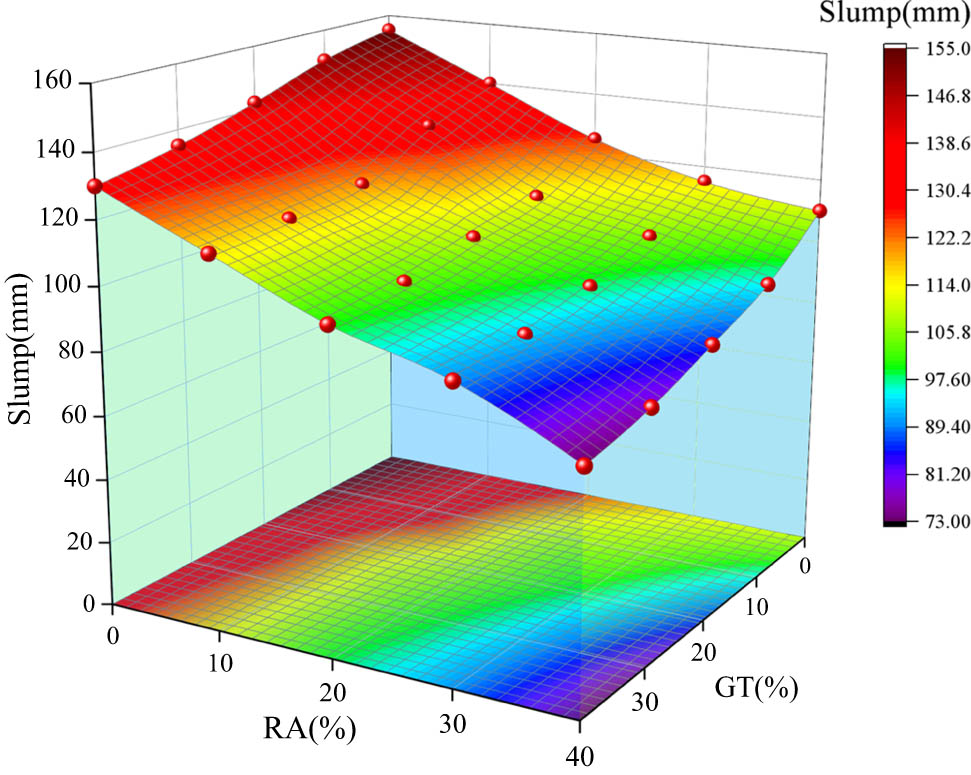

However, GT’s changes in GTRAC’s compactness have certain limitations, whether based on filling efficiency or promoting the hydration process. Due to the property limitation of GT’s own active tailings material, its high-water absorption determines the increase in internal water content and the decrease in surface water content (30–40% replacement rate) after excessive mixing. At the same time, under the dual influence of GT and RA on the water phase, the workability performance of GTRAC also shows a specific correlation change law as shown in Figure 6. The results show that, because of the small particle size and large specific surface area of GT, it needs to absorb a large amount of water to wet the surface. Therefore, the initial slump of fresh concrete mixed with GT and RA gradually decreases.

Initial slump of GTRAC.

3.1.2 Compressive strength performance of GTRAC

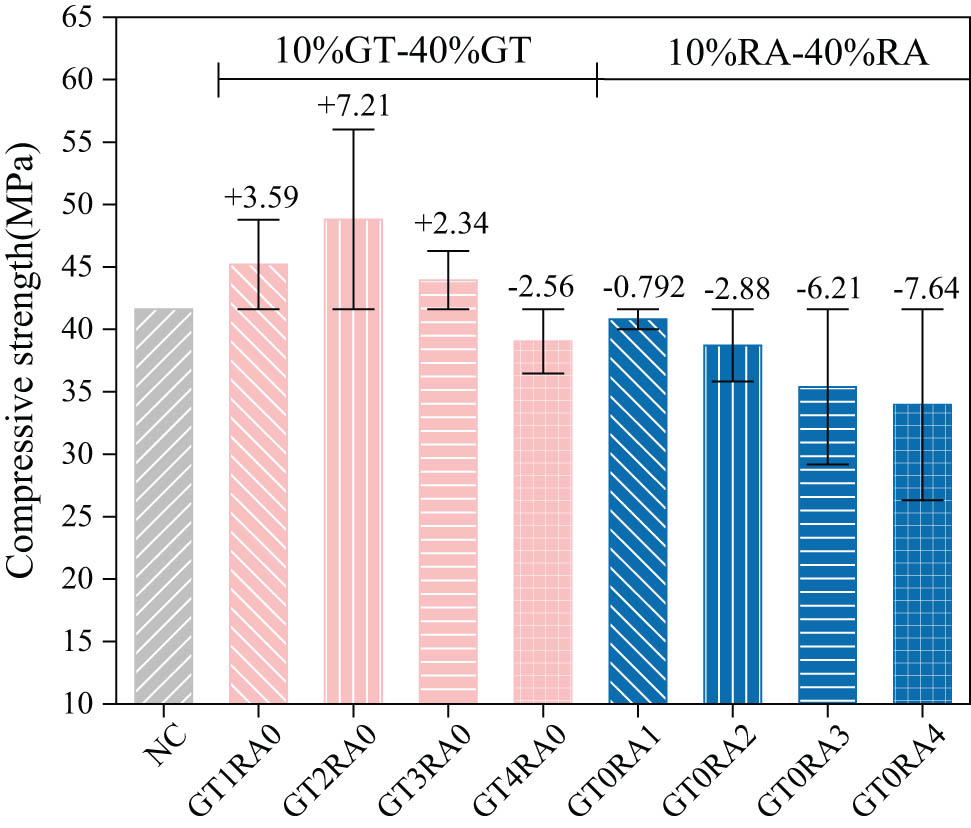

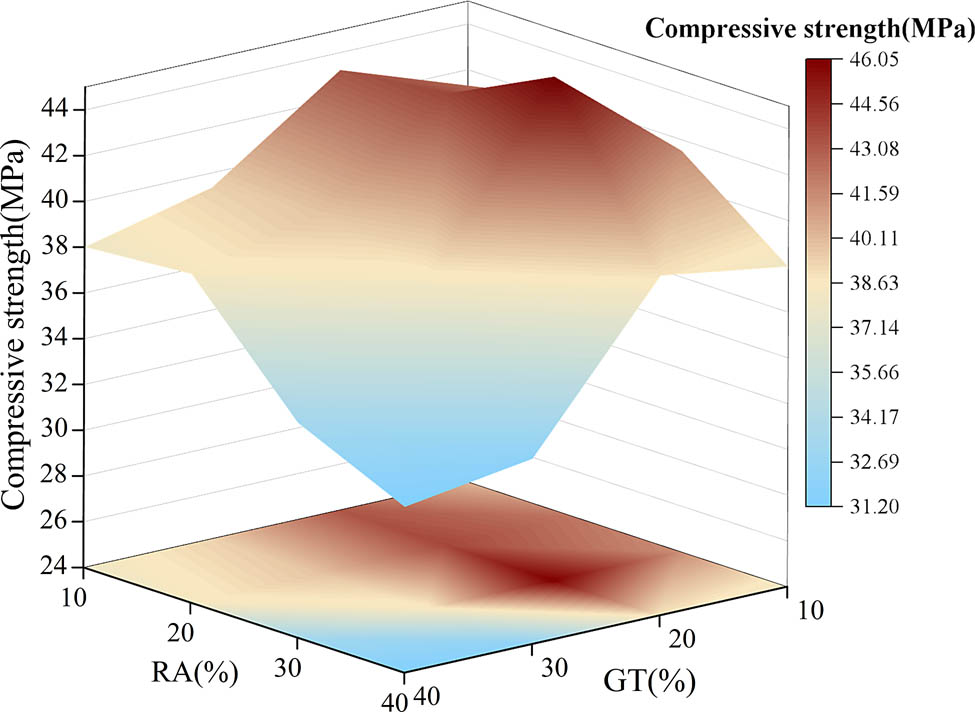

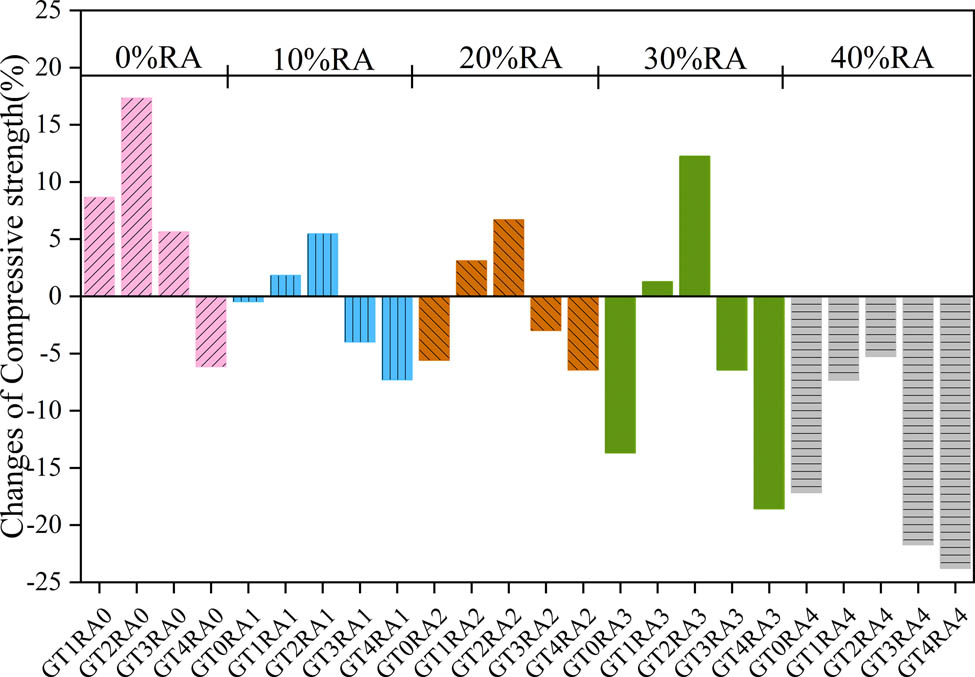

The mechanical properties of concrete are related to cement strength, water–cement ratio, and other factors. In order to investigate the effect of different admixtures of GT and RA on the mechanical properties of concrete, the method of varying the amount of water-reducing agent added was used to make fresh concrete achieving the same slump level (about 150 mm). The effect of GT and RA on concrete’s compressive strength is illustrated in Figures 7–9. As shown in the figures, for the concrete material system mixed with GT or RA alone, the compressive strength first increases and decreases with the rise of the amount of GT and decreases significantly with the increase of RA. GT alone can increase the compressive strength by up to 17.45%, due to the fine grain size of the GT improving the internal structure and thus the compressive strength, which is consistent with the conclusions obtained by Wang et al. [16] and Lee et al. [20]. At the same time, the presence of initial cracks in the RA [9] reduces the compressive strength by up to 17.17%. It is worth mentioning that, under the influence of GT and RA, the compressive strength properties of GTRAC have been improved to a certain extent. When the same amount of RA is incorporated, the compressive strength improves as the GT replacement rate increases (not more than 30%) significantly. When the GT content is 20% and the RA content is 30%, the compressive strength of GTRAC is at the maximum rate of improvement of 12.24%. However, the significant factor that changes the compressive strength of GTRAC continues to be the rate of RA substitution. When the RA replacement rate is 40%, GT does not have any gain effect on improving GTRAC compressive strength performance and even has a negative effect.

