Abstract

Marine concrete is a kind of construction material which is seeking its growing application in marine engineering. However, the marine concrete structures are exposed to aggressive environment and harmful ions. Therefore, it is crucial to improve the durability of marine concrete. The concrete structure located in the tidal zone is subjected to the dry–wet cycles caused by tidal action, chloride ion (Cl−) erosion in seawater, and CO2 erosion in air. When these factors work together, they cause great damage to the marine concrete structure. In view of the three environmental factors, namely, Cl− erosion, carbonation, and dry–wet cycles, taking fly ash, fibers, and nanomaterials as examples, this article expounds the research status of durability of marine concrete, introduces the latest research progress, the addition of fibers, fly ash, and nanomaterials can improve the Cl− corrosion resistance and dry–wet cycles resistance of marine concrete, while the addition of fly ash is unfavorable for carbonation resistance. And the future development trend of marine concrete is prospected.

1 Introduction

Marine concrete refers to the concrete used in marine engineering construction. With the development and utilization of marine resources, many countries in the world are increasing the construction of marine structures, such as cross-sea bridges, undersea tunnels, offshore drilling platforms, ports, and wharves. Concrete is the most common material in marine engineering construction, and it is very important to improve its durability. The marine concrete structures exposed to an aggressive environment, not only suffer from chloride ion (Cl−) erosion in seawater and carbon dioxide (CO2) erosion in air but also bear the effects of dry–wet cycles caused by tides action. The combined action of these environmental factors greatly reduces the durability of marine concrete structures and eventually makes them lose their bearing capacity. The investigation shows [1] that more than 80% of seaports and wharves in China have suffered from severe steel corrosion, and some reinforced concrete structures have been corroded within less than 10 years. The annual economic loss caused by corrosion of steel bars is more than 14.3 billion euros.

Scholars at home and abroad have done lots of research on the durability of concrete under the action of a single factor, and fruitful results have been achieved. However, the marine concrete structures in actual engineering do not work under the action of a single factor. When the marine concrete is subjected to the combined action of multi-factors, the damage is not a simple superposition of a single factor, and the interaction between various factors makes the deterioration mechanism of marine concrete more complicated. Therefore, it is very important to explore the deterioration mechanism of marine concrete under the combined action of various factors to improve the durability of marine concrete structures.

With the wide application of concrete, traditional concrete has been unable to meet the needs of engineering. Mixing different admixtures in concrete to prepare high-performance concrete (HPC) can effectively meet the needs of various working conditions. At present, the commonly used admixtures in engineering are fibers, fly ash, nanomaterials, silica fume, slag, etc.

Aiming at three aspects, namely, Cl− erosion, carbonation and dry–wet cycles, and taking fly ash, fiber, and nanomaterials as examples, this article summarizes the research status of the marine concrete durability under the action of single and multi-factors, and prospects the future research direction of marine concrete.

2 Research status of concrete durability

2.1 Research status of resistance of concrete to Cl− erosion

There are a lot of chloride salts such as NaCl and MgCl2 in seawater, and the biggest hazard to marine concrete is mainly the corrosion of steel bars in concrete caused by Cl−. Cl− can combine with hydration products in concrete to generate Friedel salt (3CaO·Al2O3·CaCl2·10H2O), which causes damage to concrete. Due to the existence of concentration gradient between the surface and inside of concrete, Cl− will diffuse into concrete along the capillary pores and cracks and reach the surface of steel bars. When the Cl− concentration reaches a certain value, it will destroy the passivation film on the surface of steel bar, causing the steel bar to corrode. With volume expansion, the value expansion will cause the concrete to crack, which seriously affects the service life of concrete structures. Over the years, scholars at home and abroad have conducted a large number of Cl− erosion tests on different types of concretes, and analyzed the effects of different admixtures on the Cl− erosion resistance of concrete.

Adding fibers into concrete can effectively improve the Cl− erosion resistance of concrete. Through experimental studies, Berrocal et al. [2] found that the addition of steel fibers and polyethylene fibers changed the corrosion pattern of steel bars in concrete, improved the compactness of concrete, and potentially reduced the depth of Cl− penetration and the extent of local corrosion. Frazao et al. [3] conducted the Cl− penetration resistance test on steel fiber concrete and believed that the incorporation of steel fibers could make the concrete resist Cl− erosion. Yehia et al. [4] studied the effect of steel fibers on the Cl− corrosion resistance of concrete, and the results showed that although the electrical conductivity of steel fiber concrete is lower, it is still improved compared with ordinary concrete, so the addition of steel fibers can improve the Cl− erosion resistance of concrete. Meng [5] studied the influence of steel fiber content on Cl− permeability of HPC, and found that an appropriate amount of steel fibers (0–2%) can reduce the depth of Cl− erosion in HPC and the Cl− diffusion coefficient of concrete, and improve its ability to resist Cl− erosion. Wang et al. [6] found that basalt fibers effectively inhibit the generation and development of chloride erosion cracks and reduce the Cl− migration rate. Su et al. [7] studied the Cl− diffusion performance of basalt–polypropylene (PP) fibers reinforced concrete, and the results showed that an appropriate amount (0.1%) of hybrid fibers reduces the Cl− concentration in concrete, while excessive hybrid fibers will increase the Cl− concentration at different depths in concrete.

The addition of fly ash can significantly improve the Cl− erosion resistance of concrete. Liu et al. [8] showed that the pozzolanic effect of fly ash leads to the reduction in concrete porosity, which in turn reduces the Cl− permeability of concrete. The research conclusion of Shaikh and Supit [9] showed that the Cl− permeability of concrete at 28 and 90 days of age can be reduced by 18 and 65%, respectively, after the addition of 8% ultrafine fly ash in concrete. Poon et al. [10] concluded that 45% fly ash reduces the Cl− permeability of concrete at 28 and 90 days of age by 62 and 84%, respectively. Fan et al. [11] studied the Cl− permeability resistance of concrete with high dosage fly ash (30–40%) by using 12 year field exposure tests in South China. As shown in Figure 1, the addition of fly ash significantly reduces the Cl− diffusion coefficient of concrete and improves the resistance of concrete to Cl− penetration. For HPC mixed with 30–40% fly ash, its chloride ion diffusion coefficient is reduced by more than 6 times. Yang et al. [12] tested the durability of Cl− diffusion performance and other indicators of typical components of a cross-sea bridge in South China that had been in service for 12 years. The study showed that fly ash could significantly improve the Cl− erosion resistance of concrete, and the Cl− diffusion coefficient of fly ash HPC was about 6 times lower than that of ordinary concrete. Wang et al. [13] and Nath and Sarker [14] found that the Cl− permeability of concrete decreases significantly after fly ash is added, and the optimal dosage of fly ash is 40%.

![Figure 1

Effect of fly ash on chloride diffusion coefficient of concrete [11].](/document/doi/10.1515/rams-2022-0049/asset/graphic/j_rams-2022-0049_fig_001.jpg)

Effect of fly ash on chloride diffusion coefficient of concrete [11].

The addition of nanomaterials can also improve the resistance of concrete to Cl− erosion. Chithra et al. [15] studied the effect of nano-SiO2 on the Cl− infiltration resistance of concrete, and found that the addition of nano-SiO2 improved the Cl− infiltration resistance of concrete. Zhang and Hui [16] studied the Cl− permeability resistance of pavement nano-concrete and found that the addition of nano-materials enhanced the Cl− permeability resistance of concrete, and the Cl− permeability resistance of nano-TiO2 concrete was higher than that of nano-SiO2 concrete with the same dosage. Lei and Feng [17] found that compared with ordinary concrete, nano-TiO2 concrete has better resistance to chloride diffusion. Qian et al. [18] found through experiments that the addition of nano-CaCO3 can effectively fill the pores, make the concrete compact, and significantly improve the Cl− infiltration resistance of concrete. Shi et al. [19] studied the Cl− permeability resistance of multi-walled carbon nanotubes (MWCNTs) reinforced concrete, and concluded that the free Cl− concentration in each depth of concrete decreased, and the Cl− diffusion coefficient decreased with the increase in the dosage of MWCNTs, and the addition of MWCNTs improved the Cl− permeability resistance of concrete. Figures 2 and 3 show the chloride diffusion depth and unsteady chloride migration coefficient D RCM measured in concrete with different MWCNT contents [20]. Compared with the control group (0 wt%), when the content of MWCNTs was 0.05, 0.10, and 0.15 wt%, the 28 days chloride diffusion depth of concrete decreased by 10.3, 13.7, and 25.7%, and the DRCM decreased by 11.2, 14.5 and 19.1%, respectively. The incorporation of MWCNTs effectively enhanced the Cl− penetration resistance of concrete, and with the increase in MWCNTs’ content, the enhancement effect also increased gradually.

![Figure 2

Chloride diffusion depth of concrete with different dosage of MWCNTs [20].](/document/doi/10.1515/rams-2022-0049/asset/graphic/j_rams-2022-0049_fig_002.jpg)

Chloride diffusion depth of concrete with different dosage of MWCNTs [20].

![Figure 3

Unstable chloride ion diffusion coefficient DRCM of concrete with different dosage of MWCNTs [20].](/document/doi/10.1515/rams-2022-0049/asset/graphic/j_rams-2022-0049_fig_003.jpg)

Unstable chloride ion diffusion coefficient DRCM of concrete with different dosage of MWCNTs [20].

