Abstract

Rubber material is widely used in railway vehicles due to its superior damping performance. The testing methods, fatigue, and aging theories of rubber materials are of great significance to improve the design, manufacture, and application of rubber components for railway vehicles. This work systematically introduces the constitutive theory, mechanical testing standards, and testing methods of rubber materials. Then, the aging mechanism is described and the research progress of rubber fatigue properties is reviewed from the perspectives of fatigue crack initiation and fatigue crack propagation. Moreover, the reinforcement methods of rubber materials are presented. Finally, according to the working conditions of rubber components in railway vehicle, the technical difficulties and future research trends of fatigue characteristics analysis of rubber materials and components are pointed out.

Acronyms

- CDM

-

continuum damage mechanics

- CED

-

cracking energy density

- EFI

-

energy field intensity

- ML

-

machine learning

- NR

-

natural rubber

- SBR

-

styrene–butadiene rubber

- SED

-

strain energy density

- SVM

-

support vector machine

1 Introduction

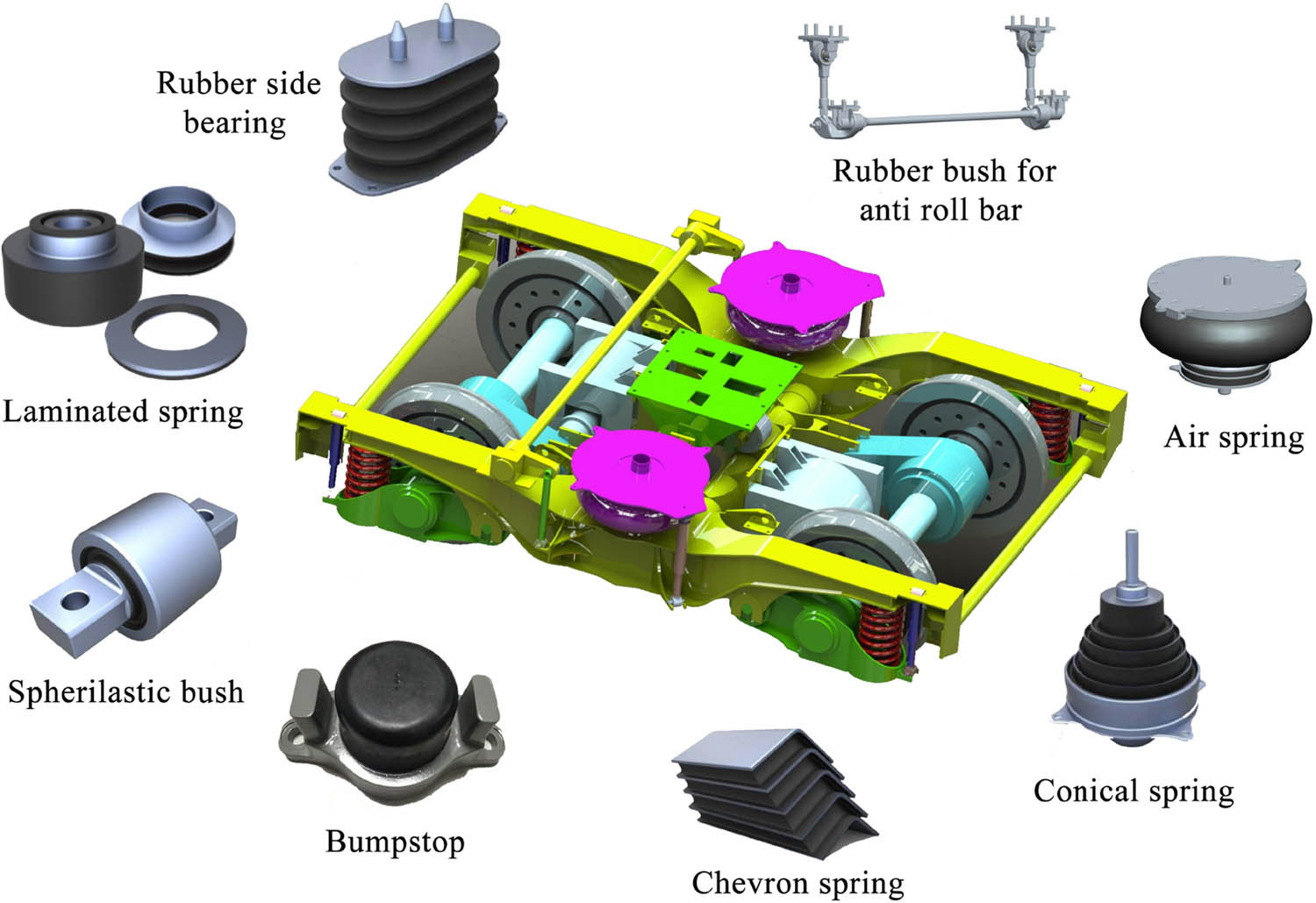

The development of science and technology is inseparable from the discovery and application of various new materials. Rubber materials and products have shown good elasticity, insulation, waterproof, and wear resistance in recent years. It is widely used in industry, agriculture, national defense, transportation, machinery manufacturing, medical, and health fields [1]. As shown in Figure 1, different rubber products invented in rail engineering greatly improved the service life, safety, and comfort of the rail vehicles and superior damping performance [2]. Using rubber products in track engineering construction can effectively increase the elasticity of track structure, reduce the dynamic stress of track structure and the load and stress, and reduce the vibration and noise caused by wheel–rail interaction [3,4]. The rubber components with superior damping performance make the train run more smoothly.

Rubber components in railway vehicle.

Due to being directly related to the ride comfort and running safety of the railway vehicle, the design and development process of the rubber components is extremely complicate. With the promotion of rail transport in remote areas and the increasing speed of rail vehicles, the service environment of the rubber components is becoming more and more severe [5,6,7]. The failure modes of rubber components are complex and the fatigue life is affected by many factors [8,9,10,11]. Testing technology is important for understanding the mechanical properties of rubber materials and components. Much progress has been made in the study of rubber aging and fatigue. Besides, rubber reinforcement technology has recently developed rapidly. Carbon black, nanomaterials, and other fillers have made rubber show more powerful properties [12,13,14,15,16,17]. On the other hand, it is found that the structural design of rubber components also determines their function and durability [18,19,20], and there is a large space for optimization.

With the urgent demand for better material properties and longer durability of rubber in the industry, a large number of works have been published recently. Although there are many state-of-the-art papers on rubber materials, few address specifically for railway vehicles application. The designers of rubber elastic components are still facing more challenges than ever. The present work focuses on systematically collecting and analyzing the vast amount of works on constitutive theories, test standards and methods, aging and fatigue studies, reinforcement, and structural design in the last decades. This detailed survey aims to fill the information gap and provide an informative overview of the railway vehicles field. This work may be of interest to the railway community and inspire in improving the measuring and testing technique, improving the designing ability, sorting out and innovating theory, test, and simulation methods in the rail vehicle industry and rubber industry.

2 Constitutive theory of rubber materials

The mechanical properties of rubber materials are different from those of conventional elastic materials. The deformation of elastic materials under tensile or compression loads is a reversible process, and the internal energy of elastic materials is equivalent to the strain energy. In the case of hyperplastic materials at a constant temperature, the free energy and strain energy are equivalent, that is, there is strain energy to a certain extent [21]. Rubber materials can be classified as hyperplastic in this definition and have incompressible properties [22,23]. Different physical models of rubber materials have different strain energy functions [24,25,26,27]. The Cauchy Green stress tensor

where

where

The commonly used constitutive model of rubber is clarified as follows:

2.1 Reduced polynomial model

The reduced polynomial model is a special form of the polynomial model in which the main parameter

The neo-Hookean model is a reduced polynomial hyperplastic constitutive model when it is a first-order polynomial. Its form is expressed as follows:

where

When the structural deformation is relatively small, the stress–strain curves obtained from a single test can be used to model the material parameters and measure other deformations. Occasionally, the component has multiple strains, or the strain of the component is large. Under this circumstance, if there is a large error between the strain energy calculated by the neo-Hookean model and the actual data, another rubber hyperelastic constitutive model should be used.

When

Because the higher order of the first strain invariant is used as the variable of strain energy density (SED) function, Yeoh model can accurately simulate rubber deformation in a wide range. The stress–strain curve of S-shaped rubber material can be obtained by Yeoh model.

2.2 Ogden model

The strain energy of the Ogden model [29] has three variables, namely, the principal elongation

where

The Ogden model believes that the independent function of the three main elongations is the SED, so the deformation of different rubbers can be described as a simple polynomial form. Usually,

2.3 Mooney–Rivlin model

Based on the theory of phase change material and through many experiments, Mooney established the strain energy function of the rubber hyperplastic constitutive model:

Since the volume parameter

Mooney–Rivlin model can better express the stress–strain characteristics of rubber materials under the condition of small strain energy [30,31]. It is noted that Mooney–Rivlin model cannot well represent the behavior of steep rise of rubber material under large strain load. Because of the simplicity of the expression and the material parameters can be easily obtained by fitting constitutive test data, Mooney-Rivlin model is most widely used in finite element analysis (Table 1).

Comparison of rubber constitutive models

| Model | Scope of application | Advantage |

|---|---|---|

| Neo-Hookean | Small and medium deformation | Simple expression and simple computation |

| Yeoh | Various deformation | Simple expression and wide applicability |

| Ogden | Various deformation | High adaptability |

| Mooney–Rivlin | Small deformation | Simple expression and wide applicability |

3 Test standards and methods of rubber materials

At present, there are many testing standards and methods to obtain the mechanical properties of rubber materials and components. Taking the standard of rubber elastic components for railway vehicles in China as an example, TB/T 2843-2007 “General technical conditions for rubber elastic components for rolling stock” is the current standard of railway industry standard in China. This standard stipulates the basic performance and requirements of rubber elastic components and rubber materials for different kinds of rolling stock. Performance tested methods and inspection rules for rubber materials, metal materials, and products are also included. In addition, the service environment requirements and packaging, storage, and transportation regulations of rubber elastic components are also mentioned.

