Abstract

The interfacial transition zone (ITZ) between the fiber and the matrix significantly influences the strengthening and toughening effect of the fiber for the matrix. The ITZ between the fiber and mortar is a weak link in strain hardening cementitious composites (SHCC), the loose structure is easily damaged, and it is the main channel of ion attack. The oil reduces the hydrophilicity of fiber and the bonding strength of fiber and mortar, which decreases flexural and compressive strengths, but increases the tensile ductility. The compressive strength increased with the increase in the microhardness of ITZ. Both freeze-thawing cycle and sulfate attack reduce the flexural and compressive strengths, and ductility of SHCC. The failure of ITZ is responsible for the performance decrease. The strength of the samples containing oiled fiber after the freeze-thawing cycle and sulfate attack decreases more significantly.

Graphical abstract

1 Introduction

At present, concrete is still a well-used construction material. However, cement hydration products’ heterogeneous structure and characteristics result in making the concrete fragile and prone to crack [1], thereby making the reinforced concrete structure often work with cracks, jeopardizing the durability of concrete structures [2,3,4]. To address the brittleness issue, fiber is often added to bridge cracks and increase the energy absorption of the material [5]. Among different kinds of fiber-reinforced composites (FRC), strain hardening cementitious composites (SHCC) have stood out with their unique multiple cracking behavior and ultra-high ductility [6,7,8,9,10,11,12]. SHCC is designed by micromechanics and fracture mechanics [13,14,15,16], which has better toughness, impact resistance, multi-fracture extension, and a high ultimate tensile strain value of up to 3–5% [17]. Benefitting from the fiber bridging cracks, the force transmission property of the SHCC is not significantly weakened by the micro-cracks, which effectively reduces the inherent defects such as fragility and strain softening of concrete [18,19,20,21,22,23].

A water film is generated between the fibers and mortar during SHCC hardening, while Ca(OH)2 crystals produced by cement hydration accumulate in the water film layer, creating the interfacial transition zone (ITZ) between the fiber and mortar [24]. The ITZ is often regarded as the “weak link” in a material. The relatively high porosity in the ITZ will provide a more accessible pathway for the aggressive ions to penetrate [25]. Many scholars have conducted theory and engineering application research on the ITZ. Feng et al. [26] investigated the effect of silica fume on the ITZ between steel fibers and matrix, and the microstructure of the ITZ was evaluated using scanning electron microscopy (SEM). The results showed that incorporating silica fume reduced the ITZ breadth and improved the micromechanical properties. Rocha Ferreira et al. [27] used SEM and X-ray diffraction to evaluate the effect of carboxyl styrene-butadiene rubber coating on the performance of the vegetable fiber. The results showed that the interaction between the polymer and natural fibers depends on the cellulose amount of fibers and their crystallinity. Hong et al. [28] studied the microstructure and bonding properties of the ITZ in fiber-reinforced concrete. The results showed that many micro-cracks presented in the fiber–mortar ITZ and the content of hydration products were much lower than that in the matrix.

Actual engineering structures are often subjected to harsh environments, such as sulfate attack and freeze-thawing cycle, but few studies have reported the effects of freeze-thawing cycle and sulfate attack on the structure of ITZ and mechanism of SHCC. Therefore, this article focuses on observing the effects of service environment and oiled fiber on the SHCC’s ITZ, combined with fiber-interface indicators to determine the connection between the microstructure and macroscopic properties.

Cement performance index

| Normal consistency (%) | Fineness modulus (%) | Setting time (min) | Compressive strength (MPa) | Flexural strength (MPa) | |||

|---|---|---|---|---|---|---|---|

| Initial | Final | 3 days | 28 days | 3 days | 28 days | ||

| 26 | 2.5 | 185 | 235 | 18.7 | 47.9 | 4.6 | 7.2 |

PVA fiber performances

| Diameter (μm) | Elastic modulus (GPa) | Tensile strength (MPa) | Elongation (%) | Density (g·cm−3) | Length (mm) |

|---|---|---|---|---|---|

| 31 | 40 | 1,600 | 6 | 1.3 | 6 |

Chemical composition of fly ash and slag (%)

| Oxide | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | TiO2 |

|---|---|---|---|---|---|---|---|

| Fly ash | 3.84 | 48.44 | 28.52 | 4.56 | 0.84 | 0.7 | 1.38 |

| Slag | 35.8 | 34.5 | 16.1 | 0.97 | 2.25 | 7.6 | 1.12 |

2 Experiment

2.1 Materials

Cement: P·O 42.5 grade Portland cement. The physical properties are shown in Table 1.

Fine aggregate: the fine aggregate is river sand produced in Pingdu, Qingdao with fineness modulus of 2.5.

PVA fiber: the REC15 type PVA fiber is from Japan Kuraray company, the performance index is shown in Table 2.

Fly ash and slag were used as admixtures, the chemical compositions are presented in Table 3.

2.2 Mix proportion

The mass proportion of cement, slag, fly ash, fine aggregate, water, and PVA fiber in SHCC is 2:1:1:2:1.61:0.098, the water-binder ratio is 0.4, the specific mixing ratio is shown in Table 4. The specific treatment and experiment schemes are shown in Table 5. The sample preparation and performance test are shown in Figure 1.

The mixture ratio of SHCC (kg·m−3)

| Cement | Slag | Fly ash | Fine aggregate | Water | PVA |

|---|---|---|---|---|---|

| 533.5 | 266.7 | 266.7 | 533.5 | 429.5 | 26.2 |

Experiment scheme

| Group | Treatment | Service environment |

|---|---|---|

| B1 | Untreated | Standard curing |

| B2 | Untreated | Freeze-thawing |

| B3 | Untreated | Soak for 7 days |

| B4 | Untreated | Soak for 60 days |

| O1 | Oiled | Standard curing |

| O2 | Oiled | Freeze-thawing |

| O3 | Oiled | Soak for 7 days |

| O4 | Oiled | Soak for 60 days |

Note: B and O represent the specimens containing the untreated fiber and the oiled fiber, respectively. 1, 2, 3, and 4 represent the conditions being original for maintenance, subjected to freeze-thawing cycle, sulfate attack for 7 days, and sulphate attack for 60 days, respectively.

SHCC sample preparation and performance test.