It can be seen that the addition of fibers, fly ash, and nanomaterials can improve the Cl− infiltration resistance of concrete, and only the appropriate dosage can have a good effect on the resistance of concrete to Cl− erosion.

2.2 Research status of concrete carbonation

The product formed by cement hydration comes into contact with CO2 in air, and a chemical reaction occurs to generate water and carbonate, which reduces the alkalinity of concrete. Such a process is called the carbonation of concrete, also known as theneutralization of concrete. Concrete is eroded by CO2 in air, so carbonation is an unavoidable process of concrete. Carbonation will increase the shrinkage of concrete, resulting in cracks, thereby greatly reducing the durability of concrete.

The carbonation resistance of concrete can be improved by adding the appropriate amount of steel fibers. Pan [21] conducted an experimental study on the carbonation performance of steel fibers reinforced concrete, and found that the addition of steel fibers optimizes the pore structure of concrete and improves the carbonation resistance of concrete. Zhang et al. [22] studied the influence of steel fibers dosage on the carbonation performance of HPC through a rapid carbonation test. The results showed that the addition of steel fibers could improve carbonation resistance of concrete and reduce carbonation rate, and the inhibition of carbonation was more obvious when the dosage of steel fibers was 2.0%. Miao [23] carried out the rapid carbonation test of steel fibers concrete, and the results showed that adding steel fibers into concrete improves the micro-pore structure of concrete and makes the internal structure more compact. When the steel fiber content varies from 0 to 2%, the carbonation resistance of concrete is best with a content of 1.5%. Table 1 and Figure 4 show the pore structure parameters and carbonation depth of concrete with different steel fiber contents [24]. When the fiber content is 0–1.5%, with the increase in fiber content, the total porosity, total pore volume, and total pore area decrease, and the pore structure of the concrete matrix develop in a better direction, and the carbonation depth also decreases. When the fiber content is 1.5%, the concrete has the optimal pore structure, the total porosity decreases by 32.13% compared with ordinary concrete, the total pore volume and area decrease by 28.54 and 42.78%, respectively, and the carbonation rate is the lowest. Therefore, it can be seen that the optimal steel fiber content is 1.5%.

Steel fiber reinforced concrete pore structure parameters [24]

| Dosage | 0 | 0.5% | 1% | 1.5% | 2% |

|---|---|---|---|---|---|

| Total porosity/% | 15.22 | 14.17 | 12.69 | 10.33 | 14.60 |

| Total pore volume (mL·g−1) | 0.0785 | 0.0664 | 0.0620 | 0.0561 | 0.0681 |

| Total pore area (m2·g−1) | 23.63 | 19.39 | 17.04 | 13.52 | 18.21 |

![Figure 4

Carbonation depth curve of concrete with different steel fiber contents [24].](/document/doi/10.1515/rams-2022-0049/asset/graphic/j_rams-2022-0049_fig_004.jpg)

Carbonation depth curve of concrete with different steel fiber contents [24].

The addition of fly ash will reduce the carbonation resistance of concrete. The addition of fly ash reduces the ability of cementation materials to produce Ca(OH)2, and its secondary hydration consumes the generated Ca(OH)2, which reduces the basicity of concrete, and thus weakens the carbonation resistance of concrete [25,26,27,28]. For example, the experimental results of Liu et al. [29] showed that with the increase in the amount of fly ash, the carbonation depth of concrete increases gradually, and the growth rate is faster in the early stage (Figure 5). Zhang et al. [30] found that the addition of fly ash has a great influence on the carbonation depth, and the greater the fly ash dosage, the deeper the carbonation depth. Byfors [31] found that the carbonation rate of fly ash concrete is higher than that of ordinary concrete. Liu and Zhu [32] and Zhao et al. [33] found that both the carbonation depth and carbonation rate of concrete increased with the increase in the fly ash content.

![Figure 5

Relationship between carbonation depth and carbonation age [29].](/document/doi/10.1515/rams-2022-0049/asset/graphic/j_rams-2022-0049_fig_005.jpg)

Relationship between carbonation depth and carbonation age [29].

The addition of an appropriate amount of nanomaterials is beneficial to improve the carbonation resistance of concrete. Wang [34] and Zhang et al. [35] studied the effect of different dosages of nano-SiO2 on the carbonation resistance of concrete, and the results showed that nano-SiO2 with a certain dosage range could improve the carbonation resistance of concrete, but if it is excessive, it will be detrimental to the carbonation resistance of concrete. Gu et al. [36] conducted a 180 days carbonation test on nano-TiO2 concrete and found that no carbonation was detected in any of the specimens. Zhang [37] found through research that the appropriate amount of nano-TiO2 can reduce the carbonation depth of concrete at each age, and the optimal amount is 1%. At the same time, there is a critical value of nano-TiO2, i.e., 3%, when the dosage exceeds the critical value, the carbonation depth of concrete will increase. Li et al. [38] carried out a carbonation test on nano-CaCO3 concrete, and tested the microscopic pore structure of concrete by mercury intrusion porosimetry. It is found that nano-CaCO3 filled pores and promoted hydration, reduced porosity, and refined micro-pores. And 3% is the best dosage to improve the carbonation resistance of concrete.

It can be seen that the addition of steel fibers, fly ash, and nanomaterials can both improve the pore structure of concrete and make the internal structure of concrete more compact. The active effect of fly ash and nanomaterials can also promote the hydration of cement, thus improving the carbonation resistance of concrete.

2.3 Research status of concrete dry–wet cycles

In the dry–wet cycles, the deformation of concrete exhibits the characteristics of dry shrinkage and wet expansion, that is, the concrete shrinks in the dry stage, while it expands in the wet stage [39]. After a complete dry shrinkage and wet expansion process, concrete will produce irreversible deformation, resulting in micro-cracks in concrete. After several dry–wet cycles, micro-cracks continue to expand, forming a continuous reticular hole structure system, resulting in macroscopic cracking of concrete and reducing its long-term performance [40]. Table 2 shows the changes in the percentage of various types of holes in concrete samples with the number of cycles [41]. In the early stage of dry–wet cycles, the cement particles are hydrated, and the hydration products fill the original large pores, resulting in a decrease in the proportion of harmful pores and multi harmful pores, and an increase in the proportion of innocuous pores and less harmful pores. With the increase in dry–wet cycles, the damage caused by it accumulates, which makes the proportion of harmful holes in concrete to increase and harmless holes to decrease, and finally shows the characteristics of pore coarsening.

Percentage of various types of holes in concrete at different dry–wet cycles [41]

| Number of dry–wet cycle | Sample number | Porosity (%) | Innocuous pore (<20 nm) (%) | Less harmful pore (20–50 nm) (%) | Harmful pore (50–200 nm) (%) | Multi harmful pore (>200 nm) (%) |

|---|---|---|---|---|---|---|

| 0 | 1 | 4.9986 | 17.35 | 27.93 | 36.02 | 18.70 |

| 10 | 2 | 2.4948 | 23.23 | 33.18 | 25.66 | 17.93 |

| 20 | 3 | 2.8318 | 20.45 | 20.70 | 26.46 | 32.39 |

| 40 | 4 | 3.6293 | 19.32 | 13.48 | 27.05 | 40.15 |

Chen et al. [42] showed that, after dry–wet cycles, the dynamic elastic modulus of concrete decreases and tends to be stable, and the weight loss rate of concrete increases and gradually slows down. Li et al. [43] explored the main mechanism of water migration on the concrete surface under dry–wet cycle conditions through theoretical derivation and numerical analysis. Zhang et al. [44,45] conducted experimental studies and numerical simulations on the dry-shrinkage and wet-expansion characteristics and internal moisture distribution of concrete under the action of dry–wet cycles, and concluded that the internal relative humidity of concrete changes periodically during the dry–wet cycles. When the concrete is wet, the internal humidity increases rapidly in a short time, and then the relative humidity reaches a stable level; during the drying process, the internal relative humidity does not drop immediately, but gradually decreases.

In domestic and foreign research works, the study of dry–wet cycles are often accompanied by the study of harmful salts erosion. Concrete is a porous hydrophilic material into which all soluble salts can penetrate and transform into volume-expanding crystals under certain humidity and temperature. When the salt solution is in contact with the surface of concrete, the solution rises to the surface of concrete along the capillary. When water evaporates, salt in the corrosion solution reaches supersaturation and precipitates crystals in the capillary. Because of the precipitation crystallization of salt, the expansion force causes the concrete hole wall to bear great compressive stress, thus accelerating the destruction of concrete. Studies have shown that in the repeated dry–wet cycles of salt solution, concrete will undergo serious physical corrosion of salt crystallization, as well as chemical corrosion caused by the interaction of various particles, which makes the corrosion process extremely complex [46].

Among the studies on concrete deterioration under the combined action of dry–wet cycles and corrosive medium, sulfate dry–wet cycles are the most widely studied. For example, Cody et al. [47] found that the corrosion rate of sulfate in concrete specimens under dry–wet cycles is much faster than that of solution-soaked concrete, which is because the dry–wet cycles aggravate the crystalline expansion of salt, thereby accelerating the destruction of concrete [48,49,50]. Yuan et al. [51] believed that the dry–wet cycles changed the migration patterns and erosion process of sulfate in concrete, which aggravated the deterioration of concrete performance. He et al. [52] studied the damage mechanism of concrete under the action of sulfate attack and dry–wet cycles, and found that the dry–wet cycles accelerated the physical crystallization and dissolution of sulfate, and aggravated the damage and deterioration of concrete.

