Abstract

Adsorbent is an important waste water-based drilling fluid treatment agent, which can adsorb and settle heavy metal ions, high polymer organics, and other soluble harmful substances in the waste drilling fluid. Traditional adsorbents such as polyaluminum chloride and polyacrylamide will produce other metal ions or toxic monomers after hydrolysis, which cannot fully meet the requirements of safety and environmental protection. Therefore, a new environmentally friendly waste water-based drilling fluid adsorbent, named RH-β-CD, was prepared by the Wilson etherification reaction, which was initiated by epichlorohydrin and ceric ammonium nitrate, and successfully grafted rhamnolipid and amine strong adsorption groups onto β-cyclodextrin. The adsorption effect and environmental protection performance of RH-β-CD on the organic matter and chromium ion in waste sulfonated water-based drilling fluid were evaluated and compared with commonly used adsorbents such as activated carbon, PAM, and polyaluminum chloride. The results show that RH-β-CD can effectively adsorb the organic matter in the filtrate of waste water-based drilling fluids, reduce its chemical oxygen consumption, and reduce the concentration of heavy metal ions in the filtrate. The effect is better than PAM, activated carbon, and polyaluminum chloride, with the BOD5/CODcr >20% and EC50 >1,000,000 mg·L−1, which is environmentally friendly.

1 Introduction

With the continuous development of drilling engineering in our country’s oil and gas field, the demand for drilling fluid has increased sharply. This makes waste drilling fluid treatment one of the key technologies that need to be solved urgently [1,2,3]. As an important treatment agent for the waste drilling fluid, the adsorbent can effectively adsorb heavy metal ions, high polymer organic matter, and other harmful substances dissolved in the liquid phase in the waste drilling fluid and settle by agglomeration and adsorption between particles, which is beneficial to the waste drilling liquid that finally achieves harmless treatment [4,5,6]. In recent years, domestic and foreign scholars have developed a large number of different types of adsorbents for the harmless treatment of the waste drilling fluid [7,8,9]. Among them, the porous structure and large specific surface area of activated carbon make it an adsorbent in the adsorption process to show the advantages of fast adsorption and good adsorption effect, but its limitation is that it is a nonselective adsorption process and may cause certain environmental problems [10]. Traditional adsorbents such as polyaluminum chloride and polyacrylamide will produce other metal ions or toxic monomers after being hydrolyzed and cannot fully meet the increasingly stringent requirements of safety and environmental friendly on-site [11].

β-Cyclodextrin is an oligosaccharide with a hollow circular truncated cone structure, which is connected by a-1,4-glycosidic bonds by multiple d-glucopyranoses. It has the characteristics of being hydrophobic inside the ring and hydrophilic outside the ring. It is widely used in medicine, food, sewage treatment, and other fields [12,13,14,15]. On the one hand, β-cyclodextrin can interact with a variety of guest molecules by noncovalent bonds to form host and guest compounds [16]. Lu et al. [17] used the host–guest interaction between cyclodextrin and azo compounds to prepare responsive supramolecular assemblies. Li [18] used the host–guest interaction between cyclodextrin and adamantane to synthesize targeted compounds. On the other hand, the surface of cyclodextrin has a large number of active hydroxyl groups, and different kinds of functional compounds can be obtained through chemical modification [14,19,20]. Qu et al. [21] used cellulose and cyclodextrin to carry out the cross-linking reaction to synthesize modified cyclodextrin compounds with adsorption of heavy metal pollutants. Zhong et al. [22] used cyclodextrin and epichlorohydrin for the cross-linking reaction and obtained cyclodextrin polymer microspheres with excellent thermal stability. Zhang et al. [23] used epichlorohydrin, corn starch, and γ-cyclodextrin for the cross-linking reaction and obtained a polymer that can absorb dye wastewater. Zheng et al. [12] used starch and cyclodextrin to carry out the cross-linking reaction to prepare a porous absorbent material with excellent adsorption performance. Therefore, modified cyclodextrin compounds have good application value in industrial wastewater treatment, heavy metal adsorption, etc. [24].

Research at domestic and overseas have shown that rhamnose as an adsorbent has the advantages of high mechanical strength, good adsorption effect, short adsorption time, and its inclusion and adsorption effect on some organic and inorganic substances, but it also has the shortcomings of lack of selective adsorption and insufficient chemical stability [25,26,27]. The molecular structure of polymers containing strong amine adsorption groups is changeable, the degree of protonation in aqueous solution is high, strong multipoint adsorption can occur, and the chemical stability and mechanical strength are high [28,29]. In this article, in response to the above problems, combined with related research results, using Wilson’s ether formation reaction, under the initiation of epichlorohydrin and cerium ammonium nitrate, rhamnolipid and amine strong adsorption groups were successfully grafted to β-cyclodextrin, a new environmentally friendly waste water-based drilling fluid adsorbent (RH-β-CD) containing hydrophobic polycyclic rings, carbonyl groups, ether bonds, and other groups was prepared and its performance was evaluated.

2 Materials and methods

2.1 Materials

Polymers containing an imine structure, hydrochloric acid, sodium hydroxide, trimethylamine, ethanol, anhydrous sodium carbonate, glutaraldehyde, and epichlorohydrin were provided by Aladdin Reagent Company as analytical reagents. β-Cyclodextrin was provided by Jinan Lvke Biological Technology Co., Ltd in technical grade. Monorhamnolipid was provided by Zhengzhou Xinghui Biological Technology Co., Ltd in technical grade. Sodium sulfite, perchloric acid, NaCl, cerium ammonium nitrate, and CaCl2 were provided by Sinopharm Reagent Co., Ltd as analytical reagents. Sodium-based bentonite was provided by Weifang Huawei Bentonite Group Co., Ltd. Sulfonated water-based drilling fluid was taken from the drilling site of a well in the southern Sichuan block.

2.2 Synthesis of RH-β-CD

The preparation process of the new environmentally friendly waste water-based drilling fluid adsorbent (RH-β-CD) is shown below, and its molecular structure diagram is shown in Figure 1.