2.3 Methods of testing

2.3.1 Oil treatment scheme

The oil bath was prepared with the oil and deionized water by the liquor ratio of 1:15 in a beaker. The mixing was carried out with a magnetic stirrer for 5 min at 60°C. After that, PVA fibers were added to the beaker and soaked for 30 min. This allows the oiling agent to deposit on the fiber surface as thin films. Later, the samples were padded at a pressure of 0.2 MPa on a padding machine (one dip, one nip). Finally, the oiled fibers were dried in an oven at 65°C for 30 min.

2.3.2 Mechanical test

GB/T17671-1999 “method of testing cements-Determination of strength” was used to determine the flexural and compressive strengths of SHCC after 28 days curing. The sample size is 40 mm × 40 mm × 160 mm.

2.3.3 Measurement of microhardness

The specimens for the ITZ microhardness test were cut into slices of 40 mm × 40 mm × 10 mm. The slices containing the ITZ between fiber and the matrix were polished with 600# sandpaper and then with 1500# sandpaper to obtain an adequately smooth surface. The HX-1000T microhardness tester measured the microhardness of ITZ. Due to the low microhardness of fiber, the indentation area is too large. The test was performed at 20 μm from the fiber, and the average microhardness is calculated from 10 tests. The Microhardness test is shown in Figure 2.

Schematic diagram of microhardness.

2.3.4 Tensile test

An electronic universal mechanical testing machine is used to load the sample. The sample is in the shape of dog-bone as shown in Figure 3(a), the loading device is shown in Figure 3(b), and the loading rate is 0.1 mm·min−1.

Loading instrument for tensile test. (a) Dimensions (units: mm) of dog-bone shaped specimens and (b) loading device.

2.3.5 Freeze-thawing cycle and aggressive ions attack experiments

The number of freeze-thawing cycle was 150 times. The test blocks were immersed in 5% Na2SO4 solution for 7 days or 60 days, and the solution was replaced every 15 days to ensure that the PH value of the solution remained constant.

3 Results and discussion

3.1 Effects of oiled fiber, freeze-thawing cycle, and sulfate attack on mechanical properties

The change in fiber hydrophilicity and service environment will change the bonding properties between the fiber and mortar, which will affect the interfacial transition zone of SHCC and impact the mechanical properties. Therefore, before studying the ITZ, the effects of oiled fiber, freeze-thawing cycle, and sulfate attack on the mechanical properties of SHCC were analyzed, as shown in Table 6.

The compressive and flexural strengths of SHCC

| Group | Flexural strength (MPa) | Compressive strength (MPa) |

|---|---|---|

| B1 | 17.4 ± 0.72 | 51.0 ± 2.1 |

| B2 | 14.4 ± 0.51 | 42.3 ± 1.7 |

| B3 | 18.3 ± 0.57 | 53.3 ± 2.5 |

| B4 | 14.7 ± 0.63 | 43.9 ± 0.9 |

| O1 | 14.4 ± 0.71 | 40.4 ± 1.4 |

| O2 | 12.7 ± 0.49 | 38.0 ± 1.9 |

| O3 | 15.9 ± 0.52 | 43.5 ± 2.3 |

| O4 | 11.7 ± 0.55 | 37.1 ± 1.1 |

Oiled fiber significantly reduced the flexural and compressive strengths of SHCC. The reason is that the oiled fiber reduces the hydrophilicity of the fiber, making the hydration products challenging to adhere to the fiber surface, reducing the friction and mechanical bite force between the fiber and the mortar, so, the strength is reduced [7]. The flexural and compressive strengths of SHCC first increase and then decrease with the increase in the sulfate attack age. This may be because of the formation of massive expansive products in the environment of sulfate attack. The products fill the porosity to make the ITZ denser, increasing the early strength [29]. However, when the stresses generated by the expansive products exceed the tensile strength of SHCC, the cracks expand, which destroys the internal structure of SHCC and leads to a decrease in strength [30]. The flexural and compressive strengths of O4 specimens is lower than O1 and B4. This indicates that SHCC with the oiled fiber is more susceptible to damage and has more significant strength loss under sulfate attack.

After 150 freeze-thawing cycles, the flexural strength of the SHCC decreased, and the flexural strength of O2 was lower than B2. The main reason is a strong affinity between the unoiled fiber and mortar, which reduces the surface peeling when damaged [31]. However, the bonding strength between the oiled fiber and mortar becomes smaller, so the breaks are more severe when subjected to freeze-thawing cycle damage.

3.2 The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on tensile properties

The uniaxial tensile stress–strain curve of SHCC is shown in Figure 4. Comparing the specimens with untreated fiber, finding that the SHCC under standard curing presents the strain hardening characteristics, the stress jitter is gentle and shows multiple cracking phenomena. After sulfate attack and freeze-thawing cycle, the tensile deformation capacity and jitter of the stress–strain curve decreases. However, the specimens after freeze-thawing cycle still exhibit strain hardening characteristics [32,33]. Different from the flexural and compressive strengths, oiled fiber enhances the tensile ductility of SHCC. The ultimate strain is up to 5.4% for original specimens which is significantly higher compared to that of sulfate attack and freeze-thawing cycling specimens, but the ultimate tensile strength decreases.

Tensile stress–strain curves of SHCC.

3.3 Influence of oiled fiber and sulfate attack on microhardness

The influence of oiled fiber and sulfate attack on the microhardness of ITZ is shown in Figure 5(a). Because the samples in the freeze-thawing cycle are severely damaged, the freeze-thawing specimens are not analyzed for microhardness.

Microhardness and its relationship with compressive strength. (a) Microhardness and (b) the relationship curve between compressive strength and microhardness.

Under sulfate attack, the microhardness first increases then decreases with the attack age. The reason is that the sulfate first attacks SHCC from ITZ and diffuses into ITZ, making the structure denser, leading to an increase in microhardness. However, when the swelling stress exceeds the tensile strength, causing cracking, spalling, and strength loss in ITZ [34,35], the microhardness decreases. Subsequent Section 3.4 will further analyze the microstructure changes in ITZ and the attack channel of sulfate into SHCC. Oiled fiber reduces the microhardness of SHCC, indicating that the de-hydrophilic treatment for fiber reduces the bonding force between the fiber and the mortar, resulting in a decrease in ITZ hardness.