The rubber elastic components test contains the static performance test, dynamic performance test, bonding strength test, compression creep test, and fatigue performance test. The standard provides principles of the test environment, test principle, test method, test equipment, specimen failure judgment, and data processing method, etc.

The standards of different countries/regions are: Chinese standard TB/T2843-2007 “General technical conditions of rubber elastic components for locomotive and rolling stock,” European standard EN 13913-2003 “Elastic foundation components of rubber suspension components for railway,” and Japanese industrial standard JISE 4710-1995, “General rules of rubber vibration isolators for railway locomotive and rolling stock.”

The main differences between TB/T 2843-2007 and EN13913-2003 are shown as follows: the dynamic creep test and test method are not specified; static and dynamic stress relaxation tests and test methods are not specified. Moreover, the main differences between TB/T 2843-2007 and JISE 4710-1995 are as follows: hardness test and test method are not specified; insulation resistance test and test method are not specified.

This standard TB/T 2843-2007 replaced TB/T 2843-1997 “General technical conditions for rubber elastic components of locomotive and rolling stock” and TB/T 2589-1995 “General technical conditions for rubber pile of electric locomotive.” The main changes are as follows: the basic properties and requirements of rubber materials used for rubber elastic components are different; the dynamic performance test of rubber elastic components is added; the static creep test of rubber elastic components is added. Besides, different test methods for static performance, bonding performance, and fatigue performance of rubber elastic components are provided.

Rubber components used in rolling stock are vulcanized rubber. In addition to the abovementioned standard TB/T 2843-2007 “General technical conditions of rubber elastic components for locomotives and rolling stock,” vulcanized rubber tensile properties, compressive properties, shear properties, tear strength, wear resistance, and low-temperature brittleness have been formulated in other standards. For example, GB/T 39693-2020 “Vulcanized rubber or thermoplastic rubber hardness determination” and GB/T 15256-2014 “vulcanized rubber or thermoplastic rubber low-temperature brittleness determination (multi-sample method)” are designed. An international standard example is ISO 3384 AMD-2019 “vulcanized rubber or thermoplastic rubber compression stress relaxation determination.” Meanwhile, some countries may also formulate standards that suit their own national conditions, such as Japan JIS K6253-2012 “vulcanized rubber or thermoplastic rubber hardness determination” and France NF T46-009-2013 “vulcanized rubber or thermoplastic rubber under constant elongation conditions of tensile permanent deformation, and under the constant tensile load of tensile permanent deformation, elongation, and creep.”

For some specific rubber elastic component standards, such as rubber spring vibration isolator, rubber suspension spring, rubber shock absorber, brake hose, oil-resistant rubber pad, rubber sealing strip, etc., we have developed more detailed independent standards, which are also in line with the railway industry standards of the People’s Republic of China.

Each country has its own standards, according to which components are manufactured or tested to ensure maximum accuracy. However, these standards will be updated to better adapt to new application with the development of science and technology.

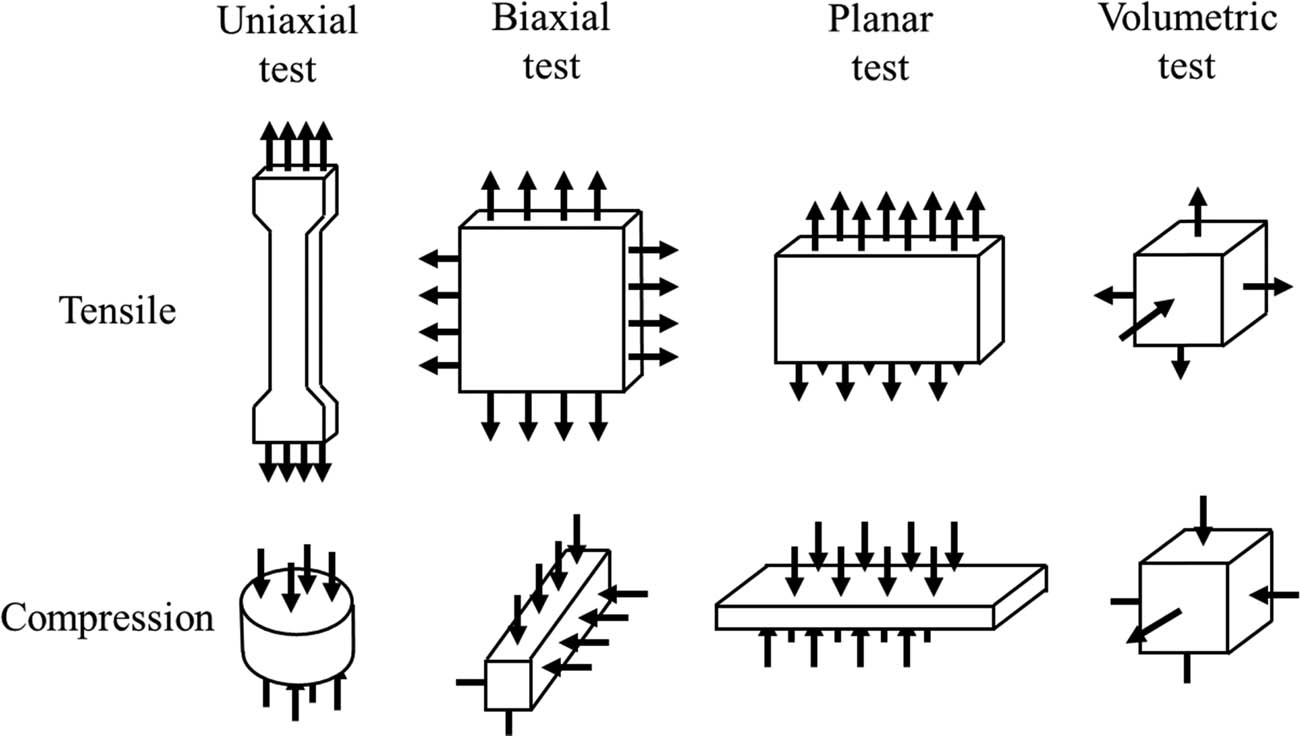

3.1 Static mechanical property test

The basic mechanical test of rubber elastic components of locomotive and rolling stock is divided into static mechanical test and dynamic mechanical test. There are eight kinds of static mechanical properties tests for rubber materials, including uniaxial, biaxial, planar, and volumetric tests under the conditions of tensile and compression (Figure 2). Many studies have found that the data obtained from the uniaxial tensile, biaxial tensile, plane tensile, and volumetric compression tests can accurately represent the basic mechanical properties of rubber materials [32,33,34]. Therefore, uniaxial tensile, biaxial tensile, plane tensile, and volumetric compression tests are internationally defined as the basic mechanical behavior of rubber materials.

Static mechanical test of rubber material.

The uniaxial tensile test is widely used due to its simple test method, there are many standards for the uniaxial tensile test of rubber material. However, these standards cannot meet the test requirements of rubber material finite element analysis. The rubber material sample side is still restricted, and cannot reach the test requirements of the pure tensile state [35,36,37].

It is difficult for rubber materials to achieve a completely unidirectional compressive strain. Due to the influence of friction factors, rubber materials cannot expand freely, and obvious shear strain will occur on the side of rubber materials, which frequently cause the maximum shear strain exceed the maximum compressive strain [38]. In order to obtain the ideal uniaxial compression data, the biaxial tensile test can be used which is exactly equivalent to the ideal compression test.

Brieu et al. [39] proposed a new mechanism for the biaxial tensile test, which can simultaneously load in-plane specimens in two main directions. The mechanism can also be adapted to any single axial tensile testing machine, thereby reducing the cost of testing on expensive test machines.

The uniaxial and equiaxial tensile test data for rubber materials were determined by Sasso et al. [40]. It is based on optical methods, and has the highest accuracy. Besides, it shows good agreement between simulation and experiment, even when it is applied to additional states of tension (such as planes).

Ru et al. [41] designed a new equiaxial tensile testing machine using a novel rope and pulley loading system that can automatically ensure equal stress in both directions and minimizes possible installation bias. The new rubber biaxial and uniaxial experiments proposed by these researchers improve the accuracy of the classical hyperplastic model by measuring more accurate parameters [42].

The plane tensile test of rubber material is similar to the uniaxial tensile test, but the difference was that the rubber specimen used in the plane tensile test was wider [43]. The results showed that when the width of the rubber specimen is more than ten times its length, the complete tensile strain can be achieved in the plane tensile strain state of the rubber material surface.

Xia et al. [44] proposed a new plane tensile test method that modified plane tension to evaluate the predictive ability of the rubber constitutive model under moderately finite deformation. The results verified that the plane tensile test was a kind of non-uniform deformation, that is, the deformation of the central region of the specimen was uniform, but the deformation of the whole region was not uniform.

The rubber material is almost incompressible. If the compressibility of rubber is considered, the cylindrical rubber specimen should be placed in a fixed rigid container for compression. Radek et al. found that the volume modulus of rubber material was 2–3 orders of magnitude higher than the shear modulus by experimenting [45].

3.2 Dynamic mechanical property test

Different from the static mechanical properties of rubber materials, the dynamic properties are the properties of rubber elastic components, mainly including stiffness and damping properties [46,47]. If the frequency of the interfering force is far less than the natural frequency of the structure, the dynamic stiffness and static stiffness are basically the same [48,49]. When the frequency of the interference force is much greater than the natural frequency of the structure, the deformation of the structure is relatively small, that is, the dynamic stiffness is relatively large. When the frequency of the interference force is close to the natural frequency of the structure, there is a resonance phenomenon, and the dynamic stiffness is the smallest, that is, the deformation is the easiest. The dynamic deformation can reach several times or even more than ten times the static deformation [50,51,52,53]. The response of the structure under dynamic load largely depended on the damping characteristics [54,55,56,57,58,59,60]. Because of the Mullins effect and hysteresis curve, rubber elastic components are widely used in train vibration reduction.

Lie et al. [61] used an artificial neural network to conduct simulation and experiment under different chamfering sizes and axial preloading.