Add a certain amount of rhamnolipid (RHA) and epichlorohydrin into a three-necked flask; then, add 60 mL of toluene and a small amount of perchloric acid, reflux, and allow to react at 80°C for 2 h. Then, filter with suction. Wash the filter cake with acetone three times and dry at 50°C to obtain the product.

Weigh a certain amount of the above product into a three-neck flask; then. add a certain amount of β-cyclodextrin (β-CD), anhydrous sodium carbonate, and distilled water, stir evenly, reflux for 3 h at 60°C, and then filter with suction and wash the filter cake three times with acetone, and finally, dry to obtain the intermediate product CTS-β-CD;

Weigh a certain amount of CTS-β-CD and disperse it in a certain amount of methanol; add 10 mL of 40% sodium hydroxide aqueous solution and then add a certain amount of 3-chloro-2-hydroxypropyl trimethyl chloride at 50°C. Ammonium aqueous solution and polymer containing the imine structure (R-PAI) are reacted for a period of time and then filter with suction. Wash the filter cake three times with ethanol and acetone respectively and dry at 50°C to obtain the target product to obtain as the product RH-β-CD.

Schematic diagram of the molecular structure of a new environmentally friendly waste water-based drilling fluid adsorbent RH-β-CD.

3 Results and analysis

3.1 FTIR of RH-β-CD

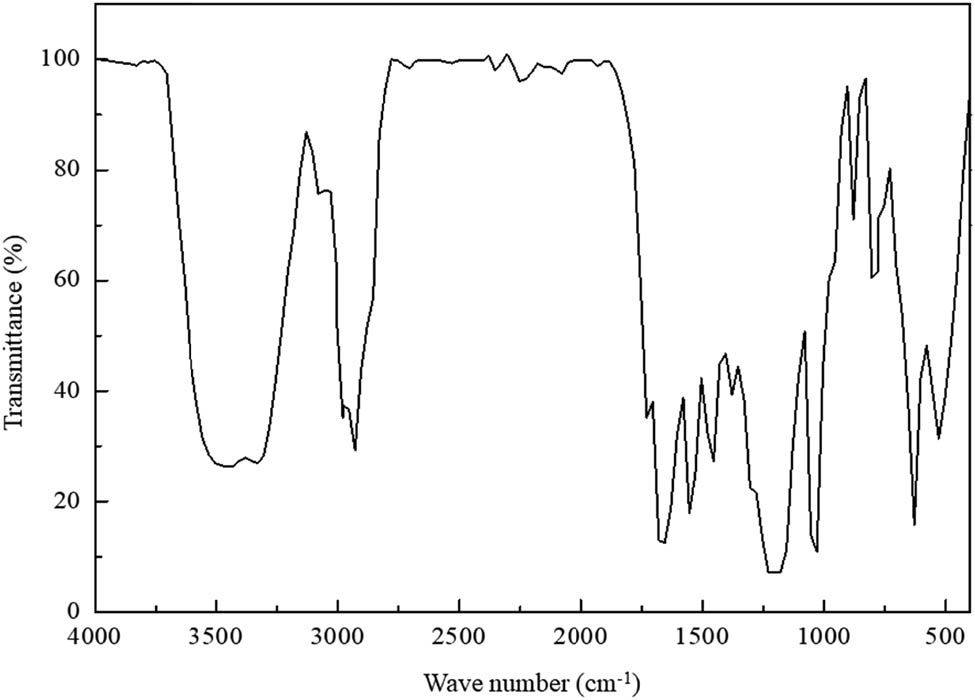

The FTIR of RH-β-CD is shown in Figure 2. It can be seen that the characteristic absorption peaks of –CH3 are at 2,966 and 2868.22 cm−1, the stretching vibration absorption peaks of C═O and the characteristic absorption peaks of primary/secondary/tertiary amides at 1650.50, and 1658.66 cm−1 is the stretching vibration of CO in the polysaccharide structure of the cyclodextrin molecule, 1016.47 cm−1 is the stretching vibration absorption peak of CO in –COO–, 1255.60 and 1208.06 cm−1 are the vibration absorption peaks of –C(CH3)– in the rhamnolipid molecule, the vibration absorption peak of C═O connected to the heterocyclic ring at 1350.22–1310.36 cm−1, and the absorption peak of the amine group N–H appears at 1640.25 cm−1. This shows that all the monomers have reacted under the action of the cross-linking agent, and the molecular chain of the synthesized product has the chain-link of the raw material.

The FTIR image of RH-β-CD.

3.2 H-NMR analysis

The H-NMR analysis of RH-β-CD is shown in Figure 3. The results show that the chemical shift δ appears at 3.6–4.0 at the proton peak on the carbon chain of cyclodextrin, the chemical shift δ at 1.3 corresponds to the proton peak on the long carbon chain of the rhamnolipid molecule, the chemical shift δ at 4.6 is the methyl proton peak on the cyclodextrin acetyl group, the peak of chemical shift δ at 5.4 is the proton peak of the hydroxyl group on the cyclodextrin backbone, and the chemical shift δ at 3.5–3.9 is the proton peak connected to the nitrogen atom in cyclodextrin. It shows that the rhamnolipid and cyclodextrin have successfully reacted.

H-NMR spectrum of RH-β-CD.