The best-fitting line of compressive strength and average microhardness is shown in Figure 5(b). The microhardness and compressive strength of SHCC are linearly correlated. The compressive strength increases with the microhardness, indicating that it is necessary to study the interfacial properties of SHCC and ITZ microhardness which are the main factors affecting the mechanical properties of SHCC.

3.4 Micro-morphology of ITZ

The ITZ of SHCC is not only different from mortar in microstructure but also in chemical composition. To more accurately analyze the influence of oiled fiber, freeze-thawing cycle, and sulfate attack on ITZ, the SEM technology was used to observe the interface morphology. The energy dispersive spectroscopy (EDS) technology was used to analyze the element changes in SHCC to explore the difference between the hydration products.

3.4.1 The effect of oiled fiber on the ITZ

As exhibited in Figure 6, the mortar completely covered the fibers without exposing the fiber surface, indicating that the untreated fibers have a solid hydrophilic and considerable bonding strength with mortar. Figure 6(b) shows that the ITZ is broken when the fiber is pulled out, indicating that ITZ is weaker than mortar and has a loose structure, often as the cracks’ origin. As shown in Figure 7, there is an oil film on the fiber surface, and the friction is slight, which is not enough to bring out the loose structure. The ITZ is relatively intact. There is no apparent rupture or collapse mark, consistent with its ductility.

The SEM images of PVA fiber in B1 specimen. (a) Fiber surface and (b) fiber port.

The SEM images of PVA fiber in O1 specimen. (a) Fiber surface and (b) fiber port.

Using EDS technology to analyze the element composition of the ITZ and mortar of B1 specimen and O1 specimen, the location in the B1 is shown in Figure 8, and the element content is displayed in Figure 9 and Table 7.

The location of the groove left by pullout fiber and mortar in B1 specimen.

Energy spectra from Element analysis.

Element composition of specimens from EDS analysis

| Group | Content/% (mass ratio) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ITZ | Mortar | |||||||||

| O | Al | Si | S | Ca | O | Al | Si | S | Ca | |

| B1 | 66.41 | 2.29 | 5.29 | 0.27 | 25.74 | 62.55 | 5.20 | 10.32 | 0.47 | 21.46 |

| O1 | 64.35 | 1.79 | 6.54 | 0.44 | 26.88 | 61.66 | 5.67 | 9.06 | 0.77 | 22.84 |

Both B1 and O1 specimens in ITZ have a higher Ca element and O element content than the mortar, while the Si content is lower than the mortar, indicating that the ITZ is an enriched zone of Ca(OH)2, but it is a poor zone of C–H–S. Ca(OH)2 has a layered structure and weak bonding strength. Once subjected to stress, it is often the origin of cracks, so the ITZ is more easily destroyed. The difference in element content between B1 and O1 specimens is slight, so it can be inferred that the oiled fiber only changes the hydrophilicity of the fiber and does not reduce the hydration products. The main reason for the decrease in the compressive and flexural strengths is that the oil decreases the adhesion between mortar and fiber.

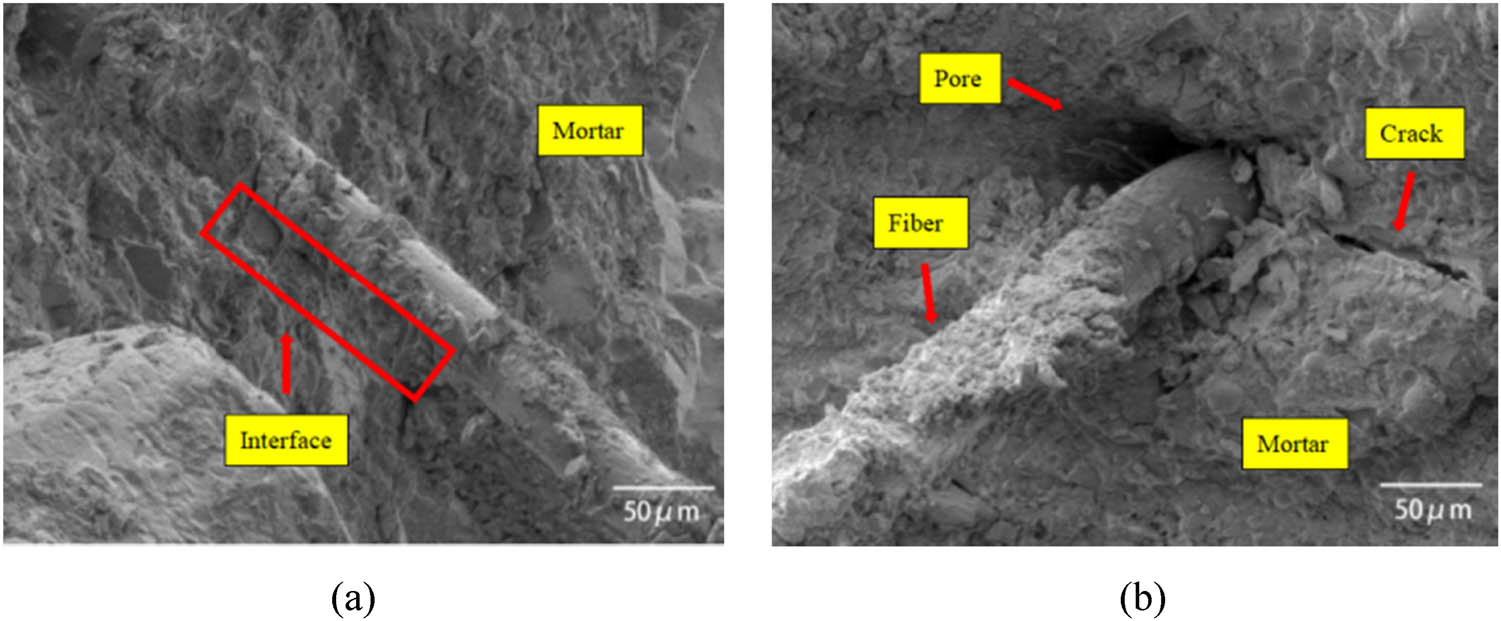

3.4.2 The effect of freeze-thawing cycle on ITZ

Figures 10 and 11 show the effects of freeze-thawing cycle on the ITZ. As shown in Figure 10, after the freeze-thawing cycle, the ITZ is looser, more pores, and cracks extend to the mortar. The main reason is that the freeze-thawing cycle makes the toughness of mortar worse, the volume of water film attached to the fiber surface and the free water in the mortar constantly change, which increase the pores between the fiber and the mortar, making the ITZ structure become loose [36].