Lee et al. [62] proposed an approximate hybrid method based on finite element analysis and empirical modeling to analyze the dynamic characteristics of the rubber bushing. This method can predict the dynamic stiffness of rubber bushings without an iterative test, but the calculation cost is high. It is suitable for the analysis of full-size vehicles with many rubber bushings under various vibration loads.

Based on the superposition principle, Luo et al. [63] established a nonlinear dynamic model of a rubber shock absorber in a railway fastening system. It simulated its nonlinear vibration behavior, and obtained all model parameters through dynamic experiments. The frequency dependence and amplitude dependence of nonlinear dynamic stiffness were further studied. The results showed that the nonlinear dynamic stiffness characteristics were closely related to the displacement amplitude and frequency, but the frequency correlation was not as great as the amplitude correlation.

4 Aging of rubber materials

Polymer materials in the process of processing, transportation, storage, and service are inevitably affected by internal and external factors. These factors lead to deterioration of material performance or even failure. This phenomenon is usually called aging. Rubber aging is often a complex and multi-factor coupling process, and different factors have different performance characteristics. According to the different influencing factors, rubber aging can be divided into natural air aging, ozone aging, chemical aging, radiation aging, etc., [64,65].

4.1 Aging mechanism

4.1.1 Thermal oxygen aging

The damage of thermal oxygen to the mechanical properties of rubber is obvious in an oxygen environment [63,64,65,66,67,68,69,70,71]. The mechanism of the thermal oxygen aging reaction of rubber is that oxygen automatically catalyzes free radical chain reaction, in which oxygen is the main factor causing aging. Heat plays a role in activating oxidation and accelerating oxidation, and oxygen-containing groups, like ketones, aldehydes, epoxides, etc., are generated in this aging reaction [72,73,74,75,76,77]. The aging process can be divided into the following four periods [78]: (1) induction period, (2) rapid oxidation period, (3) slow oxidation period, and (4) diffusion-forbidden period (Table 2).

The thermal oxygen aging reaction of rubber

| Aging process | Mechanism of thermal oxygen aging reaction |

|---|---|

| Induction period |

|

| (Heat, oxygen, light, or catalyst) | |

| Rapid oxidation period |

|

|

|

|

| Slow oxidation period |

|

|

|

|

| Diffusion-forbidden period |

|

|

|

|

|

|

4.1.2 Ozone aging

Ozone is an extremely rare gas in the atmosphere, but it is extremely destructive to plastic materials. Ozone can have an irreversible chemical reaction with unsaturated bonds and reductive groups in the chemical structure of plastic materials, resulting in oxidative degradation of plastic materials [79]. Ozone aging of natural rubber is a process from surface to interior and from middle to both sides [80]. Rubber ozone aging first begins on the surface, especially in the stress concentration or compound particles and rubber interface [81]. The aging process usually begins with generating a thin film, and then the film cracks. If it is used under dynamic conditions, the film is more likely to constantly break and expose the fresh surface, making ozone aging worse. The cracking molecular chain in the double bond is more likely to participate in ozone aging, and produces more carbon and oxygen bonds until destruction [82]. Unsaturated rubber is the least resistant to ozone because ozone is most likely to undergo rapid electrophilic addition reactions with the double bonds on the main chain. The oxidation resistance of rubber is enhanced using antioxidants with added chemical elements [83,84].

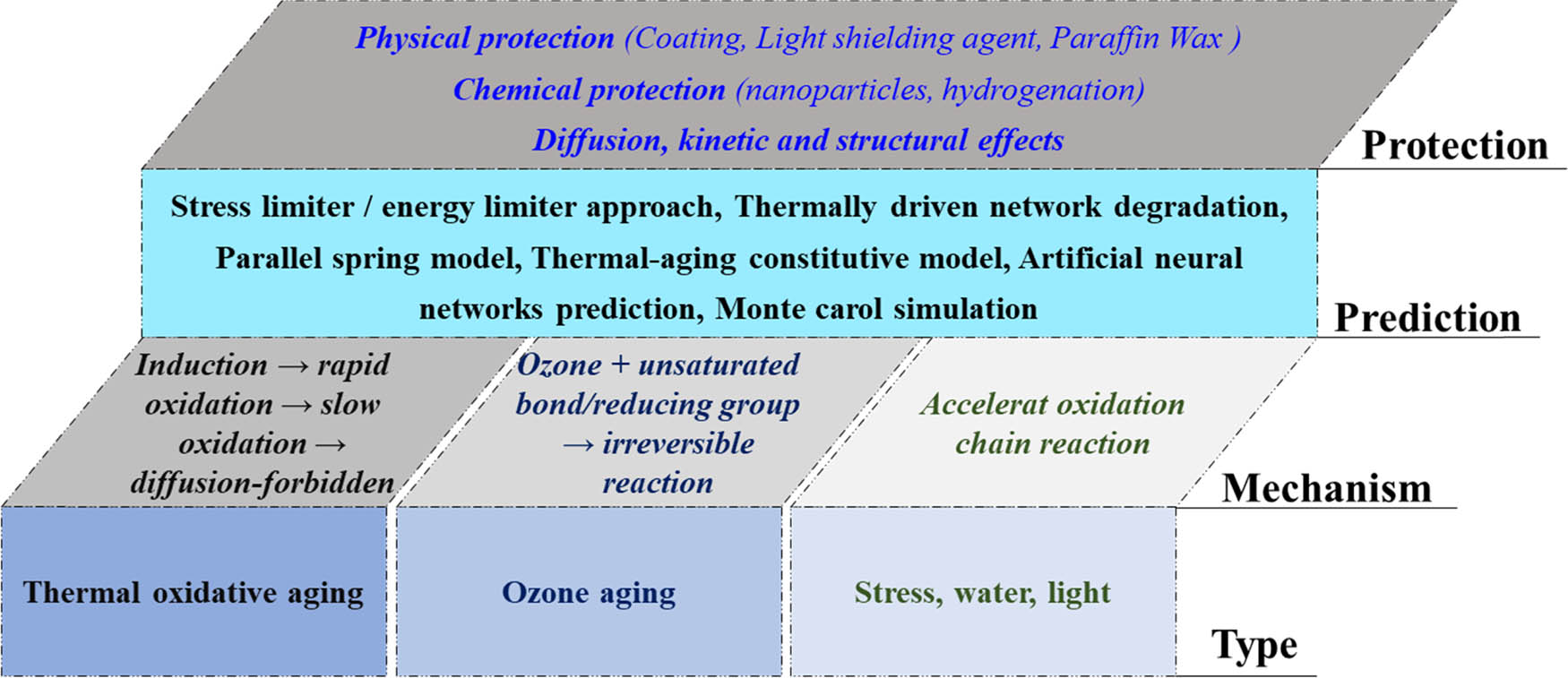

In addition, there are mechanical stress, moisture, and light radiation, which are important factors in rubber aging (Figure 3).

Research progress of rubber material aging.

4.2 The aging analysis model

Two new methods for predicting failure characteristics are proposed. The first one is the stress limiter method, which uses “damage” parameters to determine the failure stress and strain of the aged material. Meanwhile, it also acquires the mechanical properties and polymer network characteristics of the receiving material [85]. The second method is an extension of the energy limiter method, which captures the stress drop at failure by replacing the SED function of the receiving elastic material with a function expressed by the energy limiter [86].

By considering a series of chemical and physical changes in the rubber filling material system, a network change theory of thermal-driven network degradation was proposed. The decomposition of the network considered the break-back mechanism of links (between filler aggregates and elastically active cross-linked chains), as well as changes in free chain motion superimposed on chemical linked networks (nascent and original networks) [87].

Some scholars had carried out swelling tests to analyze the relationship between the SED obtained by mechanical experiments and the cross-linking density obtained by chemical experiments. The results of the swelling test were substituted into the Flory-Reihner equation to obtain the cross-linking density, and an equation assuming that the cross-linking structure was a spring model was proposed. The relationship between SED and cross-linking density was summarized, and a method to predict the aging behavior of NR/BR blends using cross-linking density was proposed [88].

Besides, there are also many life prediction models based on experimental methods [89,90,91,92,93], artificial neural networks [94], Monte Carlo methods [95], and so on.

4.3 Protection strategies against ageing

Given that the rubber aging is a complex comprehensive chemical reaction process and it is impossible to absolutely prevent rubber aging, physical or chemical measures can be taken to delay the aging rate of rubber and achieve the purpose of extending the service life of the rubber [96,97].

Physical protection means avoiding the interaction between rubber and various aging factors as far as possible, such as using a surface layer or treatment, adding a light-blocking agent, adding paraffin, etc., [98]. Chemical protection refers to the addition of certain substances to prevent or delay rubber aging [99]. The results showed that the tensile strength, tear strength, and modulus of NR are increased after the aging test, while the elongation at break was decreased due to introduction of Al2O3 nanoparticles into NR. These were attributed to cross-linking maturation reactions that result in the conversion of poly sulfur bonds to disulfide and monoculture bonds [100]. The physical, chemical, and thermal properties of diene polymer were improved by hydrogenated degreasing NR. The thermal aging and ozone resistance of hydrogenated defatted NR blends were also improved [101]. The diffusion, kinetics, and structural effects were used to prevent rubber aging. The aging process of rubber under different dynamic modes was studied, including the mathematical model of the aging and destruction process under extreme conditions. The aging process of rubber as a thermodynamic open nonlinear system was also considered. The results showed that the aging process can be controlled by the organization of internal physical and chemical processes as well as by the organization of external influences (through thermodynamic forces and flows). According to the Onsager principle, conjugation of thermodynamic forces and flows is possible under certain aging conditions. The diffusion and structure aspects of aging of elastomer compositions and their products were considered [102].