3.3 Evaluation of adsorption performance

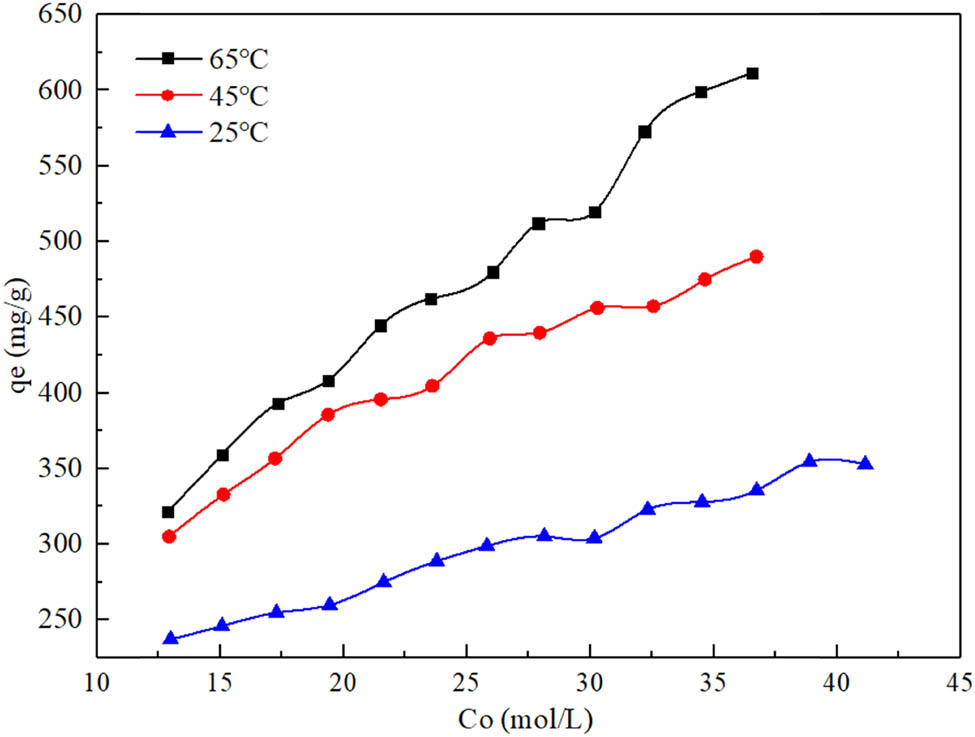

The concentration–absorbance linear adsorption fitting curve and the adsorption isotherm of RH-β-CD are shown in Figures 4 and 5. It can be seen that the adsorption isotherms of RH-β-CD at different temperatures are roughly linear, indicating that the adsorption process of the treatment agent in the solution is uniform and a single-layer adsorption process. The adsorption process depends on the surface adsorption of a certain number of active sites, which is a chemical adsorption process [30]. The single-layer adsorption can effectively enhance the adsorption strength and adsorption capacity of RH-β-CD, thereby ensuring that it has a better adsorption effect.

The concentration–absorbance linear adsorption fitting curve of RH-β-CD.

The adsorption isotherm of RH-β-CD.

3.4 Particle size distribution

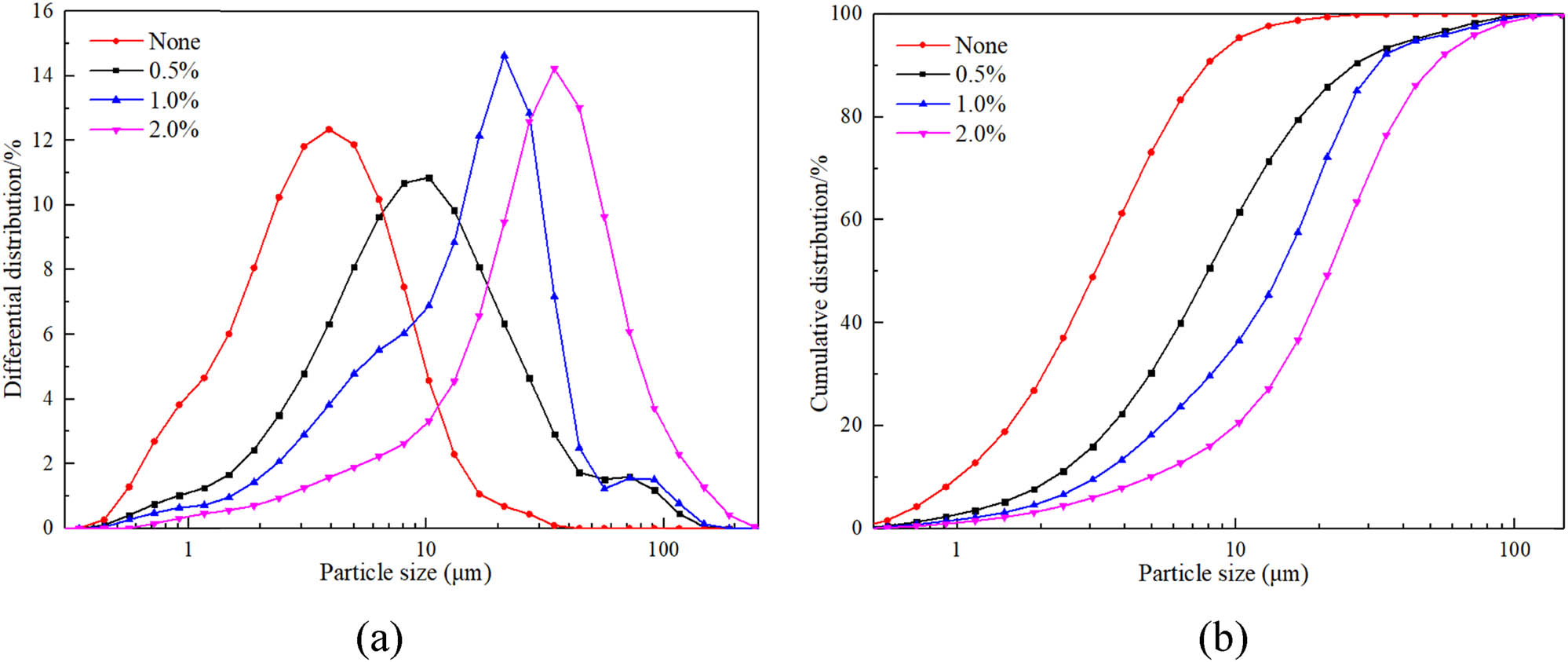

The particle size distribution is shown in Figure 6. The results show that after adding RH-β-CD, the particle size differential distribution curve and cumulative distribution curve shifted to the right, and the right shift gradually increased with the increase in the amount. This shows that as the concentration of RH-β-CD increases, the average particle size of bentonite particles keeps increasing. When the concentration reaches 2.0%, the average particle size of the clay particles added with the new RH-β-CD is 16.315 μm, which is much larger than the blank sample, indicating that RH-β-CD can overlap each other in the solution to form a network structure and its cavity can trap free clay particles in the solution. At the same time, it can adsorb clay particles through electrostatic attraction and aggregate clay particles, resulting in an increase in the average particle size and has better adsorption performance and flocculation effect.