The addition of fibers can improve the resistance to dry–wet cycles of concrete. Fu [53] found that adding PP fibers effectively improved the dry–wet resistance of concrete, and the optimal dosage is 2%. Li and Zhang [54] studied the sulfate erosion resistance of basalt–PP hybrid fibers reinforced concrete under the action of dry–wet cycles. The results showed that fibers blending can improve the balance of three-dimensional distribution of fibers and the coordination between aggregate and fibers from different levels. It makes the concrete denser, and has a significant improvement effect on the concrete’s resistance to sulfate dry–wet cycles damage.

Adding fly ash into concrete can improve concrete’s resistance to dry–wet cycles. Liu et al. [55] discussed the damage degree of fly ash concrete and found that adding fly ash can improve the dry–wet cycle resistance of concrete, and 20% fly ash has the most significant effect on improving the resistance of the dry–wet cycle. Zhang et al. [56] conducted exposure tests in the natural tidal environment, measured the microstructure parameters of fly ash concrete after different exposure times, and found that fly ash effectively reduced the porosity of concrete and improved its pore size distribution. A denser pore structure is formed, which improves the durability of concrete.

The dry–wet cycling resistance of concrete can be improved by adding nanomaterials. Li and Gao [57] showed that the corrosion resistance of concrete mixed with 1% nano-CaCO3 was greatly improved after dry–wet cycles in a corrosive salt solution. The addition of nano-SiO2 reduced the formation of Ca(OH)2 and the alkalinity of cement slurry delayed the crystallization of ettringite and gypsum, and improved the corrosion resistance of concrete. Huo and Ding [58] studied the influence of nano-CaCO3 on the dry–wet cycles performance of recycled concrete, and the study showed that nano-CaCO3 improved the compactness of recycled concrete and thus improved its dry–wet cycles resistance. It can be seen that adding nanomaterials into concrete can improve the dry–wet cycles resistance of concrete to a certain extent.

Although a lot of achievements have been made in the research on the dry–wet cycles of concrete, the dry–wet cycle methods involved in these research works are self-developed and there is no unified standard. Due to different test methods, the comparability between these test results is poor. Now some scholars began to explore the dry–wet cycles system. Qiao et al. [59] studied the influence of dry–wet cycles on sulfate erosion of concrete, and the results showed that the shorter the dry–wet cycles period, the faster the concrete deterioration rate. Guo et al. [60] designed four different dry–wet ratios and conducted a study on the dry–wet cycles system of concrete based on sulfate erosion, and found that the wetting process and the drying process affect each other. The increase in wetting time can make the micro-pores and micro-cracks in concrete fill with expansion products earlier, while the increase in drying time can make the crystal growth to generate a greater crystallization pressure, and the interaction between the two will eventually lead to the deterioration of the concrete.

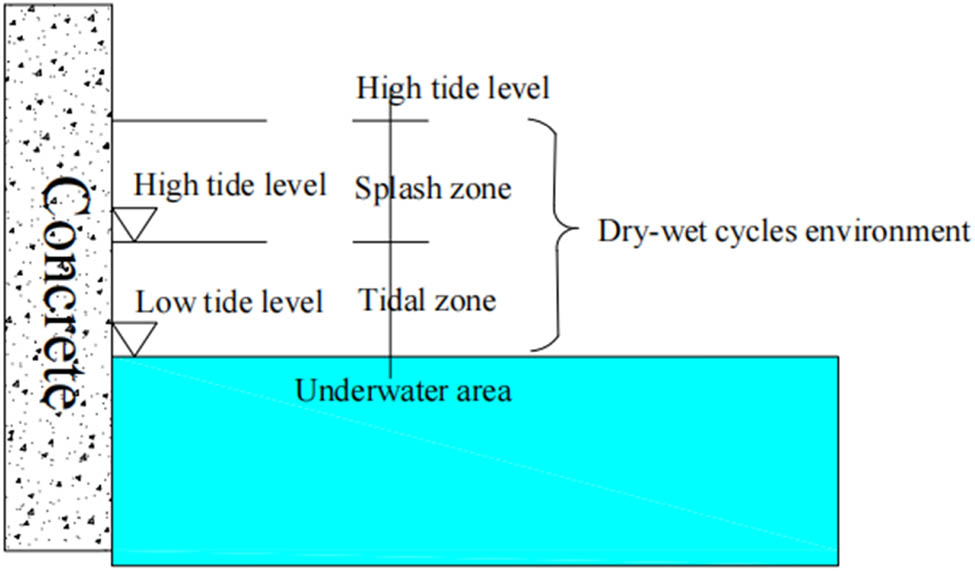

2.4 Research status of Cl− erosion of concrete under dry–wet cycles condition

Concrete structures in the ocean can be divided into underwater zone, tidal zone, splash zone, and atmospheric zone according to their contact with sea water (Figure 6), and different zones suffer from different degrees of Cl− erosion. The concrete structures in the tidal zone are in a saturated, semi-saturated, and dry state due to the alternation of dry and wet conditions, and at the same time, it is eroded by Cl− in seawater, which greatly accelerates the damage of concrete structures.

Schematic diagram of marine concrete service environment.

Studies have shown that the dry–wet cycles accelerate the Cl− infiltration into concrete structures. Zhang and Yu [61] took salt lake brine as erosion medium and carried out dry–wet cycle tests. The results showed that the diffusion rate of Cl− into concrete is accelerated by the dry–wet cycles. The increase in the number of wet–dry cycles resulted in the decrease in Cl− diffusion velocity as a power function. Hua et al. [62] showed that the increase in the number of dry–wet cycles significantly aggravated the diffusion process of Cl−. When the number of dry–wet cycles reached 300, the erosion of Cl− would lead to rapid and obvious degradation of the performance of concrete beams. Ye et al. [63] measured the Cl− invasion in outdoor concrete exposed to the marine environment for a long time, and found that the service life of concrete in the underwater area was longer than that in the splash area. Li and Li [64] conducted a test of Cl− transport in concrete under alternating dry and wet conditions. The study showed that Cl− intrusion in concrete under alternating dry and wet conditions is much more serious than permanently immersed in chloride solution. Lin and Liu [65] carried out a study on Cl− transportation in concrete under alternate wet and dry conditions, and found that the Cl− concentration in the alternating wet and dry environment is much higher than that when the concrete has been in contact with salt water. Hu and Du [66] studied the effect of Cl− infiltration resistance of concrete under the coupled action of chloride salts and dry–wet cycles, and found that the Cl− diffusion rate in concrete under alternating wet and dry environment is much higher than that when the concrete has been in contact with the solution. This further indicates that the dry–wet cycles accelerate the corrosion of concrete by Cl−.

However, some scholars believe that the dry–wet cycles improve the Cl− infiltration resistance of concrete. For example, Wang et al. [67] introduced “concrete pore sinuosity” to represent the pore structure characteristics of concrete, which is defined as the ratio of pore specific surface area to pore volume, reflecting the tortuosity of microscopic pores inside the material, as shown in equation (1):

where PSI is the pore sinuosity (106 m−1); SSA is the specific surface area (m2·g−1); and VC is the void content (cm3·g−1).

For pores of the same volume, a large porosity sinuosity indicates that the pores are long and thin, while small porosity sinuosity indicates that the pores are short and thick. There is a negative correlation between concrete pore sinuosity and concrete Cl− diffusion coefficient, that is, the greater the concrete pore sinuosity of concrete, the better the Cl− permeability resistance. Through experiments, it is found that the dry–wet cycles promote the increase in pore sinuosity, prolong the Cl− permeation path, and improve the Cl− permeation resistance of concrete. Mo and Zhu [68] used the unsteady Cl− migration coefficient to characterize the Cl− infiltration resistance of concrete under dry–wet cycle conditions, and obtained the same results as the literature [67]. At present, due to the differences in test conditions, analysis methods, and test methods, a unified view has not been formed at home and abroad. Besides, the differences in test conclusions are obvious, so the research results have little reference value. Therefore, it is necessary to conduct a standardized study on concrete durability under the joint action of the two, propose a standard test method, provide a basis for future test data sharing, and conduct regular verification of each test result according to the standard.

Adding an appropriate amount of fibers into concrete can improve the Cl− permeability resistance of concrete under wet–dry cycle conditions. Sun et al. [69] found in their study that PP fibers can significantly reduce the number of harmful pores in concrete, and its hydrophobicity can inhibit the migration of Cl− with water, so that concrete shows good resistance to dry–wet cycles and Cl− erosion. Wang [70] adopted the dry–wet cycles method to simulate the marine environment and came to the conclusion after analyzing the test results: the addition of PP fibers has a great influence on the pore structure of concrete. Adding 0.1% PP fibers to concrete can greatly improve the concrete’s ability to resist chlorine salt dry–wet cycles damage; however, adding excess PP fibers (with a content of more than 0.3%) will reduce this ability. The results showed that under the same dry–wet cycles, the improvement effect of fibers on the Cl− permeability of concrete increases first and then decreases with the increase in fibers’ dosage. With the increase in dry–wet cycles period, the maximum immersion depth and free Cl− content of concrete with the same fiber content increased. Wei [71] studied the Cl− diffusion properties of fiber-reinforced concrete under the action of alternating dry and wet conditions and found that compared with plain concrete, the addition of steel fibers and imitation steel fibers has an inhibitory effect on the permeability of Cl− in concrete, but excessive fiber content will increase the Cl− diffusion coefficient and reduce the Cl− erosion resistance of concrete.

