Abstract

Recycled rubber particles can be produced by using waste tires. Adding recycled rubber particles to concrete can form rubber concrete (RC). RC can not only reduce the amount of natural sand and reduce the cost of concrete but also improve the static compressive toughness of concrete. Adding steel fiber into RC can improve the strength of concrete. In order to study the compressive toughness of steel fiber rubber concrete (SFRC), rubber particles washed with NaOH are added to steel fiber reinforced concrete. This can enhance the bonding performance between the recycled rubber particles and concrete. The volume ratio of recycled rubber is 5, 10, and 15%. Prismatic and cubic test blocks were prepared and their compressive tests were carried out. The results show that the stress interaction between the rubber particles and steel fiber in concrete significantly improves the compressive strength, elastic modulus, and stress–strain relationship of concrete. The compressive toughness and ductility of concrete are improved. When the content of rubber particles is 15–20%, the compressive toughness of SFRC is improved most obviously. Through experiments, the toughness index and specific toughness of rubber steel fiber reinforced concrete are calculated, which explores a new way and method for studying the compressive toughness of similar recycled material concrete.

1 Introduction

Waste tire is a kind of recyclable solid waste. Its reuse is the consensus of many countries and international organizations, such as WTO [1]. The treatment and utilization of waste tire can achieve the win-win goal of economic benefits and environmental protection [2]. At present, there are about 1.5 billion untreated waste tires in the world. China is a large country of automobile production and consumption [3]. According to the statistics of the United Nations Environment Programme, in 2021, Europe produced about 4 million tons of waste tires, North America produced about 15 million tons of waste tires, Japan produced about 3.5 million tons of waste tires, and China produced 9.5 million tons of waste tires [4]. The total amount of waste tires produced in the world is as high as 55 million tons. Among these waste tires, the reuse rate is 92% in Europe, 83% in North America, 75% in Japan, and only 50% in China [5]. Randomly stacking or simply burning waste tires not only occupies land resources, but also seriously pollutes the environment [6]. Processing waste tires into particles to form recycled rubber and adding recycled rubber to concrete can not only improve the toughness of concrete, but also replace fine aggregate, so as to reduce the damage of sand mining activities to the environment [7,8].

Adding rubber particles into concrete can improve plasticity and toughness, enhance energy dissipation capacity, and reduce compressive strength and elastic modulus [5,9,10,11,12]. Through the splitting tensile test, it is found that the toughness of the prismatic specimen mixed with rubber particles is significantly higher than that of plain concrete. Even if the specimen is cracked with small crack length, it is difficult to break [13,14,15,16]. The energy dissipation capacity of rubber concrete (RC) to dynamic load is obviously better than that of normal concrete (NC). Crumbs and waste rubber particles are mixed in the concrete, the volume content of the mixture is 12.5, 25, 37.5, and 50%, respectively. It is found that the compressive strength and elastic modulus of RC decrease significantly through the compression test, the toughness is closely related to the content of rubber [17,18,19,20,21,22,23,24].

Adding steel fiber or other fibers into concrete can enhance the impact toughness and ductility of concrete and improve the crack resistance and durability of concrete through the synergistic effect between fiber and rubber [25,26]. In order to reduce the decline in strength of RC, steel fiber is added into RC. Through splitting tensile test, it is found that the crack development of steel fiber rubber concrete (SFRC) is obviously slower than that of NC [27]. The test shows that adding rubber particles and hook shaped steel fiber into concrete can improve the strain performance of concrete through their cooperative work. The crack of concrete develops slowly and the crack width is smaller than that of NC [28,29,30,31].

Through the compression test and bending test, the results show that the shrinkage rate of concrete with steel fiber recycled aggregate concrete mixed with rubber is significantly lower than that of NC [32]. The adhesion between rubber particles and concrete matrix is obviously improved [33]. More researchers combine steel fibers or other fibers with rubber particles to form a large number of types of concrete, so as to meet the needs of various projects for different properties of concrete, so as to increase the application range of concrete [34,35,36,37,38,39]. For example, the ductility of reinforced concrete, RC, SFRC, polypropylene RC, and hybrid fiber concrete pipes is studied. The results show that the strength and ductility of concrete pipes mixed with hybrid fibers (steel fiber and polypropylene fiber) are better than those mixed with single fiber [40].

The research on the static pressure strength of recycled RC or steel fiber reinforced concrete is relatively mature, and their toughness and ductility are also studied, but the research on the static compression toughness of SFRC is less. Adding recycled rubber particles directly to concrete will reduce the compressive strength of concrete, but the treated rubber particles will increase their bonding performance with concrete [41]. There are two main treatment methods, one is to wrap the recycled rubber particles with cement slurry, and the other is to wash the recycled rubber particles with NaOH [42]. According to the analysis of existing research results, the effect of washing recycled rubber particles with NaOH is better than wrapping cement slurry. Cleaning the rubber particles with NaOH solution can remove the impurities attached to the rubber particles and improve the adhesion between the rubber particles and cement. The compressive strength of RC washed with NaOH solution is significantly higher than that of ordinary RC [43]. In order to study the compression toughness of SFRC, recycled rubber particles produced by waste tires were used to replace some natural fine aggregate, and the recycled rubber particles were washed with NaOH. NC, recycled RC, SFRC cube and prism specimens were prepared for compression test. The slump, density, compressive strength, elastic modulus, ductility, and compressive toughness of different kinds of concrete are analyzed and evaluated from multiple indexes.