Compressive strength of concrete from GT and RA.

Compressive strength of GTRAC.

Changes in compressive strength of GTRAC.

This is due to the characteristics of the properties of GT and RA raw materials leading to different effects on changes in compressive strength. When the replacement rate of GT and RA does not exceed 30%, due to the small aggregate fineness of GT, the concrete can be evenly wrapped during the concrete forming process, which has the effect of filling and repairing micro-cracks or micro-defects [17], thereby improving GTRAC Strength of. However, due to the influence of water absorption, GT and RA’s replacement rate exceeds 30%, and GT and RA jointly absorb the free water that participates in the curing reaction of cement-based materials, resulting in a decrease in the compressive strength of GTRAC.

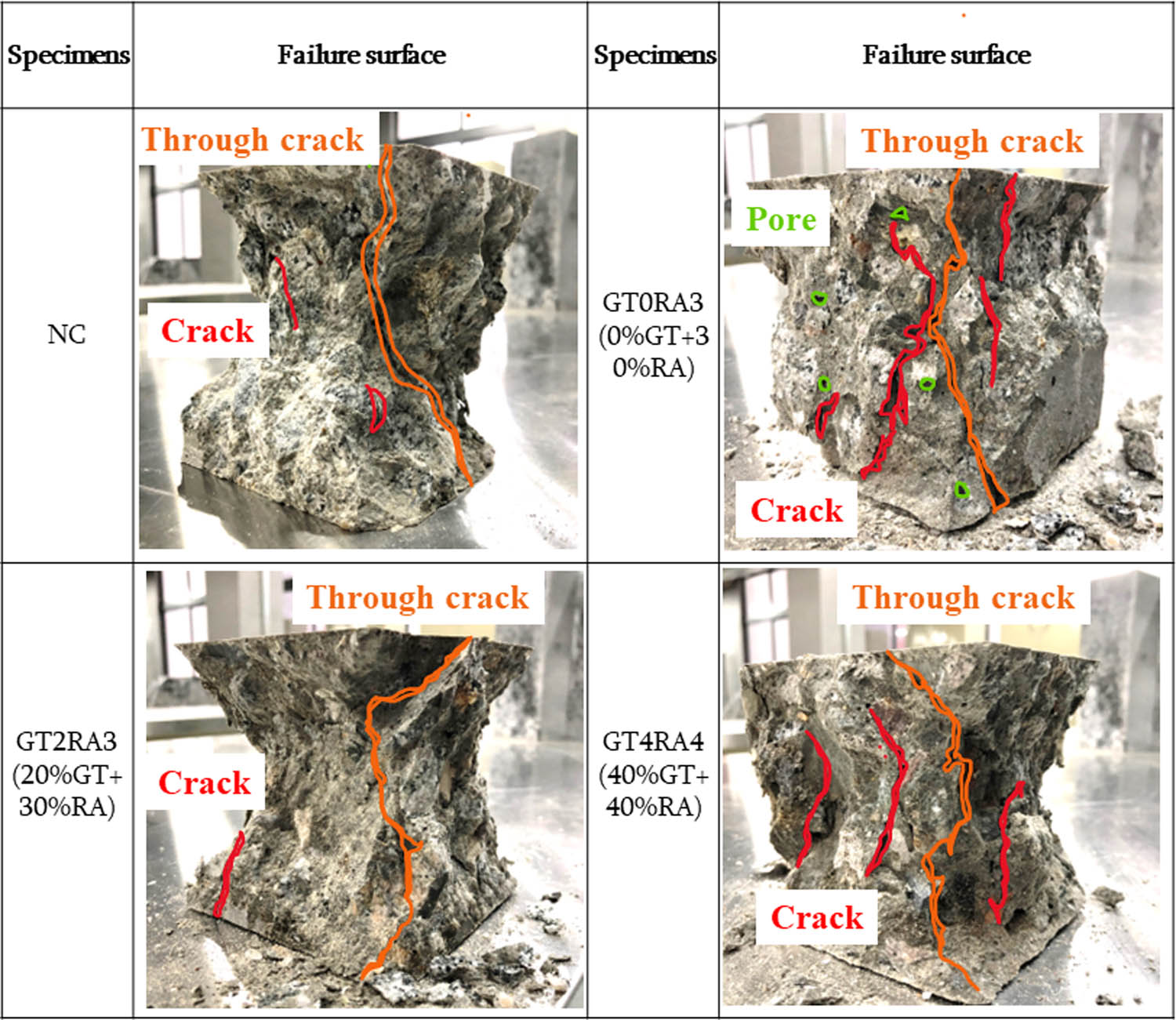

In addition, the above-mentioned related conclusions can also be obtained from the elevation view of the compression failure form of the experiment (shown in Figure 10); 20% GT is introduced to improve the stability of aggregates and the bonding ability between aggregates in GTRAC. However, as the replacement rate of GT and RA continued to increase, the binding capacity between aggregate aggregates decreased significantly, and a more significant proportion of side peeling occurred. It is because RA produced more internal micro-cracks during the crushing process of abandoned buildings [5,7]. In the loading process, the development speed of internal cracks in RA is more significant than that between cement-based interfaces. The fragmentation of concrete is the most unfavorable mode caused by aggregate damage.

Failure surface of GTRAC.