5 Fatigue of rubber materials

In analogy with the fatigue damage process of metal materials, the fatigue damage process of rubber materials can usually be divided into two stages as follows. In the first stage, microscopic defects gradually sprout and accumulate to form cracks in the regions within the material where there are no visible cracks originally; in the second stage, cracks continue to expand in the core area where tiny cracks are formed in the first stage until the material produces local or overall fracture [103]. Initially, the prediction model of fatigue life of rubber materials was based on these two stages separately. And with the in-depth study of the microscopic crack formation mechanism and the continuous expansion of the continuous medium mechanics method, Gent et al. [104] first pointed out that the macroscopically visible cracks in rubber materials during fatigue loading ascribe to the continuous expansion of microscopic initial defects, and the above two physical processes can be unified in terms of the intrinsic mechanism, i.e., the two processes of microscopic fatigue crack nucleation and expansion in rubber materials should be combined. The formation of macroscopic fatigue cracks should be studied by combining the two processes of nucleation and expansion of microscopic fatigue cracks in rubber materials.

5.1 Crack initiation approaches

The life prediction methods for the fatigue crack initiation stage of rubber materials include two types of methods: continuous medium mechanics method and continuous damage mechanics method. Since the fatigue life is related to the magnitude of the local load on the material, the continuum mechanics approach generally assumes that the material remains internally homogeneous and continuous throughout the stage from initial loading to crack initiation. Therefore, a fatigue predictor related to the local force or deformation state of the material is usually used as a physical quantity to describe the magnitude of the load, and based on the theory of continuum mechanics, a power series function is established between this predictor and the fatigue crack sprouting life on account of the results of simple material or component fatigue tests. The commonly used fatigue predictors are strain-, stress- and energy-related physical quantities and other parameters.

5.1.1 Strain-related physical quantities

In 1940, Cadwell et al. [105] investigated the fatigue life of filled vulcanizates and found that the fatigue life of NR grew with increasing cyclic minimum strain at constant amplitude and used experimental data to obtain empirical relationships between strain and fatigue life under uniaxial and shear deformation conditions, respectively. Based on the experimental data of Roberts and Benzies [106], an analysis by Ro [107], which used strain-based physical quantities such as octahedral shear strain and maximum shear strain as fatigue life assessment parameters, showed that none of these strain parameters could well unify the test results of uniaxial tension with biaxial tension.

Luo [108] proposed an effective strain criterion, which unified multimodal and multiaxial loading into a single parameter and expressed it in an analytical form without rotating the plane to search for the maximum damage parameter, for fatigue design of vibration-resistant members. Luo [109] also presented a new method for fatigue damage prediction based on the shear modulus and effective tensile strain of rubber materials put forward and validated in three independent fatigue programs. Shangguan et al. [110] raised seven fatigue life prediction models using different damage parameters to predict the fatigue life of rubber isolators via the measurement of the fatigue life of dumbbell cylindrical specimens. It is also pointed out that the model with Luo stress or Saintier stress as the damage parameter can predict fatigue life up to two times better than the other models. In addition, criteria based on effective tensile strain [111] were developed and validated on published experimental data of 30 positive R and negative R-ratio fatigue cases [112]. Li et al. [113] utilized a combination of material property tests and finite element analysis to predict the fatigue life of NR materials employing the maximum total principal strains as the fatigue parameter. Gehrmann et al. [114] introduced a method to convert strain variations into constant equivalent strains conforming to the Wöhler curve. The finite element simulation results showed that the method can be applied to specimens with other geometries or components. Luo et al. [115] conducted fatigue failure tests using hourglass-type rubber specimens and experimentally determined the conventional S–N curve adopting the maximum principal strain as the fatigue parameter to establish the relationship between steady state temperature rise and maximum principal strain. Shangguan et al. [116] investigated the relationship between the tensile fatigue life of rubber specimens with three different geometries and various commonly used damage parameters, as well as the dependence of the geometries for the fatigue life prediction model. Kim et al. [117] concluded that Green – Lagrange should be more suitable as a damage parameter for estimating the fatigue life of rubber compared to the SED method.

5.1.2 Stress-related physical quantities

Saintier et al. [118] pointed out that the direction given by the maximum first principal stress during a cycle can correctly predict the direction of cracking under non-proportional multiaxial fatigue loading if the plane rotation of the material was considered. Saintier et al. [119] also investigated the sprouting of cracks for NR under the abovementioned loads and came up with two fatigue cracking criteria based on the first and second invariants of the Cauchy stress tensor, and pointed out that the latter was a better predictor. Gosar et al. [120] put forward a new multi-axial energy-based method introducing mean stress corrections to combine elastic strain and complementary energy changes to form an energy damage parameter, which was used for fatigue life prediction of air springs in commercial vehicles. Chung and Kim [121] proposed a rain flow counting method with multiple stress components for variable amplitude loading and found the plane with the maximum damage parameter taking the critical surface method.

5.1.3 Energy-related physical quantities

A study by Ro [107] showed that utilizing strain energy as a fatigue damage covariate to predict fatigue life of rubber materials was superior to other strain-based damage covariates, but the stress–strain relationship was assumed to be linear in that study, which was not consistent with reality. Li and Xin [122] proposed a simple bending fatigue life prediction method for toothed v-belts by combining material property tests with finite element analysis and regarding the maximum SED as the damage parameter. Wang et al. [123] performed fatigue tests on rubber beads to determine the cycle number and the finite element method was employed to analyze the steady state rolling of several bead compounds to obtain their maximum SED range. Kim et al. [124] used the finite element method for steady state rolling analysis to acquire the SED range in the strip edge region to gain the tire strip edge failure life due to high-speed conditioning tests. Shangguan et al. [116] pointed out that different strain and energy bases can be used as effective damage parameters for predicting uniaxial tensile fatigue life of filled NR, and the relationship between tensile fatigue life and damage parameters can be considered independent of geometry. Shangguan et al. [125] established fatigue life prediction models at three different temperatures using engineering strain as the damage parameter, but the relationship model between temperature and fatigue life prediction was not constructed. Thereafter, Zhang et al. [126] chose strain energy as the fatigue damage parameter and investigated the effect of thermal aging and fatigue damage on the fatigue life of rubber based on data from specimens of uniaxially stretched dumbbell rubber at different temperatures. Moon et al. [127] indicated that the predicted life of the hollow bamboo specimens was underestimated due to shear deformation and suggested that both positive and shear strains be included to improve the accuracy. Liao and Zhu [128] presented a new energy field intensity (EFI) concept and established an EFI-based framework for fatigue analysis of notched engineering components under multi-axial stress states.

The fatigue life of rubber can be well predicted using SED under simple uniaxial loading conditions, but it is much more difficult under complex loading conditions. In this regard, the critical surface method is proposed to predict the fatigue crack sprouting of rubber materials under multi-axial loading conditions. The fatigue prediction factor is associated with a certain material plane, and the crack emergence parameters in this plane can be calculated by the critical surface method [119], by which good results are achieved.

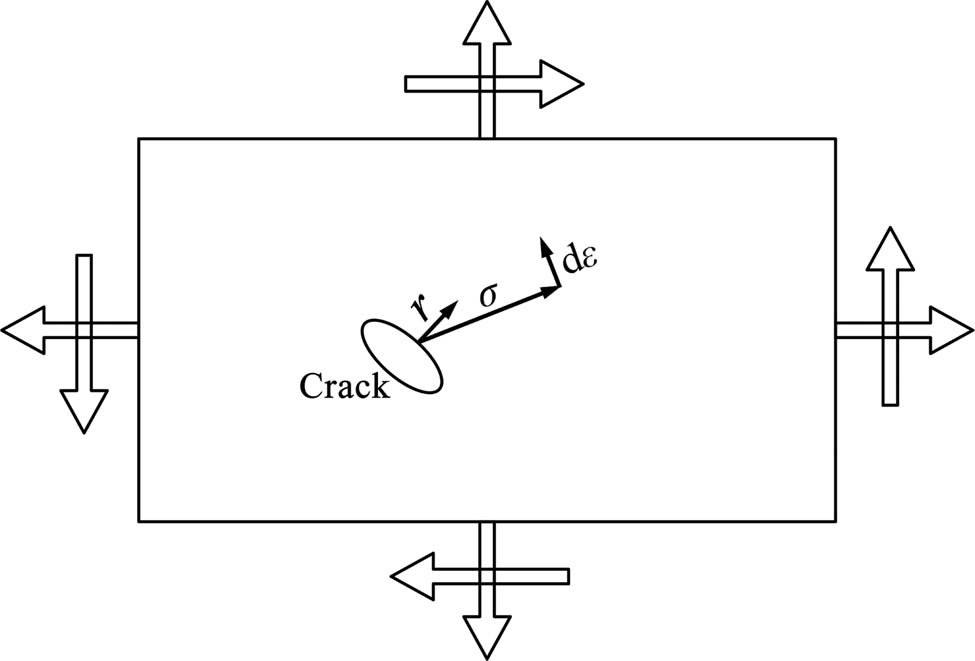

Moon et al. [127] pointed out that the energy driving the expansion of microcracks within a rubber material is a fraction of the SED, which was defined as the cracking energy density (CED) (Figure 4). By defining the direction of the cracking surface, the method is extended from the macrostrain range to the finite strain range, enabling it to be applied to the fatigue life calculation of rubber materials in the finite deformation range, which greatly improves the practical value of the method. Following this, he investigated the property and evolution of cracks in naturally filled rubber by direct observation, comparing the damaged surface behavior with predictions based on CED [129]. Xu et al. [130] proposed a fatigue life prediction method for rubber bushing stud shear connectors based on the critical surface and finite element method. Nyaaba et al. [131] used assumed intrinsic defects, fatigue crack expansion laws, and rubber intrinsic structure laws to calculate local crack driving forces for a type of tire component based on past strain loading. Saintier and his team [119] found that the critical plane method could predict fatigue life and determine the site and direction of crack emergence, with the major drawback that it could not take size or gradient effects into consideration. Harbour et al. [132] investigated the effect of variable amplitude loading conditions on the fatigue life of multi-axial rubber specimens by searching the critical surface through normal strain. Luo [108] applied the effective strain criterion in combination with the critical surface method for fatigue life prediction under non-proportional loading. Zine et al. [133] determined parameters based on SED and predicted the occurrence and possible directions of primary cracks, confirming the superiority of the CED criterion over the SED criterion.