The effect of RH-β-CD on the particle size distribution of bentonite slurry at different dosages: (a) differential distribution and (b) cumulative distribution.

3.5 Biological toxicity test

The biological toxicity test is shown in Figure 7 and Tables 1 and 2, referring to the National Standards of the People’s Republic of China GB/T 15441-1995 and GB/T 11914. When the luminosity of the luminescent bacteria is 50%, according to the linear regression equation (y = 80.82 – 2.06x), the EC50 value of RH-β-CD is about 14.96 × 104 mg·L−1. The test results show that EC50 >100,000 mg·L−1 and BOD5/CODCr >20%. This shows that the new waste water-based drilling fluid adsorbent RH-β-CD is nontoxic and relatively easy to biodegrade.

The biological toxicity EC50 test linear regression curve of RH-β-CD.

Biological toxicity test results of RH-β-CD

| Sample | Result | Standard | |||

|---|---|---|---|---|---|

| EC50 | EC50 fitted value | Toxicity classification | EC50 | Toxicity classification | |

| RH-β-CD | >100,000 | 14,960,000 | Nontoxic | <1 | Highly toxic |

| 1–100 | Highly toxic | ||||

| 100–1,000 | Moderate toxicity | ||||

| 1,000–10,000 | Slightly poisonous | ||||

| >10,000 | Practically nontoxic | ||||

| >30,000 | Emission Standards | ||||

Biodegradability test results of RH-β-CD

| Sample | BOD5 (mg·L−1) | CODCr (mg·L−1) | BOD5/CODCr (%) | Biodegradability |

|---|---|---|---|---|

| RH-β-CD | 10.4 | 48.2 | 21.57 | Relatively easy to degrade |

3.6 Evaluation of the treatment effect of RH-β-CD on the waste drilling fluid

(1) In the process of drilling, the waste water-based drilling fluid comes from a wide range of sources, is difficult to deal with, and does great harm to the environment. Its treatment has always been one of the difficult problems for oilfield enterprises, and its treatment cost accounts for a high proportion of the total drilling cost, which is the main technical problem restricting oilfield production and development. The typical waste water-based drilling fluid from a well in Shengli Oilfield was selected, and the filtrate was used as the test liquid to evaluate the treatment effect of pollutants after preliminary solid–liquid separation. Its main components can be seen in Table 3. Refer to GB 8978-1996, GB/T7574-1987, and other standards. The adsorption effect of different dosages of RH-β-CD on seven pollution items of waste drilling fluid (total chromium, total mercury, total arsenic, total lead, COD, hydrocarbon, pH value) was determined, and the results are shown in Table 4. It can be seen from the test results that RH-β-CD can effectively adsorb the harmful substances in the waste water-based drilling fluid at a 2.0% increase, and the relevant testing indicators of the waste drilling fluid filtrate after the treatment have reached the national standard [3,31]. It shows that it has excellent adsorption and wastewater treatment effects.

Analysis of main properties and pollutants of the waste water-based drilling fluid

| Components | Content |

|---|---|

| pH | 10.04 |

| ρ (g·cm−3) | 1.12 |

| Hydrocarbon (mg·L−1) | 25.45 |

| COD (mg·L−1) | 446.8 |

| Fe (mg·L−1) | 2.2342 |

| Cr (mg·L−1) | 0.6163 |

| Pb (mg·L−1) | 1.2029 |

| Cu (mg·L−1) | 6.2345 |

| Color | Brown black |

Treatment effect of RH-β-CD waste water-based drilling fluid filtrate pollutants

| Concentration (%) | pH | COD | Hydrocarbon | Cr | Pb | ||||

|---|---|---|---|---|---|---|---|---|---|

| Test value (mg·L−1) | Removal efficiency (%) | Test value (mg·L−1) | Removal efficiency (%) | Test value (mg·L−1) | Removal efficiency (%) | Test value (mg·L−1) | Removal efficiency (%) | ||

| 0.5 | 7–8 | 184.54 | 58.70 | 18.34 | 27.94 | 0.5284 | 14.26 | 0.6584 | 45.27 |

| 1.0 | 6–7 | 137.45 | 69.24 | 5.38 | 78.86 | 0.2845 | 53.84 | 0.2846 | 76.34 |

| 1.5 | 6–7 | 63.56 | 85.77 | 4.28 | 83.18 | 0.0925 | 84.99 | 0.0944 | 92.15 |

| 2.0 | 6 | 27.45 | 93.86 | 1.63 | 93.60 | 0.0174 | 97.18 | 0.01654 | 98.62 |

| Standard | 6–9 | 100 | — | 5.0 | — | 0.50 | — | 1.0 | — |

(2) Effect of different types of treatment agents on COD of the waste water-based drilling fluid. Refer to GB 11914-89. We comparatively evaluated the effects of four commonly used treatment agents (activated carbon, cyclodextrin, polyacrylamide, polyaluminum chloride) and the new RH-β-CD treatment agent on reducing the chemical oxygen consumption of waste water-based drilling fluids. The test result is shown in Figure 8. Five different treatment agents have a certain effect on reducing the COD value of the waste water-based drilling fluid filtrate. Among them, RH-β-CD has the best effect, with a COD reduction rate of 69.23%, followed by activated carbon with a COD reduction rate of 48.2%. This shows that RH-β-CD and activated carbon can effectively adsorb the organic matter in the waste water-based drilling fluid filtrate and reduce its chemical oxygen consumption. This is because the rhamnolipid in RH-β-CD has good surface activity and can reduce the surface tension of the filtrate. Cyclodextrin has a hydrophilic hydroxyl group on the outside and a hydrophobic cavity on the inside. The imine structure can be fully protonated in water and electrostatically attracted to free fine particles. The synergistic effect of the three can firmly adsorb the organic substances free in the water in the hydrophobic cavity of the RH-β-CD molecule, so it has a better effect.

The influence of different treatment agents on the COD value of the waste water-based drilling fluid filtrate.