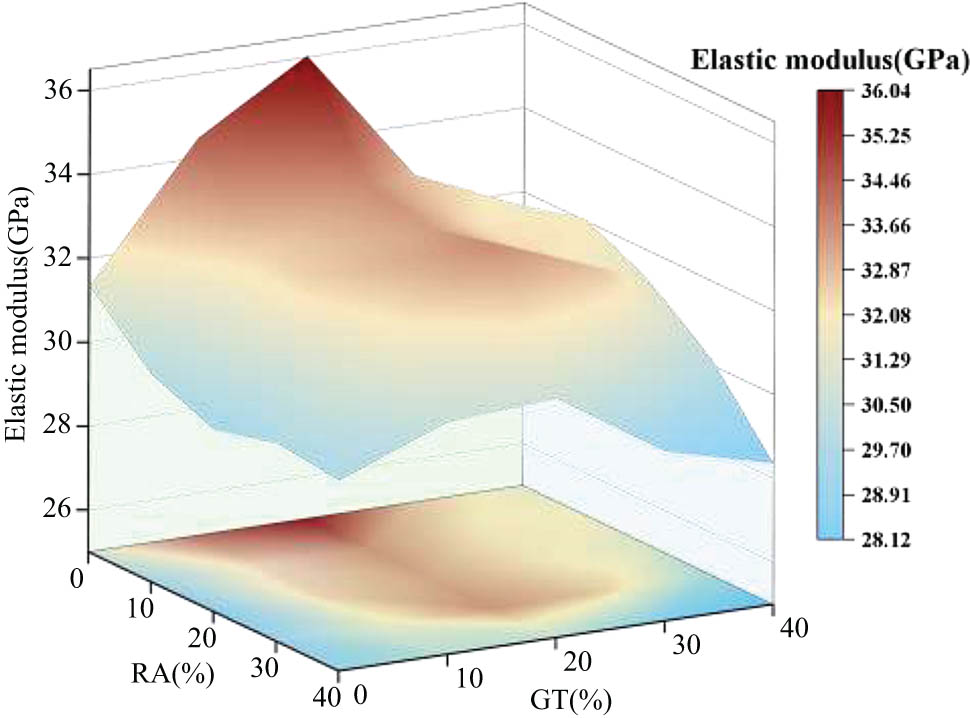

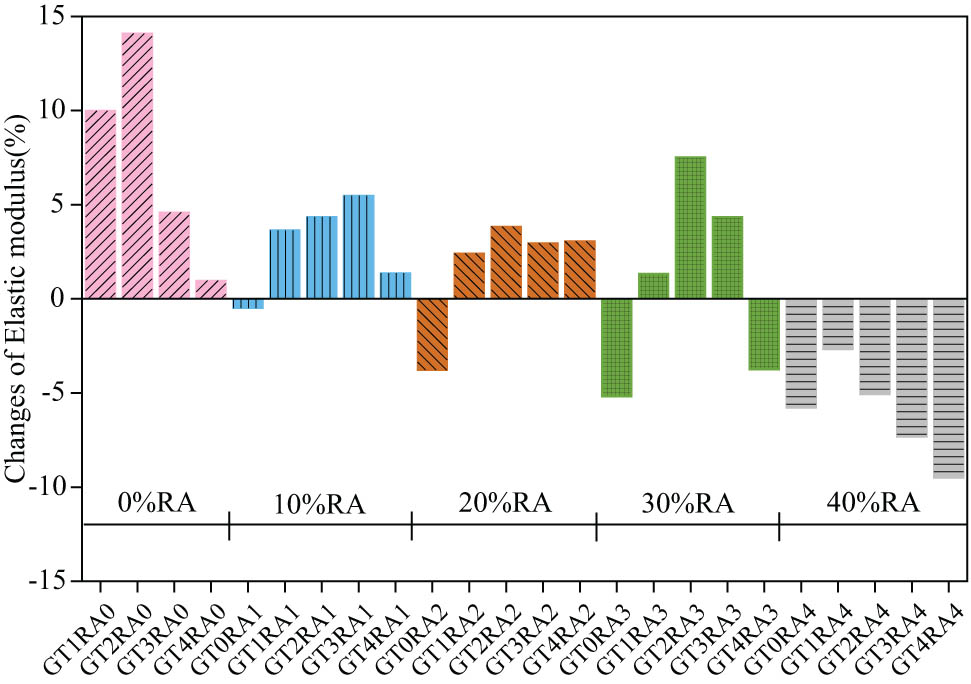

3.1.3 Elastic modulus changes of GTRAC

The elasticity modulus of GTRAC is shown in Figures 11 and 12. The modulus of elasticity follows approximately the same trend as the compressive strength. Several micro-cracks on the cement paste and aggregate surface are observed due to the adherence of the old mortar on the RA surface, resulting in a weakening of the transition zone at the old interface and thus a reduction in the modulus of elasticity [6]. However, GT has a promoting effect on ensuring the elastic modulus of GTRAC. When the replacement rates of GT and RA are 20 and 30%, respectively (under the dual doping system), GTRAC has the best elastic modulus (which is 7.14% greater than the elastic modulus of NC). Furthermore, when the GT substitution rate exceeds 30%, the continued increase of GT does not significantly improve the elastic modulus of GTRAC. Because there are ITZ or internal micro-cracks (without orientation) between aggregate and cement, coarse aggregate and cement in concrete, these factors determine the elastic modulus of concrete. Therefore, the reasons for the change of the elastic modulus of GT and RA are as follows: (1) The presence of micro-cracks and excessive ITZ in RA can cause the bond between the aggregates to fail prematurely under load, giving the concrete less stiffness and more significant lateral de-formation. (2) Due to the filling effect of GT’s ultrafine aggregate, the structure and distribution of the internal aggregates and hardened gel of GTRAC are changed. (3) RA itself has the characteristics of many edges and corners, a rough surface, and easy adhesion [7]. When combined with the gel, it can produce a solid physical bond. These three factors produce coupling effects and interact during the GTRAC stress period, leading to changes in the overall stiffness.

Elastic modulus of GTRAC.

Changes of elastic modulus of GTRAC.

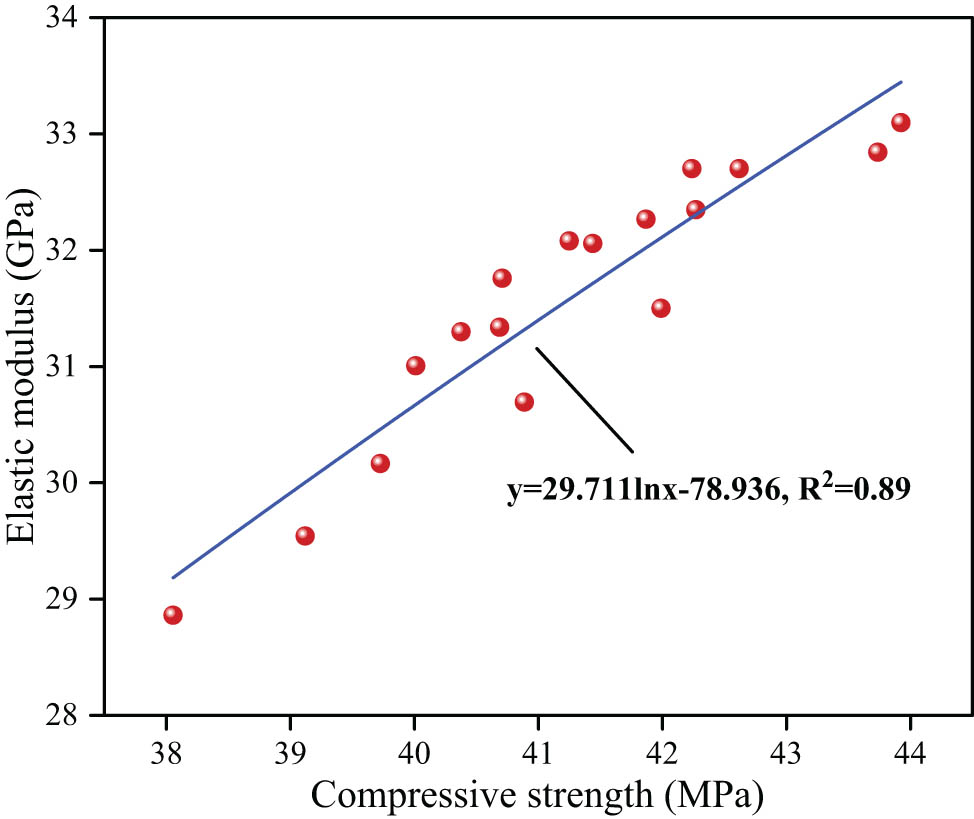

In addition, the relationship between compressive strength and modulus of elasticity of GTRAC is shown in Figure 13. According to the linear relationship between the modulus of elasticity and compressive strength, the fitting equation for the relationship between elastic modulus and compressive strength is in equation (4) [36]:

In this article, a well-determined coefficient between compressive strength and modulus of elasticity can be determined in equation (5):

where E is the modulus of elasticity and f c is the compressive strength. R 2 is the correlation coefficient, which is used to evaluate the coincidence degree between compressive strength and elastic modulus. The closer R 2 value is to 1, the higher the coincidence degree is. The result shows that the R 2 of the regression equation was close to 0.9, indicating that the compressive strength and modulus of elasticity of GTRAC were well correlated and the regression equation was fitted successfully.

Relationship between compressive strength and modulus of elasticity of GTRAC.

3.2 Material characteristic analysis on GTRAC

To further explore the mechanical improvement mechanism of GTRAC, a series of meso-tests were conducted to analyze the changes of meso-structure and hydrate formation based on the influence of the addition of GT.

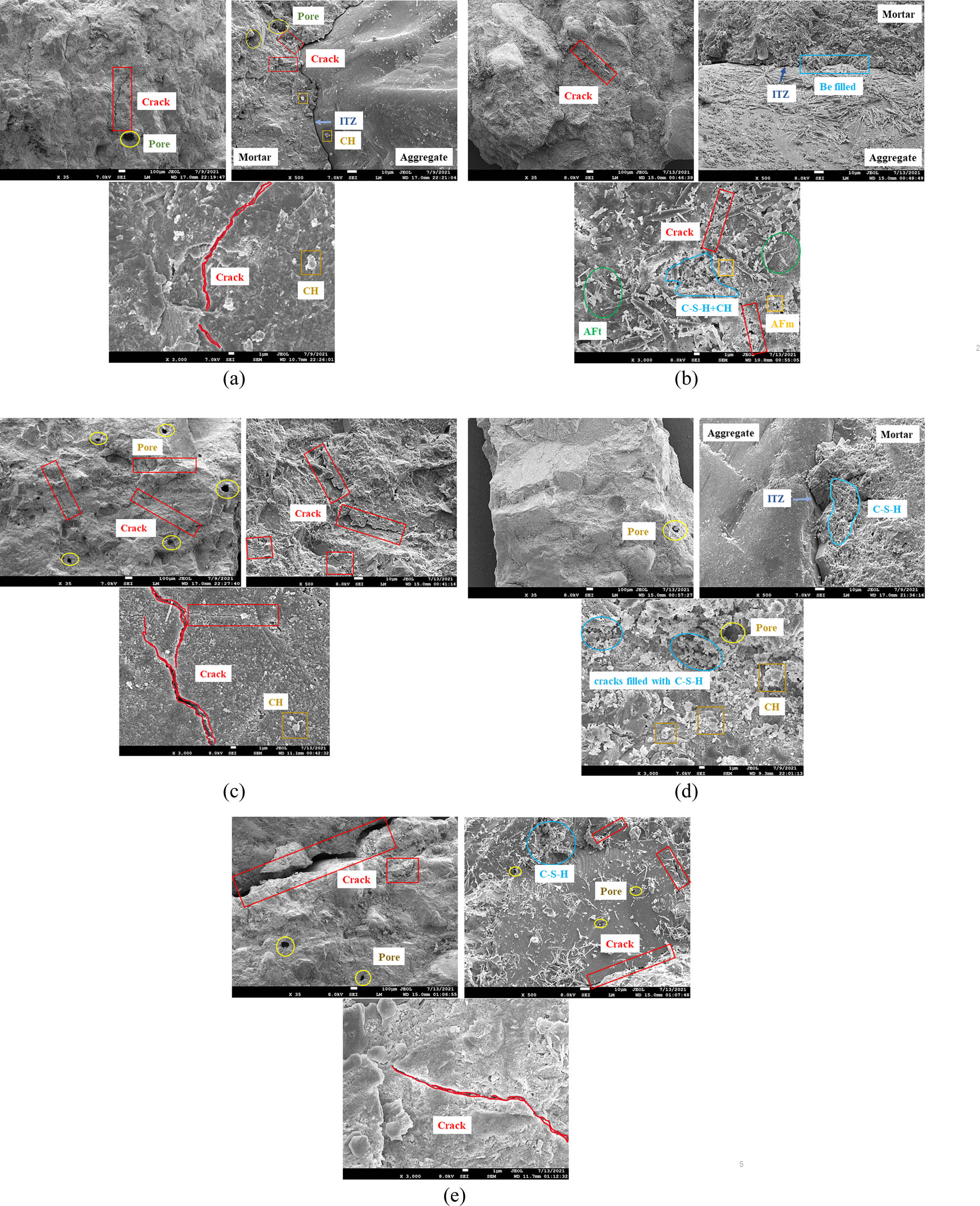

3.2.1 Material morphology analysis on GTRAC

In this article, the microstructure of GTRAC was investigated using SEM in terms of morphology, densification, and hydration products. It can be obtained from Figure 14 that the amount of GT substituted in 20% (Figure 14b) increases the compactness between the cementitious materials compared to concrete without GT. Similarly, the addition of 30% RA (Figure 14c) results in more cracks and larger pores between the gelling materials than without RA, all of which are consistent with the findings of previous scholarly studies [9]. When GT is substituted at 20% (Figure 14d), the hydration products are partially calcified, such as CH and other substances. They are filled into the ITZ of the aggregate and cement mortar together with the dense and fibrous C–S–H gel, further improving the strength of the ITZ. At the same time, the pore structure and internal crack space are filled with visible new crystals and covered by many hydration products, which ultimately results in a denser concrete structure.

Mesomorphological and mineral crystals analysis on GTRAC: (a) NC, (b) GT2RA0, (c) GT0RA3, (d) GT2RA3, and (e) GT4RA3.

However, GT promotes the increase in the formation of CH and C–S–H to a limit. The addition of 40% GT (Figure 14e) will not lead to the formation of many alkaline hydrates such as CH but will increase the pore structure and the number or width of cracks. It depends on whether the water phase is evenly distributed during the hydration process. Due to higher water absorption and lower fineness of GT, an increase in GT replacement rate will decrease the degree of hydration. When the RA substitution rate increases, the initial micro-cracks or micro-defects in the concrete increase. Finally, the combination of substances reduces the bonding ability. Likewise, these changes in the pore structure can be demonstrated in Figure 17.