Schematic diagram of CED of rubber materials. (

For scenarios of different rubber materials and usage, each of the above fatigue predictors has its own merits and defects. Liu et al. [134] evaluated the relative performance of the models which consist of different damage indices using rubber stents as the study object. Ayoub et al. [135] found that the prediction methods based on stress and cracking energy showed the best predictive validity for isometric tests after comparison. Shangguan et al. [136] also established three fatigue life prediction models based on SED, maximum principal Green–Lagrange strain, and effective stress [137], and compared their respective predicted fatigue lives with the test life using a typical powertrain rubber vibration isolator as an example. Wang et al. [138] compared and evaluated the existing major fatigue life prediction methods using the life data obtained from the tests to investigate the multi-axial fatigue performance of vulcanized NR.

5.1.4 Damage rule

The above methods for studying the fatigue life of rubber materials are based on the continuous medium mechanics theory, which have great limitations and are only suitable for predicting the test results of the fatigue life of rubber components under uniaxial or extra multi-axial loading methods and simple amplitude cyclic loading conditions [139]. Another approach for fatigue crack sprouting life prediction is based on the continuum damage mechanics (CDM) theory [140], which generally constructs the relationship between load and damage fatigue life by defining the damage stress (or effective stress) and the damage kinetic function.

Wang et al. [141] defined the damage strain energy function and damage evolution equation using a CDM approach and described the SED of the damaged part using the Ogden intrinsic model. Ayoub et al. [140] came up with a fatigue criterion based on the CDM theory to predict the fatigue life of rubber-like materials. Subsequently, for the multi-axial fatigue damage parameter for rubber, the equivalent force was proposed, a three-dimensional model was derived, and the fatigue life of styrene–butadiene rubber (SBR) was predicted by introducing the CED criterion [142]. Ayoub et al. [143] also used the Ogden strain energy function and the CED function to describe the damage strain energy release rate, deriving a general expression for the damage parameter. Harbour et al. [132] explained the difference in crack development in materials that produced many cracks in NR compared to SBR by predicting the linear damage law. Rangarajan and Ramarathnam [144] designed and implemented an experimental procedure binding fatigue life measurements and characterization of the intrinsic response of rubber. Tao et al. [145] and Pan et al. [146] tried some methods to improve on the CDM concept.

5.1.5 Other predictors

With the development of technology, artificial intelligence-based life expectancy prediction methods are maturing. Liu et al. [147] developed a support vector machine (SVM) model with empirical reliability and rubber fatigue life as input and output variables, respectively, which is a probability distribution model. Xiang et al. [148] established a back propagation artificial neural network model for predicting the fatigue performance of NR composites. Marco et al. [149] constructed a nonlinear correlation between the input and output variables of the model based on machine learning (ML). Liu et al. [150] raised a rubber fatigue life prediction model based on random forest algorithm with strain amplitude, which regarded average strain and strain ratio as input variables and fatigue life of NR under equal amplitude load as output variable. Neuhaus et al. [151] proposed a new model considering various effects of high temperature on fatigue life. Choi et al. [152] used six ML models for fatigue life prediction and the comparison concluded that deep neural network exhibited the highest accuracy Liu et al. [153] developed a back propagation neural network model for predicting fatigue life and brought forward an improved sine cosine algorithm to optimize its parameters. Liu et al. [154] developed a fatigue life prediction model for vibration isolated rubber materials using an SVM model and optimized the parameters by an improved gravity search algorithm.

5.2 Crack propagation approaches

The fatigue crack propagation approach of rubber is based on Griffith’s fracture mechanics theory [155], which focuses on individual preexisting cracks or flaws. The crack growth criteria were proposed based on the energy balance hypothesis, which hold that crack growth is a process of converting potential energy stored in elastic bodies into new crack surface energy. The energy release rate and the CED are two essential components to predict fatigue lifetime of rubber materials.

In the crack propagation fatigue test of rubber material, the energy release rate (or CED) at the crack tip can be calculated from the stress–strain field obtained from the material test. Noted that all the specimens are specially designed and with preexisting cracks. Besides, the crack growth rate can be calculated by monitoring the crack growth size and loading times. Therefore, the fatigue crack propagation rate and fatigue life of rubber materials can be predicted under other loading cycle conditions.

In 1953, Rivlin and Thomas [156] first applied Griffith’s theory to study the tensile strength of rubber material with local cracks. He found that when the energy release rate exceeded a certain critical value, cracks will propagate continuously in rubbers, and the critical value is independent of the geometrical size of specimens. Thomas [157,158] extended the Griffith’s approach to analyze the growth of cracks under cyclic loads in NR. He discovered a square-law relationship between peak energy release rate and crack growth rate for NR. Gent et al. [104] verified Thomas’s finding through experiments. He proposed that the relationship between the crack growth rate and energy release rate was a rubber material property independent of the structure and load form. After analyzing many test data of unfilled NR and SBR, Lake and Lindley [159,160] divided the crack growth behavior of rubber materials into four stages based on the maximum energy release rate per cycle,

where

![Figure 5

Lake–Lindley’s crack growth model of rubber materials. Adapted with permission from ref. [160].](/document/doi/10.1515/rams-2022-0054/asset/graphic/j_rams-2022-0054_fig_005.jpg)

Lake–Lindley’s crack growth model of rubber materials. Adapted with permission from ref. [160].

Paris et al. [161] and Paris and Erdogan [162] found a similar power-law between the peak energy release rate and fatigue crack growth rate in metallic alloys. Without considering the internal strain crystallization effect, Paris’s model based on equivalent tearing energy could be combined with the calculation method of crack growth rate to predict the fatigue crack growth life of rubber materials under cyclic loading with incomplete relaxation. Experiments showed that considering the internal strain crystallization effect, the fatigue crack growth rate of the rubber material was not only related to cyclic maximum energy release rate, it was also affected by the minimum energy release rate within the cycle [107]. Mars et al. [163], Mars and Fatemi [164,165], and Mars [166] summarized the above work and proposed that rubber crack propagation was caused by internal microcrack propagation driven by cracking energy. Specifically, they combined the CED theory with fracture mechanics method to calculate the fatigue life of rubber material under finite deformation to achieve better prediction. Different from the previous use of maximum energy release rate as the driving force of crack growth, they assumed that the intrinsic microcrack of rubber material has the possibility to expand in all directions, and the crack growth in each direction is driven by the crack energy in that direction, and the actual crack direction should be the fastest crack growth direction. This method can not only predict the fatigue crack initiation life of rubber material, but also predict the potential crack direction. Meanwhile, the critical plane method was recently innovatively applied to the calculation of rubber crack growth in engineering fatigue life assessment [167,168].

Moreover, Aït-Bachir et al. [170] focused on the steady state crack growth with the condition that the damage zone did not reach the boundary of the domain, and derived the energy release rate of a center cracked region with Configurational Mechanics. Based on arbitrary far-field homogeneous multiaxial loading conditions. their approach demonstrated that the energy release rate of a small crack is proportional to the size of the crack, irrespective of the state of loading or the orientation of the crack. Using the strain energy release rate as the variable, Papadopoulos et al. [169] proposed an efficient mathematical equation to characterize the transitions of fatigue crack growth rate in NR and SBR.

Fukahori et al. [171] proposed a new elastic-viscous transition diagram to explain the transition in the relationship between critical strain energy release rate and critical crack growth rate. The diagram consists of three zones: elastic-brittle fracture zone, a viscous-ductile fracture zone and an intermediate transition zone between the elastic and viscous zones. The transition zone, characterized by stick-slip motion, is the result of unstable fluctuations of crack growth rate due to the energy dissipation near the glass transition temperature. Netzker et al. [172] analyzed the fracture behavior of rubber materials based on a global energy balance. They claimed that the measured fracture sensitivity values and the energy losses were mainly related to the development and increase of a dissipative zone. Saintier et al. [118] investigated that the crack orientation was dependent not only on the type of loading (tension, torsion, etc.) but also on the maximum level of loading. The condition was more complex when strain crystallization induces reinforcement in rubbers. Their fatigue model showed that if large strain conditions were correctly considered, cracks were found to propagate systematically in the direction given by the maximal first principal stress reached during a cycle, even under non-proportional loading. By relating the crack surface density to the ratio between the global energy dissipated and the fatigue-related energy, Marco et al. [173] built a new fatigue criterion for carbon black filled NR.

Asare and Busfield [174] validated the fracture mechanics approach when they successfully predicted the fatigue crack growth behavior at both room temperature and high temperature. In fact, the cyclic stress softening associated with fatigue of filled rubber was quantitatively accounted for the first time. The fatigue behavior at different temperature was assessed through the crack growth approach and a lower crack growth resistance was found at higher temperatures. A very recent work by Schieppati et al. [175] proposed a new procedure for building fatigue master curves of a non-crystallizing rubber.