2 Experiment process

2.1 Material and specimen preparation

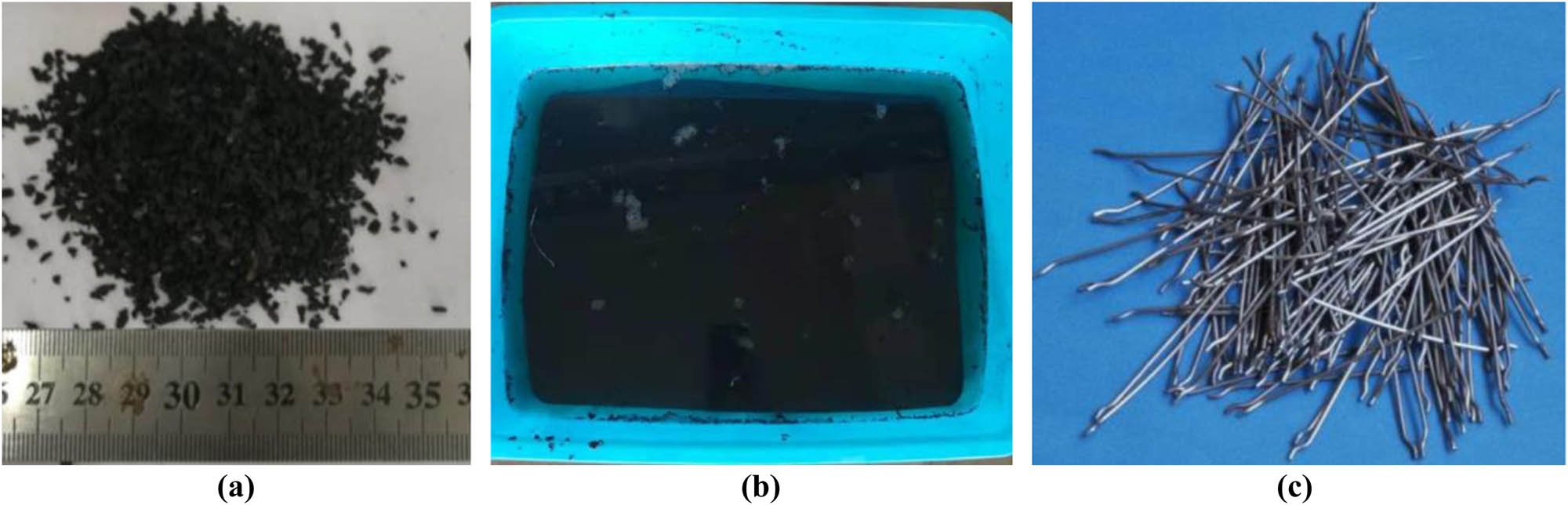

The cement is Lafarge PO 42.5 ordinary Portland cement, with a density of 3,150 kg·m−3. The coarse aggregate shall be natural crushed stone with particle size of 5–14 mm and density of 2,650 kg·m−3. The density of natural sand used for fine aggregate is 2,640 kg·m−3 and the fineness modulus is 3.4. The particle size distribution of coarse and fine aggregates is shown in Figure 1. The hook-end steel fiber is characterized by high tensile strength, good toughness, improved impact and fatigue resistance of concrete, improved impermeability of concrete, and low price. In the previous study, it was found that the compressive strength and tensile strength of hook-end steel fiber reinforced concrete were higher than that of milled steel fiber reinforced concrete. The steel fiber is of end hook type [44], with a length of 60 mm and the aspect ratio of 80. Steel fiber shall be added according to 0.5% of the volume fraction of concrete. The rubber particle size is 1.18–2.36 mm, after soaking in 5% NaOH solution for 24 h, it is taken out and flushed to pH value of 7 for standby. Superplasticizer containing high-grade polycarboxylate ether is used, and the dosage is 0.3% of the weight of cement. The purpose of adding superplasticizer is to obtain the required workability. Rubber particles and steel fibers are shown in Figure 2.

Particle size distribution of fine and coarse aggregate.

Rubber particles and steel fibers. (a) Rubber particles; (b) rubber NaOH washing modification; and (c) steel fibers.

By changing the proportion of steel fiber and rubber particles, specimens of NC group 1, steel fiber concrete (SFC) group 1, RC group 3, and SFRC group 3 were prepared, respectively. The target value of cube compressive strength of NC was 40 MPa. The volume substitution rate of rubber particles to fine aggregate in RC and SFRC is 5, 10, and 15%. Table 1 shows the mix proportion of different types of concrete. The mix proportion design refers to the code of steel fiber reinforced concrete and the code of standard for test methods of concrete’s physical and mechanical properties. The samples of each mix proportion include 6 prisms (100 mm × 100 mm × 300 mm) and 9 cubes (100 mm × 100 mm × 100 mm). Prismatic samples are used to test the 28 days compressive strength and obtain the stress–strain relationship, and cube test blocks are used to determine the bulk density and 7, 14, and 28 days compressive strength. All mixtures are vibrated on a disc vibrator after pouring in the laboratory (Figure 3). After 24 h, the mixtures are taken out of the mold for curing, and compression test is conducted after reaching the age.

Concrete mix proportion of various test pieces

| Test piece no. | Steel fiber (kg) | Cement (kg) | Water (kg) | Crushed stone (kg) | Sand (kg) | Superplasticizer (kg) |

|---|---|---|---|---|---|---|

| NC | — | 430 | 202 | 907 | 814 | 13.1 |

| SFC | 39 | 430 | 202 | 907 | 814 | 13.1 |

| RC-5 | — | 430 | 202 | 907 | 773 | 13.1 |

| RC-10 | — | 430 | 202 | 907 | 732 | 13.1 |

| RC-15 | — | 430 | 202 | 907 | 692 | 13.1 |

| SFRC-5 | 39 | 430 | 202 | 907 | 773 | 13.1 |

| SFRC-10 | 39 | 430 | 202 | 907 | 732 | 13.1 |

| SFRC-15 | 39 | 430 | 202 | 907 | 692 | 13.1 |

Note: NC is normal concrete; SFC is steel fiber concrete; RC-5 is rubber concrete with 5% recycled rubber by volume; RC-10 is rubber concrete with 10% recycled rubber by volume; RC-15 is rubber concrete with 15% recycled rubber by volume; SFRC-5 is steel fiber rubber concrete with the volume content of rubber of 5%; SFRC-10 is steel fiber rubber concrete with the volume content of rubber of 10%; SFRC-15 is steel fiber rubber concrete with the volume content of rubber of 15%.

Pouring and vibrating of test block.

2.2 Test set up

Slump tests shall be conducted for each concrete mixture before pouring (Figure 4). The loading rate of prismatic axial compression test is 0.3 MPa·s−1, which is loaded until the specimen is damaged, and the stress–strain curve under uniform loading was recorded. Cube specimens were tested for cube compressive strength at 7, 14, and 28 days of age. The test device for cube and prism samples is shown in Figure 5.

Slump test.

Test device of prismatic and cube samples. (a) Prism axial compression test; and (b) cube compression test.

3 Test results and discussion

3.1 Slump

The designed slump of fresh concrete is 30–60 mm. Figure 6 shows that the measured slump of various concrete mixtures is basically within the design mix proportion range. Compared with NC, the slump of either steel fiber reinforced concrete or RC, or SFRC decreased significantly. In addition, the slump of RC is greater than that of steel fiber reinforced concrete and SFRC. The slump of RC and rubber SFC decreases with the increase in rubber particle volume content. The greater the rubber content, the more the slump decreases. The reason is that the friction between concrete compounds increases due to the rough surface of rubber particles. With the increase in rubber content, the segregation of rubber particles appears in the concrete mixture during pouring and vibration. The reason is that the relative density of rubber particles is low and floats up during mixing and vibration. Therefore, it is recommended to use concrete admixtures to reduce voids and improve the micro-structure of the mixture.

Slump of different concrete mix proportion.

The slump of SFRC decreases more than that of RC. The measured slump of SFRC-15 is only 46 mm, which is reduced by 9 mm and 20% compared with that of RC-15. Adding superplasticizer into RC and SFRC can obtain the workability similar to that of NC. In addition, compared with the mixture containing fine rubber particles with particle size of 1.2 mm, the mixture containing coarse rubber particles with particle size of 2.3 mm has better workability.

3.2 Density

In order to accurately determine the density of various concrete, the size of each sample is measured with a digital vernier caliper and the volume is calculated. It is found that adding rubber particles to concrete will reduce the density of concrete. The reason is that the volume of rubber particles used to replace fine aggregate is larger than sand, but the density is smaller than sand. At the same time, due to the nonpolarity of rubber particles, the increase in rubber content will also lead to the adhesion of air to the surface of rubber particles. The effect of rubber particle substitution rate on the density of NC and steel fiber reinforced concrete is shown in Figure 7. Compared with NC, after adding 5, 10, and 15% rubber particles in RC, the average density of concrete is reduced by 1.3, 2.2, and 3.0% respectively. When adding rubber particles to steel fiber reinforced concrete, the mixture with the same replacement rate also has a similar change trend. The average density of SFRC is 2,387 kg·m−3, which depends on the substitution rate of rubber particles, but has no obvious relationship with the particle size of rubber particles.

Effect of rubber particle content on concrete density.