The SEM images of PVA fiber in B2 specimen. (a) Fiber surface and (b) fiber port.

The SEM images of PVA fiber in O2 specimen. (a) Fiber surface and (b) fiber port.

As exhibited in Figure 11, comparing the B2 and O2 specimens, the fiber surface is smooth in O2 specimen, and the ITZ structure is loose and porous, which reveals that the freeze-thawing cycle destroys the ITZ structure and reduces the bonding strength between the fiber and mortar. Oiled fiber has less bonding strength after freeze-thawing cycle.

Using EDS technology to analyze the elemental composition of the ITZ and mortar in B2 specimen and O2 specimen, the element content is shown in Figure 12 and Table 8.

Energy spectra from element analysis.

Element composition from EDS analysis

| Group | Content/% (mass ratio) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ITZ | Mortar | |||||||||

| O | Al | Si | S | Ca | O | Al | Si | S | Ca | |

| B2 | 63.97 | 4.19 | 4.36 | 0.36 | 27.12 | 64.69 | 3.50 | 10.06 | 0.40 | 21.35 |

| O2 | 66.06 | 2.08 | 5.04 | 0.81 | 26.01 | 63.47 | 3.60 | 9.50 | 0.51 | 22.92 |

The ITZ in B2 and O2 specimens with high Ca and low Si content further proves that ITZ is the weak link in SHCC. The element types for B1, B2, and O2 specimens are similar, indicating that the source of freeze-thawing damage is the volume change when water turns into ice, and the hydration product types of ITZ do not change.

3.4.3 The influence of sulfate attack on the ITZ

The microstructure of the ITZ by sulfate attack for 7 days and 60 days is shown in Figures 13 and 14.

The SEM images of PVA fiber after sulfate attack for 7 days. (a) Untreated and (b) oiled.

The SEM images of PVA fiber after sulfate attack for 60 days. (a) Untreated and (b) oiled.

Figures 13 and 14 show that there are many hydration products on the surface of the fibers after sulfate attack for 7 days. Compared with the specimens without sulfate attack, the structure is denser, and products produced by sulfate attack fill the loose system and improve the denseness of ITZ. While the specimens with sulfate attack for 60 days had less adhesion on fiber surface, and the system is more flexible. This shows that the long-term sulfate attack reduces the drawing property of fiber, resulting in decreased flexural strength, compressive strength, and ductility for SHCC. Oiled fiber reduces the bonding strength between the fiber and mortar, making the fiber surface smoother.

EDS technology was used to analyze the element composition of the ITZ and mortar in B4 and O4 samples. The element content is shown in Table 9.

Element composition of specimens by EDS analysis

| Group | Content/% (mass ratio) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ITZ | Mortar | |||||||||

| O | Al | Si | S | Ca | O | Al | Si | S | Ca | |

| B4 | 66.30 | 3.32 | 4.75 | 2.19 | 23.44 | 62.32 | 3.10 | 8.33 | 1.21 | 25.04 |

| O4 | 68.20 | 1.38 | 6.13 | 2.23 | 21.26 | 63.50 | 3.35 | 7.47 | 1.48 | 24.42 |

Energy spectrum analysis shows that the S content in ITZ is significantly higher than that in the mortar, indicating that the ITZ is the primary way for sulfate attack to invade SHCC, and the sulfate ions first invade the ITZ in SHCC.

To further prove the intrusion path of sulfate attack in SHCC, the ITZ in B4 specimen was analyzed by EDS mapping-scanning, and the results are shown in Figure 15.

Distribution diagram of the element. (a) EDS mapping-scanning of B4 specimen, (b) S K α 1, (c) Ca K α 1, and (d) Si K α 1.

The groove in SEM is the ITZ in SHCC. The content of the S element in ITZ is significantly higher than mortar, and the element distribution is denser. It shows that the sulfate attack is more likely to first invade the ITZ in SHCC. The ITZ is the primary channel for sulfate attack.

In summary, ITZ between fiber and mortar is a weak link in SHCC, an enriched zone containing Ca(OH)2, which results in main channel of ion attack. The oil reduces the hydrophilicity of fiber, reduces the interaction of fiber-matrix, which decreases flexural and compressive strengths, but lowers the threshold for crack initiation and increases the tensile ductility. Freeze-thawing cycle and sulfate attack for 60 days destroy the ITZ structure, reduce the fiber–mortar bonding strength, which is the main reason for the decrease in the flexural and compressive strengths.

4 Conclusion

The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on the flexural and compressive strengths and flexibility of ITZ between the fiber and mortar of SHCC were studied, and the main conclusions are below:

The flexural and compressive strengths of SHCC is related to the bonding strength between the fiber and mortar. The greater the friction bonding strength between the fiber and mortar, the higher the mechanical properties for SHCC. The oiled fiber reduces the fiber hydrophilicity, decreasing flexural and compressive strengths, but increases the tensile ductility. Oiled fiber mitigates the microhardness of ITZ. The microhardness increases first and then decreases with an increase in the sulfate attack age.

The ITZ between fiber and mortar is the weak link in SHCC, the structure is loose and prone to damage, usually the origin of cracks. The EDS results show that the Ca(OH)2 content of ITZ is higher than that of mortar, but C–H–S content is lower than mortar. Moreover, ITZ is the primary channel for sulfate attacks, so ITZ is more likely to cause performance damage.

Sulfate attack and freeze-thawing cycle reduce the flexural strength, compressive strength, and ductility of SHCC. Microscopic analysis shows that ITZ damage between fiber and mortar is the main reason for declining performance. Oiled fiber increases the ductility of the sample subjected to freeze-thawing cycle and sulfate erosion, but the strength decreases. The strength of the samples containing oiled fiber after freeze-thawing cycle and sulfate attack reduces more significantly.

Acknowledgments

The authors would like to acknowledge all the members of Mr. Song Gao's team for their advice and assistance.