(3) Adsorption of different types of treatment agents to heavy metal ions. The adsorption of four types of treatment agents (activated carbon, cyclodextrin, polyacrylamide, polyaluminum chloride) and the new RH-β-CD treatment agent to chromium ions and lead ions in waste water-based drilling fluids were comparatively evaluated. The test result is shown in Figure 9; five different treatment agents have a certain degree of adsorption of chromium ions in the waste water-based drilling fluid loss. Among them, RH-β-CD has the best effect. The chromium ion content is reduced by more than 50%, followed by polyaluminum chloride, and the chromium ion is reduced by 45%. This shows that RH-β-CD and polyaluminum chloride can effectively adsorb heavy metal ions in waste water-based drilling fluid loss.

The influence of different treatment agents on the content of metal ions in the waste water-based drilling fluid filtrate.

4 Conclusions

Using Wilson’s ether formation reaction, under the initiation of epichlorohydrin and cerium ammonium nitrate, the rhamnolipid and amine strong adsorption groups were successfully grafted onto β-cyclodextrin, and a new environmentally friendly waste water-based drilling fluid adsorbent RH-β-CD was prepared.

The adsorption effect and environmental protection performance of RH-β-CD on organics and chromium ions in waste sulfonated water-based drilling fluids were evaluated, and the performance was compared with commonly used adsorbents such as activated carbon, PAM, and polyaluminum chloride. The results show that RH-β-CD can effectively adsorb the organic matter in the waste water-based drilling fluid filtrate, reduce its chemical oxygen consumption, and reduce the concentration of heavy metal ions in the filtrate. Its effect is better than the current commonly used PAM, activated carbon, and polyaluminum chloride.

The results of the biotoxicity test and biodegradability test show that the BOD5/CODCr >20% and EC50 >100,000 mg·L−1 for the new waste water-based drilling fluid adsorbent RH-β-CD, which is nontoxic, relatively easy to biodegrade, and is environmentally friendly.

-

Funding information: This work was financially supported by the Major Science and Technology Projects of CNPC, China (No. 2019F-33).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Qi, C. Application actuality of shale gas drilling fluid technology at home and abroad. Chemical Industry Times, Vol. 28, No. 10, 2014, pp. 40–46.Search in Google Scholar

[2] Xu, J., Z. Qiu, and K. Lv. Studies on deepwater drilling fluid. Drilling Fluid & Completion Fluid, Vol. 25, No. 5, 2008, pp. 9–10.Search in Google Scholar

[3] Liu, Y., F. Meng, J. Huang, L. Ni, Y. Shen, and L. Zhang. Polyphenylene sulfide-coated wrench composites by nanopinning effect. Nanotechnology Reviews, Vol. 10, No. 1, 2021, pp. 166–177.10.1515/ntrev-2021-0014Search in Google Scholar

[4] Mahvi, A., M. Malakootian, and M. Heidari. Comparison of polyaluminum silicate chloride and electrocoagulation process, in natural organic matter removal from surface water in Ghochan, Iran. Journal of Water Chemistry and Technology, Vol. 33, No. 6, 2011, pp. 377–385.10.3103/S1063455X11060051Search in Google Scholar

[5] Javid, N. and M. Malakootian. Removal of bisphenol A from aqueous solutions by modified-carbonized date pits by ZnO nano-particles. Desalination and Water Treatment, Vol. 95, 2017, pp. 144–151.10.5004/dwt.2017.21592Search in Google Scholar

[6] Wang, C., C. Qi, and X. Liu. Research progress on treating technology of waste drilling fluids. Inner Mongolia Petrochemical Industry, Vol. 40, No. 22, 2014, pp. 102–106.Search in Google Scholar

[7] Malakootian, M., K. Kannan, M. Gharaghani, Y. Shahamat, and H. Mahdizadeh. Removal of metronidazole from wastewater by Fe/charcoal micro electrolysis fluidized bed reactor. Journal of Environmental Chemical Engineering, Vol. 7, No. 6, 2019, id. 103457.10.1016/j.jece.2019.103457Search in Google Scholar

[8] Meng, T., S. Lian, X. Yang, and R. Meng. Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams. Nanotechnology Reviews, Vol. 10, No. 1, 2021, pp. 292–303.10.1515/ntrev-2021-0024Search in Google Scholar

[9] Jiang, G., X. Ni, W. Li, X. Quan, and X. Luo. Super-amphiphobic, strong self-cleaning and high-efficiency water-based drilling fluids. Petroleum Exploration and Development, Vol. 47, No. 2, 2020, pp. 421–429.10.1016/S1876-3804(20)60059-3Search in Google Scholar

[10] Zhong, H., X. Kong, X. Gao, Z. Qiu, W. Li, Z. An, et al. Filtration and structure of bentonite-β-cyclodextrin polymer microspheres suspensions: Effect of thermal aging time. Journal of Molecular Liquids, Vol. 341, 2021, id. 116914.10.1016/j.molliq.2021.116914Search in Google Scholar

[11] Huang, X., K. Lv, J. Sun, Z. Lu, Y. Bai, H. Shen, et al. Enhancement of thermal stability of drilling fluid using laponite nanoparticles under extreme temperature conditions. Materials Letters, Vol. 248, 2019, pp. 146–149.10.1016/j.matlet.2019.04.005Search in Google Scholar

[12] Zheng, X., C. Qiu, J. Long, A. Jiao, X. Xu, Z. Jin, et al. Preparation and characterization of porous starch/β-cyclodextrin microsphere for loading curcumin: Equilibrium, kinetics and mechanism of adsorption. Food Bioscience, Vol. 41, 2021, id. 101081.10.1016/j.fbio.2021.101081Search in Google Scholar

[13] Deng, W., L. Yu, M. Ma, and G. Yang. Synthesis of β-cyclodextrin polymer and adsorption study for α-naphthol and 3,5-bisnitro salicylic acid. Applied Chemical Industry, Vol. 42, No. 9, 2013, pp. 1662–1666.Search in Google Scholar

[14] Javid, N., Z. Honarmandrad, and M. Malakootian. Ciprofloxacin removal from aqueous solutions by ozonation with calcium peroxide. Desalination and Water Treatment, Vol. 174, 2020, pp. 178–185.10.5004/dwt.2020.24855Search in Google Scholar