3.3 Compressive strength

The cube compressive strength test results of 7, 14, and 28 days old samples of each mix proportion are shown in Table 2. The results show that the strength of steel fiber reinforced concrete at each age is the highest, followed by NC, and the strength of both RC and SFRC is lower than that of NC and steel fiber reinforced concrete. The results of 28 days cube compressive strength of RC and SFRC are shown in Figure 8, which shows that the concrete strength decreases with the increase in rubber particle content.

Density and compressive strength of cube samples

| Test piece no | Density (kg·m−3) 28 days | Compressive strength (N·mm−2) | ||

|---|---|---|---|---|

| 7 days | 14 days | 28 days | ||

| NC | 2,403 | 30.9 | 37.3 | 46.3 |

| SFC | 2,354 | 34.7 | 38.8 | 48.6 |

| RC-5 | 2,375 | 27.3 | 32.3 | 40.4 |

| RC-10 | 2,347 | 23.7 | 28.3 | 36.4 |

| RC-15 | 2,329 | 21.8 | 25.9 | 34.3 |

| SFRC-5 | 2,413 | 28.9 | 33.7 | 42.9 |

| SFRC-10 | 2,383 | 26.3 | 29.8 | 38.6 |

| SFRC-15 | 2,372 | 24.2 | 27.3 | 36.7 |

Cube compressive strength of concrete with different mix proportions.

For three age concrete cube samples, when the content of rubber particles increases, the cube compressive strength of RC and SFRC decreases. The cube strengths of NC and steel fiber reinforced concrete are 46.3 MPa and 48.6 MPa, respectively. Compared with the cube compressive strength of NC at 28 days, the strength of RC decreased by 12.7, 21.4, and 25.9% when the content of rubber particles was 5, 10, and 15%, respectively. Compared with the cube compressive strength of steel fiber reinforced concrete at 28 days, when the rubber particle content is 5, 10, and 15%, the strength of SFRC decreases by 11.7, 20.6, and 24.5%, respectively.

When the content of rubber particles increases from 0 to 15%, the 7–14 days compressive strength of RC cube decreases by 29.5 and 30.6%, respectively, compared with NC. The cube compressive strength of SFRC at 7–14 days decreased by 30.3 and 29.6%, respectively.

The static test shows that whether steel fiber is added to NC or RC, the strength increases at each age stage, and the strength decline of concrete mixed with steel fiber is less than that of concrete without steel fiber.

Table 3 shows the axial compression test results of prisms at the age of 28 days. The average compressive strength of NC prism is 41.3 MPa. The average compressive strength of steel fiber reinforced concrete prism is 43.2 MPa, which is 1.05 times higher than that of NC, indicating that the improvement in end-hook steel fiber on the compressive strength of concrete is not significant, which may be due to the small volume content of steel fiber. The effect of steel fiber is related to volume fraction and aspect ratio. The increase in compressive strength of SFRC offsets the decrease caused by the addition of rubber particles [45,46,47]. Compared with steel fiber reinforced concrete, when the content of rubber particles is 5, 10, and 15%, the strength of SFRC decreases to 37.6, 35.2, and 32.4 MPa, 13, 18.5, and 25%, respectively. For RC without steel fiber, the reduction rates are 15.7, 19.4, and 27.8%, respectively. The decreasing trend of compressive strength of RC and SFRC is similar, and the decreasing range is also close.

Axial compression test results of prismatic specimens

| Test piece no | Modulus of elasticity (103 N·mm−2) | Axial compressive strength (N·mm−2) | Toughness (10−2 N·mm−2) | Toughness index | Specific toughness (%) |

|---|---|---|---|---|---|

| NC | 33.1 | 41.3 | 20.17 | 1.14 | 0.488 |

| SFC | 35.2 | 43.2 | 26.01 | 1.18 | 0.604 |

| RC-5 | 29.8 | 34.8 | 21.88 | 1.13 | 0.627 |

| RC-10 | 28.5 | 33.3 | 23.21 | 1.26 | 0.699 |

| RC-15 | 26.8 | 29.8 | 23.44 | 1.33 | 0.786 |

| SFRC-5 | 32.3 | 37.6 | 28.26 | 1.23 | 0.753 |

| SFRC-10 | 30.1 | 35.2 | 29.85 | 1.25 | 0.854 |

| SFRC-15 | 28.8 | 32.4 | 30.36 | 1.33 | 0.932 |

The main reason for the reduction in compressive strength after adding rubber particles into concrete is that the inter-facial transition zone becomes weaker, and the bonding between rubber and cement matrix is separated by voids, resulting in separation around cement matrix and rubber particles [48,49,50]. In the RC mixed with steel fiber, the function of rubber particles is the same as that of RC. Although this effect can be ignored when the amount of rubber particles is small, the effect of adding rubber particles is similar whether the concrete composite is reinforced with steel fiber or not.

3.4 Modulus of elasticity

In order to evaluate the ability of SFRC to resist elastic deformation, it is necessary to study its elastic modulus.

Figure 9 shows the relationship between rubber content and elastic modulus of concrete. It is obvious that adding rubber particles will reduce the elastic modulus of NC and steel fiber reinforced concrete. The elastic modulus of NC is 33.1 GPa. When the content of rubber particles is 5, 10 and 15%, the elastic modulus of RC decreases by 10, 13.9, and 19%, respectively. When the rubber content is 5, 10, and 15%, the elastic modulus of SFRC is 8.2, 14.5, and 18.2% lower than that of SFC, respectively. The elastic modulus of SFRC is higher than that of RC, but lower than that of NC and SFC, indicating that steel fiber can increase the elastic modulus of concrete, but rubber particles reduce the elastic modulus of concrete more.

Elastic modulus of concrete with different mix proportions.

Comparing the test value of concrete elastic modulus with the elastic modulus calculated by formula (1), it is found that the elastic modulus calculated by formula (1) is smaller than the test value, but the deviation is very small. Therefore, it is acceptable to use the empirical formula (1) to predict the elastic modulus of RC and SFC [51,52,53,54,55].

where E

c is the elastic modulus of concrete, W

c is the density of concrete, and

The NC elastic modulus calculated by formula (1) is 29.6 GPa, while the test value is 33.1 GPa. There is a difference between the theoretical calculation value and the test measured value. The density of RC is 2,375–2,329 kg·m−3, the axial compressive strength is 34.8–29.8 MPa, and the calculated value of elastic modulus is between 29.3–26.2 GPa. The elastic modulus of SFRC is also calculated by formula (1). The average compressive strength is 37.6–32.4 MPa, the density is 2,413–2,372 kg·m−3, and the elastic modulus is 31.5, 29.2, and 27.9 GPa, respectively. The comparison between the theoretical calculated value and the measured value of concrete elastic modulus with different mix proportions is shown in Figure 9. The results show that the elastic modulus decreases with the increase in rubber particle content, and the decreasing trend of elastic modulus of RC and SFRC is basically the same.

There is no significant difference between the calculated elastic modulus and the measured compressive strength, as shown in Figure 10. It is feasible to calculate the elastic modulus of RC or steel fiber reinforced concrete by formula (1), which reduces the test workload, and the calculation results can also meet the needs of engineering application [56].

Relationship between elastic modulus and compressive strength of concrete.

3.5 Stress–strain curve

Figures 11 and 12 are stress–strain curves of axial compression test of concrete prisms with different mix proportions. The average value of 28 days axial compression test of three samples is used for stress, and the strain limit value is 2% [57]. For concrete samples mixed with rubber particles, the strain corresponding to the peak load increases with the increase in the rubber particle content. In the falling section of the curve after the peak load, the concrete strain also increases with the increase in the rubber particle content.

Stress–strain curve of RC.