-

Funding information: This work was supported by the National Natural Science Foundation of China (51978353 and 52008223), the Natural Science Foundation of Shandong Province (ZR2020QE252), the China Postdoctoral Science Foundation (2021M700874), the Open Fund of the State Key Laboratory of High-Performance Civil Engineering Materials (PM321022), the Open Fund of the State Key Laboratory of Green Building Materials (2020GBM05), and the Ningbo 2025 Science and Technology Major Project (2020Z035).

-

Author contributions: Shun-Li Ban: Writing Original Draft, Conceptualization. Dong-Yi Lei: Writing - Review & Editing, Validation, Investigation. Song Gao: Methodology, Investigation, Data Curation. Hao Wang: Conceptualization, Methodology, Term. Yao-Yao Gong: Writing - Review & Editing, Formal analysis.

-

Conflict of interest: We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled.

References

[1] Lu, C., J. Yu, and C. K. Y. Leung. Tensile performance and impact resistance of strain hardening cementitious composites (SHCC) with recycled fibers. Construction and Building Materials, Vol. 171, 2018, pp. 566–576.10.1016/j.conbuildmat.2018.03.108Search in Google Scholar

[2] Hisseine, O. A. and A. Tagnit-Hamou. Characterization and nano-engineering the interface properties of PVA fibers in strain-hardening cementitious composites incorporating high-volume ground-glass pozzolans. Construction and Building Materials, Vol. 234, 2020, id. 117213.10.1016/j.conbuildmat.2019.117213Search in Google Scholar

[3] Lei D. Y., L. P. Guo, Y. Li, J. P. Liu, B. Chen, D. X. Li, et al. Micro-mechanical model for ultra-high strength and ultra-high ductility cementitious composites (UHS-UHDCC). Construction and Building Materials, Vol. 267, 2020, id. 120668.10.1016/j.conbuildmat.2020.120668Search in Google Scholar

[4] Lei, D. Y., L. P. Guo, Y. Li, Z. Zheng, J. P. Liu, S. C. Li, et al. The investigating on mechanical properties of ultra-high strength and ultra-high ductility cementitious composites (UHS-UHDCC). Journal of Building Engineering, Vol. 43, 2021, id. 102486.10.1016/j.jobe.2021.102486Search in Google Scholar

[5] Aveston, J. and A. Kelly. Theory of multiple fracture of fibrous composites. Materials Science, Vol. 8, 1973, pp. 352–362.10.1007/BF00550155Search in Google Scholar

[6] Li, V. C. and C. K. Y. Leung. Steady-state and multiple cracking of short random fiber composites. Engineering Mechanics, Vol. 118, 1992, pp. 2246–2264.10.1061/(ASCE)0733-9399(1992)118:11(2246)Search in Google Scholar

[7] Pan, Z., C. Wu, J. Liu, W. Wang, and J. Liu. Study on mechanical properties of cost-effective polyvinyl alcohol engineered cementitious composites (PVA-ECC). Construction and Building Materials, Vol. 78, 2015, pp. 397–404.10.1016/j.conbuildmat.2014.12.071Search in Google Scholar

[8] Li, V. C. On engineered cementitious composites (ECC). Advanced Concrete Technology, Vol. 1, 2003, pp. 215–230.10.3151/jact.1.215Search in Google Scholar

[9] Lu, Z., D. Hou, L. Meng, G. Sun, C. Lu, and Z. Li. Mechanism of cement paste reinforced by graphene oxide/carbon nanotubes composites with enhanced mechanical properties. RSC Advances, Vol. 5, 2015, pp. 100598–100605.10.1039/C5RA18602ASearch in Google Scholar

[10] Yu, J. and C. K. Y. Leung. Strength improvement of strain-hardening cementitious composites with ultrahigh-volume fly ash. Materials in Civil Engineering, Vol. 29, 2017, id. 05017003.10.1061/(ASCE)MT.1943-5533.0001987Search in Google Scholar

[11] Yu, K. Q., J. T. Yu, J. G. Dai, Z. D. Lu, and S. P. Shah. Development of ultra-high performance engineered cementitious composites using polyethylene (PE) fibers. Construction and Building Materials, Vol. 158, 2018, pp. 217–227.10.1016/j.conbuildmat.2017.10.040Search in Google Scholar

[12] Chen, Y., J. Yu, and C. K. Y. Leung. Use of high strength strain-hardening cementitious composites for flexural repair of concrete structures with significant steel corrosion. Construction and Building Materials, Vol. 167, 2018, pp. 325–337.10.1016/j.conbuildmat.2018.02.009Search in Google Scholar

[13] Li, V. C. and H. C. Wu. Conditions for pseudo strain-hardening in fiber reinforced brittle matrix composites. Applied Mechanics Reviews, Vol. 45, 1992, pp. 390–398.10.1115/1.3119767Search in Google Scholar

[14] Lu, C., C. K. Leung, and V. C. Li. Numerical model on the stress field and multiple cracking behavior of engineered cementitious composites (ECC). Construction and Building Materials, Vol. 133, 2017, pp. 118–127.10.1016/j.conbuildmat.2016.12.033Search in Google Scholar

[15] Lu, C. and C. K. Leung. A new model for the cracking process and tensile ductility of strain hardening cementitious composites (SHCC). Cement and Concrete Research, Vol. 79, 2016, pp. 353–365.10.1016/j.cemconres.2015.10.009Search in Google Scholar

[16] Leung, C. K. Y. Design criteria for pseudoductile fiber-reinforced composites. Engineering Mechanics, Vol. 122, 1996, pp. 10–18.10.1061/(ASCE)0733-9399(1996)122:1(10)Search in Google Scholar

[17] Arain, M. F., M. Wang, J. Chen, and H. Zhang. Study on PVA fiber surface modification for strain-hardening cementitious composites (PVA-SHCC). Construction and Building Materials, Vol. 197, 2019, pp. 107–116.10.1016/j.conbuildmat.2018.11.072Search in Google Scholar

[18] Gao, S., J. Jin, G. Hu, and L. Qi. Experimental investigation of the interface bond properties between SHCC and concrete under sulfate attack. Construction and Building Materials, Vol. 217, 2019, pp. 651–663.10.1016/j.conbuildmat.2019.05.121Search in Google Scholar