[15] Malakootian, M., M. Khatami, H. Mahdizadeh, A. Nasiri, and M. Amiri Gharaghani. Study on the photocatalytic degradation of p-nitroaniline on glass plates by thermo immobilized ZnO nanoparticle. Inorganic and Nano-Metal Chemistry, Vol. 50, No. 3, 2020, pp. 124–135.10.1080/24701556.2019.1662807Search in Google Scholar

[16] Xie, B., X. Zhang, Y. Li, W. Liu, and M. Luo. Application a novel thermo-sensitive copolymer as a potential rheological modifier for deepwater water-based drilling fluids. Colloids and Surfaces A: Physicochemical and Engineering Aspects, Vol. 581, 2019, id. 123848.10.1016/j.colsurfa.2019.123848Search in Google Scholar

[17] Lu, Y., H. Zou, H. Yuan, S. Gu, W. Yuan, and M. Li. Triple stimuli-responsive supramolecular assemblies based on host-guest inclusion complexation between β-cyclodextrin and azobenzene. European Polymer Journal, Vol. 91, 2017, pp. 396–407.10.1016/j.eurpolymj.2017.04.028Search in Google Scholar

[18] Li, P. Preparation of a novel nano polymer emulsion plugging agent using in drilling fluids for shale gas exploration. Fresenius Environmental Bulletin, Vol. 29, No. 3, 2020, pp. 1798–1803.Search in Google Scholar

[19] Yan, X., Y. Kang, L. You, C. Xu, C. Lin, and J. Zhang. Drill-in fluid loss mechanisms in brittle gas shale: a case study in the Longmaxi Formation, Sichuan Basin, China. Journal of Petroleum Science and Engineering, Vol. 174, 2019, pp. 394–405.10.1016/j.petrol.2018.11.026Search in Google Scholar

[20] Gao, X., H. Zhong, Z. Qiu, J. Jin, D. Li, and J. Li. Preparation of microsphere β-cyclodextrin polymer filter loss reducer for drilling fluids. Drilling Fluid & Completion Fluid, Vol. 38, No. 01, 2021, pp. 21–26.Search in Google Scholar

[21] Qu, J., Q. Meng, X. Lin, W. Han, Q. Jiang, L. Wang, et al. Microwave-assisted synthesis of β-cyclodextrin functionalized celluloses for enhanced removal of Pb(II) from water: Adsorptive performance and mechanism exploration. Science of The Total Environment, Vol. 752, 2021, id. 141854.10.1016/j.scitotenv.2020.141854Search in Google Scholar PubMed

[22] Zhong, H., X. Gao, Z. Qiu, Y. Lin, J. Jin, Z. Tang, et al. Mechanism of filtration loss reduction of environment-friendly β-cyclodextrin polymer microspheres under high temperature. Acta Petrolei Sinica, Vol. 42, No. 08, 2021, pp. 1091–1102.Search in Google Scholar

[23] Zhang, H., Y. Zhang, B. Cheng, and Y. Li. Preparing γ-cyclodextrin-immobilized starch and the study of its removal properties to dyestuff from wastewater. Polish Journal of Environmental Studies, Vol. 28, No. 3, 2019, pp. 1701–1711.10.15244/pjoes/90028Search in Google Scholar

[24] Zou, C., M. Liang, X. Chen, and X. Yan. β-Cyclodextrin modified cationic acrylamide polymers for flocculating waste drilling fluids. Journal of Applied Polymer Science, Vol. 131, No. 9, 2013, pp. 93–98.10.1002/app.40197Search in Google Scholar

[25] Fan, Y., G. Wang, J. Fu, and X. Zheng. Bioremediation of waste drilling fluid: comparison of biostimulation and bioaugmentation. Desalination & Water Treatment, Vol. 48, No. 1–3, 2012, pp. 329–334.10.1080/19443994.2012.698838Search in Google Scholar

[26] Li, J., J. He, J. Shi, Z. Chen, and G. Zeng. Preparation of Rhamnolipid Carbon Adsorbent and Its Adsorption Performance. Journal of Inorganic Materials, Vol. 6, 2006, pp. 61–66.Search in Google Scholar

[27] Cui, Y., M. Nie, H. Nie, Z. Diwu, and H. Sun. Preparation and characterization of graphere oxide and its adsorption and separation properties of rhamnolipid from fermentation broth. Environmental Chemistry, Vol. 10, 2019, pp. 2294–2299.Search in Google Scholar

[28] Zhong, H., Z. Qiu, D. Sun, D. Zhang, and W. Huang. Inhibitive properties comparison of different polyetheramines in water-based drilling fluid. Journal of Natural Gas Science & Engineering, Vol. 26, 2015, pp. 99–107.10.1016/j.jngse.2015.05.029Search in Google Scholar

[29] Wang, C. Experimental study on harmless treatment technology of oil-based drilling fluid solid waste based on a novel chemical curing agent. Fresenius Environmental Bulletin, Vol. 29, No. 3, 2020, pp. 1857–1865.Search in Google Scholar

[30] Jia, J., H. Liu, and D. Zhao. Experimental study on the influence of drilling fluid plugging property on the shale wellbore stability. Fresenius Environmental Bulletin, Vol. 29, No. 3, 2020, pp. 1886–1894.Search in Google Scholar

[31] Foo, K. and B. Hameed. Insights into the modeling of adsorption isotherm systems. Chemical Engineering Journal, Vol. 156, No. 1, 2010, pp. 2–10.10.1016/j.cej.2009.09.013Search in Google Scholar

© 2022 Yong Guo et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers

- A review on the properties of concrete reinforced with recycled steel fiber from waste tires

- Copper ternary oxides as photocathodes for solar-driven CO2 reduction

- Properties of fresh and hardened self-compacting concrete incorporating rice husk ash: A review

- Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey

- Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles

- Delivery systems in nanocosmeceuticals

- Study on the preparation process and sintering performance of doped nano-silver paste

- Analysis of the interactions between nonoxide reinforcements and Al–Si–Cu–Mg matrices