Stress–strain curve of SFRC.

The shape of the stress–strain curve has also changed significantly. The stress value corresponding to the failure of concrete increases with the increase in the rubber particles. The performance of RC sample is obviously different from that of NC, showing good ductility. Comparing the stress–strain curve shapes of RC and NC, it is clear that the increase in rubber particle content enhances the growth of concrete plasticity. The failure state of RC is accompanied by large deformation, and the curve shows a slow downward trend. The strain value corresponding to the stress of RC during failure increases significantly with the increase in rubber particle content. The maximum stress and failure stress of RC stress–strain curve depend on the content of rubber particles [58].

Compared with steel fiber reinforced concrete, the peak stress of SFRC decreases significantly. The more the rubber content, the greater the peak stress decline, while the ultimate strain has little relationship with the content of rubber particles. However, with the increase in the rubber particle content, the stress–strain curve of SFRC becomes more and more gentle after the peak stress. The strain value corresponding to the peak stress increases obviously with the increase in the rubber content, which also shows that adding rubber particles to steel fiber reinforced concrete reduces the strength of concrete, but the ductility of SFRC has been significantly improved. Therefore, it can be concluded that the effect of steel fiber increases the strength of concrete, while rubber particles significantly improve the ductility of concrete, both of which have a positive impact on the compression performance of concrete.

3.6 Compressive toughness

In structural members, whether beams, columns, or walls, the main role of concrete is compression. Therefore, the research on the compressive toughness of SFRC is more targeted than the flexural toughness.

The compressive toughness of concrete can be obtained by calculating the area under the stress–strain curve. The ultimate strain of all kinds of concrete is taken as 2%. The calculation results of compressive toughness of all kinds of concrete with different rubber particle contents are shown in Figure 13. Table 3 shows that the toughness of RC and SFRC increases with the increase in rubber content. No matter how much the content of rubber particles increases, the toughness of SFRC is always higher than that of RC. Due to the limitation of the number of test blocks, in the follow-up research, we can try to study the toughness of RC with large volume content (volume ratio more than 15%), and compare the test results with the toughness of steel fiber reinforced concrete. For SFRC (Figure 13), the toughness value is the largest when the rubber content is 15%, but the difference in toughness value is very small compared with SFRC with rubber content of 10%.

Compressive toughness of different concrete mix proportions.

Therefore, with the increase in rubber content, the compressive toughness of steel fiber RC shows an increasing trend. The toughness of concrete can be improved by adding rubber to concrete, but the increase range is significantly lower than that of adding steel fiber.

The toughness index is calculated by dividing the area under the stress–strain curve by 80% of the peak stress of the stress–strain curve or by the peak stress corresponding to the ultimate strain [59], the calculation results are shown in Table 3. In addition, Table 3 also calculates the specific toughness of concrete, that is, the ratio of concrete toughness to compressive strength. Among the concrete with different mix proportions, SFRC with 15% rubber particles has the highest toughness index and specific toughness, while NC has the lowest (Figure 14). Whether the concrete type is NC or SFC, adding rubber particles to the mixture can improve the toughness index and specific toughness.

Toughness index of different concrete mix proportions.

The toughness index of RC-10 is higher than that of SFRC-5 and SFRC-10, indicating that the toughness and energy dissipation performance of concrete mixed with rubber particles are more effective than that of steel fiber under compressive load. If the coarse and fine rubber particles are mixed, the toughness index of concrete can be increased by more than 6 times, and the maximum replacement rate of rubber instead of aggregate can reach 25% [60].

In any case, adding rubber particles to concrete will improve the toughness index of concrete. The increasing trend of specific toughness is the same as that of toughness index, as shown in Figure 15. As for the changes in toughness index and specific toughness of concrete with rubber particle replacement rate exceeding 15%, further research is needed.

Specific toughness of different concrete mix proportions.

4 Conclusion

By studying the compressive strength, elastic modulus and compressive toughness of eight groups of concrete with different mix proportions, the following conclusions are obtained.

Using recycled rubber particles produced by waste tires to replace some fine aggregates of concrete will reduce the compressive strength of recycled rubber NC and SFRC. The elastic modulus of concrete shows the same downward trend as the compressive strength.

The properties of NC after adding recycled rubber change from brittleness to toughness. With the increase in recycled rubber content, the strain value increases obviously, which indicates that it can withstand greater deformation in the stage after the peak of stress–strain curve.

The addition of recycled rubber particles has a great influence on the toughness of concrete. The increase in recycled rubber particle content increases the area under the stress–strain curve and enhances the energy dissipation capacity of concrete. Due to the existence of steel fiber and the addition of recycled rubber particles, the combination of recycled rubber particles and steel fiber significantly improves the toughness of concrete.

The toughness index of SFRC increases with the increase in the amount of rubber particles. Therefore, SFRC has good energy dissipation performance in engineering structures that need energy absorption.

Acknowledgments

Thank professor Xu Qiang and state key laboratory of geohazard prevention and geoenvironment protection for their guidance.

-

Funding information: This study was Supported by the Open Fund Declaration of State Key Laboratory of Geohazard Prevention and Geoenvironment Protection, Chengdu University of Technology (Grant no. SKLGP2019K019), Guangzhou Basic and Applied Basic Research Project (202201010750), and Sichuan Provincial research and development program (Grant no. 2020YFS0061).

-

Author contributions: Yongtao Gao, Bin Wang, and Changjiang Liu wrote the article. David Hui, Qiang Xu, Qihua Zhao, Yiwen Qin, and Wei Dong checked the manuscript.

-

Conflict of interest: One of the co-authors – Prof. David Hui – is an Editor in Chief of Reviews in Advanced Materials Science.

-

Data availability statement: All data generated or analyzed during this study are included in this published article or are available from the corresponding author on reasonable request.

References

[1] Abdullah, W., M. AbdulKadir, and M. Muhammad. Effect of high temperature on mechanical properties of rubberized concrete using recycled tyre rubber as fine aggregate replacement. Journal of Engineering Technology, Vol. 36, No. 8 Part A, 2018, pp. 906–913.10.30684/etj.36.8A.10Search in Google Scholar

[2] Siddika, A., M. A. Al Mamun, R. Alyousef, Y. H. Mugahed Amran, F. Aslani, and H. Alabduljabbar. Properties and utilizations of waste tire rubber in concrete: A review. Construction and Building Materials, Vol. 224, 2019, pp. 711–731.10.1016/j.conbuildmat.2019.07.108Search in Google Scholar

[3] Aslani, F. and J. Kelin. Assessment and development of high-performance fibre-reinforced lightweight self-compacting concrete including recycled crumb rubber aggregates exposed to elevated temperatures. Journal of Cleaner Production, Vol. 200, 2018, pp. 1009–1025.10.1016/j.jclepro.2018.07.323Search in Google Scholar

[4] Wang, Q. Z., N. N. Wang, M. L. Tseng, Y. M. Huang, and N. L. Li. Waste tire recycling assessment: Road application potential and carbon emissions reduction analysis of crumb rubber modified asphalt in China. Journal of Cleaner Production, Vol. 249, 2020, id. 119411.10.1016/j.jclepro.2019.119411Search in Google Scholar

[5] Pham, T. M., M. Elchalakani, A. Karrech, and H. Hao. Axial impact behavior and energy absorption of rubberized concrete with/without fiber-reinforced polymer confinement. International Journal of Protective Structures, Vol. 10, 2019, pp. 154–173.10.1177/2041419618800771Search in Google Scholar