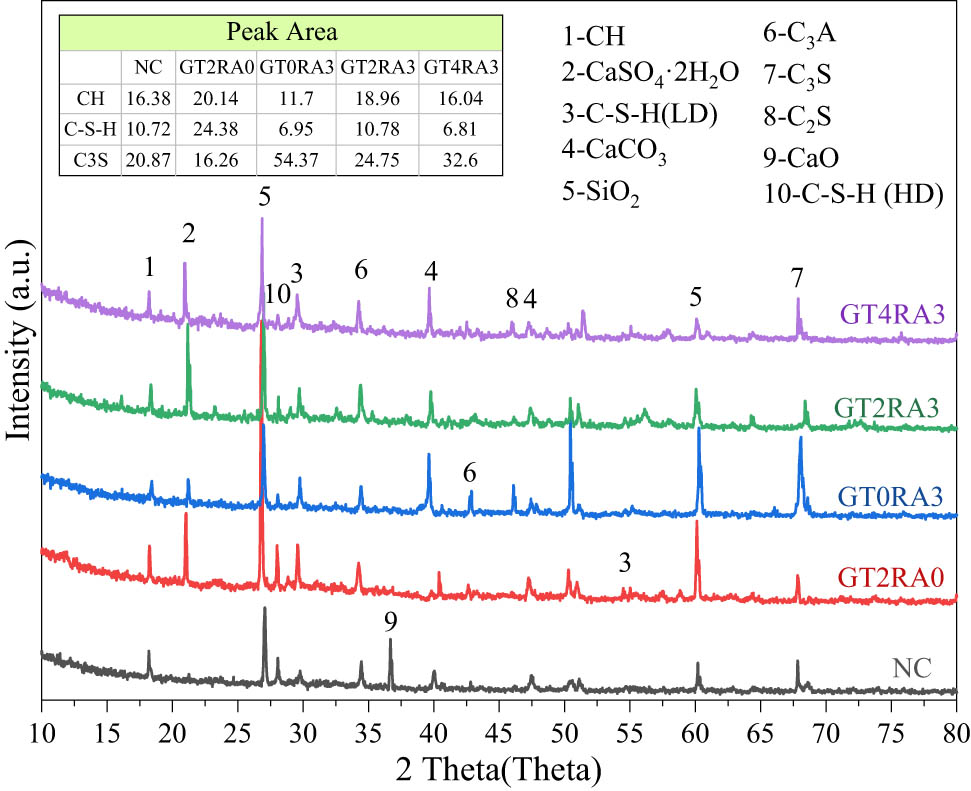

3.2.2 Mineral composition changes of GTRAC

The compound composition analysis results of GTRAC hydration products are shown in Figure 15. The results showed that the RAC without GT addition (GT0RA3) had higher peaks of C3S and C2S due to many water-free and inactive cement clinker particles attached to the RA surface, which were not susceptible to secondary hydration reactions. Meanwhile, the addition of 20% GT (GT2RA3) to the RAC had a significant positive effect on improving the XRD peak intensities and peak areas of C–S–H and CH as well as the consumption of C3S and C2S compared to the RAC without GT. As can be seen from the figure, compared to GT0RA3, the CH and C–S–H peak areas of GT2RA3 increased by 62.5 and 55.1%. The peak area of C3S decreased by 54.5%, respectively, which is reasonable because the addition of GT consumed a large amount of CH produced by the hydration of C2S and C3S in the cement and combined with it to produce a dense C–S–H gel. The gel adheres to ITZ or cracks and enhances ITZ adhesion, which in turn makes the matrix structure tight.

Hydration product analysis of GTRAC.

However, GT did not lead to the production of many hydration products. Compared with GT0RA3, GT4RA3 added with 40% GT consumed 40% of the C3S peak area but contributed little to promoting CH and C–S–H production. Even the peak area of C–S–H decreased by 2%. It indicates that 40% GT addition did not play a role in the reaction, which may be due to the agglomeration effect of GT, which was also pointed out in the study of Liu et al. [17]. Many GT particles agglomerated to become larger, weakening the volcanic ash reaction. At the same time, most free water would be consumed during the agglomeration process, leading to the uneven distribution of the aqueous phase. C2S and C3S are difficult to react with water, thereby affecting the process of hydration reaction. Moreover, a large amount of GT introduces more weak interfaces, leading to a decrease in adhesion between gel systems.

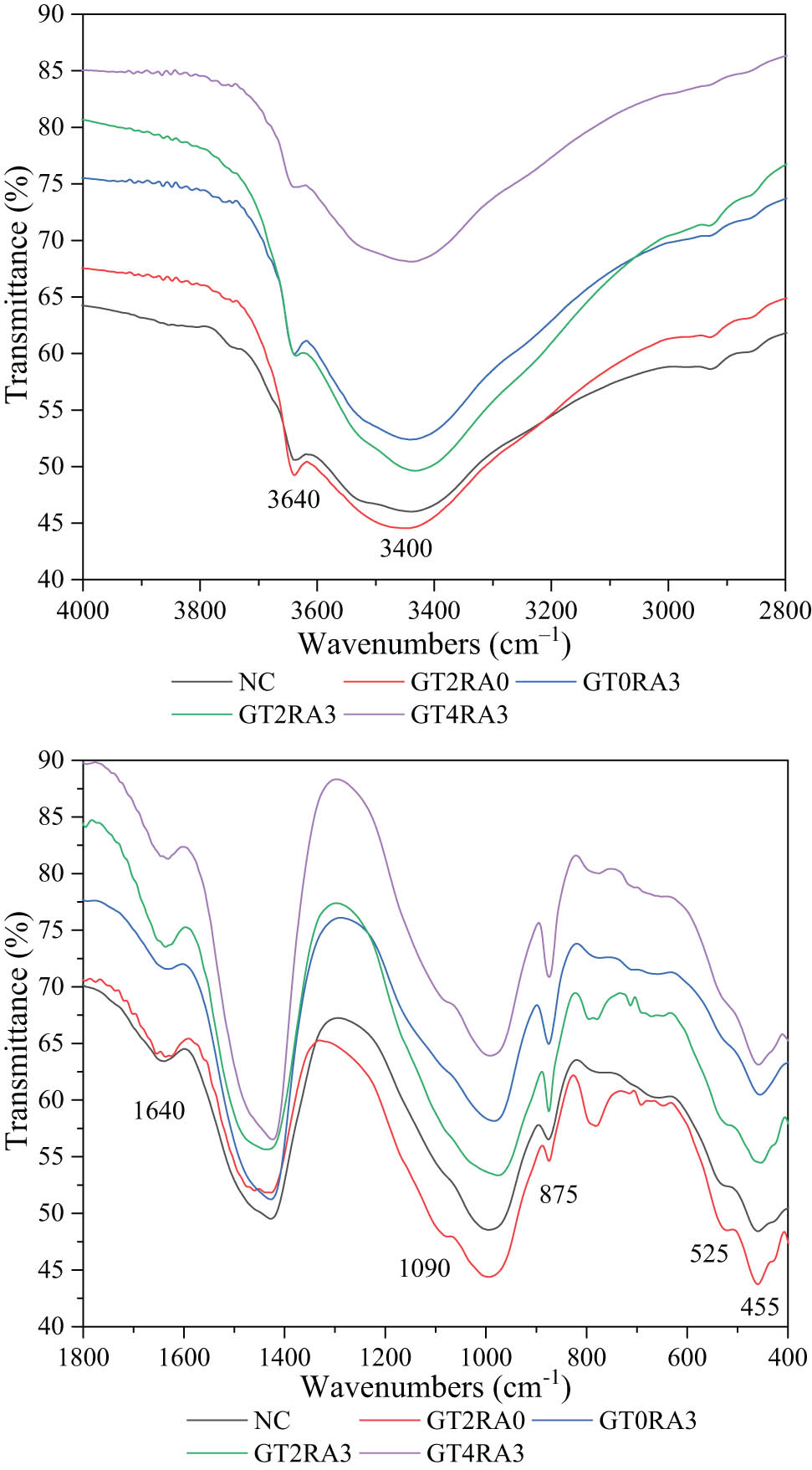

3.2.3 Functional group changes in the GTRAC

The changes in the functional groups of the GTRAC are determined based on the FTIR experiment and shown in Figure 16. The

Functional group analysis on GTRAC.