The addition of fly ash can improve the Cl− permeability resistance of concrete under dry–wet cycle conditions. Gao et al. [72] studied the effect of fly ash dosage on the Cl− diffusivity of concrete based on the field exposure test in the natural tidal environment, and found that the Cl− apparent diffusion coefficient of concrete and instant diffusion coefficient decreases with the increase in fly ash dosage, which indicates that the Cl− resistance of fly ash concrete is stronger in the early stage, and is gradually weakened in the later stage. Zhang et al. [73] and Petcherdchoo [74] found that the addition of fly ash can effectively reduce the concentration of Cl− in concrete through field exposure tests under the environment of marine tidal. Chen et al. [75] found that the Cl− transport rules of fly ash concrete changed significantly under the action of dry–wet cycles, from the original diffusion-based transport form to the capillary action-based transport form.

An appropriate dosage of nanomaterials can improve the Cl− infiltration resistance of concrete under dry–wet cycle conditions. Zhang and Sun [76] studied the Cl− permeability resistance of nano-concrete under the action of dry–wet cycles, and showed that the dry–wet cycles accelerated the migration of Cl− in marine concrete, and nanomaterials could improve the Cl− resistance of concrete under the action of dry–wet cycles. Han et al. [77] found that the addition of nano-modified mineral admixtures can effectively reduce the porosity of concrete, improve the binding capacity of Cl−, and reduce the influence of dry–wet cycles on concrete. Ji et al. [78] studied the durability of nano-SiO2 modified concrete under the combined action of dry–wet cycles and salt-bine solution immersion. The results showed that the Cl− permeability coefficient decreases gradually with the increase in nano-SiO2. When the nano-SiO2 dosage is 2%, the Cl− permeability coefficient of concrete is reduced by 55% compared with the reference sample. When the content exceeds 2%, the improvement effect does not change significantly.

The combined action of dry–wet cycles and Cl− erosion accelerates the deterioration of concrete compared to that due to the action of each individually. However, there is still controversy about the effect of dry–wet cycles on the Cl− permeability of concrete. A large number of studies have shown that the appropriate dosage of fibers, fly ash, and nanomaterials can significantly improve the Cl− erosion resistance of concrete.

2.5 Research status of concrete carbonation under dry–wet cycle conditions

Under the influence of ocean tides, concrete is susceptible to damage by dry–wet cycles. Under the condition of dry–wet cycles, due to the capillary siphon effect, the migration of external harmful ions to the interior of the concrete is accelerated, causing damage to concrete, thereby accelerating the carbonation process of concrete. At the same time, under the action of dry–wet cycles, the crystalline stress generated by cement hydration is easy to accumulate in concrete, resulting in the generation of micro-cracks, deteriorating the pore structure, and reducing the carbonation resistance of concrete [79].

Adding an appropriate amount of fly ash into concrete can reduce the effect of dry–wet cycles on carbonation of concrete. Feng et al. [80] found in the study on the durability of fly ash concrete under dry–wet–carbonation coupled damage, adding fly ash would reduce the alkalinity of concrete and change its internal pore structure, and the carbonation resistance of concrete would decrease with the increase in fly ash. The carbonation depth of concrete increases with the number of dry–wet cycles and presents different power function relationships with the number of cycles (Figure 7). Wu [81] conducted a carbonation test of fly ash concrete under the action of dry–wet cycles. The results showed that with the increase in the number of dry–wet cycles, the carbonation depth increased in a power function. Zheng et al. [82] studied the durability of high-dosage fly ash concrete under the coupled action of dry–wet cycles and carbonation, and the results showed that the coupling effect caused further damage to the concrete, and the addition of a large amount of fly ash would reduce the carbonation resistance of concrete. Xu et al. [79] simulated the ocean tidal environment and studied the carbonation behavior of concrete with different mix ratios under dry–wet cycle conditions. The results showed that the dry–wet cycles accelerated the carbonation process of concrete. However, the addition of fly ash can reduce the influence of dry–wet cycles on the carbonation resistance of concrete.

![Figure 7

Curve of carbonation depth of fly ash concrete [80].](/document/doi/10.1515/rams-2022-0049/asset/graphic/j_rams-2022-0049_fig_007.jpg)

Curve of carbonation depth of fly ash concrete [80].

It can be seen that the dry–wet cycles will accelerate the carbonation of concrete and cause further damage to concrete. The addition of fly ash can significantly improve the internal pore structure of concrete and weaken the effect of the dry–wet cycles on the carbonation resistance of concrete. At present, there is no report on fibers and nanomaterials to improve the carbonation resistance of concrete under dry–wet cycle conditions. In addition, the current research on concrete under the combined action of dry–wet cycles and carbonation are all laboratory experiments, and some experiments are greatly affected by human factors, and there are many accidental factors, which cannot guarantee the accuracy of the test results. Therefore, it is necessary to carry out finite element simulation research on concrete under the interaction of dry–wet cycles and carbonation, explore the change law of concrete microstructure and internal deterioration mechanism under the coupling of the two, verify the results of simulation test and theoretical analysis, and improve the reliability of the results.

2.6 Research status of concrete under the combined action of Cl− erosion and carbonation

With the development and construction of coastal areas, the high concentration of CO2 in the air and Cl− in seawater make the service environment of concrete structures worse. Many scholars have carried out extensive research on the durability of concrete structures under the combined action of Cl− erosion and carbonation.

Some scholars believe that carbonation of concrete hinders the diffusion of Cl−. Tumidajski and Chan [83] found that the presence of CO2 reduced the diffusion performance of Cl− in ordinary concrete by immersing concrete in a sulfate–chloride composite solution flushed with CO2 gas. Puatatsananon and Saouma [84] used the method of alternating chloride salt solution immersion and carbonation test to simulate the marine environment, and studied the effect of carbonation on Cl− erosion. It is believed that carbonation generates calcium carbonate, which reduces the pores of concrete, thereby hindering Cl− diffusion in concrete. Zheng et al. [85] obtained the same result through research: carbonation reduces the internal porosity of concrete, improves the compactness of concrete, and reduces the Cl− diffusion coefficient. Chindaprasirt et al. [86] studied the effect of CO2 on the Cl− permeability coefficient and Cl− diffusion coefficient of cement mortar, and found that carbonation slowed down the diffusion of Cl−. Goñi and Guerrero [87] conducted an accelerated carbonation test on Friedel salt in cement slurry containing 3% NaCl, and found that although carbonation decomposed Friedel salt, the free Cl− content did not increase significantly, indicating that carbonation hinders the diffusion of Cl−. Hassnan [88] carbonated the cement paste first and then immersed it in chloride salt solution, and found that the ability of the test block after carbonation to combine with Cl− was almost zero, which further demonstrated that carbonation hindered the diffusion of Cl− in concrete.

Other scholars believe that carbonation of concrete promotes the diffusion of Cl−. Papadakis et al. [89] showed through the carbonation experiment of concrete mixed with a certain amount of chloride salt that carbonation promotes the decomposition of Friedel salt and accelerates the penetration of Cl− in concrete. Suryavanshi and Narayan [90] found that under carbonation, chlorides in Friedel salts are released into the pore solution, so steel bars have a higher risk of corrosion in chloride-contaminated concrete structures. Niu and Sun [91] conducted an alternate test between salt solution immersion and carbonation of concrete, and studied the influence of carbonation on Cl− diffusion in concrete. The results showed that carbonation accelerates the diffusion rate of Cl− in concrete and increases the content of Cl− in concrete. Although carbonation will release free Cl− from partially bound Cl− and increase the free Cl− content in concrete, the results show that the increase in Cl− is mainly due to the redistribution of concrete microstructure caused by carbonation. This has also been confirmed by some scholars. Su [92] tested the pore structure of carbonated and uncarbonated concrete at 28 days and found that the porosity of concrete decreased after carbonation, from 6.8628% before carbonation to 6.8107%. However, the average pore size and the most probable pore size of concrete after carbonation increased from 38.68 and 20.05 nm before carbonation to 45.71 and 33.52 nm, respectively. The diffusion rate of Cl− in concrete is proportional to the square of concrete pore size [93], so carbonation accelerates the diffusion rate of Cl−, thereby increasing the Cl− content in concrete. Jin [93] immersed the carbonated concrete in a corrosive solution and found that carbonation increases the Cl− content in concrete and the concrete Cl− apparent diffusion coefficient, and the change range becomes larger with the increase in carbonation time. Sun [94] studied the degradation mechanism of concrete under the alternating action of carbonation and Cl− erosion, and confirmed that carbonation accelerates the diffusion of Cl− in concrete. Wang et al. [67] discussed the relationship between carbonation resistance and Cl− permeability resistance of concrete, and analyzed it by using the concept of “concrete pore tortuosity.” The results showed that the increase in carbonation depth would reduce the Cl− diffusion coefficient and enhance the Cl− permeability resistance of concrete. Wan [95] believed that the main reason for the influence of carbonation on Cl− erosion was the change in the concrete pore structure. The test showed that carbonation increases the Cl− diffusion coefficients of both concrete and mortar. Since the hardened cement paste in mortar is more concentrated, the increase in the proportion of macropores caused by carbonation of mortar is more obvious, and the Cl− permeability is greatly improved. Recent studies have shown [96,97,98] that although the total porosity of the carbonated concrete decreases, the most probable pore diameter increases, which improves the connectivity of the internal pores and makes Cl− more permeable.