[6] Marcos-Meson, V., G. Fischer, C. Edvardsen, T. L. Skovhus, and A. Michel. Durability of steel fibre reinforced concrete (SFRC) exposed to acid attack – a literature review. Construction and Building Materials, Vol. 200, 2019, pp. 490–501.10.1016/j.conbuildmat.2018.12.051Search in Google Scholar

[7] Koushkbaghi, M., M. J. Kazemi, H. Mosavi, and E. Mohseni. Acid resistance and durability properties of steel fiber reinforced concrete incorporating rice husk ash and recycled aggregate. Construction and Building Materials, Vol. 202, 2019, pp. 266–275.10.1016/j.conbuildmat.2018.12.224Search in Google Scholar

[8] Mohamed, O. A. and W. Al Hawat. Influence of fly ash and basalt fibers on strength and chloride penetration resistance of self-consolidating concrete. Materials Science Forum, Vol. 866, 2016, pp. 3–8.10.4028/www.scientific.net/MSF.866.3Search in Google Scholar

[9] Hassanli, R., O. Youssf, and J. E. Mills. Seismic performance of precast posttensioned segmental FRP-confined and unconfined crumb rubber concrete columns. Journal of Composites for Construction, Vol. 21, 2017, id. 04017006. Youssf, O., M. A. Elgawady, and J. E. Mills. Static cyclic behaviour of FRP-confined crumb rubber concrete columns. Engineer Structure, Vol. 113, 2016, pp. 371–387.10.1061/(ASCE)CC.1943-5614.0000789Search in Google Scholar

[10] Hassanli, R., O. Youssf, and J. E. Mills. Experimental investigations of reinforced rubberized concrete structural members. Journal of Building Engineering, Vol. 10, 2017, pp. 149–165.10.1016/j.jobe.2017.03.006Search in Google Scholar

[11] Mendis, A. S. M., S. Al-Deen, and M. Ashraf. Effect of rubber particles on the flexural behaviour of reinforced crumbed rubber concrete beams. Construction and Building Materials, Vol. 154, 2017, pp. 644–657.10.1016/j.conbuildmat.2017.07.220Search in Google Scholar

[12] Ismail, M. K. and A. A. A. Hassan. Ductility and cracking behavior of reinforced self-consolidating rubberized concrete beams. Journal of Materials in Civil Engineering, Vol. 29, 2017, id. 04016174.10.1061/(ASCE)MT.1943-5533.0001699Search in Google Scholar

[13] Park, Y., A. Abolmaali, Y. H. Kim, and M. Ghahremannejad. Compressive strength of fly ash-based geopolymer concrete with crumb rubber partially replacing sand. Construction and Building Materials, Vol. 118, 2016, pp. 43–51.10.1016/j.conbuildmat.2016.05.001Search in Google Scholar

[14] Khan, M. and M. Ali. Improvement in concrete behavior with fly ash, silica-fume and coconut fibres. Construction and Building Materials, Vol. 203, 2019, pp. 174–187.10.1016/j.conbuildmat.2019.01.103Search in Google Scholar

[15] Alsaif, A., S. A. Bernal, M. Guadagnini, and K. Pilakoutas. Durability of steel fibre reinforced rubberised concrete exposed to chlorides. Construction and Building Materials, Vol. 188, 2018, pp. 130–142.10.1016/j.conbuildmat.2018.08.122Search in Google Scholar

[16] Martuscelli, C. C., J. C. Santos, P. R. Oliveira, T. H. Panzera, M. T. P. Aguilar, and C. T. Garcia. Polymer-cementitious composites containing recycled rubber particles. Construction and Building Materials, Vol. 170, 2018, pp. 446–454.10.1016/j.conbuildmat.2018.03.017Search in Google Scholar

[17] Luhar, S., S. Chaudhary, and I. Luhar. Development of rubberized geopolymer concrete: Strength and durability studies. Construction and Building Materials, Vol. 204, 2019, pp. 740–753.10.1016/j.conbuildmat.2019.01.185Search in Google Scholar

[18] Valadares, F., M. Bravo, and J. De Brito. Concrete with used tire rubber aggregates: mechanical performance. ACI Materials Journal, Vol. 109, 2012, pp. 283–292.10.14359/51683818Search in Google Scholar

[19] Najim, K. B. and M. R. Hall. Crumb rubber aggregate coatings/pre-treatments and their effects on interfacial bonding, air entrapment and fracture toughness in self-compacting rubberised concrete (SCRC). Materials and Structures, Vol. 46, 2013, pp. 2029–2043.10.1617/s11527-013-0034-4Search in Google Scholar

[20] Mahmod, H. M., A. A. F. N. Aznieta, and S. J. Gatea. Evaluation of rubberized fibre mortar exposed to elevated temperature using destructive and non-destructive testing. KSCE Journal of Civil Engineering, Vol. 21, 2017, pp. 1347–1358.10.1007/s12205-016-0721-0Search in Google Scholar

[21] Onuaguluchi, O. and N. Banthia. Scrap tire steel fiber as a substitute for commercial steel fiber in cement mortar: engineering properties and cost-benefit analyses. Resources, Conservation and Recycling, Vol. 134, 2018, pp. 248–256.10.1016/j.resconrec.2018.03.014Search in Google Scholar

[22] Gupta, T., S. Siddique, R. K. Sharma, and S. Chaudhary. Effect of elevated temperature and cooling regimes on mechanical and durability properties of concrete containing waste rubber fiber. Construction and Building Materials, Vol. 137, 2017, pp. 35–45.10.1016/j.conbuildmat.2017.01.065Search in Google Scholar

[23] Marques, A. M., J. R. Correia, and J. Brito. Post-fire residual mechanical properties of concrete made with recycled rubber aggregate. Fire Safety Journal, Vol. 58, 2013, pp. 49–57.10.1016/j.firesaf.2013.02.002Search in Google Scholar

[24] Ahmed, H. U., R. H. Faraj, N. Hilal, A. A. Mohammed, and A. F. H. Sherwani. Use of recycled fibers in concrete composites: A systematic comprehensive review. Composites Part B: Engineering, Vol. 215, 2021, id. 108769.10.1016/j.compositesb.2021.108769Search in Google Scholar

[25] Flores Medina, N., D. Flores-Medina, and F. Hernández-Olivares. Influence of fibers partially coated with rubber from tire recycling as aggregate on the acoustical properties of rubberized concrete. Construction and Building Materials, Vol. 129, 2016, pp. 25–36.10.1016/j.conbuildmat.2016.11.007Search in Google Scholar

[26] Thomas, B. S., R. C. Gupta, P. Mehra, and S. Kumar. Performance of high strength rubberized concrete in aggressive environment. Construction and Building Materials, Vol. 83, 2015, pp. 320–326.10.1016/j.conbuildmat.2015.03.012Search in Google Scholar

[27] Isa, M. N., K. Pilakoutas, M. Guadagnini, and H. Angelakopoulos. Mechanical performance of affordable and eco-efficient ultra-high performance concrete (UHPC) containing recycled tyre steel fibres. Construction and Building Materials, Vol. 255, 2020, id. 119272.10.1016/j.conbuildmat.2020.119272Search in Google Scholar

[28] Youssf, O., M. A. ElGawady, and J. E. Mills. Experimental investigation of crumb rubber concrete columns under seismic loading. Structures, Vol. 3, 2015, pp. 13–27.10.1016/j.istruc.2015.02.005Search in Google Scholar