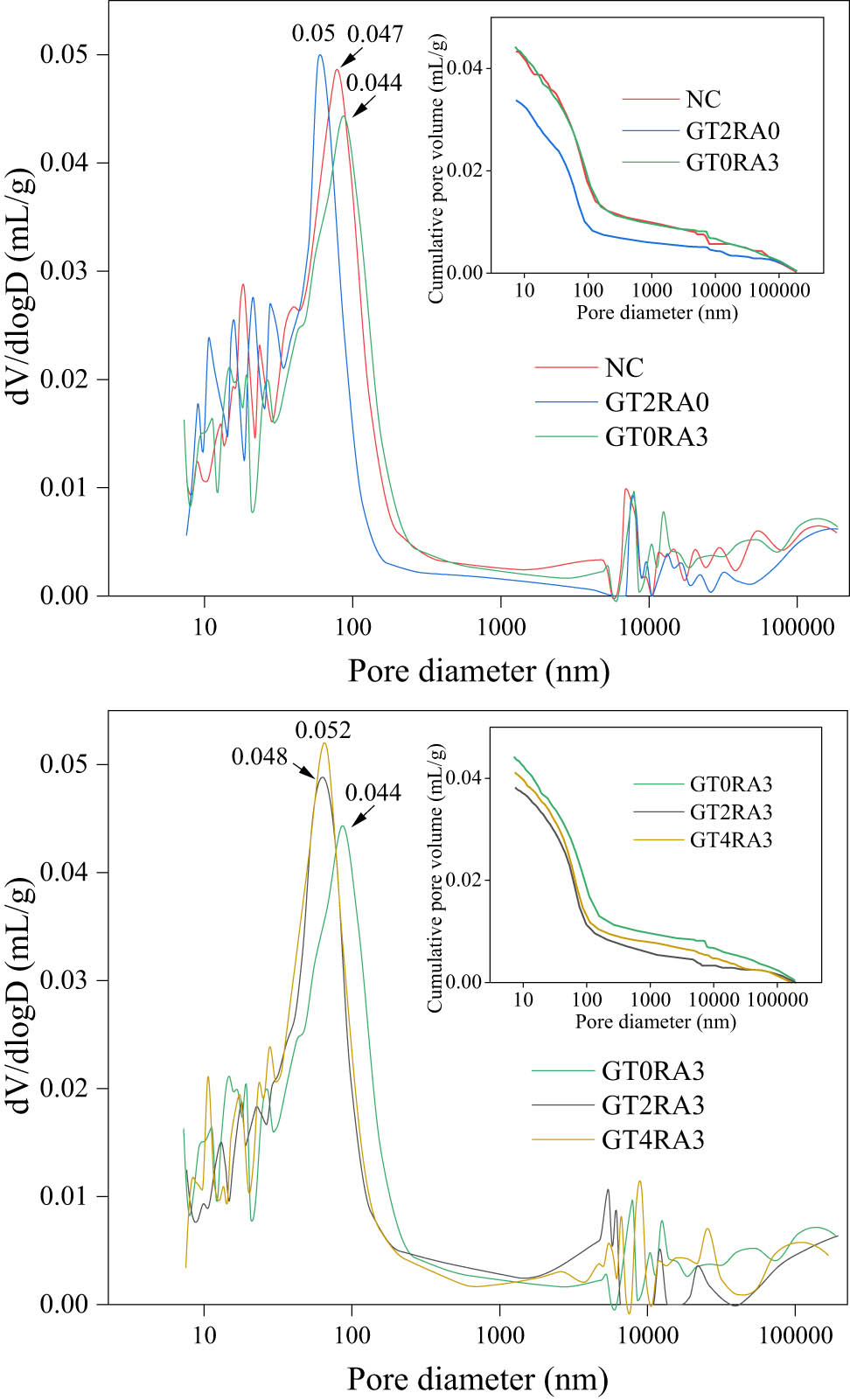

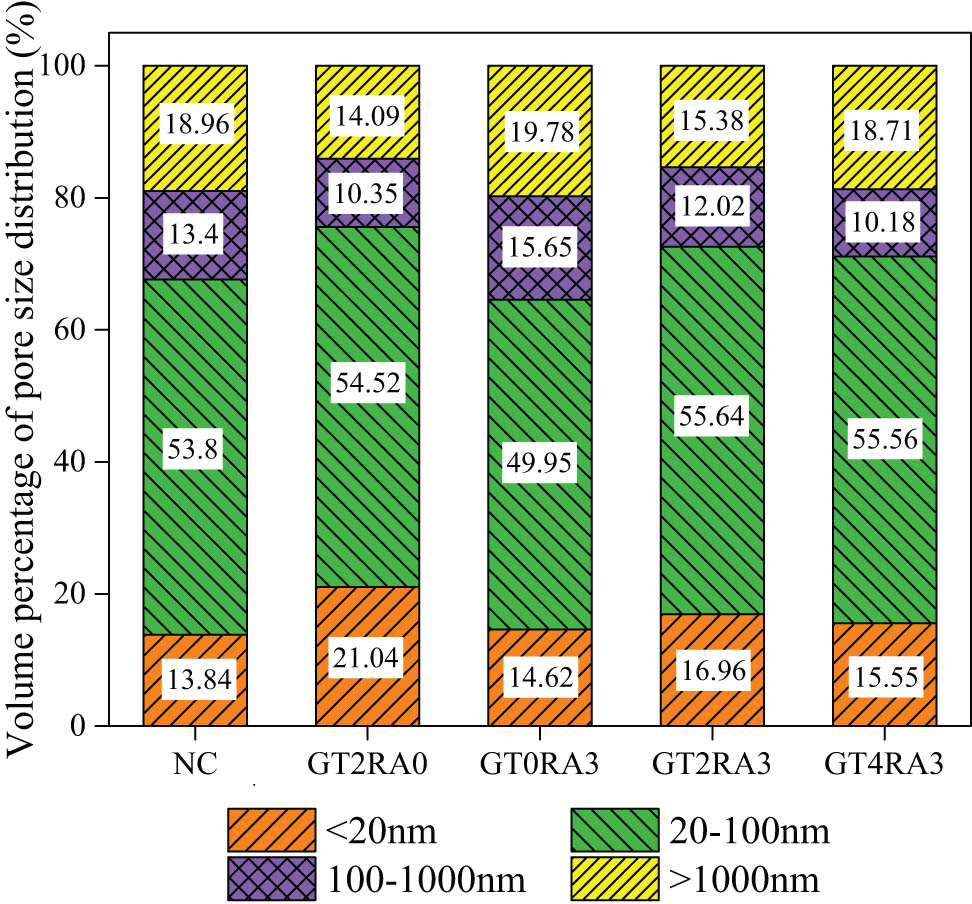

3.2.4 Evolution of pore structure on GTRAC

The pore structure is a key factor in determining the mechanical properties of concrete, which can be characterized by an MIP test. Figure 17 and Table 6 show the effect of GT and RA on the pore size distribution, porosity, total pore volume, and total pore area of the GTRAC. The cumulative pore volume percentages are shown in Figure 18. According to the classification of the pore, a pore size <20 nm is harmless, 20–100 nm is less harmful, 100–1,000 nm is harmful, and a pore size greater than 1,000 nm is more harmful. The results showed that the main peak height of GT2RA0 increased from 0.047 to 0.050 mL·g−1 and shifted to the left by 16.22 nm, the pore envelope area decreased, and the porosity decreased by 1.33% compared with that of NC. At the same time, the total pore volume of GTRAC decreased, and the percentage of small pores increased by 52.0%. The percentage of significant pores decreased, indicating that the addition of 20% GT had good pore structure and densification properties, which improved the strength [20]. Furthermore, due to the addition of RA in GT0RA3, the main peak height decreased by 0.003 mL·g−1 and shifted to the right by 8.8 nm, and the harmful pore envelope region (>100 nm) was 3.07% larger than that of NC. It is because there are a lot of holes in the ITZ of RAC [9], and the increase in its dosage mainly affects the larger pore structure and the distribution of internal pores in GTRAC, leading to the decrease in strength. It quantitatively explains why GT and RA change the mechanical properties of concrete. Notably, comparing the pore structure distribution curves of GT0RA3 and GT2RA3, it can be found that GT2RA3 can promote the peak of the pore size distribution curve in GTRAC to shift to the left and rise by 0.004 mL·g−1, and 1.33 m2·g−1 reduced the total accumulated pore area. Meanwhile, the porosity decreases by 1.34%, from 15.88 to 14.54%, reducing the envelope area of harmful pores (>100 nm) by 8.03%. Nevertheless, this change is insignificant for the harmless pore area (<20 nm). It is because the fineness modulus of GT is very low. When acting together with RA, the old mortar pores on the RA surface are repaired, although the initial cracks cannot be filled to improve the mechanical properties.

Pore size distribution of GTRAC.

Porosity, summary of pore size statistics, total pore size, and area

| Specimen number | Porosity (%) | Mean pore diameter (nm) | Mode pore diameter (nm) | Median pore diameter (nm) | Total intrusion volume (mL·g−1) | Total pore area (m2·g−1) |

|---|---|---|---|---|---|---|

| NC | 14.61 | 36.24 | 74.99 | 65.13 | 0.0433 | 5.30 |

| GT2RA0 | 13.27 | 35.36 | 58.77 | 58.77 | 0.0337 | 4.31 |

| GT0RA3 | 15.88 | 42.13 | 83.79 | 81.83 | 0.0441 | 5.65 |

| GT2RA3 | 14.54 | 40.55 | 64.39 | 63.23 | 0.0381 | 4.32 |

| GT4RA3 | 14.92 | 42.09 | 70.22 | 65.99 | 0.0410 | 4.37 |

Pore volume percentage of GTRAC.

However, when the content of GT was further increased to 40%, the effect of improving the pore distribution was not obvious under the negative effect of easy agglomeration, and the percentage of each accumulated pore showed a decrease. The porosity increased to 14.92% and was greater than that of NC (14.60%). It indicates that the high-water absorption of GT leads to its limited ability to repair the concrete by improving the pore structure space. In conclusion, the appropriate combination of GT and RA materials can improve the pore size distribution of GTRAC to increase its compactness and improve its mechanical properties.

3.2.5 Optimal combined dosage of GT and RA and mechanical improvement mechanism

Based on the above research results, this article analyzes the relationship between compressive strength, elastic modulus, and water absorption. It proposes the best combination of GT and RA based on linear fitting (Figure 19). It can find that the compressive strength and elastic modulus are negatively correlated with water absorption, which indicates that the addition of GT can increase the compactness of GTRAC, thereby improving the mechanical properties. By comparing the point areas on the two fitting curves, the group with the best mechanical properties is obtained as GT2RA3. At the same time, this article analyzes the mechanism of how GT improves the mechanical performance of GTRAC. According to the analysis of the material characterization results of GTRAC under the combined action of GT and RA, (1) the particle size of GT is smaller than that of the natural river sand. The right amount of GT (20%) has a good physical filling effect and can replace part of sand as aggregate to form a reasonable gradation to improve the mechanical properties. (2) GT has a promoting effect on the hydration process. The existence of GT has improved the defect of poor bonding between the new concrete grout interface and the old concrete interface. This is because many calcium hydroxide and calcium alumina crystals are enriched at the interface between the old slurry and the new slurry. The active minerals in GT will react with these crystals to promote the formation of C–S–H gel, thereby improving the mechanical properties of GTRAC.

Effect mechanism diagram of GTRAC.

3.2.6 Comprehensive performance evaluation of GTRAC and other types of RAC

The unit price of each raw material is shown in Table 7. All prices are from the average market price of raw materials announced in China in April 2022 and converted to USD (1 USD = 6.69 CNY). The all-around performance of GTRAC was evaluated in comparison with that of other mineral dopant RAC at optimum mix ratios and is shown in Table 8. A comprehensive evaluation of the mechanical properties of these novel RAC systems was performed based on the same water–cement ratio (W/C = 0.44) and standard cube strength C30, mainly including the following four aspects. The performance was evaluated by comparing the optimum substitution, reaction mechanism, mechanical properties, and value engineering, and the degrees of advantages and disadvantages were indicated by asterisks.

Unit price of raw materials

| Raw materials | Water | Cement | Natural sand | Natural stone | RA | FA | SF | BP | IT | GT |

|---|---|---|---|---|---|---|---|---|---|---|

| Unit price (USD·ton−1) | 0.42 | 72.6 | 21.31 | 16.85 | 8.92 | 32.69 | 67.50 | 0 | 0 | 0 |

Notes: The price of water is the price of domestic water for residents.