[19] Kim, M. J., H. J. Choi, W. Shin, T. Oh, and D. Y. Yoo. Development of impact resistant high-strength strain-hardening cementitious composites (HS-SHCC) superior to reactive powder concrete (RPC) under flexure. Journal of Building Engineering, Vol. 44, 2021, id. 102652.10.1016/j.jobe.2021.102652Search in Google Scholar

[20] Yu, J., H. Li, C. K. Y. Leung, X. Lin, J. Lam, I. Sham, et al. Sham. Matrix design for waterproof engineered cementitious composites (ECCs). Construction and Building Materials, Vol. 139, 2017, pp. 438–446.10.1016/j.conbuildmat.2017.02.076Search in Google Scholar

[21] Yu, J., J. Yao, X. Lin, H. Li, J. Lam, C. Leung, et al. Tensile performance of sustainable strain-hardening cementitious composites with hybrid PVA and recycled PET fibers. Cement and Concrete Research, Vol. 107, 2018, pp. 110–123.10.1016/j.cemconres.2018.02.013Search in Google Scholar

[22] Curosu, I., M. Liebscher, G. Alsous, E. Muja, H. Li, A. Drechsler, et al. Tailoring the crack-bridging behavior of strain-hardening cement-based composites (SHCC) by chemical surface modification of poly (vinyl alcohol) (PVA) fibers. Cement and Concrete Composites, Vol. 114, 2020, id. 103722.10.1016/j.cemconcomp.2020.103722Search in Google Scholar

[23] Mohammedameen, A., M. E. Gülşan, R. Alzeebaree, A. Çevik, and A. Niş. Mechanical and durability performance of FRP confined and unconfined strain hardening cementitious composites exposed to sulfate attack. Construction and Building Materials, Vol. 207, 2019, pp. 158–173.10.1016/j.conbuildmat.2019.02.108Search in Google Scholar

[24] Özbay, E., O. Karahan, M. Lachemi, K. Hossain, and C. D. Atis. Dual effectiveness of freezing–thawing and sulfate attack on high-volume slag-incorporated ECC. Composites Part B: Engineering, Vol. 45, 2013, pp. 1384–1390.10.1016/j.compositesb.2012.07.038Search in Google Scholar

[25] Fang, G. H. and M. Z. Zhang. The evolution of interfacial transition zone in alkali-activated fly ash-slag concrete. Cement and Concrete Research, Vol. 129, 2020, id. 105963.10.1016/j.cemconres.2019.105963Search in Google Scholar

[26] Feng, H., L. Li, P. Zhang, D. Gao, J. Zhao, L. Feng, et al. Microscopic characteristics of interface transition zone between magnesium phosphate cement and steel fiber. Construction and Building Materials, Vol. 253, 2020, id. 119179.10.1016/j.conbuildmat.2020.119179Search in Google Scholar

[27] Rocha Ferreira, S., A. Rodrigues Sena Neto, F. de Andrade Silva, F. Gomes de Souza, and R. Dias Toledo Filho. The influence of carboxylated styrene butadiene rubber coating on the mechanical performance of vegetable fibers and on their interface with a cement matrix. Construction and Building Materials, Vol. 262, 2020, id. 120770.10.1016/j.conbuildmat.2020.120770Search in Google Scholar

[28] Hong, L., Y. D. Chen, T. D. Li, P. Gao, and L. Z. Sun. Microstructure and bonding behavior of fiber-mortar interface in fiber-reinforced concrete. Construction and Building Materials, Vol. 232, 2020, id. 117235.10.1016/j.conbuildmat.2019.117235Search in Google Scholar

[29] Gao, Y., G. D. Schutter, and G. Ye. Micro and meso-scale pore structure in mortar in relation to aggregate content. Cement and Concrete Research, Vol. 52, 2013, pp. 149–160.10.1016/j.cemconres.2013.05.011Search in Google Scholar

[30] Yue, G., Z. Ma, M. Liu, C. Liang, and G. Ba. Damage behavior of the multiple ITZs in recycled aggregate concrete subjected to aggressive ion environment. Construction and Building Materials, Vol. 245, 2020, id. 118419.10.1016/j.conbuildmat.2020.118419Search in Google Scholar

[31] Yun, H. D. Effect of accelerated freeze-thawing cycling on mechanical properties of hybrid PVA and PE fiber-reinforced strain-hardening cement-based composites (SHCC). Composites Part B: Engineering, Vol. 52, 2013, pp. 11–20.10.1016/j.compositesb.2013.03.021Search in Google Scholar

[32] Meng, Z., Q. Liu, Y. Zhang, J. Sun, C. Yang, H. Li, et al. Tensile properties of hybrid fiber-reinforced strain-hardening cementitious composite exposed to elevated temperature. Journal of Building Engineering, Vol. 34, 2021, id. 101886.10.1016/j.jobe.2020.101886Search in Google Scholar

[33] Lu, Z. Y., J. Yao, and C. K. Y. Leung. Using graphene oxide to strengthen the bond between PE fiber and matrix to improve the strain hardening behavior of SHCC. Cement and Concrete Research, Vol. 126, 2019, id. 105899.10.1016/j.cemconres.2019.105899Search in Google Scholar

[34] Li, H., Q. J. Guo, and J. B. Wang. Meso-/Micro-structure of interfacial transition zone and durability of recycled aggregate concrete: a review. Composites Part B: Engineering, Vol. 34, 2020, pp. 13050–13057.Search in Google Scholar

[35] Lu, Z., R. Yin, J. Yao, and C. Leung. Surface modification of polyethylene fiber by ozonation and its influence on the mechanical properties of Strain-Hardening Cementitious Composites. Composites Part B: Engineering, Vol. 177, 2019, id. 107446.10.1016/j.compositesb.2019.107446Search in Google Scholar

[36] Nam, J., G. Kim, and B. Lee. Frost resistance of polyvinyl alcohol fiber and polypropylene fiber reinforced cementitious composites under freeze thaw cycling. Composites Part B: Engineering, Vol. 90, 2016, pp. 241–250.10.1016/j.compositesb.2015.12.009Search in Google Scholar

© 2022 Song Gao et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers

- A review on the properties of concrete reinforced with recycled steel fiber from waste tires