At present, there is no unified conclusion on the effect of concrete carbonation on Cl− diffusion, and the research on the coupling of the two is still insufficient and needs to be further improved. Most of the experimental studies mainly focus on the effect of concrete carbonation on chloride ion erosion, while the research on the effect of chloride ion erosion on carbonation is lacking. However, for the marine environment, chloride ion erosion is the main cause of concrete durability problems. Therefore, it is very necessary to study the influence of chloride ion erosion on carbonation, and it is suggested that simulation tests and theoretical analysis should be carried out in the future.

2.7 Research status of concrete durability under the combined action of dry–wet cycles, Cl− erosion, and carbonation

In practical engineering, the service environment of marine concrete is complex, and it is not affected by a single factor. The marine concrete located in the tidal area is most commonly affected by dry–wet cycles, Cl− erosion, and carbonation. The durability research under the combined action of dry–wet cycles, Cl− erosion, and carbonation is rarely reported.

The combined action of the three factors makes the deterioration law of marine concrete more complicated. Qian et al. [99] carried out a carbonation and chlorine salt dry–wet cycles test on HPC specimens of marine concrete structures, and the test results showed that under the carbonation and chlorination dry–wet cycles, the compressive strength of concrete increases first and then decreases, and long-term carbonation would cause the decrease in the compressive strength. There is a critical carbonation depth which is related to the compressive strength, carbonation will increase the compressive strength before reaching the critical carbonation depth, and decrease the compressive strength after reaching the critical carbonation depth. Fan [100] conducted a study on the mechanical properties and microstructure of concrete under the coupled action of chloride salt dry–wet cycles and carbonation. The cured specimens were subjected to chloride salt dry–wet cycles first, and then the specimens were taken out and placed in a carbonation box for carbonation. The research results showed that after the coupling effect of dry–wet cycles and carbonation, the elastic modulus of concrete decreases, and the pore size distribution curve of concrete deviates to the direction of large pore size, which is mainly caused by the influence of the dry–wet cycles of chloride salt. Yuan et al. [101] carried out the Cl− erosion test of carbonated concrete under the mechanism of the dry–wet cycle, and the results showed that carbonation increased the content of free Cl− in concrete, slowed down the decay of Cl− concentration, and adversely affected the Cl− erosion resistance of concrete. Through SEM analysis, it is found that carbonation reaction has a certain deterioration effect on the microstructure of concrete, which will accelerate the invasion of harmful media. Reducing the water–binder ratio can significantly improve the compactness of concrete, enhance the resistance to Cl− erosion of concrete, and reduce the aggravation of Cl− erosion caused by carbonation reaction.

Although the above research carried out the concrete durability test under the combined action of three factors, the number of test cycles was small and the period was short, which could not effectively simulate the real marine atmospheric environment. It is recommended to carry out a long-term indoor simulation test and seaside exposure test, and compare the indoor test data with the test data of the real environment, to improve the indoor accelerated test and simulate the real environment to the maximum extent. At the same time, it is also proposed to carry out a correlation study between the deterioration of concrete caused by artificial accelerated tests and natural environment, to lay a foundation for improving the effectiveness of the accelerated test results in the evaluation of concrete durability in the marine environment in the future.

In summary, the effects of various admixtures on the durability of concrete are summarized in Table 3.

Influence of admixture types on concrete properties

| Admixture | Resistance to Cl− erosion | Resistance to carbonation | Resistance to dry–wet cycles | |

|---|---|---|---|---|

| Fly ash | ↑ | ↓ | ↑ | |

| Fiber | Steel fiber | ↑ | ↑ | ↑ |

| Polyethylene fiber | ||||

| Basalt fiber | ||||

| Basalt–PP fiber | ||||

| Nanomaterial | Nano-SiO2 | ↑ | ↑ | ↑ |

| Nano-TiO2 | ||||

| Nano-CaCO3 | ||||

| MWCNT | ||||

Note: “↑” means “improve,” “↓” means “reduce.”

3 Measures to enhance durability of marine concrete

The durability of concrete structures is the result of a combination of internal and external factors. In addition to adding admixtures, the following measures can also be adopted to improve the durability of concrete:

Control the water–cement ratio. Generally speaking, the smaller the water–cement ratio of concrete, the better its mechanical properties and durability. This is because the water consumption required for cement hydration is far less than the actual mixing water consumption, and the excess water will form capillary channels after the cement hardens. And the larger the water–cement ratio, the denser the capillary channels and the larger the average pore size, which in turn affects the strength, permeability, and later drying shrinkage of concrete. At present, the method of reducing the water–cement ratio is generally used in engineering to improve the durability of marine concrete. However, if the water–cement ratio is too low, the workability of the concrete will be deteriorated, and the cohesion will be too large, making it difficult to remove air bubbles in the concrete, which will reduce the durability of the concrete and significantly increase the project cost.

Appropriately increasing the thickness of the concrete protective layer can effectively limit the carbonation of concrete and control the corrosion of chloride salts. Generally, the penetration depth of Cl− and the depth of carbonation are proportional to the square root of time. Therefore, increasing the thickness of the protective layer can prolong the penetration time of Cl− into the steel surface.

The use of resin, paint, asphalt tar, and other coatings can improve the compactness of the concrete surface, isolate the direct contact between the concrete and the outside world, and have a significant effect on preventing the carbonation of the concrete or the corrosion of Cl−.

4 Conclusion and prospects

In conclusion, the durability of concrete has attracted extensive attention from scholars at home and abroad. A lot of research has been done on Cl− erosion, carbonation, dry–wet cycles, and fruitful research results have been achieved. Compared with the action of a single factor, the deterioration of concrete under the action of multi-factors is more serious. Adding admixtures to concrete can improve the durability of concrete to a certain extent. For example, the addition of fly ash can improve the resistance of concrete to Cl− corrosion, but it is not good for the ability to resist carbonation; the addition of fibers can improve the ability of concrete to resist Cl− corrosion and carbonation; the addition of nanomaterials can enhance the resistance of concrete to Cl− corrosion, carbonation, and dry–wet cycles. However, due to the different test conditions and systems, there is no unified conclusion about the optimal dosage of various admixtures.

It is vital to improve the durability of marine concrete. In order to make the research results more effective to guide the design and construction of practical projects, there are still many key problems that need to be solved urgently:

At present, a large number of research works are still at the stage based on the action of a single environmental factor or two factors, and the research on the durability of concrete under the combined action of multi-factors is still relatively lacking. It is suggested that the deterioration law of concrete can be studied from the perspective of combined action of multi-factors in the future, so as to provide a reliable basis for improving the durability of concrete in practical applications.

At present, there have been a lot of achievements in macroscopic phenomenon research on concrete durability, but the hidden microscopic mechanism still remains to be further explored. It is suggested that the degradation law of concrete microstructure can be studied at the micro scale to provide a reliable basis for the degradation mechanism of concrete.

With the consumption of natural aggregates, especially the increasing shortage of freshwater and fine sand, the raw materials for cement-based materials need to have more choices and sources. For coastal and offshore buildings, the cost and difficulty of transporting fresh water and ordinary fine aggregates are very high, but these areas are rich in seawater and sea sand resources. If these raw materials can be effectively used to prepare seawater sea sand concrete, it can not only reduce construction costs, but also protect the ecological environment. However, the large amount of chloride salts contained in seawater and sea sand will affect the mechanical properties and durability of concrete, resulting in the development and utilization of seawater and sea sand is still in its infancy. In the future, the research on endogenous Cl− in seawater sea sand concrete should be strengthened, so as to promote the use of seawater sea sand concrete, alleviate the problem of insufficient resources of water and river sand in inland rivers, and truly take it from the sea and use it in the sea.

Concrete will be damaged by physical, chemical, and biological actions during its service, which will eventually lead to its deterioration. The mechanism of concrete deterioration caused by physical and chemical action has been widely studied; however, the deterioration of concrete durability caused by biological effects in marine environment is rarely explored by researchers. The macroscopic effects of algae and animals are more significant in the destruction of marine life. They can not only penetrate deep into the concrete and grow freely between cement and aggregate, causing the concrete to crack, but also produce biological acids, metabolites, and humic organic matter, which can also lead to the gradual deterioration of concrete durability, spalling of concrete, and corrosion of steel reinforcement. It will cause huge damage to the social economy and environment. Therefore, more attention should be paid to the destruction of marine organisms, and more reasonable, efficient, economical, and environmentally friendly anticorrosion control measures for marine concrete should be sought.

Acknowledgment

This work is financially supported by the National Natural Science Foundation of China. No. (52078109).

-

Funding information: This work is financially supported by the National Natural Science Foundation of China. No. (52078109).

-

Author contributions: Maohua Zhang: conceptualization, funding acquisition, and project administration; Ronghua Xu: writing – original draft, writing – review & editing, and investigation; Ke Liu: supervision, investigation, and resources; Shanghui Sun: supervision, investigation, and resources.

-

Conflict of interest: The authors declare that there is no conflict of interest.