[29] Moustafa, A., A. Gheni, and M. A. ElGawady. Shaking-table testing of high energy-dissipating rubberized concrete columns. Journal of Bridge Engineering, Vol. 22, 2017, id. 04017042.10.1061/(ASCE)BE.1943-5592.0001077Search in Google Scholar

[30] Saeed, S. M., M. Y. Aman, K. A. Ahmad, A. Batari, A. T. A. Yero, and A. U. Chinade. Effect of crumb rubber modifier on the fatigue performance of warm mix asphalt, Springer, Singapore, 2019, pp. 1367–1376.10.1007/978-981-10-8016-6_98Search in Google Scholar

[31] Gupta, T., A. Tiwari, S. Siddique, R. K. Sharma, and S. Chaudhary. Response assessment under dynamic loading and microstructural investigations of rubberized concrete. Journal of Materials in Civil Engineering, Vol. 29, 2017, id. 04017062.10.1061/(ASCE)MT.1943-5533.0001905Search in Google Scholar

[32] Hashmi, A. F., M. Shariq, and A. Baqi. An investigation into age-dependent strength, elastic modulus and deflection of low calcium fly ash concrete for sustainable construction. Construction and Building Materials, Vol. 283, 2021, id. 122772.10.1016/j.conbuildmat.2021.122772Search in Google Scholar

[33] Ali, B., L. A. Qureshi, S. H. A. Shah, S. U. Rehman, I. Hussain, and M. Iqbal. A step towards durable, ductile and sustainable concrete: Simultaneous incorporation of recycled aggregates, glass fiber and fly ash. Construction and Building Materials, Vol. 251, 2020, id. 118980.10.1016/j.conbuildmat.2020.118980Search in Google Scholar

[34] Elghazouli, A. Y., D. V. Bompa, B. Xu, A. M. Ruiz-Teran, and P. J. Stafford. Performance of rubberised reinforced concrete members under cyclic loading. Engineer Structure, Vol. 166, 2018, pp. 526–545.10.1016/j.engstruct.2018.03.090Search in Google Scholar

[35] Ridgley, K. E., A. A. Abouhussien, A. A. A. Hassan, and B. Colbourne. Evaluation of abrasion resistance of self-consolidating rubberized concrete by acoustic emission analysis. Journal of Materials in Civil Engineering, Vol. 30, 2018, id. 04018196.10.1061/(ASCE)MT.1943-5533.0002402Search in Google Scholar

[36] Al-Tayeb, M. M., B. H. Abu Bakar, H. M. Akil, and H. Ismail. Performance of rubberized and hybrid rubberized concrete structures under static and impact load conditions. Experimental Mechanics, Vol. 53, 2013, pp. 377–384.10.1007/s11340-012-9651-zSearch in Google Scholar

[37] Mohammed, B. S., M. Adamu, and N. Shafifiq. Establishing relationship between modulus of elasticity and strength of nano silica modified roller compacted rubbercrete. International Journal of Geomate, Vol. 13, 2017, pp. 103–110.10.21660/2017.39.23401Search in Google Scholar

[38] Afroughsabet, V. and T. Ozbakkaloglu. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Construction and Building Materials, Vol. 94, 2015, pp. 73–82.10.1016/j.conbuildmat.2015.06.051Search in Google Scholar

[39] Ali, B., R. Kurda, and B. Herki. Effect of varying steel fiber content on strength and permeability characteristics of high strength concrete with micro silica. Materials, Vol. 13, No. 24, 2020, id. 5739.10.3390/ma13245739Search in Google Scholar PubMed PubMed Central

[40] Jafari, K. and V. Toufifigh. Experimental and analytical evaluation of rubberized polymer concrete. Construction and Building Materials, Vol. 155, 2017, pp. 495–510.10.1016/j.conbuildmat.2017.08.097Search in Google Scholar

[41] Ma, Q. W., J. C. Le, and Y. Jiang. Effect of NaOH pretreatment on mechanical properties of rubber concrete. Journal of China & Foreign Highway, Vol. 31, No. 6, 2011, pp. 229–233 (in Chinese).Search in Google Scholar

[42] Yang, C. H., Y. Tian, L. Wang, S. W. Chang, and T. Yang. Influence of NaOH pretreatments on the properties of rubber concrete. Journal of Civil, Architectural & Environmental Engineering, Vol. 38, No. 2, 2016, pp. 44–50 (in Chinese).Search in Google Scholar

[43] Liu, C. J., X. C. Huang, Y. Y. Wu, X. W. Deng, J. Liu, Z. L. Zheng, et al. Review on the research progress of cement-based and geopolymer materials modified by graphene and graphene oxide. Nanotechnology Reviews, Vol. 9, 2020, pp. 155–169.10.1515/ntrev-2020-0014Search in Google Scholar

[44] Gesoglu, M., E. Güneyisi, O. Hansu, S. Ipek, and D. S. Asaad. Influence of waste rubber utilization on the fracture and steel–concrete bond strength properties of concrete. Construction and Building Materials, Vol. 101, 2015, pp. 1113–1121.10.1016/j.conbuildmat.2015.10.030Search in Google Scholar

[45] Raffoul, S., R. Garcia, K. Pilakoutas, M. Guadagnini, and N. F. Medina. Optimisation of rubberised concrete with high rubber content: An experimental investigation. Construction and Building Materials, Vol. 124, 2016, pp. 391–404.10.1016/j.conbuildmat.2016.07.054Search in Google Scholar

[46] Bompa, D. V. and A. Y. Elghazouli. Creep properties of recycled tyre rubber concrete. Construction and Building Materials, Vol. 209, 2019, pp. 126–134.10.1016/j.conbuildmat.2019.03.127Search in Google Scholar

[47] Youssf, O., R. Hassanli, and J. E. Mills. Mechanical performance of FRP-confined and unconfined crumb rubber concrete containing high rubber content. Journal of Building Engineering, Vol. 11, 2017, pp. 115–126.10.1016/j.jobe.2017.04.011Search in Google Scholar

[48] Leone, M., G. Centonze, D. Colonna, F. Micelli, and M. A. Aiello. Fiber-reinforced concrete with low content of recycled steel fiber: Shear behaviour. Construction and Building Materials, Vol. 161, 2018, pp. 141–155.10.1016/j.conbuildmat.2017.11.101Search in Google Scholar

[49] Demir, F., B. Yesilata, P. Turgut, H. Bulut, and Y. Isiker. Investigation of the effects of pH, aging and scrap tire content on the dissolution behaviors of new scrap tire-concrete mixture structures. Journal of Cleaner Production, Vol. 93, 2015, pp. 38–46.10.1016/j.jclepro.2015.01.043Search in Google Scholar

[50] Akinyele, J. O., R. W. Salim, and W. K. Kupolati. The impact of rubber crumb on the mechanical and chemical properties of concrete. Engineering Structures and Technologies, Vol. 7, 2016, pp. 197–204.10.3846/2029882X.2016.1152169Search in Google Scholar

[51] Park, Y., A. Abolmaali, M. Mohammadagha, and S. H. Lee. Flexural characteristic of rubberized hybrid concrete reinforced with steel and synthetic fibers. Advances in Civil Engineering Materials, Vol. 3, 2014, id. 20140011.10.1520/ACEM20140011Search in Google Scholar

[52] Farhan, H., A. R. Dawson, and N. H. Thom. Damage propagation rate and mechanical properties of recycled steel fiber-reinforced and cement-bound granular materials used in pavement structure. Construction and Building Materials, Vol. 172, 2018, pp. 112–124.10.1016/j.conbuildmat.2018.03.239Search in Google Scholar