- Copper ternary oxides as photocathodes for solar-driven CO2 reduction

- Properties of fresh and hardened self-compacting concrete incorporating rice husk ash: A review

- Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey

- Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles

- Delivery systems in nanocosmeceuticals

- Study on the preparation process and sintering performance of doped nano-silver paste

- Analysis of the interactions between nonoxide reinforcements and Al–Si–Cu–Mg matrices

- Research Articles

- Study on the influence of structural form and parameters on vibration characteristics of typical ship structures

- Deterioration characteristics of recycled aggregate concrete subjected to coupling effect with salt and frost

- Novel approach to improve shale stability using super-amphiphobic nanoscale materials in water-based drilling fluids and its field application

- Research on the low-frequency multiline spectrum vibration control of offshore platforms

- Multiple wide band gaps in a convex-like holey phononic crystal strip

- Response analysis and optimization of the air spring with epistemic uncertainties

- Molecular dynamics of C–S–H production in graphene oxide environment

- Residual stress relief mechanisms of 2219 Al–Cu alloy by thermal stress relief method

- Characteristics and microstructures of the GFRP waste powder/GGBS-based geopolymer paste and concrete

- Development and performance evaluation of a novel environmentally friendly adsorbent for waste water-based drilling fluids

- Determination of shear stresses in the measurement area of a modified wood sample

- Influence of ettringite on the crack self-repairing of cement-based materials in a hydraulic environment

- Multiple load recognition and fatigue assessment on longitudinal stop of railway freight car

- Synthesis and characterization of nano-SiO2@octadecylbisimidazoline quaternary ammonium salt used as acidizing corrosion inhibitor

- Perforated steel for realizing extraordinary ductility under compression: Testing and finite element modeling

- The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on strain hardening cement-based composites

- Perforated steel block of realizing large ductility under compression: Parametric study and stress–strain modeling

- Study on dynamic viscoelastic constitutive model of nonwater reacted polyurethane grouting materials based on DMA

- Mechanical behavior and mechanism investigation on the optimized and novel bio-inspired nonpneumatic composite tires

- Effect of cooling rate on the microstructure and thermal expansion properties of Al–Mn–Fe alloy

- Research on process optimization and rapid prediction method of thermal vibration stress relief for 2219 aluminum alloy rings

- Failure prevention of seafloor composite pipelines using enhanced strain-based design

- Deterioration of concrete under the coupling action of freeze–thaw cycles and salt solution erosion

- Creep rupture behavior of 2.25Cr1Mo0.25V steel and weld for hydrogenation reactors under different stress levels

- Statistical damage constitutive model for the two-component foaming polymer grouting material

- Nano-structural and nano-constraint behavior of mortar containing silica aggregates

- Influence of recycled clay brick aggregate on the mechanical properties of concrete

- Effect of LDH on the dissolution and adsorption behaviors of sulfate in Portland cement early hydration process

- Comparison of properties of colorless and transparent polyimide films using various diamine monomers

- Study in the parameter influence on underwater acoustic radiation characteristics of cylindrical shells

- Experimental study on basic mechanical properties of recycled steel fiber reinforced concrete

- Dynamic characteristic analysis of acoustic black hole in typical raft structure

- A semi-analytical method for dynamic analysis of a rectangular plate with general boundary conditions based on FSDT

- Research on modification of mechanical properties of recycled aggregate concrete by replacing sand with graphite tailings

- Dynamic response of Voronoi structures with gradient perpendicular to the impact direction

- Deposition mechanisms and characteristics of nano-modified multimodal Cr3C2–NiCr coatings sprayed by HVOF

- Effect of excitation type on vibration characteristics of typical ship grillage structure

- Study on the nanoscale mechanical properties of graphene oxide–enhanced shear resisting cement

- Experimental investigation on static compressive toughness of steel fiber rubber concrete

- Study on the stress field concentration at the tip of elliptical cracks

- Corrosion resistance of 6061-T6 aluminium alloy and its feasibility of near-surface reinforcements in concrete structure

- Effect of the synthesis method on the MnCo2O4 towards the photocatalytic production of H2

- Experimental study of the shear strength criterion of rock structural plane based on three-dimensional surface description

- Evaluation of wear and corrosion properties of FSWed aluminum alloy plates of AA2020-T4 with heat treatment under different aging periods

- Thermal–mechanical coupling deformation difference analysis for the flexspline of a harmonic drive

- Frost resistance of fiber-reinforced self-compacting recycled concrete

- High-temperature treated TiO2 modified with 3-aminopropyltriethoxysilane as photoactive nanomaterials

- Effect of nano Al2O3 particles on the mechanical and wear properties of Al/Al2O3 composites manufactured via ARB

- Co3O4 nanoparticles embedded in electrospun carbon nanofibers as free-standing nanocomposite electrodes as highly sensitive enzyme-free glucose biosensors

- Effect of freeze–thaw cycles on deformation properties of deep foundation pit supported by pile-anchor in Harbin

- Temperature-porosity-dependent elastic modulus model for metallic materials

- Effect of diffusion on interfacial properties of polyurethane-modified asphalt–aggregate using molecular dynamic simulation

- Experimental study on comprehensive improvement of shear strength and erosion resistance of yellow mud in Qiang Village

- A novel method for low-cost and rapid preparation of nanoporous phenolic aerogels and its performance regulation mechanism

- In situ bow reduction during sublimation growth of cubic silicon carbide

- Adhesion behaviour of 3D printed polyamide–carbon fibre composite filament

- An experimental investigation and machine learning-based prediction for seismic performance of steel tubular column filled with recycled aggregate concrete

- Effects of rare earth metals on microstructure, mechanical properties, and pitting corrosion of 27% Cr hyper duplex stainless steel

- Application research of acoustic black hole in floating raft vibration isolation system

- Multi-objective parametric optimization on the EDM machining of hybrid SiCp/Grp/aluminum nanocomposites using Non-dominating Sorting Genetic Algorithm (NSGA-II): Fabrication and microstructural characterizations

- Estimating of cutting force and surface roughness in turning of GFRP composites with different orientation angles using artificial neural network

- Displacement recovery and energy dissipation of crimped NiTi SMA fibers during cyclic pullout tests

Articles in the same Issue

- Review Articles

- State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers

- A review on the properties of concrete reinforced with recycled steel fiber from waste tires