Evaluation of the comprehensive performance of GTRAC with other mineral admixtures RAC

| Material system (W/C = 0.44) | Optimal replacement value (%) | Mechanical properties (Compared with NC) | Maximum of compressive strength (MPa) | Cost (USD·m−3) | Comprehensive evaluation | ||||

|---|---|---|---|---|---|---|---|---|---|

| Mineral | RA | Optimum substitution | Reaction mechanism | Performance improvement | Value engineering | ||||

| RAC only | 0 | 25 |

|

36.0–40.0 [24,25,37] | 63.09 |

|

|

|

|

| RAC + Fly ash (FARAC) | 10 | 25 |

|

42.4 [12] | 64.58 |

|

|

|

|

| RAC + Silica fume (SFRAC) | 5 | 30 |

|

42.0–45.0 [38,39] | 63.77–65.45 |

|

|

|

|

| 10 | 25 | ||||||||

| RAC + Brick powder (BPRAC) | 5 | 30 |

|

33.5 [40] | 62.05 |

|

|

|

|

| RAC + Iron tailings (ITRAC) | 20 | 30 |

|

40.4–41.2 [41,42] | 59.32 |

|

|

|

|

| RAC + GT (GTRAC) (This study) | 20 | 30 |

|

45.0 | 59.32 |

|

|

|

|

Notes: Calculate the cost according to 1 cubic meter of C30 concrete. Among them, water:cement:sand:stone = 0.38:1:1.11:2.72, and various mixing amounts are calculated according to the substitution ratio of mass.

3.2.7 RA and mineral utilization

With regard to the optimum substitution rates for RA and minerals in Table 8, the substitution rate of BPRAC for brick is only 5%, which is a very low utilization rate compared to other mineral RACs. Also, the compressive strength is only 33.51 MPa [40]. These two deficiencies are key to the lack of widespread utilization of BPRAC.

3.2.8 Reaction mechanism

The main mechanisms of action of mineral dopants to improve the mechanical properties of RAC are the morphological effect, the filling effect, and the volcanic ash effect. The studies show that FARAC [12] and SFRAC [38,39] have all three of these effects. However, for BPRAC and ITRAC, only the filling effect and the morphological effect are reflected in the compressive strength. That is why they only have 33.51 [37] and 40.4 MPa [41]. The good volcanic ash activity is the advantage of GTRAC over other tailings and is the key to its ability to replace natural sand and increase the strength of RAC, and be widely utilized.

3.2.9 Performance improvement

From Table 8, the addition of reactive mineral admixtures to RAC can improve the overall performance. Fly ash and silica fume can improve the workability and strength of RAC better. However, compared with GT, brick power, iron tailings, and steel slag of RAC show a weaker performance improvement and have little application value. From Table 8, the addition of reactive mineral admixtures to RAC can improve the overall performance. Kou et al. [12] and Dilbas et al. [38] showed that fly ash and silica fume could better improve the workability and strength of RACs. However, macroscopic and microscopic studies of the mechanical properties of BPRAC [40] and ITRAC [41,42] show that although BP and IT can improve the pore structure of RAC to increase the compressive strength, the increase in compressive strength is not significant and has little application value.

Although fly ash can improve the workability of mixing materials [12], the massive application of fly ash will lead to a too large slump, and fly ash particles are easy to float and bleed, which is not conducive to the practical application of engineering. Meanwhile, the contribution of silica fume to RAC is mainly before 28 days. Therefore, SFRAC is generally considered inferior to pure cement concrete or fly ash concrete in terms of long-term strength growth. Their low early strength and substitution amount make it challenging to obtain practical engineering applications. GTRAC has an advantage over FARAC [12] and SFRAC [38,39] in reusing waste material for almost the same compressive strength. At the same time, GT enhanced RAC performance and offers advantages in all four areas while providing good workability. It is essential to GTRAC’s advantage over other mineral RAC materials.

3.2.10 Value engineering

Based on a comprehensive survey of the raw material usage, types, and unit prices of ready-mixed concrete in China (Table 7), C30 ordinary concrete with a standard ratio [23] (water:cement:sand:stone = 0.38:1:1.11:2.72) was selected as the economic evaluation index. Since BP, IT, and GT are solid waste, their prices are calculated at 0. The calculation results of the total price of one cubic meter of concrete are shown in Table 8. After calculation, the price of C30 standard concrete is 65.55 USD per cubic meter, and the price of recycled concrete that replaces 25% RA is 63.09 USD per cubic meter. From the cost calculation results in Table 8, due to the high price of SF itself, there is no advantage in reducing the price after incorporation. The amount of BP added is relatively small, and its own low-price advantage is difficult to exert. The cost per cubic meter of FARAC, ITRAC, and GTRAC was reduced by 2.376, 4.24, and 4.24%, respectively, compared with RAC incorporating 25% RA. However, considering the performance of other performances, GTRAC has wider application prospects than FARAC and ITRAC.

In summary, compared to other mineral RAC systems, GTRAC in this study is a new product that improves the overall performance of RA concrete by considering the renewable use of solid waste resources. GTRAC has a good balance between good workability and mechanical properties and has good prospects for engineering applications.

4 Conclusions

As the waste of graphite mining and abandoned construction waste, GT and RA have already caused considerable damage to the natural ecological environment. Similarly, solving the massive accumulation of dumped construction waste is a critical issue. Incorporating GT and RA into concrete is an effective and sustainable development method. In this article, GT was added to RAC instead of river sand, and the mechanical properties and material characterization of GTRAC were studied. The following conclusions can be drawn from this study.

GT significantly inhibited the workability of RAC. The maximum compressive strength of concrete is 20% of the replacement rate of GT and 30% of the replacement rate of RA, and the strength is increased by 15.01%. The elastic modulus change is linearly related to the compressive strength, which also increases by 7.14%. In addition, the optimal material system reduces the water absorption of GTRAC, and the variation of surface water content was opposite to that of water absorption.

The microscopic analysis combined with SEM, XRD, FTIR, and MIP showed that the homogeneously dispersed GT had a good filling effect. GT effectively enhanced the bond between the aggregate and the cement matrix by changing the microscopic morphology, improving the pore size structure distribution, and acting as a densifier. In addition, the addition of GT changed the hydration products of RAC, the functional groups, or bonding positions of key hydration compounds to influence the mechanical properties of the RAC material system.

Compared with other solid waste RAC, GTRAC has great advantages in optimum substitution, reaction mechanism, mechanical properties, and value engineering. In conclusion, 20% GT content to 30% RA replacement ratio are the optimal admixture of GTRAC.

Acknowledgment

The authors also thank the team members from ASIM Group, China, and the support from Foshan Intelligent Land and Ocean Engineering Materials Engineering Technology Research and Development Center, Foshan, China.

-

Funding information: The authors acknowledge the financial support provided by the Science and Technology Innovation Platform of Foshan City (Grant No. 2016AG100341, Guangdong Province, China) and 2021 Guangdong Provincial Department of Education, Guangdong University Scientific Research Project-Special Project for Young Innovative Talents (2021KQNCX083).

-

Author contributions: Chen Zhang: software, formal analysis, investigation, data curation, conceptualization. Ben Li: methodology, software, formal analysis, Investigation, data curation, writing—original draft, visualization. Fanghong Wu: resources, data curation, writing—review and editing. Ying Yu: data curation, writing—review and editing. Yu Zhang: data curation, writing—review and editing. Hu Xu: data curation, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

-

Conflict of interest: We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of the manuscript.

-

Data availability statement: Data available on request due to constraints required for subsequent corresponding work. Readers in need can ask and we can provide. Thank you very much for your understanding.

References

[1] Xie, T., A. Gholampour, and T. Ozbakkaloglu. Toward the development of sustainable concretes with recycled concrete aggregates: comprehensive review of studies on mechanical properties. Journal of Materials in Civil Engineering, Vol. 30, No. 9, 2018, id. 4018211.10.1061/(ASCE)MT.1943-5533.0002304Search in Google Scholar

[2] Huang, B., X. Wang, H. Kua, Y. Geng, R. Bleischwitz, and J. Ren. Construction and demolition waste management in China through the 3R principle. Resources, Conservation and Recycling, Vol. 129, 2018, pp. 36–44.10.1016/j.resconrec.2017.09.029Search in Google Scholar

[3] Behera, M., S. K. Bhattacharyya, A. K. Minocha, R. Deoliya, and S. Maiti. Recycled aggregate from C&D waste & its use in concrete – a breakthrough towards sustainability in construction sector: a review. Construction and Building Materials, Vol. 68, 2014, pp. 501–516.10.1016/j.conbuildmat.2014.07.003Search in Google Scholar

[4] Bravo, M., J. De Brito, J. Pontes, and L. Evangelista. Mechanical performance of concrete made with aggregates from construction and demolition waste recycling plants. Journal of Cleaner Production, Vol. 99, 2015, pp. 59–74.10.1016/j.jclepro.2015.03.012Search in Google Scholar

[5] Xiao, J., J. Li, and C. Zhang. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cement and Concrete Research, Vol. 35, No. 6, 2005, pp. 1187–1194.10.1016/j.cemconres.2004.09.020Search in Google Scholar

[6] Silva, R. V., J. De Brito, and R. K. Dhir. Establishing a relationship between modulus of elasticity and compressive strength of recycled aggregate concrete. Journal of Cleaner Production, Vol. 112, No. Pt.4, 2016, pp. 2171–2186.10.1016/j.jclepro.2015.10.064Search in Google Scholar

[7] Silva, R. V., J. De Brito, and R. K. Dhir. The influence of the use of recycled aggregates on the compressive strength of concrete: a review. European Journal of Environmental and Civil Engineering, Vol. 19, No. 7/8, 2015, pp. 825–849.10.1080/19648189.2014.974831Search in Google Scholar

[8] Topçu, I. B. Physical and mechanical properties of concretes produced with waste concrete. Cement and Concrete Research, Vol. 27, 1997, pp. 1817–1823.10.1016/S0008-8846(97)00190-7Search in Google Scholar

[9] Xiao, J., W. Li, and Z. Sun. Properties of interfacial transition zones in recycled aggregate concrete tested by nanoindentation. Cement & Concrete Composites, Vol. 37, 2013, pp. 276–292.10.1016/j.cemconcomp.2013.01.006Search in Google Scholar

[10] Lee, G. C. and H. B. Choi. Study on interfacial transition zone properties of recycled aggregate by micro-hardness test. Construction and Building Materials, Vol. 40, 2013, pp. 455–460.10.1016/j.conbuildmat.2012.09.114Search in Google Scholar