References

[1] Hou, B. R., D. Zhang, and P. Wang. Marine corrosion and protection: current status and prospect. Chinese Academy Sciences, Vol. 3112, 2016, pp. 1326–1331 (in Chinese).Search in Google Scholar

[2] Berrocal, G. C., I. Löfgren, and K. Lundgren. The effect of fibres on steel bar corrosion and flexural behaviour of corroded RC beams. Engineering Structures, Vol. 163, 2018, pp. 409–425.10.1016/j.engstruct.2018.02.068Search in Google Scholar

[3] Frazao, C., A. Camoes, J. Barros, and D. Gonçalves. Durability of steel fiber reinforced self-compacting concrete. Construction Building Materials, Vol. 80, 2015, pp. 155–166.10.1016/j.conbuildmat.2015.01.061Search in Google Scholar

[4] Yehia, S., A. Douba, O. Abdullahi, and S. Farrag. Mechanical and durability evaluation of fiber-reinforced self-compacting concrete. Construction and Building Materials, Vol. 121, 2016, pp. 120–133.10.1016/j.conbuildmat.2016.05.127Search in Google Scholar

[5] Meng, L. Q. Experimental study on influence of steel fiber on the durability of high performance concrete. Master’s thesis, Henan Polytechnic University, 2019 (in Chinese).Search in Google Scholar

[6] Wang, Z. S., Y. K. Li, J. Wei, J. L. Lu, H. C. Guo, and J. B. Tian. Experimental study on corrosion behavior and mechanical properties of basalt fiber concrete by chlorine attack. Journal of Experimental Mechanics, Vol. 35, No. 6, 2020, pp. 1060–1070 (in Chinese).Search in Google Scholar

[7] Su, L., D. T. Niu, D. G. Hang, and Q. Fu. Chloride diffusion performance of basalt-polypropylene fiber reinforced concrete in marine environment. Journal of Building Materials, Vol. 11, No. 29, 2021, pp. 1–15 (in Chinese).Search in Google Scholar

[8] Liu, R., A. S. Durham, and K. L. Rens. Effects of post-mercury-control fly ash on fresh and hardened concrete properties. Construction and Building Materials, Vol. 25, No. 8, 2011, pp. 3283–3290.10.1016/j.conbuildmat.2011.03.016Search in Google Scholar

[9] Shaikh, F. U. A. and S. W. M. Supit. Compressive strength and durability properties of high volume fly ash (HVFA) concretes containing ultrafine fly ash (UFFA). Construction and Building Materials, Vol. 82, 2015, pp. 192–205.10.1016/j.conbuildmat.2015.02.068Search in Google Scholar

[10] Poon, C. S., L. Lam, and Y. L. Wong. A study on high strength concrete prepared with large volumes of low calcium fly ash. Cement and Concrete Research, Vol. 30, No. 3, 2000, pp. 447–455.10.1016/S0008-8846(99)00271-9Search in Google Scholar

[11] Fan, Z. H., H. C. Yang, and F. Yu. Durability test of high volume fly ash concrete based on long-term exposure test. Bulletin of The Chinese Ceramic Society, Vol. 39, No. 8, 2020, pp. 2622–2627 + 2649 (in Chinese).Search in Google Scholar

[12] Yang, H. C., Z. T. Hu, F. Yu, and Z. H. Fan. Field test and evaluation analysis on durability of fly ash concrete structures in seawater environment. The Ocean Engineering, Vol. 37, No. 2, 2019, pp. 1005–9865 (in Chinese).Search in Google Scholar

[13] Wang, J. D., M. Lv, Y. R. Zhang, J. Wu, and J. Z. Zhang. Research on correlation of permeability of fly ash concrete. Journal of Zhejiang University Technology, Vol. 48, No. 2, 2020, pp. 217–221 (in Chinese).Search in Google Scholar

[14] Nath, P. and P. Sarker. Effect of fly ash on the durability properties of high strength concrete. Procedia Engineering, Vol. 14, No. 3, 2011, pp. 1149–1156.10.1016/j.proeng.2011.07.144Search in Google Scholar

[15] Chithra, S., S. R. R. Senthil Kumar, and K. Chinnaraju. The effect of colloidal nano-silica on workability, mechanical and durability properties of high performance concrete with copper slag as partial fine aggregate. Construction and Building Materials, Vol. 1, No. 13, 2016, pp. 794–804.10.1016/j.conbuildmat.2016.03.119Search in Google Scholar

[16] Zhang, M. H. and L. Hui. Pore structure and chloride permeability of concrete containing nano-particles for pavement. Construction and Building Materials, Vol. 25, No. 2011, 2010, pp. 608–616.10.1016/j.conbuildmat.2010.07.032Search in Google Scholar

[17] Lei, Y. and X. Feng. Bilateral chloride diffusion model of nanocomposite concrete in marine engineering. Construction and Building Materials, Vol. 263, 2020, pp. 120634.10.1016/j.conbuildmat.2020.120634Search in Google Scholar

[18] Qian, K .L., T. Meng, X. Q. Qian, and S. L. Zhan. Research on some properties of fly ash concrete with nano-CaCO3 middle slurry. Key Engineering Materials, Vol. 405–406, 2009, pp. 186–190.10.4028/www.scientific.net/KEM.405-406.186Search in Google Scholar

[19] Shi, T., Q. F. Zhao, Z. J. Hu, and Y. M. Liu. Chloride ion penetration resistance of multi-walled carbon nanotubes reinforced concrete. Acta Materiae Compositae Sinica, Vol. 12, No. 1, 2021, pp. 1–11 (in Chinese).Search in Google Scholar

[20] Li, G. Y. and Z. K. Wang. Effect of CNTs on the corrosion performance of reinforced concrete. Journal of Huazhong University of Science and Technology (Natural Science Edition), Vol. 46, No. 3, 2018, pp. 103–107 (in Chinese).Search in Google Scholar

[21] Pan, H. M. Study on carbonation and steel-bar corrosion of steel-fiber reinforced concrete. Master’s thesis, Southwest Jiaotong University, 2006 (in Chinese).Search in Google Scholar

[22] Zhang, C. S., L. Q. Meng, A. Y. Ji, J. L. Liang, and L. L. Li. Mechanism study of steel fiber content on the carbonation resistance of high performance concrete. Bulletin of The Chinese Ceramic Society, Vol. 37, No. 10, pp. 3206–3212 (in Chinese).Search in Google Scholar

[23] Miao, Y. Y. Investigation of carbonation of steel fiber reinforced concrete. Master’s thesis, Xi’an University of Architecture and Technology, 2010 (in Chinese).Search in Google Scholar

[24] Wang, Y. Steel fiber reinforced concrete durability in the atmospheric environment based on multi-factor effects. Doctoral dissertation, Xi’an University of Architecture and Technology, 2011 (in Chinese).Search in Google Scholar

[25] Yang, H. M., H. Q. Yang, Y. C. Wang, and J. J. Yan. Experimental study of carbonation and frost resistance of concrete mixed with fly ash. Fly Ash, Vol. 22, No. 2, 2010, pp. 11–13 (in Chinese).Search in Google Scholar

[26] Yang, Q. R. and Q. B. Yang. Study on the carbonation performances of concrete with fly ash and air entraining agent. Fly Ash Comprehensive Utilization, Vol. 1, 2006, pp. 3–5 (in Chinese).Search in Google Scholar

[27] Gao, Y. M., H. S. Shim, and R. H. Hurt. Effects of carbon on air entrainment in fly ash concrete: the role of soot and carbon black. Energy Fuels, Vol. 11, No. 2, 1997, pp. 457–462.10.1021/ef960113xSearch in Google Scholar

[28] Zhou, Y., J. Zhou, M. X. Tang, P. Li, J. Q. Peng, C. Wang, et al. Influences of fly ash and slag powder on the chloride penetration resistance and carbonation resistance of concrete. Concrete, Vol. 7, 2021, pp. 60–64 (in Chinese).Search in Google Scholar

[29] Liu, H. F., H. J. Ma, N. Liu, B. Wu, H. Yang, and W. W. Yang. Influence of fly ash and desert sand on the carbonation resistance property of concrete. Bulletin of The Chinese Ceramic Society, Vol. 36, No. 11, 2017, pp. 3823–3828 + 3847 (in Chinese).Search in Google Scholar

[30] Zhang, Y., D. T. Niu, and S. B. Li. Experimental study on fly ash concrete carbonation. Science Technology and Engineering, Vol. 17, No. 27, 2017, pp. 275–278 (in Chinese).Search in Google Scholar

[31] Byfors, K. Carbonation of concrete with silica fume and fly ash. Nordic Concrete Research, Vol. 4, 1985, pp. 26–35.Search in Google Scholar

[32] Liu, J. Z. and L. Zhu. Study on carbonation resistance of fly ash concrete. China Concrete and Cement Products, Vol. 10, 2018, pp. 28–30 (in Chinese).Search in Google Scholar

[33] Zhao, Q. X., L. J. Qi, and H. M. Pan. Critical use level of fly ash based on the carbonation durability of concrete. Journal of Building Materials, Vol. 18, No. 1, 2015, pp. 118–122 (in Chinese).Search in Google Scholar

[34] Wang, H. G. Drying shrinkage and carbonation of pavement concrete with nano-particles. Master’s thesis, Northeast Forestry University, 2012 (in Chinese).Search in Google Scholar

[35] Zhang, P., K. X. Zhang, and S. D. Fu. Carbonation resistance and anti-permeability of nano-particles and steel fiber reinforced concrete. Journal of Civil Engineering and Management, Vol. 34, No. 2, 2017, pp. 73–76 (in Chinese).Search in Google Scholar

[36] Gu, C. P., Q. N. Wang, J. T. Liu, and S. Wei. The effect of nano-TiO2 on the durability of ultra-high performance concrete with and without a flexural load. Ceramics, Vol. 62, No. 4, 2018, pp. 374–381.10.13168/cs.2018.0033Search in Google Scholar