6 Reinforcement of rubber materials

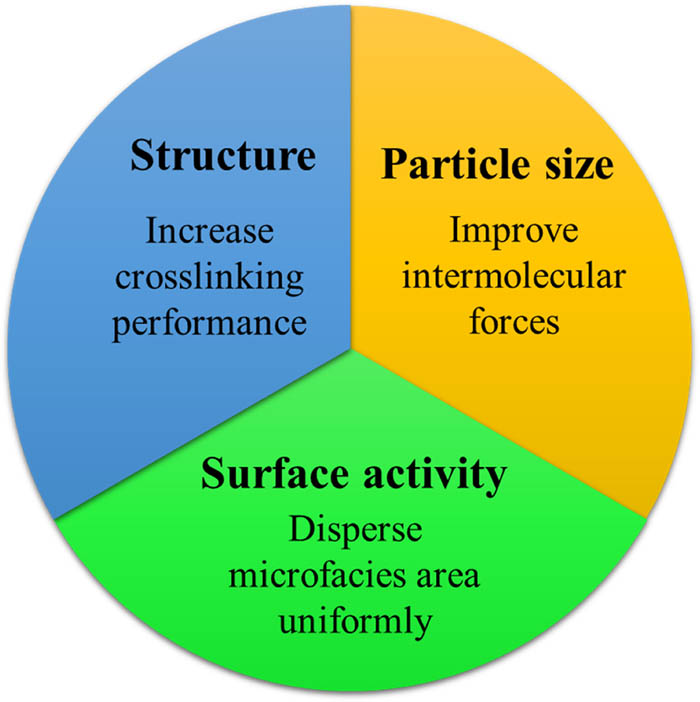

Unlike plastics with high crystallinity or high vitrification temperature, rubber has a large free volume, low intermolecular force, and lack of crystallinity. Therefore, in terms of strength and elongation, hardness, wear resistance, fatigue, and other compressive performance, most rubbers cannot be applied without reinforcement. Pure rubber products are also difficult to process due to the high elasticity of the rubber. Generally, it can only be manufactured by liquid forming or limited to simple products. Since the rubber began to be applied in industry, people have been committed to the study of rubber reinforcement mode and mechanism and the development of related technology (Figure 6). The development process ranges from the use of zinc oxide to the carbon black [176,177,178], and further to the development and application of various filling reinforcing agents and reinforcing technologies [179,180,181]. It can be said that the search for efficient, simple, and economical reinforcing methods and strengthening agents has always been the focus and hotspot of rubber science research. Rubber strengthening research is an important subject of the rubber industry, technology, and science [182,183,184,185,186,187,188,189,190].

Particle size is the first factor to affect the rubber reinforcement [191]. According to the study, the free volume of rubber, namely, the void size, is about 0.6 nm. The high matching of the particle size to the cavity size of the rubber leads to the smaller impurity effect of the reinforcing agent in the rubber matrix, and the stronger ability to hinder the growth of rubber microcracks. The particle size element also includes some surface activity factors [192,193]. The smaller particle size causes a larger specific surface area, contributing to the larger proportion of atoms on the particle surface to the total atomic number. Since the surface effect significantly improves the interaction force between particles and rubber macromolecules, the ability to restrict the movement of rubber macromolecules is enhanced. To some extent, it makes up for the deficiency of weak interfacial interactions and the lack of “conventional chemical forces.”

For graphitized carbon black and fluorinated carbon black rubber hard phase [194], some scholars proposed that the smaller enough size can still strengthen the rubber well even though the interface adhesion between them and rubber is poor. Therefore, nanoscale reinforcement of rubber is an alternative and promising choice. Scholars dispersed C60 into ethylene–propylene rubber, which increased the tensile strength of ethylene–propylene rubber by 3.83 times, proving the importance of nanoparticle size. Therefore, to prepare high reinforced rubber filler, the filler should be equipped with nanoscale particle size distribution. The research of inorganic reinforced materials with nanometer-size has once been a research focus. The common preparation methods of nano-inorganic materials mainly include blending, in-situ generation, sol–gel, and intercalation.

Surface activity is the second factor in the three factors of rubber reinforcer [195,196,197,198]. The enhancement advantages of nano enhancers come from various nano effects. Due to the large surface free energy of nanoparticles, nanoparticles are easy to form aggregates and uneven dispersion in the rubber matrix, which hinders the surface effect of nanoparticles in rubber. Therefore, the increasing surface activity of nanoparticles can enhance the dispersion of nanoparticles in rubber and the interfacial force [199]. It is necessary to maximize the reinforcing effect of reinforcing particles and prepare high-performance rubber with good dynamic mechanical properties.

Most of the enhanced phases of thermoplastic elastomers exhibit uniform dispersion [200,201,202]. Researchers found that a uniform "mixing" of hard and soft regions of the microphase was formed in the molecular chain of the block polymer. The dispersion of the nanoscale regions derived from the thermodynamic phase separation is uniform and plays a role in cross-linking and strengthening the whole system. The “self-strengthening” property of block thermoplastic elastomers also proves the importance of uniform dispersion.

If the dispersion of rubber reinforcement in rubber realizes the uniform distribution effect of hard and soft phases in thermoplastic elastomer [203], the enhancement effect of rubber reinforcement will be brought to the extreme. This can achieve rolling resistance and internal lag heat reduction, and further achieve the greatest advantage of rubber material performance.

The organic modification was carried out from the surface activity of the reinforcer to reduce the surface free energy of inorganic particles and reduce the hysteresis effect [204]. Research shows that every 10% reduction in the lag loss will reduce the fuel consumption of tire drive by 5%.

The structure was the last factor [205,206]. Researchers worked on nano-preparation technology and surface activity improvement of inorganic enhancers. The molecular design was thought to get better compatibility with the rubber matrix of organic reinforcement and expected to solve the friction between the reinforcement and rubber endogenous heat problem. There were two main methods for the design and synthesis of nano-polymer reinforced fillers [207]: in-situ polymerization technology and cross-linking technology. The in-situ polymerization technology has better processing performance and nano-enhancement after cross-linking. However, the high price and inconvenient demolding limit its application in rubber reinforcement. The cross-linking technology was used to design polymer materials and prepare nano-sized hard phases as rubber reinforcement filler. The advantages were that the structure can be designed from the molecule, and further modified and surface treated. Under the surface functional effect, the organic combination of filler and rubber can be realized, and the lag loss caused by inorganic particles such as carbon black can be greatly reduced.

The reinforcement mechanism of rubber materials and structures.

Carbon black is another important reinforcing agent and filler for rubber, and its consumption is about 40–50% of that of rubber. The filling of carbon black can reduce the amount of rubber, and increase the wear resistance and life of rubber products [208]. Rubber reinforcement theory was widely used in the following theoretical models: molecular chain sliding theory, binder theory, filler network theory, carbon black surface structure theory, and van der Waals network theory. The molecular chain sliding theory and binding glue theory confirmed that the molecular chains formed by carbon black particles and rubber particles slide on the surface of particles under stress and explain the Mullins phenomenon. But black carbon particles were rigid particles, which ignored the interactions between nanoparticles [209,210]. Filler network theory, carbon black surface structure theory, and van der Waals network theory considered the existence of network structure and deformation of network structure under stress. However, these theories were limited due to many parameters and the lack of definite methods.

In addition to carbon black and silica [211,212,213,214], clay [16,215,216,217], montmorillonite [218,219,220], calcium carbonate [221,222,223,224], and staple fiber [225,226,227] were all commonly used in rubber reinforced fillers. Clay rubber nanocomposites had good processing properties, physical properties, and barrier properties. Calcium carbonate rubber composite material had good performance and price advantage. Short fiber reinforced rubber composite had both the elasticity of rubber and the strength and stiffness of fiber. Its products have high strength, high modulus, tear resistance, swelling resistance, and other excellent properties.

7 Rubber components for railway vehicles

With the development of finite element analysis, rubber material tests and analysis methods are more accurate. Because of the excellent elastic properties, rubber elastic components are widely used in railway vehicles. Many scholars have conducted in-depth research on the stiffness, damping, fatigue, and so on.

Sjöberg and Kari [228] experimentally studied the influence of nonlinear excitation on dynamic stiffness and damping of filled rubber isolator. Experimental results showed that the maximum excitation amplitude on the isolator was usually determined by the stiffness at the reference frequency, and the influence of envelope amplitude increases with the frequency of the approaching component. Yang et al. [229] proposed the concepts of fragment elastic modulus and fragment stiffness factor, and determined the solution equation. The methods for evaluating nonlinear tensile stiffness of bearings and the concepts of initial tensile stiffness were developed and offset initial tensile stiffness for stiffness characteristics of rubber isolators was described. Fredette and Singh [230] developed an analytical spectral element method to characterize the dynamic characteristics of viscoelastic isolators at ultrahigh frequencies. It extended the stiffness spectrum based on fractional calculus damping mechanisms to capture all 6% of freedom including coupling terms. This approach provided physical insights and a compact way to describe viscoelastic isolators.

To establish the hyperplastic material constants of bushings, Javořík et al. tested the elastomer material of bushings under uniaxial tensile, equiaxial tensile, and pure shear deformation modes [231]. The numerical model was in good agreement with the actual performance of the bushing, and the key point of the casing was found through the numerical analysis of the finite element model.

Li et al. [232] tested the mechanical properties of the high-damping rubber bearing model and studied the relationships among shear strain, equivalent stiffness, yield stiffness, force, and equivalent damping. The bearing remains stable even when the model was damaged, while the vertical and circumferential residual compression deformation existed. Kong et al. [233] introduced evidence theory to deal with uncertainty in air springs. The polynomial chaotic method based on evidence theory, was proposed to solve the problem of efficiently calculating the response of air spring system with evidence variables.

Mirza et al. [234] took spherical bearings as an example to introduce a method for modeling and durability evaluation of elastomers for rail vehicles. This approach enabled the assessment of various components of fatigue loads and the identification of the most damaging contributions and failure modes. In addition, the approach enabled component redesign and validation, significantly increasing the working life. Luo [235] analyzed Metacone springs for rail vehicles using the effective stress method. The analytic functions were used to determine the magnitude and direction of effective stresses, and three-dimensional tensors of all principal stress ranges were considered to estimate fatigue damage.

The synthesis, property, processing, and application of elastomers have become hot topics at the moment. More and more researchers are devoting to the research of theory, test methods, and the simulation technology of rubber elastic components, which provide an essential security blanket to the railway vehicle and passenger line.

8 Challenge and future work

Considering the literature study presented in the previous sections, the fatigue and aging of rubber materials were the biggest challenges in the application of rubber components in railway vehicles. Future research can focus on the following aspects. First, the advantages of different types of rubber need to be further studied to meet specific engineering requirements. In previous studies, NR and SBR appeared to be popular options in the research works and industry. Benefiting from industrial demand, a variety of rubbers with excellent cost effective and mechanical properties are studied in the lab, such as hydrogenated nitrile butadiene rubber which can withstand hostile environment [236]. Magnetorheological elastomer shows good application prospect in vibration absorber, base isolator, and sensing device [237]. Second, there is an emerging trend in using nanofillers to achieve better reinforcement in fatigue lifetime, such as carbon black [238] and carbon nanotubes [239]. Third, the effect of temperature on the fatigue and degradation of rubber materials is not clear. Due to non-availability of standard procedure in the study of heat on rubber specimen, the experimental approach varies for each researcher. Besides, more attention is focused on built models to quantitate the effects of aging on the fatigue life of rubbers. For the design of rubber components in railway vehicles, there is an urgent need for standardizing the related research following an acceptable guideline.