[53] Gheni, A. A., M. A. ElGawady, and J. J. Myers. Mechanical characterization of concrete masonry units manufactured with crumb rubber aggregate. ACI Materials Journal, Vol. 114, 2017, pp. 65–76.10.14359/51689482Search in Google Scholar

[54] Aslani, F. and M. Khan. Properties of high-performance self-compacting rubberized concrete exposed to high temperatures. Journal of Materials in Civil Engineering, Vol. 31, 2019, id. 04019040.10.1061/(ASCE)MT.1943-5533.0002672Search in Google Scholar

[55] Onuaguluchi, O. and D. K. Panesar. Hardened properties of concrete mixtures containing pre-coated crumb rubber and silica fume. Journal of Cleaner Production, Vol. 82, 2014, pp. 125–131.10.1016/j.jclepro.2014.06.068Search in Google Scholar

[56] Raza, S. S., L. A. Qureshi, and B. Ali. Residual mechanical strength of glass fiber reinforced reactive powder concrete exposed to elevated temperatures. SN Applied Sciences, Vol. 2, No. 9, 2020, id. 03412.10.1007/s42452-020-03412-8Search in Google Scholar

[57] Hassanli, R., J. E. Mills, D. Li, and T. Benn. Experimental and numerical study on the behavior of rubberized concrete. Advances in Civil Engineering Materials, Vol. 6, 2017, id. 20160026.10.1520/ACEM20160026Search in Google Scholar

[58] Mohammadi, and I., H. Khabbaz. Shrinkage performance of Crumb Rubber Concrete (CRC) prepared by water-soaking treatment method for rigid pavements. Cement & Concrete Composites, 62, 2015, 106-116.10.1016/j.cemconcomp.2015.02.010Search in Google Scholar

[59] Liew, K. M. and A. Akbar. The recent progress of recycled steel fiber reinforced concrete. Construction and Building Materials, Vol. 232, 2020, id. 117232.10.1016/j.conbuildmat.2019.117232Search in Google Scholar

[60] Akbar, A. and K. M. Liew. Multicriteria performance evaluation of fiber-reinforced cement composites: An environmental perspective. Composites Part B: Engineering, Vol. 218, 2021, id. 108937.10.1016/j.compositesb.2021.108937Search in Google Scholar

© 2022 Yongtao Gao et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers

- A review on the properties of concrete reinforced with recycled steel fiber from waste tires

- Copper ternary oxides as photocathodes for solar-driven CO2 reduction

- Properties of fresh and hardened self-compacting concrete incorporating rice husk ash: A review

- Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey

- Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles

- Delivery systems in nanocosmeceuticals

- Study on the preparation process and sintering performance of doped nano-silver paste

- Analysis of the interactions between nonoxide reinforcements and Al–Si–Cu–Mg matrices

- Research Articles

- Study on the influence of structural form and parameters on vibration characteristics of typical ship structures

- Deterioration characteristics of recycled aggregate concrete subjected to coupling effect with salt and frost

- Novel approach to improve shale stability using super-amphiphobic nanoscale materials in water-based drilling fluids and its field application

- Research on the low-frequency multiline spectrum vibration control of offshore platforms

- Multiple wide band gaps in a convex-like holey phononic crystal strip

- Response analysis and optimization of the air spring with epistemic uncertainties

- Molecular dynamics of C–S–H production in graphene oxide environment

- Residual stress relief mechanisms of 2219 Al–Cu alloy by thermal stress relief method

- Characteristics and microstructures of the GFRP waste powder/GGBS-based geopolymer paste and concrete

- Development and performance evaluation of a novel environmentally friendly adsorbent for waste water-based drilling fluids

- Determination of shear stresses in the measurement area of a modified wood sample

- Influence of ettringite on the crack self-repairing of cement-based materials in a hydraulic environment

- Multiple load recognition and fatigue assessment on longitudinal stop of railway freight car

- Synthesis and characterization of nano-SiO2@octadecylbisimidazoline quaternary ammonium salt used as acidizing corrosion inhibitor

- Perforated steel for realizing extraordinary ductility under compression: Testing and finite element modeling

- The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on strain hardening cement-based composites

- Perforated steel block of realizing large ductility under compression: Parametric study and stress–strain modeling

- Study on dynamic viscoelastic constitutive model of nonwater reacted polyurethane grouting materials based on DMA

- Mechanical behavior and mechanism investigation on the optimized and novel bio-inspired nonpneumatic composite tires

- Effect of cooling rate on the microstructure and thermal expansion properties of Al–Mn–Fe alloy

- Research on process optimization and rapid prediction method of thermal vibration stress relief for 2219 aluminum alloy rings

- Failure prevention of seafloor composite pipelines using enhanced strain-based design

- Deterioration of concrete under the coupling action of freeze–thaw cycles and salt solution erosion

- Creep rupture behavior of 2.25Cr1Mo0.25V steel and weld for hydrogenation reactors under different stress levels

- Statistical damage constitutive model for the two-component foaming polymer grouting material

- Nano-structural and nano-constraint behavior of mortar containing silica aggregates

- Influence of recycled clay brick aggregate on the mechanical properties of concrete

- Effect of LDH on the dissolution and adsorption behaviors of sulfate in Portland cement early hydration process

- Comparison of properties of colorless and transparent polyimide films using various diamine monomers

- Study in the parameter influence on underwater acoustic radiation characteristics of cylindrical shells

- Experimental study on basic mechanical properties of recycled steel fiber reinforced concrete

- Dynamic characteristic analysis of acoustic black hole in typical raft structure

- A semi-analytical method for dynamic analysis of a rectangular plate with general boundary conditions based on FSDT

- Research on modification of mechanical properties of recycled aggregate concrete by replacing sand with graphite tailings

- Dynamic response of Voronoi structures with gradient perpendicular to the impact direction

- Deposition mechanisms and characteristics of nano-modified multimodal Cr3C2–NiCr coatings sprayed by HVOF

- Effect of excitation type on vibration characteristics of typical ship grillage structure

- Study on the nanoscale mechanical properties of graphene oxide–enhanced shear resisting cement

- Experimental investigation on static compressive toughness of steel fiber rubber concrete

- Study on the stress field concentration at the tip of elliptical cracks

- Corrosion resistance of 6061-T6 aluminium alloy and its feasibility of near-surface reinforcements in concrete structure

- Effect of the synthesis method on the MnCo2O4 towards the photocatalytic production of H2

- Experimental study of the shear strength criterion of rock structural plane based on three-dimensional surface description

- Evaluation of wear and corrosion properties of FSWed aluminum alloy plates of AA2020-T4 with heat treatment under different aging periods

- Thermal–mechanical coupling deformation difference analysis for the flexspline of a harmonic drive

- Frost resistance of fiber-reinforced self-compacting recycled concrete

- High-temperature treated TiO2 modified with 3-aminopropyltriethoxysilane as photoactive nanomaterials

- Effect of nano Al2O3 particles on the mechanical and wear properties of Al/Al2O3 composites manufactured via ARB

- Co3O4 nanoparticles embedded in electrospun carbon nanofibers as free-standing nanocomposite electrodes as highly sensitive enzyme-free glucose biosensors

- Effect of freeze–thaw cycles on deformation properties of deep foundation pit supported by pile-anchor in Harbin