- Copper ternary oxides as photocathodes for solar-driven CO2 reduction

- Properties of fresh and hardened self-compacting concrete incorporating rice husk ash: A review

- Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey

- Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles

- Delivery systems in nanocosmeceuticals

- Study on the preparation process and sintering performance of doped nano-silver paste

- Analysis of the interactions between nonoxide reinforcements and Al–Si–Cu–Mg matrices

- Research Articles

- Study on the influence of structural form and parameters on vibration characteristics of typical ship structures

- Deterioration characteristics of recycled aggregate concrete subjected to coupling effect with salt and frost

- Novel approach to improve shale stability using super-amphiphobic nanoscale materials in water-based drilling fluids and its field application

- Research on the low-frequency multiline spectrum vibration control of offshore platforms

- Multiple wide band gaps in a convex-like holey phononic crystal strip

- Response analysis and optimization of the air spring with epistemic uncertainties

- Molecular dynamics of C–S–H production in graphene oxide environment

- Residual stress relief mechanisms of 2219 Al–Cu alloy by thermal stress relief method

- Characteristics and microstructures of the GFRP waste powder/GGBS-based geopolymer paste and concrete

- Development and performance evaluation of a novel environmentally friendly adsorbent for waste water-based drilling fluids

- Determination of shear stresses in the measurement area of a modified wood sample

- Influence of ettringite on the crack self-repairing of cement-based materials in a hydraulic environment

- Multiple load recognition and fatigue assessment on longitudinal stop of railway freight car

- Synthesis and characterization of nano-SiO2@octadecylbisimidazoline quaternary ammonium salt used as acidizing corrosion inhibitor

- Perforated steel for realizing extraordinary ductility under compression: Testing and finite element modeling

- The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on strain hardening cement-based composites

- Perforated steel block of realizing large ductility under compression: Parametric study and stress–strain modeling

- Study on dynamic viscoelastic constitutive model of nonwater reacted polyurethane grouting materials based on DMA

- Mechanical behavior and mechanism investigation on the optimized and novel bio-inspired nonpneumatic composite tires

- Effect of cooling rate on the microstructure and thermal expansion properties of Al–Mn–Fe alloy

- Research on process optimization and rapid prediction method of thermal vibration stress relief for 2219 aluminum alloy rings

- Failure prevention of seafloor composite pipelines using enhanced strain-based design

- Deterioration of concrete under the coupling action of freeze–thaw cycles and salt solution erosion

- Creep rupture behavior of 2.25Cr1Mo0.25V steel and weld for hydrogenation reactors under different stress levels

- Statistical damage constitutive model for the two-component foaming polymer grouting material

- Nano-structural and nano-constraint behavior of mortar containing silica aggregates

- Influence of recycled clay brick aggregate on the mechanical properties of concrete

- Effect of LDH on the dissolution and adsorption behaviors of sulfate in Portland cement early hydration process

- Comparison of properties of colorless and transparent polyimide films using various diamine monomers

- Study in the parameter influence on underwater acoustic radiation characteristics of cylindrical shells

- Experimental study on basic mechanical properties of recycled steel fiber reinforced concrete

- Dynamic characteristic analysis of acoustic black hole in typical raft structure

- A semi-analytical method for dynamic analysis of a rectangular plate with general boundary conditions based on FSDT

- Research on modification of mechanical properties of recycled aggregate concrete by replacing sand with graphite tailings

- Dynamic response of Voronoi structures with gradient perpendicular to the impact direction

- Deposition mechanisms and characteristics of nano-modified multimodal Cr3C2–NiCr coatings sprayed by HVOF

- Effect of excitation type on vibration characteristics of typical ship grillage structure

- Study on the nanoscale mechanical properties of graphene oxide–enhanced shear resisting cement

- Experimental investigation on static compressive toughness of steel fiber rubber concrete

- Study on the stress field concentration at the tip of elliptical cracks

- Corrosion resistance of 6061-T6 aluminium alloy and its feasibility of near-surface reinforcements in concrete structure

- Effect of the synthesis method on the MnCo2O4 towards the photocatalytic production of H2

- Experimental study of the shear strength criterion of rock structural plane based on three-dimensional surface description

- Evaluation of wear and corrosion properties of FSWed aluminum alloy plates of AA2020-T4 with heat treatment under different aging periods

- Thermal–mechanical coupling deformation difference analysis for the flexspline of a harmonic drive

- Frost resistance of fiber-reinforced self-compacting recycled concrete

- High-temperature treated TiO2 modified with 3-aminopropyltriethoxysilane as photoactive nanomaterials

- Effect of nano Al2O3 particles on the mechanical and wear properties of Al/Al2O3 composites manufactured via ARB

- Co3O4 nanoparticles embedded in electrospun carbon nanofibers as free-standing nanocomposite electrodes as highly sensitive enzyme-free glucose biosensors

- Effect of freeze–thaw cycles on deformation properties of deep foundation pit supported by pile-anchor in Harbin

- Temperature-porosity-dependent elastic modulus model for metallic materials

- Effect of diffusion on interfacial properties of polyurethane-modified asphalt–aggregate using molecular dynamic simulation

- Experimental study on comprehensive improvement of shear strength and erosion resistance of yellow mud in Qiang Village

- A novel method for low-cost and rapid preparation of nanoporous phenolic aerogels and its performance regulation mechanism

- In situ bow reduction during sublimation growth of cubic silicon carbide

- Adhesion behaviour of 3D printed polyamide–carbon fibre composite filament

- An experimental investigation and machine learning-based prediction for seismic performance of steel tubular column filled with recycled aggregate concrete

- Effects of rare earth metals on microstructure, mechanical properties, and pitting corrosion of 27% Cr hyper duplex stainless steel

- Application research of acoustic black hole in floating raft vibration isolation system

- Multi-objective parametric optimization on the EDM machining of hybrid SiCp/Grp/aluminum nanocomposites using Non-dominating Sorting Genetic Algorithm (NSGA-II): Fabrication and microstructural characterizations

- Estimating of cutting force and surface roughness in turning of GFRP composites with different orientation angles using artificial neural network

- Displacement recovery and energy dissipation of crimped NiTi SMA fibers during cyclic pullout tests