[37] Zhang, J. Experimental study on mechanical properties and micro structure of nano-TiO2 concrete after carbonation and freeze-thaw. Master’s thesis, Inner Mongolia University of Technology, 2021 (in Chinese).10.3390/ma14216568Search in Google Scholar

[38] Li, G., Z. Zhuang, Y. J. Lv, K. J. Wang, and H. David. Enhancing carbonation and chloride resistance of autoclaved concrete by incorporating nano-CaCO3. Nanotechnology Reviews, Vol. 09, No. 1, 2020, pp. 998–1008.10.1515/ntrev-2020-0078Search in Google Scholar

[39] Gao, Y., J. Zhang, and W. Sun. Concrete deformation and interior humidity during dry-wet cycles. Journal of Tsinghua University (Science and Technology), Vol. 52, No. 2, 2012, pp. 144–149 (in Chinese).Search in Google Scholar

[40] Wang, Q. and D. Y. Yang. Influence of the dry- wet circulation on the concrete sulfate attack. Concrete, Vol. 3, No. 27, 2008, pp. 22–24 (in Chinese).Search in Google Scholar

[41] Shao, H. J., Z. L. Li, S. P. Xiao, X. W. Yao, and N. Zhang. Mechanical properties and microstructure of concrete under drying-wetting cycles. Bulletin of The Chinese Ceramic Society, Vol. 40, No. 9, 2021, pp. 2948–2955 (in Chinese).Search in Google Scholar

[42] Chen, D. P., J. J. Zou, L. Zhao, S. D. Xu, T. F. Xiang, and C. L. Liu. Degradation of dynamic elastic modulus of concrete under periodic temperature-humidity action. Materials, Vol. 13, No. 3, 2020, id. 611.10.3390/ma13030611Search in Google Scholar

[43] Li, C. Q., K. F. Li, and Z. Y. Chen. Numerical analysis of moisture influential depth in concrete during drying-wetting cycles. Tsinghua Science and Technology, Vol. 5, 2008, pp. 696–701.10.1016/S1007-0214(08)70113-5Search in Google Scholar

[44] Zhang, J., Y. Gao, Y. D. Han, and W. Sun. Shrinkage and interior humidity of concrete under dry-wet cycles. Drying Technology, Vol. 30, No. 6, 2012, pp. 583–596.10.1080/07373937.2011.653614Search in Google Scholar

[45] Zhang, J., Y. Gao, and Y. D. Han. Interior humidity of concrete under dry-wet cycles. Journal of Materials in Civil Engineering, Vol. 24, No. 3, 2012, pp. 289–298.10.1061/(ASCE)MT.1943-5533.0000382Search in Google Scholar

[46] Li, G. H. Effect of nano-materials on durability of concrete. Doctoral dissertation, Southwest Jiaotong University, 2006 (in Chinese).Search in Google Scholar

[47] Cody, A. M., H. Lee, and R. D. Cody. The effects of chemical environment on the nucleation, growth, and stability of ettringite [Ca3Al(OH)6]2(SO4)3·26H2O. Cement Concrete Research, Vol. 34, No. 5, 2004, pp. 869–881.10.1016/j.cemconres.2003.10.023Search in Google Scholar

[48] Monteiro, J. M. P. and K. E. Kurtis. Time to failure for concrete exposed to severe sulfate attack. Cement Concrete Research, Vol. 33, No. 7, 2003, pp. 987–993.10.1016/S0008-8846(02)01097-9Search in Google Scholar

[49] Yu, H. F., Y. S. Tang, and L. M. Yang. Microstructural evolution of concrete under the attack of chemical, salt crystallization, and bending stress. Journal of Materials in Civil Engineering, Vol. 29, No. 7, 2017, pp. 411–419.10.1061/(ASCE)MT.1943-5533.0001869Search in Google Scholar

[50] Ma, H. Y., W. Gong, H. F. Yu, and W. Sun. Durability of concrete subjected to dry-wet cycles in various types of salt lake brines. Construction and Building Materials, Vol. 193, No. 12, 2018, pp. 286–294.10.1016/j.conbuildmat.2018.10.211Search in Google Scholar

[51] Yuan, X. L., B. X. Li, G. Cui, and S. C. Zhao. Analysis of damage mechanism for concrete exposed to wetting-drying and sulfate environment. Highway, Vol. 2, 2009, pp. 163–166 (in Chinese).Search in Google Scholar

[52] He, R., S. N. Zheng, V. Gan, Z. D. Wang, J. H. Fan, and Y. Shao. Damage mechanism and interfacial transition zone characteristics of concrete under sulfate erosion and Dry-Wet cycles. Construction and Building Materials, Vol. 255(C), 2020, pp. 119340.10.1016/j.conbuildmat.2020.119340Search in Google Scholar

[53] Fu, P. Change of mechanical properties of fiber reinforced concrete under the action of dry and wet cycles. Non-Metallic Mines, Vol. 43, No. 4, 2020, pp. 56–58 (in Chinese).Search in Google Scholar

[54] Li, Y. and S. Zhang. Resistance to sulfate attack of hybrid fiber concrete under dry-wet cycles. Journal of Northeastern University (Natural Science), Vol. 37, No. 6, 2016, pp. 895–898 + 903 (in Chinese).Search in Google Scholar

[55] Liu, Y., Z. K. Wang, Z. X. Li, and Q. L. Gao. Analysis on the damage degree of fly ash concrete under freeze-thaw-dry-wet coupling cycle. Concrete, Vol. 5, 2020, pp. 32–35 + 39 (in Chinese).Search in Google Scholar

[56] Zhang, J. Z., R. H. Fang, M. Lv, Y. R. Zhang, Y. H. Cao, and Y. H. Gao. Time dependent microstructure evolution of fly ash concrete in the natural tidal environment. Journal of Natural Disasters, Vol. 28, No. 5, 2019, pp. 9–16 (in Chinese).Search in Google Scholar

[57] Li, G. H. and B. Gao. Effect of NM level CaCO3 on performance of the concrete in drying-wetting cycle in corrosive environment. Journal of Chongqing Jiaotong University, Vol. 26, No. 2, 2007, pp. 131–135 (in Chinese).Search in Google Scholar

[58] Huo, J. M. and Q. Ding. Influence of nanomaterials on dry-wet corrosion cycle performance of rubber recycled concrete. China Concrete and Cement Products, Vol. 5, 2016, pp. 27–31 (in Chinese).Search in Google Scholar

[59] Qiao, H. X., D. S. Chen, Z. M. He, Q. Feng, and H. J. He. Assessment of the accelerated testing system of sulfate erosion for concrete of saline soil area. Concrete, Vol. 10, 2012, pp. 1–3 (in Chinese).Search in Google Scholar

[60] Guo, J. J., K. Wang, K. P. Chen, L. Yang, C. Wan, and H. Li. Research on dry-wet cycle system of concrete under sulfate attack. China Concrete and Cement Products, Vol. 8, 2021, pp. 19–23 + 27 (in Chinese).Search in Google Scholar

[61] Zhang, L. M. and H. F. Yu. Influence of dry-wet cycles on chloride diffusion coefficient. Journal of Hunan University (Natural Sciences), Vol. 41, No. 3, 2014, pp. 26–30 (in Chinese).Search in Google Scholar

[62] Hua, Y. T., S. P. Yin, Y. L. Yu, and S. Li. Research on chloride diffusion and flexural behavior of beams strengthened with TRC subjected to dry-wet cycles. Construction Building Materials, Vol. 229(C), 2019, id. 116906.10.1016/j.conbuildmat.2019.116906Search in Google Scholar

[63] Ye, H. L., N. G. Jin, X. Y. Jin, C. Q. Fu, and W. Chen. Chloride ingress profiles and binding capacity of mortar in cyclic drying-wetting salt fog environments. Construction and Building Materials, Vol. 127, 2016, pp. 733–742.10.1016/j.conbuildmat.2016.10.059Search in Google Scholar

[64] Li, C. Q. and K. F. Li. Chloride ion transport in cover concrete under drying-wetting cycles: theory, experiment and modeling. Bulletin of The Chinese Ceramic Society, Vol. 253, No. 4, 2010, pp. 581–589 (in Chinese).Search in Google Scholar

[65] Lin, G. and Y. H. Liu. Modeling chloride penetration into concrete under drying-wetting cycles. Wuhan Polytechnic University, Vol. 28, No. 3, 2009, pp. 68–71 (in Chinese).Search in Google Scholar

[66] Hu, Y. J. and Y. L. Du. Effect of mineral admixtures and water/binder ratios on the resistance to the chloride ions penetration into concrete. Applied Mechanics Materials, Vol. 1449, No. 99–100, 2011, pp. 758–761.10.4028/www.scientific.net/AMM.99-100.758Search in Google Scholar

[67] Wang, J. G., J. X. Zhang, Y. Y. Guo, and T. J. Zhou. Influence mechanism of different factors on chloride ion penetration of concrete. Concrete, Vol. 8, 2018, pp. 49–53 (in Chinese).Search in Google Scholar

[68] Mo, Y. Y. and H. Z. Zhu. Influence from normal dry-wet cycle on concrete mechanical performance and resistance to chloride ion penetration. Water Resources and Hydropower Engineering, Vol. 51, No. 7, 2020, pp. 171–176 (in Chinese).Search in Google Scholar

[69] Sun, R., D. M. Wang, Y. Gu. Effect of mineral admixture on the durability of concrete under the coupling of dry-wet cycles and chloride ions erosion. Abstract Collection of Papers of the Eighth Academic Conference of Cement Branch of China Portland Society, 2019, p. 71 (in Chinese).Search in Google Scholar