9 Conclusion

Mechanical properties of rubber materials include static mechanical properties and dynamic mechanical properties. To obtain the static mechanical properties, different from metal materials, rubber materials need to carry out more than three basic tests, including uniaxial, biaxial, planar and volumetric tests under the condition of tensile and compression, to describe its complex mechanical behavior based on the material constitutive model. Dynamic mechanical properties are the characteristics of rubber components and often determine their function. The structural response under static load is largely determined by the stiffness characteristics, while the structural response under dynamic load is largely determined by the damping characteristics. Due to the complex service environment of train elastic elements, it is necessary to improve the constitutive model applicable to both large and small deformation. As there is no standard procedure and geometric description of rubber specimen in the study, the experimental approach varies from research to research. Additional works need to be done before the results are comparable. Potential future trends in the study of rubber materials and components are identified, such as coupling thermo-mechanical in cyclic loading analysis and exploring alternative fillers to improve the durability of rubbers

Protection against aging and fatigue are the biggest challenges in the application of rubber materials. The mechanisms of thermal oxygen aging and ozone aging, as two main factors causing aging, are discussed. The crack nucleation and crack propagation approaches, as two popular approaches to evaluate the fatigue failure in rubber, are discussed. In crack nucleation approach, several predictors were used but none appears to be robustly successful in multiaxial fatigue prediction. The crack propagation approach unified the microcosmic crack initiation process and macroscopic fatigue crack propagation process of rubber material. The main challenge remains on the computation of the energy release rate associated with the crack in question.

By means of finite element simulation software, the fatigue life of rubber materials and rubber products is predicted under different loads and service conditions. Accurate fatigue simulation analysis of rubber material also depends on the study of fatigue durability mechanism of rubber material and reliable material fatigue test. On this basis, an effective mathematical model to describe the fatigue characteristics of rubber material is needed. In the fatigue life simulation of rubber products, different definitions of fatigue life under different service conditions should be considered. Therefore, corresponding fatigue criteria and life simulation methods should be selected according to the actual fatigue failure index of rubber products.

-

Funding information: This work was financially supported by The National Key R&D Program of China (2020YFE0204900-02). The authors would like to express their thanks.

-

Author contributions: Wei Kang: investigation and writing – original draft; Jiefu Liu: writing – review and editing and supervision; Wei Xiong: writing – review and editing; Tianyu You: writing – review and editing; Xinxin Wang: writing – review and editing; Kexing Zeng: writing – review and editing; Yingao Deng: writing – review and editing; Zichao Guo: writing – review and editing; Ke Yuan: conceptualization, supervision, and writing – review and editing.

-

Conflict of interest: Authors state no conflict of interest.

References

[1] Ikeda, Y., A. Kato, S. Kohjiya, and Y. Nakajima. Rubber science, Springer, Singapore, 2018.10.1007/978-981-10-2938-7Search in Google Scholar

[2] Tchemodanova, S. P., K. Tatsis, M. Sanayei, E. Chatzi, and V. Dertimanis. State estimation for prediction of fatigue life for a rollercoaster connection subjected to operational multiaxial nonproportional loading. Journal of Structural Engineering, Vol. 147, 2021, id. 04021041.10.1061/(ASCE)ST.1943-541X.0002961Search in Google Scholar

[3] Carleo, F., E. Barbieri, R. Wheal, and J. C. Busfield. Limitations of viscoelastic constitutive models for carbon-black reinforced rubber in medium dynamic strains and medium strain rates. Polymers, Vol. 10, 2018, pp. 988–988.10.3390/polym10090988Search in Google Scholar PubMed PubMed Central

[4] Wang, Y., P. Zhao, H. Liu, F. Zhang, Z. Li, T. Xu, et al. Structure and temperature induced crystallization of natural rubber with different milling times. Polymer Science, Series A, Vol. 63, 2021, pp. 228–237.10.1134/S0965545X21030135Search in Google Scholar

[5] Huang, Y., Z. Liu, H. Xu, and R. Hong. Conductive thermoplastic vulcanizates based on carbon black-filled bromo-isobutylene-isoprene rubber (BIIR)/polypropylene (PP). Reviews on Advanced Materials Science, Vol. 60, 2021, pp. 303–312.10.1515/rams-2021-0013Search in Google Scholar

[6] Tharasana, C., A. Wongaunjai, P. Sornsanee, V. Jitprarop, and N. Tangboriboon. Alternative of bone china and porcelain as ceramic hand molds for rubber latex glove films formation via dipping process. Reviews on Advanced Materials Science, Vol. 59, 2020, pp. 523–537.10.1515/rams-2020-0042Search in Google Scholar

[7] Barot, T., D. Rawtani, and P. Kulkarni. Nanotechnology-based materials as emerging trends for dental applications. Reviews on Advanced Materials Science, Vol. 60, 2021, pp. 173–189.10.1515/rams-2020-0052Search in Google Scholar

[8] Thompson, L., J. Azadmanjiri, M. Nikzad, I. Sbarski, J. Wang, and A. Yu. Cellulose nanocrystals: Production, functionalization and advanced applications. Reviews on Advanced Materials Science, Vol. 58, 2019, pp. 1–16.10.1515/rams-2019-0001Search in Google Scholar

[9] Chanda, S. and D. Bajwa. A review of current physical techniques for dispersion of cellulose nanomaterials in polymer matrices. Reviews on Advanced Materials Science, Vol. 60, 2021, pp. 325–341.10.1515/rams-2021-0023Search in Google Scholar

[10] Ahmed, A., X. Wang, and M. Yang. Biocompatible materials of pulsatile and rotary blood pumps: A brief review. Reviews on Advanced Materials Science, Vol. 59, 2020, pp. 322–339.10.1515/rams-2020-0009Search in Google Scholar

[11] Bhaska, S., M. Kumar, and A. Patnaik. Mechanical and Tribological overview of ceramic particulates reinforced aluminium alloy composites. Reviews on Advanced Materials Science, Vol. 58, 2019, pp. 280–294.10.1515/rams-2019-0033Search in Google Scholar

[12] Meng, T., S. Ahmed, D. Dai, and Y. Yu. Effects of load types and critical molar ratios on strength properties and geopolymerization mechanism. Reviews on Advanced Materials Science, Vol. 60, 2021, pp. 216–222.10.1515/rams-2021-0019Search in Google Scholar

[13] Xu, Z., Z. Huang, C. Liu, X. Deng, D. Hui, and S. Deng. Research progress on mechanical properties of geopolymer recycled aggregate concrete. Reviews on Advanced Materials Science, Vol. 60, 2021, pp. 158–172.10.1515/rams-2021-0021Search in Google Scholar

[14] Ali, Md. A. M., M. Z. Omar, H. Hashim, M. S. Salleh, and I. F. Mohamed. Recent development in graphene-reinforced aluminium matrix composite: A review. Reviews on Advanced Materials Science, Vol. 60, 2021, pp. 801–817.10.1515/rams-2021-0062Search in Google Scholar

[15] Figiela, B., H. Šimonová, and K. Korniejenko. State of the art, challenges, and emerging trends: Geopolymer composite reinforced by dispersed steel fibers. Reviews on Advanced Materials Science, Vol. 61, 2022, pp. 1–15.10.1515/rams-2021-0067Search in Google Scholar

[16] Luo, Y., K. Yuan, L. Shen, and J. Liu. Sandwich panel with in-plane honeycombs in different Poisson’s ratio under low to medium impact loads. Reviews on Advanced Materials Science, Vol. 60, 2021, pp. 145–157.10.1515/rams-2021-0020Search in Google Scholar

[17] Selyutina, N. S. and Y. V. Petrov. Comparative analysis of dynamic plasticity models. Reviews on Advanced Materials Science, Vol. 57, 2018, pp. 199–211.10.1515/rams-2018-0065Search in Google Scholar

[18] Zhang, P., X. Han, Y. Zheng, J. Wan, and D. Hui. Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete. Reviews on Advanced Materials Science, Vol. 60, 2021, pp. 418–437.10.1515/rams-2021-0039Search in Google Scholar

[19] Lou, W., W. Zhang, T. Jin, X. Liu, and W. Dai. Synergistic effects of multiple environmental factors on degradation of hydrogenated nitrile rubber seals. Polymers, Vol. 10, 2018, pp. 897–897.10.3390/polym10080897Search in Google Scholar PubMed PubMed Central

[20] Zisan, M. B. and A. Igarashi. Lateral load performance and seismic demand of unbonded scrap tire rubber pad base isolators. Earthquake Engineering and Engineering Vibration, Vol. 20, 2021, pp. 803–821.10.1007/s11803-021-2053-4Search in Google Scholar

[21] Li, X. and Y. Wei. Classic strain energy functions and constitutive tests of rubber-like materials. Rubber Chemistry and Technology, Vol. 88, 2015, pp. 604–627.10.5254/rct.15.84879Search in Google Scholar

[22] Wu, Y., H. Wang, and A. Li. Parameter identification methods for hyperelastic and hyper-viscoelastic models. Applied Sciences, Vol. 6, 2016, id. 386.10.3390/app6120386Search in Google Scholar

[23] Íñiguez-Macedo, S., R. Lostado-Lorza, R. Escribano-García, and M. Martinez-Calvo. Finite element model updating combined with multi-response optimization for hyper-elastic materials characterization. Materials, Vol. 12, 2019, id. 1019.10.3390/ma12071019Search in Google Scholar

[24] Bergström, J. S. and L. B. Hilbert Jr. A constitutive model for predicting the large deformation thermomechanical behavior of fluoropolymers. Mechanics of Materials, Vol. 37, 2005, pp. 899–913.10.1016/j.mechmat.2004.09.002Search in Google Scholar