- Research Articles

- Study on the influence of structural form and parameters on vibration characteristics of typical ship structures

- Deterioration characteristics of recycled aggregate concrete subjected to coupling effect with salt and frost

- Novel approach to improve shale stability using super-amphiphobic nanoscale materials in water-based drilling fluids and its field application

- Research on the low-frequency multiline spectrum vibration control of offshore platforms

- Multiple wide band gaps in a convex-like holey phononic crystal strip

- Response analysis and optimization of the air spring with epistemic uncertainties

- Molecular dynamics of C–S–H production in graphene oxide environment

- Residual stress relief mechanisms of 2219 Al–Cu alloy by thermal stress relief method

- Characteristics and microstructures of the GFRP waste powder/GGBS-based geopolymer paste and concrete

- Development and performance evaluation of a novel environmentally friendly adsorbent for waste water-based drilling fluids

- Determination of shear stresses in the measurement area of a modified wood sample

- Influence of ettringite on the crack self-repairing of cement-based materials in a hydraulic environment

- Multiple load recognition and fatigue assessment on longitudinal stop of railway freight car

- Synthesis and characterization of nano-SiO2@octadecylbisimidazoline quaternary ammonium salt used as acidizing corrosion inhibitor

- Perforated steel for realizing extraordinary ductility under compression: Testing and finite element modeling

- The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on strain hardening cement-based composites

- Perforated steel block of realizing large ductility under compression: Parametric study and stress–strain modeling

- Study on dynamic viscoelastic constitutive model of nonwater reacted polyurethane grouting materials based on DMA

- Mechanical behavior and mechanism investigation on the optimized and novel bio-inspired nonpneumatic composite tires

- Effect of cooling rate on the microstructure and thermal expansion properties of Al–Mn–Fe alloy

- Research on process optimization and rapid prediction method of thermal vibration stress relief for 2219 aluminum alloy rings

- Failure prevention of seafloor composite pipelines using enhanced strain-based design

- Deterioration of concrete under the coupling action of freeze–thaw cycles and salt solution erosion

- Creep rupture behavior of 2.25Cr1Mo0.25V steel and weld for hydrogenation reactors under different stress levels

- Statistical damage constitutive model for the two-component foaming polymer grouting material

- Nano-structural and nano-constraint behavior of mortar containing silica aggregates

- Influence of recycled clay brick aggregate on the mechanical properties of concrete

- Effect of LDH on the dissolution and adsorption behaviors of sulfate in Portland cement early hydration process

- Comparison of properties of colorless and transparent polyimide films using various diamine monomers

- Study in the parameter influence on underwater acoustic radiation characteristics of cylindrical shells

- Experimental study on basic mechanical properties of recycled steel fiber reinforced concrete

- Dynamic characteristic analysis of acoustic black hole in typical raft structure

- A semi-analytical method for dynamic analysis of a rectangular plate with general boundary conditions based on FSDT

- Research on modification of mechanical properties of recycled aggregate concrete by replacing sand with graphite tailings

- Dynamic response of Voronoi structures with gradient perpendicular to the impact direction

- Deposition mechanisms and characteristics of nano-modified multimodal Cr3C2–NiCr coatings sprayed by HVOF

- Effect of excitation type on vibration characteristics of typical ship grillage structure

- Study on the nanoscale mechanical properties of graphene oxide–enhanced shear resisting cement

- Experimental investigation on static compressive toughness of steel fiber rubber concrete

- Study on the stress field concentration at the tip of elliptical cracks

- Corrosion resistance of 6061-T6 aluminium alloy and its feasibility of near-surface reinforcements in concrete structure

- Effect of the synthesis method on the MnCo2O4 towards the photocatalytic production of H2

- Experimental study of the shear strength criterion of rock structural plane based on three-dimensional surface description

- Evaluation of wear and corrosion properties of FSWed aluminum alloy plates of AA2020-T4 with heat treatment under different aging periods

- Thermal–mechanical coupling deformation difference analysis for the flexspline of a harmonic drive

- Frost resistance of fiber-reinforced self-compacting recycled concrete

- High-temperature treated TiO2 modified with 3-aminopropyltriethoxysilane as photoactive nanomaterials

- Effect of nano Al2O3 particles on the mechanical and wear properties of Al/Al2O3 composites manufactured via ARB

- Co3O4 nanoparticles embedded in electrospun carbon nanofibers as free-standing nanocomposite electrodes as highly sensitive enzyme-free glucose biosensors

- Effect of freeze–thaw cycles on deformation properties of deep foundation pit supported by pile-anchor in Harbin

- Temperature-porosity-dependent elastic modulus model for metallic materials

- Effect of diffusion on interfacial properties of polyurethane-modified asphalt–aggregate using molecular dynamic simulation

- Experimental study on comprehensive improvement of shear strength and erosion resistance of yellow mud in Qiang Village

- A novel method for low-cost and rapid preparation of nanoporous phenolic aerogels and its performance regulation mechanism

- In situ bow reduction during sublimation growth of cubic silicon carbide

- Adhesion behaviour of 3D printed polyamide–carbon fibre composite filament

- An experimental investigation and machine learning-based prediction for seismic performance of steel tubular column filled with recycled aggregate concrete

- Effects of rare earth metals on microstructure, mechanical properties, and pitting corrosion of 27% Cr hyper duplex stainless steel

- Application research of acoustic black hole in floating raft vibration isolation system

- Multi-objective parametric optimization on the EDM machining of hybrid SiCp/Grp/aluminum nanocomposites using Non-dominating Sorting Genetic Algorithm (NSGA-II): Fabrication and microstructural characterizations

- Estimating of cutting force and surface roughness in turning of GFRP composites with different orientation angles using artificial neural network

- Displacement recovery and energy dissipation of crimped NiTi SMA fibers during cyclic pullout tests

Articles in the same Issue

- Review Articles

- State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers

- A review on the properties of concrete reinforced with recycled steel fiber from waste tires

- Copper ternary oxides as photocathodes for solar-driven CO2 reduction

- Properties of fresh and hardened self-compacting concrete incorporating rice husk ash: A review

- Basic mechanical and fatigue properties of rubber materials and components for railway vehicles: A literature survey

- Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles

- Delivery systems in nanocosmeceuticals

- Study on the preparation process and sintering performance of doped nano-silver paste

- Analysis of the interactions between nonoxide reinforcements and Al–Si–Cu–Mg matrices

- Research Articles

- Study on the influence of structural form and parameters on vibration characteristics of typical ship structures

- Deterioration characteristics of recycled aggregate concrete subjected to coupling effect with salt and frost

- Novel approach to improve shale stability using super-amphiphobic nanoscale materials in water-based drilling fluids and its field application

- Research on the low-frequency multiline spectrum vibration control of offshore platforms

- Multiple wide band gaps in a convex-like holey phononic crystal strip

- Response analysis and optimization of the air spring with epistemic uncertainties

- Molecular dynamics of C–S–H production in graphene oxide environment

- Residual stress relief mechanisms of 2219 Al–Cu alloy by thermal stress relief method

- Characteristics and microstructures of the GFRP waste powder/GGBS-based geopolymer paste and concrete

- Development and performance evaluation of a novel environmentally friendly adsorbent for waste water-based drilling fluids

- Determination of shear stresses in the measurement area of a modified wood sample

- Influence of ettringite on the crack self-repairing of cement-based materials in a hydraulic environment

- Multiple load recognition and fatigue assessment on longitudinal stop of railway freight car

- Synthesis and characterization of nano-SiO2@octadecylbisimidazoline quaternary ammonium salt used as acidizing corrosion inhibitor

- Perforated steel for realizing extraordinary ductility under compression: Testing and finite element modeling

- The influence of oiled fiber, freeze-thawing cycle, and sulfate attack on strain hardening cement-based composites

- Perforated steel block of realizing large ductility under compression: Parametric study and stress–strain modeling

- Study on dynamic viscoelastic constitutive model of nonwater reacted polyurethane grouting materials based on DMA

- Mechanical behavior and mechanism investigation on the optimized and novel bio-inspired nonpneumatic composite tires

- Effect of cooling rate on the microstructure and thermal expansion properties of Al–Mn–Fe alloy

- Research on process optimization and rapid prediction method of thermal vibration stress relief for 2219 aluminum alloy rings

- Failure prevention of seafloor composite pipelines using enhanced strain-based design

- Deterioration of concrete under the coupling action of freeze–thaw cycles and salt solution erosion

- Creep rupture behavior of 2.25Cr1Mo0.25V steel and weld for hydrogenation reactors under different stress levels

- Statistical damage constitutive model for the two-component foaming polymer grouting material

- Nano-structural and nano-constraint behavior of mortar containing silica aggregates

- Influence of recycled clay brick aggregate on the mechanical properties of concrete

- Effect of LDH on the dissolution and adsorption behaviors of sulfate in Portland cement early hydration process

- Comparison of properties of colorless and transparent polyimide films using various diamine monomers

- Study in the parameter influence on underwater acoustic radiation characteristics of cylindrical shells

- Experimental study on basic mechanical properties of recycled steel fiber reinforced concrete

- Dynamic characteristic analysis of acoustic black hole in typical raft structure

- A semi-analytical method for dynamic analysis of a rectangular plate with general boundary conditions based on FSDT

- Research on modification of mechanical properties of recycled aggregate concrete by replacing sand with graphite tailings

- Dynamic response of Voronoi structures with gradient perpendicular to the impact direction

- Deposition mechanisms and characteristics of nano-modified multimodal Cr3C2–NiCr coatings sprayed by HVOF

- Effect of excitation type on vibration characteristics of typical ship grillage structure

- Study on the nanoscale mechanical properties of graphene oxide–enhanced shear resisting cement

- Experimental investigation on static compressive toughness of steel fiber rubber concrete

- Study on the stress field concentration at the tip of elliptical cracks

- Corrosion resistance of 6061-T6 aluminium alloy and its feasibility of near-surface reinforcements in concrete structure

- Effect of the synthesis method on the MnCo2O4 towards the photocatalytic production of H2

- Experimental study of the shear strength criterion of rock structural plane based on three-dimensional surface description

- Evaluation of wear and corrosion properties of FSWed aluminum alloy plates of AA2020-T4 with heat treatment under different aging periods

- Thermal–mechanical coupling deformation difference analysis for the flexspline of a harmonic drive

- Frost resistance of fiber-reinforced self-compacting recycled concrete

- High-temperature treated TiO2 modified with 3-aminopropyltriethoxysilane as photoactive nanomaterials

- Effect of nano Al2O3 particles on the mechanical and wear properties of Al/Al2O3 composites manufactured via ARB

- Co3O4 nanoparticles embedded in electrospun carbon nanofibers as free-standing nanocomposite electrodes as highly sensitive enzyme-free glucose biosensors

- Effect of freeze–thaw cycles on deformation properties of deep foundation pit supported by pile-anchor in Harbin

- Temperature-porosity-dependent elastic modulus model for metallic materials

- Effect of diffusion on interfacial properties of polyurethane-modified asphalt–aggregate using molecular dynamic simulation

- Experimental study on comprehensive improvement of shear strength and erosion resistance of yellow mud in Qiang Village

- A novel method for low-cost and rapid preparation of nanoporous phenolic aerogels and its performance regulation mechanism

- In situ bow reduction during sublimation growth of cubic silicon carbide

- Adhesion behaviour of 3D printed polyamide–carbon fibre composite filament

- An experimental investigation and machine learning-based prediction for seismic performance of steel tubular column filled with recycled aggregate concrete

- Effects of rare earth metals on microstructure, mechanical properties, and pitting corrosion of 27% Cr hyper duplex stainless steel

- Application research of acoustic black hole in floating raft vibration isolation system

- Multi-objective parametric optimization on the EDM machining of hybrid SiCp/Grp/aluminum nanocomposites using Non-dominating Sorting Genetic Algorithm (NSGA-II): Fabrication and microstructural characterizations

- Estimating of cutting force and surface roughness in turning of GFRP composites with different orientation angles using artificial neural network

- Displacement recovery and energy dissipation of crimped NiTi SMA fibers during cyclic pullout tests