[11] Chenhui, J., Wu, X., and Hu, D. Influence of interface transition zone on concrete properties and improvement measures. China Building Materials Science and Technology, Vol. 2, 2006, pp. 27–30 (in Chinese).Search in Google Scholar

[12] Kou, S.-C., C.-S. Poon, and F. Agrela. Influence of fly ash as a cement addition on the hardened properties of recycled aggregate concrete. Materials and Structures, Vol. 41, 2008, pp. 1191–1201.10.1617/s11527-007-9317-ySearch in Google Scholar

[13] Abid, S. R., A. H. Nahhab, H. K. H. Al-aayedi, and A. M. Nuhair. Expansion and Strength Properties of Concrete Containing Contaminated Recycled Concrete Aggregate. Case Studies in Construction Materials, Vol. 9, 2018, id. e00201.10.1016/j.cscm.2018.e00201Search in Google Scholar

[14] Mukharjee, B. B. and S. V. Barai. Influence of Nano-Silica on the properties of recycled aggregate concrete. Construction and Building Materials, Vol. 55, 2014, pp. 29–37.10.1016/j.conbuildmat.2014.01.003Search in Google Scholar

[15] Li, M. M. X. Y., T. Li, X. Y. Quan, and Q. Q. Yan. Study on mechanical properties of recycled aggregate concrete with iron tailings. Concrete, Vol. 3, 2020, pp. 101–104 (in Chinese).Search in Google Scholar

[16] Wang, C., D. Shi, F. Zhang, X. Yu, G. Lin, and Z. Zhou. Degradation characteristics of GT cement mortar subjected to freeze-thaw cycles. Construction and Building Materials, Vol. 234, 2020, id. 118245.10.1016/j.conbuildmat.2019.117422Search in Google Scholar

[17] Yang, Y., M. Pang, C. Du, Z. Y. Liu, Z. H. Chen, N. X. Wang, et al. Effect of GT as substitute sand on mechanical properties of concrete. European Journal of Environmental and Civil Engineering, Vol. 23, 2020, pp. 57–64.Search in Google Scholar

[18] Peng, Y., Y. Liu, B. Zhan, and G. Xu. Preparation of autoclaved aerated concrete by using GT as an alternative silica source. Construction and Building Materials, Vol. 267, 2021, id. 121792.10.1016/j.conbuildmat.2020.121792Search in Google Scholar

[19] Liu, H., K. Liu, Z. Lan, and D. Zhang. Mechanical and electrical characteristics of graphite tailing concrete. Advances in Materials Science and Engineering, Vol. 2018, 2018, pp. 1–9.10.1155/2018/9297628Search in Google Scholar

[20] Kathirvel P., S.-J. Kwon, H.-S. Lee, S. Karthick, and V. Saraswathy. Graphite ore tailings as partial replacement of sand in concrete. ACI Materials Journal, Vol. 116, No. 2, 2019, pp. 481–492.10.14359/51702191Search in Google Scholar

[21] Kathirvel, P., S.-J. Kwon, H.-S. Lee, S. Karthick, and V. Saraswathy. Graphite ore tailings as partial replacement of sand in concrete. ACI Materials Journal, Vol. 115, No. 3, 2018, pp. 481–492.10.14359/51702191Search in Google Scholar

[22] Peng, Y., J. Zhang, J. Liu, J. Ke, and F. Wang. Properties and microstructure of reactive powder concrete having a high content of phosphorous slag powder and silica fume. Construction and Building Materials, Vol. 101, 2015, pp. 482–487.10.1016/j.conbuildmat.2015.10.046Search in Google Scholar

[23] JGJ 55-2011. General concrete mixing ratio design regulations, China construction. Beijing, China: Industry Press, Beijing, China, 2011.Search in Google Scholar

[24] Thomas, J., N. N. Thaickavil, and P. M. Wilson. Strength and durability of concrete containing recycled concrete aggregates. Journal of Building Engineering, Vol. 19, 2018, pp. 349–365.10.1016/j.jobe.2018.05.007Search in Google Scholar

[25] De Brito, J., J. Ferreira, J. Pacheco, D. Soares, and M. Guerreiro. Structural, material, mechanical and durability properties and behaviour of recycled aggregates concrete. Journal of Building Engineering, Vol. 6, 2016, pp. 1–16.10.1016/j.jobe.2016.02.003Search in Google Scholar

[26] Poon, C. S., Z. H. Shui, and L. Lam. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cement and Concrete Research, Vol. 34, No. 1, 2004, pp. 31–36.10.1016/S0008-8846(03)00186-8Search in Google Scholar

[27] GB/T 50081—2002. Standard for test methods for mechanical properties of ordinary concrete. Beijing, China, 2003.Search in Google Scholar

[28] JGJ/T70-2009. Standard for basic performance test methods of building Mortar, 2009.Search in Google Scholar

[29] GB/T 50080—2016. Standard for test methods for the performance of ordinary concrete mixes. China Construction Industry Press, Beijing, China, 2016.Search in Google Scholar

[30] GB/T 21650-2011. Pore size distribution and porosity of solid materials by Mercury Porosimetry and gas adsorption. Part 1: Mercury Porosimetry. ISO, Geneva, Switzerland, 2011.Search in Google Scholar

[31] GB/T 16594-2008. General rules for measurement of length in micron scale by SEM. ISO, Geneva, Switzerland, 2008.Search in Google Scholar

[32] GB/T 30904-2014. Inorganic chemicals for industrial use: crystal form analysis on X-Ray Diffraction method. ISO, Geneva, Switzerland, 2014.Search in Google Scholar

[33] ISO 19618-2017. Measurement Method for normal spectral emissivity using blackbody reference with an FTIR spectrometer. ISO, Geneva, Switzerland, 2017.Search in Google Scholar

[34] Baozhong, Z. A preliminary study on the relationship between water absorption and concrete strength. Science and Technology Information, Vol. 15, 2011, pp. 681–732 (in Chinese).Search in Google Scholar

[35] Feng, J., C. Liangliang, Z. Peng, Z. Honghong, M. Zhaoze, M. Xiegang, et al. Research on the correlation between water absorption and strength of recycled concrete. Journal of Yangtze River Academy of Sciences, Vol. 36, No. 3, 2019, pp. 139–144 (in Chinese).Search in Google Scholar

[36] Shen, Y., G. X. Wang, Q. W. Pei, M. Q. Zhu, and F. Qu. Study on compressive strength and elastic modulus of C30 waste ceramic recycled aggregate concrete. Silicate Bulletin, Vol. 37, No. 12, 2018, pp. 3795–3801.Search in Google Scholar

[37] Ozbakkaloglu, T., A. Gholampour, and T. Xie. Mechanical and durability properties of recycled aggregate concrete: effect of recycled aggregate properties and content. Journal of Materials in Civil Engineering, Vol. 30, No. 2, 2018, id. 1.10.1061/(ASCE)MT.1943-5533.0002142Search in Google Scholar

[38] Dilbas, H., M. Simsek, and O. Cakir. An investigation on mechanical and physical properties of recycled aggregate concrete (RAC) with and without silica fume. Construction and Building Materials, Vol. 61, 2014, pp. 50–59.10.1016/j.conbuildmat.2014.02.057Search in Google Scholar

[39] Wang, S., T. Li, T. Yang, B. Zhang, and J. Ju. Experimental study on seismic behavior of RAC columns with silica fume and hybrid fiber. Journal of Building Structures, Vol. 34, No. 5, 2013, pp. 122–129 (in Chinese).Search in Google Scholar

[40] Letelier, V., J. M. Ortega, P. Muñoz, E. Tarela, and G. Moriconi. Influence of waste brick powder in the mechanical properties of recycled aggregate concrete. Sustainability, Vol. 10, No. 4, 2018, pp. 1037–105310.3390/su10041037Search in Google Scholar

[41] Xu, F., S. Wang, T. Li, B. Liu, B. Li, and Y. Zhou. Mechanical properties and pore structure of recycled aggregate concrete made with iron ore tailings and polypropylene fibers. Journal of Building Engineering, Vol. 33, 2021, id. 101572.10.1016/j.jobe.2020.101572Search in Google Scholar

[42] Li, T., S. Wang, F. Xu, X. Meng, B. Li, and M. Zhan. Study of the basic mechanical properties and degradation mechanism of recycled concrete with tailings before and after carbonation. Journal of Cleaner Production, Vol. 259(C), 2020, id. 120923.10.1016/j.jclepro.2020.120923Search in Google Scholar

© 2022 Chen Zhang et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers

- A review on the properties of concrete reinforced with recycled steel fiber from waste tires

- Copper ternary oxides as photocathodes for solar-driven CO2 reduction

- Properties of fresh and hardened self-compacting concrete incorporating rice husk ash: A review

- Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey

- Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles

- Delivery systems in nanocosmeceuticals

- Study on the preparation process and sintering performance of doped nano-silver paste

- Analysis of the interactions between nonoxide reinforcements and Al–Si–Cu–Mg matrices

- Research Articles

- Study on the influence of structural form and parameters on vibration characteristics of typical ship structures

- Deterioration characteristics of recycled aggregate concrete subjected to coupling effect with salt and frost

- Novel approach to improve shale stability using super-amphiphobic nanoscale materials in water-based drilling fluids and its field application

- Research on the low-frequency multiline spectrum vibration control of offshore platforms

- Multiple wide band gaps in a convex-like holey phononic crystal strip

- Response analysis and optimization of the air spring with epistemic uncertainties

- Molecular dynamics of C–S–H production in graphene oxide environment

- Residual stress relief mechanisms of 2219 Al–Cu alloy by thermal stress relief method

- Characteristics and microstructures of the GFRP waste powder/GGBS-based geopolymer paste and concrete

- Development and performance evaluation of a novel environmentally friendly adsorbent for waste water-based drilling fluids

- Determination of shear stresses in the measurement area of a modified wood sample

- Influence of ettringite on the crack self-repairing of cement-based materials in a hydraulic environment

- Multiple load recognition and fatigue assessment on longitudinal stop of railway freight car

- Synthesis and characterization of nano-SiO2@octadecylbisimidazoline quaternary ammonium salt used as acidizing corrosion inhibitor

- Perforated steel for realizing extraordinary ductility under compression: Testing and finite element modeling

- The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on strain hardening cement-based composites

- Perforated steel block of realizing large ductility under compression: Parametric study and stress–strain modeling