- Temperature-porosity-dependent elastic modulus model for metallic materials

- Effect of diffusion on interfacial properties of polyurethane-modified asphalt–aggregate using molecular dynamic simulation

- Experimental study on comprehensive improvement of shear strength and erosion resistance of yellow mud in Qiang Village

- A novel method for low-cost and rapid preparation of nanoporous phenolic aerogels and its performance regulation mechanism

- In situ bow reduction during sublimation growth of cubic silicon carbide

- Adhesion behaviour of 3D printed polyamide–carbon fibre composite filament

- An experimental investigation and machine learning-based prediction for seismic performance of steel tubular column filled with recycled aggregate concrete

- Effects of rare earth metals on microstructure, mechanical properties, and pitting corrosion of 27% Cr hyper duplex stainless steel

- Application research of acoustic black hole in floating raft vibration isolation system

- Multi-objective parametric optimization on the EDM machining of hybrid SiCp/Grp/aluminum nanocomposites using Non-dominating Sorting Genetic Algorithm (NSGA-II): Fabrication and microstructural characterizations

- Estimating of cutting force and surface roughness in turning of GFRP composites with different orientation angles using artificial neural network

- Displacement recovery and energy dissipation of crimped NiTi SMA fibers during cyclic pullout tests

Articles in the same Issue

- Review Articles

- State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers

- A review on the properties of concrete reinforced with recycled steel fiber from waste tires

- Copper ternary oxides as photocathodes for solar-driven CO2 reduction

- Properties of fresh and hardened self-compacting concrete incorporating rice husk ash: A review

- Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey

- Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles

- Delivery systems in nanocosmeceuticals

- Study on the preparation process and sintering performance of doped nano-silver paste

- Analysis of the interactions between nonoxide reinforcements and Al–Si–Cu–Mg matrices

- Research Articles

- Study on the influence of structural form and parameters on vibration characteristics of typical ship structures

- Deterioration characteristics of recycled aggregate concrete subjected to coupling effect with salt and frost

- Novel approach to improve shale stability using super-amphiphobic nanoscale materials in water-based drilling fluids and its field application

- Research on the low-frequency multiline spectrum vibration control of offshore platforms

- Multiple wide band gaps in a convex-like holey phononic crystal strip

- Response analysis and optimization of the air spring with epistemic uncertainties

- Molecular dynamics of C–S–H production in graphene oxide environment

- Residual stress relief mechanisms of 2219 Al–Cu alloy by thermal stress relief method

- Characteristics and microstructures of the GFRP waste powder/GGBS-based geopolymer paste and concrete

- Development and performance evaluation of a novel environmentally friendly adsorbent for waste water-based drilling fluids

- Determination of shear stresses in the measurement area of a modified wood sample

- Influence of ettringite on the crack self-repairing of cement-based materials in a hydraulic environment

- Multiple load recognition and fatigue assessment on longitudinal stop of railway freight car

- Synthesis and characterization of nano-SiO2@octadecylbisimidazoline quaternary ammonium salt used as acidizing corrosion inhibitor

- Perforated steel for realizing extraordinary ductility under compression: Testing and finite element modeling

- The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on strain hardening cement-based composites

- Perforated steel block of realizing large ductility under compression: Parametric study and stress–strain modeling

- Study on dynamic viscoelastic constitutive model of nonwater reacted polyurethane grouting materials based on DMA

- Mechanical behavior and mechanism investigation on the optimized and novel bio-inspired nonpneumatic composite tires

- Effect of cooling rate on the microstructure and thermal expansion properties of Al–Mn–Fe alloy

- Research on process optimization and rapid prediction method of thermal vibration stress relief for 2219 aluminum alloy rings

- Failure prevention of seafloor composite pipelines using enhanced strain-based design

- Deterioration of concrete under the coupling action of freeze–thaw cycles and salt solution erosion

- Creep rupture behavior of 2.25Cr1Mo0.25V steel and weld for hydrogenation reactors under different stress levels

- Statistical damage constitutive model for the two-component foaming polymer grouting material

- Nano-structural and nano-constraint behavior of mortar containing silica aggregates

- Influence of recycled clay brick aggregate on the mechanical properties of concrete

- Effect of LDH on the dissolution and adsorption behaviors of sulfate in Portland cement early hydration process

- Comparison of properties of colorless and transparent polyimide films using various diamine monomers

- Study in the parameter influence on underwater acoustic radiation characteristics of cylindrical shells

- Experimental study on basic mechanical properties of recycled steel fiber reinforced concrete

- Dynamic characteristic analysis of acoustic black hole in typical raft structure

- A semi-analytical method for dynamic analysis of a rectangular plate with general boundary conditions based on FSDT

- Research on modification of mechanical properties of recycled aggregate concrete by replacing sand with graphite tailings

- Dynamic response of Voronoi structures with gradient perpendicular to the impact direction

- Deposition mechanisms and characteristics of nano-modified multimodal Cr3C2–NiCr coatings sprayed by HVOF

- Effect of excitation type on vibration characteristics of typical ship grillage structure

- Study on the nanoscale mechanical properties of graphene oxide–enhanced shear resisting cement

- Experimental investigation on static compressive toughness of steel fiber rubber concrete

- Study on the stress field concentration at the tip of elliptical cracks

- Corrosion resistance of 6061-T6 aluminium alloy and its feasibility of near-surface reinforcements in concrete structure

- Effect of the synthesis method on the MnCo2O4 towards the photocatalytic production of H2

- Experimental study of the shear strength criterion of rock structural plane based on three-dimensional surface description

- Evaluation of wear and corrosion properties of FSWed aluminum alloy plates of AA2020-T4 with heat treatment under different aging periods

- Thermal–mechanical coupling deformation difference analysis for the flexspline of a harmonic drive

- Frost resistance of fiber-reinforced self-compacting recycled concrete

- High-temperature treated TiO2 modified with 3-aminopropyltriethoxysilane as photoactive nanomaterials

- Effect of nano Al2O3 particles on the mechanical and wear properties of Al/Al2O3 composites manufactured via ARB

- Co3O4 nanoparticles embedded in electrospun carbon nanofibers as free-standing nanocomposite electrodes as highly sensitive enzyme-free glucose biosensors

- Effect of freeze–thaw cycles on deformation properties of deep foundation pit supported by pile-anchor in Harbin

- Temperature-porosity-dependent elastic modulus model for metallic materials

- Effect of diffusion on interfacial properties of polyurethane-modified asphalt–aggregate using molecular dynamic simulation

- Experimental study on comprehensive improvement of shear strength and erosion resistance of yellow mud in Qiang Village

- A novel method for low-cost and rapid preparation of nanoporous phenolic aerogels and its performance regulation mechanism

- In situ bow reduction during sublimation growth of cubic silicon carbide

- Adhesion behaviour of 3D printed polyamide–carbon fibre composite filament

- An experimental investigation and machine learning-based prediction for seismic performance of steel tubular column filled with recycled aggregate concrete

- Effects of rare earth metals on microstructure, mechanical properties, and pitting corrosion of 27% Cr hyper duplex stainless steel

- Application research of acoustic black hole in floating raft vibration isolation system

- Multi-objective parametric optimization on the EDM machining of hybrid SiCp/Grp/aluminum nanocomposites using Non-dominating Sorting Genetic Algorithm (NSGA-II): Fabrication and microstructural characterizations

- Estimating of cutting force and surface roughness in turning of GFRP composites with different orientation angles using artificial neural network

- Displacement recovery and energy dissipation of crimped NiTi SMA fibers during cyclic pullout tests