[25] Marckmann, G., E. Verron, L. Gornet, L. Chagnon, P. Charrier, and P. Fort. A theory of network alteration for the Mullins effect. Journal of the Mechanics and Physics of Solids, Vol. 50, 2002, pp. 2011–2028.10.1016/S0022-5096(01)00136-3Search in Google Scholar

[26] Boyce, M. C. and E. M. Arruda. Constitutive models of rubber elasticity: a review. Rubber Chemistry and Technology, Vol. 73, 2000, pp. 504–523.10.5254/1.3547602Search in Google Scholar

[27] Yeoh, O. H. Characterization of elastic properties of carbon-black-filled rubber vulcanizates. Rubber Chemistry and Technology, Vol. 63, 1990, pp. 792–805.10.5254/1.3538289Search in Google Scholar

[28] Rivlin, R. S. Large elastic deformations of isotropic materials. I. Fundamental concepts. Collected Papers of RS Rivlin, Springer, New York, 1997, pp. 23–54.10.1007/978-1-4612-2416-7_5Search in Google Scholar

[29] Ogden, R. W. Large deformation isotropic elasticity-On the correlation of theory and experiment for incompressible rubber like solids. Rubber Chemistry and Technology, Vol. 46, 1973, pp. 398–416.10.5254/1.3542910Search in Google Scholar

[30] Adeel, Y. J., A. I. Muhammad, and A. Zeeshan. Characterization of hyperelastic (Rubber) material using uniaxial and biaxial tension tests. Advanced Materials Research, Trans Tech Publications Ltd, Vol. 570, 2012, pp. 1–7.10.4028/www.scientific.net/AMR.570.1Search in Google Scholar

[31] Kim, B., S. B. Lee, J. Lee, S. Cho, H. Park, S. Yeom, et al. A comparison among Neo-Hookean model, Mooney-Rivlin model, and Ogden model for chloroprene rubber. International Journal of Precision Engineering and Manufacturing, Vol. 13, 2012, pp. 759–764.10.1007/s12541-012-0099-ySearch in Google Scholar

[32] Woo, C. S. and W. D. Kim. Design of mechanical testing specimens for rubber material using finite element analysis. Multidiscipline Modeling in Materials and Structures, Vol. 3, 2007, pp. 325–336.10.1163/157361107781389535Search in Google Scholar

[33] Eberlein, R. and S. Holenstein. Efficient material parameter calibration of elastomer specimen in uniaxial tension, planar shear and equibiaxial tension. Kautschuk, Gummi, Kunststoffe, Vol. 7–8, 2018, pp. 36–40.Search in Google Scholar

[34] Montella, G., A. Calabrese, and G. Serino. Mechanical characterization of a Tire Derived Material: Experiments, hyperelastic modeling and numerical validation. Construction and Building Materials, Vol. 66, 2014, pp. 336–347.10.1016/j.conbuildmat.2014.05.078Search in Google Scholar

[35] Liu, C., C. M. Cady, M. L. Lovato, and E. B. Oeler. Uniaxial tension of thin rubber liner sheets and hyperelastic model investigation. Journal of Materials Science, Vol. 50, 2015, pp. 1401–1411.10.1007/s10853-014-8700-7Search in Google Scholar

[36] Starkova, O. and A. Aniskevich. Poisson’s ratio and the incompressibility relation for various strain measures with the example of a silica-filled SBR rubber in uniaxial tension tests. Polymer Testing, Vol. 29, 2010, pp. 310–318.10.1016/j.polymertesting.2009.12.005Search in Google Scholar

[37] Kody, R. S. and A. J. Lesser. Yield behavior and energy absorbing characteristics of rubber-modified epoxies subjected to biaxial stress states. Polymer Composites, Vol. 20, 1999, pp. 250–259.10.1002/pc.10352Search in Google Scholar

[38] Fujikawa, M., N. Maeda, J. Yamabe, Y. Kodama, and M. Koishi. Determining stress–strain in rubber with in-plane biaxial tensile tester. Experimental Mechanics, Vol. 54, 2014, pp. 1639–1649.10.1007/s11340-014-9942-7Search in Google Scholar

[39] Brieu, M., J. Diani, and N. Bhatnagar. A new biaxial tension test fixture for uniaxial testing machine-A validation for hyperelastic behavior of rubber-like materials. Journal of Testing and Evaluation, Vol. 35, 2007, id. 364.10.1520/JTE100688Search in Google Scholar

[40] Sasso, M., G. Palmieri, G. Chiappini, and D. Amodio. Characterization of hyperelastic rubber-like materials by biaxial and uniaxial stretching tests based on optical methods. Polymer Testing, Vol. 27, 2008, pp. 995–1004.10.1016/j.polymertesting.2008.09.001Search in Google Scholar

[41] Ru, M., X. Q. Lei, X. M. Liu, and Y. J. Wei. An equal-biaxial test device for large deformation in cruciform specimens. Experimental Mechanics, Vol. 62, 2022, pp. 1–7.10.1007/s11340-021-00810-wSearch in Google Scholar

[42] Garishin, O., V. Shadrin, and Y. Kornev. Mechanical studies of rubber micro-and nanocomposites promising for the tire industry. uniaxial and biaxial tests. Materials Physics & Mechanics, Vol. 42, 2019, pp. 445–454.Search in Google Scholar

[43] Hamdi, A., M. Abdelaziz, N. Hocine, P. Heuillet, and N. Benseddiq. A fracture criterion of rubber-like materials under plane stress conditions. Polymer Testing, Vol. 25, 2006, pp. 994–1005.10.1016/j.polymertesting.2006.06.005Search in Google Scholar

[44] Xia, Y., Y. Dong, Y. Xia, and W. Li. A novel planar tension test of rubber for evaluating the prediction ability of the modified eight-chain model under moderate finite deformation. Rubber Chemistry and Technology, Vol. 78, 2005, pp. 879–892.10.5254/1.3547920Search in Google Scholar

[45] Radek, K., K. Jiøí, H. Jan, and K. Jan. Investigation of the mechanical properties of a cork/rubber composite. Materiali in Tehnologije, Vol. 50, 2016, pp. 579–583.10.17222/mit.2015.172Search in Google Scholar

[46] Cui, K., J. Qin, C. Di, and Y. Yang. Finite element analysis and simulation of the sealing performance of y-ring rubber seal. Applied Mechanics and Materials, Trans Tech Publications Ltd, Vol. 444, 2014, pp. 1379–1383.10.4028/www.scientific.net/AMM.444-445.1379Search in Google Scholar

[47] Liu, J., K. Deng, S. Liu, X. Yan, D. Zou, and Y. Lin. Mechanical behavior and structure optimization of compressed PHP packer rubber. Journal of Materials Engineering and Performance, Vol. 30, 2021, pp. 3691–3704.10.1007/s11665-021-05686-4Search in Google Scholar

[48] Lee, Y., J. Kim, K. Kim, T. Ahn, B. Choi, H. Lee, et al. Prediction of dynamic stiffness on rubber components considering preloads. Materialwissenschaft und Werkstofftechnik, Vol. 44, 2013, pp. 372–379.10.1002/mawe.201300139Search in Google Scholar

[49] Horton, J. and G. Tupholme. Stiffness of annular bonded rubber flanged bushes. Rubber Chemistry and Technology, Vol. 79, 2006, pp. 233–248.10.5254/1.3547935Search in Google Scholar

[50] Yu, W., L. Zhijun, L. Baolin, and G. Mingshuai. Stiffness characteristic comparison between metal-rubber and rubber isolator under sonic vibration. Journal of Vibroengineering, Vol. 16, 2014, pp. 645–655.Search in Google Scholar

[51] Zhang, R. and A. Li. Probability distribution characteristics and statistical parameters of the horizontal stiffness of rubber isolation bearings. Journal of Earthquake Engineering, Vol. 26, 2022, pp. 2437–2449.10.1080/13632469.2020.1762806Search in Google Scholar

[52] Zhou, G., X. Mi, H. Zhang, D. Liao, and K. Wu. Nonlinear finite element analysis and experimental study on the stiffness of rubber joint. Journal of the Chinese Institute of Engineers, Vol. 43, 2020, pp. 603–612.10.1080/02533839.2020.1719898Search in Google Scholar

[53] Persson, B. N. J., O. Albohr, G. Heinrich, and H. Ueba. Crack propagation in rubber-like materials. Journal of Physics: Condensed Matter, Vol. 17, 2005, id. R1071.10.1088/0953-8984/17/44/R01Search in Google Scholar

[54] Yu, F., A. Lu, J. Lu, Z. Wang, Q. Zhang, C. Geng, et al. Effect of phenyl content, sample thickness and compression on damping performances of silicone rubber: A study by dynamic mechanical analysis and impact damping test. Polymer Testing, Vol. 80, 2019, id. 106101.10.1016/j.polymertesting.2019.106101Search in Google Scholar

[55] Yu, W., L. Baolin, and L. Yuru. Effect of loading speed on the damping performance of metal rubber material. Rare Metal Materials and Engineering, Vol. 41, 2012, pp. 381–383.10.1016/S1875-5372(12)60032-0Search in Google Scholar

[56] Burgoa, A., R. Hernandez, and J. L. Vilas. New ways to improve the damping properties in high-performance thermoplastic vulcanizates. Polymer International, Vol. 69, 2020, pp. 467–475.10.1002/pi.5977Search in Google Scholar

[57] Shengbo, L., Y. Hui, J. Hongyuan, and C. Liang. Analysis of dynamic performance of metal rubber damping ring applied in high-speed rotor system. Acta Physica Sinica, Vol. 61, 2012, pp. 10702–10702.10.7498/aps.61.010702Search in Google Scholar

[58] Zheng, X., Z. Ren, L. Shen, B. Zhang, and H. Bai. Dynamic performance of laminated high-damping and high-stiffness composite structure composed of metal rubber and silicone rubber. Materials, Vol. 14, 2021, id. 187.10.3390/ma14010187Search in Google Scholar PubMed PubMed Central