- Study on dynamic viscoelastic constitutive model of nonwater reacted polyurethane grouting materials based on DMA

- Mechanical behavior and mechanism investigation on the optimized and novel bio-inspired nonpneumatic composite tires

- Effect of cooling rate on the microstructure and thermal expansion properties of Al–Mn–Fe alloy

- Research on process optimization and rapid prediction method of thermal vibration stress relief for 2219 aluminum alloy rings

- Failure prevention of seafloor composite pipelines using enhanced strain-based design

- Deterioration of concrete under the coupling action of freeze–thaw cycles and salt solution erosion

- Creep rupture behavior of 2.25Cr1Mo0.25V steel and weld for hydrogenation reactors under different stress levels

- Statistical damage constitutive model for the two-component foaming polymer grouting material

- Nano-structural and nano-constraint behavior of mortar containing silica aggregates

- Influence of recycled clay brick aggregate on the mechanical properties of concrete

- Effect of LDH on the dissolution and adsorption behaviors of sulfate in Portland cement early hydration process

- Comparison of properties of colorless and transparent polyimide films using various diamine monomers

- Study in the parameter influence on underwater acoustic radiation characteristics of cylindrical shells

- Experimental study on basic mechanical properties of recycled steel fiber reinforced concrete

- Dynamic characteristic analysis of acoustic black hole in typical raft structure

- A semi-analytical method for dynamic analysis of a rectangular plate with general boundary conditions based on FSDT

- Research on modification of mechanical properties of recycled aggregate concrete by replacing sand with graphite tailings

- Dynamic response of Voronoi structures with gradient perpendicular to the impact direction

- Deposition mechanisms and characteristics of nano-modified multimodal Cr3C2–NiCr coatings sprayed by HVOF

- Effect of excitation type on vibration characteristics of typical ship grillage structure

- Study on the nanoscale mechanical properties of graphene oxide–enhanced shear resisting cement

- Experimental investigation on static compressive toughness of steel fiber rubber concrete

- Study on the stress field concentration at the tip of elliptical cracks

- Corrosion resistance of 6061-T6 aluminium alloy and its feasibility of near-surface reinforcements in concrete structure

- Effect of the synthesis method on the MnCo2O4 towards the photocatalytic production of H2

- Experimental study of the shear strength criterion of rock structural plane based on three-dimensional surface description

- Evaluation of wear and corrosion properties of FSWed aluminum alloy plates of AA2020-T4 with heat treatment under different aging periods

- Thermal–mechanical coupling deformation difference analysis for the flexspline of a harmonic drive

- Frost resistance of fiber-reinforced self-compacting recycled concrete

- High-temperature treated TiO2 modified with 3-aminopropyltriethoxysilane as photoactive nanomaterials

- Effect of nano Al2O3 particles on the mechanical and wear properties of Al/Al2O3 composites manufactured via ARB

- Co3O4 nanoparticles embedded in electrospun carbon nanofibers as free-standing nanocomposite electrodes as highly sensitive enzyme-free glucose biosensors

- Effect of freeze–thaw cycles on deformation properties of deep foundation pit supported by pile-anchor in Harbin

- Temperature-porosity-dependent elastic modulus model for metallic materials

- Effect of diffusion on interfacial properties of polyurethane-modified asphalt–aggregate using molecular dynamic simulation

- Experimental study on comprehensive improvement of shear strength and erosion resistance of yellow mud in Qiang Village

- A novel method for low-cost and rapid preparation of nanoporous phenolic aerogels and its performance regulation mechanism

- In situ bow reduction during sublimation growth of cubic silicon carbide

- Adhesion behaviour of 3D printed polyamide–carbon fibre composite filament

- An experimental investigation and machine learning-based prediction for seismic performance of steel tubular column filled with recycled aggregate concrete

- Effects of rare earth metals on microstructure, mechanical properties, and pitting corrosion of 27% Cr hyper duplex stainless steel

- Application research of acoustic black hole in floating raft vibration isolation system

- Multi-objective parametric optimization on the EDM machining of hybrid SiCp/Grp/aluminum nanocomposites using Non-dominating Sorting Genetic Algorithm (NSGA-II): Fabrication and microstructural characterizations

- Estimating of cutting force and surface roughness in turning of GFRP composites with different orientation angles using artificial neural network

- Displacement recovery and energy dissipation of crimped NiTi SMA fibers during cyclic pullout tests

Articles in the same Issue

- Review Articles

- State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers

- A review on the properties of concrete reinforced with recycled steel fiber from waste tires

- Copper ternary oxides as photocathodes for solar-driven CO2 reduction

- Properties of fresh and hardened self-compacting concrete incorporating rice husk ash: A review

- Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey

- Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles

- Delivery systems in nanocosmeceuticals

- Study on the preparation process and sintering performance of doped nano-silver paste

- Analysis of the interactions between nonoxide reinforcements and Al–Si–Cu–Mg matrices

- Research Articles

- Study on the influence of structural form and parameters on vibration characteristics of typical ship structures

- Deterioration characteristics of recycled aggregate concrete subjected to coupling effect with salt and frost

- Novel approach to improve shale stability using super-amphiphobic nanoscale materials in water-based drilling fluids and its field application

- Research on the low-frequency multiline spectrum vibration control of offshore platforms

- Multiple wide band gaps in a convex-like holey phononic crystal strip

- Response analysis and optimization of the air spring with epistemic uncertainties

- Molecular dynamics of C–S–H production in graphene oxide environment

- Residual stress relief mechanisms of 2219 Al–Cu alloy by thermal stress relief method

- Characteristics and microstructures of the GFRP waste powder/GGBS-based geopolymer paste and concrete

- Development and performance evaluation of a novel environmentally friendly adsorbent for waste water-based drilling fluids

- Determination of shear stresses in the measurement area of a modified wood sample

- Influence of ettringite on the crack self-repairing of cement-based materials in a hydraulic environment

- Multiple load recognition and fatigue assessment on longitudinal stop of railway freight car

- Synthesis and characterization of nano-SiO2@octadecylbisimidazoline quaternary ammonium salt used as acidizing corrosion inhibitor

- Perforated steel for realizing extraordinary ductility under compression: Testing and finite element modeling

- The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on strain hardening cement-based composites

- Perforated steel block of realizing large ductility under compression: Parametric study and stress–strain modeling

- Study on dynamic viscoelastic constitutive model of nonwater reacted polyurethane grouting materials based on DMA

- Mechanical behavior and mechanism investigation on the optimized and novel bio-inspired nonpneumatic composite tires

- Effect of cooling rate on the microstructure and thermal expansion properties of Al–Mn–Fe alloy

- Research on process optimization and rapid prediction method of thermal vibration stress relief for 2219 aluminum alloy rings

- Failure prevention of seafloor composite pipelines using enhanced strain-based design

- Deterioration of concrete under the coupling action of freeze–thaw cycles and salt solution erosion

- Creep rupture behavior of 2.25Cr1Mo0.25V steel and weld for hydrogenation reactors under different stress levels

- Statistical damage constitutive model for the two-component foaming polymer grouting material

- Nano-structural and nano-constraint behavior of mortar containing silica aggregates

- Influence of recycled clay brick aggregate on the mechanical properties of concrete

- Effect of LDH on the dissolution and adsorption behaviors of sulfate in Portland cement early hydration process

- Comparison of properties of colorless and transparent polyimide films using various diamine monomers

- Study in the parameter influence on underwater acoustic radiation characteristics of cylindrical shells

- Experimental study on basic mechanical properties of recycled steel fiber reinforced concrete

- Dynamic characteristic analysis of acoustic black hole in typical raft structure

- A semi-analytical method for dynamic analysis of a rectangular plate with general boundary conditions based on FSDT

- Research on modification of mechanical properties of recycled aggregate concrete by replacing sand with graphite tailings

- Dynamic response of Voronoi structures with gradient perpendicular to the impact direction

- Deposition mechanisms and characteristics of nano-modified multimodal Cr3C2–NiCr coatings sprayed by HVOF

- Effect of excitation type on vibration characteristics of typical ship grillage structure

- Study on the nanoscale mechanical properties of graphene oxide–enhanced shear resisting cement

- Experimental investigation on static compressive toughness of steel fiber rubber concrete

- Study on the stress field concentration at the tip of elliptical cracks

- Corrosion resistance of 6061-T6 aluminium alloy and its feasibility of near-surface reinforcements in concrete structure

- Effect of the synthesis method on the MnCo2O4 towards the photocatalytic production of H2

- Experimental study of the shear strength criterion of rock structural plane based on three-dimensional surface description

- Evaluation of wear and corrosion properties of FSWed aluminum alloy plates of AA2020-T4 with heat treatment under different aging periods

- Thermal–mechanical coupling deformation difference analysis for the flexspline of a harmonic drive

- Frost resistance of fiber-reinforced self-compacting recycled concrete

- High-temperature treated TiO2 modified with 3-aminopropyltriethoxysilane as photoactive nanomaterials

- Effect of nano Al2O3 particles on the mechanical and wear properties of Al/Al2O3 composites manufactured via ARB

- Co3O4 nanoparticles embedded in electrospun carbon nanofibers as free-standing nanocomposite electrodes as highly sensitive enzyme-free glucose biosensors

- Effect of freeze–thaw cycles on deformation properties of deep foundation pit supported by pile-anchor in Harbin

- Temperature-porosity-dependent elastic modulus model for metallic materials

- Effect of diffusion on interfacial properties of polyurethane-modified asphalt–aggregate using molecular dynamic simulation

- Experimental study on comprehensive improvement of shear strength and erosion resistance of yellow mud in Qiang Village

- A novel method for low-cost and rapid preparation of nanoporous phenolic aerogels and its performance regulation mechanism

- In situ bow reduction during sublimation growth of cubic silicon carbide

- Adhesion behaviour of 3D printed polyamide–carbon fibre composite filament

- An experimental investigation and machine learning-based prediction for seismic performance of steel tubular column filled with recycled aggregate concrete

- Effects of rare earth metals on microstructure, mechanical properties, and pitting corrosion of 27% Cr hyper duplex stainless steel

- Application research of acoustic black hole in floating raft vibration isolation system

- Multi-objective parametric optimization on the EDM machining of hybrid SiCp/Grp/aluminum nanocomposites using Non-dominating Sorting Genetic Algorithm (NSGA-II): Fabrication and microstructural characterizations

- Estimating of cutting force and surface roughness in turning of GFRP composites with different orientation angles using artificial neural network

- Displacement recovery and energy dissipation of crimped NiTi SMA fibers during cyclic pullout tests