[70] Wang, L. Study on concrete durability of polypropylene fiber under wet and dry cycles. Master’s thesis. Xi’an University of Architecture and Technology, 2011 (in Chinese).Search in Google Scholar

[71] Wei, Y. X. Study on mechanical properties and chloride ion diffusion of fiber-reinforced concrete under wetting-drying cycles. Master’s thesis, Zhengzhou University, 2020 (in Chinese).Search in Google Scholar

[72] Gao, Y. H., X. Y. Zhou, M. Lv, Y. H. Zhang, and J. Z. Zhang. Time-dependent chloride diffusivity of fly ash concrete in marine tidal environment. Journal of Hydroelectric Engineering, Vol. 3810, 2019, pp. 14–23 (in Chinese).Search in Google Scholar

[73] Zhang, J. Z., J. Zhao, Y. H. Zhang, Y. H. Gao, and Y. Y. Zheng. Instantaneous chloride diffusion coefficient and its time dependency of concrete exposed to a marine tidal environment. Construction and Building Materials, Vol. 167, 2018, pp. 225–234.10.1016/j.conbuildmat.2018.01.107Search in Google Scholar

[74] Petcherdchoo, A. Time dependent models of apparent diffusion coefficient and surface chloride for chloride transport in fly ash concrete. Construction Building Materials, Vol. 38, No. 1, 2013, pp. 497–507.10.1016/j.conbuildmat.2012.08.041Search in Google Scholar

[75] Chen, S. D., W. Sun, H. F. Yu, and Y. S. Zhang. Research on chloride ions diffusion of fly ash concrete under drying and wetting cycle. Concrete, Vol. 11, 2011, pp. 1–3 + 7 (in Chinese).Search in Google Scholar

[76] Zhang, M. H. and Y. Y. Sun. Cl− penetration resistance of concrete with nano-particles under the action of dry-wet cycle. Journal of Harbin Institute of Technology, Vol. 51, No. 8, 2019, pp. 167–176.Search in Google Scholar

[77] Han, X. Q., S. L. Zhan, Q. Xu, X. D. Tang, L. B. Wang, and K. L. Qian. Effect of dry-wet cycling on resistance of concrete to chloride ion permeation erosion. Acta Materiae Compositae Sinica, Vol. 37, No. 1, 2020, pp. 198–204 (in Chinese).Search in Google Scholar

[78] Ji, Y., J. Zhang, Q. Song, H. M. Zhu, and C. C. Shang. Effect of nano-SiO2 on concrete performance in bittern corrosion environment. Bulletin of The Chinese Ceramic Society, Vol. 272, No. 5, 2019, pp. 1425–1432 (in Chinese).Search in Google Scholar

[79] Xu, W. B., B. Deng, C. Wang, Y. W. Fang, and W. Zhan. Simulation test study on concrete carbonation behavior in marine tidal conditions. Railway Engineering, Vol. 1, 2014, pp. 125–128 (in Chinese).Search in Google Scholar

[80] Feng, X. S., Z. K. Wang, X. J. Liu, X. N. Kang, and Y. Liu. Carbonation properties of fly ash concrete under different cyclic coupling damage. Journal of Agricultural University of Hebei, Vol. 43, No. 4, 2020, pp. 127–132 (in Chinese).Search in Google Scholar

[81] Wu, Y. C. Experimental study on carbonation behavior of fly ash concrete under complex environment. Jiangxi Hydraulic Science Technology, Vol. 45, No. 3, 2019, pp. 157–162 (in Chinese).Search in Google Scholar

[82] Zheng, W. W., J. M. Gao, B. Qi, and L. S. Ma. Durability of high-volume fly ash concrete under the coupled action of dry-wet cycle and carbonation. China Concrete and Cement Products, Vol. 22412, 2014, pp. 23–27 (in Chinese).Search in Google Scholar

[83] Tumidajski, P. J. and G. W. Chan. Effect of sulfate and carbon dioxide on chloride diffusivity. Cement and Concrete Research, Vol. 26, No. 4, 1996, pp. 551–556.10.1016/0008-8846(96)00019-1Search in Google Scholar

[84] Puatatsananon, W. and V. E. Saouma. Nonlinear coupling of carbonation and chloride diffusion in concrete. Journal of Materials in Civil Engineering, Vol. 17, No. 3, 2005, pp. 264–275.10.1061/(ASCE)0899-1561(2005)17:3(264)Search in Google Scholar

[85] Zheng, Y. L., J. Q. Zheng, and M. Zhang. Experimental study on effect of concrete carbonation degrees on chloride diffusion coefficient. Journal of Tongji University (natural science), Vol. 38, No. 3, 2010, pp. 412–416 (in Chinese).Search in Google Scholar

[86] Chindaprasirt, P., S. Rukzon, and V. Sirivivatnanon. Effect of carbon dioxide on chloride penetration and chloride ion diffusion coefficient of blended Portland cement mortar. Construction and Building Materials, Vol. 22, No. 8, 2008, pp. 1701–1707.10.1016/j.conbuildmat.2007.06.002Search in Google Scholar

[87] Goñi, S. and A. Guerrero. Accelerated carbonation of Friedel’s salt in calcium aluminate cement paste. Cement Concrete Research, Vol. 33, No. 1, 2003, pp. 21–26.10.1016/S0008-8846(02)00910-9Search in Google Scholar

[88] Hassnan, Z. Binding of external chloride by cement pastes. Doctoral dissertation, University of Toronto(Canada), 2001.Search in Google Scholar

[89] Papadakis, V. G., C. G. Vayenas, and M. N. Fardis. Fundamental modeling and experimental investigation of concrete carbonation. Aci Material Journal, Vol. 88, No. 4, 1991, pp. 363–373.10.14359/1863Search in Google Scholar

[90] Suryavanshi, A. K. and S. R. Narayan. Stability of Friedel’s salt in carbonated concrete structural elements. Cement and Concrete Research, Vol. 26, No. 5, 1996, pp. 729–741.10.1016/S0008-8846(96)85010-1Search in Google Scholar

[91] Niu, D. T. and C. T. Sun. Study on interaction of concrete carbonation and chloride corrosion. Bulletin of The Chinese Ceramic Society, Vol. 41, No. 8, 2013, pp. 1094–1099 (in Chinese).Search in Google Scholar

[92] Su, Q. Durability and life prediction of sea sand concrete structures under coastal environment (in Chinese, dissertation). Doctoral dissertation, Xi’ an University of Architecture and Technology, 2010 (in Chinese).Search in Google Scholar

[93] Jin, Z. Q., W. Sun, and Q. Y. Li. Effect of carbonation on chloride diffusion in concrete. Journal of University of Science and Technology Beijing, Vol. 8, 2008, pp. 921–925 (in Chinese).Search in Google Scholar

[94] Sun, C. T. Study on concrete and service life prediction based on chloride corrosion. Doctoral dissertation, Xi’ an University of Architecture and Technology, 2011 (in Chinese).Search in Google Scholar

[95] Wan, X. M. Deterioration mechanisms of reinforced concrete structures under combined mechanical and environmental action. Doctoral dissertation, Xi’ an University of Architecture and Technology, 2011 (in Chinese).Search in Google Scholar

[96] Zhang, P., T. J. Zhao, P. G. Guo, and F. H. Wittmann. Influence of freeze-thaw cycles and carbonation action on chloride penetration into concrete. Journal of Southeast University (Natural Science Edition), Vol. 36(S2), 2006, pp. 238–242 (in Chinese).Search in Google Scholar

[97] Yuan, C. F. and D. T. Niu. Research on the durability of fly ash concrete in marine atmospheric environment. Bulletin of The Chinese Ceramic Society, Vol. 31, No. 1, 2012, pp. 1–6 (in Chinese).Search in Google Scholar

[98] Ba, G. Z., Q. Su, T. J. Zhao, and L. S. Zhang. Effects of carbonation on chloride penetration in sea sand concrete. Journal of Qingdao Technological University, Vol. 32, No. 2, 2011, pp. 18–22 (in Chinese).Search in Google Scholar

[99] Qian, W. X., X. J. Chen, Y. B. Cai, and H. X. Zhuang. Carbonation properties of marine concrete under stress and chloride environment. China Concrete and Cement Products, Vol. 5, 2018, pp. 1–5 (in Chinese).Search in Google Scholar

[100] Fan, H. J. Study on the mechanical properties and microstructure of concrete under the coupling action of chloride dry-wet cycle and carbonation. New Building Materials, Vol. 47, No. 5, 2020, pp. 29–32 (in Chinese).Search in Google Scholar

[101] Yuan, C. F., D. T. Niu, and G. Z. Qi. Experimental study on chloride penetration into concrete after carbonation under wet and dry cycle mechanism. Journal of Xi’ an University of Aarchitecture and Technology (Natural Science), Vol. 44, No. 3, 2012, pp. 339–344 + 375 (in Chinese).Search in Google Scholar

© 2022 Maohua Zhang et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers

- A review on the properties of concrete reinforced with recycled steel fiber from waste tires

- Copper ternary oxides as photocathodes for solar-driven CO2 reduction

- Properties of fresh and hardened self-compacting concrete incorporating rice husk ash: A review

- Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey

- Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles

- Delivery systems in nanocosmeceuticals

- Study on the preparation process and sintering performance of doped nano-silver paste

- Analysis of the interactions between nonoxide reinforcements and Al–Si–Cu–Mg matrices

- Research Articles